JP2006128010A - Sealed battery - Google Patents

Sealed battery Download PDFInfo

- Publication number

- JP2006128010A JP2006128010A JP2004317137A JP2004317137A JP2006128010A JP 2006128010 A JP2006128010 A JP 2006128010A JP 2004317137 A JP2004317137 A JP 2004317137A JP 2004317137 A JP2004317137 A JP 2004317137A JP 2006128010 A JP2006128010 A JP 2006128010A

- Authority

- JP

- Japan

- Prior art keywords

- elastic ring

- battery

- exhaust opening

- sealed battery

- safety valve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Abstract

Description

本発明は、密閉電池の改良に関し、とくに水分による腐食を有効に防止できる密閉電池に関する。 The present invention relates to an improvement in a sealed battery, and more particularly to a sealed battery that can effectively prevent corrosion due to moisture.

密閉電池は、電池の内圧が異常に高くなるときに外装缶が破壊されるのを防止するために安全弁を設けている。安全弁は、内圧が設定圧力よりも高くなると開弁して、内部のガスや電解液等を排出して内圧を低下させる。この安全弁は、封口板に設けた凸部電極に内蔵している。安全弁を内蔵する凸部電極は、開弁した安全弁を通過したガス等の流体を排気するために排気開口を設けている。 The sealed battery is provided with a safety valve to prevent the outer can from being destroyed when the internal pressure of the battery becomes abnormally high. The safety valve opens when the internal pressure becomes higher than the set pressure, and discharges internal gas, electrolyte, and the like to lower the internal pressure. This safety valve is built in the convex electrode provided on the sealing plate. The convex electrode incorporating the safety valve is provided with an exhaust opening for exhausting a fluid such as gas that has passed through the opened safety valve.

この構造の電池は、排気開口から水が侵入して腐食させる弊害がある。とくにリチウムイオン二次電池は電圧が高く、金属部分の電食が発生しやすい。電食で金属が腐食されると、電解液が漏れて電池を使用できなくなるなどの弊害が発生する。この弊害は、電池に水分が付着しない状態で使用して解消できる。ただ、電池は種々の環境で使用されるので、水分の付着を皆無にはできない。たとえば、電池を強制送風して冷却しながら充電するとき、空気と一緒に塵や水分が侵入することがある。このように種々の環境で使用される電池は、水が付着しても腐食しないようにすることが大切である。 The battery having this structure has a harmful effect that water enters from the exhaust opening and corrodes. In particular, a lithium ion secondary battery has a high voltage and is liable to cause electrolytic corrosion of metal parts. If the metal is corroded by electrolytic corrosion, problems such as leakage of the electrolyte and the inability to use the battery occur. This problem can be solved by using the battery without moisture. However, since the battery is used in various environments, it is impossible to eliminate moisture adhesion. For example, when charging a battery while forcibly blowing and cooling it, dust and moisture may enter along with the air. Thus, it is important that batteries used in various environments do not corrode even if water adheres to them.

耐水性を向上するために、電池の端面を防水キャップでカバーする構造が開発されている(特許文献1参照)。

この公報に記載される電池は、防水キャップを電池の先端部に水密に装着して、水密構造としている。さらに、この防水キャップは、凸部電極を外部に接続するために、中心に端子金属を水密に貫通して固定している。端子金属は、内面を電池の凸部電極に接触して電気接続する。この構造の電池は、防水キャップで外形が大きくなる欠点がある。このため、防水キャップを装着する状態で、電池を電池の装着部に簡単に装着できなくなり、また、この電池を組み合わせてパック電池にすると外形が大きくなる欠点がある。また、防水キャップの凸リング部を電池の外周溝に入れて水密な状態で電池に連結するので、凸リング部がずれると、防水構造にできなくなる。この欠点を少なくするために、凸リング部を強く外周溝に入れると、安全弁が開弁する状態で、ガス等をスムーズに排出できなくなる。さらに、この構造の電池は、接触不良が発生しやすい欠点がある。それは、端子金属を介して電池に接続するので、端子金属と凸部電極との接触不良を皆無にできないからである。また、この構造は、防水キャップの構造が複雑なために、製造コストが高くなる欠点もある。 The battery described in this publication has a watertight structure in which a waterproof cap is watertightly attached to the tip of the battery. Further, this waterproof cap has a terminal metal penetrating in a watertight manner and fixed to the center in order to connect the convex electrode to the outside. The terminal metal contacts the convex electrode of the battery for electrical connection. The battery having this structure has a drawback that the outer shape becomes large due to the waterproof cap. For this reason, it is not possible to easily attach the battery to the battery mounting portion with the waterproof cap attached, and there is a disadvantage that the outer shape becomes large when the battery is combined to form a battery pack. Moreover, since the convex ring part of the waterproof cap is inserted into the outer peripheral groove of the battery and connected to the battery in a watertight state, if the convex ring part is displaced, a waterproof structure cannot be obtained. In order to reduce this defect, if the convex ring portion is strongly inserted into the outer peripheral groove, gas or the like cannot be discharged smoothly with the safety valve opened. Further, the battery having this structure has a drawback that contact failure is likely to occur. This is because the contact failure between the terminal metal and the convex electrode cannot be completely eliminated because the battery is connected to the battery via the terminal metal. In addition, this structure has a drawback that the manufacturing cost is high because the structure of the waterproof cap is complicated.

本発明は、さらにこの欠点を解決することを目的に開発されたものである。本発明の重要な目的は、極めて簡単な構造で、封口板の安全弁を水密構造に閉塞でき、しかも安全弁が開弁するときには、ガス等をスムーズに排気して電池の内圧上昇を防止でき、さらに安全弁の排気開口を防水構造とするための接触不良を皆無にできる電池を提供することにある。 The present invention has been developed for the purpose of solving this drawback. An important object of the present invention is that the safety valve of the sealing plate can be closed to a watertight structure with a very simple structure, and when the safety valve opens, the gas etc. can be smoothly exhausted to prevent an increase in the internal pressure of the battery. It is an object of the present invention to provide a battery that can eliminate contact failure for making the exhaust opening of a safety valve waterproof.

本発明の密閉電池は、前述の目的を達成するために以下の構成を備える。

本発明の密閉電池は、封口板1の凸部電極2に、安全弁3の排気開口4を設けており、外装缶5の内圧が上昇して安全弁3が開弁する状態では、排気開口4から電池内の内容物を排出する。さらに、密閉電池は、凸部電極2の周壁に排気開口4を設けると共に、この凸部電極2を、ゴム状弾性体をリング状に成形して内周面6Aを凸部電極2の表面に弾性的に押圧する形状としている弾性リング6に挿入している。密閉電池は、弾性リング6でもって排気開口4を直接に閉塞し、あるいは、弾性リング6を凸部電極2の周壁と電池の端面とに密着させて実質的に排気開口4を閉塞している。弾性リング6は、安全弁3の閉弁状態においては、排気開口4を閉塞し、安全弁3の開弁状態においては、安全弁3から排出される内容物を排気開口4から外部に排出する状態とするようにしている。

本明細書において、排気開口から排出される電池内の内容物とは、ガスや電解液等の流体だけでなく、電池の内圧上昇によって電池内に発生する種々の異物、例えば、熱で溶融されたプラスチックや破裂した金属片やバリ等のように、ガスや電解液等の流体と共に排出される全てのものを含む広い意味で使用する。

The sealed battery of the present invention has the following configuration in order to achieve the above-described object.

In the sealed battery of the present invention, the

In this specification, the contents in the battery discharged from the exhaust opening are not only fluids such as gas and electrolyte, but are also melted by various foreign matters generated in the battery due to an increase in the internal pressure of the battery, for example, heat. It is used in a broad sense including everything that is discharged with fluids such as gas and electrolyte, such as plastic, ruptured metal pieces and burrs.

本発明の密閉電池は、弾性リング6を電池の端面に接着して固定することができる。本発明の密閉電池は、外装缶5の周囲を熱収縮チューブ7で被覆し、この熱収縮チューブ7の内部に弾性リング6を入れて、熱収縮チューブ7で電池の端面に固定することができる。本発明の密閉電池は、凸部電極2にリード板8を接続して、リード板8で弾性リング6の上面を押圧して、弾性リング6を電池の端面に固定することができる。

The sealed battery of the present invention can be fixed by adhering the

本発明の密閉電池は、排気開口4を凸部電極2の下部に開口することができる。本発明の密閉電池は、リチウムイオン二次電池とすることができる。本発明の密閉電池は、弾性リング6を、合成ゴム、天然ゴム、軟質の合成樹脂、独立気泡を有する合成樹脂発泡体の何れかとすることができる。さらに、本発明の密閉電池は、弾性リング6が撥水性を有し、あるいは弾性リング6に撥水処理をすることができる。

In the sealed battery of the present invention, the

本発明の電池は、極めて簡単な構造で、封口板に設けた安全弁の排気開口を水密に閉塞できる特徴がある。それは、本発明の電池が、凸部電極を弾性リングに入れて、弾性リングの内周面を凸部電極の表面に弾性的に押圧して、弾性リングで排気開口を水密に閉塞するからである。とくに、この構造の電池は、小さい弾性リングに凸部電極を入れて、排気開口を水密に閉塞できるので、その構造を極めて簡単にできる。 The battery of the present invention has a very simple structure and is characterized in that the exhaust opening of the safety valve provided on the sealing plate can be closed in a watertight manner. This is because the battery of the present invention inserts the convex electrode into the elastic ring, elastically presses the inner peripheral surface of the elastic ring against the surface of the convex electrode, and closes the exhaust opening in a watertight manner with the elastic ring. is there. In particular, the battery having this structure can be very simple because the exhaust opening can be closed in a watertight manner by inserting a convex electrode in a small elastic ring.

また、本発明の電池は、排気開口を水密に閉塞しながら、安全弁が開弁するときには、電池内のガス等をスムーズに排気して電池の内圧上昇を防止できる特徴がある。この特徴は、凸部電極を挿入している弾性リングに、安全弁が開弁すると排気開口を開口する弾性のものを使用しているからである。 In addition, the battery of the present invention is characterized in that when the safety valve is opened while the exhaust opening is closed in a watertight manner, the gas in the battery is smoothly exhausted to prevent an increase in the internal pressure of the battery. This feature is because the elastic ring into which the convex electrode is inserted uses an elastic ring that opens the exhaust opening when the safety valve opens.

さらにまた、本発明の電池の特筆すべき特徴は、安全弁の排気開口を防水構造としなから、凸部電極の接触不良を皆無にできることである。それは、本発明の電池が、弾性リングに凸部電極を挿入して凸部電極の排気開口を閉塞するので、凸部電極を外部に接続する電極としてそのまま使用するからである。すなわち、従来の電池のように、端子金属を介して外部に接続する必要がないために、端子金属と凸部電極との接触不良を皆無にできる特徴がある。 Furthermore, a notable feature of the battery of the present invention is that the exhaust opening of the safety valve is not waterproof, so that contact failure of the convex electrode can be eliminated. This is because the battery of the present invention inserts the convex electrode into the elastic ring and closes the exhaust opening of the convex electrode, so that the convex electrode is used as it is as an electrode connected to the outside. That is, unlike the conventional battery, since there is no need to connect to the outside via the terminal metal, there is a feature that the contact failure between the terminal metal and the convex electrode can be eliminated.

さらに、本発明の請求項2ないし4に記載している電池は、弾性リングを封口板の表面に固定しているので、弾性リングの位置がずれることがなく、安全弁が閉弁される状態では、凸部電極の排気開口を弾性リングで確実に閉塞して防水構造にできる特徴がある。また、この電池は、弾性リングを簡単な構造で、しっかりと封口板の表面に配置して、凸部電極の排気開口を閉塞する位置に固定できる特徴がある。

Further, in the battery according to

さらにまた、本発明の請求項8の電池は、弾性リングが撥水性を有するので、弾性リングが水を撥水してより効果的に凸部電極の排気開口を防水できる特徴がある。 Furthermore, the battery according to claim 8 of the present invention is characterized in that since the elastic ring has water repellency, the elastic ring can repel water and waterproof the exhaust opening of the convex electrode more effectively.

以下、本発明の実施例を図面に基づいて説明する。ただし、以下に示す実施例は、本発明の技術思想を具体化するための密閉電池を例示するものであって、本発明は電池を以下のものに特定しない。 Embodiments of the present invention will be described below with reference to the drawings. However, the example shown below illustrates the sealed battery for embodying the technical idea of the present invention, and the present invention does not specify the battery as follows.

さらに、この明細書は、特許請求の範囲を理解しやすいように、実施例に示される部材に対応する番号を、「特許請求の範囲」および「課題を解決するための手段の欄」に示される部材に付記している。ただ、特許請求の範囲に示される部材を、実施例の部材に特定するものでは決してない。 Further, in this specification, in order to facilitate understanding of the scope of claims, numbers corresponding to the members shown in the examples are indicated in the “claims” and “means for solving problems” sections. It is added to the members. However, the members shown in the claims are not limited to the members in the embodiments.

本発明の密閉電池は、リチウムイオン二次電池において特に有効である。それは、リチウムイオン二次電池の電圧が3.6Vと他の電池に比較して高いので、水による電食が発生しやすいからである。ただ、本発明は、密閉電池をリチウムイオン二次電池には特定しない。電池には、ニッケル水素電池やニッケルカドミウム電池等、安全弁を備える全ての二次電池とすることができる。 The sealed battery of the present invention is particularly effective in a lithium ion secondary battery. This is because the voltage of the lithium ion secondary battery is 3.6 V, which is higher than that of other batteries, so that electric corrosion due to water is likely to occur. However, the present invention does not specify a sealed battery as a lithium ion secondary battery. The battery can be any secondary battery equipped with a safety valve, such as a nickel metal hydride battery or a nickel cadmium battery.

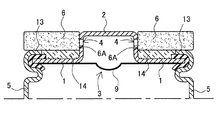

図1ないし図3に示す電池は、封口板1の凸部電極2の内部に安全弁3を内蔵している。図の安全弁3は、内圧が設定圧力まで上昇すると破壊して開弁する薄膜プレート9を備える。薄膜プレート9は、アルミニウムやアルミニウム合金の薄膜である。この薄膜プレート9は、局部的に薄くして、設定圧力で破壊しやすくしており、あるいは図に示すように、下方に突出させる形状として破壊しやすくできる。図に示すように、凸部電極2の内部にアルミニウムやアルミニウム合金からなる薄膜プレート9を設けている安全弁3は、設定圧力で確実に破壊されて安全性を向上できるが、凸部電極2の内部に侵入する水で特に腐食しやすい。このため、この構造の安全弁3を備える電池は、弾性リング6で水の侵入を防止して、信頼性を著しく向上できる。すなわち、水で腐食せず、しかも内圧が設定圧力よりも高くなると確実に開弁して、異常な高圧になるのを防止できる。

The battery shown in FIGS. 1 to 3 has a

ただし、本発明は、安全弁3の構造を薄膜プレート9を破壊するタイプには特定しない。たとえば、図4に示すように、弁体10を弾性体11で弁座12に押圧している安全弁3を内蔵する電池にも使用できる。この安全弁3は、電池の内圧が設定圧力よりも低いときは、弾性体11が弁体10を弁座12に押圧して閉弁している。しかしながら、電池の内圧が設定圧力よりも高くなると、弾性体11で押されるいる弁体10が弁座12から離れて開弁される。また、いずれの構造の安全弁であっても、凸部電極の内部に水が侵入して、金属部分が腐食されると電池として正常に動作しなくなるので、本発明の電池は、安全弁の構造を特定しない。

However, the present invention does not specify the structure of the

凸部電極2は、周壁に排気開口4を開口している。図の電池は、金属板の封口板1をプレス成形して、上端面を閉塞する円筒状の凸部電極2を設けている。円筒状の凸部電極2は、周壁の外周面に、後で記述する弾性リング6の内周面6Aを均一に密着できる。ただ、本発明の電池は、凸部電極を円筒状に特定しない。凸部電極は、四角形等の多角筒状とすることもできる。円筒や角筒等の筒状の凸部電極2は、弾性リング6を抜けないように挿入して、電池の端面で排気開口4を閉塞できる。このため、弾性リング6を端面に接着したり、あるいは熱収縮チューブ7等で固定することなく、電池の端面に固定できる。ただ、本発明の密閉電池は、凸部電極を筒状には特定せず、凸部電極を上端に向かって細くなるテーパー状とすることもできる。

The

電池は、安全弁3が開弁するときに、電池の内部のガスや電解液等の内容物を排気開口4に通過させて外部に排出する。安全弁3が閉弁する状態で、排気開口4を通過して凸部電極2の内部に水が侵入するのを阻止するために、図の電池は、凸部電極2を弾性リング6に挿入している。いいかえると、凸部電極2の周囲に弾性リング6を配置している。

When the

弾性リング6は、ゴム状弾性体をリング状に成形して、内周面6Aを凸部電極2の表面に弾性的に押圧する形状としている。この弾性リング6は、図1ないし図3に示すように、内周面6Aを弾性的に凸部電極2の周壁に押圧して、周壁に設けている排気開口4を閉塞する。弾性リング6は、安全弁3が閉弁する状態では、排気開口4を閉塞する。ただし、安全弁3が開弁するときは、安全弁3を通過した電池内の内容物を、排気開口4から電池の外部に排出する必要がある。したがって弾性リング6の内周面6Aが排気開口4を閉塞する弾性押圧力は、安全弁3が開弁するときには、排気開口4から内容物を排出できる圧力に設定している。

The

弾性リング6が内周面6Aを凸部電極2の周壁表面に押し付ける圧力は、弾性リング6の弾性、すなわち弾性率と、凸部電極2の外形に対する弾性リング6の内形の比率で特定される。弾性リング6は、伸縮させない状態での内形を、凸部電極2の外形よりも小さくして、内周面6Aを凸部電極2の表面に弾性的に押し付けて、排気開口4を閉塞する。この弾性リング6は、内形を凸部電極2の外形に近くするにしたがって、内周面6Aが凸部電極2表面を押圧する圧力は弱くなる。反対に、弾性リング6の内形を凸部電極2の外形に比較して小さくするほど、弾性リング6は強く伸長されて、内周面6Aを凸部電極2表面に強く押圧する。また、弾性リング6を柔軟な材質で製作すると、内周面6Aが凸部電極2表面を押圧する圧力は弱くなり、反対に弾性リング6を硬くて変形し難い材質で製作すると、内周面6Aが凸部電極2表面に強く押圧される。弾性リング6の内周面6Aが凸部電極2表面に押圧される圧力は、安全弁3が閉弁する状態では、弾性リング6が排気開口4を確実に閉弁し、安全弁3が開く状態では、電池内の内容物を排気開口4から電池外に排出できる圧力とする。安全弁3が閉弁する状態では、排気開口4に圧力が作用しない。弾性リング6は、この状態の排気開口4を閉弁すればよいので、強く凸部電極2表面を押圧する必要はない。

The pressure with which the

図1ないし図3の弾性リング6は、外形を電池端面の外形にほぼ等しくしている。この弾性リング6は、封口板1の上面と、かしめ凸条13の表面をカバーする状態で端面に固定される。弾性リングは、図示しないが、かしめ凸条の内側に固定することもできる。この弾性リングは、外形をかしめ凸条の内形に等しく、あるいはかしめ凸条の内形よりもわずかに大きくし、弾性変形させて、かしめ凸条の内側で封口板の表面に固定される。

The outer shape of the

弾性リング6は、合成ゴム、天然ゴム、軟質の合成樹脂、あるいは独立気泡を有する合成樹脂発泡体等のゴム状弾性体で製作される。これらの材料で製作される弾性リング6は、水の侵入を確実に阻止できる特長がある。さらに、弾性リング6に撥水性を有する材料を使用して、あるいは、弾性リング6に撥水処理をして、より効果的に凸部電極の排気開口4を防水できる。ただ、弾性リングは、連続気泡を有する合成樹脂発泡体で製作することもできる。この弾性リングは、安全弁の開弁状態におけるガスの排出効果を向上できる特長がある。さらに、連続気泡を有する弾性リングは、連続気泡をミクロオーダーの細かい気泡とし、あるいは表面や内部に撥水処理をして、水の侵入を効果的に防止できる。

The

弾性リング6が排気開口4を閉塞する状態は、図1ないし図3に示すように、内周面6Aの幅を排気開口4の幅よりも広くして、内周面6Aで直接に排気開口4を閉塞する状態と、図5に示すように、内周面6Aで排気開口4を完全には閉塞しないが、内周面6Aを凸部電極2の表面に、下面6Bを電池端面に密着させて排気開口4を外部から遮断して実質的に閉塞する状態とがある。図5に示す電池は、弾性リング6の下面6Bをかしめ凸条13に密着させて、排気開口4を外部から遮断して閉塞している。いずれの状態も、排気開口4を弾性リング6が閉塞するので、排気開口4から凸部電極2の内部に水が侵入することはない。図示しないが、弾性リングの下面を電池端面に密着させて排気開口を閉塞する電池は、安全弁が開く状態において、弾性リングの下面と電池端面との間に電池の内容物を通過させて外部に排出することもできる。このとき、弾性リングは、電池端面との接触部分において変形し、あるいは位置をずらして電池内の内容物を外部に排出する状態となる。

The state in which the

図1の電池は、外装缶5の周囲を熱収縮チューブ7で被覆し、この熱収縮チューブ7の内部に弾性リング6を入れて、熱収縮チューブ7で弾性リング6を電池の端面に固定している。熱収縮チューブ7は、端縁を弾性リング6の表面側をカバーするように曲げて、弾性リング6を確実に固定する。

In the battery of FIG. 1, the

図2の電池は、弾性リング6を電池の端面に接着して固定している。端面は、接着剤14で接着して固定され、あるいは粘着層を介して固定され、あるいはまた両面接着テープを介して端面に固定される。弾性リング6は、かしめ凸条13に接着して固定され、あるいは封口板1の表面に接着して固定される。

In the battery shown in FIG. 2, the

図3の電池は、凸部電極2に溶接して固定しているリード板8で弾性リング6の上面を押圧して、弾性リング6を電池の端面に固定している。この状態で固定される弾性リング6は、圧縮しない状態での厚さ、すなわち高さを、電池の端面と凸部電極2の頂上との上下差よりも大きくしている。この弾性リング6は、リード板8が弾性リング6を弾性的に多少押し潰す状態で、弾性リング6の下面6Bを電池端面に密着する状態で固定できる。

The battery of FIG. 3 presses the upper surface of the

1…封口板

2…凸部電極

3…安全弁

4…排気開口

5…外装缶

6…弾性リング 6A…内周面 6B…下面

7…熱収縮チューブ

8…リード板

9…薄膜プレート

10…弁体

11…弾性体

12…弁座

13…かしめ凸条

14…接着剤

DESCRIPTION OF

Claims (8)

凸部電極(2)の周壁に排気開口(4)を設けると共に、この凸部電極(2)を、ゴム状弾性体をリング状に成形して、内周面(6A)を凸部電極(2)の表面に弾性的に押圧する形状としている弾性リング(6)に挿入して、弾性リング(6)でもって直接に排気開口(4)を閉塞し、あるいは、弾性リング(6)を凸部電極(2)の周壁と電池の端面とに密着させて実質的に排気開口(4)を閉塞しており、

この弾性リング(6)が、安全弁(3)の閉弁状態においては排気開口(4)を閉塞し、安全弁(3)の開弁状態においては、安全弁(3)から排出される内容物を排気開口(4)から外部に排出する状態とするようにしてなる密閉電池。 In the state where the relief electrode (2) of the sealing plate (1) is provided with the exhaust opening (4) of the safety valve (3), the internal pressure of the outer can (5) rises and the safety valve (3) opens. A sealed battery configured to discharge the contents in the battery from the exhaust opening (4),

An exhaust opening (4) is provided on the peripheral wall of the convex electrode (2), and the convex electrode (2) is formed by molding a rubber-like elastic body into a ring shape, and the inner peripheral surface (6A) is formed on the convex electrode ( 2) Insert into the elastic ring (6) that is elastically pressed against the surface of (2) and directly close the exhaust opening (4) with the elastic ring (6), or project the elastic ring (6) The exhaust opening (4) is closed substantially in close contact with the peripheral wall of the partial electrode (2) and the end face of the battery,

The elastic ring (6) closes the exhaust opening (4) when the safety valve (3) is closed, and exhausts the contents discharged from the safety valve (3) when the safety valve (3) is open. A sealed battery configured to be discharged from the opening (4).

The sealed battery according to claim 1, wherein the elastic ring (6) has water repellency or is subjected to water repellency treatment.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004317137A JP2006128010A (en) | 2004-10-29 | 2004-10-29 | Sealed battery |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004317137A JP2006128010A (en) | 2004-10-29 | 2004-10-29 | Sealed battery |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006128010A true JP2006128010A (en) | 2006-05-18 |

| JP2006128010A5 JP2006128010A5 (en) | 2010-01-14 |

Family

ID=36722500

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004317137A Pending JP2006128010A (en) | 2004-10-29 | 2004-10-29 | Sealed battery |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2006128010A (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009302019A (en) * | 2008-06-17 | 2009-12-24 | Panasonic Corp | Sealed battery |

| CN102272981A (en) * | 2009-07-17 | 2011-12-07 | 松下电器产业株式会社 | Battery module and battery pack using same |

| CN104282850A (en) * | 2013-07-03 | 2015-01-14 | 株式会社神户制钢所 | Battery casing and battery casing safety valve forming method |

| JP2015204285A (en) * | 2014-04-11 | 2015-11-16 | 三星エスディアイ株式会社Samsung SDI Co.,Ltd. | Secondary battery |

| CN108461663A (en) * | 2017-02-21 | 2018-08-28 | 丰田自动车株式会社 | Cylinder battery |

| CN110890490A (en) * | 2019-12-14 | 2020-03-17 | 安徽飞凯电子技术有限公司 | Lithium battery cap |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000106170A (en) * | 1998-09-29 | 2000-04-11 | Sanoh Industrial Co Ltd | Connecting plate |

| JP2001126681A (en) * | 1999-10-27 | 2001-05-11 | Sony Corp | Battery |

| JP2002170539A (en) * | 2000-11-29 | 2002-06-14 | Sony Corp | Battery |

| JP2002246004A (en) * | 2001-02-21 | 2002-08-30 | Toshiba Battery Co Ltd | Battery connection structure |

-

2004

- 2004-10-29 JP JP2004317137A patent/JP2006128010A/en active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000106170A (en) * | 1998-09-29 | 2000-04-11 | Sanoh Industrial Co Ltd | Connecting plate |

| JP2001126681A (en) * | 1999-10-27 | 2001-05-11 | Sony Corp | Battery |

| JP2002170539A (en) * | 2000-11-29 | 2002-06-14 | Sony Corp | Battery |

| JP2002246004A (en) * | 2001-02-21 | 2002-08-30 | Toshiba Battery Co Ltd | Battery connection structure |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009302019A (en) * | 2008-06-17 | 2009-12-24 | Panasonic Corp | Sealed battery |

| CN102272981A (en) * | 2009-07-17 | 2011-12-07 | 松下电器产业株式会社 | Battery module and battery pack using same |

| CN104282850A (en) * | 2013-07-03 | 2015-01-14 | 株式会社神户制钢所 | Battery casing and battery casing safety valve forming method |

| JP2015204285A (en) * | 2014-04-11 | 2015-11-16 | 三星エスディアイ株式会社Samsung SDI Co.,Ltd. | Secondary battery |

| CN108461663A (en) * | 2017-02-21 | 2018-08-28 | 丰田自动车株式会社 | Cylinder battery |

| CN110890490A (en) * | 2019-12-14 | 2020-03-17 | 安徽飞凯电子技术有限公司 | Lithium battery cap |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110429214B (en) | Cap assembly for secondary battery and secondary battery | |

| JPH1064507A (en) | Connecting structure for battery | |

| JP2005003181A (en) | Gasket | |

| JP2012234785A (en) | Sealed battery and sealing body thereof | |

| JP2543325Y2 (en) | Battery | |

| JP4078519B2 (en) | Pressure release valve | |

| JP4615215B2 (en) | Electrochemical battery end cap assembly | |

| US6806000B2 (en) | Post seal for lead acid batteries | |

| JP2006128010A (en) | Sealed battery | |

| US20020039678A1 (en) | Sealed type lead acid battery | |

| JP4166938B2 (en) | Snap-through gasket for Galivani batteries | |

| JP3612931B2 (en) | Cylindrical alkaline battery | |

| JP2001015094A (en) | Cylindrical battery and manufacture thereof | |

| JP2009501407A (en) | Storage battery | |

| JP2003272574A (en) | Sealed battery | |

| JPH09120811A (en) | Sealed storage battery | |

| JP2004039341A (en) | Gasket for fuel cell | |

| JPH10199495A (en) | Sealed structure of sealed battery and gasket to be used therefor | |

| JP5114004B2 (en) | Cylindrical battery | |

| JP2006294669A (en) | Pressure release valve | |

| JP2002260624A (en) | Control valve type lead-acid battery | |

| JP2005285404A (en) | Closed mold secondary battery | |

| JP3077215B2 (en) | Battery | |

| JP4789442B2 (en) | Battery seal and battery | |

| JP2004186060A (en) | Battery |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20061204 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091125 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100513 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100629 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100805 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20101026 |