EP4101774A1 - Sealing device and method for sealing packagings - Google Patents

Sealing device and method for sealing packagings Download PDFInfo

- Publication number

- EP4101774A1 EP4101774A1 EP21179145.4A EP21179145A EP4101774A1 EP 4101774 A1 EP4101774 A1 EP 4101774A1 EP 21179145 A EP21179145 A EP 21179145A EP 4101774 A1 EP4101774 A1 EP 4101774A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- web

- sealing

- moistening

- cover film

- operating state

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000007789 sealing Methods 0.000 title claims abstract description 89

- 238000004806 packaging method and process Methods 0.000 title claims abstract description 31

- 238000000034 method Methods 0.000 title claims abstract description 17

- 239000013039 cover film Substances 0.000 claims abstract description 73

- 239000007921 spray Substances 0.000 claims abstract description 71

- 239000010408 film Substances 0.000 claims abstract description 49

- 239000007788 liquid Substances 0.000 claims abstract description 36

- 238000003825 pressing Methods 0.000 claims abstract description 21

- 238000005507 spraying Methods 0.000 claims abstract description 16

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 30

- 239000011888 foil Substances 0.000 claims description 9

- 238000009736 wetting Methods 0.000 claims description 8

- 239000003599 detergent Substances 0.000 description 7

- 238000013461 design Methods 0.000 description 4

- 238000012545 processing Methods 0.000 description 4

- 238000011161 development Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 239000004372 Polyvinyl alcohol Substances 0.000 description 2

- 238000004851 dishwashing Methods 0.000 description 2

- 238000010030 laminating Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 229920002451 polyvinyl alcohol Polymers 0.000 description 2

- 235000019422 polyvinyl alcohol Nutrition 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000001427 coherent effect Effects 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 230000002950 deficient Effects 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 238000011017 operating method Methods 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 239000004094 surface-active agent Substances 0.000 description 1

- 239000008399 tap water Substances 0.000 description 1

- 235000020679 tap water Nutrition 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

- 238000009463 water soluble packaging Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B11/00—Wrapping, e.g. partially or wholly enclosing, articles or quantities of material, in strips, sheets or blanks, of flexible material

- B65B11/50—Enclosing articles, or quantities of material, by disposing contents between two sheets, e.g. pocketed sheets, and securing their opposed free margins

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B7/00—Closing containers or receptacles after filling

- B65B7/16—Closing semi-rigid or rigid containers or receptacles not deformed by, or not taking-up shape of, contents, e.g. boxes or cartons

- B65B7/162—Closing semi-rigid or rigid containers or receptacles not deformed by, or not taking-up shape of, contents, e.g. boxes or cartons by feeding web material to securing means

- B65B7/164—Securing by heat-sealing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B51/00—Devices for, or methods of, sealing or securing package folds or closures; Devices for gathering or twisting wrappers, or necks of bags

- B65B51/10—Applying or generating heat or pressure or combinations thereof

- B65B51/16—Applying or generating heat or pressure or combinations thereof by rotary members

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B47/00—Apparatus or devices for forming pockets or receptacles in or from sheets, blanks, or webs, comprising essentially a die into which the material is pressed or a folding die through which the material is moved

- B65B47/04—Apparatus or devices for forming pockets or receptacles in or from sheets, blanks, or webs, comprising essentially a die into which the material is pressed or a folding die through which the material is moved by application of mechanical pressure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B51/00—Devices for, or methods of, sealing or securing package folds or closures; Devices for gathering or twisting wrappers, or necks of bags

- B65B51/02—Applying adhesives or sealing liquids

- B65B51/023—Applying adhesives or sealing liquids using applicator nozzles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B51/00—Devices for, or methods of, sealing or securing package folds or closures; Devices for gathering or twisting wrappers, or necks of bags

- B65B51/02—Applying adhesives or sealing liquids

- B65B51/026—Applying adhesives or sealing liquids using rotating applicators

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B51/00—Devices for, or methods of, sealing or securing package folds or closures; Devices for gathering or twisting wrappers, or necks of bags

- B65B51/10—Applying or generating heat or pressure or combinations thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B7/00—Closing containers or receptacles after filling

- B65B7/02—Closing containers or receptacles deformed by, or taking-up shape, of, contents, e.g. bags, sacks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B9/00—Enclosing successive articles, or quantities of material, e.g. liquids or semiliquids, in flat, folded, or tubular webs of flexible sheet material; Subdividing filled flexible tubes to form packages

- B65B9/02—Enclosing successive articles, or quantities of material between opposed webs

- B65B9/04—Enclosing successive articles, or quantities of material between opposed webs one or both webs being formed with pockets for the reception of the articles, or of the quantities of material

- B65B9/042—Enclosing successive articles, or quantities of material between opposed webs one or both webs being formed with pockets for the reception of the articles, or of the quantities of material for fluent material

Definitions

- the invention relates to a sealing device for sealing packages according to the preamble of claim 1 and a method for operating such a sealing device.

- Detergents and dishwashing detergents for domestic use are increasingly being packaged in the form of powders or liquids in water-soluble packaging.

- the packaging consists of water-soluble film and contains a unit dose of the detergent or dishwashing liquid.

- the filled and sealed packaging unit is placed in the washing machine or dishwasher. On contact with water, the foil packaging dissolves and releases the contents in the intended amount.

- a base film web and a cover film web are used, which are formed from water-soluble films.

- the base film is deep-drawn into appropriate matrices under the action of heat and vacuum.

- the molding process creates cavities in the base film that are filled with the product.

- a cover film is then sealed onto the base film. The contents in the molds are enclosed by the sealing of both foils.

- the sealed packaging units are separated from the coherent film webs so that they can be used individually by the user.

- water sealing can also be considered for sealing such packaging.

- dampening units with a felt roller are used, by means of which water is applied to the cover film.

- the moistened felt roll rolls on the water-soluble foil web, causing its surface to be dissolved.

- the cover film with the partially dissolved surface is then pressed onto the prepared base film by means of a pressure roller, the dissolving of the film surface causing a seal.

- Arrangement and method of this type are, for example, from GB 2 475 538 A known. Because of the cylindrical shape of the drum, filling and sealing must occur in quick succession and in close proximity to the top of the drum so that the product remains in the deep-drawn cavity and does not leak out. This limits the capacity of such a machine type.

- flatbed machines are used in which format plates with molded matrices are moved around in a manner comparable to a conveyor belt and perform a horizontal movement during the process steps relevant to deep-drawing, filling and sealing.

- larger output quantities per unit of time are possible because one or more format plates, each with several matrices, can run through a process step at the same time.

- the latter requires that the individual process stations along the horizontal movement path are locally relatively far apart from one another.

- the EP 3 323 740 B1 a device and a method in which an electromechanical spraying system with a row of outlet nozzles for contactless spraying of a water-containing liquid onto the web of cover foil is used in a manner comparable to an inkjet printer.

- the electromechanical spray system moistens the web of cover film on the circumference of the pressure roller, i.e. just before the sealing point. Nevertheless, a certain film section remains between the moistening point and the sealing point, which can dry out in the event of a machine standstill and can lead to the consequences described above when the machine is restarted.

- the invention is based on the object of further developing the generic sealing device in such a way that improved restart behavior is achieved.

- the invention is also based on the object of specifying a method for operating such a sealing device, which avoids the formation of defective packaging when restarting after a machine standstill.

- the moistening unit has a moistening roller and a spray device for the water-containing liquid, the moistening unit being switchable between a first operating state and a second operating state.

- the moistening roller acts on the web of cover film at a roller moistening point.

- the spraying device acts in the feed area on a spraying section of the web of cover film located between the roller moistening point and the sealing point.

- the cover film web in the first operating state, is wetted with the water-containing liquid by means of the moistening roller in the feed area at the roller moistening point, guided to the base film running horizontally on the flatbed machine and vertically pressed and sealed with it at the sealing point by means of the pressing device.

- the sealing device is switched to a second operating state.

- the spray section of the web of cover film lying in the feed area between the roller moistening point and the sealing point is wetted with the water-containing liquid by means of the spray device.

- the sealing device is then switched back to the first operating state and wetting by means of the moistening roller is resumed.

- the cover film web is guided with its wetted spray section to the base film running horizontally on the flatbed machine and is pressed and sealed vertically with this at the sealing point by means of the pressing device along the spray section.

- the basic idea is therefore to use the well-established dampening roller, which is known and proven from drum machines, in a flatbed machine in normal operation and to accept the comparatively large distance between the roller dampening point and the sealing point. This ensures reliable and uniform moistening of the upper web of cover foil in normal operation using simple means.

- the problems described above with temporary machine downtime and the subsequent restart of the machine are solved by using the spray device.

- the spray device When starting up again and shortly before the transition to normal operation, the dried film area is at least approximately completely moistened again and thus brought into a state capable of being sealed. This renewed moistening takes place in the feed area, in which the web of cover film is fed from top to bottom to the pressing device.

- the spray section extends at least approximately from the roller moistening point to the sealing point. This ensures that the partially dried film section is completely wetted again with moisture and consequently can be properly sealed on completely without gaps in the moistening and thus gaps in the sealing quality occurring.

- the spray device has a spray nozzle for dispensing the water-containing liquid in a jet fan and is designed to cover the entire spray section by means of the jet fan.

- the width of the spray fan ensures that the entire spray section is remoistened in just one single operation. The shortness of the time required for this contributes to the homogeneity of the moisture condition reached, to a rapid resumption of normal operation and to a seamless transition from the remoistened film section to the usually moistened cover film web.

- the spray device comprises a single spray nozzle mounted on a carriage, which can be moved transversely to the web of cover film by means of the carriage is. In connection with an even water supply, an even wetting can be achieved with minimal effort.

- a nozzle with intermittent piezo-delivery can be provided in order to generate a pulsating spray pattern.

- the spray nozzle can preferably be acted upon by a pressure source with the water-containing liquid and is designed for the continuous delivery of the water-containing liquid. In this way, a homogeneous water film can be generated with commercially available and inexpensive assemblies.

- the feed area is designed so that, in the second operating state, the cover film web is fed at least along the larger part of the spray section at an angle of 70° to 110° and in particular at an angle of 80° to 100° to the horizontal, i.e. at least approximately vertically to lead.

- the plane of the web of cover film in its spraying section is therefore at least approximately orthogonal to the plane of the horizontally guided web of base film.

- the spray direction is on the one hand approximately perpendicular to the spray section, which ensures effective wetting, and on the other hand approximately parallel to the base film, as a result of which it experiences practically no unintentional wetting.

- the pressing device is positioned at the sealing point in the first operating state and is remote therefrom in the second operating state.

- the sealing device has a stretching device which, in the second operating state, acts on the covering film web in the spraying section. After the pressing device has been removed, it is possible by means of the stretching device to bring the covering film web completely into the upright position, starting from the sealing point, and to keep it stretched there in a flat state. This enables an exact Remoistening right up to the sealing point without affecting the lower base film web. The sealing process can then be continued seamlessly.

- the moistening roller is preferably lifted off the web of cover film. This contributes to the fact that the remoistening can be carried out directly up to the roller dampening point, without the dampening roller being in the way. After reapplying the moistening roller, a seamless, continuous moistened film surface is created.

- FIG. 1 shows a side view of a section of a flatbed packaging machine for producing packaging units from a deep-drawn base film web 1 and a cover film web 2 sealed onto the base film web 1.

- At least the cover film web 2, here also the base film web 1 consist of a water-soluble film, for which PVOH (polyvinyl alcohol) is preferably selected.

- the packaging units are filled with detergent, detergent or the like.

- the packaging machine has several processing stations, but is in 1 for the sake of simplicity, only excerpts are shown in the area of their sealing station with the sealing device according to the invention. This is preceded by a deep-drawing station (not shown) and a filling station. The sealing device shown is followed by a separating station and a removal station.

- a cover film web 2 is then applied to the base film web prepared in this way in the sealing station shown here using the sealing device according to the invention and sealed, resulting in a multi-layer web with individually filled, tightly sealed film cavities. These are cut out as packaging units in the separating station already mentioned at the outset and finally removed from the format plates 18 in the removal station for further use.

- the sealing device has a moistening unit 4 for wetting the web of cover film 2 with the water-containing liquid 3 .

- the aqueous liquid here is water with added Surfactants provided. However, tap water can also be useful.

- the moistening unit 4 comprises a moistening roller 8 and a spray device 10, both of which are designed and provided for applying the water-containing liquid 3 to the web of cover film 2.

- the sealing device according to the invention also has a pressing device 5 which is designed and provided for the vertical pressing and sealing of the cover film web 2 moistened by means of the moistening unit 4 with the base film web 1 at a sealing point 6 .

- the pressing device 5 is designed in the embodiment shown as a laminating roller, which rests at the sealing point 6 in a line on the format plates with the interposition of the package of base and cover film web 1, 2 with vertical pressure.

- pressure stamps or the like can also be used.

- the cover film web 2 which has been moistened beforehand and thus partially dissolved on its surface, is sealed onto the base film web 1 in a cohesive manner.

- the sealing device has a feed area 7 in which the cover film web 2 is fed from top to bottom to the pressing device 5, i.e. essentially transversely to the conveying direction 17 of the format plates 18 with the base film web 1.

- the moistening unit 4 acts on the web of cover film 2 in this feed area 7 .

- the web of cover film 2 is moistened in the feed area 7, ie where the web of cover film 2 is moved from top to bottom.

- a stretching device 16 holds the cover film web 2 in position within the feed area 7 and in the stretched state under longitudinal tension.

- the sealing device 10 in a first operating state, in which a normal, continuous sealing process is carried out.

- the spray device 10 is passive. Rather, the moistening is carried out solely by means of the moistening roller 8 , which is designed here as a felt roller and rests on the surface of the web of cover film 2 in the feed area 7 at a roller moistening point 9 .

- the roller dampening point 9 can be in the form of a line.

- the web of cover film 2 lies above a small angle of wrap on the moistening roller 8, so that the roller moistening point 9 has the shape of a narrow but flat strip.

- the dampening roller 8 partially protrudes from above into a water bowl 19 filled with the liquid 3 .

- the moistening roller 8 may simply roll on the surface of the web of cover film 2 without its own drive.

- the moistening roller 8 preferably has its own drive, by means of which it rotates in the opposite direction to the direction in which the web of cover film 2 is pulled off.

- the web of cover film 2 moistened in this way is then continuously withdrawn in normal operation, fed to the pressing device 5 and sealed on as described above.

- Such interruptions in which there is no continuous movement and further processing, lead to undesired drying of the cover film webs 2, which have already been moistened but not yet sealed and are at a standstill, in the area between the roller moistening point 9 and the sealing point 6.

- the sealing device is switched to a second operating state, which 2 is shown.

- the changeover can take place while the machine is at a standstill or immediately afterwards when the packaging machine is restarted.

- the sealing device is thus placed in a state in which the moistening roller is initially passive when the machine is started up again, and in which the already mentioned spraying device is used instead.

- the spray device 10 acts in the supply area 7 on a between the roller moistening point 9 and the sealing point 6 lying spray section 11 of the cover sheet web 2 a.

- the spray section 11 of the web of cover film 2 in the feed area 7 between the roller moistening point 9 and the sealing point 6, which was previously wetted and has now dried on, is wetted again with the water-containing liquid 3 by means of the spraying device 10.

- “Hold in position” means here that in the second operating state the web of cover film 2 is guided at least along the larger part of the spray section 11 at an angle a of 70° to 110° and preferably of 80° to 100° to the horizontal.

- the stretching device 16 is towards the operating position 1 move to the right until it is positioned exactly above the sealing point 6 and thereby guides and holds the web of cover film 2 in the feed area 7, specifically in the spray section 11, at an angle (a) of approximately 90° to the horizontal.

- the repositioning of the pressing device 5 and the stretching device 16 also causes a repositioning of the cover film web 2 in the feed area 7 to the right, i.e.

- the dampening roller is still in the second operating state 2 compared to the first, normal operating state 1 including their water bowl 19 raised to the extent that the section of Cover sheet web 2 is exposed between the previous roller moistening point 9 and the sealing point 6 in the horizontal direction towards the spray device 10 .

- the spray section 11 The area of the web of cover film 2 reached by the spray device 10 between the roller moistening point 9 and the sealing point 6 is referred to here as the spray section 11 .

- the spray device 10 has a spray nozzle 13 for dispensing the water-containing liquid 3 in a jet fan 12 .

- the opening angle of the jet fan 12 and the distance between the spray nozzle 13 and the web of cover film 2 are matched to one another such that the spray section 11 is completely covered by the jet fan 12 in relation to the longitudinal direction of the second film web 2 .

- spray nozzles can be arranged side by side. This would open up the possibility of moistening the spray section 11 along the entire width of the web of cover film 2 by means of overlapping, conical jet fans 12 with a single spray blast.

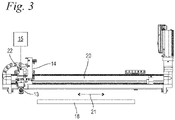

- a single spray nozzle 13 is provided, which is shown in the end view according to FIG 3 shown in additional detail. Accordingly, the spray nozzle 13 is mounted together with an associated control unit 22 on a carriage 14 and by means of this carriage 14 on a guide rail 20 according to a double arrow 21 transverse to In the longitudinal direction of the web of cover film 2, it can be moved.

- the control unit 22 includes a needle valve, not shown, and is responsible for setting and maintaining a specific flow rate of the water-containing liquid 3 through the spray nozzle 13 .

- a pressure source 15 is also provided for the water-containing liquid 3 , from which the spray nozzle 13 is acted upon and fed with the water-containing liquid 3 through the control unit 22 .

- the pressure source 15 can be a pump and in the present case is a pressure tank. However, other suitable pressure sources 15 can also be selected.

- the assembly of the liquid pump 15 and spray nozzle 13 is designed, in particular with the cooperation of the control unit 22, for a continuous delivery of liquid and thus for the continuous generation of the jet fan 12 as an upright flat jet. The jet fan 12 is thus moved continuously and in a continuous movement along the entire width of the web of cover film 2, with the result that the spray section 11 is wetted with the water-containing liquid 3 over the entire width.

- the sealing device returns to its first operating state 1 offset, the spray device 10 taken out of operation, and the wetting of the web of cover film 2 by means of the moistening roller 8 resumed.

- the cover film web 2 with its wetted spray section 11 must be guided to the base film 1 running horizontally on the flatbed machine and pressed vertically with it at the sealing point 6 by means of the pressing device 5 along the spray section 11 in the manner described above and sealed .

- the spray section 11 is completely sealed and the web of cover film 2 moistened in the usual way by means of the moistening roller 8 reaches the sealing point 6, normal sealing operation resumes and the restarting of the packaging machine can be regarded as complete.

- the packaging units sealed by means of the spray section 8 during the restart are tight. Depending on the requirement profile, they can be used as a regular product or sorted out. In any case, the tightness achieved is sufficient for proper operation of the packaging machine.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Containers And Plastic Fillers For Packaging (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

- Supplying Of Containers To The Packaging Station (AREA)

Abstract

Die Erfindung betrifft eine Vorrichtung und ein Verfahren zum Versiegeln von Verpackungen auf einer Flachbettmaschine, wobei die Verpackung aus einer Basisfolienbahn (1) und einer wasserlöslichen Deckfolienbahn (2) gebildet ist. Die Versiegelungsvorrichtung umfasst eine Flüssigkeitszufuhr für eine wasserhaltige Flüssigkeit (3), mindestens eine Befeuchtungseinheit (4) und eine Andrückeinrichtung (5) zur vertikalen Verpressung und Versiegelung der Deckfolienbahn (2) mit der Basisfolienbahn (1). Die Befeuchtungseinheit (4) weist eine Befeuchtungswalze (8) und eine Sprüheinrichtung (10) für die wasserhaltige Flüssigkeit (3) auf, wobei die Befeuchtungseinheit (4) zwischen einem ersten Betriebszustand und einem zweiten Betriebszustand umschaltbar ist. Im ersten Betriebszustand wirkt die Befeuchtungswalze (8) an einer Walzenbefeuchtungsstelle (9) auf die Deckfolienbahn (2) ein. Bei oder nach einem Maschinenstillstand wird die Versiegelungsvorrichtung in einen zweiten Betriebszustand versetzt, wobei die Sprüheinrichtung (10) im Zufuhrbereich (7) auf einen zwischen der Walzenbefeuchtungsstelle (9) und der Versiegelungsstelle (6) liegenden Sprühabschnitt (11) der Deckfolienbahn (2) einwirkt.The invention relates to a device and a method for sealing packaging on a flatbed machine, the packaging being formed from a base film web (1) and a water-soluble cover film web (2). The sealing device comprises a liquid supply for an aqueous liquid (3), at least one moistening unit (4) and a pressing device (5) for vertically pressing and sealing the web of cover film (2) to the web of base film (1). The moistening unit (4) has a moistening roller (8) and a spray device (10) for the aqueous liquid (3), the moistening unit (4) being switchable between a first operating state and a second operating state. In the first operating state, the moistening roller (8) acts on the web of cover film (2) at a roller moistening point (9). During or after a machine standstill, the sealing device is switched to a second operating state, with the spraying device (10) in the feed area (7) acting on a spraying section (11) of the web of cover film (2) located between the roller moistening point (9) and the sealing point (6). .

Description

Die Erfindung betrifft eine Versiegelungsvorrichtung zum Versiegeln von Verpackungen nach dem Oberbegriff des Anspruchs 1 sowie ein Verfahren zum Betrieb einer solchen Versiegelungsvorrichtung.The invention relates to a sealing device for sealing packages according to the preamble of

Zunehmend werden Wasch- oder Spülmittel für den häuslichen Gebrauch in Form von Pulvern oder Flüssigkeiten in wasserlöslichen Verpackungen abgepackt. Die Verpackungen bestehen aus wasserlöslicher Folie und enthalten eine Einheitsdosis des Wasch- bzw. Spülmittels als Füllgut. Die befüllte und versiegelte Verpackungseinheit wird in die Wasch- bzw. Spülmaschine eingelegt. Bei Kontakt mit Wasser löst sich die Folienverpackung auf und gibt den Inhalt in der vorgesehenen Menge frei.Detergents and dishwashing detergents for domestic use are increasingly being packaged in the form of powders or liquids in water-soluble packaging. The packaging consists of water-soluble film and contains a unit dose of the detergent or dishwashing liquid. The filled and sealed packaging unit is placed in the washing machine or dishwasher. On contact with water, the foil packaging dissolves and releases the contents in the intended amount.

Bei der Herstellung einer solchen Verpackungseinheit kommen eine Basisfolienbahn und eine Deckfolienbahn zum Einsatz, die aus wasserlöslichen Folien gebildet sind. Üblicherweise wird die Basisfolie unter Einwirkung von Wärme und Vakuum in entsprechende Matrizen tiefgezogen. Durch den Formvorgang entstehen Mulden in der Basisfolie, die mit dem Füllgut befüllt werden. Anschließend wird auf die Basisfolie eine Deckfolie aufgesiegelt. Mittels der Versiegelung beider Folien wird das in den Formen befindliche Füllgut eingeschlossen. Abschließend werden die versiegelten Verpackungseinheiten aus den zusammenhängenden Folienbahnen ausgetrennt, so dass sie seitens des Benutzers einzeln verwendbar sind.In the production of such a packaging unit, a base film web and a cover film web are used, which are formed from water-soluble films. Usually, the base film is deep-drawn into appropriate matrices under the action of heat and vacuum. The molding process creates cavities in the base film that are filled with the product. A cover film is then sealed onto the base film. The contents in the molds are enclosed by the sealing of both foils. Finally, the sealed packaging units are separated from the coherent film webs so that they can be used individually by the user.

Zur Versiegelung derartiger Verpackungen kommt neben dem an sich für Folien bekannten Heißsiegelverfahren auch eine Wassersiegelung in Betracht. Auf Trommelmaschinen, bei denen die Matrizen auf umlaufenden Trommeln angeordnet sind, werden Befeuchtungseinheiten mit einer Filzrolle eingesetzt, mittels derer Wasser auf die Deckfolie aufgetragen wird. Die befeuchtete Filzrolle rollt auf der wasserlöslichen Folienbahn ab, wodurch deren Oberfläche angelöst wird. Die Deckfolie mit angelöster Oberfläche wird dann mittels einer Andrückwalze auf die vorbereitete Basisfolie aufgepresst, wobei die Anlösung der Folienoberfläche eine Versiegelung bewirkt. Anordnung und Verfahren dieser Art sind beispielsweise aus der

Alternativ zu den genannten Trommelmaschinen werden Flachbettmaschinen eingesetzt, bei denen Formatplatten mit eingeformten Matrizen vergleichbar zu einem Förderband umlaufend bewegt werden und dabei währen der für das Tiefziehen, Füllen und Versiegeln relevanten Prozessschritte eine horizontale Bewegung ausführen. Hiermit sind im Vergleich zu Trommelmaschinen größere Ausbringungsmengen pro Zeiteinheit möglich, da eine oder mehrere Formatplatten mit jeweils mehreren Matrizen gleichzeitig einen Prozessschritt durchlaufen können. Letzteres bedingt aber, dass die einzelnen Prozessstationen entlang der horizontalen Bewegungsbahn örtlich vergleichsweise weit voneinander entfernt sind.As an alternative to the drum machines mentioned, flatbed machines are used in which format plates with molded matrices are moved around in a manner comparable to a conveyor belt and perform a horizontal movement during the process steps relevant to deep-drawing, filling and sealing. Compared to drum machines, larger output quantities per unit of time are possible because one or more format plates, each with several matrices, can run through a process step at the same time. However, the latter requires that the individual process stations along the horizontal movement path are locally relatively far apart from one another.

Im Falle einer Produktionsunterbrechung, also eines temporären Maschinenstillstandes macht sich diese Entfernung nachteilig bemerkbar. Zwischen der Befeuchtungseinrichtung und der Versiegelungsstelle befindet sich ein vergleichsweise langer Abschnitt der befeuchteten Deckfolienbahn, welcher noch nicht aufgesiegelt ist und beim Stillstand anfängt zu trocknen. Beim Wiederanfahren nach dem Maschinenstillstand hat dieser Folienabschnitt nicht mehr den gewünschten Feuchtigkeitsgrad und kann nicht mehr ohne weiteres in der erforderlichen Qualität aufgesiegelt werden. Es entstehen nicht ordnungsgemäß verschlossene Produkte, aus denen das Füllmaterial austritt und die Verpackungsmaschine verschmutzt, was zu neuerlichem Maschinenstillstand führen kann. Außerdem können die nicht ordnungsgemäß verschlossenen Produkte im Maschinenauslauf nicht ordnungsgemäß ausgetragen werden.In the event of a production interruption, i.e. a temporary machine standstill, this distance has a negative impact. There is a comparatively long section of the moistened cover film web between the moistening device and the sealing point, which is not yet sealed and when standstill begins to dry. When restarting after the machine has stopped, this film section no longer has the desired degree of moisture and can no longer be easily sealed with the required quality. Improperly sealed products are created, from which the filling material escapes and contaminates the packaging machine, which can lead to renewed machine downtime. In addition, the improperly sealed products in the machine outlet cannot be properly discharged.

Eine Wiederbefeuchtung des kritischen, angetrockneten Folienabschnittes ist mit der Befeuchtungswalze nicht möglich. Als Alternative dazu beschreibt die

Der Erfindung liegt die Aufgabe zugrunde, die gattungsgemäße Versiegelungsvorrichtung derart weiterzubilden, dass ein verbessertes Wiederanfahrverhalten erzielt ist.The invention is based on the object of further developing the generic sealing device in such a way that improved restart behavior is achieved.

Diese Aufgabe wird durch eine Versiegelungsvorrichtung mit den Merkmalen des Anspruchs 1 gelöst.This object is achieved by a sealing device having the features of

Der Erfindung liegt des Weiteren die Aufgabe zugrunde, ein Verfahren zum Betrieb einer solchen Versiegelungsvorrichtung anzugeben, welches die Bildung schadhafter Verpackungen beim Wiederanfahren nach einem Maschinenstillstand vermeidet.The invention is also based on the object of specifying a method for operating such a sealing device, which avoids the formation of defective packaging when restarting after a machine standstill.

Diese Aufgabe wird durch ein Verfahren mit den Merkmalen des Anspruchs 9 gelöst.This object is achieved by a method having the features of

Nach der Erfindung ist vorgesehen, dass die Befeuchtungseinheit eine Befeuchtungswalze und eine Sprüheinrichtung für die wasserhaltige Flüssigkeit aufweist, wobei die Befeuchtungseinheit zwischen einem ersten Betriebszustand und einem zweiten Betriebszustand umschaltbar ist. Im ersten Betriebszustand wirkt die Befeuchtungswalze an einer Walzenbefeuchtungsstelle auf die Deckfolienbahn ein. Im zweiten Betriebszustand wirkt die Sprüheinrichtung im Zufuhrbereich auf einen zwischen der Walzenbefeuchtungsstelle und der Versiegelungsstelle liegenden Sprühabschnitt der Deckfolienbahn ein.According to the invention, it is provided that the moistening unit has a moistening roller and a spray device for the water-containing liquid, the moistening unit being switchable between a first operating state and a second operating state. In the first operating state, the moistening roller acts on the web of cover film at a roller moistening point. In the second operating state, the spraying device acts in the feed area on a spraying section of the web of cover film located between the roller moistening point and the sealing point.

Gemäß dem zugehörigen erfindungsgemäßen Verfahren wird im ersten Betriebszustand die Deckfolienbahn mittels der Befeuchtungswalze im Zufuhrbereich an der Walzenbefeuchtungsstelle mit der wasserhaltigen Flüssigkeit benetzt, zu der auf der Flachbettmaschine horizontal laufenden Basisfolie geführt und mit dieser an der Versiegelungsstelle mittels der Andrückeinrichtung vertikal verpresst und versiegelt.According to the associated method according to the invention, in the first operating state, the cover film web is wetted with the water-containing liquid by means of the moistening roller in the feed area at the roller moistening point, guided to the base film running horizontally on the flatbed machine and vertically pressed and sealed with it at the sealing point by means of the pressing device.

Bei oder nach einem Maschinenstillstand wird die Versiegelungsvorrichtung in einen zweiten Betriebszustand versetzt. Beim Wiederanfahren wird im zweiten Betriebszustand der im Zufuhrbereich zwischen der Walzenbefeuchtungsstelle und der Versiegelungsstelle liegende Sprühabschnitt der Deckfolienbahn mittels der Sprüheinrichtung mit der wasserhaltigen Flüssigkeit benetzt. Anschließend wird die Versiegelungsvorrichtung zurück in den ersten Betriebszustand versetzt und die Benetzung mittels der Befeuchtungswalze wieder aufgenommen. Die Deckfolienbahn wird mit ihrem benetzten Sprühabschnitt zu der auf der Flachbettmaschine horizontal laufenden Basisfolie geführt und mit dieser an der Versiegelungsstelle mittels der Andrückeinrichtung entlang des Sprühabschnitts vertikal verpresst und versiegelt.During or after a machine downtime, the sealing device is switched to a second operating state. When restarting, in the second operating state, the spray section of the web of cover film lying in the feed area between the roller moistening point and the sealing point is wetted with the water-containing liquid by means of the spray device. The sealing device is then switched back to the first operating state and wetting by means of the moistening roller is resumed. The cover film web is guided with its wetted spray section to the base film running horizontally on the flatbed machine and is pressed and sealed vertically with this at the sealing point by means of the pressing device along the spray section.

Die Grundidee besteht demnach darin, im gewöhnlichen Betrieb die an sich von Trommelmaschinen bekannte und bewährte Befeuchtungswalze nun auch in einer Flachbettmaschine einzusetzen und dabei den vergleichsweise großen Abstand zwischen der Walzenbefeuchtungsstelle und der Versiegelungsstelle in Kauf zu nehmen. Hierdurch ist im gewöhnlichen Betrieb mit einfachen Mitteln eine zuverlässige und gleichmäßige Befeuchtung der oberen Deckfolienbahn sichergestellt. Die eingangs beschriebenen Probleme beim temporären Maschinenstillstand und bei dem darauf folgenden Wiederanfahren der Maschine werden durch den Einsatz der Sprüheinrichtung gelöst. Beim Wiederanfahren und kurz vor Überleitung in den gewöhnlichen Betrieb wird der angetrocknete Folienbereich zumindest näherungsweise vollständig erneut befeuchtet und damit in einen versieglungsfähigen Zustand gebracht. Diese erneute Befeuchtung erfolgt im Zufuhrbereich, in dem die Deckfolienbahn von oben nach unten der Andrückeinrichtung zugeführt wird. Hierdurch wird erreicht, dass nur die Deckfolie, nicht aber die tiefgezogene Basisfolienbahn mit dem bereits eingefüllten Produkt befeuchtet wird. Letzteres bleibt trocken und nimmt deshalb keinen Schaden. Der wiederbefeuchtete Bereich kann nun ordnungsgemäß aufgesiegelt werden, sodass dicht verschlossene Verpackungseinheiten entstehen. Ein Austritt der Füllung und eine Verschmutzung der Maschine sind zuverlässig vermieden. Die versiegelten Einheiten können sämtliche nachfolgende Verarbeitungsstationen ordnungsgemäß durchlaufen und als fertige, vereinzelte Verpackungseinheiten entnommen werden. Möglicherweise genügen diese mit der wiederbefeuchteten Deckfolienbahn versiegelten Verpackungseinheiten nicht den gestellten Qualitätsanforderungen, sodass sie als Schlechtteile auszusortieren sind. Zumindest aber behindern sie nicht den wiederaufgenommenen ordnungsgemäßen Betrieb, sodass letzterer störungsfrei stattfinden kann.The basic idea is therefore to use the well-established dampening roller, which is known and proven from drum machines, in a flatbed machine in normal operation and to accept the comparatively large distance between the roller dampening point and the sealing point. This ensures reliable and uniform moistening of the upper web of cover foil in normal operation using simple means. The problems described above with temporary machine downtime and the subsequent restart of the machine are solved by using the spray device. When starting up again and shortly before the transition to normal operation, the dried film area is at least approximately completely moistened again and thus brought into a state capable of being sealed. This renewed moistening takes place in the feed area, in which the web of cover film is fed from top to bottom to the pressing device. This ensures that only the cover film is moistened with the product that has already been filled in, but not the thermoformed base film web. The latter remains dry and is therefore not damaged. The remoistened area can now be properly sealed to form tightly sealed packaging units. Leakage of the filling and contamination of the machine are reliably avoided. The sealed units can pass through all subsequent processing stations properly and as finished, individual packaging units can be removed. It is possible that these packaging units sealed with the remoistened web of cover film do not meet the quality requirements, so that they have to be sorted out as bad parts. But at least they don't hinder the resumed proper operation, so that the latter can take place without problems.

Für eine störungsfreie Wiederaufnahme des Betriebes kann es unter Umständen ausreichen, nur einen Teilbereich des angetrockneten Folienabschnittes erneut zu befeuchten. In vorteilhafter Weiterbildung der Erfindung erstreckt sich jedoch der Sprühabschnitt zumindest näherungsweise von der Walzenbefeuchtungsstelle bis zur Versiegelungsstelle. Hierdurch wird erreicht, dass der angetrocknete Folienabschnitt vollständig wieder mit Feuchtigkeit benetzt und folglich vollständig ordnungsgemäß aufgesiegelt werden kann, ohne dass Lücken in der Befeuchtung und damit Lücken in der Siegelqualität entstehen.For a trouble-free resumption of operation, it may be sufficient under certain circumstances to moisten only a partial area of the dried film section again. In an advantageous development of the invention, however, the spray section extends at least approximately from the roller moistening point to the sealing point. This ensures that the partially dried film section is completely wetted again with moisture and consequently can be properly sealed on completely without gaps in the moistening and thus gaps in the sealing quality occurring.

In einer bevorzugten Ausführungsform weist die Sprüheinrichtung eine Sprühdüse zur Abgabe der wasserhaltigen Flüssigkeit in einem Strahlfächer auf und ist zur Abdeckung des vollständigen Sprühabschnittes mittels des Strahlfächers ausgelegt. Über die Breite des Sprühfächers wird erreicht, dass eine Wiederbefeuchtung des vollständigen Sprühabschnittes in nur einem einzigen Arbeitsgang abgeschlossen wird. Die Kürze der hierfür erforderlichen Zeit trägt zur Homogenität des erreichten Feuchtezustandes, zu einer schnellen Wiederaufnahme des gewöhnlichen Betriebes und zu einem nahtlosen Übergang des wiederbefeuchteten Folienabschnitts zur gewöhnlich befeuchteten Deckfolienbahn bei.In a preferred embodiment, the spray device has a spray nozzle for dispensing the water-containing liquid in a jet fan and is designed to cover the entire spray section by means of the jet fan. The width of the spray fan ensures that the entire spray section is remoistened in just one single operation. The shortness of the time required for this contributes to the homogeneity of the moisture condition reached, to a rapid resumption of normal operation and to a seamless transition from the remoistened film section to the usually moistened cover film web.

Es kann zweckmäßig sein, mehrere solcher Düsen nebeneinander in einer Reihe anzuordnen und damit die Breite der Deckfolienbahn abzudecken. In vorteilhafter Weiterbildung umfasst die Sprüheinrichtung jedoch eine auf einem Schlitten montierte einzelne Sprühdüse, welche mittels des Schlittens quer zur Deckfolienbahn verfahrbar ist. In Verbindung mit einer gleichmäßigen Wasserförderung lässt sich hierdurch mit minimalem Aufwand eine gleichmäßige Benetzung erzielen.It can be expedient to arrange several such nozzles next to one another in a row and thus to cover the width of the web of cover film. In an advantageous further development, however, the spray device comprises a single spray nozzle mounted on a carriage, which can be moved transversely to the web of cover film by means of the carriage is. In connection with an even water supply, an even wetting can be achieved with minimal effort.

Für die Ausgestaltung der Sprüheinrichtung kommen verschiedene Bauformen in Betracht. Beispielsweise kann eine Düse mit intermittierender Piezo-Förderung vorgesehen sein, um ein pulsierendes Sprühraster zu erzeugen. Bevorzugt ist jedoch die Sprühdüse von einer Druckquelle mit der wasserhaltigen Flüssigkeit beaufschlagbar und zur kontinuierlichen Abgabe der wasserhaltigen Flüssigkeit ausgelegt. Mit handelsüblichen und kostengünstigen Baugruppen lässt sich auf diese Weise ein homogener Wasserfilm erzeugen.Various designs can be considered for the design of the spray device. For example, a nozzle with intermittent piezo-delivery can be provided in order to generate a pulsating spray pattern. However, the spray nozzle can preferably be acted upon by a pressure source with the water-containing liquid and is designed for the continuous delivery of the water-containing liquid. In this way, a homogeneous water film can be generated with commercially available and inexpensive assemblies.

In einer bevorzugten Ausführungsform ist der Zufuhrbereich dazu ausgelegt, im zweiten Betriebszustand die Deckfolienbahn zumindest entlang des größeren Teils des Sprühabschnittes in einem Winkel von 70° bis 110° und insbesondere in einem Winkel von 80° bis 100° zur Horizontalen, also zumindest näherungsweise vertikal zu führen. Damit liegt die Ebene der Deckfolienbahn in ihrem Sprühabschnitt zumindest näherungsweise orthogonal zur Ebene der horizontal geführten Basisfolienbahn. In der Folge liegt die Sprührichtung einerseits etwa senkrecht zum Sprühabschnitt, was für eine wirkungsvolle Benetzung sorgt, und andererseits etwa parallel zur Basisfolie, wodurch diese praktisch keinerlei unbeabsichtigte Befeuchtung erfährt.In a preferred embodiment, the feed area is designed so that, in the second operating state, the cover film web is fed at least along the larger part of the spray section at an angle of 70° to 110° and in particular at an angle of 80° to 100° to the horizontal, i.e. at least approximately vertically to lead. The plane of the web of cover film in its spraying section is therefore at least approximately orthogonal to the plane of the horizontally guided web of base film. As a result, the spray direction is on the one hand approximately perpendicular to the spray section, which ensures effective wetting, and on the other hand approximately parallel to the base film, as a result of which it experiences practically no unintentional wetting.

In vorteilhafter Weiterbildung ist die Andrückeinrichtung im ersten Betriebszustand an der Versiegelungsstelle positioniert im zweiten Betriebszustand davon entfernt. Dabei weist die Versiegelungsvorrichtung eine im zweiten Betriebszustand auf die Deckfolienbahn im Sprühabschnitt einwirkende Streckvorrichtung auf. Nachdem die Andrückeinrichtung entfernt wurde, ist es mittels der Streckvorrichtung möglich, die Deckfolienbahn ausgehend von der Siegelstelle vollständig in die aufrechte Position zu bringen dort gestreckt in einem ebenen Zustand zu halten. Dies ermöglicht eine exakte Wiederbefeuchtung bis unmittelbar an die Siegelstelle heran, ohne die untere Basisfolienbahn zu beeinträchtigen. In der Folge kann der Siegelvorgang nahtlos fortgesetzt werden.In an advantageous further development, the pressing device is positioned at the sealing point in the first operating state and is remote therefrom in the second operating state. In this case, the sealing device has a stretching device which, in the second operating state, acts on the covering film web in the spraying section. After the pressing device has been removed, it is possible by means of the stretching device to bring the covering film web completely into the upright position, starting from the sealing point, and to keep it stretched there in a flat state. This enables an exact Remoistening right up to the sealing point without affecting the lower base film web. The sealing process can then be continued seamlessly.

Bevorzugt ist im zweiten Betriebszustand die Befeuchtungswalze von der Deckfolienbahn abgehoben. Dies trägt dazu bei, dass die Wiederbefeuchtung unmittelbar bis an die Walzenbefeuchtungsstelle heran durchgeführt werden kann, ohne dass die Befeuchtungswalze im Wege ist. Nach Wiederanlegen der Befeuchtungswalze entsteht eine nahtlos durchgehend befeuchtete Folienoberfläche.In the second operating state, the moistening roller is preferably lifted off the web of cover film. This contributes to the fact that the remoistening can be carried out directly up to the roller dampening point, without the dampening roller being in the way. After reapplying the moistening roller, a seamless, continuous moistened film surface is created.

Ein Ausführungsbeispiel der Erfindung ist nachfolgend anhand der Zeichnung näher beschrieben. Es zeigen:

- Fig. 1

- in einer seitlichen Ansicht eine erfindungsgemäße Versiegelungsvorrichtung beim gewöhnlichen Betrieb in einer Flachbett-Verpackungsmaschine mit einer Befeuchtungswalze zur Befeuchtung der aufzusiegelnden Deckfolienbahn,

- Fig. 2

- die Anordnung nach

Fig. 1 nach einem Maschinenstillstand und bei der Vorbereitung des Wiederanfahrens der Maschine mit einer Sprüheinrichtung zur erneuten Befeuchtung der Deckfolienbahn, und - Fig. 3

- in einer Stirnansicht die Sprüheinrichtung nach

Fig. 2 mit einer einzelnen, auf einem quer verfahrbaren Schlitten montierten Sprühdüse.

- 1

- in a side view, a sealing device according to the invention during normal operation in a flatbed packaging machine with a moistening roller for moistening the web of cover film to be sealed,

- 2

- according to the

arrangement 1 after a machine downtime and when preparing to restart the machine with a spray device for rewetting the web of cover foil, and - 3

- the spray device in a

front view 2 with a single spray nozzle mounted on a traversing carriage.

Die Verpackungsmaschine weist mehrere Verarbeitungsstationen auf, ist aber in

Mehrere Formatplatten 18 mit jeweils mehreren eingeformten, hier nicht dargestellten Matrizen werden nach Art eines Förderbandes geradlinig, horizontal und hier auch kontinuierlich durch die einzelnen Verarbeitungsstationen entsprechend einem Pfeil 17 gefördert und dann umlaufend zurückgeführt. Es kann aber auch ein intermittierender Betrieb zweckmäßig sein. In der Tiefziehstation wird die flach und horizontal auf den Formatplatten 18 aufliegende Basisfolienbahn 1 auf eine Temperatur der plastischen Verformbarkeit aufgeheizt und mittels Vakuum in die Matrizen der Formatplatten 18 tiefgezogen und dort gehalten. Dadurch entstehen in der Basisfolienbahn 1 tiefgezogene Mulden bzw. Kavitäten, die in der nachfolgenden Füllstation mit dem Füllmaterial, also mit dem Spül- oder Waschmittel befüllt werden. Auf die solchermaßen vorbereitete Basisfolienbahn wird anschließend in der hier gezeigten Siegelstation mittels der erfindungsgemäßen Versiegelungseinrichtung eine Deckfolienbahn 2 auf die Basisfolienbahn aufgebracht und aufgesiegelt, in dessen Folge eine mehrschichtige Bahn mit einzelnen befüllten, dicht verschlossenen Folienkavitäten entsteht. Diese werden in der eingangs schon erwähnten Vereinzelungsstation als Verpackungseinheiten ausgeschnitten und abschließend in der Entnahmestation aus den Formatplatten 18 zur weiteren Verwendung entnommen.

Gemäß

Die solchermaßen befeuchtete Deckfolienbahn 2 wird nun im gewöhnlichen Betrieb weiter kontinuierlich abgezogen, der Andrückeinrichtung 5 zugeführt und wie oben beschrieben aufgesiegelt. Es kann jedoch zu temporären Betriebsunterbrechungen bzw. Maschinenstillständen kommen, an deren Ende nach einem Wiederanfahren der Verpackungsmaschine die darin vorhandenen Materialien weiter und störungsfrei zu Verpackungseinheiten verarbeitet werden sollen. Solche Unterbrechungen, in denen die kontinuierliche Bewegung und Weiterverarbeitung ausbleibt, führen zu einem unerwünschten Antrocknen der schon befeuchteten, aber noch nicht aufgesiegelten und im Stillstand befindlichen Deckfolienbahnen 2 im Bereich zwischen der Walzenbefeuchtungsstelle 9 und der Versiegelungsstelle 6.The web of

Für die Wiederaufnahme des Betriebes und für eine erforderliche Wiederbefeuchtung des angetrockneten Folienabschnittes wird gemäß des erfindungsgemäßen Betriebsverfahrens die Versiegelungsvorrichtung in einen zweiten Betriebszustand umgeschaltet, welcher in

Aus der Zusammenschau der

In diesem Zustand erfolgt nun beim Wiederanfahren der Verpackungsmaschine die erneute Benetzung des zuvor angetrockneten Abschnittes der Deckfolienbahn 2 mit der wasserhaltigen Flüssigkeit 3, was mittels der Sprüheinrichtung 10 durchgeführt wird. Der von der Sprüheinrichtung 10 erreichte Bereich der Deckfolienbahn 2 zwischen der Walzenbefeuchtungsstelle 9 und der Versiegelungsstelle 6 wird hier als Sprühabschnitt 11 bezeichnet. Es kann unter Umständen ausreichen, einen Sprühabschnitt 11 zu benetzen, der nicht vollständig die Strecke zwischen der Walzenbefeuchtungsstelle 9 und der Versiegelungsstelle 6 abdeckt. Durch die vorstehend beschriebenen Maßnahmen und eine entsprechende Ausbildung der Sprüheinrichtung 10 erstreckt sich jedoch der Sprühabschnitt 11 gemäß der Darstellung nach

Hierzu weist die Sprüheinrichtung 10 eine Sprühdüse 13 zur Abgabe der wasserhaltigen Flüssigkeit 3 in einem Strahlfächer 12 auf. Der Öffnungswinkel des Strahlfächers 12 und der Abstand der Sprühdüse 13 zur Deckfolienbahn 2 sind so aufeinander abgestimmt, dass der Sprühabschnitt 11 bezogen auf die Längsrichtung der zweiten Folienbahn 2 vollständig mittels des Strahlfächers 12 abgedeckt wird.For this purpose, the

Es können mehrere solcher Sprühdüsen nebeneinander angeordnet werden. Dies würde die Möglichkeit eröffnen, den Sprühabschnitt 11 entlang der gesamten Breite der Deckfolienbahn 2 mittels überlappender, kegelförmiger Strahlfächer 12 mit einem einzigen Sprühstoß zu befeuchten. In der gezeigten bevorzugten Ausführungsform ist jedoch nur eine einzelne Sprühdüse 13 vorgesehen, welche in der Stirnansicht gemäß

Nachdem nun der angetrocknete Sprühabschnitt 11 erneut befeuchtet wurde, wird die Versiegelungsvorrichtung wieder zurück in ihren ersten Betriebszustand nach

Ebenso wie die regulär befeuchteten und versiegelten Verpackungseinheiten sind die während des Wiederanfahrens mittels des Sprühabschnitts 8 versiegelten Verpackungseinheiten dicht. Je nach Anforderungsprofil können sie als ordentliches Produkt verwendet oder aber aussortiert werden. Die erzielte Dichtigkeit reicht jedenfalls für einen ordnungsgemäßen Betrieb der Verpackungsmaschine aus.Just like the regularly moistened and sealed packaging units, the packaging units sealed by means of the

Claims (9)

dadurch gekennzeichnet, dass die Befeuchtungseinheit (4) eine Befeuchtungswalze (8) und eine Sprüheinrichtung (10) für die wasserhaltige Flüssigkeit (3) aufweist, wobei die Befeuchtungseinheit (4) zwischen einem ersten Betriebszustand und einem zweiten Betriebszustand umschaltbar ist, wobei im ersten Betriebszustand die Befeuchtungswalze (8) an einer Walzenbefeuchtungsstelle (9) auf die Deckfolienbahn (2) einwirkt, und wobei im zweiten Betriebszustand die Sprüheinrichtung (10) im Zufuhrbereich (7) auf einen zwischen der Walzenbefeuchtungsstelle (9) und der Versiegelungsstelle (6) liegenden Sprühabschnitt (11) der Deckfolienbahn (2) einwirkt.Sealing device for sealing packaging on a flatbed machine, the packaging being formed from a base film web (1) and a cover film web (2), at least the cover film web (2) being formed from a water-soluble film, the sealing device having a liquid supply for an aqueous liquid (3), at least one moistening unit (4) for wetting the cover film web (2) with the aqueous liquid (3) and a pressing device (5) for vertical pressing and sealing of the cover film web (2) with the base film web (1) at a sealing point ( 6) in the wetted state with the liquid (3), the sealing device having a feed area (7) in which the web of cover film (2) is fed to the pressing device (5) from top to bottom, and the moistening unit (4) in feed area (7) acts on the covering foil web (2),

characterized in that the moistening unit (4) has a moistening roller (8) and a spray device (10) for the water-containing liquid (3), the moistening unit (4) being switchable between a first operating state and a second operating state, with the first operating state the moistening roller (8) acts on the cover film web (2) at a roller moistening point (9), and wherein in the second operating state the spraying device (10) in the feed area (7) acts on a spraying section between the roller moistening point (9) and the sealing point (6). (11) acts on the web of cover film (2).

dadurch gekennzeichnet, dass sich der Sprühabschnitt (11) zumindest näherungsweise von der Walzenbefeuchtungsstelle (9) bis zur Versiegelungsstelle (6) erstreckt.Sealing device according to claim 1,

characterized in that the spray section (11) extends at least approximately from the roller moistening point (9) to the sealing point (6).

dadurch gekennzeichnet, dass die Sprüheinrichtung (10) eine Sprühdüse (13) zur Abgabe der wasserhaltigen Flüssigkeit (3) in einem Strahlfächer (12) aufweist und zur Abdeckung des vollständigen Sprühabschnittes (11) mittels des Strahlfächers (12) ausgelegt ist.Sealing device according to claim 1 or 2,

characterized in that the spray device (10) has a spray nozzle (13) for dispensing the water-containing liquid (3) in a jet fan (12) and is designed to cover the entire spray section (11) by means of the jet fan (12).

dadurch gekennzeichnet, dass die Sprüheinrichtung (10) eine auf einem Schlitten (14) montierte einzelne Sprühdüse (13) umfasst, welche mittels des Schlittens (14) quer zur Deckfolienbahn (2) verfahrbar ist.Sealing device according to claim 3,

characterized in that the spray device (10) comprises a single spray nozzle (13) mounted on a carriage (14) which can be moved transversely to the web of cover film (2) by means of the carriage (14).

dadurch gekennzeichnet, dass die Sprühdüse (13) von einer Druckquelle (15) mit der wasserhaltigen Flüssigkeit (3) beaufschlagbar und zur kontinuierlichen Abgabe der wasserhaltigen Flüssigkeit (3) ausgelegt ist.Sealing device according to claim 3 or 4,

characterized in that the spray nozzle (13) can be acted upon by a pressure source (15) with the water-containing liquid (3) and is designed for the continuous delivery of the water-containing liquid (3).

dadurch gekennzeichnet, dass der Zufuhrbereich (7) dazu ausgelegt ist, im zweiten Betriebszustand die Deckfolienbahn (2) zumindest entlang des größeren Teils des Sprühabschnittes (11) in einem Winkel (a) von 70° bis 110° und insbesondere in einem Winkel (a) von 80° bis 100° zur Horizontalen zu führen.Sealing device according to one of claims 1 to 5,

characterized in that the feed area (7) is designed to feed the web of cover film (2) at least along the larger part of the spray section (11) in the second operating state at an angle (a) of 70° to 110° and in particular at an angle (a ) from 80° to 100° to the horizontal.

dadurch gekennzeichnet, dass die Andrückeinrichtung (5) im ersten Betriebszustand an der Versiegelungsstelle (6) positioniert im zweiten Betriebszustand davon entfernt ist, und dass die Versiegelungsvorrichtung eine im zweiten Betriebszustand auf die Deckfolienbahn (2) im Sprühabschnitt (11) einwirkende Streckvorrichtung (16) aufweist.Sealing device according to one of claims 1 to 6,

characterized in that the pressing device (5) in the first operating state at the sealing point (6) positioned in the second Operating state is removed therefrom, and in that the sealing device has a stretching device (16) acting on the covering film web (2) in the spraying section (11) in the second operating state.

dadurch gekennzeichnet, dass im zweiten Betriebszustand die Befeuchtungswalze (8) von der Deckfolienbahn (2) abgehoben ist.Sealing device according to one of claims 1 to 7,

characterized in that in the second operating state the moistening roller (8) is lifted off the web of cover film (2).

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP21179145.4A EP4101774B1 (en) | 2021-06-11 | 2021-06-11 | Sealing device and method for sealing packagings |

| PL21179145.4T PL4101774T3 (en) | 2021-06-11 | 2021-06-11 | Sealing device and method for sealing packagings |

| ES21179145T ES2967199T3 (en) | 2021-06-11 | 2021-06-11 | Sealing device and procedure for sealing containers |

| CA3162802A CA3162802A1 (en) | 2021-06-11 | 2022-06-10 | Sealing apparatus and method for sealing packages |

| CN202210653204.XA CN115465498A (en) | 2021-06-11 | 2022-06-10 | Sealing device and method for sealing packages |

| US17/837,873 US11845579B2 (en) | 2021-06-11 | 2022-06-10 | Sealing apparatus and method for sealing packages |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP21179145.4A EP4101774B1 (en) | 2021-06-11 | 2021-06-11 | Sealing device and method for sealing packagings |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP4101774A1 true EP4101774A1 (en) | 2022-12-14 |

| EP4101774B1 EP4101774B1 (en) | 2023-10-18 |

Family

ID=76444266

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP21179145.4A Active EP4101774B1 (en) | 2021-06-11 | 2021-06-11 | Sealing device and method for sealing packagings |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US11845579B2 (en) |

| EP (1) | EP4101774B1 (en) |

| CN (1) | CN115465498A (en) |

| CA (1) | CA3162802A1 (en) |

| ES (1) | ES2967199T3 (en) |

| PL (1) | PL4101774T3 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4190707A1 (en) * | 2021-12-03 | 2023-06-07 | Fameccanica.Data S.p.A. | Wetting unit and forming machine and method for producing unit dose articles |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2475538A (en) | 2009-11-23 | 2011-05-25 | Rideau Machinery Inc | Rotary thermoforming machine |

| CN105416638A (en) * | 2015-12-15 | 2016-03-23 | 佛山市博维环保材料有限公司 | Water soluble film automatic packing machine and packing process |

| EP3323740B1 (en) | 2016-11-17 | 2019-11-06 | Harro Höfliger Verpackungsmaschinen GmbH | Sealing device and method for sealing packagings |

| WO2020031096A1 (en) * | 2018-08-10 | 2020-02-13 | T.M.E. S.p.A. | Method and packaging machine for manufacturing a compostable pod for brewing products and compostable pod for brewing products |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20070119542A1 (en) * | 2005-11-30 | 2007-05-31 | Williams David R | Labeling method and apparatus |

| EP2234893A1 (en) * | 2007-11-26 | 2010-10-06 | ExxonMobil Oil Corporation | Labeling method and apparatus |

| CA2876991A1 (en) * | 2012-06-23 | 2013-12-27 | Rideau Machinery Inc. | Improvements to continuous motion rotatable forming of soluble pouches |

| CA2871901C (en) * | 2014-10-24 | 2021-07-20 | Multi-Pack Solutions | Systems and methods for forming dual layer water soluble packets |

| CA2943138A1 (en) * | 2015-09-25 | 2017-03-25 | Multi-Pack Solutions, LLC | Packaging machine with independently controllable movers |

| CA3001218C (en) * | 2015-10-06 | 2023-08-08 | Satellite Industries, Inc. | Odor control product package and method of forming the same |

| US20170101203A1 (en) * | 2015-10-07 | 2017-04-13 | Cloud Packaging Solutions, LLC | System for forming packages from film material |

| US20170101204A1 (en) * | 2015-10-07 | 2017-04-13 | Cloud Packaging Solutions, LLC | System for Forming Packages From Film Material |

| EP3541708B1 (en) * | 2016-11-15 | 2022-05-11 | Mespack Cloud, Llc | Machine for cutting pouches with shaped perimeter edge, method and pouch |

| US10781000B2 (en) * | 2017-06-19 | 2020-09-22 | The Procter & Gamble Company | Apparatus and process for forming water soluble pouches |

| EP4159418A1 (en) * | 2021-10-01 | 2023-04-05 | The Procter & Gamble Company | Process of sealing water-soluble polyvinylalcohol films |

-

2021

- 2021-06-11 EP EP21179145.4A patent/EP4101774B1/en active Active

- 2021-06-11 PL PL21179145.4T patent/PL4101774T3/en unknown

- 2021-06-11 ES ES21179145T patent/ES2967199T3/en active Active

-

2022

- 2022-06-10 CA CA3162802A patent/CA3162802A1/en active Pending

- 2022-06-10 CN CN202210653204.XA patent/CN115465498A/en active Pending

- 2022-06-10 US US17/837,873 patent/US11845579B2/en active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2475538A (en) | 2009-11-23 | 2011-05-25 | Rideau Machinery Inc | Rotary thermoforming machine |

| CN105416638A (en) * | 2015-12-15 | 2016-03-23 | 佛山市博维环保材料有限公司 | Water soluble film automatic packing machine and packing process |

| EP3323740B1 (en) | 2016-11-17 | 2019-11-06 | Harro Höfliger Verpackungsmaschinen GmbH | Sealing device and method for sealing packagings |

| WO2020031096A1 (en) * | 2018-08-10 | 2020-02-13 | T.M.E. S.p.A. | Method and packaging machine for manufacturing a compostable pod for brewing products and compostable pod for brewing products |

Also Published As

| Publication number | Publication date |

|---|---|

| PL4101774T3 (en) | 2024-03-18 |

| CA3162802A1 (en) | 2022-12-11 |

| US20220396384A1 (en) | 2022-12-15 |

| ES2967199T3 (en) | 2024-04-29 |

| CN115465498A (en) | 2022-12-13 |

| EP4101774B1 (en) | 2023-10-18 |

| US11845579B2 (en) | 2023-12-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0710605B1 (en) | Method and device for maximising the unit rate of a vacuum packaging machine | |

| EP2423112B1 (en) | Method and device for manufacturing packages for cigarettes | |

| WO2008086992A1 (en) | Processing line for plate-like elements, in particular solar cells, and method for processing plate-like elements | |

| EP1717150A1 (en) | Method and apparatus for producing filled and sealed blister packages | |

| EP2766262A1 (en) | Thermoforming packing machine | |

| DE2115161A1 (en) | Device for the production of handles on thermoplastic carrier bags | |

| DE112014002193T5 (en) | Unwinding and cutting process | |

| EP4101774B1 (en) | Sealing device and method for sealing packagings | |

| EP3875246B1 (en) | Deep-drawing device, packaging machine with a deep-drawing device and method for operating the deep-drawing device | |

| EP3323740B1 (en) | Sealing device and method for sealing packagings | |

| EP0113874B1 (en) | Machine for wrapping and strapping a compressable stack | |

| EP1500438B1 (en) | Device for applying a mass on a roll of material | |

| DE3215436C2 (en) | Device for producing a package | |

| DE10313370B3 (en) | Waste plastic film strip transfer equipment for a container thermoforming machine, has a carriage with clamp to grip film end and transporting rolls feeding film end to a shredder | |

| EP1834531B1 (en) | Treatment of a filter material rod of the tobacco processing industry | |

| DE10348182B4 (en) | Apparatus and method for producing containers provided with a band | |

| DE4017923C1 (en) | Thermoplastic films moulding machine - compensates for shrinkage of film and incorporates several work stations | |

| DE3710055C2 (en) | ||

| EP3613556A1 (en) | Device and method for deep-drawing of film | |

| EP3967637B1 (en) | Device and method for splicing and continuously providing a film sheet | |

| EP2394940A2 (en) | Stacking device for stacking flat workpieces | |

| DE19882815B4 (en) | Web feed device and method for feeding a web end | |

| DE102022128000A1 (en) | METHOD FOR OPERATING A PACKAGING MACHINE FOR FOOD PRODUCTS, AND PACKAGING MACHINE | |

| WO2023202860A1 (en) | Method for operating a packaging machine for food products, and packaging machine | |

| WO2011066911A1 (en) | Method and apparatus for changing tow bales |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| 17P | Request for examination filed |

Effective date: 20230525 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B65B 47/04 20060101ALI20230613BHEP Ipc: B65B 9/04 20060101ALI20230613BHEP Ipc: B65B 7/16 20060101AFI20230613BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20230628 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230717 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502021001725 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240218 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231018 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2967199 Country of ref document: ES Kind code of ref document: T3 Effective date: 20240429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231018 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240218 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240119 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240118 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231018 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231018 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240118 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231018 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231018 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20240619 Year of fee payment: 4 |

|