EP3882425B1 - Sliding door assembly - Google Patents

Sliding door assembly Download PDFInfo

- Publication number

- EP3882425B1 EP3882425B1 EP20164516.5A EP20164516A EP3882425B1 EP 3882425 B1 EP3882425 B1 EP 3882425B1 EP 20164516 A EP20164516 A EP 20164516A EP 3882425 B1 EP3882425 B1 EP 3882425B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- contact

- sliding door

- door assembly

- contact elements

- elements

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000004020 conductor Substances 0.000 claims description 39

- 230000005540 biological transmission Effects 0.000 claims description 16

- 229910052751 metal Inorganic materials 0.000 claims description 9

- 239000002184 metal Substances 0.000 claims description 9

- 230000008878 coupling Effects 0.000 claims description 4

- 238000010168 coupling process Methods 0.000 claims description 4

- 238000005859 coupling reaction Methods 0.000 claims description 4

- 230000004907 flux Effects 0.000 claims 2

- 230000037431 insertion Effects 0.000 claims 1

- 238000003780 insertion Methods 0.000 claims 1

- 238000006073 displacement reaction Methods 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 6

- 230000000295 complement effect Effects 0.000 description 4

- 229910052782 aluminium Inorganic materials 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 230000005484 gravity Effects 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 238000005299 abrasion Methods 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000007175 bidirectional communication Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000012777 electrically insulating material Substances 0.000 description 1

- 238000005265 energy consumption Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 230000000977 initiatory effect Effects 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 230000003313 weakening effect Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05D—HINGES OR SUSPENSION DEVICES FOR DOORS, WINDOWS OR WINGS

- E05D15/00—Suspension arrangements for wings

- E05D15/06—Suspension arrangements for wings for wings sliding horizontally more or less in their own plane

- E05D15/0621—Details, e.g. suspension or supporting guides

- E05D15/066—Details, e.g. suspension or supporting guides for wings supported at the bottom

- E05D15/0691—Top guides

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05D—HINGES OR SUSPENSION DEVICES FOR DOORS, WINDOWS OR WINGS

- E05D15/00—Suspension arrangements for wings

- E05D15/56—Suspension arrangements for wings with successive different movements

- E05D15/565—Suspension arrangements for wings with successive different movements for raising wings before sliding

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05F—DEVICES FOR MOVING WINGS INTO OPEN OR CLOSED POSITION; CHECKS FOR WINGS; WING FITTINGS NOT OTHERWISE PROVIDED FOR, CONCERNED WITH THE FUNCTIONING OF THE WING

- E05F15/00—Power-operated mechanisms for wings

- E05F15/60—Power-operated mechanisms for wings using electrical actuators

- E05F15/603—Power-operated mechanisms for wings using electrical actuators using rotary electromotors

- E05F15/632—Power-operated mechanisms for wings using electrical actuators using rotary electromotors for horizontally-sliding wings

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2201/00—Constructional elements; Accessories therefor

- E05Y2201/40—Motors; Magnets; Springs; Weights; Accessories therefor

- E05Y2201/47—Springs

- E05Y2201/48—Leaf or leg springs

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2201/00—Constructional elements; Accessories therefor

- E05Y2201/60—Suspension or transmission members; Accessories therefor

- E05Y2201/622—Suspension or transmission members elements

- E05Y2201/684—Rails; Tracks

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2201/00—Constructional elements; Accessories therefor

- E05Y2201/60—Suspension or transmission members; Accessories therefor

- E05Y2201/622—Suspension or transmission members elements

- E05Y2201/708—Sliders

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2400/00—Electronic control; Electrical power; Power supply; Power or signal transmission; User interfaces

- E05Y2400/65—Power or signal transmission

- E05Y2400/656—Power or signal transmission by travelling contacts

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2400/00—Electronic control; Electrical power; Power supply; Power or signal transmission; User interfaces

- E05Y2400/65—Power or signal transmission

- E05Y2400/656—Power or signal transmission by travelling contacts

- E05Y2400/658—Power or signal transmission by travelling contacts with current rails

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2900/00—Application of doors, windows, wings or fittings thereof

- E05Y2900/10—Application of doors, windows, wings or fittings thereof for buildings or parts thereof

- E05Y2900/13—Type of wing

- E05Y2900/132—Doors

Definitions

- the invention relates to a sliding door arrangement with a frame and a door leaf that can be displaced relative to the frame.

- Sliding door assemblies of the type mentioned are known from the prior art, for example DE 201 18 906 U1 , showing a sliding door assembly with a leaf manually slidable relative to the frame.

- DE 201 18 906 U1 showing a sliding door assembly with a leaf manually slidable relative to the frame.

- EP 2 933 417 A1 a sliding door arrangement with a frame and a wing that can be displaced relative to the frame is known, wherein the wing can be moved by a motor by means of a motor drive. This increases the ease of use.

- the wing is only supplied with energy in the closed position in order to charge a battery arranged on the wing.

- a sliding wall which consists of two or more glass sliding wall panels with a carriage.

- the individual walls are movable and stackable via a switch.

- One of the carriages is equipped with a motor, with current collector profiles being integrated into the roller of the carriage.

- the current collector profiles create an electrical connection between the resilient power lines integrated in the running profiles and the resilient interfaces on the motor.

- the object of the invention is to ensure a permanent power supply of components arranged on the leaf side in a sliding door arrangement with simple structural means.

- the invention solves this problem by a sliding door arrangement with the features of claim 1.

- the sliding door arrangement has a (stationary) frame (fixed frame), a door leaf that can be moved (horizontally) relative to the frame, which is coupled to a guide slider and, by means of the guide slider, in a frame arranged guide rail is guided, and at least one wing-side arranged consumers of electrical energy (at least one wing-side arranged and to be supplied with electrical energy component).

- the sliding door arrangement is characterized in that conductor elements ("conductor tracks”) are arranged on or in the guide rail, which extend along the longitudinal direction of the guide rail (direction of displacement), and that the guide slider first contact elements and electrically second contact elements connected thereto, wherein the first contact elements are in contact with the conductor elements, wherein the second contact elements are in contact with contact surfaces arranged on the leaf side, which are electrically connected to the consumer, and wherein the second contact elements extend along a direction of extension towards the door leaf and are elastic and deformable along the direction of extension, for example reversibly compressible, in order to compensate (along the direction of extension) a distance between the guide slider and contact surfaces.

- conductor elements conductor tracks

- a permanent transmission of electrical energy from the frame to the door leaf is created with simple design means. Because electrical energy is transmitted on or in the guide rail, electrical contact points are largely protected from environmental influences. There is no need for trailing cables or the like.

- a sliding contact with the conductor elements is realized by the first contact elements. Since the second contact elements are reversibly deformable, electrical energy can be transmitted from the frame to the door leaf, at least to a certain extent, even if the frame and the door leaf are at different distances from one another.

- the second contact elements can be used to compensate for manufacturing and assembly tolerances and, for example, also a sash lift (lifting movement by raising or lowering a sliding sash). It is a permanent transmission of electrical energy possible from the frame to the leaf, regardless of the sliding position of the door leaf.

- the guide slider Since the guide slider is coupled to the door leaf, the guide slider moves with the door leaf when it is moved.

- the first contact elements are in particular formed on a different side of the body of the guide slider than the second contact elements.

- the guide slider can be made of an electrically insulating material, for example plastic.

- the contacting is in particular designed in such a way that a first contact element is in (sliding) electrical contact with one of the conductor elements.

- a first contact element is electrically connected to a second contact element.

- the conductor elements can, for example, each be designed as a round bar, for example made of metal.

- the guide rail is in particular designed as a profile, for example as an extruded profile, with the guide rail being open on the front side and on one longitudinal side.

- the guide rail has in particular a base section (rear wall), wall sections (side walls) protruding therefrom and further wall sections which protrude into the clear cross-section of the guide rail (grip sections).

- the guide rail can, for example, be designed as an aluminum profile.

- the door leaf is in particular a lifting/sliding leaf that can not only be moved (horizontally) relative to the frame, but can also be raised and lowered. When the door leaf is raised, it can be moved (horizontally). In a lowered state of the door leaf, sealing of the door leaf on the frame can be achieved or simplified. In addition, the door leaf can be locked on the frame when it is lowered and in the closed position (door leaf pushed closed). For this purpose, locking elements that correspond to one another can be provided on the door leaf and on the frame.

- the door leaf can be moved or shifted via one or more carriages along a running rail arranged in the direction of gravity below the door leaf on the frame.

- the guide rail is arranged in the direction of gravity above the door leaf on the frame, with the door leaf being guided on the guide rail by means of the guide slider and being able to be moved or shifted along the guide rail.

- the first contact elements can each be designed as metal strips, preferably convexly curved. This creates a simple and robust contact element which can compensate for manufacturing and assembly tolerances to a certain extent (spring effect). This contributes to reliable electrical contact between the first contact elements and the conductor elements. The spring action ensures that the first contact elements are in contact with the conductor elements even in the case of mechanical wear (abrasion) (transmission of electrical energy possible).

- the second contact elements can each be designed as metal strips shaped into a ring or into an ellipse.

- a structurally simple and stable contact element is thus created which can be reversibly deformed over a comparatively large area. This favors a compensation of manufacturing and assembly tolerances and a compensation of the wing stroke.

- the second contact elements are so dimensionally stable transversely to the direction of extension (direction of lift of the door leaf) that the risk of the second contact elements buckling is largely reduced. It is thus possible to prevent the second contact elements from touching one another and initiating a short circuit.

- the first contact elements and the second contact elements can each be electrically connected to one another by means of a contact block, with a first contact element and a second contact element being fastened to the contact block, in particular being screwed.

- a simple mechanical and electrical connection of the contact elements is created.

- the first contact elements can each be screwed to the contact block at one end (attachment section) by means of a screw.

- the first contact elements can each extend from this end (fixed end) to a free end.

- a depression for the fastening section of the first contact element can be formed on the contact element. This can prevent the first contact element from twisting relative to the contact block.

- the second contact elements can each be interrupted at one point, with outwardly protruding lugs being formed at the interruption. These lugs can be inserted into an opening on the guide slider and rest against the contact block.

- the second holding elements can each be screwed to the contact block by means of a holding plate covering the interruption and a screw passed through the interruption.

- the first contact elements can be offset from one another along the central longitudinal direction of the guide slider (displacement direction). As a result, the overall height of the guide slider can be kept low. This also reduces the risk of short circuits.

- the second contact elements can be offset from one another along the central longitudinal direction of the guide slider (displacement direction). As a result, a lower local component weakening of the guide slider can be achieved. In addition, the risk of a short circuit due to the second contact elements touching one another is reduced.

- concave recesses can be formed in the guide slider that extend along the central longitudinal direction of the guide slider (displacement direction), in each of which a second contact element is seated. This facilitates alignment and assembly of the second contact elements. In addition, a safeguard against twisting or bending of the second contact elements is thus created.

- the second contact elements are arranged in sections in the recess and, starting from the recess, extend away from the guide slider.

- the recesses are offset from one another along the central longitudinal direction of the guide slider (direction of displacement).

- a drive element e.g. a toothed wheel

- a drive element can expediently be arranged in the guide slider, which drives an output element fastened to the frame, for example a toothed belt which has open ends and is fastened to the frame.

- the gear can be rotatably coupled to a shaft or have a shaft section, via which the gear wheel can be coupled to a wing-side electric drive unit. Deflection rollers, corresponding recesses and a retaining plate can also be provided on the guide slider.

- the conductor elements can be attached to or in the guide rail by means of an electrically insulating conductor element carrier that extends along the guide rail, wherein the conductor elements can be attached to the conductor element carrier by means of a snap connection and/or the conductor element carrier can be attached to the guide rail by means of a snap connection can.

- the conductor element carrier is designed as an elastically deforming joining part, for example made of plastic.

- Longitudinally oriented grooves for the conductor elements can be formed on the conductor element carrier, each of which more than half encompasses an (inserted) conductor element in cross section, for example by more than 180°.

- a web extending along the longitudinal direction of the guide rail and having a peg-shaped cross section can be formed on the guide rail, with a corresponding web receptacle being formed on the conductor element carrier, which encompasses the web (in the inserted state) in cross section by more than half, e.g. by more than 180° .

- a contacting unit can be attached to the narrow side of the door leaf (upper side of the leaf) facing the guide rail (in the installed position), the contacting unit having an insulating carrier plate and two contact plates attached to the carrier plate, with the contact surfaces each facing through one of the guide rails Surface of the contact plates are formed.

- Terminal lugs for electrical connection to wing-side energy consumers, such as a controller, can be formed on the contact plates.

- a pocket can be formed on the carrier plate for each contact plate, which accommodates the contact plate at least in sections, one or more latching lugs being formed on each pocket, so that the contact plate can be fastened or is fastened to the carrier plate by means of a snap-in connection. This facilitates manufacture and assembly.

- An electrical power supply (e.g. a power supply unit) can expediently be provided on the frame side, which is electrically connected via connecting lines to (electrical) contact elements of a plug-in unit (connector plug), the plug-in unit being able to be pushed into the guide rail and the contact elements being pushed into the guide rail come into electrical contact with the conductor elements.

- the plug-in unit can be designed to be complementary (partially complementary or fully complementary) to the guide rail.

- the contact elements of the plug-in unit can be designed as concave metal strips.

- the contact elements of the plug-in unit can structurally correspond to the first contact elements of the guide slider.

- the contact elements can each be attached to the plug-in unit by means of a contact block, with the contact block being inserted into an opening provided for this purpose in the plug-in unit.

- the contact blocks can correspond to the contact blocks described above in connection with the first and second contact elements on the guide slider. The production can be favored by a higher proportion of identical parts.

- a controller arranged on the wing side can advantageously be provided as a consumer, which has a data transmission device, the electrical energy supply (e.g. power supply unit) likewise having a data transmission device, the data transmission devices each being designed to transmit and receive data signals modulated onto electrical lines and wherein the data transmission devices are electrically connected to one another. Bidirectional communication is thus possible between the controller and the power supply. It cannot with the electrical connection only electrical energy but also signals can be transmitted. In this way, the energy supply (e.g. the power pack) and the controller can exchange signals, e.g. control signals.

- the electrical connection can include the connecting lines, the plug-in unit, the conductor elements, the guide slider, the contacting unit and connecting lugs extending therefrom, to which a wing-side control is connected.

- an electric drive unit for moving the door leaf can be arranged on the wing side as a (further) consumer, with the drive unit driving the drive element (gear wheel) arranged in the guide slider. This allows the door leaf to be moved automatically.

- the electric drive unit can be controlled by the controller.

- the drive unit can have an electric motor, which can optionally be followed by a reduction gear (reduction gear between electric motor and drive element).

- a (manually or motor-operated) clutch device can be provided between the electric drive unit and the drive element (gear wheel), by means of which a power flow can be established between the drive unit and the drive element and a power flow between the drive unit and the drive element can be interrupted.

- This makes it easier to connect and disconnect the electric drive unit from the vehicle Guide slider or from the drive element. This favors assembly of the door leaf on the frame and also its disassembly.

- an accumulator arranged on the wing side can be provided for supplying energy to consumers of electrical energy arranged on the wing side, for example the controller and/or the electric drive unit.

- the door leaf can also be moved automatically if a mains-connected energy supply, for example the mains power supply, is disrupted.

- the current levels to be transmitted can be kept low as a result, so that the electrical lines and contacts can be designed to be smaller.

- the energy supply of the sliding door arrangement can be set up in such a way that the electrical power provided by the energy supply to the controller or the battery would not be sufficient to drive the electrical drive unit.

- An energy supply to these components is ensured by the accumulator, which can be permanently charged via the electrical connection between the frame and the door leaf.

- a further door leaf can be provided on the sliding door arrangement, which is guided on the frame and can be displaced relative to the frame. This creates a lift/sliding door combination with several door leaves.

- the other door leaf can be designed analogously to the door leaf described above.

- the additional door leaf can thus have the components that the (first) door leaf described above also has.

- the further door leaf can have a control arranged on the leaf side, which has a data transmission device which is designed to send and receive data signals modulated onto electrical lines and is connected to data transmission devices for the power supply on the frame (e.g. power pack) and/or the control on the leaf side of the (first ) door leaf is electrically connected.

- a control arranged on the leaf side, which has a data transmission device which is designed to send and receive data signals modulated onto electrical lines and is connected to data transmission devices for the power supply on the frame (e.g. power pack) and/or the control on the leaf side of the (first ) door leaf is electrically connected.

- data signals can be transmitted not only between the power pack and the controller of the (first) door leaf, but also between the (first) door leaf and the other door leaf.

- a combination of several door leaves that are electrically connected to one another can exchange control and/or status information.

- the drive components arranged in the guide slider and the coupling device can be designed as in EP 2 933 417 A1 described, the disclosure of which is hereby incorporated by reference.

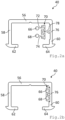

- FIG. 12 shows a sliding door assembly, designated generally by the reference numeral 10.

- FIG. The sliding door arrangement 10 has a stationary frame 12 (fixed frame 12) and a door leaf 14 which can be displaced horizontally relative to the frame 12.

- the frame 12 includes a lower frame member 16, an upper frame member 18 and two side frame members 20 (only one side frame member 20 shown).

- the door leaf 14 has a leaf frame 22 which delimits a leaf panel 24, for example a glazing.

- the wing frame 22 has a lower profile 26, an upper profile 28 and side profiles 30,32.

- a running rail 34 is arranged on the lower frame part 16 of the frame 12 .

- the door leaf 14 has two carriages 36, 38 on the lower profile 26, which run in the running rail 34.

- the door leaf 14 can be displaced relative to the frame 12 by means of the carriages 36 , 38 .

- a guide rail 40 is arranged on the upper frame part 18 of the frame 12 .

- a guide slider 42 is slidably guided in the guide rail 40 .

- the door leaf 14 is coupled to the guide slider 42 and is thereby guided at the upper end of the door leaf 14 .

- the door leaf 14 is designed as a lifting/sliding leaf, which is not only horizontally displaceable, but can also be raised and lowered. When the door leaf 14 is in a raised state, it can be moved horizontally relative to the frame 12 . When the door leaf 14 is in a lowered state, effective sealing of the door leaf 14 relative to the frame 12 is promoted.

- a contacting unit 48 is arranged on the upper profile 28 of the door leaf 14 .

- the door leaf 14 has several components on or in the side profile 32 that have to be supplied with electrical energy, namely an electric drive unit 50, an electric/electronic control 52 and a battery 54.

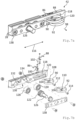

- FIGS 2a and 2b show the guide rail 40 in a schematic sectional view.

- the guide rail 40 has a base section 56, wall sections 58, 60 protruding therefrom and further wall sections 62, 64 which protrude into the clear cross-section of the guide rail 40 (gripping sections 62, 64).

- the guide rail 40 can, for example, be designed as an aluminum profile.

- Two conductor elements 66 , 68 are arranged in the guide rail 40 and extend along the longitudinal direction of the guide rail 40 .

- the conductor elements 66 , 68 are fastened in the guide rail 40 by means of an electrically insulating conductor element carrier 70 which extends along the guide rail 40 . Fastening is by means of snap connections.

- the conductor element carrier 70 is designed to be elastically deformable, for example made of plastic.

- Longitudinal grooves 72, 74 are formed on the conductor element carrier 70, in each of which a conductor element 66, 68 can be inserted.

- the longitudinal grooves 72, 74 surround the conductor elements 66, 68 more than half in the inserted state in cross section.

- Also formed in the guide rail 40 is a web 76 which extends in the longitudinal direction of the guide rail 40 and has a peg-shaped cross section.

- a corresponding web receptacle 78 is formed on the conductor element carrier 70 and, in the inserted state, encompasses more than half of the cross section of the web 76 .

- FIG 3 shows the plug-in unit 46 on its own.

- the plug-in unit 46 or its housing 80 is designed to complement the guide rail 40, so that the plug-in unit 46 can be pushed into the guide rail 40 at the front (cf. Fig.4 ).

- the plug-in unit 46 has electrical contact elements 82, 84 which are designed as concave metal strips are (cf. Fig.3 ).

- the contact elements 82, 84 are each attached at one end to the plug-in unit 46 by means of a screw.

- the contact elements 82, 84 are each fastened to the plug-in unit 46 by means of a contact block 81, 83, the contact block being inserted into an opening provided for this purpose (without a reference number) in the plug-in unit 46.

- the contact blocks 81, 83 can structurally correspond to the contact blocks 100, 102, which are described below in connection with the guide slider 42.

- the contact elements 82, 84 are arranged offset to one another along the central longitudinal direction of the plug-in unit 46.

- the contact elements 82, 84 are electrically connected to the electrical energy supply 44 in the form of a power pack by means of connecting lines.

- FIG 4 shows the door leaf 14 and the guide rail 40 in a partial sectional view, with the plug-in unit 46 being inserted into the guide rail 40 .

- the plug-in unit 46 rests on the wall sections 62, 64 of the guide rail 40.

- the electrical contact elements 82, 84 are in electrical contact with the electrical conductor elements 66, 68 (not provided with reference numbers for the sake of clarity). This contact is made when the plug-in unit 46 is pushed in.

- the figures 5 , 7a , 7b and 8th show the guide slider 42.

- the guide slider 42 has first contact elements 86, 88 and second contact elements 90, 92 electrically connected thereto (cf. Figures 7a and b ).

- the first contact elements 86, 88 are arranged on a different body side of the guide slider 42 than the second contact elements 90, 92.

- the first contact elements 86, 88 are in contact with the conductor elements 66, 68 (cf. Fig.8 ).

- the second contact elements 90, 92 are in contact with contact surfaces 94, 96 arranged on the wing side (cf. Fig.5 and 6 ), which are electrically or electronically connected to at least one of the wing-side consumers, e.g. the controller 52.

- the second contact elements 90, 92 extend away from the guide slider 42 along a direction of extension 98 (cf. Fig.7a ), ie in the installed state towards the door leaf 14 (cf. Fig.5 ).

- the second contact elements 90, 92 are elastic and deformable, for example compressible, along the direction of extent 98 in order to compensate for a distance between the guide slider 42 and contact surfaces 94, 96 along the direction of extent 98.

- the first contact elements 86, 88 are each designed as convex metal strips (cf. Figures 7a and b ). As a result, the contact elements 86, 88 can compensate for manufacturing or assembly tolerances and reliably contact the conductor elements 66, 68 (cf. Fig.8 ).

- the second contact elements 90, 92 are each designed as metal strips shaped into a ring or into an ellipse (cf. Figures 7a and b ).

- the first contact elements 86, 88 and the second contact elements 90, 92 are each electrically connected to one another by means of a contact block 100, 102, with a first contact element 86, 88 and a second contact element 90, 92 being screwed to the contact block 100, 102.

- the contact elements 86, 88, 90, 92 are mechanically and electrically connected.

- the first contact elements 86, 88 are each screwed to the contact block 100, 102 at one end (fixing section) by means of a screw.

- the first contact elements 86, 88 each extend from this end to a free end.

- a depression for the fastening section of the first contact element 86, 88 is formed on the contact block 100, 102 (cf. Fig.7b ). This prevents the first contact elements 86, 88 from twisting relative to the contact block 100, 102.

- the second contact elements 90, 92 are each interrupted at one point, with outwardly protruding lugs 104, 106 being formed at the interruption (cf. Fig.7b ).

- the lugs 104, 106 are inserted into an opening on the guide slider 42 and lie against the contact block 100, 102.

- the second holding elements 90, 92 are each screwed to the contact block 100, 102 by means of a retaining plate 108, 110 covering the interruption and a screw 112, 114 passed through the interruption.

- the first contact elements 86, 88 are offset from one another along the central longitudinal direction 116 of the guide slider 42 (displacement direction 116).

- the second contact elements 90, 92 are offset from one another along the central longitudinal direction 116 of the guide slider 42.

- Concave recesses 118, 120 are formed in the guide slider 42 and extend along the central longitudinal direction 116, in each of which a second contact element 90, 92 is seated (cf. Figures 7a and b ).

- the second contact elements 90, 92 are arranged in sections in the recess 118, 120 and extend away from the guide slider 42.

- the recesses 118, 120 are arranged offset to one another along the central longitudinal direction 116 of the guide slider 42.

- a drive element 122 in the form of a gear wheel is arranged in the guide slider 42 and drives a driven element 124 in the form of a toothed belt fastened to the frame 12 (cf. Fig.5 ).

- the toothed belt 124 has open ends and is fixed to the frame 12 (not shown).

- the gear wheel 122 has a shaft section 126 connected thereto in a torque-proof manner, via which the gear wheel 122 can be coupled to the electric drive unit 50 .

- Deflection rollers 128, 130, bearing journals 132, 134 for the deflection rollers, a corresponding recess 136 for receiving gear wheel 122 and deflection rollers 128, 130 and a retaining plate 138 are also provided on the guide slider 42.

- figure 6 shows the contacting unit 48 on its own. In the mounted state, the contacting unit 48 is attached to the narrow side of the door leaf 14 (upper side of the leaf) facing the guide rail 40 (cf. Fig.5 ).

- the contacting unit 48 has an insulating carrier plate 140 and two contact plates 142, 144 fastened to the carrier plate 140 (cf. Fig.6 ).

- the contact surfaces 94 , 96 are each formed by a surface of the contact plates 142 , 144 which faces the guide rail 40 .

- the contact plates 142, 144 are arranged separately on the carrier plate 140 and are separated from one another by a web 146 projecting from the carrier plate 140.

- the carrier plate 140 has fastening holes 148, 150 and can be fastened to the door leaf 14 by means of screws.

- each contact plate 142, 144 On the support plate 140, a pocket 152, 154 is formed for each contact plate 142, 144, which accommodates the contact plate in each case at least in sections, with each Pocket one or more locking lugs 156, 158 are formed so that the contact plate 142, 144 can be attached to the support plate 140 by means of a locking connection.

- Each contact plate has a connecting lug 147, 149 for electrical contacting.

- the control 52 arranged on the wing side is provided as a further consumer (cf. Fig.1 ), which has a data transmission device, wherein the electrical energy supply 44 also has a data transmission device in the form of a power pack, the data transmission devices being designed to send and receive data signals modulated onto electrical lines and connected to one another via electrical lines, as described above.

- the electric drive unit 50 arranged on the leaf side for moving the door leaf 14 is provided as a further consumer (cf. Fig.1 , 5 and 8th ).

- the electric drive unit 50 drives the gear wheel 122 arranged in the guide slider 42 .

- the electric drive unit 50 is electrically or electronically coupled to the controller 52 and is controlled by the controller 52 .

- the drive unit 50 has an electric motor 160, which can optionally be followed by a reduction gear 162 (reduction gear 162 between the electric motor 160 and the gear wheel 122).

- a clutch device 164 which can be actuated manually in the example, is provided between electric drive unit 50 and gear wheel 122, by means of which a power flow can be established between drive unit 50 and gear wheel 122 and a power flow between drive unit 50 and gear wheel 122 can be interrupted.

- the coupling device 164 By bringing the coupling device 164 into the uncoupled position (cf. Fig.8 ), the door leaf 14 can be easily inserted into or removed from the frame 12.

- the accumulator 54 arranged on the wing side is provided for the energy supply of electrical energy consumers arranged on the wing side (cf. Fig.1 ).

- the accumulator 54 is charged by the power pack 44 independently of the sliding position of the door leaf 14 .

- the accumulator 54 supplies the controller 52 and the electric drive unit 50 with electrical energy.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Wing Frames And Configurations (AREA)

- Power-Operated Mechanisms For Wings (AREA)

- Sealing With Elastic Sealing Lips (AREA)

- Closing And Opening Devices For Wings, And Checks For Wings (AREA)

- Special Wing (AREA)

Description

Die Erfindung betrifft eine Schiebetüranordnung mit einem Rahmen und einem relativ zum Rahmen verschiebbaren Türflügel.The invention relates to a sliding door arrangement with a frame and a door leaf that can be displaced relative to the frame.

Schiebetüranordnungen der eingangs genannten Art sind aus dem Stand der Technik bekannt, bspw. aus

Des Weiteren ist aus

Der Erfindung liegt die Aufgabe zugrunde, bei einer Schiebetüranordnung mit einfachen konstruktiven Mitteln eine dauerhafte Energieversorgung von flügelseitig angeordneten Komponenten sicherzustellen.The object of the invention is to ensure a permanent power supply of components arranged on the leaf side in a sliding door arrangement with simple structural means.

Die Erfindung löst diese Aufgabe durch eine Schiebetüranordnung mit den Merkmalen des Anspruchs 1. Die Schiebetüranordnung weist einen (ortsfesten) Rahmen (Festrahmen), einen relativ zum Rahmen (horizontal) verschiebbaren Türflügel, der mit einem Führungsgleiter gekoppelt und mittels des Führungsgleiters in einer am Rahmen angeordneten Führungsschiene geführt ist, und mindestens einen flügelseitig angeordneten Verbraucher elektrischer Energie auf (mindestens eine flügelseitig angeordnete und mit elektrischer Energie zu versorgende Komponente).The invention solves this problem by a sliding door arrangement with the features of claim 1. The sliding door arrangement has a (stationary) frame (fixed frame), a door leaf that can be moved (horizontally) relative to the frame, which is coupled to a guide slider and, by means of the guide slider, in a frame arranged guide rail is guided, and at least one wing-side arranged consumers of electrical energy (at least one wing-side arranged and to be supplied with electrical energy component).

Die Schiebetüranordnung zeichnet sich dadurch aus, dass an oder in der Führungsschiene Leiterelemente ("Leiterbahnen") angeordnet sind, die sich entlang der Längsrichtung der Führungsschiene (Verschieberichtung) erstrecken, und dass der Führungsgleiter erste Kontaktelemente und elektrisch damit verbundene zweite Kontaktelemente aufweist, wobei die ersten Kontaktelemente mit den Leiterelementen in Kontakt sind, wobei die zweiten Kontaktelemente mit flügelseitig angeordneten Kontaktflächen in Kontakt sind, die elektrisch mit dem Verbraucher verbunden sind, und wobei sich die zweiten Kontaktelemente entlang einer Erstreckungsrichtung zum Türflügel hin erstrecken und elastisch und entlang der Erstreckungsrichtung verformbar, bspw. reversibel komprimierbar sind, um (entlang der Erstreckungsrichtung) eine Distanz zwischen Führungsgleiter und Kontaktflächen auszugleichen.The sliding door arrangement is characterized in that conductor elements ("conductor tracks") are arranged on or in the guide rail, which extend along the longitudinal direction of the guide rail (direction of displacement), and that the guide slider first contact elements and electrically second contact elements connected thereto, wherein the first contact elements are in contact with the conductor elements, wherein the second contact elements are in contact with contact surfaces arranged on the leaf side, which are electrically connected to the consumer, and wherein the second contact elements extend along a direction of extension towards the door leaf and are elastic and deformable along the direction of extension, for example reversibly compressible, in order to compensate (along the direction of extension) a distance between the guide slider and contact surfaces.

Somit ist mit einfachen konstruktiven Mitteln eine permanente Übertragung elektrischer Energie vom Rahmen auf den Türflügel geschaffen. Indem die Übertragung elektrischer Energie an oder in der Führungsschiene erfolgt, sind elektrischen Kontaktstellen weitgehend vor Umgebungseinflüssen geschützt. Auf Schleppkabel oder dergleichen kann verzichtet werden. Durch die ersten Kontaktelemente ist ein Schleifkontakt zu den Leiterelementen realisiert. Dadurch, dass die zweiten Kontaktelemente reversibel verformbar sind, kann eine Übertragung elektrischer Energie vom Rahmen auf den Türflügel, jedenfalls in gewissem Umfang, auch dann erfolgen, wenn der Rahmen und der Türflügel unterschiedlich voneinander beabstandet sind. Somit können durch die zweiten Kontaktelemente Fertigungs- und Montagetoleranzen und bspw. auch ein Flügelhub (Hubbewegung durch Anheben bzw. Absenken eines Schiebeflügels) ausgeglichen werden. Es ist eine permanente Übertragung von elektrischer Energie vom Rahmen auf den Flügel möglich, und zwar unabhängig von der Verschiebeposition des Türflügels.Thus, a permanent transmission of electrical energy from the frame to the door leaf is created with simple design means. Because electrical energy is transmitted on or in the guide rail, electrical contact points are largely protected from environmental influences. There is no need for trailing cables or the like. A sliding contact with the conductor elements is realized by the first contact elements. Since the second contact elements are reversibly deformable, electrical energy can be transmitted from the frame to the door leaf, at least to a certain extent, even if the frame and the door leaf are at different distances from one another. Thus, the second contact elements can be used to compensate for manufacturing and assembly tolerances and, for example, also a sash lift (lifting movement by raising or lowering a sliding sash). It is a permanent transmission of electrical energy possible from the frame to the leaf, regardless of the sliding position of the door leaf.

Da der Führungsgleiter mit dem Türflügel gekoppelt ist, bewegt sich der Führungsgleiter beim Verschieben des Türflügels mit diesem mit. Die ersten Kontaktelemente sind insbesondere an einer anderen Körperseite des Führungsgleiters ausgebildet als die zweiten Kontaktelemente. Der Führungsgleiter kann aus einem elektrisch isolierenden Werkstoff ausgebildet sein, bspw. aus Kunststoff.Since the guide slider is coupled to the door leaf, the guide slider moves with the door leaf when it is moved. The first contact elements are in particular formed on a different side of the body of the guide slider than the second contact elements. The guide slider can be made of an electrically insulating material, for example plastic.

Die Kontaktierung ist insbesondere derart ausgeführt, dass jeweils ein erstes Kontaktelement mit einem der Leiterelemente in (gleitendem) elektrischem Kontakt ist. Jeweils ein erstes Kontaktelement ist mit einem zweiten Kontaktelement elektrisch verbunden. Die Leiterelemente können bspw. jeweils als Rundstange ausgebildet sein, bspw. aus Metall.The contacting is in particular designed in such a way that a first contact element is in (sliding) electrical contact with one of the conductor elements. In each case, a first contact element is electrically connected to a second contact element. The conductor elements can, for example, each be designed as a round bar, for example made of metal.

Die Führungsschiene ist insbesondere als Profil ausgebildet, bspw. als Strangpressprofil, wobei die Führungsschiene jeweils stirnseitig und zu einer Längsseite hin offen ist. Die Führungsschiene weist insbesondere einen Grundabschnitt (Rückwand), davon abragende Wandabschnitte (Seitenwände) und weitere Wandabschnitte auf, die in den lichten Querschnitt der Führungsschiene hineinragen (Hintergriffsabschnitte). Die Führungsschiene kann bspw. als Aluminium-Profil ausgebildet sein.The guide rail is in particular designed as a profile, for example as an extruded profile, with the guide rail being open on the front side and on one longitudinal side. The guide rail has in particular a base section (rear wall), wall sections (side walls) protruding therefrom and further wall sections which protrude into the clear cross-section of the guide rail (grip sections). The guide rail can, for example, be designed as an aluminum profile.

Bei dem Türflügel handelt es sich insbesondere um einen Hebe-/Schiebeflügel, der nicht nur (horizontal) relativ zum Rahmen verschoben, sondern auch angehoben und abgesenkt werden kann. In einem angehobenen Zustand des Türflügels kann dieser (horizontal) verschoben werden. In einem abgesenkten Zustand des Türflügels kann eine Abdichtung des Türflügels am Rahmen erreicht oder vereinfacht sein. Zudem kann der Türflügel im abgesenkten Zustand und in geschlossener Stellung (Türflügel zugeschoben) am Rahmen verriegelt sein. Hierzu können am Türflügel und am Rahmen miteinander korrespondierende Schließelemente vorgesehen sein.The door leaf is in particular a lifting/sliding leaf that can not only be moved (horizontally) relative to the frame, but can also be raised and lowered. When the door leaf is raised, it can be moved (horizontally). In a lowered state of the door leaf, sealing of the door leaf on the frame can be achieved or simplified. In addition, the door leaf can be locked on the frame when it is lowered and in the closed position (door leaf pushed closed). For this purpose, locking elements that correspond to one another can be provided on the door leaf and on the frame.

Der Türflügel kann über einen oder mehrere Laufwagen entlang einer in Schwerkraftrichtung unterhalb des Türflügels am Rahmen angeordneten Laufschiene verfahren bzw. verschoben werden. Die Führungsschiene ist in Schwerkraftrichtung oberhalb des Türflügels am Rahmen angeordnet, wobei der Türflügel mittels des Führungsgleiters an der Führungsschiene geführt ist und entlang der Führungsschiene verfahren bzw. verschoben werden kann.The door leaf can be moved or shifted via one or more carriages along a running rail arranged in the direction of gravity below the door leaf on the frame. The guide rail is arranged in the direction of gravity above the door leaf on the frame, with the door leaf being guided on the guide rail by means of the guide slider and being able to be moved or shifted along the guide rail.

Im Rahmen einer bevorzugten Ausgestaltung können die ersten Kontaktelemente jeweils als, vorzugsweise konvex gewölbter, Metallstreifen ausgebildet sein. Dadurch ist ein einfaches und robustes Kontaktelement geschaffen, welches Fertigungs- und Montagetoleranzen in gewissem Umfang ausgleichen kann (Federwirkung). Dies trägt zu einem zuverlässigen elektrischen Kontakt zwischen den ersten Kontaktelementen und den Leiterelementen bei. Durch die Federwirkung wird sichergestellt, dass die ersten Kontaktelemente auch bei mechanischem Verschleiß (Abrieb) an den Leiterelementen anliegen (Übertragung elektrischer Energie möglich).Within the scope of a preferred embodiment, the first contact elements can each be designed as metal strips, preferably convexly curved. This creates a simple and robust contact element which can compensate for manufacturing and assembly tolerances to a certain extent (spring effect). This contributes to reliable electrical contact between the first contact elements and the conductor elements. The spring action ensures that the first contact elements are in contact with the conductor elements even in the case of mechanical wear (abrasion) (transmission of electrical energy possible).

Alternativ oder ergänzend können die zweiten Kontakteelemente jeweils als zu einem Ring oder zu einer Ellipse geformten Metallstreifen ausgebildet sein. Somit ist ein konstruktiv einfaches und stabiles Kontaktelement geschaffen, welches über einen vergleichsweise großen Bereich reversibel verformbar ist. Dies begünstigt einen Ausgleich von Fertigungs- und Montagetoleranzen und einen Ausgleich des Flügelhubs. Die zweiten Kontaktelemente sind quer zur Erstreckungsrichtung (Hubrichtung des Türflügels) so formstabil, dass das Risiko eines Ausknickens der zweiten Kontaktelemente weitgehend reduziert ist. Somit kann verhindert werden, dass sich die zweiten Kontaktelemente berühren und einen Kurzschluss einleiten.Alternatively or additionally, the second contact elements can each be designed as metal strips shaped into a ring or into an ellipse. A structurally simple and stable contact element is thus created which can be reversibly deformed over a comparatively large area. This favors a compensation of manufacturing and assembly tolerances and a compensation of the wing stroke. The second contact elements are so dimensionally stable transversely to the direction of extension (direction of lift of the door leaf) that the risk of the second contact elements buckling is largely reduced. It is thus possible to prevent the second contact elements from touching one another and initiating a short circuit.

In vorteilhafter Weise können die ersten Kontaktelemente und die zweiten Kontaktelemente jeweils mittels eines Kontaktblocks elektrisch miteinander verbunden sein, wobei jeweils ein erstes Kontaktelement und ein zweites Kontaktelement am Kontaktblock befestigt sind, insbesondere verschraubt sind. Auf diese Weise ist eine einfache mechanische und elektrische Verbindung der Kontaktelemente geschaffen. Durch Anordnung der Kontaktblöcke in entsprechenden Aussparungen im Führungsgleiter können die Kontaktblöcke und die Kontaktelemente am Führungsgleiter gesichert werden.Advantageously, the first contact elements and the second contact elements can each be electrically connected to one another by means of a contact block, with a first contact element and a second contact element being fastened to the contact block, in particular being screwed. In this way, a simple mechanical and electrical connection of the contact elements is created. By arranging the contact blocks in corresponding recesses in the guide slider, the contact blocks and the contact elements can be secured on the guide slider.

Die ersten Kontaktelemente können jeweils an einem Ende (Befestigungsabschnitt) mittels einer Schraube am Kontaktblock verschraubt werden. Von diesem Ende (festes Ende) können sich die ersten Kontaktelemente jeweils zu einem freien Ende erstrecken. Am Kontaktelement kann eine Vertiefung für den Befestigungsabschnitt des ersten Kontaktelements ausgebildet sein. Dadurch kann ein Verdrehen des ersten Kontaktelements relativ zum Kontaktblock verhindert werden.The first contact elements can each be screwed to the contact block at one end (attachment section) by means of a screw. The first contact elements can each extend from this end (fixed end) to a free end. A depression for the fastening section of the first contact element can be formed on the contact element. This can prevent the first contact element from twisting relative to the contact block.

Die zweiten Kontaktelemente können jeweils an einer Stelle unterbrochen sein, wobei an der Unterbrechung nach außen abstehende Nasen ausgebildet sind. Diese Nasen können in eine Öffnung am Führungsgleiter eingesteckt werden und am Kontaktblock anliegen. Mittels eines die Unterbrechung bedeckenden Halteblechs und einer durch die Unterbrechung hindurchgeführten Schraube können die zweiten Halteelemente jeweils am Kontaktblock verschraubt werden. Durch Positionierung der Nasen in den Öffnungen im Führungsgleiter ("Zwangsposition") ist die korrekte Position sichergestellt und die zweiten Kontaktelemente können sich nicht verdrehen.The second contact elements can each be interrupted at one point, with outwardly protruding lugs being formed at the interruption. These lugs can be inserted into an opening on the guide slider and rest against the contact block. The second holding elements can each be screwed to the contact block by means of a holding plate covering the interruption and a screw passed through the interruption. By positioning the lugs in the openings in the guide slider ("forced position"), the correct position is ensured and the second contact elements cannot twist.

In zweckmäßiger Weise können die ersten Kontaktelemente entlang der Mittellängsrichtung des Führungsgleiters (Verschieberichtung) versetzt zueinander angeordnet sein. Dadurch kann die Bauhöhe des Führungsgleiters gering gehalten werden. Zudem lässt sich somit das Risiko von Kurzschlüssen reduzieren.Expediently, the first contact elements can be offset from one another along the central longitudinal direction of the guide slider (displacement direction). As a result, the overall height of the guide slider can be kept low. This also reduces the risk of short circuits.

In vorteilhafter Weise können die zweiten Kontaktelemente entlang der Mittellängsrichtung des Führungsgleiters (Verschieberichtung) versetzt zueinander angeordnet sein. Dadurch lässt sich eine geringere lokale Bauteilschwächung des Führungsgleiters erreichen. Zudem ist die Gefahr eines Kurzschlusses durch gegenseitige Berührung der zweiten Kontaktelemente reduziert.Advantageously, the second contact elements can be offset from one another along the central longitudinal direction of the guide slider (displacement direction). As a result, a lower local component weakening of the guide slider can be achieved. In addition, the risk of a short circuit due to the second contact elements touching one another is reduced.

Im Rahmen einer bevorzugten Ausgestaltung können im Führungsgleiter sich entlang der Mittellängsrichtung des Führungsgleiters (Verschieberichtung) erstreckende konkave Ausnehmungen ausgebildet sein, in denen jeweils ein zweites Kontaktelement sitzt. Dies erleichtert Ausrichtung und Montage der zweiten Kontaktelemente. Zudem ist somit eine Sicherung gegen Verdrehen oder Verbiegen der zweiten Kontaktelemente geschaffen. Die zweiten Kontaktelemente sind abschnittsweise in der Ausnehmung angeordnet und erstrecken sich ausgehend von der Ausnehmung vom Führungsgleiter weg. Die Ausnehmungen sind entlang der Mittellängsrichtung des Führungsgleiters (Verschieberichtung) versetzt zueinander angeordnet.Within the framework of a preferred embodiment, concave recesses can be formed in the guide slider that extend along the central longitudinal direction of the guide slider (displacement direction), in each of which a second contact element is seated. This facilitates alignment and assembly of the second contact elements. In addition, a safeguard against twisting or bending of the second contact elements is thus created. The second contact elements are arranged in sections in the recess and, starting from the recess, extend away from the guide slider. The recesses are offset from one another along the central longitudinal direction of the guide slider (direction of displacement).

In zweckmäßiger Weise kann im Führungsgleiter ein Antriebselement (bspw. ein Zahnrad) angeordnet sein, welches ein am Rahmen befestigtes Abtriebselement antreibt, bspw. einen Zahnriemen, der offene Enden aufweist und am Rahmen befestigt ist. Dadurch ist auch eine Antriebsfunktion in den Führungsgleiter integriert. Das Zahnrad kann drehfest mit einer Welle gekoppelt sein oder einen Wellenabschnitt aufweisen, worüber das Zahnrad mit einer flügelseitigen elektrischen Antriebseinheit gekoppelt werden kann. Am Führungsgleiter können zudem Umlenkrollen, entsprechende Aussparungen und ein Halteblech vorgesehen sein.A drive element (e.g. a toothed wheel) can expediently be arranged in the guide slider, which drives an output element fastened to the frame, for example a toothed belt which has open ends and is fastened to the frame. As a result, a drive function is also integrated into the guide slider. The gear can be rotatably coupled to a shaft or have a shaft section, via which the gear wheel can be coupled to a wing-side electric drive unit. Deflection rollers, corresponding recesses and a retaining plate can also be provided on the guide slider.

In vorteilhafter Weise können die Leiterelemente mittels eines elektrisch isolierenden und sich entlang der Führungsschiene erstreckenden Leiterelementträgers an oder in der Führungsschiene befestigt sein, wobei die Leiterelemente mittels einer Schnappverbindung am Leiterelementträger befestigt sein können und/oder wobei der Leiterelementträger mittels einer Schnappverbindung an der Führungsschiene befestigt sein kann. Dies begünstigt die Montage, indem die Bauelemente (lösbar oder unlösbar) formschlüssig gefügt werden können. Der Leiterelementträger ist als elastisch verformendes Fügeteil ausgebildet, bspw. aus Kunststoff.Advantageously, the conductor elements can be attached to or in the guide rail by means of an electrically insulating conductor element carrier that extends along the guide rail, wherein the conductor elements can be attached to the conductor element carrier by means of a snap connection and/or the conductor element carrier can be attached to the guide rail by means of a snap connection can. This facilitates assembly, as the components (detachable or non-detachable) can be joined in a form-fitting manner. The conductor element carrier is designed as an elastically deforming joining part, for example made of plastic.

Am Leiterelementträger können in Längsrichtung orientierte Nuten für die Leiterelemente ausgebildet sein, die jeweils ein (eingesetztes) Leiterelement im Querschnitt mehr als hälftig umgreifen, bspw. um mehr als 180°. An der Führungsschiene kann ein sich entlang der Längsrichtung der Führungsschiene erstreckende Steg mit zapfenförmigem Querschnitt ausgebildet sein, wobei am Leiterelementträger eine korrespondierende Stegaufnahme ausgebildet ist, die den Steg (im eingesetzten Zustand) im Querschnitt mehr als hälftig umgreift, bspw. um mehr als 180°.Longitudinally oriented grooves for the conductor elements can be formed on the conductor element carrier, each of which more than half encompasses an (inserted) conductor element in cross section, for example by more than 180°. A web extending along the longitudinal direction of the guide rail and having a peg-shaped cross section can be formed on the guide rail, with a corresponding web receptacle being formed on the conductor element carrier, which encompasses the web (in the inserted state) in cross section by more than half, e.g. by more than 180° .

Im Rahmen einer bevorzugten Ausgestaltung kann an der (in Einbaulage) der Führungsschiene zugewandten Schmalseite des Türflügels (Flügeloberseite) eine Kontaktierungseinheit befestigt sein, wobei die Kontaktierungseinheit eine isolierende Trägerplatte und zwei an der Trägerplatte befestigte Kontaktbleche aufweist, wobei die Kontaktflächen jeweils durch eine der Führungsschiene zugewandte Oberfläche der Kontaktbleche ausgebildet sind. Dies begünstigt eine konstruktiv einfache und robuste Ausgestaltung der Kontaktflächen. An den Kontaktblechen können Anschlussfahnen zum elektrischen Anschluss an flügelseitige Energieverbraucher ausgebildet sein, wie bspw. eine Steuerung.As part of a preferred embodiment, a contacting unit can be attached to the narrow side of the door leaf (upper side of the leaf) facing the guide rail (in the installed position), the contacting unit having an insulating carrier plate and two contact plates attached to the carrier plate, with the contact surfaces each facing through one of the guide rails Surface of the contact plates are formed. This favors a structurally simple and robust configuration of the contact surfaces. Terminal lugs for electrical connection to wing-side energy consumers, such as a controller, can be formed on the contact plates.

In vorteilhafter Weise kann an der Trägerplatte für jedes Kontaktblech eine Tasche ausgebildet sein, die das Kontaktblech jeweils zumindest abschnittsweise aufnimmt, wobei an jeder Tasche eine oder mehrere Rastnasen ausgebildet sind, so dass das Kontaktblech mittels einer Rastverbindung an der Trägerplatte befestigbar oder befestigt ist. Dies erleichtert Fertigung und Montage.Advantageously, a pocket can be formed on the carrier plate for each contact plate, which accommodates the contact plate at least in sections, one or more latching lugs being formed on each pocket, so that the contact plate can be fastened or is fastened to the carrier plate by means of a snap-in connection. This facilitates manufacture and assembly.

In zweckmäßiger Weise kann rahmenseitig eine elektrische Energieversorgung (bspw. ein Netzteil) vorgesehen sein, die über Anschlussleitungen elektrisch mit (elektrischen) Kontaktelementen einer Steckeinheit (Anschlussstecker) verbunden ist, wobei die Steckeinheit in die Führungsschiene einschiebbar ist und die Kontaktelemente beim Einschieben in die Führungsschiene in elektrischen Kontakt mit den Leiterelementen gelangen. Dies trägt zu einer einfachen elektrischen Kontaktierung bei und begünstigt die Montage. Die Steckeinheit kann komplementär (teilkomplementär oder vollkomplementär) zur Führungsschiene ausgebildet sein. Die Kontaktelemente der Steckeinheit können als konkav geformte Metallstreifen ausgebildet sein. Die Kontaktelemente der Steckeinheit können konstruktiv den ersten Kontaktelementen des Führungsgleiters entsprechen.An electrical power supply (e.g. a power supply unit) can expediently be provided on the frame side, which is electrically connected via connecting lines to (electrical) contact elements of a plug-in unit (connector plug), the plug-in unit being able to be pushed into the guide rail and the contact elements being pushed into the guide rail come into electrical contact with the conductor elements. This contributes to a simple electrical contact and facilitates the assembly. The plug-in unit can be designed to be complementary (partially complementary or fully complementary) to the guide rail. The contact elements of the plug-in unit can be designed as concave metal strips. The contact elements of the plug-in unit can structurally correspond to the first contact elements of the guide slider.

Die Kontaktelemente können jeweils mittels eines Kontaktblocks an der Steckeinheit befestigt sein, wobei der Kontaktblock in eine dafür vorgesehene Öffnung in der Steckeinheit eingesetzt ist. Die Kontaktblöcke können den oben im Zusammenhang mit den ersten und zweiten Kontaktelementen am Führungsgleiter beschriebenen Kontaktblöcken entsprechen. Durch einen höheren Anteil an Gleichteilen kann hiermit die Fertigung begünstigt werden.The contact elements can each be attached to the plug-in unit by means of a contact block, with the contact block being inserted into an opening provided for this purpose in the plug-in unit. The contact blocks can correspond to the contact blocks described above in connection with the first and second contact elements on the guide slider. The production can be favored by a higher proportion of identical parts.

In vorteilhafter Weise kann als Verbraucher eine flügelseitig angeordnete Steuerung vorgesehen sein, die eine Datenübertragungseinrichtung aufweist, wobei die elektrische Energieversorgung (bspw. Netzteil) ebenfalls eine Datenübertragungseinrichtung aufweist, wobei die Datenübertragungseinrichtungen jeweils zum Senden und Empfangen von auf elektrische Leitungen aufmodulierten Datensignalen ausgebildet sind und wobei die Datenübertragungseinrichtungen elektrisch miteinander verbunden sind. Somit ist zwischen Steuerung und Energieversorgung eine bidirektionale Kommunikation möglich. Es können mit der elektrischen Verbindung nicht nur elektrische Energie, sondern auch Signale übertragen werden. Somit können Energieversorgung (bspw. das Netzteil) und Steuerung Signale, bspw. Steuersignale austauschen. Die elektrische Verbindung kann die Anschlussleitungen, die Steckeinheit, die Leiterelemente, den Führungsgleiter, die Kontaktierungseinheit und hiervon abgehende Anschlussfahnen umfassen, an denen eine flügelseitige Steuerung angeschlossen ist.A controller arranged on the wing side can advantageously be provided as a consumer, which has a data transmission device, the electrical energy supply (e.g. power supply unit) likewise having a data transmission device, the data transmission devices each being designed to transmit and receive data signals modulated onto electrical lines and wherein the data transmission devices are electrically connected to one another. Bidirectional communication is thus possible between the controller and the power supply. It cannot with the electrical connection only electrical energy but also signals can be transmitted. In this way, the energy supply (e.g. the power pack) and the controller can exchange signals, e.g. control signals. The electrical connection can include the connecting lines, the plug-in unit, the conductor elements, the guide slider, the contacting unit and connecting lugs extending therefrom, to which a wing-side control is connected.

In zweckmäßiger Weise kann flügelseitig als (weiterer) Verbraucher eine elektrische Antriebseinheit zum Verschieben des Türflügels angeordnet sein, wobei die Antriebseinheit das im Führungsgleiter angeordnete Antriebselement (Zahnrad) antreibt. Dies erlaubt ein automatisches Verschieben des Türflügels. Die elektrische Antriebseinheit kann durch die Steuerung angesteuert werden. Die Antriebseinheit kann einen Elektromotor aufweisen, dem optional ein Untersetzungsgetriebe nachgeschaltet sein kann (Untersetzungsgetriebe zwischen Elektromotor und Antriebselement).Expediently, an electric drive unit for moving the door leaf can be arranged on the wing side as a (further) consumer, with the drive unit driving the drive element (gear wheel) arranged in the guide slider. This allows the door leaf to be moved automatically. The electric drive unit can be controlled by the controller. The drive unit can have an electric motor, which can optionally be followed by a reduction gear (reduction gear between electric motor and drive element).

In vorteilhafter Weise kann zwischen der elektrischen Antriebseinheit und dem Antriebselement (Zahnrad) eine (manuell oder motorisch betätigbare) Kupplungseinrichtung vorgesehen sein, mittels welcher wahlweise ein Kraftfluss zwischen der Antriebseinheit und dem Antriebselement herstellbar und ein Kraftfluss zwischen der Antriebseinheit und dem Antriebselement unterbrechbar ist. Dies erleichtert ein An- und Abkoppeln der elektrischen Antriebseinheit vom Führungsgleiter bzw. vom Antriebselement. Dies begünstigt eine Montage des Türflügels am Rahmen und auch dessen Demontage.Advantageously, a (manually or motor-operated) clutch device can be provided between the electric drive unit and the drive element (gear wheel), by means of which a power flow can be established between the drive unit and the drive element and a power flow between the drive unit and the drive element can be interrupted. This makes it easier to connect and disconnect the electric drive unit from the vehicle Guide slider or from the drive element. This favors assembly of the door leaf on the frame and also its disassembly.

Im Rahmen einer bevorzugten Ausgestaltung kann ein flügelseitig angeordneter Akkumulator zur Energieversorgung von flügelseitig angeordneten Verbrauchern elektrischer Energie vorgesehen sein, bspw. von Steuerung und/oder elektrischer Antriebseinheit. Dadurch kann ein automatisches Verschieben des Türflügels auch dann erfolgen, wenn eine netzgebundene Energieversorgung, bspw. das Stromnetz gestört ist. Zudem können dadurch die zu übertragenden Stromstärken gering gehalten werden, so dass die elektrischen Leitungen und Kontakte geringer ausgelegt werden können.Within the scope of a preferred embodiment, an accumulator arranged on the wing side can be provided for supplying energy to consumers of electrical energy arranged on the wing side, for example the controller and/or the electric drive unit. As a result, the door leaf can also be moved automatically if a mains-connected energy supply, for example the mains power supply, is disrupted. In addition, the current levels to be transmitted can be kept low as a result, so that the electrical lines and contacts can be designed to be smaller.

Im Konkreten kann die Energieversorgung der Schiebetüranordnung derart eingerichtet sein, dass die durch die Energieversorgung an die Steuerung bzw. den Akku bereitgestellte elektrische Leistung nicht zum Antrieb der elektrischen Antriebseinheit ausreichen würde. Eine Energieversorgung dieser Komponenten ist durch den Akkumulator sichergestellt, der über die elektrische Verbindung zwischen Rahmen und Türflügel ggf. dauerhaft geladen werden kann.In concrete terms, the energy supply of the sliding door arrangement can be set up in such a way that the electrical power provided by the energy supply to the controller or the battery would not be sufficient to drive the electrical drive unit. An energy supply to these components is ensured by the accumulator, which can be permanently charged via the electrical connection between the frame and the door leaf.

In vorteilhafter Weise kann an der Schiebetüranordnung ein weiterer Türflügel vorgesehen sein, der am Rahmen geführt und relativ zum Rahmen verschiebbar ist. Somit ist ein Hebe-Schiebetür-Verbund mit mehreren Türflügeln geschaffen.Advantageously, a further door leaf can be provided on the sliding door arrangement, which is guided on the frame and can be displaced relative to the frame. This creates a lift/sliding door combination with several door leaves.

Der weitere Türflügel kann analog zu dem voranstehend beschriebenen Türflügel ausgebildet sein. So kann der weitere Türflügel die Komponenten aufweisen, die auch der oben beschriebene (erste) Türflügel aufweist.The other door leaf can be designed analogously to the door leaf described above. The additional door leaf can thus have the components that the (first) door leaf described above also has.

Bspw. kann der weitere Türflügel eine flügelseitig angeordnete Steuerung aufweisen, die eine Datenübertragungseinrichtung aufweist, welche zum Senden und Empfangen von auf elektrische Leitungen aufmodulierten Datensignalen ausgebildet und mit Datenübertragungseinrichtungen der rahmenseitigen Energieversorgung (bspw. Netzteil) und/oder der flügelseitig angeordneten Steuerung des (ersten) Türflügels elektrisch verbunden ist.For example, the further door leaf can have a control arranged on the leaf side, which has a data transmission device which is designed to send and receive data signals modulated onto electrical lines and is connected to data transmission devices for the power supply on the frame (e.g. power pack) and/or the control on the leaf side of the (first ) door leaf is electrically connected.

Somit können Datensignale nicht nur zwischen Netzteil und Steuerung des (ersten) Türflügels, sondern auch zwischen (erstem) Türflügel und weiterem Türflügel übertragen werden. Somit kann ein Verbund aus mehreren elektrisch miteinander verbundenen Türflügel Steuer- und/oder Statusinformationen austauschen.In this way, data signals can be transmitted not only between the power pack and the controller of the (first) door leaf, but also between the (first) door leaf and the other door leaf. In this way, a combination of several door leaves that are electrically connected to one another can exchange control and/or status information.

Die im Führungsgleiter angeordneten Antriebskomponenten und die Kupplungseinrichtung kann ausgebildet sein wie in

Die Erfindung wird im Folgenden anhand der Figuren näher erläutert, wobei gleiche oder funktional gleiche Elemente mit identischen Bezugszeichen versehen sind, ggf. jedoch lediglich einmal. Es zeigen:

- Fig.1

- ein Ausführungsform einer Schiebetüranordnung in einer schematischen Schnittansicht;

- Fig.2a,b

- die Führungsschiene der Schiebetüranordnung aus

Fig.1 in Explosionsdarstellung (Figur 2a ) und im montierten Zustand (Figur 2b ) jeweils in schematischer Schnittansicht; - Fig.3

- die Steckeinheit der Schiebetüranordnung aus

Fig.1 in einer perspektivischen Ansicht; - Fig.4

- die Führungsschiene und den Festrahmen der Schiebetüranordnung aus

Fig.1 in einer Schnittansicht mit montierter Steckeinheit; - Fig.5

- den Führungsgleiter der Schiebetüranordnung aus

Fig.1 im montierten Zustand in einem perspektivischen Teilschnitt; - Fig.6

- die Kontaktierungseinheit der Schiebetüranordnung aus

Fig.1 in einer perspektivischen Ansicht; - Fig.7a,b

- den Führungsgleiter der Schiebetüranordnung in Alleinstellung in perspektivischer Ansicht, einmal im montierten Zustand (

Fig.7a ) und einmal in einer Explosionsdarstellung (Fig.7b ); und

- Fig.8

- die elektrische Antriebseinheit und die Kupplungseinrichtung der Schiebetüranordnung aus

Fig.1 in einer schematischen Schnittansicht.

- Fig.1

- an embodiment of a sliding door assembly in a schematic sectional view;

- Fig.2a,b

- the guide rail of the sliding door assembly

Fig.1 in exploded view (Figure 2a ) and when assembled (Figure 2b ) each in a schematic sectional view; - Fig.3

- the plug-in unit of the sliding door assembly

Fig.1 in a perspective view; - Fig.4

- the guide rail and the fixed frame of the sliding door assembly

Fig.1 in a sectional view with the assembled plug-in unit; - Fig.5

- the guide slider of the sliding door arrangement

Fig.1 in the assembled state in a perspective partial section; - Fig.6

- the contacting unit of the sliding door arrangement

Fig.1 in a perspective view; - Fig. 7a,b

- the guide slider of the sliding door arrangement on its own in a perspective view, once in the assembled state (

Fig.7a ) and once in an exploded view (Fig.7b ); and

- Fig.8

- the electric drive unit and the clutch device of the sliding door arrangement

Fig.1 in a schematic sectional view.

Der Rahmen 12 weist einen unteren Rahmenteil 16, einen oberen Rahmenteil 18 und zwei seitliche Rahmenteile 20 auf (nur ein seitlicher Rahmenteil 20 dargestellt). Der Türflügel 14 weist einen Flügelrahmen 22 auf, der ein Flügelfeld 24 begrenzt, bspw. eine Verglasung. Der Flügelrahmen 22 weist ein unteres Profil 26, ein oberes Profil 28 und seitliche Profile 30, 32 auf.The

Am unteren Rahmenteil 16 des Rahmens 12 ist eine Laufschiene 34 angeordnet. Der Türflügel 14 weist am unteren Profil 26 zwei Laufwägen 36, 38 auf, die in der Laufschiene 34 laufen. Mittels der Laufwägen 36, 38 kann der Türflügel 14 relativ zum Rahmen 12 verschoben werden. Am oberen Rahmenteil 18 des Rahmens 12 ist eine Führungsschiene 40 angeordnet. In der Führungsschiene 40 ist ein Führungsgleiter 42 verschieblich geführt. Der Türflügel 14 ist mit dem Führungsgleiter 42 gekoppelt und dadurch am oberen Ende des Türflügels 14 geführt.A running

Der Türflügel 14 ist als Hebe-/Schiebeflügel ausgebildet, welcher nicht nur horizontal verschiebbar ist, sondern auch angehoben und abgesenkt werden kann. In einem angehobenen Zustand des Türflügels 14 kann dieser relativ zum Rahmen 12 horizontal verschoben werden. In einem abgesenkten Zustand des Türflügels 14 ist eine wirksame Abdichtung des Türflügels 14 relativ zum Rahmen 12 begünstigt.The

Im seitlichen Rahmenteil 20 des Rahmens 12 ist eine elektrische Energieversorgung 44 in Form eines Netzteils angeordnet, bspw. ein 230Volt/24Volt Netzteil. Diese ist über Anschlussleitungen (nicht dargestellt) elektrisch mit einer Steckeinheit 46 verbunden, die stirnseitig in die Führungsschiene 40 eingesteckt ist. Am oberen Profil 28 des Türflügels 14 ist eine Kontaktierungseinheit 48 angeordnet. Der Türflügel 14 weist am oder im seitlichen Profil 32 mehrere Komponenten auf, die mit elektrischer Energie versorgt werden müssen, und zwar eine elektrische Antriebseinheit 50, eine elektrische/elektronische Steuerung 52 und einen Akkumulator 54.An

In der Führungsschiene 40 sind zwei Leiterelemente 66, 68 angeordnet, die sich entlang der Längsrichtung der Führungsschiene 40 erstrecken. Die Leiterelemente 66, 68 sind mittels eines elektrisch isolierenden und sich entlang der Führungsschiene 40 erstreckenden Leiterelementträgers 70 in der Führungsschiene 40 befestigt. Eine Befestigung erfolgt mittels Schnappverbindungen.Two

Der Leiterelementträger 70 ist elastisch verformbar ausgebildet, bspw. aus Kunststoff. Am Leiterelementträger 70 sind Längsnuten 72, 74 ausgebildet, in die jeweils ein Leiterelement 66, 68 eingesetzt werden kann. Die Längsnuten 72, 74 umgreifen die Leiterelemente 66, 68 im eingesetzten Zustand im Querschnitt mehr als hälftig. In der Führungsschiene 40 ist zudem ein sich entlang der Längsrichtung der Führungsschiene 40 erstreckender Steg 76 mit zapfenförmigem Querschnitt ausgebildet. Am Leiterelementträger 70 ist eine korrespondierende Stegaufnahme 78 ausgebildet, die den Steg 76 im eingesetzten Zustand im Querschnitt mehr als hälftig umgreift.The

Die Steckeinheit 46 weist elektrische Kontaktelemente 82, 84 auf, die als konkav geformte Metallstreifen ausgebildet sind (vgl.