JP4986716B2 - Car wash machine washing brush and car wash machine - Google Patents

Car wash machine washing brush and car wash machine Download PDFInfo

- Publication number

- JP4986716B2 JP4986716B2 JP2007149139A JP2007149139A JP4986716B2 JP 4986716 B2 JP4986716 B2 JP 4986716B2 JP 2007149139 A JP2007149139 A JP 2007149139A JP 2007149139 A JP2007149139 A JP 2007149139A JP 4986716 B2 JP4986716 B2 JP 4986716B2

- Authority

- JP

- Japan

- Prior art keywords

- brush

- car wash

- wash machine

- bristle material

- washing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000005406 washing Methods 0.000 title claims description 83

- 239000000463 material Substances 0.000 claims description 124

- 238000004140 cleaning Methods 0.000 claims description 44

- 229920005992 thermoplastic resin Polymers 0.000 claims description 30

- 229920002725 thermoplastic elastomer Polymers 0.000 claims description 28

- 230000002093 peripheral effect Effects 0.000 claims description 20

- 239000006260 foam Substances 0.000 claims description 12

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 6

- 238000001035 drying Methods 0.000 claims description 4

- 238000005507 spraying Methods 0.000 claims description 4

- 239000012459 cleaning agent Substances 0.000 claims description 3

- 239000000203 mixture Substances 0.000 claims description 2

- 235000019589 hardness Nutrition 0.000 claims 3

- 229920001971 elastomer Polymers 0.000 description 19

- 239000000806 elastomer Substances 0.000 description 15

- 238000004519 manufacturing process Methods 0.000 description 12

- 239000004711 α-olefin Substances 0.000 description 11

- 230000000052 comparative effect Effects 0.000 description 10

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 8

- 229910000831 Steel Inorganic materials 0.000 description 8

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 8

- 229920000642 polymer Polymers 0.000 description 8

- 239000010959 steel Substances 0.000 description 8

- 238000012360 testing method Methods 0.000 description 8

- 229920000089 Cyclic olefin copolymer Polymers 0.000 description 7

- -1 polyethylene Polymers 0.000 description 7

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 6

- 239000005977 Ethylene Substances 0.000 description 6

- 229910052782 aluminium Inorganic materials 0.000 description 5

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 5

- 210000000078 claw Anatomy 0.000 description 5

- 229920001577 copolymer Polymers 0.000 description 5

- 238000000034 method Methods 0.000 description 5

- 229920000098 polyolefin Polymers 0.000 description 5

- 239000004793 Polystyrene Substances 0.000 description 4

- 239000000956 alloy Substances 0.000 description 4

- 229910045601 alloy Inorganic materials 0.000 description 4

- 229920001400 block copolymer Polymers 0.000 description 4

- 238000005187 foaming Methods 0.000 description 4

- 239000004088 foaming agent Substances 0.000 description 4

- 230000006872 improvement Effects 0.000 description 4

- 229910052742 iron Inorganic materials 0.000 description 4

- 229920000092 linear low density polyethylene Polymers 0.000 description 4

- 239000004707 linear low-density polyethylene Substances 0.000 description 4

- 229920002223 polystyrene Polymers 0.000 description 4

- 229920005989 resin Polymers 0.000 description 4

- 239000011347 resin Substances 0.000 description 4

- 239000005060 rubber Substances 0.000 description 4

- QLZJUIZVJLSNDD-UHFFFAOYSA-N 2-(2-methylidenebutanoyloxy)ethyl 2-methylidenebutanoate Chemical compound CCC(=C)C(=O)OCCOC(=O)C(=C)CC QLZJUIZVJLSNDD-UHFFFAOYSA-N 0.000 description 3

- 239000004698 Polyethylene Substances 0.000 description 3

- 239000004743 Polypropylene Substances 0.000 description 3

- 230000009471 action Effects 0.000 description 3

- HGVPOWOAHALJHA-UHFFFAOYSA-N ethene;methyl prop-2-enoate Chemical compound C=C.COC(=O)C=C HGVPOWOAHALJHA-UHFFFAOYSA-N 0.000 description 3

- 239000005038 ethylene vinyl acetate Substances 0.000 description 3

- 229920006244 ethylene-ethyl acrylate Polymers 0.000 description 3

- 239000005042 ethylene-ethyl acrylate Substances 0.000 description 3

- 229920006225 ethylene-methyl acrylate Polymers 0.000 description 3

- 239000005043 ethylene-methyl acrylate Substances 0.000 description 3

- 238000001125 extrusion Methods 0.000 description 3

- 229920001684 low density polyethylene Polymers 0.000 description 3

- 239000004702 low-density polyethylene Substances 0.000 description 3

- 239000007769 metal material Substances 0.000 description 3

- 229920001200 poly(ethylene-vinyl acetate) Polymers 0.000 description 3

- 229920000573 polyethylene Polymers 0.000 description 3

- 229920001155 polypropylene Polymers 0.000 description 3

- 230000009467 reduction Effects 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 229920003002 synthetic resin Polymers 0.000 description 3

- 239000000057 synthetic resin Substances 0.000 description 3

- 206010016807 Fluid retention Diseases 0.000 description 2

- 238000005275 alloying Methods 0.000 description 2

- QYMGIIIPAFAFRX-UHFFFAOYSA-N butyl prop-2-enoate;ethene Chemical compound C=C.CCCCOC(=O)C=C QYMGIIIPAFAFRX-UHFFFAOYSA-N 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 238000011109 contamination Methods 0.000 description 2

- 229920006245 ethylene-butyl acrylate Polymers 0.000 description 2

- 229920001903 high density polyethylene Polymers 0.000 description 2

- 239000004700 high-density polyethylene Substances 0.000 description 2

- 229920001179 medium density polyethylene Polymers 0.000 description 2

- 239000004701 medium-density polyethylene Substances 0.000 description 2

- 238000002844 melting Methods 0.000 description 2

- 230000008018 melting Effects 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 238000007790 scraping Methods 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- 229920003051 synthetic elastomer Polymers 0.000 description 2

- 239000005061 synthetic rubber Substances 0.000 description 2

- 229920001862 ultra low molecular weight polyethylene Polymers 0.000 description 2

- ATRRKUHOCOJYRX-UHFFFAOYSA-N Ammonium bicarbonate Chemical compound [NH4+].OC([O-])=O ATRRKUHOCOJYRX-UHFFFAOYSA-N 0.000 description 1

- 229910000013 Ammonium bicarbonate Inorganic materials 0.000 description 1

- 239000004156 Azodicarbonamide Substances 0.000 description 1

- 239000004677 Nylon Substances 0.000 description 1

- 229930182556 Polyacetal Natural products 0.000 description 1

- UIIMBOGNXHQVGW-DEQYMQKBSA-M Sodium bicarbonate-14C Chemical compound [Na+].O[14C]([O-])=O UIIMBOGNXHQVGW-DEQYMQKBSA-M 0.000 description 1

- 241000936942 Verrucomicrobia subdivision 6 Species 0.000 description 1

- BZHJMEDXRYGGRV-UHFFFAOYSA-N Vinyl chloride Chemical compound ClC=C BZHJMEDXRYGGRV-UHFFFAOYSA-N 0.000 description 1

- 235000012538 ammonium bicarbonate Nutrition 0.000 description 1

- 239000001099 ammonium carbonate Substances 0.000 description 1

- 238000000137 annealing Methods 0.000 description 1

- XOZUGNYVDXMRKW-AATRIKPKSA-N azodicarbonamide Chemical compound NC(=O)\N=N\C(N)=O XOZUGNYVDXMRKW-AATRIKPKSA-N 0.000 description 1

- 235000019399 azodicarbonamide Nutrition 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- VJRITMATACIYAF-UHFFFAOYSA-N benzenesulfonohydrazide Chemical compound NNS(=O)(=O)C1=CC=CC=C1 VJRITMATACIYAF-UHFFFAOYSA-N 0.000 description 1

- DQXBYHZEEUGOBF-UHFFFAOYSA-N but-3-enoic acid;ethene Chemical compound C=C.OC(=O)CC=C DQXBYHZEEUGOBF-UHFFFAOYSA-N 0.000 description 1

- CQEYYJKEWSMYFG-UHFFFAOYSA-N butyl acrylate Chemical compound CCCCOC(=O)C=C CQEYYJKEWSMYFG-UHFFFAOYSA-N 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- HQQADJVZYDDRJT-UHFFFAOYSA-N ethene;prop-1-ene Chemical group C=C.CC=C HQQADJVZYDDRJT-UHFFFAOYSA-N 0.000 description 1

- 238000011086 high cleaning Methods 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 239000010445 mica Substances 0.000 description 1

- 229910052618 mica group Inorganic materials 0.000 description 1

- 229920001778 nylon Polymers 0.000 description 1

- 229920006324 polyoxymethylene Polymers 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 238000003672 processing method Methods 0.000 description 1

- 238000009751 slip forming Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 230000003746 surface roughness Effects 0.000 description 1

- 238000010998 test method Methods 0.000 description 1

- 125000000383 tetramethylene group Chemical group [H]C([H])([*:1])C([H])([H])C([H])([H])C([H])([H])[*:2] 0.000 description 1

- 125000005147 toluenesulfonyl group Chemical group C=1(C(=CC=CC1)S(=O)(=O)*)C 0.000 description 1

- 239000004636 vulcanized rubber Substances 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

Images

Description

本発明は、自動車あるいは車両の外面の被洗浄面に付着した汚れ等を洗浄する為の洗車機に使用する洗車機用洗浄ブラシ、及びその洗車機用洗浄ブラシを搭載した洗車機に関するものである。 The present invention relates to a washing brush for a car wash machine used in a car wash machine for washing dirt or the like adhering to a surface to be washed of an automobile or a vehicle, and a car wash machine equipped with the washing brush for the car wash machine. .

自動車あるいは車両の外面の被洗浄面に付着した汚れ等を洗浄する為の洗車機に使用する洗浄ブラシの毛材、その毛材を軸体に装着した洗浄ブラシ、及びその洗浄ブラシを搭載した洗車機に関しては、使用目的に応じて、さまざまな改良がなされ、例えば、洗車機用ブラシの毛材であって、長手方向に延びる芯部と、その芯部から周方向に間隔をおき、径方向に向かって周方向に湾曲して一体に延びる複数の翼部とよりなり、それらの翼部は、同じ方向に向かって湾曲する湾曲面を備え、その凸曲面が車体面への接触面となることを特徴とする洗車機用ブラシの毛材(特許文献1)が考案されている。 Washing brush bristle used in a car washing machine for washing dirt or the like adhering to the surface to be washed of an automobile or vehicle, washing brush with the bristle attached to the shaft, and car wash equipped with the washing brush As for the machine, various improvements are made according to the purpose of use. For example, it is a bristle material for a brush for a car wash machine, and has a core part extending in the longitudinal direction and spaced from the core part in the circumferential direction. A plurality of wings that are curved in the circumferential direction and extend integrally, and each of the wings includes a curved surface that curves in the same direction, and the convex curved surface serves as a contact surface to the vehicle body surface. A bristle material for a brush for a car wash machine (Patent Document 1) is devised.

また、剛性度が1200kg/cm2〜5000kg/cm2の熱可塑性樹脂で構成された分岐形状の断面をなす発泡糸で、発泡倍率が1.1〜1.7倍であることを特徴とする回転ブラシ用発泡糸(特許文献2)がある。 Further, the rigidity degree of foam yarns forming a cross-section of the branch shape made of a thermoplastic resin 1200kg / cm 2 ~5000kg / cm 2 , wherein the expansion ratio is 1.1 to 1.7 times There is a foam yarn for rotating brush (Patent Document 2).

特許文献1の洗車機用ブラシの毛材は、ポリエチレン等の熱可塑性樹脂の押出成形により長尺形状に形成された非発泡糸である。その為、回転軸の長さ方向、及び周方向に多数の前記毛材を植設することにより構成された洗車機用ブラシは、毛材の毛腰が強く、被洗浄面にたいする接触圧を高くして毛材を当接することができるので、高い洗浄性能を有する。しかしながら、前記毛材は、非発泡糸であり、硬度が高く、硬いので、被洗浄面に当接すると、被洗浄面にたいして傷を付着させやすいという課題を有していた。特に、近年、微細なアルミ片を有するメタリック塗装、微細な雲母片を有するパール塗装等の被洗浄面の高光沢化に伴い、前記の如くの硬質な非発泡糸からなる毛材により、被洗浄面にたいする傷付きが目立ち、問題となっている。

The bristle material of the brush for car wash machines of

特許文献2の回転ブラシ用発泡糸は、上記特許文献1に示した非発泡糸と同様の長尺形状であり、ポリエチレン等のポリオレフィン系熱可塑性樹脂を、発泡押出成形した発泡糸である。従って、発泡糸は、非発泡糸に比べて硬度が低く、柔軟である為、被洗浄面に当接しても、傷を付着させ難い。しかしながら、発泡糸は、柔軟であることから、毛腰が極めて弱く、回転ブラシの回転に伴い、回転軸に巻き付きやすい。その為、回転ブラシの作用半径が小さくなることから、洗い残しが発生しやすくなり、洗浄性能が劣るという課題を有していた。

The foamed yarn for rotating brushes of

本発明は、上記従来の課題を解決するもので、被洗浄面にブラシ用毛材による傷を付着させること無く、優れた洗浄性能が発揮される洗車機用洗浄ブラシ、及びその洗車機用洗浄ブラシを搭載した洗車機を提供することを目的としている。 SUMMARY OF THE INVENTION The present invention solves the above-described conventional problems, and provides a washing brush for a car wash machine that exhibits excellent washing performance without causing scratches caused by the brush bristle material on the surface to be washed, and the washing for the car wash machine. The purpose is to provide a car wash machine equipped with a brush.

前記従来の課題を解決する為に、請求項1の発明の洗車機用洗浄ブラシは、自動車あるいは車両の外面の被洗浄面に付着した汚れ等を洗浄する為の洗車機に使用する洗車機用洗浄ブラシにおいて、前記洗車機用洗浄ブラシは、ブラシ用毛材及び軸体を有し、前記ブラシ用毛材は前記軸体の外周部に形成されてあると共に、硬度が異なる外層部及び芯部を有する長尺形状にて形成されてあり、前記外層部は前記芯部の硬度よりも小の硬度を有すると共に、前記芯部の外周面の一部又は全部を被覆して形成されてあるもので、ブラシ用毛材は、硬度が高く、硬質な芯部により毛腰を保持しながら、硬度が低く、軟質な外層部が被洗浄面に当接する。その為、ブラシ用毛材は、硬質な芯部により毛腰が保持されることから、洗車機用洗浄ブラシの回転時において、軸体に巻き付くこと無く、作用半径を維持することができるので、洗い残しが発生することが無く、優れた洗浄性能が発揮される。また、被洗浄面にたいして接触圧を高くしてブラシ用毛材が当接しても、被洗浄面には軟質な外層部が当接するので、被洗浄面に傷を付着させることが無い。 In order to solve the above-mentioned conventional problems, the washing brush for a car wash machine according to the first aspect of the present invention is for a car wash machine used for a car wash machine for washing dirt or the like adhering to an automobile or a surface to be washed of a vehicle. In the cleaning brush, the cleaning brush for a car wash machine includes a brush bristle material and a shaft body, and the brush bristle material is formed on an outer peripheral portion of the shaft body, and has an outer layer portion and a core portion having different hardness. The outer layer portion has a hardness smaller than the hardness of the core portion, and is formed by covering a part or all of the outer peripheral surface of the core portion. Thus, the bristle material for brushes has high hardness, and the soft outer layer portion comes into contact with the surface to be cleaned while holding the hair and waist with the hard core portion. Therefore, the bristle material for the brush can maintain the working radius without being wound around the shaft body when the washing brush for the car wash machine is rotated because the bristle waist is held by the hard core part. No washing residue occurs and excellent cleaning performance is exhibited. Further, even if the contact pressure is increased with respect to the surface to be cleaned and the bristle material for brush comes into contact with the surface to be cleaned, the soft outer layer portion comes into contact with the surface to be cleaned.

なお、硬度とは、物質の硬さを表わし、JISK6253加硫ゴム及び熱可塑性ゴムの硬さ試験方法に記載のデュロメータ硬さ試験により測定した硬度である。外層部の硬度は40°以上70°未満、芯部の硬度は70°以上90°以下に設定されるのが望ましい。外層部の硬度が40°未満の場合、柔らかすぎて、被洗浄面に当接した際に摩耗しやすく、耐久性に劣り、70°以上の場合、硬すぎて、被洗浄面に傷を付着させやすくなる。芯部の硬度が70°未満の場合、柔らかすぎて、ブラシ用毛材に強固な毛腰を付与することが難しく、90°を超える場合、硬すぎて、被洗浄面への当接を繰り返すと、早期に毛折れが発生し、耐久性が劣る。 In addition, hardness represents the hardness of a substance and is the hardness measured by the durometer hardness test described in the hardness test method of JISK6253 vulcanized rubber and thermoplastic rubber. The hardness of the outer layer portion is preferably set to 40 ° or more and less than 70 °, and the hardness of the core portion is preferably set to 70 ° or more and 90 ° or less. If the hardness of the outer layer is less than 40 °, it is too soft and wears easily when it comes into contact with the surface to be cleaned. It is inferior in durability, and if it is 70 ° or more, it is too hard to cause scratches on the surface to be cleaned. It becomes easy to let you. When the hardness of the core is less than 70 °, it is too soft and it is difficult to impart strong bristle to the brush bristle material. When it exceeds 90 °, it is too hard and repeats contact with the surface to be cleaned. Then, the hair breaks early and the durability is inferior.

請求項2の発明の洗車機用洗浄ブラシは、特に、請求項1の発明の洗車機用洗浄ブラシにおいて、ブラシ用毛材を構成する外層部は、熱可塑性樹脂及び/又は熱可塑性エラストマーを有する発泡体にて形成されてあるもので、外層部は柔軟性に優れた発泡体であることから、ブラシ用毛材が被洗浄面に当接する際の無傷性能が向上する。発泡倍率は3倍以下に設定されるのが望ましい。発泡倍率が3倍を超えると、ブラシ用毛材の生産時において、発泡不良が発生しやすくなり、ブラシ用毛材に強度低下が生じ、耐久性が劣ることになる。

The washing brush for a car wash machine of the invention of

上記熱可塑性樹脂は、ポリエチレン、エチレンビニルアセテート、エチレンメチルアクリレート、エチレンエチルアクリレート、エチレンブチルアクリレート、ポリプロピレン、ポリスチレン等のポリオレフィン系熱可塑性樹脂が採用される。 Examples of the thermoplastic resin include polyolefin-based thermoplastic resins such as polyethylene, ethylene vinyl acetate, ethylene methyl acrylate, ethylene ethyl acrylate, ethylene butyl acrylate, polypropylene, and polystyrene.

また、上記熱可塑性エラストマーは、エチレン−αオレフィン共重合体エラストマー、エチレン−αオレフィン架橋共重合体エラストマー、スチレン・エチレン・ブロック共重合体エラストマー等が採用される。 Examples of the thermoplastic elastomer include ethylene-α olefin copolymer elastomer, ethylene-α olefin crosslinked copolymer elastomer, and styrene / ethylene block copolymer elastomer.

上記の如くの熱可塑性樹脂、熱可塑性エラストマーは、それぞれ単独に使用しても構わないし、ブレンドして併用しても構わない。熱可塑性樹脂と熱可塑性エラストマーをブレンドして用いることは、一般的にはポリマーアロイと呼ばれている。熱可塑性樹脂が単独で使用される場合、発泡倍率は2倍を超えて3倍以下、熱可塑性エラストマーが単独で使用される場合、発泡倍率は1倍を超えて1.2倍未満、ポリマーアロイされる場合、発泡倍率は1.2倍以上2倍以下が望ましい。熱可塑性樹脂が単独で使用される場合、発泡倍率が2倍以下の場合、硬すぎて、被洗浄面に傷を付着させやすくなる。熱可塑性エラストマーが単独で使用される場合、発泡倍率が1.2倍以上の場合、柔らかすぎて、摩耗しやすく、耐久性が劣る。 The above thermoplastic resins and thermoplastic elastomers may be used alone or in combination. The blending of a thermoplastic resin and a thermoplastic elastomer is generally called a polymer alloy. When the thermoplastic resin is used alone, the expansion ratio is more than 2 times to 3 times or less, and when the thermoplastic elastomer is used alone, the expansion ratio is more than 1 time and less than 1.2 times. In this case, the expansion ratio is desirably 1.2 times or more and 2 times or less. When the thermoplastic resin is used alone, when the expansion ratio is 2 times or less, it is too hard to easily cause scratches on the surface to be cleaned. When the thermoplastic elastomer is used alone, when the expansion ratio is 1.2 times or more, it is too soft, easily worn, and inferior in durability.

熱可塑性エラストマーは、分子中に弾性を有するゴム成分であるソフトセグメント(軟質相)と、塑性変形を防止する為の分子拘束成分、すなわち樹脂成分であるハードセグメント(硬質相)の両成分を有しており、ハードセグメントである樹脂成分を重合する際に、ソフトセグメントであるゴム成分も同時に重合することにより形成され、合成樹脂と合成ゴムの双方の機能を併せ持つ。その為、熱可塑性エラストマーは、熱可塑性樹脂に比べて軟質であるので、単独で使用される場合、あるいはポリマーアロイされる場合には、熱可塑性樹脂を単独で使用する場合よりも低発泡で使用される。 Thermoplastic elastomers have both a soft segment (soft phase) that is a rubber component having elasticity in the molecule and a molecular constraint component to prevent plastic deformation, that is, a hard segment (hard phase) that is a resin component. When the resin component that is the hard segment is polymerized, the rubber component that is the soft segment is also polymerized at the same time, and has both functions of a synthetic resin and a synthetic rubber. Therefore, the thermoplastic elastomer is softer than the thermoplastic resin, so when used alone or when polymer alloyed, it is used with lower foaming than when the thermoplastic resin is used alone. Is done.

請求項3の発明の洗車機用洗浄ブラシは、特に、請求項1又は2の発明の洗車機用洗浄ブラシにおいて、ブラシ用毛材を構成する芯部は、熱可塑性樹脂及び/又は熱可塑性エラストマーを有する非発泡体にて形成されてあるもので、芯部は剛性に優れた非発泡体であることから、ブラシ用毛材の毛腰を強く設定することができる為、洗浄性能が向上する。 The washing brush for a car wash machine according to a third aspect of the invention is, in particular, the washing brush for a car wash machine according to the first or second aspect, wherein the core part constituting the bristle material for the brush is a thermoplastic resin and / or a thermoplastic elastomer. Since the core is a non-foamed body with excellent rigidity, the bristle of the bristle material for the brush can be set strongly, so that the cleaning performance is improved. .

なお、上記の熱可塑性樹脂、及び熱可塑性エラストマーは、請求項2の発明の洗車機用洗浄ブラシにおいて示した熱可塑性樹脂、及び熱可塑性エラストマーと同様のものを用いることができ、単独使用、あるいは併用される。

The thermoplastic resin and the thermoplastic elastomer can be the same as the thermoplastic resin and the thermoplastic elastomer shown in the washing brush for a car wash machine of the invention of

請求項4の発明の洗車機用洗浄ブラシは、特に、請求項1から3のいずれかの発明の洗車機用洗浄ブラシにおいて、ブラシ用毛材は長手方向の端部に細分割部が形成されてあるもので、細分割部が被洗浄面の細かな凹凸部分に当接し、凹凸部分に付着した汚れを掻き出す為、洗浄性能が大幅に向上する。 The washing brush for a car wash machine according to a fourth aspect of the invention is particularly the washing brush for a car wash machine according to any one of the first to third aspects, wherein the brush bristle is formed with a subdivided portion at the end in the longitudinal direction. Therefore, the finely divided portion comes into contact with the fine uneven portion of the surface to be cleaned, and the dirt adhering to the uneven portion is scraped, so that the cleaning performance is greatly improved.

請求項5の発明の洗車機用洗浄ブラシは、特に、請求項1から4のいずれかの発明の洗車機用洗浄ブラシにおいて、ブラシ用毛材は芯線及び帯状体に挟み付けられ、折り合わされて形成されたチャンネルブラシにて、軸体の外周部に形成されてあり、前記チャンネルブラシは係止具にて前記軸体に固定されてあるもので、洗車機用洗浄ブラシを製作する際、連続的にチャンネルブラシを形成し、軸体の外周面に係止具にて固定すればよいので、作業性が向上する。その為、洗車機用洗浄ブラシの生産コストの低減につながる。

The cleaning brush for a car wash machine of the invention of

請求項6の発明の洗車機は、駆動源と、被洗浄面に散布する洗浄剤及び洗浄水を噴出させるノズルと、洗浄後の被洗浄面を乾燥させる乾燥手段を備えると共に、請求項1から5のいずれか1項に記載の洗車機用洗浄ブラシを搭載したもので、被洗浄面に傷を付着させること無く、優れた洗浄性能を有する洗車機用洗浄ブラシが搭載されてある為、洗車機は、駆動源により洗車機用洗浄ブラシを低速に設定すると共に、洗浄時間を短時間に設定した場合においても、洗い残しの発生が防止され、優れた洗浄性能が発揮される。また、高速回転した場合においても、被洗浄面に傷を付着させることが無い。

The car wash machine of the invention of

請求項1の発明の洗車機用洗浄ブラシは、ブラシ用毛材が硬質な芯部により毛腰を保持しながら、軟質な外層部により被洗浄面に当接する為、被洗浄面に傷を付着させること無く、優れた洗浄性能を発揮することができる。 In the washing brush for a car wash machine according to the first aspect of the invention, since the bristle material for the brush contacts the surface to be cleaned by the soft outer layer portion while holding the fur waist by the hard core portion, scratches are attached to the surface to be cleaned. Excellent cleaning performance can be demonstrated without causing

請求項2の発明の洗車機用洗浄ブラシは、ブラシ用毛材を構成する外層部は、柔軟な発泡体であることから、ブラシ用毛材が被洗浄面に当接する際の無傷性能が向上する。 In the washing brush for a car wash machine according to the second aspect of the invention, since the outer layer part constituting the bristle material for the brush is a flexible foam, the intact performance when the bristle material for the brush contacts the surface to be cleaned is improved. To do.

請求項3の発明の洗車機用洗浄ブラシは、ブラシ用毛材を構成する芯部は、硬質な非発泡体であることから、ブラシ用毛材の毛腰を強く設定して、被洗浄面に当接することができる為、洗浄性能が向上する。 In the washing brush for a car wash machine according to the invention of claim 3, since the core part constituting the bristle material for the brush is a hard non-foamed material, the bristle of the bristle material for the brush is strongly set, and the surface to be washed The cleaning performance is improved.

請求項4の発明の洗車機用洗浄ブラシは、細分割部により、被洗浄面の細かな凹凸部分に付着している汚れが掻き出される為、洗浄性能が大幅に向上する。 In the washing brush for a car wash machine according to the fourth aspect of the present invention, the dirt adhering to the fine uneven portions of the surface to be cleaned is scraped out by the finely divided portion, so that the cleaning performance is greatly improved.

請求項5の発明の洗車機用洗浄ブラシは、洗車機用洗浄ブラシの生産コストの低減につながり、安価にて洗車機用洗浄ブラシを提供することができる。

The washing brush for a car wash machine of the invention of

請求項6の発明の洗車機は、駆動源により洗車機用洗浄ブラシを低速に設定すると共に、洗浄時間を短時間に設定した場合においても、洗い残しの発生が防止され、優れた洗浄性能が発揮される。また、高速回転した場合においても、被洗浄面に傷を付着させることが無い。

The car wash machine of the invention of

以下、本発明の実施の形態について図面を参照しながら説明する。なお、この実施の形態により本発明が限定されるものではない。 Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, this invention is not limited by this embodiment.

(実施例1)

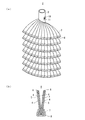

図1(a)は、本発明の洗車機用洗浄ブラシの正面図、図1(b)は、チャンネルブラシの断面図、図2(a)は、ブラシ片を前面側から見た斜視図、図2(b)は、図2(a)のA−A断面図、図3は、本発明の洗車機用洗浄ブラシを構成する係止具が固定された軸体を前面側から見た斜視図、図4は、チャンネルブラシの製造状態を前面側から見た斜視図である。

Example 1

1A is a front view of a washing brush for a car wash machine of the present invention, FIG. 1B is a cross-sectional view of a channel brush, and FIG. 2A is a perspective view of a brush piece viewed from the front side, 2B is a cross-sectional view taken along the line AA of FIG. 2A, and FIG. 3 is a perspective view of the shaft body to which the locking member constituting the washing brush for a car wash machine of the present invention is fixed viewed from the front side. FIG. 4 and FIG. 4 are perspective views of the manufacturing state of the channel brush as viewed from the front side.

図1(a)、及び図1(b)において、洗車機用洗浄ブラシ1は、ブラシ用毛材2を芯線7、及び帯状体8にて挟み付けると共に、折り合わして形成された長尺形状のチャンネルブラシ9が、アルミニウム、鉄等の金属材料、あるいは塩化ビニル、ポリアセタール等の合成樹脂材料からなる略円筒形状の軸体3の外周部に螺旋状に巻き付けられると共に、チャンネルブラシ9の両端部に係止具10を覆い被せ、係止具10の両端部をネジ11にて軸体3に固定して形成されている。

1 (a) and 1 (b), a

チャンネルブラシ9を構成する芯線7は、概丸形断面を有する略円柱形状で、アルミニウム、鉄等の金属材料からなる。また、帯状体8は、概コ字状断面を有する長尺形状で、アルミニウム、鉄等の金属材料からなる。ブラシ用毛材2は、外層部4、及び芯部5を有すると共に、端部に細分割部6が形成された長尺形状であり、芯線7、及び帯状体8にて挟み付けられると共に、概V字断面を有するように折り合わされている。ブラシ用毛材2は、洗車機用洗浄ブラシ1の回転に伴い、外層部4、及び細分割部6が被洗浄面に当接する。芯部5は、被洗浄面には直接、当接することは無く、ブラシ用毛材2に毛腰を付与する。

The core wire 7 constituting the

次に、図2を用いて、ブラシ用毛材2について詳述する。

Next, the brush bristle

図2(a)、及び図2(b)において、ブラシ用毛材2は、外層部4が芯部5の外周面を被覆して形成された概波形断面を有する長尺形状であり、両端部には細分割部6が形成されている。ブラシ用毛材2は、概波形断面を有していることから、表面に形成された複数の湾曲部12に洗浄水を一時的に溜めることができるので、洗車中の保水性が高まり、洗車機用洗浄ブラシ1の洗浄性能の向上につながる。ブラシ用毛材2の厚みは0.3〜3mm程度、幅は1〜10mm程度に設定される。厚みが0.3mm未満の場合には、耐久性が劣り、3mmを超える場合には、柔軟性が損なわれる。幅が1mm未満の場合には、毛腰が弱く、10mmを超える場合には、柔軟性が劣ることになる。また、細分割部6に形成されたブラシ毛の1本あたりの幅、及び長さは、ブラシ用毛材2の幅、長さにもよるが、幅は0.01〜0.5mm程度、長さは10〜50mm程度に設定されるのが望ましい。幅が0.01mm未満の場合には、切れやすく耐久性が劣り、0.5mmを超える場合には、被洗浄面の細かな凹凸部分に付着した汚れの掻き取り性能が劣る。長さが10mm未満の場合には、汚れの掻き取り性能が劣り、50mmを超える場合には、毛腰が極めて弱くなる。なお、ブラシ用毛材2の断面形状は、特に限定されるものではなく、概丸形断面でもよく、例えば、十字形断面、M字形断面、N字形断面、卍形断面等の異形断面形状であっても構わない。

2 (a) and 2 (b), the

ブラシ用毛材2を構成する外層部4は、超低密度ポリエチレン、低密度ポリエチレン、直鎖状低密度ポリエチレン、中密度ポリエチレン、高密度ポリエチレン、エチレンビニルアセテート、エチレンメチルアクリレート、エチレンエチルアクリレート、エチレンブチルアクリレート、ポリプロピレン、ポリスチレン等のポリオレフィン系熱可塑性樹脂と、エチレン−αオレフィン共重合体エラストマー、エチレン−αオレフィン架橋共重合体エラストマー、スチレン・エチレン・ブロック共重合体エラストマー等の熱可塑性エラストマーをブレンドしてポリマーアロイすると共に、発泡剤を配合して発泡化した発泡体である。発泡倍率は1.2倍以上2倍以下に設定される。また、ポリマーアロイする場合、熱可塑性エラストマーは、熱可塑性樹脂100重量部にたいして、10重量部以下にて配合されるのが望ましい。熱可塑性エラストマーを、10重量部を超えて熱可塑性樹脂に配合すると、分散不良が発生しやすく、ブラシ用毛材2の耐久性が劣ることになる。

The

また、上記発泡剤としては、従来から発泡体の製造に用いられているものであれば、特に限定されず、例えば、重炭酸ナトリウム、重炭酸アンモニウム、アゾジカルボンアミド、ベンゼンスルホニルヒドラジド、ジニトロソペンタメチレンテトラミン、トルエンスルホニルヒドラジド、4,4−オキシビスベンゼンスルホニルヒドラジド等の熱分解型発泡剤が好適に用いられ、前記材質は単独で用いられても併用されても構わない。 The foaming agent is not particularly limited as long as it has been conventionally used in the production of foams. For example, sodium bicarbonate, ammonium bicarbonate, azodicarbonamide, benzenesulfonylhydrazide, dinitrosopenta Pyrolytic foaming agents such as methylenetetramine, toluenesulfonyl hydrazide, 4,4-oxybisbenzenesulfonyl hydrazide are preferably used, and the above materials may be used alone or in combination.

熱可塑性エラストマーは、分子中に弾性を有するゴム成分であるソフトセグメント(軟質相)と、塑性変形を防止する為の分子拘束成分、すなわち樹脂成分であるハードセグメント(硬質相)の両成分を有しており、ハードセグメントである樹脂成分を重合する際に、ソフトセグメントであるゴム成分も同時に重合することにより形成され、合成樹脂と合成ゴムの双方の機能を併せ持つ。例えば、エチレン−αオレフィン共重合体エラストマー、エチレン−αオレフィン架橋共重合体エラストマーは、ハードセグメントにポリエチレン等のポリオレフィンを用い、ソフトセグメントにはエチレン・プロピレン・ジエン共重合体(EPDM)が用いられる。また、スチレン・エチレン・ブロック共重合体エラストマーは、ハードセグメントにポリスチレン、ソフトセグメントにエチレン・ブチレンが用いられている。 Thermoplastic elastomers have both a soft segment (soft phase) that is a rubber component having elasticity in the molecule and a molecular constraint component to prevent plastic deformation, that is, a hard segment (hard phase) that is a resin component. When the resin component that is the hard segment is polymerized, the rubber component that is the soft segment is also polymerized at the same time, and has both functions of a synthetic resin and a synthetic rubber. For example, ethylene-α olefin copolymer elastomer and ethylene-α olefin crosslinked copolymer elastomer use polyolefin such as polyethylene for the hard segment and ethylene / propylene / diene copolymer (EPDM) for the soft segment. . The styrene / ethylene block copolymer elastomer uses polystyrene for the hard segment and ethylene / butylene for the soft segment.

一方、ブラシ用毛材2を構成する芯部5は、超低密度ポリエチレン、低密度ポリエチレン、直鎖状低密度ポリエチレン、中密度ポリエチレン、高密度ポリエチレン、エチレンビニルアセテート、エチレンメチルアクリレート、エチレンエチルアクリレート、エチレンブチルアクリレート、ポリプロピレン、ポリスチレン等のポリオレフィン系熱可塑性樹脂と、エチレン−αオレフィン共重合体エラストマー、エチレン−αオレフィン架橋共重合体エラストマー、スチレン・エチレン・ブロック共重合体エラストマー等の熱可塑性エラストマーをブレンドしてポリマーアロイした非発泡体である。熱可塑性エラストマーは、熱可塑性樹脂100重量部にたいして、10重量部以下にて配合される。

On the other hand, the

従って、芯部5の硬度は、外層部4に比べて高く、硬質である。外層部4の硬度は40°以上70°未満、芯部5の硬度は70°以上90°以下に設定される。外層部4の硬度が40°未満の場合、柔らかすぎて、被洗浄面に当接した際に摩耗しやすく、耐久性に劣り、70°以上の場合、硬すぎて、被洗浄面に傷を付着させやすくなる。芯部5の硬度が70°未満の場合、柔らかすぎて、ブラシ用毛材2に強固な毛腰を付与することが難しく、90°を超える場合、硬すぎて、被洗浄面への当接を繰り返すと、早期に毛折れが発生し、耐久性が劣る。

Accordingly, the hardness of the

外層部4、及び芯部5は、熱可塑性樹脂と熱可塑性エラストマーがポリマーアロイされて形成されているので、外層部4、及び芯部5が熱可塑性樹脂のみにより形成されている場合に比べて、ブラシ用毛材2に優れた弾力性、すなわち形状復元力を付与することができる。その為、ブラシ用毛材2は、被洗浄面への当接を繰り返しても、毛癖が付き難く、毛折れ、毛切れ等の発生を防ぐことができるので、洗車機用洗浄ブラシ1の耐久性が向上する。また、外層部4、及び芯部5が熱可塑性エラストマーのみにより形成されている場合に比べて、ブラシ用毛材2のコストを低減させることができるので、洗車機用洗浄ブラシ1の生産コストの削減につながる。

Since the

なお、外層部4、及び芯部5は、熱可塑性樹脂、あるいは熱可塑性エラストマーを、単独で使用してもよい。熱可塑性樹脂、熱可塑性エラストマー、ポリマーアロイの選択に関しては、洗車機用洗浄ブラシ1の使用される環境、コスト等を勘案して、適宜、決定されるものである。

In addition, the

ブラシ用毛材2は、次の手順にて製造される。最初に2つのホッパーを用意し、一方のホッパーには、外層部4を形成するペレット状、あるいは粉末状の熱可塑性樹脂、熱可塑性エラストマー、発泡剤等を混入し、融点以上の温度にて加熱して溶融する。他方のホッパーには、芯部5を形成する熱可塑性樹脂、熱可塑性エラストマー等を混入し、融点以上の温度にて加熱して溶融する。次に、押出機の先端に取り付けられた二層構造を有する概波形の口金を通して、外層部4、及び芯部5を同時に押し出して紡糸する。押し出し後、加熱しながら延伸機にて長手方向に延伸をかけ、延伸後、アニーリングと呼ばれる工程にて冷却固化させることにより、長尺形状のモノフィラメントが形成される。前記の如くの製造方法は、一般的には押出成形と呼ばれている。次に、得られたモノフィラメントを所望の長さに切断し、モノフィラメントの長手方向の両端部の所定長さを、所定回転速度で回転している分割刃やカッターを有する細分割加工機にて加工することにより、両端部に細分割部6が形成されたブラシ用毛材2が製造される。

The brush bristle

モノフィラメントの長手方向に延伸をかける上記の如くの方法は、一軸延伸と呼ばれている。一軸延伸は、一方向にのみ延伸応力をかける加工方法であり、延伸方向にたいして平行の方向は、分子配向が起こるので、引張強さが著しく向上するが、延伸方向にたいして直角の方向は、引張強さが向上しない為、延伸方向にたいして平行の方向に、裂けやすくなるという性質を有している。その為、ブラシ用毛材2は、細分割部6を形成することが可能となる。なお、分子配向とは、線状分子が溶融または固体状態において、外力の作用により、一定方向に配列することである。

The above-described method of stretching the monofilament in the longitudinal direction is called uniaxial stretching. Uniaxial stretching is a processing method in which stretching stress is applied only in one direction. In the direction parallel to the stretching direction, molecular orientation occurs, so the tensile strength is remarkably improved, but the direction perpendicular to the stretching direction is tensile strength. Therefore, it has a property that it is easy to tear in a direction parallel to the stretching direction. Therefore, the brush bristle

また、フィラメントに延伸を施すこと無く、カッターやトムソン型等を用いて、細分割部6を形成し、ブラシ用毛材2を製造することも可能である。

Further, it is also possible to manufacture the brush bristle

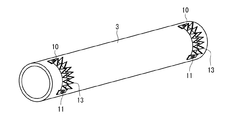

次に、図3、及び図4を用いて、洗車機用洗浄ブラシ1の製造方法について説明する。

Next, the manufacturing method of the

最初に、図3の如く、略円筒形状の軸体3の外周部の両端部近傍に、複数の爪13を有する係止具10を、ネジ11にて固定する。次に、図4の如く、断面が概コ字状の長尺の帯状体8にたいして、両端部に細分割部6が形成された複数本のブラシ用毛材2の略中央部が、帯状体8の上部になるよう基台14に設置する。次いで、縦ロール15を使用して、芯線7にてブラシ用毛材2を挟み付けると共に、芯線7を概コ字状の帯状体8の内部に押し込む。次に、帯状体8の両側に設置された横ロール16を使用して、帯状体8を両側から、かしめる。その結果、図1(b)の如く、両端部に細分割部6を有する長尺形状のブラシ用毛材2の略中央部が芯線7、及び帯状体8に挟み付けられて折り合わされたチャンネルブラシ9が形成される。

First, as shown in FIG. 3, a

そして、チャンネルブラシ9の一方の端部に形成されたブラシ用毛材2は切り取られ、前記チャンネルブラシ9の端部は、図3に示した一方の係止具10の両側に形成された爪13の間に挿入され、爪13を内側に折り畳むことにより、固定される。次に、軸体3を回転させながら、1本の長尺形状に形成されたチャンネルブラシ9を、軸体3の外周部の周りに捩りを加えて螺旋状に巻き付け、チャンネルブラシ9の他方の端部に形成されたブラシ用毛材2を切り取り、軸体3の外周部に取り付けられた他方の係止具10に形成された爪13にて、チャンネルブラシ9の他方の端部を固定し、洗車機用洗浄ブラシ1が製造される。

Then, the brush bristle

なお、軸体3の外周部にブラシ用毛材2を装着して、洗車機用洗浄ブラシ1を形成する方法は、上記に示したチャンネルブラシ9を、軸体3の外周部に螺旋状に巻き付けて固定する方法以外にも、例えば、複数本の長尺形状のチャンネルブラシ9を用意し、軸体3の外周部の等分箇所に、前記チャンネルブラシ9を配置し、チャンネルブラシ9の両端部のブラシ用毛材2を切り取り、チャンネルブラシ9の両端部に概Ω形状の係止具10を覆い被せ、前記係止具10をネジ11にて固定して洗車機用洗浄ブラシ1を形成しても構わない。複数本のチャンネルブラシ9を、軸体3の外周部に配置する際、長尺形状のチャンネルブラシ9を軸体3の長手方向にたいして、直線状に配置してもよいし、チャンネルブラシ9に捩りを加えて、軸体3の長手方向に配置してもよい。

In addition, the method for forming the

また、チャンネルブラシ9を形成すること無く、例えば、軸体3の外周部に、ブラシ用毛材2を植え付ける複数の穴部を設け、前記穴部にたいしてブラシ用毛材2をステープルで挟み付け、ブラシ用毛材2を二つ折りにして、穴部の底面にたいして打ち込み、ブラシ用毛材2を軸体3に固定する丸線型ブラシ、あるいは穴部にたいしてブラシ用毛材2を薄い平板で押さえ込み、ブラシ用毛材2を二つ折りにして、穴部の内周面に嵌合するように穴部の底面にたいして前記平板を打ち込み、ブラシ用毛材2を軸体3に固定する平線型ブラシ、あるいは穴部にたいしてブラシ用毛材2をナイロン等の引き込み線で押さえ込み、ブラシ用毛材2を二つ折りにして、前記引き込み線を軸体3の内周面に這わせて、ブラシ用毛材2を軸体3に固定する引込型ブラシ、あるいは複数本のブラシ用毛材2を止め金具を介して軸体3の外周部に直接固定する組付型ブラシ等も採用できる。なお、前記の如くの穴部は、軸体3の外周部に等分間隔で設けても良いし、千鳥状に設けても良い。穴部の穴径は、ブラシ用毛材2の植毛量に応じて、適時、設定される。

Further, without forming the

次に、本発明の洗車機用洗浄ブラシ1の洗浄性能、及び被洗浄面にたいする傷の付着について試験した。下記に示した要領で測定し、その結果を表1に示した。

Next, the cleaning performance of the cleaning

実施例1として、厚みが0.65mm、幅が5mm、長さが240mmの概波形断面を有するブラシ用毛材2を複数本用意した。ブラシ用毛材2の両端部には、1本あたりの幅が0.05mm、長さが15mmのブラシ毛からなる細分割部6を形成した。次に、アルミニウムからなる芯線7と帯状体8にてブラシ用毛材2を挟み付けて、折り合わされたブラシ用毛材2を有するチャンネルブラシ9を形成した。チャンネルブラシ9の一方の端部に形成されたブラシ用毛材2は、チャンネルブラシ9の長手方向50mmに亘って、帯状体8の近傍にて切り取り、直径が114mmで且つ長さが360mmの鉄製の略円筒形状の軸体3の外周部の端部近傍に、ネジ11にて装着された係止具10を用いて固定した。そして、チャンネルブラシ9を軸体3の外周部に螺旋状に巻き付けて配置し、チャンネルブラシ9の他方の端部に形成されたブラシ用毛材2も、チャンネルブラシ9の長手方向50mmに亘って、帯状体8の近傍にて切り取り、係止具10を用いて固定して試験用の洗車機用洗浄ブラシ1を1本製作した。なお、ブラシ用毛材2は、外層部4が芯部5の外周面を被覆した長尺形状で、外層部4は、直鎖状低密度ポリエチレン100重量部にたいし、エチレン−αオレフィン共重合体エラストマーを5重量部配合した1.3倍発泡の発泡体であり、芯部5は、直鎖状低密度ポリエチレン100重量部にたいし、エチレン−αオレフィン共重合体エラストマーを5重量部配合した非発泡体である。外層部4の硬度は67°、芯部5の硬度は75°であった。また、帯状体8の幅は5mmで、軸体3の外周部に螺旋状に巻き付けられ、隣り合う帯状体8の間隔は25mmに設定した。

As Example 1, a plurality of

比較例1として、低密度ポリエチレンを有する非発泡糸からなるブラシ用毛材を用いた以外は、上記実施例1の洗車機用洗浄ブラシ1と同一条件の洗車機用洗浄ブラシを1本製作した。比較例1のブラシ用毛材の硬度は80°であった。

As Comparative Example 1, one washing brush for a car wash machine having the same conditions as the

比較例2として、エチレンビニルアセテート100重量部にたいし、エチレン−αオレフィン共重合体エラストマーを5重量部配合した1.3倍発泡の発泡糸からなるブラシ用毛材を用いた以外は、上記実施例1の洗車機用洗浄ブラシ1と同一条件の洗車機用洗浄ブラシを1本製作した。比較例2のブラシ用毛材の硬度は65°であった。

As Comparative Example 2, except that a brush bristle material composed of a 1.3-fold foamed yarn in which 5 parts by weight of ethylene-α-olefin copolymer elastomer was blended with 100 parts by weight of ethylene vinyl acetate was used above. One washing brush for car wash machine having the same conditions as the

次に、上記の如く構成された実施例1、比較例1、及び比較例2の試験用の洗車機用洗浄ブラシ1を、それぞれ回転試験機に取り付け、240rpmの一定の回転速度で回転させる一方、一面に人工汚れを塗布した白色ソリッド塗装鋼板を用意し、前記回転速度で回転している軸体3の外周部にチャンネルブラシ9により取り付けられたブラシ用毛材2の先端が描く仮想円上から30mmだけ軸体3の回転軸方向に近接した位置に前記白色ソリッド塗装鋼板を、その汚れ面が軸体3に対向した状態に配設すると共に、6L毎分の散布量にて洗浄水を吹き付けながら1分間に亘って鋼板の汚れ面にブラシ用毛材2を当接させることによって鋼板の汚れを除去した。

Next, the

そして、鋼板の汚れ面におけるブラシ用毛材2によって汚れを除去した部分の明度を、日本電色工業株式会社製の色差計NR−1で測定して、下記基準により、洗浄性能を判断した。

○・・・明度の向上が+5以上

×・・・明度の向上が+5未満

And the brightness of the part which removed the stain | pollution | contamination by the

○ ・ ・ ・ Brightness improvement is +5 or more × ・ ・ ・ Brightness improvement is less than +5

次に、実施例1、比較例1、及び比較例2の試験用の洗車機用洗浄ブラシ1を、それぞれ回転試験機に取り付け、240rpmの一定の回転速度で回転させる一方、黒色メタリック塗装鋼板を用意し、前記回転速度で回転している軸体3の外周部にチャンネルブラシ9により取り付けられたブラシ用毛材2の先端が描く仮想円上から30mmだけ軸体3の回転軸方向に近接した位置に前記黒色メタリック塗装鋼板を、軸体3に対向した状態に配設すると共に、6L毎分の散布量にて洗浄水を吹き付けながら30秒間に亘ってブラシ用毛材を当接させた。

Next, the test

そして、ブラシ用毛材2が当接した鋼板の表面の平均粗さを、株式会社ミツトヨ製の面粗度計Surftest301で測定して、下記基準により、被洗浄面にたいする傷の付着を判断した。

○・・・ブランクの平均粗さの値との差が0.01μ以下であった

×・・・ブランクの平均粗さの値との差が0.01μを超えていた

And the average roughness of the surface of the steel plate which the

○ ・ ・ ・ The difference from the average roughness value of the blank was 0.01 μm or less. × ・ ・ ・ The difference from the average roughness value of the blank was over 0.01 μm.

上記試験結果より、実施例1の洗車機用洗浄ブラシ1は、ブラシ用毛材2を構成する硬質な芯部5により毛腰を保持しながら、被洗浄面にたいして、ブラシ用毛材2を構成する軟質な外層部4、及びブラシ用毛材2の有する細分割部6が当接するので、ブラシ用毛材2は軸体3に巻き付くこと無く、作用半径を維持して、細分割部6が被洗浄面の細かな凹凸部分に付着している汚れを掻き取るので、洗車機用洗浄ブラシ1は優れた洗浄性能を有するものであった。また、ブラシ用毛材2の外層部4は軟質であることから、被洗浄面に当接しても、被洗浄面の平均粗さはブランク値と差が無く、ブラシ用毛材2による被洗浄面にたいする傷の付着は認められなかった。

From the above test results, the

比較例1の洗車機用洗浄ブラシは、被洗浄面にたいして、硬質な非発泡糸からなるブラシ用毛材が当接する。その為、ブラシ用毛材は、毛腰を強く設定して被洗浄面に当接することができることから、ブラシ用毛材は軸体に巻き付くこと無く、作用半径を維持して、細分割部が被洗浄面の細かな凹凸部分に付着している汚れを掻き取るので、洗車機用洗浄ブラシは優れた洗浄性能を有する。しかしながら、硬質な非発泡糸が直接、被洗浄面に当接するので、被洗浄面の平均粗さはブランク値と0.06μの差があり、ブラシ用毛材による被洗浄面にたいする傷の付着が認められた。 In the cleaning brush for a car wash machine of Comparative Example 1, the bristle material for brush made of hard non-foamed yarn comes into contact with the surface to be cleaned. Therefore, since the bristle material for brushes can be set in contact with the surface to be cleaned with a strong bristles, the bristle material for brushes does not wrap around the shaft body, maintains the working radius, and subdivides Scrapes dirt adhering to the fine irregularities of the surface to be cleaned, so that the car brush washing brush has excellent cleaning performance. However, since the hard non-foamed yarn is in direct contact with the surface to be cleaned, the average roughness of the surface to be cleaned is different from the blank value by 0.06 μm, and the brush hair material is not attached to the surface to be cleaned. Admitted.

比較例2の洗車機用洗浄ブラシは、被洗浄面にたいして、軟質な発泡糸からなるブラシ用毛材が当接する。その為、ブラシ用毛材が、被洗浄面に当接しても、被洗浄面の平均粗さはブランク値と差が無く、ブラシ用毛材による被洗浄面にたいする傷の付着は認められなかった。しかしながら、ブラシ用毛材は軟質な発泡糸であることから、ブラシ用毛材は軸体に巻き付きながら回転し、作用半径が小さくなる為、洗い残しが発生し、洗車機用洗浄ブラシは洗浄性能が劣るものであった。 In the cleaning brush for a car wash machine of Comparative Example 2, the brush bristle material made of soft foamed yarn comes into contact with the surface to be cleaned. Therefore, even when the brush bristle material abuts the surface to be cleaned, the average roughness of the surface to be cleaned is not different from the blank value, and no adhesion of scratches to the surface to be cleaned by the brush bristle material was observed. . However, since the bristle material for brushes is a soft foam yarn, the bristle material for brushes rotates while being wound around the shaft, and the working radius becomes small, so that unwashed residue is generated. Was inferior.

上記の如く構成された洗車機用洗浄ブラシ1の動作、作用は下記の通りである。

The operation and action of the

洗車機用洗浄ブラシ1は、ブラシ用毛材2を構成する硬度が高く、硬質な芯部5により毛腰を保持しながら、硬度が低く、軟質な外層部4が被洗浄面に当接する。その為、ブラシ用毛材2は、硬質な芯部5により毛腰が保持されることから、洗車機用洗浄ブラシ1の回転時において、軸体3に巻き付くこと無く、作用半径を維持することができるので、洗い残しが発生することが無く、優れた洗浄性能が発揮される。また、被洗浄面にたいして接触圧を高くしてブラシ用毛材2が当接しても、被洗浄面には軟質な外層部4が当接するので、被洗浄面に傷を付着させることが無い。

The

ブラシ用毛材2を構成する外層部4は、熱可塑性樹脂、及び熱可塑性エラストマーを有するポリマーアロイされた発泡体にて形成されてあり、外層部4は柔軟性に優れた発泡体であることから、ブラシ用毛材2が被洗浄面に当接する際の無傷性能が向上する。

The

ブラシ用毛材2を構成する芯部5は、熱可塑性樹脂、及び熱可塑性エラストマーを有するポリマーアロイされた非発泡体にて形成されてあり、芯部5は剛性に優れた非発泡体であることから、ブラシ用毛材2の毛腰を強く設定することができる為、洗車機用洗浄ブラシ1の洗浄性能が向上する。

The

ブラシ用毛材2は長手方向の端部に細分割部6が形成されてあり、細分割部6が被洗浄面の細かな凹凸部分に当接し、汚れを掻き出す為、洗車機用洗浄ブラシ1の洗浄性能が大幅に向上する。

The brush bristle

ブラシ用毛材2は芯線7、及び帯状体8に挟み付けられ、折り合わされて形成されたチャンネルブラシ9にて、軸体3の外周部に形成されてあり、チャンネルブラシ9は係止具10にて軸体3に固定されてあることから、洗車機用洗浄ブラシ1を製作する際、連続的にチャンネルブラシ9を形成し、軸体3の外周面に螺旋状に巻き付けて係止具10にて固定すればよいので、作業性が向上する。その為、洗車機用洗浄ブラシ1の生産コストの低減につながる。

The brush bristle

また、ブラシ用毛材2は、チャンネルブラシ9により傾斜角度を有して軸体3の外周部に巻き付けられて装着されているので、洗車中における洗車機用洗浄ブラシ1の保水性が高まり、洗浄性能が飛躍的に向上する。

Moreover, since the

(実施例2)

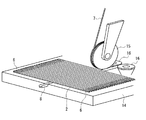

図5は、本発明の洗車機用洗浄ブラシが搭載されてある洗車機の正面図である。

(Example 2)

FIG. 5 is a front view of a car wash machine on which the car brush washing brush of the present invention is mounted.

図5において、洗車機20は、本発明の洗車機用洗浄ブラシ1が搭載されてあり、洗車機用洗浄ブラシ1は駆動源17により回転駆動される。ノズル18からは、被洗浄面にたいして、洗浄剤、及び洗浄水等が散布され、洗車機用洗浄ブラシ1により、被洗浄面に付着している汚れが除去され、洗浄後は洗車機20の乾燥手段である乾燥機19により被洗浄面が乾燥される。

In FIG. 5, the

上記の如く構成された洗車機20の動作、作用は下記の通りである。

The operation and action of the

洗車機20は、被洗浄面に傷を付着させること無く、優れた洗浄性能を有する洗車機用洗浄ブラシ1が搭載されてある為、駆動源17により洗車機用洗浄ブラシ1を低速に設定すると共に、洗浄時間を短時間に設定した場合においても、洗い残しの発生が防止され、優れた洗浄性能が発揮される。また、高速回転した場合においても、被洗浄面に傷を付着させることが無い。

Since the

本発明の洗車機用洗浄ブラシは、主に、自動車あるいは車両の外面の被洗浄面に付着した汚れ等を洗浄する為の洗車機に搭載する洗車機用洗浄ブラシとして使用する。 The washing brush for a car wash machine according to the present invention is mainly used as a washing brush for a car wash machine mounted on a car wash machine for washing dirt or the like adhering to an automobile or a surface to be cleaned of a vehicle.

1 洗車機用洗浄ブラシ

2 ブラシ用毛材

3 軸体

4 外層部

5 芯部

6 細分割部

7 芯線

8 帯状体

9 チャンネルブラシ

10 係止具

11 ネジ

12 湾曲部

13 爪

14 基台

15 縦ロール

16 横ロール

17 駆動源

18 ノズル

19 乾燥機

20 洗車機

DESCRIPTION OF

Claims (6)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007149139A JP4986716B2 (en) | 2007-06-05 | 2007-06-05 | Car wash machine washing brush and car wash machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007149139A JP4986716B2 (en) | 2007-06-05 | 2007-06-05 | Car wash machine washing brush and car wash machine |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2008302724A JP2008302724A (en) | 2008-12-18 |

| JP2008302724A5 JP2008302724A5 (en) | 2010-07-15 |

| JP4986716B2 true JP4986716B2 (en) | 2012-07-25 |

Family

ID=40231825

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007149139A Active JP4986716B2 (en) | 2007-06-05 | 2007-06-05 | Car wash machine washing brush and car wash machine |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4986716B2 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011030891A (en) * | 2009-08-04 | 2011-02-17 | Yonezu Brush Kk | Car washing brush |

| US8990993B2 (en) * | 2011-11-02 | 2015-03-31 | Belanger, Inc. | Vehicle wash component |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0621371B2 (en) * | 1990-06-28 | 1994-03-23 | 株式会社サンワード | Foam yarn for rotating brush |

| JP3418959B2 (en) * | 1992-09-07 | 2003-06-23 | タケウチテクノ株式会社 | Washing body of vehicle washing device |

| JP2002321601A (en) * | 2001-04-25 | 2002-11-05 | Takeuchi Techno Co Ltd | Bristle material of brush for car washer |

| JP3722026B2 (en) * | 2001-08-07 | 2005-11-30 | 株式会社ダイフク | Car wash machine |

| JP4570322B2 (en) * | 2002-11-06 | 2010-10-27 | 株式会社コーワ | Cleaning brush |

| JP4029842B2 (en) * | 2004-01-19 | 2008-01-09 | 株式会社ダイフク | Car wash machine |

| JP4518832B2 (en) * | 2004-03-31 | 2010-08-04 | 株式会社コーワ | Channel brush |

| JP4716697B2 (en) * | 2004-08-20 | 2011-07-06 | 株式会社コーワ | Cleaning brush for car wash machine |

| JP2006137394A (en) * | 2004-11-15 | 2006-06-01 | Yasui:Kk | Rotary brush for car washing machine |

| JP4614815B2 (en) * | 2005-02-23 | 2011-01-19 | 株式会社コーワ | Brush piece of washing brush for car wash machine |

-

2007

- 2007-06-05 JP JP2007149139A patent/JP4986716B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2008302724A (en) | 2008-12-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4986716B2 (en) | Car wash machine washing brush and car wash machine | |

| JP2009131386A (en) | Side brush for road surface sweeping vehicle and road surface sweeping vehicle | |

| JP4869673B2 (en) | Brush piece of washing brush for car wash machine, washing brush for car wash machine and car wash machine | |

| JP3275088B2 (en) | Brush roller for automatic car washer | |

| JP5751674B2 (en) | Brush hair | |

| JP2009126376A (en) | Washing brush for car wash, and car wash | |

| JP5118367B2 (en) | Brush piece of washing brush for car wash machine, washing brush for car wash machine and car wash machine | |

| JP2008061723A (en) | Washing brush for car wash and car wash | |

| JP2007244815A (en) | Bristle material of washing brush for car wash, washing brush for car wash and car wash | |

| JP4570322B2 (en) | Cleaning brush | |

| JP2012061983A (en) | Bristle material for brush of washing brush for car washing machine, washing brush for car washing machine, and car washing machine | |

| JP4347656B2 (en) | Brush hair | |

| JP2006231144A (en) | Brush bristle material for cleaning liquid crystal screen and brush for cleaning liquid crystal screen | |

| JP2006036176A (en) | Washing brush | |

| JP4554196B2 (en) | Brush hair | |

| JP3059331U (en) | Cleaning body for automatic car wash brush and automatic car wash brush using the same | |

| JP2001506174A (en) | Plastic hair for washing brush of automatic car wash | |

| JPH0457908A (en) | Foamed yarn for rotary brush | |

| JP2008099935A (en) | Washing brush for car wash and car wash | |

| JP4614815B2 (en) | Brush piece of washing brush for car wash machine | |

| JP3097369U (en) | Car wash brush | |

| JP3035692B2 (en) | Holder for sliding member | |

| JP2005082952A5 (en) | ||

| JPH0542742Y2 (en) | ||

| JP2009262842A (en) | Washing brush for car washing machine and car washing machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100602 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100602 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20100602 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120307 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120405 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120424 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4986716 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150511 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |