JP2007507602A - 電子ビームエンハンスト大面積堆積システム - Google Patents

電子ビームエンハンスト大面積堆積システム Download PDFInfo

- Publication number

- JP2007507602A JP2007507602A JP2006523827A JP2006523827A JP2007507602A JP 2007507602 A JP2007507602 A JP 2007507602A JP 2006523827 A JP2006523827 A JP 2006523827A JP 2006523827 A JP2006523827 A JP 2006523827A JP 2007507602 A JP2007507602 A JP 2007507602A

- Authority

- JP

- Japan

- Prior art keywords

- plasma

- large area

- electron beam

- source

- deposition system

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/34—Sputtering

- C23C14/3471—Introduction of auxiliary energy into the plasma

- C23C14/3478—Introduction of auxiliary energy into the plasma using electrons, e.g. triode sputtering

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physical Vapour Deposition (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/644,567 US20050040037A1 (en) | 2003-08-20 | 2003-08-20 | Electron beam enhanced large area deposition system |

| PCT/US2004/015273 WO2005020277A2 (en) | 2003-08-20 | 2004-05-13 | Electron beam enhanced large area deposition system |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2007507602A true JP2007507602A (ja) | 2007-03-29 |

| JP2007507602A5 JP2007507602A5 (enExample) | 2007-07-26 |

Family

ID=34194125

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006523827A Pending JP2007507602A (ja) | 2003-08-20 | 2004-05-13 | 電子ビームエンハンスト大面積堆積システム |

Country Status (3)

| Country | Link |

|---|---|

| US (2) | US20050040037A1 (enExample) |

| JP (1) | JP2007507602A (enExample) |

| WO (1) | WO2005020277A2 (enExample) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104498898B (zh) * | 2008-08-04 | 2017-10-24 | 北美Agc平板玻璃公司 | 通过等离子体增强的化学气相沉积形成涂层的方法 |

| JP6508746B2 (ja) | 2014-12-05 | 2019-05-08 | エージーシー フラット グラス ノース アメリカ,インコーポレイテッドAgc Flat Glass North America,Inc. | マクロ粒子低減コーティングを利用したプラズマ源ならびにマクロ粒子低減コーティングを用いたプラズマ源を薄膜コーティングおよび表面改質に使用する方法 |

| ES2883288T3 (es) | 2014-12-05 | 2021-12-07 | Agc Glass Europe Sa | Fuente de plasma de cátodo hueco |

| US9799491B2 (en) * | 2015-10-29 | 2017-10-24 | Applied Materials, Inc. | Low electron temperature etch chamber with independent control over plasma density, radical composition and ion energy for atomic precision etching |

| US9721764B2 (en) | 2015-11-16 | 2017-08-01 | Agc Flat Glass North America, Inc. | Method of producing plasma by multiple-phase alternating or pulsed electrical current |

| US9721765B2 (en) | 2015-11-16 | 2017-08-01 | Agc Flat Glass North America, Inc. | Plasma device driven by multiple-phase alternating or pulsed electrical current |

| US10242846B2 (en) | 2015-12-18 | 2019-03-26 | Agc Flat Glass North America, Inc. | Hollow cathode ion source |

| US10573499B2 (en) | 2015-12-18 | 2020-02-25 | Agc Flat Glass North America, Inc. | Method of extracting and accelerating ions |

| US11257685B2 (en) * | 2018-09-05 | 2022-02-22 | Tokyo Electron Limited | Apparatus and process for electron beam mediated plasma etch and deposition processes |

| CN112680700B (zh) * | 2020-12-04 | 2022-07-26 | 安徽工业大学 | 一种电子束辅助碳基超润滑固体薄膜制备装置及方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3393142A (en) * | 1964-08-20 | 1968-07-16 | Cons Vacuum Corp | Cathode sputtering apparatus with plasma confining means |

| US3436332A (en) * | 1965-07-15 | 1969-04-01 | Nippon Electric Co | Stabilized low pressure triode sputtering apparatus |

| JPH09111443A (ja) * | 1995-10-12 | 1997-04-28 | Mitsubishi Heavy Ind Ltd | 薄膜コーティング方法及び装置 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4336277A (en) * | 1980-09-29 | 1982-06-22 | The Regents Of The University Of California | Transparent electrical conducting films by activated reactive evaporation |

| JPH01268859A (ja) * | 1988-04-20 | 1989-10-26 | Casio Comput Co Ltd | 透明導電膜の形成方法および形成装置 |

| US5182496A (en) * | 1992-04-07 | 1993-01-26 | The United States Of America As Represented By The Secretary Of The Navy | Method and apparatus for forming an agile plasma mirror effective as a microwave reflector |

| US6416635B1 (en) * | 1995-07-24 | 2002-07-09 | Tokyo Electron Limited | Method and apparatus for sputter coating with variable target to substrate spacing |

| CU22559A1 (es) * | 1996-01-17 | 1999-05-03 | Ct Ingenieria Genetica Biotech | Sistema de expresión de antígenos heterologos en e. coli como proteínas de fusión |

| US5874807A (en) * | 1997-08-27 | 1999-02-23 | The United States Of America As Represented By The Secretary Of The Navy | Large area plasma processing system (LAPPS) |

-

2003

- 2003-08-20 US US10/644,567 patent/US20050040037A1/en not_active Abandoned

-

2004

- 2004-05-13 WO PCT/US2004/015273 patent/WO2005020277A2/en not_active Ceased

- 2004-05-13 JP JP2006523827A patent/JP2007507602A/ja active Pending

-

2009

- 2009-08-27 US US12/548,510 patent/US20090314633A1/en not_active Abandoned

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3393142A (en) * | 1964-08-20 | 1968-07-16 | Cons Vacuum Corp | Cathode sputtering apparatus with plasma confining means |

| US3436332A (en) * | 1965-07-15 | 1969-04-01 | Nippon Electric Co | Stabilized low pressure triode sputtering apparatus |

| JPH09111443A (ja) * | 1995-10-12 | 1997-04-28 | Mitsubishi Heavy Ind Ltd | 薄膜コーティング方法及び装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2005020277A3 (en) | 2005-05-12 |

| WO2005020277A2 (en) | 2005-03-03 |

| US20090314633A1 (en) | 2009-12-24 |

| US20050040037A1 (en) | 2005-02-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA2103770C (en) | Plasma-enhanced magnetron-sputtered deposition of materials | |

| US6787010B2 (en) | Non-thermionic sputter material transport device, methods of use, and materials produced thereby | |

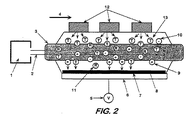

| US20090314633A1 (en) | Electron beam enhanced large area deposition system | |

| CA2411174C (en) | A process and apparatus for plasma activated deposition in a vacuum | |

| CA2326202C (en) | Method and apparatus for deposition of biaxially textured coatings | |

| Jung et al. | Deposition of Ti thin film using the magnetron sputtering method | |

| Musa et al. | Pure metal vapor plasma source with controlled energy of ions | |

| US20110308461A1 (en) | Electron Beam Enhanced Nitriding System (EBENS) | |

| US5650201A (en) | Method for producing carbon nitride films | |

| Leonhardt et al. | Applications of electron-beam generated plasmas to materials processing | |

| KR102533881B1 (ko) | 단일 빔 플라즈마 소스 | |

| Yamamoto et al. | The sp3 bond fraction in carbon films prepared by mass-separated ion beam deposition | |

| Viloan et al. | Tuning the stress in TiN films by regulating the doubly charged ion fraction in a reactive HiPIMS discharge | |

| Lazar et al. | Ion flux characteristics and efficiency of the deposition processes in high power impulse magnetron sputtering of zirconium | |

| US8134287B1 (en) | Low voltage closed drift anode layer ion source | |

| JP2007507602A5 (enExample) | ||

| US20090014316A1 (en) | Sputter-enhanced evaporative deposition apparatus and method | |

| Bárdoš et al. | New microwave and hollow cathode hybrid plasma sources | |

| Muratore et al. | Control of plasma flux composition incident on TiN films during reactive magnetron sputtering and the effect on film microstructure | |

| Van Hattum et al. | Distinct processes in radio-frequency reactive magnetron plasma sputter deposition of silicon suboxide films | |

| Sarangi et al. | Characterisation of a saddle field fast atom beam source and its application to the growth of diamond-like carbon films | |

| JP2001172763A (ja) | 金属含有硬質炭素膜の形成方法 | |

| Zimmermann et al. | The potential of plasma activation for EB-PVD of EBC systems on CMC components | |

| Anders | Plasma and Ion Assistance in Physical Vapor Deposition: A Historical Perspective | |

| Samuelsson | Fundamental aspects of HiPIMS under industrial conditions |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070509 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070509 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100818 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20110209 |