EP4166239B1 - Squeeze bottle dispenser with actuator securing device - Google Patents

Squeeze bottle dispenser with actuator securing device Download PDFInfo

- Publication number

- EP4166239B1 EP4166239B1 EP21202967.2A EP21202967A EP4166239B1 EP 4166239 B1 EP4166239 B1 EP 4166239B1 EP 21202967 A EP21202967 A EP 21202967A EP 4166239 B1 EP4166239 B1 EP 4166239B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- guide

- protective sleeve

- sleeve

- protective

- liquid reservoir

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000001681 protective effect Effects 0.000 claims description 184

- 239000007788 liquid Substances 0.000 claims description 116

- 238000006073 displacement reaction Methods 0.000 claims description 19

- -1 polyethylene terephthalate Polymers 0.000 claims description 10

- 229920003023 plastic Polymers 0.000 claims description 7

- 229920000139 polyethylene terephthalate Polymers 0.000 claims description 6

- 239000005020 polyethylene terephthalate Substances 0.000 claims description 6

- 229920000089 Cyclic olefin copolymer Polymers 0.000 claims description 5

- 239000004698 Polyethylene Substances 0.000 claims description 5

- 229920000573 polyethylene Polymers 0.000 claims description 5

- 238000003780 insertion Methods 0.000 claims description 4

- 230000037431 insertion Effects 0.000 claims description 4

- 239000004033 plastic Substances 0.000 claims description 4

- 239000004743 Polypropylene Substances 0.000 claims description 3

- 229920001155 polypropylene Polymers 0.000 claims description 3

- MTNDZQHUAFNZQY-UHFFFAOYSA-N imidazoline Chemical compound C1CN=CN1 MTNDZQHUAFNZQY-UHFFFAOYSA-N 0.000 claims description 2

- 229920001123 polycyclohexylenedimethylene terephthalate Polymers 0.000 claims description 2

- 239000004713 Cyclic olefin copolymer Substances 0.000 claims 2

- 239000006196 drop Substances 0.000 description 6

- 230000004913 activation Effects 0.000 description 3

- 238000009423 ventilation Methods 0.000 description 3

- 230000008901 benefit Effects 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 229920001577 copolymer Polymers 0.000 description 2

- 239000003889 eye drop Substances 0.000 description 2

- 229940012356 eye drops Drugs 0.000 description 2

- 210000004709 eyebrow Anatomy 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 206010010725 Conjunctival irritation Diseases 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000000203 droplet dispensing Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000002372 labelling Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D47/00—Closures with filling and discharging, or with discharging, devices

- B65D47/04—Closures with discharging devices other than pumps

- B65D47/06—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages

- B65D47/18—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages for discharging drops; Droppers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B11/00—Single-unit hand-held apparatus in which flow of contents is produced by the muscular force of the operator at the moment of use

- B05B11/0005—Components or details

- B05B11/0027—Means for neutralising the actuation of the sprayer ; Means for preventing access to the sprayer actuation means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B11/00—Single-unit hand-held apparatus in which flow of contents is produced by the muscular force of the operator at the moment of use

- B05B11/0005—Components or details

- B05B11/0027—Means for neutralising the actuation of the sprayer ; Means for preventing access to the sprayer actuation means

- B05B11/0032—Manually actuated means located downstream the discharge nozzle for closing or covering it, e.g. shutters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B11/00—Single-unit hand-held apparatus in which flow of contents is produced by the muscular force of the operator at the moment of use

- B05B11/0005—Components or details

- B05B11/0037—Containers

- B05B11/0038—Inner container disposed in an outer shell or outer casing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B11/00—Single-unit hand-held apparatus in which flow of contents is produced by the muscular force of the operator at the moment of use

- B05B11/01—Single-unit hand-held apparatus in which flow of contents is produced by the muscular force of the operator at the moment of use characterised by the means producing the flow

- B05B11/04—Deformable containers producing the flow, e.g. squeeze bottles

- B05B11/048—Deformable containers producing the flow, e.g. squeeze bottles characterised by the container, e.g. this latter being surrounded by an enclosure, or the means for deforming it

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D1/00—Containers having bodies formed in one piece, e.g. by casting metallic material, by moulding plastics, by blowing vitreous material, by throwing ceramic material, by moulding pulped fibrous material, by deep-drawing operations performed on sheet material

- B65D1/32—Containers adapted to be temporarily deformed by external pressure to expel contents

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D23/00—Details of bottles or jars not otherwise provided for

- B65D23/08—Coverings or external coatings

- B65D23/0885—Rigid shells for receiving the bottle or part of it

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B11/00—Single-unit hand-held apparatus in which flow of contents is produced by the muscular force of the operator at the moment of use

- B05B11/0005—Components or details

- B05B11/0062—Outlet valves actuated by the pressure of the fluid to be sprayed

- B05B11/0064—Lift valves

- B05B11/0067—Lift valves having a valve seat located downstream the valve element

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B11/00—Single-unit hand-held apparatus in which flow of contents is produced by the muscular force of the operator at the moment of use

- B05B11/0005—Components or details

- B05B11/0062—Outlet valves actuated by the pressure of the fluid to be sprayed

- B05B11/0072—A valve member forming part of an outlet opening

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2215/00—Child-proof means

Definitions

- Generic squeeze bottle dispensers are widely used. They are used in particular for pharmaceutical liquids, for example eye drops.

- a squeeze bottle dispenser of the type described is known, for example, from the document EN 10 2016 210 992 B3 known.

- the primary object of the invention is to provide a squeeze bottle dispenser that offers a high degree of safety against unintentional activation and/or activation by children at play.

- a squeeze bottle dispenser which has a liquid reservoir designed as a squeeze bottle and a discharge head with a discharge opening.

- the discharge head is preferably manufactured as a separate assembly and coupled to the liquid reservoir, for example by means of a snap-in connection or a threaded connection.

- designs are also possible in which the discharge head and the liquid reservoir, or at least their outer surfaces, are formed by a one-piece component.

- the liquid dispenser is preferably filled with a pharmaceutical liquid, for example with a liquid containing imidazoline for relieving conjunctival irritation.

- the liquid reservoir preferably has an internal volume of less than 50 ml, in particular less than 20 ml.

- the liquid reservoir is designed as a squeeze bottle.

- the squeeze bottle body is preferably designed with an inherent rigidity that allows the internal volume to be reduced by at least 5% when pressure of 20 Newtons is applied on both sides.

- the wall of the liquid reservoir is preferably made of a soft plastic, in particular polyethylene terephthalate (PET), polyethylene (PE) or a cycloolefin copolymer (COC).

- the dispenser according to the invention can be designed to discharge a liquid jet or a spray.

- the squeeze bottle dispenser is designed as a drop dispenser.

- the squeeze bottle dispenser preferably has drop-forming means in the area of the discharge opening, in particular in the form of a drop-forming surface surrounding the discharge opening, where discharged liquid collects until the amount of liquid is sufficient for a drop to form, which detaches from the drop-forming means and falls down.

- a squeeze bottle dispenser has a protective sleeve that is captively connected to the liquid reservoir. This is axially displaceable repeatedly relative to the liquid reservoir between a Protective position and a release position.

- the displaceability can be purely translational. However, it is also possible for the protective sleeve to be displaceable translationally and rotationally, for example superimposed in the manner of a thread movement or sequentially in the manner of a bayonet movement.

- a captive attachment of the protective sleeve to the squeeze bottle dispenser means that the protective sleeve cannot be separated from the squeeze bottle dispenser during normal use.

- separation is possible using brute force does not contradict the captiveness for the purposes of the invention.

- the protective sleeve In the protective position, the protective sleeve is arranged relative to the liquid reservoir in such a way that it either completely prevents compression of the liquid reservoir or at least makes it extremely difficult by covering access to the outer wall of the liquid reservoir. This prevents liquid from escaping.

- the protective sleeve In the release position, however, the protective sleeve allows the liquid reservoir to be compressed and thus the liquid to be discharged.

- the protective sleeve is displaced so far in relation to the liquid reservoir that it no longer represents any obstacle or at least allows the liquid reservoir to be subjected to a force that is easier than in the protective position.

- the protective sleeve can be displaced at least translationally relative to the liquid reservoir.

- the degree of displaceability in the axial direction relative to the main axis is preferably at least 20 mm, in particular preferably at least 30 mm. This dimension describes the axial path that the protective sleeve can move between opposite end positions, i.e. between the release position and the end position associated with the protection position.

- the protective sleeve is sufficiently rigid to prevent a significant reduction in the internal volume of the liquid reservoir when force is applied to the protective sleeve.

- the protective sleeve is preferably made of a rigid plastic, in particular polycyclohexylenedimethylene terephthalate / glycol-modified (PCTG), polypropylene (PP), a cycloolefin copolymer (COC), a cycloolefin polymer (COP), polyethylene terephthalate (PET) or a hard polyethylene (HDPE).

- PCTG polycyclohexylenedimethylene terephthalate / glycol-modified

- PP polypropylene

- COC cycloolefin copolymer

- COP cycloolefin polymer

- PET polyethylene terephthalate

- HDPE hard polyethylene

- the squeeze bottle dispenser has at least one guide surface along which the protective sleeve can be displaced in a guided manner.

- the outside of the liquid reservoir directly as a guide surface.

- a design in which a component separate from the liquid reservoir provides the guide surface is preferred.

- One possible design provides for at least one guide surface to be provided on the outside of a guide ring.

- This guide ring is attached to the liquid reservoir, the discharge head or in an intermediate area in between.

- An inside of the guide ring is designed in such a way that the ring cannot or can hardly be displaced in the axial direction relative to the liquid reservoir.

- the guide ring On the outside, the guide ring has a sliding surface along which the protective sleeve can be slidably displaced.

- a design in which the guide ring is attached to a tapered neck area of the liquid dispenser is particularly advantageous.

- its inner diameter is smaller than the diameter of the liquid reservoir and the discharge head on both sides of the tapered neck area.

- Such a ring can be installed by placing the guide ring in the neck area before the discharge head is attached to the liquid reservoir.

- the guide ring is designed in such a way that it can also be mounted when the discharge head is already attached to the bottle neck.

- This can be achieved, for example, by a guide ring interrupted by a separating slot, which is temporarily widened in the axial direction or from the side for assembly.

- the guide ring can be designed as an interrupted guide ring that has an interruption in a segment that spans a maximum of 120° and which preferably spans a maximum of 10°.

- Such an interruption in the ring structure or at least a slotted design is advantageous in order to be able to widen the guide ring during automated assembly.

- a guide ring provided with an interruption or slot and the protective sleeve held thereby are coordinated with one another in such a way that the guide sleeve prevents the guide ring from widening to a level that would be sufficient to pull the guide ring over the liquid reservoir or the discharge head and thus separate the protective sleeve from the squeeze bottle dispenser.

- An alternative design of a guide ring provides that the guide ring is designed as a multi-part guide ring, in particular as a two-part guide ring. It has at least two guide ring segments which are connected to one another at at least one end, preferably at both ends, to form the joined guide ring, in particular preferably by means of a snap-in connection. With such a design, the guide ring is only assembled from the multiple guide ring segments in the area of the neck area of the liquid reservoir.

- an insertion bevel is preferably provided on the protective sleeve and/or on the guide ring.

- the protective sleeve is preferably pushed on from a side facing away from the discharge opening.

- the insertion bevel is provided on the upper edge of the protective sleeve or on the lower end of the guide ring.

- the guide ring can have at least one guide structure on its outside that extends in the direction of movement of the protective sleeve, for example in the form of a short vertical groove. This allows a protective sleeve provided with a corresponding inward-facing guide structure to not only be guided longitudinally by means of the guide ring, but also to be secured in a rotationally fixed manner to the guide ring. It has been shown that this results in greater guide stability and a reduced tendency to tilt.

- the guide ring preferably also forms a stop that limits the displacement of the protective sleeve in at least one direction of movement.

- the guide ring can also form a locking edge of a displacement lock, which will be explained below.

- An alternative design of the guide surface provides that at least one guide surface is provided on an inner side of a guide sleeve surrounding the protective sleeve.

- This guide sleeve can be held on the liquid reservoir or on the discharge head or between the liquid reservoir and discharge head, in particular using an intermediate ring.

- the guide sleeve surrounds the liquid reservoir and is stationary in the axial direction or only slightly movable axially relative to it.

- the guide sleeve has at least one recess through which the liquid reservoir can be compressed.

- two recesses opposite one another are provided.

- the recesses preferably have an extension in the axial direction of at least 10 mm, preferably of at least 15 mm.

- the protective sleeve can be arranged between the guide sleeve, which is largely stationary axially to the liquid reservoir, and the outer wall of the liquid reservoir. If the protective sleeve is in its protective position, it is located in the area of at least one recess, so that it is impossible to apply force to the liquid reservoir. If the protective sleeve is in its release position, it at least partially releases the recess and thus enables the squeeze bottle reservoir to be compressed.

- the guide sleeve is preferably attached to the squeeze bottle dispenser using an intermediate ring.

- the intermediate ring can also be designed as a slotted ring or as a ring with an interruption to make assembly easier.

- a guide ring made up of several ring segments in the manner described is also possible.

- the intermediate ring is preferably designed for axial fixation on the guide sleeve.

- the intermediate ring and the guide sleeve are preferably locked together in a form-fitting manner, with a groove being provided on one of the parts and a web engaging therein on the other part.

- the protective sleeve can be guided by the guide ring or the guide sleeve in such a way that the outside of the guide ring and the inside of the protective sleeve or the outside of the protective sleeve and the inside of the guide sleeve have a substantially identical cylindrical shape.

- interlocking guide structures are provided on the guide surface and opposite thereto on the protective sleeve, by means of which the protective sleeve is guided in a rotationally fixed manner relative to the guide surface or by means of which the protective sleeve is guided in a rotationally and translationally guided manner relative to the guide surface, for example in the manner of a threaded movement or a bayonet movement.

- a recessed guide groove can be provided on one side, into which a guide web or a guide cam on the opposite side engages.

- Such a structure leads to more reliable guidance, in which tilting can be easily avoided. If the guide groove has a helical shape at least in sections, the thread movement mentioned is achieved.

- the guide groove can have a partial section at one or both axially spaced ends that extends circumferentially to the main axis so that it does not run in the axial direction of the main axis.

- a displacement lock can be provided by means of which the protective sleeve can be secured against displacement in its protective position. To move it into the release position, the displacement lock must first be released using a separate operation.

- the displacement protection device can have at least one elastically deflectable locking element which is fixed either to the liquid reservoir and the guide sleeve or to the securing sleeve and which, in the protective position, interacts with a locking edge provided on the other side in such a way that a translational or a rotational movement and thus indirectly a translational movement of the protective sleeve relative to the liquid reservoir is prevented.

- the user In order to bring the liquid dispenser into the release position, the user must first deflect the locking element by applying direct manual force so that it can be guided past the locking edge.

- the elastically deflectable locking element can be attached in particular to the protective sleeve or to the guide sleeve, in particular as a one-piece molded section that is connected to surrounding wall parts of the sleeve via an elastically deformable material bridge. It is particularly preferred if the deflectable locking element is provided on the protective sleeve itself. If it is a protective sleeve that can be displaced within a guide sleeve, the corresponding locking edge is preferably provided on the guide sleeve, in particular as the edge of an opening through which the locking element can be pressed in. This opening can be identical to the recess through which the Force is applied to the squeeze bottle. If the protective sleeve is mounted on an internal guide surface of a guide ring, the locking edge is preferably provided on this guide ring.

- the elastically deflectable locking element as a rocker element with two opposing arms on either side of a tilting axis.

- One of the arms can then be used to lock with the locking edge, while the other arm is manually operated to release the lock.

- the rocker element thus causes a reversal of direction for the purpose of releasing the lock.

- the protective sleeve In the protective position, the protective sleeve surrounds the liquid reservoir at least in those areas where it would be accessible from the outside. In the release position, the protective sleeve is translationally displaced relative to the liquid reservoir. Designs are conceivable in which the translational displacement of the protective sleeve occurs in the direction of the discharge opening or away from the discharge opening.

- the protective sleeve is closer to the dispensing opening in the release position than in the protective position. This makes it possible to use an upper edge of the protective sleeve as a contact surface that is placed in the area of the skin where liquid is to be applied. In the case of eye drops, for example, the contact surface can be placed in the area of the eyebrow to enable particularly safe and reproducible dispensing.

- the contact surface of the protective sleeve is arranged in the release position such that it is positioned a maximum of 15 mm away from the discharge opening in relation to the main axis and in particular preferably protrudes beyond the discharge opening.

- holding means are provided, in particular in the form of stops on the guide ring and on the protective sleeve, in order to prevent the protective sleeve from being pulled off the guide ring.

- Another design, in which the protective sleeve is displaced away from the discharge opening in the release position, is preferably implemented using the guide sleeve described. This is able to securely hold the protective sleeve displaced away from the discharge opening.

- the extension of the dispenser as a whole caused by the displacement of the protective sleeve can offer a considerable advantage in handling.

- holding means are preferably provided which prevent the protective sleeve from being pulled off in the opposite direction to the discharge opening.

- these can be stops on the protective sleeve and the guide sleeve.

- a particularly advantageous design provides that the stop on the side of the guide sleeve is formed by an edge which delimits the actuation recess.

- the protective sleeve In the case of a design with a guide sleeve, in order to be able to move the protective sleeve arranged inside the guide sleeve into the release position, the user must be able to grasp the protective sleeve. This can be done through the recess. However, to make handling easier, the protective sleeve can also have a distal end section that protrudes beyond the guide sleeve at the lower end even when the protective sleeve is in the protective position. The additional length of the protective sleeve can be used when the protective sleeve is designed with a closed base to arrange electronic dispenser components such as a counter within the receiving space defined in this way.

- the protective sleeve covers the liquid reservoir at least in phases.

- the protective sleeve can be made of transparent plastic. Printing on the outside of the liquid reservoir or on a label attached to the outside can thus be read through the protective sleeve. If a guide sleeve is provided, this can also be made of transparent plastic.

- the squeeze bottle dispenser preferably has a protective cap which protects the discharge opening when fitted and which is removed to use the dispenser and then fitted again.

- a protective cap can in particular be a protective cap with at least one ventilation opening, whereby this ventilation opening is preferably still closed in the delivery state.

- the protective cap can provide additional security by interacting with the protective sleeve in such a way that when the protective cap is in place or at least when the protective cap has not yet been opened for the first time, the displacement of the protective sleeve is prevented, in particular by arranging the protective cap at the point where the protective sleeve must be moved to be moved into the release position.

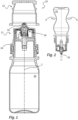

- Fig.1 and 2 initially show a squeeze bottle dispenser 10 without actuation safety device, which is further developed by additions to form a liquid dispenser according to the invention with actuation safety device.

- the squeeze bottle dispenser 10 also has a liquid reservoir 20, which is designed as a squeeze bottle and whose walls can therefore be pressed in to reduce the internal volume of the liquid reservoir 20 and increase the pressure accordingly.

- the discharge head is attached to the open end of the liquid reservoir 20.

- the pressure during the compression of the liquid reservoir 20 forces the liquid contained therein towards the discharge head when the discharge opening is oriented downwards and reaches the discharge opening 16 after a discharge valve 18 has been opened due to pressure.

- the squeeze bottle dispenser 10 can, for example, be a drop dispenser, in particular for ophthalmic use, whose discharge opening is designed to dispense drops, in particular by means of a drop formation surface surrounding the discharge opening 16 on the outside, in particular with a surrounding sharp-edged tear-off edge.

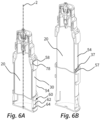

- the Fig. 3 to 6B show a first embodiment of a dispenser according to the invention. This is based on the drop dispenser of Fig.1 , which is due to the Fig.5 clearly visible components 70, 50, 30.

- the Fig. 3 and 4 show the liquid dispenser 10 in the assembled state before and after removal of the protective cap 22.

- the additional components 30, 50, 70 represent components of a safety device intended to prevent accidental discharge of liquid.

- the components together form a child safety lock that is difficult for small children to overcome.

- the guide sleeve 50 is provided on its inner side with guide surfaces 52 in the form of two guide grooves 53 extending in the direction of the main axis 2, opposite one another.

- guide webs 33 are provided on the outside of the protective sleeve 30.

- the protective sleeve 30 can thus only be moved in a translational manner when inserted into the guide sleeve 50.

- the protective sleeve 30 has stop webs 37 on both sides at the upper edge that protrude outwards and prevent the protective sleeve 30 from being completely pulled out of the guide sleeve 50. As soon as the stop 37 hits the lower edge of the window recesses 54, which forms another stop, the protective sleeve 30 cannot be pulled out any further.

- the guide sleeve 50 has a locking opening 59, the lower end edge of which forms a locking edge 64.

- a locking element 62 is provided which can be elastically deflected inwards and which is an integral part of the protective sleeve 30 in the form of a tongue cut out in a U-shape.

- the assembly of the guide sleeve 50 and the protective sleeve 30 inserted therein is attached to the liquid reservoir 20 of the liquid dispenser 10 by means of an intermediate ring 70.

- the intermediate ring 70 is in the Fig.5 As can be seen, the intermediate ring is not designed to be closed all the way round, but is provided with an interruption 74. This interruption 74 allows the intermediate ring to be pushed onto a tapered area 20B of the liquid reservoir 20 from above or below, but in particular also from the side. It can then be pressed together sufficiently far so that the combination of guide sleeve 50 and protective sleeve 30 can be pushed on from below.

- Fig. 6A shows the child safety lock mounted in this way in a sectional view. It can be seen that a groove 78 on the outside of the intermediate ring 70 is used to fasten an inward-facing retaining web 58 of the guide sleeve 50.

- Fig. 6A shows the protective position of the protective sleeve 30.

- the protective sleeve 30 blocks its recesses 54 in this position so that the user is not able to compress the liquid reservoir 20.

- the user In order to make the dispenser ready for operation, the user must first elastically press in the locking element 62. Once this has been done, the user can pull the protective sleeve downwards by applying force to the protective sleeve 30 against the guide sleeve 50 or the discharge head 12, so that the state of the Fig. 6B The downward shift is achieved by the stops 37, 57. In the position of the Fig. 6B the dispenser as a whole is now significantly extended, so that it is easier to handle and the dispenser can be placed securely, for example above an eye to be treated. If the liquid reservoir is now subjected to force on both sides through the recesses 54, the pressure in the liquid reservoir increases, so that the dispensing valve 18 opens and liquid is dispensed through the discharge opening 16.

- a bevel on the locking element 62 causes it to be indirectly elastically deflected inwards until it springs back into the opening 59 and restores the protective state.

- the design of the Fig. 7A and 7B differs from that of the Fig. 3 to 6B by the fact that the protective sleeve is extended at its lower end so that it can also be used in the protective position of the Fig. 7A protrudes downwards beyond the guide sleeve 50. This can facilitate the transfer to the release position of the Fig. 7B facilitate.

- Fig. 8 and 9 The design of the Fig. 8 and 9 is that of the previous Fig. 3 to 7B quite similar. A significant difference is that here no purely translational movement of the protective sleeve 30 is provided, but rather a superimposed translational and rotational movement.

- a predominantly helical guide groove 35 is provided on an outer side of the protective sleeve 30, which only changes into horizontal sections at its ends.

- a guide cam 55 is arranged within the groove, which is provided on the inside of the guide sleeve 50.

- the helical guide groove 35 ensures that the Fig.8 in the release position of the Fig.9 firstly, the locking element 62 must be pressed in as already described, but then the protective sleeve 30 is not pulled out directly, but is unscrewed, as it were, by a rotary movement and a translational movement indirectly caused thereby.

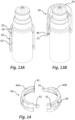

- Fig. 10 to 13B has fundamental differences to the previous embodiments.

- a guide ring 40 which is pushed onto a tapered area 20B of the liquid reservoir 20 from above or below, but in particular from the side, similar to the intermediate ring 70, and a protective sleeve 30, which is pushed onto the liquid reservoir 20 surrounding the guide ring 40.

- insertion bevels 38 are provided, which are used for ensure that the guide ring 40 is temporarily compressed so that it can expand again below the guide bevels 38.

- the guide ring 40 fulfils a number of functions. From the protective position of the Fig. 13A it is not possible to pull the protective sleeve 30 downwards, since the bevels previously used during assembly only work in the opposite direction. Furthermore, it is initially not possible to move the protective sleeve 30 upwards, since a locking element 62 designed as a rocker element rests with an upper edge on the locking edge 64 of the guide ring 40. Only when the lower half of the locking element 62 is pressed, the upper half is tilted outwards, so that the protective sleeve can then be moved upwards. The end position is in the Fig. 13B visible position is reached in which a stop 64 of the guide ring 40 comes to rest against an inwardly pointing stop 31 of the protective sleeve 30.

- Fig. 13B shows the release position in which a force can now be applied to the liquid reservoir 20. Deviating from Fig. 13B This force is applied when the dispenser is in an angled position with the discharge opening 16 pointing downwards.

- the upper end edge of the protective sleeve 30 can be used in this release position by placing the contact surface 34 there on a part of the user's skin in order to allow the most precise drop dispensing possible.

- the contact surface 34 can be placed on the user's eyebrow, for example.

- Fig. 14 shows an alternative design of a guide ring 40. This is not provided with an interruption 44 that allows for expansion, but is instead formed from two ring segments 40A, 40B that can be connected to one another via cooperating coupling means 41. This allows the guide ring of the Fig. 14 to be attached after the liquid reservoir 20 and the discharge head 12 have already been connected to one another by feeding the two ring segments in the tapered region 20B from opposite sides and locking them around the bottle neck.

- the guide ring 40 of the Fig. 14 furthermore has a guide structure 48 on the outside. These are short vertical grooves. These grooves can interact with corresponding webs on the inside of the protective sleeve 30 so that the protective sleeve 30 cannot rotate about the main axis 2 relative to the guide ring. This allows for secure guidance and a low tendency to tilt.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Ceramic Engineering (AREA)

- Closures For Containers (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

Description

Die Erfindung betrifft primär einen Quetschflaschenspender mit einer Betätigungssicherung, insbesondere einer Kindersicherung. Ein Quetschflaschenspender im Sinne der Erfindung ist ein Flüssigkeitsspender, beispielsweise zur Abgabe von pharmazeutischen Flüssigkeiten, der über einen formstabilen Flüssigkeitsspeicher verfügt, dessen Wandungen zumindest zum Teil elastisch eindrückbar sind, so dass hierdurch die Flüssigkeit im Flüssigkeitsspeicher druckbeaufschlagt werden kann.The invention primarily relates to a squeeze bottle dispenser with an actuation safety device, in particular a child safety device. A squeeze bottle dispenser in the sense of the invention is a liquid dispenser, for example for dispensing pharmaceutical liquids, which has a dimensionally stable liquid reservoir, the walls of which can be elastically compressed at least in part, so that the liquid in the liquid reservoir can be pressurized.

Die durch die Betätigung bewirkte Volumenverringerung des Flüssigkeitsspeichers und die damit einhergehende Druckerhöhung verursachen, dass Flüssigkeit in einen Austragkopf des Quetschflaschenspenders und zu der dort vorgesehenen Austragöffnung gedrückt werden. Meist ist bei gattungsgemäßen wie auch erfindungsgemäßen Quetschflaschenspendern der Austragöffnung ein Auslassventil vorgeschaltet, welches bei ausreichendem Flüssigkeitsdruck öffnet.The reduction in volume of the liquid reservoir caused by the actuation and the associated increase in pressure cause liquid to be pressed into a discharge head of the squeeze bottle dispenser and to the discharge opening provided there. In squeeze bottle dispensers of the generic type as well as those according to the invention, an outlet valve is usually installed upstream of the discharge opening, which opens when there is sufficient liquid pressure.

Gattungsgemäße Quetschflaschenspender sind weit verbreitet. Insbesondere werden Sie für pharmazeutische Flüssigkeiten, beispielsweise Augentropfenflüssigkeit, verwendet. Ein Quetschflaschenspender der beschriebenen Art ist beispielsweise aus dem Dokument

Insbesondere bei Quetschflaschenspendern, die pharmazeutische Flüssigkeiten enthalten, ist es wichtig, dass diese Flüssigkeit nicht durch spielende Kinder oder anderweitig unbeabsichtigt ausgetragen wird.Especially with squeeze bottle dispensers that contain pharmaceutical liquids, it is important that this liquid is not spilled by children playing or otherwise unintentionally.

Quetschflaschenspender mit Kindersicherung sind aus der nachveröffentlichten Europäischen Patentanmeldung 21155900.0 bekannt.Squeeze bottle dispensers with child safety locks are known from the subsequently published European patent application 21155900.0.

Aus der

Aufgabe der Erfindung ist es primär, einen Quetschflaschenspender zur Verfügung zu stellen, der ein hohes Maß an Sicherheit gegen ungewollte Betätigung und/oder gegen Betätigung durch spielende Kinder bietet.The primary object of the invention is to provide a squeeze bottle dispenser that offers a high degree of safety against unintentional activation and/or activation by children at play.

Hierfür wird ein Quetschflaschenspender vorgeschlagen, der einen als Quetschflasche ausgebildeten Flüssigkeitsspeicher sowie einen Austragkopf mit einer Austragöffnung aufweist. Bevorzugt ist der Austragkopf als separate Baugruppe gefertigt und mit dem Flüssigkeitsspeicher gekoppelt, beispielsweise durch eine Rastverbindung oder eine Gewindeverbindung. Es sind jedoch auch Bauweisen möglich, bei denen der Austragkopf und der Flüssigkeitsspeicher bzw. zumindest deren Außenflächen durch ein einstückiges Bauteil gebildet sind.For this purpose, a squeeze bottle dispenser is proposed which has a liquid reservoir designed as a squeeze bottle and a discharge head with a discharge opening. The discharge head is preferably manufactured as a separate assembly and coupled to the liquid reservoir, for example by means of a snap-in connection or a threaded connection. However, designs are also possible in which the discharge head and the liquid reservoir, or at least their outer surfaces, are formed by a one-piece component.

Der Flüssigkeitsspender ist vorzugsweise mit einer pharmazeutischen Flüssigkeit befüllt, beispielsweise miteiner Imidazolin enthaltenden Flüssigkeit zur Linderung bei Bindehautreizungen. Der Flüssigkeitsspeicher weist vorzugsweise ein Innenvolumen von weniger als 50 ml auf, insbesondere von weniger als 20 ml.The liquid dispenser is preferably filled with a pharmaceutical liquid, for example with a liquid containing imidazoline for relieving conjunctival irritation. The liquid reservoir preferably has an internal volume of less than 50 ml, in particular less than 20 ml.

Der Flüssigkeitsspeicher ist als Quetschflasche ausgebildet. Vorzugsweise ist der Quetschflaschenkörper mit einer Eigensteifigkeit ausgebildet, die es gestattet, bei beidseitigem Druck von jeweils 20 Newton das Innenvolumen mindestens um 5% zu reduzieren. Die Wandung des Flüssigkeitsspeichers ist vorzugsweise aus einem weichen Kunststoff gefertigt, insbesondere aus Polyethylenterephthalat (PET), aus Polyethylen (PE) oder aus einem cycloolefinem Copolymer (COC).The liquid reservoir is designed as a squeeze bottle. The squeeze bottle body is preferably designed with an inherent rigidity that allows the internal volume to be reduced by at least 5% when pressure of 20 Newtons is applied on both sides. The wall of the liquid reservoir is preferably made of a soft plastic, in particular polyethylene terephthalate (PET), polyethylene (PE) or a cycloolefin copolymer (COC).

Es sind verschiedene Arten des Flüssigkeitsaustrags möglich. So kann der erfindungsgemäße Spender zur Abgabe eines Flüssigkeitsstrahls oder eines Sprays ausgebildet sein. Vorzugsweise jedoch ist der Quetschflaschenspender als Tropfenspender ausgebildet. Hierfür weist der Quetschflaschenspender vorzugsweise im Bereich der Austragöffnung Tropfenbildungsmittel auf, insbesondere in Form einer eine die Austragöffnung umgebende Tropfenbildungsfläche, wo sich ausgetragene Flüssigkeit sammelt, bis die Flüssigkeitsmenge ausreicht, dass sich ein Tropfen bildet, der sich von den Tropfenbildungsmittels löst und hinabfällt.Various types of liquid discharge are possible. The dispenser according to the invention can be designed to discharge a liquid jet or a spray. Preferably, however, the squeeze bottle dispenser is designed as a drop dispenser. For this purpose, the squeeze bottle dispenser preferably has drop-forming means in the area of the discharge opening, in particular in the form of a drop-forming surface surrounding the discharge opening, where discharged liquid collects until the amount of liquid is sufficient for a drop to form, which detaches from the drop-forming means and falls down.

Erfindungsgemäß weist ein erfindungsgemäßer Quetschflaschenspender eine unverlierbar mit dem Flüssigkeitsspeicher verbundene Schutzhülse auf. Diese ist bezogen auf eine Hauptachse des Spenders, die durch die Austragrichtung des Spenders und/oder die Mittelachse des Flüssigkeitsspeichers gebildet ist, axial gegenüber dem Flüssigkeitsspeicher wiederholt verlagerbar zwischen einer Schutzstellung und einer Freigabestellung. Die Verlagerbarkeit kann dabei eine rein translative sein. Möglich ist jedoch auch, dass die Schutzhülse translativ und rotativ verlagerbar ist, beispielsweise überlagert in Art einer Gewindebewegung oder sequentiell in Art einer Bajonettbewegung.According to the invention, a squeeze bottle dispenser according to the invention has a protective sleeve that is captively connected to the liquid reservoir. This is axially displaceable repeatedly relative to the liquid reservoir between a Protective position and a release position. The displaceability can be purely translational. However, it is also possible for the protective sleeve to be displaceable translationally and rotationally, for example superimposed in the manner of a thread movement or sequentially in the manner of a bayonet movement.

Unter einer unverlierbaren Anbringung der Schutzhülse am Quetschflaschenspender wird im Sinne der Erfindung verstanden, dass im normalen Gebrauch eine Trennung der Schutzhülse vom Quetschflaschenspender nicht eintritt. Dass mit roher Gewalt eine Trennung möglich ist, steht der Unverlierbarkeit im Sinne der Erfindung nicht entgegen.For the purposes of the invention, a captive attachment of the protective sleeve to the squeeze bottle dispenser means that the protective sleeve cannot be separated from the squeeze bottle dispenser during normal use. The fact that separation is possible using brute force does not contradict the captiveness for the purposes of the invention.

In der Schutzstellung ist die Schutzhülse derart relativ zum Flüssigkeitsspeicher angeordnet, dass sie ein Zusammendrücken des Flüssigkeitsspeichers entweder vollständig unterbindet oder zumindest in einem hohen Maße erschwert, indem sie den Zugang zur Außenwandung des Flüssigkeitsspeichers überdeckt. Der Austrag von Flüssigkeit wird hierdurch verhindert.In the protective position, the protective sleeve is arranged relative to the liquid reservoir in such a way that it either completely prevents compression of the liquid reservoir or at least makes it extremely difficult by covering access to the outer wall of the liquid reservoir. This prevents liquid from escaping.

In der Freigabestellung ermöglicht die Schutzhülse dagegen das Zusammendrücken des Flüssigkeitsspeichers und damit den Austrag von Flüssigkeit. Die Schutzhülse ist hierfür gegenüber dem Flüssigkeitsspeicher soweit verlagert, dass sie keinerlei Hindernis mehr darstellt oder zumindest eine gegenüber der Schutzstellung vereinfachte Kraftbeaufschlagung des Flüssigkeitsspeichers gestattet.In the release position, however, the protective sleeve allows the liquid reservoir to be compressed and thus the liquid to be discharged. For this purpose, the protective sleeve is displaced so far in relation to the liquid reservoir that it no longer represents any obstacle or at least allows the liquid reservoir to be subjected to a force that is easier than in the protective position.

Die Schutzhülse ist zum beschriebenen Zweck zumindest auch translativ gegenüber dem Flüssigkeitsspeicher verlagerbar. Das Maß der Verlagerbarkeit in axialer Richtung bezogen auf die Hauptachse beträgt vorzugsweise mindestens 20 mm, insbesondere vorzugweise mindestens30 mm. Dieses Maß beschreibt den axialen Weg, den die Schutzhülse zwischen gegenüberliegenden Endlagen beweglich ist, also zwischen der der Freigabestellung und der der Schutzstellung zugeordneten Endlage.For the purpose described, the protective sleeve can be displaced at least translationally relative to the liquid reservoir. The degree of displaceability in the axial direction relative to the main axis is preferably at least 20 mm, in particular preferably at least 30 mm. This dimension describes the axial path that the protective sleeve can move between opposite end positions, i.e. between the release position and the end position associated with the protection position.

Die Schutzhülse ist ausreichend starr, um eine nennenswerte Verringerung des Innenvolumens des Flüssigkeitsspeichers bei Kraftbeaufschlagung der Schutzhülse zu verhindern. Vorzugsweise ist die Schutzhülse aus einem starren Kunststoff gefertigt, insbesondere aus Polycyclohexylenedimethylene Terephthalate / glycol-modified (PCTG), aus Polypropylen (PP), aus einem cycloolefinen Copolymer (COC), aus einem cycloolefinen Polymer (COP), aus Polyethylenterephthalat (PET) oder aus einem Hart-Polyethylen (HDPE). Die Schutzhülse muss zur Erzielung ihrer Stabilität nicht zwingend aus einem steiferen Material als der Flüssigkeitsspeicher gefertigt sein. Alternativ kann die höhere Stabilität auch über eine größere Wandungsstärke erzielt werden.The protective sleeve is sufficiently rigid to prevent a significant reduction in the internal volume of the liquid reservoir when force is applied to the protective sleeve. The protective sleeve is preferably made of a rigid plastic, in particular polycyclohexylenedimethylene terephthalate / glycol-modified (PCTG), polypropylene (PP), a cycloolefin copolymer (COC), a cycloolefin polymer (COP), polyethylene terephthalate (PET) or a hard polyethylene (HDPE). The protective sleeve does not necessarily have to be made of a stiffer material than the liquid reservoir to achieve its stability. Alternatively, the higher stability can also be achieved by using a greater wall thickness.

Um eine geführte Verlagerung der Schutzhülse zu gestatten, weist der Quetschflaschenspender mindestens eine Führungsfläche auf, entlang derer die Schutzhülse geführt verlagerbar ist. Zwar ist es grundsätzlich möglich, unmittelbar die Außenseite des Flüssigkeitsspeichers als Führungsfläche zu verwenden. Bevorzugt ist jedoch eine Gestaltung, bei der ein vom Flüssigkeitsspeicher getrenntes Bauteil die Führungsfläche zur Verfügung stellt.In order to allow a guided displacement of the protective sleeve, the squeeze bottle dispenser has at least one guide surface along which the protective sleeve can be displaced in a guided manner. In principle, it is possible to use the outside of the liquid reservoir directly as a guide surface. However, a design in which a component separate from the liquid reservoir provides the guide surface is preferred.

Eine mögliche Bauweise sieht vor, dass mindestens eine Führungsfläche an einer Außenseite eines Führungsrings vorgesehen ist. Dieser Führungsring ist am Flüssigkeitsspeicher, am Austragkopf oder in einem dazwischenliegenden Zwischenbereich befestigt. Eine Innenseite des Führungsrings ist derart ausgebildet, dass der Ring in axialer Richtung nicht oder kaum gegenüber dem Flüssigkeitsspeicher verlagerbar ist. An der Außenseite weist der Führungsring eine Gleitfläche auf, entlang derer die Schutzhülse gleitend verlagerbar ist.One possible design provides for at least one guide surface to be provided on the outside of a guide ring. This guide ring is attached to the liquid reservoir, the discharge head or in an intermediate area in between. An inside of the guide ring is designed in such a way that the ring cannot or can hardly be displaced in the axial direction relative to the liquid reservoir. On the outside, the guide ring has a sliding surface along which the protective sleeve can be slidably displaced.

Insbesondere von Vorteil ist eine Gestaltung, bei der der Führungsring an einem verjüngten Halsbereich des Flüssigkeitsspenders befestigt ist. Sein Innendurchmesser ist in diesem Falle kleiner als der Durchmesser des Flüssigkeitsspeichers und des Austragkopfes beidseitig des verjüngten Halsbereichs. Die Montage eines solchen Rings kann erfolgen, indem der Führungsring im Halsbereich platziert wird, bevor der Austragkopf am Flüssigkeitsspeicher befestigt wird.A design in which the guide ring is attached to a tapered neck area of the liquid dispenser is particularly advantageous. In this case, its inner diameter is smaller than the diameter of the liquid reservoir and the discharge head on both sides of the tapered neck area. Such a ring can be installed by placing the guide ring in the neck area before the discharge head is attached to the liquid reservoir.

Als vorteilhaft im Sinne einer flexibleren Montagereihenfolge wird es allerdings angesehen, wenn der Führungsring derart gestaltet ist, dass er auch bei bereits am Flaschenhals angebrachtem Austragkopf montierbar ist. Dies kann beispielsweise durch einen mit einem Trennschlitz unterbrochenen Führungsring erreicht werden, der zur Montage in axialer Richtung odervon der Seite temporär aufgeweitet wird. Insbesondere kann der Führungsring als unterbrochener Führungsring ausgebildet sein, der in einem Segment, welches maximal 120° überspannt und welches vorzugsweise maximal 10° überspannt, eine Unterbrechung aufweist. Eine solche Unterbrechung der Ringstruktur oder eine zumindest geschlitzte Gestaltung ist von Vorteil, um den Führungsring bei der automatisierten Montage aufweiten zu können. Vorzugsweise sind ein mit Unterbrechung oder Schlitzung versehener Führungsring und die dadurch gehaltene Schutzhülse derart aufeinander abgestimmt, dass die Führungshülse eine Aufweitung des Führungsrings unterbindet, die ausreichen würde, um den Führungsring über den Flüssigkeitsspeicher oder den Austragkopf zu ziehen und damit die Schutzhülse vom Quetschflaschenspender zu trennen.However, it is considered advantageous in terms of a more flexible assembly sequence if the guide ring is designed in such a way that it can also be mounted when the discharge head is already attached to the bottle neck. This can be achieved, for example, by a guide ring interrupted by a separating slot, which is temporarily widened in the axial direction or from the side for assembly. In particular, the guide ring can be designed as an interrupted guide ring that has an interruption in a segment that spans a maximum of 120° and which preferably spans a maximum of 10°. Such an interruption in the ring structure or at least a slotted design is advantageous in order to be able to widen the guide ring during automated assembly. Preferably, a guide ring provided with an interruption or slot and the protective sleeve held thereby are coordinated with one another in such a way that the guide sleeve prevents the guide ring from widening to a level that would be sufficient to pull the guide ring over the liquid reservoir or the discharge head and thus separate the protective sleeve from the squeeze bottle dispenser.

Eine alternative Bauweise eines Führungsrings sieht vor, dass der Führungsring als mehrteiliger Führungsring ausgebildet ist, insbesondere als zweiteiliger Führungsring. Er weist mindestens zwei Führungsringsegmente auf, die zur Bildung des gefügten Führungsrings an mindestens einem Ende, vorzugsweise an jeweils beiden Enden, miteinander verbunden werden, insbesondere vorzugsweise mittels einer Rastverbindung. Bei einer solchen Gestaltung wird der Führungsring erst im Bereich des Halsbereichs des Flüssigkeitsspeichers aus den mehreren Führungsringsegmente zusammengesetzt.An alternative design of a guide ring provides that the guide ring is designed as a multi-part guide ring, in particular as a two-part guide ring. It has at least two guide ring segments which are connected to one another at at least one end, preferably at both ends, to form the joined guide ring, in particular preferably by means of a snap-in connection. With such a design, the guide ring is only assembled from the multiple guide ring segments in the area of the neck area of the liquid reservoir.

Um im Zuge der Montage die Schutzhülse auf den Führungsring zu schieben, ist an der Schutzhülse und oder am Führungsring vorzugweise eine Einführschräge vorgesehen. Vorzugsweise wird die Schutzhülse bei der Montage von einer der Austragöffnung abgewandten Seite aufgeschoben. Die Einführschräge ist in diesem Falle am oberen Rand der Schutzhülse oder am unteren Ende des Führungsrings vorgesehen.In order to slide the protective sleeve onto the guide ring during assembly, an insertion bevel is preferably provided on the protective sleeve and/or on the guide ring. During assembly, the protective sleeve is preferably pushed on from a side facing away from the discharge opening. In this case, the insertion bevel is provided on the upper edge of the protective sleeve or on the lower end of the guide ring.

Der Führungsring kann an seiner Außenseite mindestens eine in Bewegungsrichtung der Schutzhülse erstreckte Führungsstruktur aufweisen, beispielsweise in Form einer kurzen vertikalen Nut. Dies gestattet es, eine mit einer hierzu korrespondierende nach innen weisende Führungsstruktur versehene Schutzhülse mittels des Führungsrings nicht nur längsbeweglich zu führen, sondern dabei gleichzeitig drehfest zum Führungsring zu sichern. Es hat sich gezeigt, dass hierdurch eine höhere Führungsstabilität und eine verringerte Verkantungsneigung zu erzielen ist.The guide ring can have at least one guide structure on its outside that extends in the direction of movement of the protective sleeve, for example in the form of a short vertical groove. This allows a protective sleeve provided with a corresponding inward-facing guide structure to not only be guided longitudinally by means of the guide ring, but also to be secured in a rotationally fixed manner to the guide ring. It has been shown that this results in greater guide stability and a reduced tendency to tilt.

Der Führungsring bildet vorzugsweise zusätzlich einen Anschlag, der die Verlagerung der Schutzhülse in zumindest einer Bewegungsrichtung limitiert. Auch kann der Führungsring eine Rastkante einerVerlagerungssicherung bilden, die im Weiteren noch erläutert wird.The guide ring preferably also forms a stop that limits the displacement of the protective sleeve in at least one direction of movement. The guide ring can also form a locking edge of a displacement lock, which will be explained below.

Eine alternative Gestaltung der Führungsfläche sieht vor, dass mindestens eine Führungsfläche an einer Innenseite einer die Schutzhülse umgebenden Führungshülse vorgesehen ist. Diese Führungshülse kann insbesondere unter Nutzung eines dazwischenliegenden Zwischenrings am Flüssigkeitsspeicher oder am Austragkopf oder zwischen Flüssigkeitsspeicher und Austragkopf gehalten sein. Die Führungshülse umgibt den Flüssigkeitsspeicher und ist in axialer Richtung hierzu ortsfest oder nur in geringem Maße hierzu axial relativbeweglich. Die Führungshülse weist mindestens eine Aussparung auf, durch die hindurch ein Zusammendrücken des Flüssigkeitsspeichers möglich ist. Vorzugsweise sind zwei einander gegenüberliegende Aussparungen vorgesehen. Die Aussparungen weisen vorzugsweise eine Erstreckung in Axialrichtung von mindestens 10 mm, vorzugsweise von mindestens 15 mm, auf.An alternative design of the guide surface provides that at least one guide surface is provided on an inner side of a guide sleeve surrounding the protective sleeve. This guide sleeve can be held on the liquid reservoir or on the discharge head or between the liquid reservoir and discharge head, in particular using an intermediate ring. The guide sleeve surrounds the liquid reservoir and is stationary in the axial direction or only slightly movable axially relative to it. The guide sleeve has at least one recess through which the liquid reservoir can be compressed. Preferably, two recesses opposite one another are provided. The recesses preferably have an extension in the axial direction of at least 10 mm, preferably of at least 15 mm.

Die Schutzhülse kann bei einer solchen Gestaltung zwischen der axial zum Flüssigkeitsspeicherweitgehend ortsfesten Führungshülse und der Außenwandung des Flüssigkeitsspeichers angeordnet sein. Ist die Schutzhülse in ihrer Schutzstellung, so befindet sie sich im Bereich der mindestens einen Aussparung, so dass eine Kraftbeaufschlagung des Flüssigkeitsspeichers unmöglich gemacht wird. Ist die Schutzhülse in ihrer Freigabestellung, so gibt sie die Aussparung zumindest zum Teil frei und ermöglicht so das Zusammendrücken des Quetschflaschenspeichers.In such a design, the protective sleeve can be arranged between the guide sleeve, which is largely stationary axially to the liquid reservoir, and the outer wall of the liquid reservoir. If the protective sleeve is in its protective position, it is located in the area of at least one recess, so that it is impossible to apply force to the liquid reservoir. If the protective sleeve is in its release position, it at least partially releases the recess and thus enables the squeeze bottle reservoir to be compressed.

Wie bereits erläutert, erfolgt die Befestigung der Führungshülse am Quetschflaschenspender vorzugsweise mittels eines Zwischenrings. Wie oben schon zum Führungsring erläutert, kann auch der Zwischenring als geschlitzter Ring oder als Ring mit einer Unterbrechung ausgebildet sein, um die Montage zu erleichtern. Auch ein aus mehreren Ringsegmenten zusammengesetzter Führungsring in beschriebener Art ist möglich.As already explained, the guide sleeve is preferably attached to the squeeze bottle dispenser using an intermediate ring. As already explained above with regard to the guide ring, the intermediate ring can also be designed as a slotted ring or as a ring with an interruption to make assembly easier. A guide ring made up of several ring segments in the manner described is also possible.

Während der beschriebene Führungsring zur gleitenden Führung der Schutzhülse dient, ist der Zwischenring vorzugweise zur axialen Fixierung an der Führungshülse ausgebildet. Vorzugsweise sind der Zwischenring und die Führungshülse miteinander formschlüssig verrastet, wobei hierzu insbesondere eine Nut an einem der Teile und ein darin eingreifender Steg am anderen Teil vorgesehen sind.While the guide ring described serves to guide the protective sleeve in a sliding manner, the intermediate ring is preferably designed for axial fixation on the guide sleeve. The intermediate ring and the guide sleeve are preferably locked together in a form-fitting manner, with a groove being provided on one of the parts and a web engaging therein on the other part.

Im einfachsten Falle kann die Führung der Schutzhülse durch den Führungsring oder die Führungshülse dadurch erfolgen, dass die Außenseite des Führungsrings und die Innenseite der Schutzhülse bzw. die Außenseite der Schutzhülse und die Innenseite der Führungshülse eine im Wesentlichen übereinstimmenden zylindrische Formgebung aufweisen.In the simplest case, the protective sleeve can be guided by the guide ring or the guide sleeve in such a way that the outside of the guide ring and the inside of the protective sleeve or the outside of the protective sleeve and the inside of the guide sleeve have a substantially identical cylindrical shape.

Bevorzugt ist es jedoch, wenn an der Führungsfläche und gegenüberliegend hierzu an der Schutzhülse ineinandergreifende Führungsstrukturen vorgesehen sind, durch die die Schutzhülse rotativ fixiert gegenüber der Führungsfläche geführt ist oder durch die die Schutzhülse gegenüber der Führungsfläche rotativ und translativ geführt beweglich ist, beispielsweise in Art einer Gewindebewegung oder eine Bajonettbewegung.However, it is preferred if interlocking guide structures are provided on the guide surface and opposite thereto on the protective sleeve, by means of which the protective sleeve is guided in a rotationally fixed manner relative to the guide surface or by means of which the protective sleeve is guided in a rotationally and translationally guided manner relative to the guide surface, for example in the manner of a threaded movement or a bayonet movement.

Insbesondere kann auf einer Seite eine vertiefte Führungsnut vorgesehen sein, in die ein Führungssteg oder eine Führungsnocke der gegenüberliegenden Seite eingreift. Eine solche Struktur führt zu einer zuverlässigeren Führung, bei der ein Verkanten gut vermeidbar ist. Wenn die Führungsnut zumindest abschnittsweise eine Helixform aufweist, wird die genannte Gewindebewegung erzielt.In particular, a recessed guide groove can be provided on one side, into which a guide web or a guide cam on the opposite side engages. Such a structure leads to more reliable guidance, in which tilting can be easily avoided. If the guide groove has a helical shape at least in sections, the thread movement mentioned is achieved.

Hierdurch wird es möglich, die Schutzhülse durch Momentenbeaufschlagung und hierdurch mittelbar verursachte axiale Verlagerung zwischen der Freigabestellung und der Schutzstellung zu verlagern.This makes it possible to move the protective sleeve between the release position and the protective position by applying a moment and thereby indirectly causing axial displacement.

Die Führungsnut kann an einem oder an beiden axial beabstandeten Enden einen Teilabschnitt aufweisen, der sich umlaufend zur Hauptachse erstreckt, so dass er nicht in axialer Richtung der Hauptachse verläuft. Mittels dieser Endabschnitte können die Schutzhülse und der Flüssigkeitsspeicher in der Schutzstellung oder der Freigabestellung gehalten werden.The guide groove can have a partial section at one or both axially spaced ends that extends circumferentially to the main axis so that it does not run in the axial direction of the main axis. By means of these end sections, the protective sleeve and the liquid reservoir can be held in the protective position or the release position.

Durch das Erfordernis, vor der Benutzung eines erfindungsgemäßen Flüssigkeitsspenders zunächst die Schutzhülse in die Freigabestellung zu verlagern, wird ein großes Maß an Sicherheit gegen unbeabsichtigte Betätigung erzielt. Um dieses Maß an Sicherheit noch zu erhöhen, insbesondere bei einer als Kindersicherung dienenden Gestaltung, kann eine Verlagerungssicherung vorgesehen sein, mittels derer die Schutzhülse in ihrer Schutzstellung gegen Verlagerung sicherbar ist. Zur Überführung in die Freigabestellung muss zunächst die Verlagerungssicherung mit einer separaten Handhabung entsichert werden.The requirement to first move the protective sleeve into the release position before using a liquid dispenser according to the invention provides a high level of security against unintentional activation. In order to increase this level of security even further, particularly in a design that serves as a child safety lock, a displacement lock can be provided by means of which the protective sleeve can be secured against displacement in its protective position. To move it into the release position, the displacement lock must first be released using a separate operation.

Insbesondere kann die Verlagerungssicherung mindestens ein elastisch auslenkbares Rastelement aufweisen, welches entweder zum Flüssigkeitsspeicher und der Führungshülse oder zur Sicherungshülse ortsfest ist und welches in der Schutzstellung mit einer auf der jeweils anderen Seite vorgesehenen Rastkante derart zusammenwirkt, dass eine translative oder aber eine rotative Bewegung und damit mittelbar eine translative Bewegung der Schutzhülse gegenüber dem Flüssigkeitsspeicher unterbunden ist. Um den Flüssigkeitsspender in die Freigabestellung zu bringen, muss der Benutzer zunächst das Rastelement durch unmittelbare manuelle Kraftbeaufschlagung auslenken, damit es an der Rastkante vorbeigeführt werden kann.In particular, the displacement protection device can have at least one elastically deflectable locking element which is fixed either to the liquid reservoir and the guide sleeve or to the securing sleeve and which, in the protective position, interacts with a locking edge provided on the other side in such a way that a translational or a rotational movement and thus indirectly a translational movement of the protective sleeve relative to the liquid reservoir is prevented. In order to bring the liquid dispenser into the release position, the user must first deflect the locking element by applying direct manual force so that it can be guided past the locking edge.

Das elastisch auslenkbare Rastelement kann insbesondere an der Schutzhülse oder an der Führungshülse angebracht sein, insbesondere als einstückig angeformter Abschnitt, der über eine elastisch verformbare Materialbrücke mit umgebenden Wandungsteilen der Hülse verbunden ist. Insbesondere bevorzugt ist es, wenn das auslenkbare Rastelement an der Schutzhülse selbst vorgesehen ist. Handelt es sich um eine Schutzhülse, die innerhalb einer Führungshülse verlagerbar ist, so ist die korrespondierende Rastkante vorzugsweise an der Führungshülse vorgesehen, insbesondere als Kante einer Durchbrechung, durch die hindurch das Rastelement eingedrückt werden kann. Diese Durchbrechung kann identisch mit der Aussparung sein, durch die hindurch im Freigabezustand die Kraftbeaufschlagung der Quetschflasche erfolgt. Wenn die Schutzhülse auf einer innenseitig vorgesehenen Führungsfläche eines Führungsrings gelagert ist, so ist die Rastkante vorzugsweise an diesem Führungsring vorgesehen.The elastically deflectable locking element can be attached in particular to the protective sleeve or to the guide sleeve, in particular as a one-piece molded section that is connected to surrounding wall parts of the sleeve via an elastically deformable material bridge. It is particularly preferred if the deflectable locking element is provided on the protective sleeve itself. If it is a protective sleeve that can be displaced within a guide sleeve, the corresponding locking edge is preferably provided on the guide sleeve, in particular as the edge of an opening through which the locking element can be pressed in. This opening can be identical to the recess through which the Force is applied to the squeeze bottle. If the protective sleeve is mounted on an internal guide surface of a guide ring, the locking edge is preferably provided on this guide ring.

Insbesondere bei einer Gestaltung mit Führungsring kann es sinnvoll sein, das elastisch auslenkbare Rastelement als Wippenelement mit zwei einander gegenüberliegenden Auslegern beidseitig einer Kippachse auszubilden. Einer der Ausleger kann dann der Verrastung mit der Rastkante dienen, während der andere Ausleger zur Entsicherung manuell betätigt wird. Das Wippenelement bewirkt somit eine Richtungsumkehr zum Zwecke der Entsicherung.Particularly in a design with a guide ring, it can be useful to design the elastically deflectable locking element as a rocker element with two opposing arms on either side of a tilting axis. One of the arms can then be used to lock with the locking edge, while the other arm is manually operated to release the lock. The rocker element thus causes a reversal of direction for the purpose of releasing the lock.

In der Schutzstellung umgibt die Schutzhülse den Flüssigkeitsspeicher zumindest in jenen Bereichen, in denen dieser von außen zugänglich wäre. In der Freigabestellung ist die Schutzhülse gegenüber dem Flüssigkeitsspeicher translativ verlagert. Dabei sind sowohl Gestaltungen denkbar, bei denen die translative Verlagerung der Schutzhülse in Richtung der Austragöffnung oder von der Austragöffnung weg erfolgt.In the protective position, the protective sleeve surrounds the liquid reservoir at least in those areas where it would be accessible from the outside. In the release position, the protective sleeve is translationally displaced relative to the liquid reservoir. Designs are conceivable in which the translational displacement of the protective sleeve occurs in the direction of the discharge opening or away from the discharge opening.

Im erstgenannten Fall ist die Schutzhülse in der Freigabestellungder Austragöffnung näher als in der Schutzstellung. Dies ermöglicht es, einen oberen Rand der Schutzhülse als Anlagefläche zu nutzen, die im Bereich der Hautpartie angelegt wird, wo Flüssigkeit appliziert werden soll. So kann die Anlagefläche beispielsweise im Falle von Augentropfen im Bereich der Augenbraue angelegt werden, um einen besonders sicheren und reproduzierbaren Austrag zu ermöglichen.In the first case, the protective sleeve is closer to the dispensing opening in the release position than in the protective position. This makes it possible to use an upper edge of the protective sleeve as a contact surface that is placed in the area of the skin where liquid is to be applied. In the case of eye drops, for example, the contact surface can be placed in the area of the eyebrow to enable particularly safe and reproducible dispensing.

Von Vorteil ist es hierfür, dass die Anlagefläche der Schutzhülse in der Freigabestellung derart angeordnet ist, dass sie bezogen auf die Hauptachse maximal 15 mm von der Austragöffnung entfernt positioniert ist und dabei insbesondere vorzugsweise über die Austragöffnung hinausragt.It is advantageous for this purpose that the contact surface of the protective sleeve is arranged in the release position such that it is positioned a maximum of 15 mm away from the discharge opening in relation to the main axis and in particular preferably protrudes beyond the discharge opening.

Eine solche Gestaltung ist insbesondere bei einer Führung der Schutzhülse auf einem innenliegenden Führungsring sinnvoll. Vorzugsweise sind Haltemittel vorgesehen, insbesondere in Form von Anschlägen am Führungsring und an der Schutzhülse, um ein Abziehen der Schutzhülse vom Führungsring zu unterbinden.Such a design is particularly useful when the protective sleeve is guided on an internal guide ring. Preferably, holding means are provided, in particular in the form of stops on the guide ring and on the protective sleeve, in order to prevent the protective sleeve from being pulled off the guide ring.

Eine andere Gestaltung, bei der die Schutzhülse in der Freigabestellung von der Austragöffnung weg verlagert ist, ist vorzugsweise mittels der beschriebenen Führungshülse realisiert. Diese ist in der Lage, die von der Austragöffnung weg verlagerte Schutzhülse sicher zu halten. Die durch die Verlagerung der Schutzhülse bewirkte Verlängerung des Spenders als Ganzem kann bei der Handhabung einen erheblichen Vorteil bieten.Another design, in which the protective sleeve is displaced away from the discharge opening in the release position, is preferably implemented using the guide sleeve described. This is able to securely hold the protective sleeve displaced away from the discharge opening. The extension of the dispenser as a whole caused by the displacement of the protective sleeve can offer a considerable advantage in handling.

Auch bei einer solchen Gestaltung sind vorzugweise Haltemittel vorgesehen, durch die ein Abziehen der Schutzhülse entgegen der Richtung der Austragöffnung unterbunden ist. Insbesondere kann es sich um Anschläge an der Schutzhülse und der Führungshülse handeln. Eine besonders vorteilhafte Gestaltung sieht vor, dass der Anschlag auf Seiten der Führungshülse durch eine die Betätigungs-Aussparung begrenzende Kante gebildet wird.Even with such a design, holding means are preferably provided which prevent the protective sleeve from being pulled off in the opposite direction to the discharge opening. In particular, these can be stops on the protective sleeve and the guide sleeve. A particularly advantageous design provides that the stop on the side of the guide sleeve is formed by an edge which delimits the actuation recess.

Um im Falle einer Gestaltung mit Führungshülse die innerhalb der Führungshülse angeordnete Schutzhülse, in die Freigabestellung verlagern zu können, muss der Nutzer in der Lage sein, die Schutzhülse zu ergreifen. Dies kann durch die Aussprung hindurch erfolgen. Um die Handhabung demgegenüber zu erleichtert, kann jedoch auch vorgesehen sein, dass die Schutzhülse einen distalen Endabschnitt aufweist, der auch in der Schutzstellung der Schutzhülse am unteren Ende über die Führungshülse hinausragt. Die zusätzliche Länge der Schutzhülse kann bei Gestaltung der Schutzhülse mit geschlossenem Boden genutzt werden, um innerhalb des so definierten Aufnahmeraums elektronische Spenderkomponenten wie bspw. ein Zählwerk anzuordnen.In the case of a design with a guide sleeve, in order to be able to move the protective sleeve arranged inside the guide sleeve into the release position, the user must be able to grasp the protective sleeve. This can be done through the recess. However, to make handling easier, the protective sleeve can also have a distal end section that protrudes beyond the guide sleeve at the lower end even when the protective sleeve is in the protective position. The additional length of the protective sleeve can be used when the protective sleeve is designed with a closed base to arrange electronic dispenser components such as a counter within the receiving space defined in this way.

Die Schutzhülse überdeckt zumindest phasenweise den Flüssigkeitsspeicher. Um eine mögliche Beschriftung auf dem Flüssigkeitsspeicher dennoch lesbarzu machen, kann die Schutzhülse aus einem transparenten Kunststoff gefertigt sein. Eine Bedruckung auf der Außenseite des Flüssigkeitsspeichers oder auf einem an der Außenseite befestigten Etikett kann somit durch die Schutzhülse hindurch gelesen werden. Ist eine Führungshülse vorgesehen, so kann auch diese aus transparentem Kunststoff hergestellt sein.The protective sleeve covers the liquid reservoir at least in phases. In order to make any labelling on the liquid reservoir legible, the protective sleeve can be made of transparent plastic. Printing on the outside of the liquid reservoir or on a label attached to the outside can thus be read through the protective sleeve. If a guide sleeve is provided, this can also be made of transparent plastic.

Auch ist es möglich, die Schutzhülse oder gegebenenfalls auch die Führungshülse zu verwenden, um hierauf eine Bedruckung, gegebenenfalls in Form eines bedruckten Etiketts, vorzusehen.It is also possible to use the protective sleeve or, if applicable, the guide sleeve to provide printing thereon, if necessary in the form of a printed label.

Weiterhin ist es auch möglich, auf der Schutzhülse oder der Führungshülse einerseits sowie auch auf dem Flüssigkeitsspeicher eine Bedruckung vorzusehen. Dies kann beispielsweise genutzt werden, um auf dem erst in der Freigabestellung erfassbaren Flüssigkeitsspeicher Handlungsanweisungen oder dergleichen anzubringen, die in der Schutzstellung der Schutzhülse noch nicht benötigt werden.It is also possible to provide printing on the protective sleeve or the guide sleeve on the one hand and on the liquid reservoir on the other. This can be used, for example, to attach instructions or similar to the liquid reservoir, which can only be detected in the release position and which are not yet required when the protective sleeve is in the protective position.