JP2004155439A - タンクの製造方法 - Google Patents

タンクの製造方法 Download PDFInfo

- Publication number

- JP2004155439A JP2004155439A JP2002321039A JP2002321039A JP2004155439A JP 2004155439 A JP2004155439 A JP 2004155439A JP 2002321039 A JP2002321039 A JP 2002321039A JP 2002321039 A JP2002321039 A JP 2002321039A JP 2004155439 A JP2004155439 A JP 2004155439A

- Authority

- JP

- Japan

- Prior art keywords

- tank

- plate

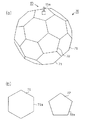

- polyhedron

- annular body

- plate material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 16

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 16

- 238000005304 joining Methods 0.000 claims abstract description 12

- 238000003825 pressing Methods 0.000 claims description 15

- 238000000034 method Methods 0.000 claims description 10

- 239000000463 material Substances 0.000 abstract description 35

- 238000003466 welding Methods 0.000 abstract description 11

- 238000007493 shaping process Methods 0.000 abstract 1

- 230000000694 effects Effects 0.000 description 14

- 239000004576 sand Substances 0.000 description 9

- 238000005096 rolling process Methods 0.000 description 2

- 230000015556 catabolic process Effects 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- NJPPVKZQTLUDBO-UHFFFAOYSA-N novaluron Chemical compound C1=C(Cl)C(OC(F)(F)C(OC(F)(F)F)F)=CC=C1NC(=O)NC(=O)C1=C(F)C=CC=C1F NJPPVKZQTLUDBO-UHFFFAOYSA-N 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

Images

Landscapes

- Shaping Metal By Deep-Drawing, Or The Like (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002321039A JP2004155439A (ja) | 2002-11-05 | 2002-11-05 | タンクの製造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002321039A JP2004155439A (ja) | 2002-11-05 | 2002-11-05 | タンクの製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2004155439A true JP2004155439A (ja) | 2004-06-03 |

| JP2004155439A5 JP2004155439A5 (enExample) | 2005-07-21 |

Family

ID=32801711

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2002321039A Pending JP2004155439A (ja) | 2002-11-05 | 2002-11-05 | タンクの製造方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2004155439A (enExample) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101269458B1 (ko) | 2013-02-25 | 2013-05-30 | 김일형 | 금속구 제조방법 |

| JP2013533831A (ja) * | 2010-05-12 | 2013-08-29 | ヴァーサボール・エルエンゲー・プロダクツ・オサケユキテュア | いくつかのジョイント部品で形成されている球体およびいくつかのジョイント部品で形成されている球体を製造する方法 |

| CN104128718A (zh) * | 2013-06-27 | 2014-11-05 | 国家电网公司 | 金属球壳拼装方法及专用于实施该方法的检测工装 |

| KR101854800B1 (ko) * | 2016-01-25 | 2018-05-09 | 현대중공업 주식회사 | 구형탱크 및 구형탱크 제작방법 |

| CN108672541A (zh) * | 2018-06-20 | 2018-10-19 | 汪川川 | 一种金属无模水压成型方法 |

| CN113816019A (zh) * | 2020-06-12 | 2021-12-21 | 中国石化工程建设有限公司 | 一种储罐 |

| JP7157890B1 (ja) | 2022-05-13 | 2022-10-20 | 川崎重工業株式会社 | 多重殻タンクの施工方法 |

| CN115740261A (zh) * | 2022-11-28 | 2023-03-07 | 中国电子科技集团公司第三十八研究所 | 一种薄壁标校球的高精度无模液压胀形方法 |

-

2002

- 2002-11-05 JP JP2002321039A patent/JP2004155439A/ja active Pending

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013533831A (ja) * | 2010-05-12 | 2013-08-29 | ヴァーサボール・エルエンゲー・プロダクツ・オサケユキテュア | いくつかのジョイント部品で形成されている球体およびいくつかのジョイント部品で形成されている球体を製造する方法 |

| KR101269458B1 (ko) | 2013-02-25 | 2013-05-30 | 김일형 | 금속구 제조방법 |

| CN104128718A (zh) * | 2013-06-27 | 2014-11-05 | 国家电网公司 | 金属球壳拼装方法及专用于实施该方法的检测工装 |

| KR101854800B1 (ko) * | 2016-01-25 | 2018-05-09 | 현대중공업 주식회사 | 구형탱크 및 구형탱크 제작방법 |

| CN108672541A (zh) * | 2018-06-20 | 2018-10-19 | 汪川川 | 一种金属无模水压成型方法 |

| CN113816019A (zh) * | 2020-06-12 | 2021-12-21 | 中国石化工程建设有限公司 | 一种储罐 |

| JP7157890B1 (ja) | 2022-05-13 | 2022-10-20 | 川崎重工業株式会社 | 多重殻タンクの施工方法 |

| WO2023219138A1 (ja) * | 2022-05-13 | 2023-11-16 | 川崎重工業株式会社 | 多重殻タンクの施工方法 |

| JP2023167843A (ja) * | 2022-05-13 | 2023-11-24 | 川崎重工業株式会社 | 多重殻タンクの施工方法 |

| CN115740261A (zh) * | 2022-11-28 | 2023-03-07 | 中国电子科技集团公司第三十八研究所 | 一种薄壁标校球的高精度无模液压胀形方法 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2004155439A (ja) | タンクの製造方法 | |

| US20090123776A1 (en) | Formed core sandwich structure and method and system for making same | |

| CN105598327A (zh) | 分层多列堆垛金属构筑成形方法 | |

| NO790041L (no) | Kuletank for fortettet naturgass o.l. og fremgangsmaate til fremstilling av en slik tank | |

| US8967229B2 (en) | Method of manufacturing a mold for press forming employing an evaporative pattern | |

| US2106496A (en) | Method of making containers | |

| CN107900270B (zh) | 一种铰链梁整体模锻成型组合模具及其加工铰链梁方法 | |

| KR20120057671A (ko) | 에어탱크의 제조방법 | |

| US6899599B1 (en) | Manufacturing process to make a valve ball | |

| CN206578204U (zh) | 用于曲面板模压成形工艺的压模 | |

| CN103552093B (zh) | 手套箱箱体及其加工方法 | |

| CA2706360A1 (en) | Method and apparatus for relieving residual stress in welded pipe joints | |

| CN107186035B (zh) | 冰桶拉伸成型工艺 | |

| CN104307952B (zh) | 曲面钢板成形方法和曲面钢板成形设备 | |

| CN103586323B (zh) | 双轴长比椭球容器液压成形方法 | |

| CN206882497U (zh) | 一种含二次翻边孔的钣金件橡皮囊成形用的组合模具 | |

| US10449633B1 (en) | Gas pressure forming method of ellipsoidal shells based on current self-resistance heating | |

| KR20110050116A (ko) | 파이프 연결구의 플랜지 가공방법 | |

| CN101342957B (zh) | 节状器皿加工方法 | |

| CN203592490U (zh) | 手套箱箱体 | |

| Wang et al. | New forming technologies used in manufacturing large vessels | |

| CN201554848U (zh) | 球形压力容器 | |

| JP3917553B2 (ja) | 金属板の膨出面形成方法及びそれを用いた立体造形物、並びに金属容器の製造方法及びその方法により得られた圧力容器 | |

| CN107081363A (zh) | 一种含二次翻边孔的钣金件橡皮囊成形方法及组合模具 | |

| JP6731867B2 (ja) | 金属製中空球体の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20041126 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20041126 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20061019 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20061024 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20061222 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20070213 |