JP2005290734A - Decorative sheet for floor material - Google Patents

Decorative sheet for floor material Download PDFInfo

- Publication number

- JP2005290734A JP2005290734A JP2004104712A JP2004104712A JP2005290734A JP 2005290734 A JP2005290734 A JP 2005290734A JP 2004104712 A JP2004104712 A JP 2004104712A JP 2004104712 A JP2004104712 A JP 2004104712A JP 2005290734 A JP2005290734 A JP 2005290734A

- Authority

- JP

- Japan

- Prior art keywords

- layer

- resin

- decorative sheet

- thermoplastic resin

- flooring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B44—DECORATIVE ARTS

- B44C—PRODUCING DECORATIVE EFFECTS; MOSAICS; TARSIA WORK; PAPERHANGING

- B44C5/00—Processes for producing special ornamental bodies

- B44C5/04—Ornamental plaques, e.g. decorative panels, decorative veneers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/32—Layered products comprising a layer of synthetic resin comprising polyolefins

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/08—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F15/00—Flooring

- E04F15/02—Flooring or floor layers composed of a number of similar elements

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F15/00—Flooring

- E04F15/02—Flooring or floor layers composed of a number of similar elements

- E04F15/02005—Construction of joints, e.g. dividing strips

- E04F15/02033—Joints with beveled or recessed upper edges

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Laminated Bodies (AREA)

- Floor Finish (AREA)

- Synthetic Leather, Interior Materials Or Flexible Sheet Materials (AREA)

Abstract

Description

本発明は、戸建て住宅、アパート、マンション、保養所、店舗等の建築物における床材に好適に使用される化粧シートに関する。 The present invention relates to a decorative sheet that is suitably used for flooring in buildings such as detached houses, apartments, condominiums, recreational facilities, and stores.

従来から床材としては、合板に木質化粧単板を張り合わせて塗装したもの、または合板と中密度繊維板(MDF)を積層させ、さらにMDFに木質化粧単板を貼り合わせて塗装したものが広く知られている。 Conventionally, flooring materials are widely painted with laminated veneer veneer on plywood, or laminated with veneer and medium density fiberboard (MDF), and then veneered with veneer veneer. Are known.

しかしながら、木質化粧単板は、天然木材を薄くスライスしたものであり、木材資源の枯渇問題、世界的な資源保護運動の高まりから、天然木材の木質化粧単板に代えて、木目模様等を印刷等により人工的に表現した化粧シートを使用した床材が提案されている。係る床材は、表面意匠の自由度や安定性に優れることは勿論、化粧シートが合成材料であることから耐候性や耐水性にも優れるなどの利点があるが、反面、その表面が化粧シートという、天然木材の突板と比較すれば遥かに平滑且つ均質な材料であるために、表面の一部に傷がつくと相対的に目立ち易いという問題がある。 However, the wood veneer veneer is a thin slice of natural wood. Due to the problem of depletion of wood resources and the global movement to protect resources, the wood veneer is printed instead of wood veneer veneer veneer. A flooring using a decorative sheet artificially expressed by, for example, has been proposed. Such flooring has advantages such as excellent weather resistance and water resistance because the decorative sheet is a synthetic material, as well as excellent flexibility and stability of the surface design. Compared to the veneer of natural wood, it is a much smoother and homogeneous material, so there is a problem that it is relatively noticeable when a part of the surface is damaged.

また、近年では室内調度の洋風化やバリアフリー化に伴い、キャスター付きの家具や車椅子等の室内での使用もますます増加しつつある。ところが、積層合板等の木質基材を用いた従来の床材は、小面積に大荷重がかかりつつ車輪が転動する際に、その軌跡に沿って凹みが残るという、いわゆる耐キャスター性の不足という問題がある。 In recent years, the use of indoor furniture such as wheelchair furniture and wheelchairs has been increasing with the westernization of rooms and barrier-free. However, the conventional flooring material using a wooden base material such as laminated plywood is deficient in so-called caster resistance, in which a dent remains along the trajectory when a wheel rolls while applying a large load to a small area. There is a problem.

上記した表面の耐傷付き性や耐キャスター性の問題を解決する発明が例えば特許文献1に提案されている。特許文献1は、木質基材の表面に化粧シートを具備してなる化粧材において、前記木質基材と前記化粧シートとの間に、高硬度の材質からなる硬質シート層を設ける構成を提案している。本願発明は、引用文献1と同様の目的を有しているが、その解決手段が全く異なる。 For example, Patent Document 1 proposes an invention that solves the above-described problems of surface scratch resistance and caster resistance. Patent Document 1 proposes a configuration in which a hard sheet layer made of a high-hardness material is provided between the wooden base material and the decorative sheet in a decorative material having a decorative sheet on the surface of the wooden base material. ing. The present invention has the same purpose as that of the cited document 1, but its solution is completely different.

本発明は、上記事情に鑑みなされたものであって、従来の木質系床材と同等の表面意匠等を有しながら、表面の耐傷付き性や耐キャスター性にも優れた床材とすることのできる化粧シートを提供することを目的とする。 The present invention has been made in view of the above circumstances, and has a floor material that has excellent surface scratch resistance and caster resistance while having a surface design equivalent to that of a conventional wooden floor material. An object of the present invention is to provide a decorative sheet.

すなわち、本発明は、印刷層が印刷されたオレフィン系熱可塑性樹脂フィルム上に、厚さ300〜500μm)のオレフィン系熱可塑性樹脂層および厚さ3〜30μmの表面保護層を少なくとも有する、床材用化粧シートに関する。 That is, the present invention provides a flooring material having at least an olefinic thermoplastic resin layer having a thickness of 300 to 500 μm and a surface protective layer having a thickness of 3 to 30 μm on the olefinic thermoplastic resin film on which the printing layer is printed. The present invention relates to a decorative sheet.

本発明の化粧シートを表面に有する床材は、耐傷付き性、耐キャスターに優れている。 The flooring material having the decorative sheet of the present invention on its surface is excellent in scratch resistance and caster resistance.

本発明の化粧シート1は、図1に示したように、接着層等を介して木質基材2表面に貼りつけて使用される。

As shown in FIG. 1, the decorative sheet 1 of the present invention is used by being attached to the surface of the

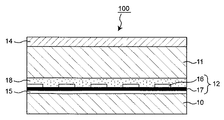

図2に本発明の化粧シートの一実施形態の概略断面図を示す。化粧シート100はオレフィン系熱可塑性樹脂フィルム10の一方の面にプライマー層15を設け、該プライマー層15上にベタ印刷層17と絵柄層16からなる印刷層12を順に印刷形成し、前記印刷層12上に接着層18を介してオレフィン系熱可塑性樹脂層11を積層し、さらにオレフィン系熱可塑性樹脂層11の表面に表面保護層14を形成したものである。

FIG. 2 shows a schematic cross-sectional view of one embodiment of the decorative sheet of the present invention. The

(オレフィン系熱可塑性樹脂フィルム10)

オレフィン系熱可塑性樹脂フィルム10は、床材としての意匠を付与する機能を担うもので、例えばポリプロピレン樹脂、ポリエチレン樹脂、エチレン−プロピレン共重合体、ポリオレフィン系熱可塑性エラストマー樹脂等のポリオレフィン系樹脂、ポリエチレンテレフタレート樹脂、ポリエチレンナフタレート樹脂、共重合ポリエステル樹脂(例:1,4−シクロヘキサンジメタノール共重合ポリエチレンテレフタレート樹脂である通称PET−G樹脂)、非晶質ポリエステル樹脂等のポリエステル系樹脂、ポリアクリロニトリル樹脂、ポリメチルメタクリレート樹脂等のアクリル樹脂、ポリ塩化ビニル樹脂等を使用することができるが、オレフィン系熱可塑性樹脂層11との接着性、積層後のシートのカール防止(異種材料を積層するとカールする傾向がある為)、建材用途での実績(耐候性等の耐久性の付与、エンボス等の加工適性)等の観点からオレフィン系樹脂フィルムを使用するのが好ましい。

(Olefin-based thermoplastic resin film 10)

The olefin-based

フィルム10は、公知の着色剤の添加により着色されていても良いし、着色されていなくても良い。フィルム10の厚みは50μm以上、好ましくは50〜150μm程度、より好ましくは50〜80μmである。該フィルムの厚みが薄すぎると隠蔽性が要求される場合、隠蔽不足となる。厚さの上限は特に限定されるものではないが、50μm以上あれば、その範囲で薄いほうが好ましく、一方厚いものを使用すればするほどコストアップにつながり、また入手が容易なものは、150μm程度までのものである。

The

(プライマー層)

プライマー層15はオレフィン系熱可塑性樹脂層11と絵柄層16、ベタ印刷層17等の印刷層との接着性を向上させる目的で設けるものであり、本発明においては、プライマー層は必ず形成しなければならないものではなく、必要により設ければよい。プライマー層を形成する樹脂としてはエステル樹脂、ウレタン樹脂、アクリル樹脂、ポリカーボネート樹脂、塩化ビニル‐酢酸ビニル共重合体、ポリビニルブチラール樹脂、ニトロセルロース樹脂等を挙げることができる。これらの樹脂は単独ないし混合して塗料組成物、又は、インキ組成物とし、ロールコート法やグラビア印刷法等の従来から公知の塗布手段を用いて、1〜6μm程度の厚さに形成すればよい。

(Primer layer)

The

(印刷層12)

図2には、印刷層12として絵柄層16およびベタ印刷層17を有する構成を示している。絵柄層16およびベタ印刷層17は、一般的にはグラビア印刷、オフセット印刷、シルクスクリーン印刷等の周知の印刷法でインキを用いてフィルム10の上に形成することができる。図2においては、絵柄層16およびベタ印刷層17の両方を設けた構成を示したが、いずれか一方の構成であっても構わない。絵柄層16としては、特に限定されるものではないが、たとえば、木目模様、石目模様、布目模様、皮紋模様、幾何学模様、文字、記号、線画、各種抽象模様柄が挙げられる。模様部の厚さは、通常1〜15μm程度である。ベタ印刷層17としては、隠蔽性を有する着色インキでベタ印刷したものであり、その厚さは、通常1〜10μm程度である。

(Print layer 12)

FIG. 2 shows a configuration having a

絵柄層16およびベタ印刷層17に用いるインキ組成物としては、ビヒクルとして、塩素化ポリエチレン、塩素化ポリプロピレン等の塩素化ポリオレフィン、ポリエステル、イソシアネートとポリオールからなるポリウレタン、ポリアクリル、ポリ酢酸ビニル、ポリ塩化ビニル、塩化ビニル‐酢酸ビニル共重合体、セルロース系樹脂、ポリアミド系樹脂等を1種ないし2種以上混合して用い、これに顔料、溶剤、各種補助剤等を加えたものを用いることができるが、環境問題や被印刷面との接着性等を考慮すると、ポリエステル、イソシアネートとポリオールからなるポリウレタン、ポリアクリル、ポリアミド系樹脂等の1種ないし2種以上混合したものを使用することが好ましい。

Examples of the ink composition used for the

(オレフィン系熱可塑性樹脂層11)

オレフィン系熱可塑性樹脂層11には、上記オレフィン系熱可塑性樹脂フィルム10に使用した同様のオレフィン系熱可塑性樹脂を使用することができる。中でも、床材として表面物性や加工性、経済性、廃棄製(焼却も含む)等、特に耐キャスター性を付与の観点から、表面強度や耐摩耗性に優れたホモポリプロピレンからなる樹脂、好ましくはホモポリプロピレン70重量%以上からなる樹脂が望ましい。本発明においては好ましくは融点150〜170℃を有するホモポリプロピレンを使用するようにする。より好ましくは曲げ弾性率1000MPa以上、引張り降伏強度30MPa以上、ロックウェル硬度75以上を有するホモポリプロピレンを使用することである。なお、ホモポリプロピレンとは、プロピレンモノマーの単独重合体を意味している。またホモポリプロピレン以外に含まれていてもよい樹脂は、床材を製法するまでの工程に製造上の問題が生じなければ特に限定されない。

(Olefin-based thermoplastic resin layer 11)

For the olefin-based

なお、融点はJIS K7121、曲げ弾性率はJIS K7171、引張り降伏強度はJIS K7161、ロックウェル硬度はJIS K7202により測定した値で表している。 The melting point is represented by JIS K7121, the flexural modulus is measured by JIS K7171, the tensile yield strength is measured by JIS K7161, and the Rockwell hardness is measured by JIS K7202.

本発明で使用するポリプロピレンは、公知の重合法により製造可能であり、市販品としては商品名 F−704NP:出光石油化学(株)製等が入手可能である。 The polypropylene used in the present invention can be produced by a known polymerization method, and as a commercial product, trade name F-704NP: manufactured by Idemitsu Petrochemical Co., Ltd. is available.

本発明においては、オレフィン系熱可塑性樹脂層11を、厚さ300μm以上に構成する。その厚さが300μmより薄いと充分な耐キャスター性を付与することができない。厚さの上限は特に制限されないが、生産性とコストの観点から、500μm以下の厚さに設定される。オレフィン系熱可塑性樹脂として透明な樹脂を使用すると、本発明においては厚いオレフィン系熱可塑性樹脂層11が存在しているために、透明感が引き立ち、そのため床材に高級感がでるという効果が付随する。

In the present invention, the olefinic

(接着層18)

接着層18は、印刷層12が形成されたフィルム10とオレフィン系熱可塑性樹脂層11とを接着させる働きをするものである。オレフィン系熱可塑性樹脂層11との積層方法としては、例えば、接着層18を介したドライラミネート法又はウエットラミネート法や、接着層18を介した又は介さない熱ラミネート法、高周波ラミネート法、透明熱可塑性樹脂を溶融状態で押し出すと同時に積層する押出ラミネート法等が適用可能である。押出ラミネート法にあっては、必要に応じて、接着層18としての酸変性オレフィン系樹脂又はオレフィン−(メタ)アクリレート共重合体樹脂等の接着性樹脂層を、樹脂層11との共押出にて同時に積層形成してもよい。また、当該積層に先立ち、樹脂層11との接着面に、例えば、コロナ放電、オゾン処理、プラズマ処理、電離放射線処理、酸処理、アルカリ処理、または、アンカー処理等の易接着化の為の表面処理を施しておいてもよい。

(Adhesive layer 18)

The

(表面保護層)

化粧シート100の表面に設ける表面保護層14について説明する。この表面保護層14は、床材(図1参照)に要求される耐擦傷性、耐摩耗性、耐水性、耐汚染性等の表面物性を付与するために設けられる。この表面保護層14を形成する樹脂としては、従来から知られている熱硬化型樹脂ないし電離放射線硬化型樹脂等の硬化型樹脂等を用いて1〜100μm、好ましくは3〜30μmの厚さに形成するのが適当である。より詳しくは、特許文献1明細書第0031〜0044段に記載されている表面保護層に関する技術的事項を本願発明にもそのまま適用可能であるので、当該記載を本願明細書の一部としてここに引用する。本願発明において好ましいものは表面硬度が硬く生産性に優れる電離放射線硬化型樹脂である。

(Surface protective layer)

The surface

(リコート樹脂層)

化粧シート100の表面に電離放射線硬化型樹脂からなる表面保護層14を設けるにあたり、該表面保護層14の形成面、すなわち図2に示す例では樹脂層11の表面、と電離放射線硬化型樹脂からなる表面保護層14との間に、十分な密着性を確保する必要がある。そのためには、樹脂層11の表面に例えばコロナ放電処理又はオゾン処理等の表面活性化処理を施すか、若しくは、樹脂層11を構成する熱可塑性樹脂と、表面保護層14を構成する電離放射線硬化型樹脂との双方に対して密着性の優れた樹脂組成物からなるリコート性樹脂層を、樹脂層11の表面に設けておくことが望ましい。

(Recoat resin layer)

In providing the surface

リコート性樹脂層としては、例えばウレタン系樹脂、エポキシ系樹脂、フェノール系樹脂、尿素樹脂、アルキド系樹脂、ポリエステル系樹脂等の熱硬化性樹脂を使用することが望ましく、中でもポリオール化合物とイソシアネート化合物との配合による2液硬化型ウレタン系樹脂を使用することが最も望ましい。ポリオール化合物としては、例えばアクリルポリオール化合物、ポリエーテルポリオール化合物、ポリエステルポリオール化合物等が使用可能であるが、中でも熱可塑性樹脂及び電離放射線硬化型樹脂との密着性と内部凝集力とのバランスの面から、ポリエステルポリオール化合物を使用することが最も望ましい。 As the recoatable resin layer, for example, it is desirable to use a thermosetting resin such as a urethane resin, an epoxy resin, a phenol resin, a urea resin, an alkyd resin, a polyester resin, among which a polyol compound and an isocyanate compound are used. It is most desirable to use a two-component curable urethane resin having the following composition. As the polyol compound, for example, an acrylic polyol compound, a polyether polyol compound, a polyester polyol compound, and the like can be used. Above all, from the viewpoint of the balance between adhesion to the thermoplastic resin and ionizing radiation curable resin and internal cohesive force. It is most desirable to use a polyester polyol compound.

リコート性樹脂層の塗布量は、乾燥後0.1〜2.0μm程度とすることが望ましい。リコート性樹脂層の形成方法としては、例えばグラビアコート法、マイクログラビアコート法、ロールコート法、ナイフコート法、エアーナイフコート法、リップコート法、ダイコート法等、従来公知の各種の塗工方法を任意に採用することができる。

い。

The coating amount of the recoatable resin layer is desirably about 0.1 to 2.0 μm after drying. Examples of the method for forming the recoatable resin layer include various conventionally known coating methods such as a gravure coating method, a micro gravure coating method, a roll coating method, a knife coating method, an air knife coating method, a lip coating method, and a die coating method. It can be arbitrarily adopted.

Yes.

(木質基材)

木質基材2としては、特に限定されず、例えば杉、檜、律、松、ラワン、チーク、メラピー等の各種素材から作られた突板、木材単板、木材合板、パティクルボード、中密度繊維板(MDF)等が挙げられる。なお、木材基材には、一方の面に、防湿効果を付与する観点から、例えば防湿層を形成していてもよい。

(Wood base)

The

木質基材2と化粧シート1とを貼り合わせることにより床材が提供される。化粧シートの木質基材への貼付方法、あるいは積層方法は限定的でなく、例えば接着剤により化粧シートを基材に貼着する方法等を採用することができる。接着剤は、基材の種類等に応じて公知の接着剤から適宜選択すれば良い。例えば、ポリ酢酸ビニル、ポリ塩化ビニル、塩化ビニル・酢酸ビニル共重合体、エチレン・アクリル酸共重合体、アイオノマー等のほか、ブタジエン・アクリルニトリルゴム、ネオプレンゴム、天然ゴム等が挙げられる。

A flooring is provided by bonding the

木質基材と化粧シートとの接着性を向上する観点から、本発明の化粧シートの表面保護層側とは反対の他方の面(裏面)に、プライマー層を設けてもよい。上記したプライマー層(15)に関する記載を、同様に該裏面プライマー層に適用することができる。この場合、ブロッキング防止の目的でシリカ、硫酸バリウム等の体質顔料を添加してもよい。 From the viewpoint of improving the adhesion between the wooden substrate and the decorative sheet, a primer layer may be provided on the other surface (back surface) opposite to the surface protective layer side of the decorative sheet of the present invention. The description regarding the primer layer (15) described above can be similarly applied to the back primer layer. In this case, extender pigments such as silica and barium sulfate may be added for the purpose of preventing blocking.

本発明の床材用化粧シートは、樹脂フィルム10の裏面には、従来設けられていたバッカーを形成することなく、表面の耐傷付き性や耐キャスター性にも優れた床材とすることができる。

The decorative sheet for flooring of the present invention can be used as a flooring material excellent in scratch resistance and caster resistance on the back surface of the

実施例

次に、本発明について、以下に実施例を挙げてさらに詳しく説明する。最初に、木質基材と積層する化粧シートを製造する。

Examples Next, the present invention will be described in more detail with reference to examples. First, a decorative sheet to be laminated with a wooden substrate is manufactured.

実施例1

両面コロナ放電処理した60μm厚さの着色ポリプロピレンフィルムの一方の面に2μm厚さの2液硬化型ウレタン系プライマー層を設けると共に他方の面に2液硬化型ウレタン系プライマー層及びアクリルウレタン系印刷インキで木目模様の印刷層を形成した。

Example 1

A two-part curable urethane primer layer and a two-part curable urethane primer layer and an acrylic urethane printing ink are provided on one side of a 60 μm-thick colored polypropylene film subjected to double-sided corona discharge treatment and the other side is provided with a two-part curable urethane primer layer and acrylic urethane type printing ink. A wood grain printed layer was formed.

次に前記印刷層上にウレタン系接着剤を介して曲げ弾性率1500MPa、引張り降伏強度38MPa、ロックウェル硬度80の透明ホモポリプロピレン樹脂(融点170℃)をTダイ押出し機で厚さが300μmとなるようにポリプロピレン熱可塑性樹脂層を押出して積層体を作製した。 Next, a transparent homopolypropylene resin (melting point: 170 ° C.) having a flexural modulus of 1500 MPa, a tensile yield strength of 38 MPa, and a Rockwell hardness of 80 is formed on the printed layer through a urethane adhesive to a thickness of 300 μm using a T-die extruder. Thus, a polypropylene thermoplastic resin layer was extruded to produce a laminate.

前記積層体の前記透明ホモポリプロピレン樹脂面に2μm厚さのウレタン系プライマー層を形成した。該ウレタン系プライマー層上に電離放射線硬化型樹脂をグラビアリバースコート法で乾燥後に15μm厚さとなるように塗布・乾燥して未硬化の電離放射線硬化型樹脂層を形成した。該未硬化の電影放射線硬化型樹脂層を、酸素濃度200PPM以下の環境下で電子線(加速電圧175keV、照射量5Mrad)を照射して、硬化させ、電離放射線硬化型樹脂からなる表面保護層を形成すると共に、該表面保護層側から版深50μmの木目導管形状エンボス版でエンボス加工を施して木目導管状凹凸模様を形成した。以上のようにして化粧シートを作製した。 A urethane primer layer having a thickness of 2 μm was formed on the transparent homopolypropylene resin surface of the laminate. On the urethane-based primer layer, an ionizing radiation curable resin was applied and dried so as to have a thickness of 15 μm after drying by a gravure reverse coating method to form an uncured ionizing radiation curable resin layer. The uncured shadow radiation curable resin layer is cured by irradiating with an electron beam (acceleration voltage 175 keV, irradiation amount 5 Mrad) in an environment having an oxygen concentration of 200 PPM or less, and a surface protective layer made of an ionizing radiation curable resin is formed. At the same time, embossing was performed from the surface protective layer side with a grain conduit shape embossing plate having a plate depth of 50 μm to form a grain conduit-like uneven pattern. A decorative sheet was produced as described above.

実施例2

木目模様の印刷層上にウレタン系接着剤を介して曲げ弾性率1500MPa、引張り降伏強度38MPa、ロックウェル硬度80の透明ホモポリプロピレン樹脂(融点170℃)をTダイ押出し機で厚さが400μmとなるように押出して積層体を作製した以外は実施例1と同様にして本発明の化粧シートを作製した。

Example 2

A transparent homopolypropylene resin (melting point: 170 ° C.) having a flexural modulus of 1500 MPa, a tensile yield strength of 38 MPa, and a Rockwell hardness of 80 is formed on a printed pattern with a wood pattern through a urethane adhesive to a thickness of 400 μm using a T-die extruder. A decorative sheet of the present invention was produced in the same manner as in Example 1 except that a laminate was produced by extrusion.

比較例1

木目模様の印刷層上にウレタン系接着剤を介して曲げ弾性率600MPa、引張り降伏強度26MPa、ロックウェル硬度72の透明ランダムポリプロピレン樹脂(融点145℃)をTダイ押出し機で厚さが300μmとなるように押出して積層体を作製した以外は実施例1と同様にして比較例とする化粧シートを作製した。

なお、本比較例で使用したランダムポリプロピレン樹脂は、エチレンとプロピレンとのランダム共重合体である。

Comparative Example 1

A transparent random polypropylene resin (melting point: 145 ° C.) having a flexural modulus of 600 MPa, a tensile yield strength of 26 MPa, and a Rockwell hardness of 72 via a urethane adhesive on a wood-patterned printed layer is 300 μm in thickness using a T-die extruder. A decorative sheet as a comparative example was produced in the same manner as in Example 1 except that a laminate was produced by extrusion.

The random polypropylene resin used in this comparative example is a random copolymer of ethylene and propylene.

比較例2

木目模様の印刷層上にウレタン系接着剤を介して曲げ弾性率1500MPa、引張り降伏強度38MPa、ロックウェル硬度80の透明ホモポリプロピレン樹脂(融点170℃)をTダイ押出し機で厚さが200μmとなるように押出して積層体を作製した以外は実施例1と同様にして比較例とする化粧シートを作製した。

Comparative Example 2

A transparent homopolypropylene resin (melting point: 170 ° C.) having a flexural modulus of 1500 MPa, a tensile yield strength of 38 MPa, and a Rockwell hardness of 80 via a urethane adhesive on the printed pattern of wood pattern is 200 μm in thickness using a T-die extruder. A decorative sheet as a comparative example was produced in the same manner as in Example 1 except that a laminate was produced by extrusion.

比較例3

木目模様の印刷層上にウレタン系接着剤を介して曲げ弾性率1500MPa、引張り降伏強度38MPa、ロックウェル硬度80の透明ホモポリプロピレン樹脂(融点170℃)50重量%、曲げ弾性率600MPa、引張り降伏強度26MPa、ロックウェル硬度72の透明ランダムポリプロピレン樹脂(融点145℃)50重量%含んだ樹脂層をTダイ押出し機で厚さが400μmとなるように押出して積層体を作製した以外は実施例1と同様にして比較例とする化粧シートを作製した。

Comparative Example 3

On the printed pattern of wood grain, urethane elastic adhesive is used, bending elastic modulus 1500MPa, tensile yield strength 38MPa, Rockwell hardness 80 transparent homopolypropylene resin (melting point 170 ° C) 50wt%, flexural modulus 600MPa, tensile yield strength Example 1 except that a laminate was produced by extruding a resin layer containing 50 wt% of a transparent random polypropylene resin (melting point 145 ° C.) of 26 MPa and Rockwell hardness 72 with a T-die extruder to a thickness of 400 μm. Similarly, a decorative sheet as a comparative example was produced.

床材の製造方法

木質基材として12mm厚さのラワン合板を使用し、実施例および比較例で得られた化粧シートを、水溶性ウレタン系エマルジョン接着剤を介して積層することにより木材基材に貼りつけ、床材を製造した。

Manufacturing method of flooring Using lauan plywood with a thickness of 12 mm as a wooden base material, and laminating decorative sheets obtained in Examples and Comparative Examples via a water-soluble urethane emulsion adhesive on a wood base material The flooring was produced by pasting.

評価(耐キャスター)

上記実施例および比較例で得られた化粧シートを使用して得られた床材について、耐キャスター性を、耐キャスター試験装置L6−O4(浅野機械製作(株)製)を使用して評価した。

Evaluation (caster resistant)

About the flooring obtained using the decorative sheet obtained in the above Examples and Comparative Examples, the caster resistance was evaluated using a caster resistance test apparatus L6-O4 (manufactured by Asano Machinery Co., Ltd.). .

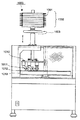

耐キャスター試験装置L6−O4の概略構成図を図3に示した。耐キャスター試験装置1000は、重り1001により荷重変更可能な加重部1002と、調節ハンドル1003と、回転可能のキャスター固定台1010(固定台:直径320mm、キャスター取り付け部の直径:260mm)と、前記キャスター固定台に等間隔(円形の固定台内に正三角形を描いた時の頂点位置)に取り付けられた3個のキャスター1011と、試料固定台1013(直径80cm、厚さ80mm)(アクリル製)とを備えてなるものである。使用したキャスターは、HANMMER CASTER社より入手した420SA−N(車輪:ナイロン製)(平均直径75mm、厚さ25mm)である。

A schematic configuration diagram of the caster resistance test apparatus L6-O4 is shown in FIG. The caster-

試験する床材(試料)(30cm×30cm)を試料固定台1013に固定し、加重部1002に30kgの重り1001を乗せて、調節ハンドル1OO3により、床材の化粧層側の表面に、3個のキャスター1011を接触させ(総荷重70kg/m2)、キャスター固定台1010を稼働し、20rpmの速度で5分間毎に反回転させて1000回転させた。

A floor material (sample) (30 cm × 30 cm) to be tested is fixed to a

耐キャスター性を、床材表面に発生した割れの有無で評価し、以下のようにランク付けした。

○:凹み深さが70μm未満

△:凹み深さが70μm以上、100μm未満

×:凹み深さが100μm以上

The caster resistance was evaluated based on the presence or absence of cracks generated on the floor material surface, and was ranked as follows.

○: Depression depth is less than 70 μm Δ: Depression depth is 70 μm or more and less than 100 μm ×: Depression depth is 100 μm or more

なお、耐キャスター性は、L6−O4(浅野機械製作(株)製)と同等の評価ができれば、他の試験機でも評価可能である。 The caster resistance can be evaluated by other testing machines as long as the evaluation can be equivalent to that of L6-O4 (manufactured by Asano Machinery Co., Ltd.).

1 化粧シート

2 木質材質

10 樹脂フィルム

11 樹脂層

12 印刷層

14 表面保護層

15 プライマー層

16 絵柄層

17 ベタ印刷層

18 接着層

100 化粧シート

1000 耐キャスター試験装置

1001 重り

1002 荷重部

1003 調節ハンドル

1010 キャスター固定台

1011 キャスター

1012 試料

1013 試料固定台

DESCRIPTION OF SYMBOLS 1

Claims (6)

The flooring material which affixes the decorative sheet for flooring materials in any one of Claims 1-5 on a wooden base material.

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004103010A JP4587692B2 (en) | 2004-03-31 | 2004-03-31 | Decorative sheet for flooring and flooring decorative material using the same |

| JP2004104712A JP2005290734A (en) | 2004-03-31 | 2004-03-31 | Decorative sheet for floor material |

| CNB2005800108585A CN100537226C (en) | 2004-03-31 | 2005-03-31 | Decorative sheet for floor material and decorative material for floor using the same |

| KR1020067022697A KR100876787B1 (en) | 2004-03-31 | 2005-03-31 | Decorative sheet for floor material and decorative material for floor using the same |

| PCT/JP2005/006401 WO2005100679A1 (en) | 2004-03-31 | 2005-03-31 | Decorative sheet for floor material and decorative material for floor using the same |

| KR1020087026230A KR20080098452A (en) | 2004-03-31 | 2005-03-31 | Decorative sheet for floor material and decorative material for floor using the same |

| HK07107983.7A HK1103770A1 (en) | 2004-03-31 | 2007-07-24 | Decorative sheet for floor material and decorative material for floor using the same |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004103010A JP4587692B2 (en) | 2004-03-31 | 2004-03-31 | Decorative sheet for flooring and flooring decorative material using the same |

| JP2004104712A JP2005290734A (en) | 2004-03-31 | 2004-03-31 | Decorative sheet for floor material |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010080009A Division JP2010190035A (en) | 2010-03-31 | 2010-03-31 | Flooring |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2005290734A true JP2005290734A (en) | 2005-10-20 |

Family

ID=35150038

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004104712A Pending JP2005290734A (en) | 2004-03-31 | 2004-03-31 | Decorative sheet for floor material |

| JP2004103010A Expired - Fee Related JP4587692B2 (en) | 2004-03-31 | 2004-03-31 | Decorative sheet for flooring and flooring decorative material using the same |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004103010A Expired - Fee Related JP4587692B2 (en) | 2004-03-31 | 2004-03-31 | Decorative sheet for flooring and flooring decorative material using the same |

Country Status (5)

| Country | Link |

|---|---|

| JP (2) | JP2005290734A (en) |

| KR (2) | KR100876787B1 (en) |

| CN (1) | CN100537226C (en) |

| HK (1) | HK1103770A1 (en) |

| WO (1) | WO2005100679A1 (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007333737A (en) * | 2006-06-16 | 2007-12-27 | Rohm & Haas Co | Stress generated on surface |

| JP2011501706A (en) * | 2007-10-15 | 2011-01-13 | フォーレシア・アンテリュール・アンデュストリー | Method for coating a part with a wood material layer and a part coated with said layer |

| JP2011073146A (en) * | 2009-09-29 | 2011-04-14 | Dainippon Printing Co Ltd | Decorative sheet for flooring and method for manufacturing the same |

| JP2014080020A (en) * | 2012-09-25 | 2014-05-08 | Dainippon Printing Co Ltd | Decorative sheet |

| JP2016037818A (en) * | 2014-08-11 | 2016-03-22 | 株式会社トッパン・コスモ | Floor decorative sheet |

| NL2034241B1 (en) * | 2023-03-01 | 2024-09-09 | Cfl Holding Ltd | Method and device for determining the durability of a floor panel |

Families Citing this family (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4923837B2 (en) * | 2006-08-10 | 2012-04-25 | 大日本印刷株式会社 | Boil / retort container lid |

| JP5141467B2 (en) * | 2008-09-22 | 2013-02-13 | 株式会社トッパン・コスモ | Decorative sheet |

| JP4840461B2 (en) * | 2008-09-30 | 2011-12-21 | 大日本印刷株式会社 | Decorative sheet for flooring |

| JP5353363B2 (en) * | 2009-03-27 | 2013-11-27 | 大日本印刷株式会社 | Decorative sheet |

| JP5699510B2 (en) * | 2010-09-30 | 2015-04-15 | 大日本印刷株式会社 | Floor decorative material |

| WO2012117736A1 (en) * | 2011-03-01 | 2012-09-07 | 大建工業株式会社 | Light-transmissive cosmetic material and light-emitting cosmetic structure |

| JP5786414B2 (en) * | 2011-03-31 | 2015-09-30 | 大日本印刷株式会社 | Decorative sheet and method for producing the same |

| JP5821461B2 (en) * | 2011-09-21 | 2015-11-24 | 大日本印刷株式会社 | Decorative sheet for floor and method for producing the same |

| JP6064421B2 (en) * | 2011-09-26 | 2017-01-25 | 大日本印刷株式会社 | Floor decorative material |

| JP2012162085A (en) * | 2012-03-29 | 2012-08-30 | Dainippon Printing Co Ltd | Decorative sheet |

| JP6507473B2 (en) * | 2013-03-13 | 2019-05-08 | 大日本印刷株式会社 | Cosmetic sheet |

| KR101895635B1 (en) * | 2013-07-11 | 2018-09-05 | (주)엘지하우시스 | Eco-friendly for elastic floor sheet and manufacturing method thereof |

| JP6459340B2 (en) * | 2013-09-30 | 2019-01-30 | 大日本印刷株式会社 | Mirror surface decorative sheet and mirror surface decorative plate using the same |

| CN107206767A (en) * | 2014-09-04 | 2017-09-26 | 帕拉姆工业(1990)有限公司 | For applying wearability and the system and method for weather resistant coatings to profile |

| EP4056367A1 (en) * | 2015-01-16 | 2022-09-14 | Beaulieu International Group NV | Covering and method for producing coverings |

| JP2018507334A (en) * | 2015-02-20 | 2018-03-15 | シャウ インダストリーズ グループ, インコーポレイテッド | Elastic flooring product and manufacturing method thereof |

| JP6561614B2 (en) * | 2015-06-18 | 2019-08-21 | 凸版印刷株式会社 | Decorative sheet and decorative board |

| CN108026730B (en) * | 2015-07-24 | 2019-11-22 | 明和科技(唐山)股份有限公司 | Light-weight environment-friendly type polypropylene composite materials floor and preparation method thereof |

| JP2016186215A (en) * | 2016-06-13 | 2016-10-27 | 凸版印刷株式会社 | Anti-slip decorative sheet |

| CN106113818B (en) * | 2016-06-22 | 2018-09-11 | 浙江利帆家具有限公司 | A kind of anti-aging polyethylene composite plastic outdoor table and its manufacturing method |

| KR102113226B1 (en) * | 2017-02-10 | 2020-05-21 | (주)엘지하우시스 | vinyl tile flooring comprising a transparent layer of polyolefin resin material and a method for manufacturing the same |

| WO2018147613A1 (en) * | 2017-02-10 | 2018-08-16 | 주식회사 엘지하우시스 | Plastic tile flooring material comprising transparent layer made of polyolefin-based resin material, and manufacturing method therefor |

| JP7163905B2 (en) | 2017-02-28 | 2022-11-01 | 大日本印刷株式会社 | Decorative sheet and board |

| AU2020248023A1 (en) * | 2019-03-26 | 2022-01-20 | Braeside Mills Operations Pty Ltd | Surface covering including a polyester-polyolefin-blend core |

| US11359386B2 (en) * | 2020-05-07 | 2022-06-14 | Dal-Tile Corporation | Floor element for forming a floor covering, a floor covering, and a method for manufacturing a floor element |

| JP2022001424A (en) * | 2020-06-22 | 2022-01-06 | 凸版印刷株式会社 | Floor decorative sheet, production method thereof, floor decorative material and production method thereof |

| KR102204060B1 (en) * | 2020-08-05 | 2021-01-18 | (주)꿈그린 | Eco-friendly decoration sheet and its manufacturing method |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6340054A (en) * | 1986-08-04 | 1988-02-20 | アキレス株式会社 | Tile type antistatic floor material |

| JPH09216326A (en) * | 1996-02-15 | 1997-08-19 | Toppan Printing Co Ltd | Decorative laminated sheet for floor material |

| JP2001181985A (en) * | 1999-12-27 | 2001-07-03 | Toppan Printing Co Ltd | Sheet for floor and floor covering material |

| JP2003011277A (en) * | 2001-06-29 | 2003-01-15 | Toppan Printing Co Ltd | Decorative material |

| JP2003013587A (en) * | 2001-06-28 | 2003-01-15 | Toppan Printing Co Ltd | Floor sheet and flooring |

| JP2003118042A (en) * | 2001-10-12 | 2003-04-23 | Shinko Kasei Kk | Adhesive floor material |

| JP2003184290A (en) * | 2001-12-20 | 2003-07-03 | Toppan Printing Co Ltd | Floorboard |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH10230580A (en) * | 1997-02-20 | 1998-09-02 | Dainippon Printing Co Ltd | Decorative sheet and its manufacture |

| JPH10278197A (en) * | 1997-04-03 | 1998-10-20 | Dainippon Printing Co Ltd | Decorative sheet and its manufacture |

| JP2001159228A (en) * | 1999-12-03 | 2001-06-12 | Dainippon Printing Co Ltd | Sheet for floor |

| JP4605844B2 (en) * | 2000-01-12 | 2011-01-05 | 大日本印刷株式会社 | Manufacturing method of decorative material for flooring |

| JP2001220886A (en) * | 2000-02-09 | 2001-08-17 | Dainippon Printing Co Ltd | Floor material sheet and floor member using the same |

| JP2001260282A (en) * | 2000-03-14 | 2001-09-25 | Dainippon Printing Co Ltd | Sheet for floor material and floor material using the same |

| JP2002265742A (en) * | 2001-03-15 | 2002-09-18 | Denki Kagaku Kogyo Kk | Building material |

-

2004

- 2004-03-31 JP JP2004104712A patent/JP2005290734A/en active Pending

- 2004-03-31 JP JP2004103010A patent/JP4587692B2/en not_active Expired - Fee Related

-

2005

- 2005-03-31 WO PCT/JP2005/006401 patent/WO2005100679A1/en active Application Filing

- 2005-03-31 KR KR1020067022697A patent/KR100876787B1/en active IP Right Grant

- 2005-03-31 CN CNB2005800108585A patent/CN100537226C/en not_active Expired - Fee Related

- 2005-03-31 KR KR1020087026230A patent/KR20080098452A/en not_active Application Discontinuation

-

2007

- 2007-07-24 HK HK07107983.7A patent/HK1103770A1/en not_active IP Right Cessation

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6340054A (en) * | 1986-08-04 | 1988-02-20 | アキレス株式会社 | Tile type antistatic floor material |

| JPH09216326A (en) * | 1996-02-15 | 1997-08-19 | Toppan Printing Co Ltd | Decorative laminated sheet for floor material |

| JP2001181985A (en) * | 1999-12-27 | 2001-07-03 | Toppan Printing Co Ltd | Sheet for floor and floor covering material |

| JP2003013587A (en) * | 2001-06-28 | 2003-01-15 | Toppan Printing Co Ltd | Floor sheet and flooring |

| JP2003011277A (en) * | 2001-06-29 | 2003-01-15 | Toppan Printing Co Ltd | Decorative material |

| JP2003118042A (en) * | 2001-10-12 | 2003-04-23 | Shinko Kasei Kk | Adhesive floor material |

| JP2003184290A (en) * | 2001-12-20 | 2003-07-03 | Toppan Printing Co Ltd | Floorboard |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007333737A (en) * | 2006-06-16 | 2007-12-27 | Rohm & Haas Co | Stress generated on surface |

| JP2011064703A (en) * | 2006-06-16 | 2011-03-31 | Rohm & Haas Co | Production of stress on surface |

| JP2011501706A (en) * | 2007-10-15 | 2011-01-13 | フォーレシア・アンテリュール・アンデュストリー | Method for coating a part with a wood material layer and a part coated with said layer |

| JP2011073146A (en) * | 2009-09-29 | 2011-04-14 | Dainippon Printing Co Ltd | Decorative sheet for flooring and method for manufacturing the same |

| JP2014080020A (en) * | 2012-09-25 | 2014-05-08 | Dainippon Printing Co Ltd | Decorative sheet |

| JP2016037818A (en) * | 2014-08-11 | 2016-03-22 | 株式会社トッパン・コスモ | Floor decorative sheet |

| NL2034241B1 (en) * | 2023-03-01 | 2024-09-09 | Cfl Holding Ltd | Method and device for determining the durability of a floor panel |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2005100679A1 (en) | 2005-10-27 |

| KR20080098452A (en) | 2008-11-07 |

| CN1938477A (en) | 2007-03-28 |

| KR100876787B1 (en) | 2009-01-09 |

| KR20070009656A (en) | 2007-01-18 |

| JP4587692B2 (en) | 2010-11-24 |

| JP2005290568A (en) | 2005-10-20 |

| CN100537226C (en) | 2009-09-09 |

| HK1103770A1 (en) | 2007-12-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2005290734A (en) | Decorative sheet for floor material | |

| JP5568932B2 (en) | Flooring decorative sheet and flooring decorative material | |

| WO2015105168A1 (en) | Decorative sheet and decorative laminate, and processes for producing same | |

| JP2003056168A (en) | Flooring and its manufacturing method | |

| JP2003049530A (en) | Floor material and its manufacturing method | |

| JP5360251B2 (en) | Water-based paint | |

| JP2016064628A (en) | Decorative sheet and decorative plate | |

| JP4679206B2 (en) | Floor decorative material | |

| JP4605844B2 (en) | Manufacturing method of decorative material for flooring | |

| JP2001055826A (en) | Decorative material for floor | |

| JP5170938B2 (en) | Floor material and method for protecting floor material surface | |

| JP5870799B2 (en) | Decorative sheet | |

| JP2003011277A (en) | Decorative material | |

| JP2010229788A (en) | Decorative material for flooring | |

| JP2003035029A (en) | Flooring | |

| JP5589510B2 (en) | Cosmetic material and decorative sheet | |

| JP2004156277A (en) | Floor material | |

| KR101456731B1 (en) | Decorative sheet and decorative plate using the decorative sheet | |

| KR20160116052A (en) | Floor decoration material | |

| JP2019181920A (en) | Floating-processed grain-toned decorative material | |

| JP4583059B2 (en) | Decorative sheet for flooring | |

| JP2005290736A (en) | Floor material | |

| JP2010190035A (en) | Flooring | |

| JP2006123235A (en) | Non-halogen type decorative sheet and non-halogen type decorative material | |

| JP2002339557A (en) | Flooring and manufacturing method therefor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070123 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20080131 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090630 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20090708 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20090708 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090825 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20100126 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20100311 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100331 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20100506 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20100611 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110603 |