EP3835539B1 - Kit for a frame - Google Patents

Kit for a frame Download PDFInfo

- Publication number

- EP3835539B1 EP3835539B1 EP19215877.2A EP19215877A EP3835539B1 EP 3835539 B1 EP3835539 B1 EP 3835539B1 EP 19215877 A EP19215877 A EP 19215877A EP 3835539 B1 EP3835539 B1 EP 3835539B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- frame

- corner connector

- kit

- another

- connector part

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000000712 assembly Effects 0.000 claims description 54

- 238000000429 assembly Methods 0.000 claims description 54

- 241000238631 Hexapoda Species 0.000 claims description 15

- 238000003780 insertion Methods 0.000 claims description 6

- 230000037431 insertion Effects 0.000 claims description 6

- 238000004806 packaging method and process Methods 0.000 claims description 3

- 238000000465 moulding Methods 0.000 description 4

- 238000011161 development Methods 0.000 description 2

- 230000018109 developmental process Effects 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/52—Devices affording protection against insects, e.g. fly screens; Mesh windows for other purposes

- E06B9/522—Dimensionally adjustable fly screens

Definitions

- the present invention relates to a kit for a frame, in particular for a frame of an insect protection device, such as an insect protection door, insect protection window or light well cover.

- an insect protection net or grid is attached to the frame, with which the opening spanned by the frame is or can be spanned.

- Such frames for insect screens generally have two parallel vertical frame struts and two horizontal frame struts connecting the parallel vertical frame struts, the frame struts being connected at their ends by means of corner connectors.

- the components corner connectors, frame struts

- the components are usually provided to the end user as individual parts in a package, so that the end user has to assemble all the components himself.

- the frame struts are designed as one-piece profile strips, the end user must shorten the profile strips himself to adapt them to the window/door size. This makes it easier to adjust the length of the frame struts to the window/door size can be adjusted, it is also known to form the frame struts from at least one inner profile bar and at least one outer profile bar, which are mutually telescopic.

- the corner connector parts of such kits have plug-in sections which are arranged at right angles to one another and which the end user must plug into a profile strip. In this case, there is only a non-positive connection between the plug-in section of the corner connector and the profile strip in the plug-in direction, so that the mounted frame can have little stability. In addition, after assembly, a corner area of the corner connector is visible between the plug-in sections.

- kits for frames known from the prior art therefore have either a large number of parts to be assembled by the end user or a relatively large package.

- the object of the present invention is therefore to eliminate the disadvantages described with reference to the prior art and in particular to specify a kit for a frame which can be assembled more easily by the end user and whose packaging has the smallest possible volume.

- kits with the features of the respective independent claims 1 and 5.

- Advantageous developments of the kit are given in the dependent claims and in the description, with individual features of the advantageous developments being able to be combined with one another in a technically sensible manner.

- kit for a frame preferably for a frame of an insect protection device, with at least two frame assemblies, each frame assembly having at least one, preferably at least two or exactly two profile strip(s) (such as inner profile strip and/or outer profile strip) and at least a corner connector part arranged on each profile strip, wherein the profile strips and the corner connector parts of the frame assembly are designed in such a way that the profile strips of all frame assemblies are arranged or can be arranged parallel to one another in a starting position and the frame assemblies can be plugged together to form a rectangular frame, in which two profile strips each are arranged telescopically to one another.

- profile strip(s) such as inner profile strip and/or outer profile strip

- the kit comprises in particular an even number of (pre-assembled) frame assemblies, with each frame assembly in particular having exactly two inner and/or outer profile strips (namely: each frame assembly has either an inner profile strip and an outer profile strip, two inner profile strips or two outer slats) or exactly four inner and/or outer slats (namely: each frame assembly has two inner slats and two outer slats).

- each profile bar A corner connector part is also arranged in the frame assembly, for which purpose the corner connector part is either designed in one piece with the profile strip or is preferably non-positively and/or positively connected as a preassembled part to the profile strip.

- corner connector which connects the profile strips arranged at right angles to one another in the final assembled state, to consist of at least two parts (corner connector parts).

- corner connector parts are designed in such a way that they can be plugged into one another or are connected to one another so that they can pivot relative to one another, forming a type of hinge.

- the profile strips of all frame assemblies can therefore initially be arranged parallel (aligned or offset) to one another, so that the pre-assembled frame assemblies can be arranged in a package to save space.

- the frame assemblies are plugged together, with the corner connector parts of different frame assemblies being plugged into one another or inner profile strips and outer profile strips of different frame assemblies being telescopically aligned with one another, with an inner profile strip of a first frame assembly being telescopically inserted/slide into the outer profile strip of a second frame assembly.

- the profile strips of a frame assembly which are connected via two corner connector parts arranged pivotably relative to one another, to first be pivoted into a right angle.

- the kit can include further inner and/or outer profile strips, via which the profile strips of different frame assemblies can be telescopically connected to one another during assembly.

- the size of the frame can be easily changed by sliding the inner and outer profile strips of the frame struts telescopically towards one another. If the frame has the desired size, it can be fixed in size with suitable means (screws, insect screens, fixing strips).

- the assembly kit according to the invention for a frame therefore has not only a very small number of frame assemblies to be assembled by the end user, but also a very small volume in the starting position.

- the frame assemblies each have two profile strips, which are arranged pivotably to one another, so that the two profile strips of the frame assembly are arranged parallel (aligned or offset) to one another in the initial position and can be pivoted into a position at right angles to one another before they are plugged together.

- a corner connector part is arranged on each profile strip, via which the profile strips can be pivoted relative to one another.

- a pivot axis is formed between the two corner connector parts, about which the profile strips can be pivoted relative to one another.

- the at least one pivot axis can be arranged in such a way that the profile strips are arranged next to one another in the initial position.

- the pivot axis can be arranged in such a way that the profile strips are arranged in alignment with one another, in which case the frame assembly has a greater length in the starting position.

- the kit has exactly four frame assemblies, the two profile strips of which can be pivoted relative to one another, the profile strips being designed as an inner profile strip and/or outer profile strip and with the inner profile strip of a first frame assembly in the right-angled position the outer profile strip of a second frame assembly can be inserted.

- the inner profile strip and the outer profile strip are matched to one another in terms of their outer contour or inner contour in such a way that they can be inserted into one another and telescopically moved/displaced relative to one another.

- the two profile strips of a frame assembly arranged pivotably relative to one another can be pivoted relative to one another about at least one pivot axis, with the pivot axes of all frame assemblies having a pivot axis being aligned parallel and in particular orthogonal to the plane spanned by the right-angled frame in the final assembly position.

- the profile strips of the frame assemblies can therefore all be pivoted in a plane spanned by the subsequent frame.

- the two profile strips are preferably secured in the right-angled position by a fixation.

- this fixation acts on the corner connector parts of the frame assemblies, which are designed to be pivotable relative to one another.

- the corner connector parts can be fixed in their mutually perpendicular position, for example, by an external fixing element such as a screw, pin or cover cap.

- corner connector parts themselves are designed in such a way that they are fixed in the right-angled position.

- the corner connector parts can be designed to form a snap or snap-in connection.

- a corner connector part has, for example, a resiliently deflectable element that is deflected when the corner connector parts are pivoted and, in the right-angled position, engages in a corresponding snap-in receptacle on the other corner connector part.

- a first corner connector part of a first frame assembly and a second corner connector part of a second frame assembly are designed to match one another in such a way that the first corner connector part can be inserted into the second corner connector part.

- the second corner connector part for example, has a receptacle whose inner contour is designed in such a way that the first corner connector part can be inserted into the second corner connector part.

- the corner connector which connects the two profile strips arranged at right angles to one another in a corner when assembled, consists of two components (corner connector parts) that are only plugged into one another during assembly by the end user.

- the plug-in connection between the first corner connector part of the first frame assembly and the second corner connector part of the second frame assembly is secured by a fixation.

- an external fixing element such as a screw, pin or cover cap can be designed for this purpose.

- the fixation is formed by a snap or latching connection formed on the first corner connector part and the second corner connector part.

- the first corner connector part or the second corner connector part has a latching element which is elastically (resiliently) deflected when mated and latches into a corresponding latching receptacle on the other corner connector part in the mated position.

- the kit has exactly four frame assemblies in this context, which each have a corner connector part at their two ends, which are designed to produce a plug-in connection.

- Each frame assembly has, in particular, an inner profile strip and an outer profile strip, which are telescopically inserted into one another (and thus parallel to one another) even in the starting position.

- the profile strips or a pair of profile strips can be arranged pivotably relative to one another and at their starting position free ends each have a corner connector part, which are designed to produce a plug connection with the corner connector parts of the other frame assembly.

- a pair of profile strips formed from an inner profile strip and an outer profile strip is pivotably connected via a corner connector part to another pair of profile strips formed from an inner profile strip and an outer profile strip, with corner connector parts being formed on the free ends (facing away from the pivotably designed corner connector parts) to form a plug connection are.

- This kit therefore includes exactly two frame assemblies to form a rectangular frame.

- the preassembled frame assembly comprises a corner connector part inserted into a profile strip

- one aspect of the invention provides that the corner connector part is inserted into the profile strip with an insertion section.

- the corner connector part is designed in particular in such a way that the section of the corner connector part that protrudes beyond the end of the profile strip does not protrude more than a few millimeters beyond the outer contour of the profile strip. A particularly compact arrangement of the frame assemblies in the starting position is thus possible.

- the kit is presented in a package in which the frame assemblies are placed, with the moldings of all the frame assemblies being parallel to each other when the kit is placed in the package.

- a frame is also proposed which is assembled from a kit described above.

- the frame is intended in particular for forming an insect protection device, for which purpose an insect protection net/grid (possibly also pleated) that is included in the kit can be attached to the frame.

- the insect screen may be provided for a window where the assembled frame has four frame braces (two vertical and two vertical). aligned horizontally).

- the frame can also be designed for an insect protection device for a door, for which purpose the assembled frame has, in addition to the outer frame struts, a center strut which, in the assembled state, is aligned in particular horizontally and connects the side frame struts of the insect protection door to one another, with a center connector connecting the outer frame struts with the center frame brace.

- the middle frame strut can be connected to the other frame struts via corresponding corner connector parts.

- a center connector can consist of three corner connector parts that can be pivoted to one another, so that a frame assembly that has the profile strips of the center strut has three profile strips (two profile strips for the outer frame strut and one profile strip for the middle frame strut).

- the corner connector parts for forming the central connector can be designed in such a way that three corner connector parts of different frame assemblies, each arranged on a profile strip, can be plugged together.

- FIG 1 shows a first kit 1a with four identical, each pre-assembled frame assemblies 3.1, 3.2, 3.3 and 3.4.

- Each frame assembly 3.1 to 3.4 has an outer profile strip 4.1 into which a first corner connector part 5.1 is inserted with an insertion section (not visible in the figures).

- the first corner connector part 5.1 is connected via a pivot axis 6 to a second corner connector part 5.2, the second corner connector part 5.2 being inserted with an insertion section (not visible in the figures) into an inner profile strip 4.2.

- the frame assemblies 3.1 to 3.4 are shown in their starting position, in which the outer profile strip 4.1 and the inner profile strip 4.2 are arranged parallel to one another and offset from one another.

- figure 2 is shown how the outer profile bar 4.1 is pivoted to the inner profile bar 4.2 about the pivot axis 6 until the outer profile bar 4.1 and the inner profile bar 4.2 are arranged at a right angle to one another. In this right-angled orientation, a locking connection 7 is formed between the first corner connector part 5.1 and the second corner connector part 5.2, so that accidental pivoting back is prevented.

- the frame assemblies 3.1 to 3.4 of the first kit la can be arranged in their respective pivoted position to each other that the inner profile bar 4.2 of the first frame assembly 3.1 can be inserted into the outer profile bar 4.1 of the second frame assembly 3.2.

- the correspondingly assembled first frame 2a is in figure 4 shown.

- the size of the frame 2a can be easily changed due to the telescoping ability of the outer profile strips 4.1 and inner profile strips 4.2.

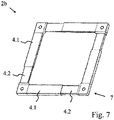

- FIG 5 a second kit 1b is shown, which has four identical, each pre-assembled frame assemblies 3.1, 3.2, 3.3 and 3.4.

- Each frame assembly 3.1 to 3.4 includes an outer profile bar 4.1 and an inner profile bar 4.2 (see also figure 7 ).

- a first corner connector part 5.3 is inserted into the outer profile strip 4.1, while a second corner connector part 5.4 is inserted into the inner profile strip 4.2.

- the first corner connector part 5.3 and the second corner connector part 5.4 are coordinated in their geometric design so that the first corner connector part 5.3 can be inserted into the second corner connector part 5.4, so that the profile strips 4.1 and 4.2 of the different frame assemblies are arranged at right angles to one another.

- FIG 6 a corresponding arrangement of the frame assemblies 3.1 to 3.4 of the second kit 1b is shown.

- the over the corner connector parts 5.3 and 5.4 assembled second frame 2b easily changed in size due to the telescoping of the outer profile strips 4.1 and inner profile strips 4.2.

- a third kit 1c is shown for a third frame 2c.

- the third kit 1c includes two identical, each pre-assembled frame assemblies 3.1 and 3.2. How in particular from together with figure 11 shows, each frame assembly 3.1 and 3.2 has a first corner connector 5.3, which is inserted into an inner profile bar 4.4, the inner profile bar 4.4 itself being pushed into a first outer profile bar 4.1.

- a corner connector part 5.1 is inserted into the first outer profile strip 4.1 and is pivotably connected via a pivot axis 6 to a corner connector part 5.2.

- the corner connector part 5.2 is in turn inserted into an inner profile strip 4.2.

- a second outer profile strip 4.3 is in turn pushed onto the inner profile strip 4.2, into which in turn a second corner connector part 5.4 is inserted.

- the moldings of the frame assemblies can be taken from the in figure 8 shown initial position, in which the profile strips are arranged parallel to one another, are pivoted about the pivot axis 6 until the figure 9 shown perpendicular position is reached. In this right-angled position, a locking connection 7 is formed between the corner connector part 5.1 and the corner connector part 5.2, so that unintentional pivoting back is prevented.

- both frame assemblies 3.1 and 3.2 After both frame assemblies 3.1 and 3.2 have been pivoted into the right-angled position, they can be aligned with one another, as is shown in figure 10 is shown. From this position, the first corner connector part 5.3 of the second frame assembly 3.2 can be inserted into the second corner connector part 5.4 of the first frame assembly 3.1, while the first corner connector part 5.3 of the first frame assembly 3.1 into the second Corner connector part 5.4 of the second frame assembly 3.2 can be inserted. The connection between the first corner connector part 5.3 and the second corner connector part 5.4 is secured against unintentional loosening by means of a locking connection 7 .

- the in figure 11 illustrated third frame 2c can be easily changed in size.

Description

Die vorliegende Erfindung betrifft einen Bausatz für einen Rahmen, insbesondere für einen Rahmen einer Insektenschutzvorrichtung, wie Insektenschutztür, Insektenschutzfenster oder Lichtschachtabdeckung. Zur Ausbildung einer Insektenschutzvorrichtung wird an dem Rahmen ein Insektenschutznetz oder -gitter angebracht, mit dem die von dem Rahmen aufgespannte Öffnung überspannt wird oder überspannt werden kann.The present invention relates to a kit for a frame, in particular for a frame of an insect protection device, such as an insect protection door, insect protection window or light well cover. To form an insect protection device, an insect protection net or grid is attached to the frame, with which the opening spanned by the frame is or can be spanned.

Solche Rahmen für Insektenschutzgitter weisen in der Regel zwei parallele vertikale Rahmenstreben und zwei die parallelen vertikalen Rahmenstreben verbindenden horizontale Rahmenstreben auf, wobei die Rahmenstreben an ihren Enden mittels Eckverbindern verbunden sind. Die Bauteile (Eckverbinder, Rahmenstreben) werden dem Endanwender in der Regel als Einzelteile in einer Verpackung bereitgestellt, sodass der Endanwender alle Bauteile selbst montieren muss. Wenn beispielsweise die Rahmenstreben als einteilige Profilleisten ausgebildet sind, so muss der Endanwender die Profilleisten zur Anpassung an die Fenster-/Türgröße entsprechend selbst kürzen. Damit die Rahmenstreben in ihrer Länge einfacher an die Fenster-/Türgröße angepasst werden können, ist es auch bekannt, die Rahmenstreben aus mindestens einer Innenprofilleiste und mindestens einer Außenprofilleiste auszubilden, die zueinander teleskopierbar sind.Such frames for insect screens generally have two parallel vertical frame struts and two horizontal frame struts connecting the parallel vertical frame struts, the frame struts being connected at their ends by means of corner connectors. The components (corner connectors, frame struts) are usually provided to the end user as individual parts in a package, so that the end user has to assemble all the components himself. If, for example, the frame struts are designed as one-piece profile strips, the end user must shorten the profile strips himself to adapt them to the window/door size. This makes it easier to adjust the length of the frame struts to the window/door size can be adjusted, it is also known to form the frame struts from at least one inner profile bar and at least one outer profile bar, which are mutually telescopic.

Die Eckverbinderteile solcher Bausätze weisen rechtwinklig zueinander angeordnete Einsteckabschnitte auf, die der Endanwender jeweils in eine Profilleiste einstecken muss. Hierbei liegt zwischen dem Einsteckabschnitt des Eckverbinders und der Profilleiste in der Einsteckrichtung nur eine kraftschlüssige Verbindung vor, sodass der montierte Rahmen eine geringe Stabilität aufweisen kann. Zudem ist nach der Montage ein Eckbereich des Eckverbinders zwischen den Einsteckabschnitten sichtbar.The corner connector parts of such kits have plug-in sections which are arranged at right angles to one another and which the end user must plug into a profile strip. In this case, there is only a non-positive connection between the plug-in section of the corner connector and the profile strip in the plug-in direction, so that the mounted frame can have little stability. In addition, after assembly, a corner area of the corner connector is visible between the plug-in sections.

Um einen ästhetisch ansprechenderen und zudem stabileren Rahmen bereitzustellen, schlägt

Die aus dem Stand der Technik bekannten Bausätze für Rahmen weisen also entweder eine große Anzahl von vom Endanwender zu montierenden Teilen oder eine relativ große Packung auf.The kits for frames known from the prior art therefore have either a large number of parts to be assembled by the end user or a relatively large package.

Aus

Aufgabe der vorliegenden Erfindung ist es daher, die mit Bezug zum Stand der Technik geschilderten Nachteile zu beseitigen und insbesondere einen Bausatz für einen Rahmen anzugeben, der vom Endanwender einfacher montierbar ist und dessen Verpackung ein möglichst kleines Volumen aufweist.The object of the present invention is therefore to eliminate the disadvantages described with reference to the prior art and in particular to specify a kit for a frame which can be assembled more easily by the end user and whose packaging has the smallest possible volume.

Gelöst wird die Aufgabe durch einen Bausatz mit den Merkmalen des jeweiligen unabhängigen Anspruchs 1 und 5. Vorteilhafte Weiterbildungen des Bausatzes sind in den abhängigen Ansprüchen und in der Beschreibung gegeben, wobei einzelne Merkmale der vorteilhaften Weiterbildungen in technisch sinnvoller Weise miteinander kombinierbar sind.The object is achieved by a kit with the features of the respective

Gelöst wird die Aufgabe insbesondere durch einen Bausatz für einen Rahmen, bevorzugt für einen Rahmen einer Insektenschutzvorrichtung, mit mindestens zwei Rahmenbaugruppen, wobei jede Rahmenbaugruppe mindestens eine, bevorzugt mindestens zwei oder genau zwei Profilleiste(en) (wie Innenprofilleiste und/oder Außenprofilleiste) und mindestens ein an jeder Profilleiste angeordnetes Eckverbinderteil umfasst, wobei die Profilleisten und die Eckverbinderteile der Rahmenbaugruppe derart ausgebildet sind, dass die Profilleisten aller Rahmenbaugruppen in einer Ausgangsstellung parallel zueinander angeordnet sind oder anordenbar sind und die Rahmenbaugruppen zu einem rechteckigen Rahmen zusammensteckbar sind, bei dem jeweils zwei Profilleisten teleskopierbar zueinander angeordnet sind.The object is achieved in particular by a kit for a frame, preferably for a frame of an insect protection device, with at least two frame assemblies, each frame assembly having at least one, preferably at least two or exactly two profile strip(s) (such as inner profile strip and/or outer profile strip) and at least a corner connector part arranged on each profile strip, wherein the profile strips and the corner connector parts of the frame assembly are designed in such a way that the profile strips of all frame assemblies are arranged or can be arranged parallel to one another in a starting position and the frame assemblies can be plugged together to form a rectangular frame, in which two profile strips each are arranged telescopically to one another.

Die Erfindung sieht in ihrem Grundgedanken also vor, dass der Bausatz insbesondere eine gerade Anzahl von (vormontierten) Rahmenbaugruppen umfasst, wobei jede Rahmenbaugruppe insbesondere genau zwei Innen- und/oder Außenprofilleisten (nämlich: jede Rahmenbaugruppe weist entweder eine Innenprofilleiste und eine Außenprofilleiste, zwei Innenprofilleisten oder zwei Außenprofilleisten auf) oder genau vier Innen- und/oder Außenprofilleisten (nämlich: jede Rahmenbaugruppe weist zwei Innenprofilleisten und zwei Außenprofilleisten) auf. An jeder Profilleiste der Rahmenbaugruppe ist zudem ein Eckverbinderteil angeordnet, wozu das Eckverbinderteil entweder einteilig mit der Profilleiste ausgebildet ist oder als vormontiertes Teil mit der Profilleiste bevorzugt kraft- und/oder formschlüssig verbunden ist.In its basic idea, the invention therefore provides that the kit comprises in particular an even number of (pre-assembled) frame assemblies, with each frame assembly in particular having exactly two inner and/or outer profile strips (namely: each frame assembly has either an inner profile strip and an outer profile strip, two inner profile strips or two outer slats) or exactly four inner and/or outer slats (namely: each frame assembly has two inner slats and two outer slats). On each profile bar A corner connector part is also arranged in the frame assembly, for which purpose the corner connector part is either designed in one piece with the profile strip or is preferably non-positively and/or positively connected as a preassembled part to the profile strip.

Es ist also vorgesehen, dass der im endmontierten Zustand die rechtwinklig zueinander angeordneten Profilleisten verbindende Eckverbinder aus mindestens zwei Teilen (Eckverbinderteilen) besteht. Wie auch weiter unten erläutert, sind die zwei Eckverbinderteile so ausgebildet, dass sie ineinander gesteckt werden können oder schwenkbar zueinander unter Ausbildung einer Art Scharnier miteinander verbunden sind.Provision is therefore made for the corner connector, which connects the profile strips arranged at right angles to one another in the final assembled state, to consist of at least two parts (corner connector parts). As also explained below, the two corner connector parts are designed in such a way that they can be plugged into one another or are connected to one another so that they can pivot relative to one another, forming a type of hinge.

Die Profilleisten aller Rahmenbaugruppen können also zunächst parallel (fluchtend oder versetzt) zueinander angeordnet werden, sodass die vormontierten Rahmenbaugruppen platzsparend in einer Verpackung angeordnet sein können.The profile strips of all frame assemblies can therefore initially be arranged parallel (aligned or offset) to one another, so that the pre-assembled frame assemblies can be arranged in a package to save space.

Zur (End-)Montage des Rahmens werden die Rahmenbaugruppen zusammengesteckt, wobei die Eckverbinderteile unterschiedlicher Rahmenbaugruppen ineinandergesteckt werden oder Innenprofilleisten und Außenprofilleisten unterschiedlicher Rahmenbaugruppen teleskopierbar zueinander ausgerichtet werden, wobei eine Innenprofilleiste einer ersten Rahmenbaugruppe teleskopierend in die Außenprofilleiste einer zweiten Rahmenbaugruppe eingesteckt/eingeschoben wird. Im zweiten Fall ist es zudem erforderlich, dass die über zwei schwenkbar zueinander angeordnete Eckverbinderteile verbundenen Profilleisten einer Rahmenbaugruppe zunächst in einen rechten Winkel geschwenkt werden.For the (final) assembly of the frame, the frame assemblies are plugged together, with the corner connector parts of different frame assemblies being plugged into one another or inner profile strips and outer profile strips of different frame assemblies being telescopically aligned with one another, with an inner profile strip of a first frame assembly being telescopically inserted/slide into the outer profile strip of a second frame assembly. In the second case, it is also necessary for the profile strips of a frame assembly, which are connected via two corner connector parts arranged pivotably relative to one another, to first be pivoted into a right angle.

Der Bausatz kann neben den vormontierten Rahmenbaugruppen weitere Innen- und/oder Außenprofilleisten umfassen, über die die Profilleisten verschiedener Rahmenbaugruppen während der Montage miteinander teleskopierbar verbunden werden.In addition to the pre-assembled frame assemblies, the kit can include further inner and/or outer profile strips, via which the profile strips of different frame assemblies can be telescopically connected to one another during assembly.

Nachdem der Bausatz zu einem Rahmen zusammengesteckt ist, kann der Rahmen einfach in seiner Größe geändert werden, wozu die Innen- und Außenprofilleisten der Rahmenstreben teleskopierend zueinander verschoben werden. Hat der Rahmen die gewünschte Größe, so kann er mit geeigneten Mitteln (Schrauben, Insektenschutzgitter, Fixierungsleisten) in seiner Größe festgelegt werden.After the kit has been put together to form a frame, the size of the frame can be easily changed by sliding the inner and outer profile strips of the frame struts telescopically towards one another. If the frame has the desired size, it can be fixed in size with suitable means (screws, insect screens, fixing strips).

Der erfindungsgemäße Bausatz für einen Rahmen weist also nicht nur eine sehr geringe Anzahl an von dem Endanwender zu montierenden Rahmenbaugruppen auf sondern in der Ausgangsstellung auch ein sehr geringes Volumen.The assembly kit according to the invention for a frame therefore has not only a very small number of frame assemblies to be assembled by the end user, but also a very small volume in the starting position.

Es kann vorgesehen sein, dass die Rahmenbaugruppen jeweils zwei Profilleisten aufweisen, die schwenkbar zueinander angeordnet sind, sodass die zwei Profilleisten der Rahmenbaugruppe in der Ausgangsstellung parallel (fluchtend oder versetzt) zueinander angeordnet sind und vor dem Zusammenstecken in eine zueinander rechtwinklige Stellung verschwenkbar sind. Hierbei ist insbesondere vorgesehen, dass an jeder Profilleiste ein Eckverbinderteil angeordnet ist, über das die Profilleisten schwenkbar zueinander sind. Hierzu ist insbesondere eine Schwenkachse zwischen den beiden Eckverbinderteilen ausgebildet, um die die Profilleisten zueinander verschwenkt werden können. Die mindestens eine Schwenkachse kann dabei so angeordnet sein, dass die Profilleisten in der Ausgangsstellung nebeneinander angeordnet sind. Alternativ kann die Schwenkachse so angeordnet sein, dass die Profilleisten fluchtend zueinander angeordnet sind, in welchem Fall die Rahmenbaugruppe in der Ausgangsstellung eine größere Länge aufweist.It can be provided that the frame assemblies each have two profile strips, which are arranged pivotably to one another, so that the two profile strips of the frame assembly are arranged parallel (aligned or offset) to one another in the initial position and can be pivoted into a position at right angles to one another before they are plugged together. In this case, it is provided in particular that a corner connector part is arranged on each profile strip, via which the profile strips can be pivoted relative to one another. For this purpose, in particular, a pivot axis is formed between the two corner connector parts, about which the profile strips can be pivoted relative to one another. The at least one pivot axis can be arranged in such a way that the profile strips are arranged next to one another in the initial position. Alternatively, the pivot axis can be arranged in such a way that the profile strips are arranged in alignment with one another, in which case the frame assembly has a greater length in the starting position.

Gemäß einem weiteren erfindungsgemäßen Aspekt weist der Bausatz genau vier Rahmenbaugruppen auf, deren jeweiligen beiden Profilleisten schwenkbar zueinander sind, wobei die Profilleisten als Innenprofilleiste und/oder Außenprofilleiste ausgebildet sind und wobei in der rechtwinkligen Stellung die Innenprofilleiste einer ersten Rahmenbaugruppe in die Außenprofilleiste einer zweiten Rahmenbaugruppe einsteckbar ist. Die Innenprofilleiste und die Außenprofilleiste sind in ihrer äußeren Kontur bzw. inneren Kontur also so aufeinander abgestimmt, dass sie ineinander eingesteckt werden können und teleskopierbar zueinander bewegt/verschoben werden können.According to a further aspect of the invention, the kit has exactly four frame assemblies, the two profile strips of which can be pivoted relative to one another, the profile strips being designed as an inner profile strip and/or outer profile strip and with the inner profile strip of a first frame assembly in the right-angled position the outer profile strip of a second frame assembly can be inserted. The inner profile strip and the outer profile strip are matched to one another in terms of their outer contour or inner contour in such a way that they can be inserted into one another and telescopically moved/displaced relative to one another.

Es ist zudem bevorzugt, dass die beiden schwenkbar zueinander angeordneten Profilleisten einer Rahmenbaugruppe um mindestens eine Schwenkachse zueinander verschwenkbar sind, wobei die Schwenkachsen aller eine Schwenkachse aufweisenden Rahmenbaugruppen in der Endmontagestellung parallel und insbesondere orthogonal zu der von dem rechtwinkligen Rahmen aufgespannten Ebene ausgerichtet sind. Die Profilleisten der Rahmenbaugruppen sind also alle in einer von dem späteren Rahmen aufgespannten Ebene schwenkbar.It is also preferred that the two profile strips of a frame assembly arranged pivotably relative to one another can be pivoted relative to one another about at least one pivot axis, with the pivot axes of all frame assemblies having a pivot axis being aligned parallel and in particular orthogonal to the plane spanned by the right-angled frame in the final assembly position. The profile strips of the frame assemblies can therefore all be pivoted in a plane spanned by the subsequent frame.

Bevorzugt sind die beiden Profilleisten in der rechtwinkligen Stellung durch eine Fixierung gesichert. Insbesondere wirkt diese Fixierung auf die verschwenkbar zueinander ausgebildeten Eckverbinderteile der Rahmenbaugruppen. Eine Fixierung der Eckverbinderteile in ihrer rechtwinklig zueinander angeordneten Stellung kann beispielsweise durch ein externes Fixierungselement, wie Schraube, Stift oder Abdeckkappe erfolgen.The two profile strips are preferably secured in the right-angled position by a fixation. In particular, this fixation acts on the corner connector parts of the frame assemblies, which are designed to be pivotable relative to one another. The corner connector parts can be fixed in their mutually perpendicular position, for example, by an external fixing element such as a screw, pin or cover cap.

Bevorzugt ist aber, dass die Eckverbinderteile selbst so ausgebildet sind, dass in der rechtwinkligen Stellung eine Fixierung erfolgt. Hierzu können die Eckverbinderteile zur Ausbildung einer Schnapp- beziehungsweise Rastverbindung ausgebildet sein. Hierzu weist ein Eckverbinderteil beispielsweise ein federnd auslenkbares Element auf, das beim Verschwenken der Eckverbinderteile ausgelenkt wird und in der rechtwinkligen Stellung in eine entsprechende Rastaufnahme an dem anderen Eckverbinderteile eingreift.However, it is preferred that the corner connector parts themselves are designed in such a way that they are fixed in the right-angled position. For this purpose, the corner connector parts can be designed to form a snap or snap-in connection. For this purpose, a corner connector part has, for example, a resiliently deflectable element that is deflected when the corner connector parts are pivoted and, in the right-angled position, engages in a corresponding snap-in receptacle on the other corner connector part.

Gemäß einem erfindungsgemäßen Aspekt sind ein erstes Eckverbinderteil einer ersten Rahmenbaugruppe und ein zweites Eckverbinderteil einer zweiten Rahmenbaugruppe so aufeinander abgestimmt ausgebildet, dass das erste Eckverbinderteil in das zweite Eckverbinderteil einsteckbar ist. Hierzu weist das zweite Eckverbinderteil beispielsweise eine Aufnahme auf, deren innere Kontur so ausgebildet ist, dass das erste Eckverbinderteil in das zweite Eckverbinderteil einsteckbar ist. Der die beiden im montierten Zustand rechtwinklig in einer Ecke zueinander angeordneten Profilleisten miteinander verbindende Eckverbinder besteht also aus zwei Bauteilen (Eckverbinderteile), die erst bei der Montage durch den Endanwender ineinandergesteckt werden.According to one aspect of the invention, a first corner connector part of a first frame assembly and a second corner connector part of a second frame assembly are designed to match one another in such a way that the first corner connector part can be inserted into the second corner connector part. Points to this the second corner connector part, for example, has a receptacle whose inner contour is designed in such a way that the first corner connector part can be inserted into the second corner connector part. The corner connector, which connects the two profile strips arranged at right angles to one another in a corner when assembled, consists of two components (corner connector parts) that are only plugged into one another during assembly by the end user.

In diesem Zusammenhang kann vorgesehen sein, dass die Steckverbindung zwischen dem ersten Eckverbinderteil der ersten Rahmenbaugruppe und dem zweiten Eckverbinderteil der zweiten Rahmenbaugruppe durch eine Fixierung gesichert ist. Hierzu kann insbesondere ein externes Fixierungselement, wie Schraube, Stift oder Abdeckkappe ausgebildet sein. Bevorzugt ist jedoch, dass die Fixierung durch eine an dem ersten Eckverbinderteil und dem zweiten Eckverbinderteil ausgebildete Schnapp- beziehungsweise Rastverbindung ausgebildet ist. Hierzu weist das erste Eckverbinderteil oder das zweite Eckverbinderteil ein Rastelement auf, das beim Zusammenstecken elastisch (federnd) ausgelenkt wird und in der zusammengesteckten Stellung in eine entsprechende Rastaufnahme an dem anderen Eckverbinderteil einrastet.In this context it can be provided that the plug-in connection between the first corner connector part of the first frame assembly and the second corner connector part of the second frame assembly is secured by a fixation. In particular, an external fixing element such as a screw, pin or cover cap can be designed for this purpose. However, it is preferred that the fixation is formed by a snap or latching connection formed on the first corner connector part and the second corner connector part. For this purpose, the first corner connector part or the second corner connector part has a latching element which is elastically (resiliently) deflected when mated and latches into a corresponding latching receptacle on the other corner connector part in the mated position.

In einer bevorzugten Ausführungsform weist der Bausatz in diesem Zusammenhang genau vier Rahmenbaugruppen auf, die an ihren beiden Enden jeweils ein Eckverbinderteil aufweisen, die zur Herstellung einer Steckverbindung ausgebildet sind. Jede Rahmenbaugruppe weist insbesondere eine Innenprofilleiste und eine Außenprofilleiste auf, die bereits in der Ausgangsstellung teleskopierbar (und damit parallel zueinander) ineinander eingeschoben sind.In a preferred embodiment, the kit has exactly four frame assemblies in this context, which each have a corner connector part at their two ends, which are designed to produce a plug-in connection. Each frame assembly has, in particular, an inner profile strip and an outer profile strip, which are telescopically inserted into one another (and thus parallel to one another) even in the starting position.

Zur weiteren Reduzierung der Anzahl der Rahmenbaugruppen kann vorgesehen sein, dass die Profilleisten bzw. jeweils ein Paar von Profilleisten schwenkbar zueinander angeordnet sind und an ihren in der Ausgangsstellung freien Enden jeweils ein Eckverbinderteil aufweisen, die zur Herstellung einer Steckverbindung mit den Eckverbinderteilen der anderen Rahmenbaugruppe ausgebildet sind. In diesem Fall ist also ein aus einer Innenprofilleiste und einer Außenprofilleiste gebildetes Profilleistenpaar über ein Eckverbinderteil schwenkbar mit einem weiteren aus einer Innenprofilleiste und einer Außenprofilleiste gebildeten Profilleistenpaar schwenkbar verbunden, wobei an den freien (den schwenkbar ausgebildeten Eckverbinderteilen abgewandten) Enden Eckverbinderteile zur Ausbildung einer Steckverbindung ausgebildet sind. Dieser Bausatz umfasst also genau zwei Rahmenbaugruppen zur Ausbildung eines rechtwinkligen Rahmens.In order to further reduce the number of frame assemblies, provision can be made for the profile strips or a pair of profile strips to be arranged pivotably relative to one another and at their starting position free ends each have a corner connector part, which are designed to produce a plug connection with the corner connector parts of the other frame assembly. In this case, a pair of profile strips formed from an inner profile strip and an outer profile strip is pivotably connected via a corner connector part to another pair of profile strips formed from an inner profile strip and an outer profile strip, with corner connector parts being formed on the free ends (facing away from the pivotably designed corner connector parts) to form a plug connection are. This kit therefore includes exactly two frame assemblies to form a rectangular frame.

Wenn die vormontierte Rahmenbaugruppe ein in eine Profilleiste eingestecktes Eckverbinderteil umfasst, so ist gemäß einem Aspekt der Erfindung vorgesehen, dass das Eckverbinderteil mit einem Einsteckabschnitt in die Profilleiste eingesteckt ist. In diesem Zusammenhang ist das Eckverbinderteil insbesondere so ausgebildet, dass der über das Ende der Profilleiste überstehende Abschnitt des Eckverbinderteils nicht mehr als einige Millimeter über die äußere Kontur der Profilleiste hervorsteht. Somit ist eine besonders kompakte Anordnung der Rahmenbaugruppen in der Ausgangsstellung möglich.If the preassembled frame assembly comprises a corner connector part inserted into a profile strip, one aspect of the invention provides that the corner connector part is inserted into the profile strip with an insertion section. In this context, the corner connector part is designed in particular in such a way that the section of the corner connector part that protrudes beyond the end of the profile strip does not protrude more than a few millimeters beyond the outer contour of the profile strip. A particularly compact arrangement of the frame assemblies in the starting position is thus possible.

Der Bausatz wird insbesondere in einer Verpackung angeboten, in der die Rahmenbaugruppen angeordnet sind, wobei die Profilleisten aller Rahmenbaugruppen parallel zueinander angeordnet sind, wenn der Bausatz in der Verpackung angeordnet ist.In particular, the kit is presented in a package in which the frame assemblies are placed, with the moldings of all the frame assemblies being parallel to each other when the kit is placed in the package.

Es wird zudem ein Rahmen vorgeschlagen, der aus einem zuvor beschriebenen Bausatz zusammengebaut ist. Der Rahmen ist insbesondere für die Ausbildung einer Insektenschutzvorrichtung vorgesehen, wozu an dem Rahmen ein von dem Bausatz umfasstes (gegebenenfalls auch plissiertes) Insektenschutznetz/- gitter befestigt werden kann. Beispielsweise kann die Insektenschutzvorrichtung für ein Fenster vorgesehen sein, bei dem der zusammengebaute Rahmen vier Rahmenstreben (zwei vertikal und zwei horizontal ausgerichtet) aufweist. Der Rahmen kann aber auch für eine Insektenschutzvorrichtung für eine Tür ausgebildet sein, wozu der zusammengebaute Rahmen neben den äußeren Rahmenstreben eine Mittelstrebe aufweist, die im montierten Zustand insbesondere horizontal ausgerichtet ist und die seitlichen Rahmenstreben der Insektenschutztür miteinander verbindet, wobei ein Mittelverbinder die äußeren Rahmenstreben mit der mittleren Rahmenstrebe verbindet. In diesem Fall kann die mittlere Rahmenstrebe über entsprechende Eckverbinderteile mit den weiteren Rahmenstreben verbunden sein. Dabei kann zur Ausbildung der Mittelstrebe ein Mittelverbinder aus drei Eckverbinderteilen bestehen, die ggf. schwenkbar zueinander ausgebildet sind, so dass eine die Profilleisten der Mittelstrebe aufweisende Rahmenbaugruppe drei Profilleisten aufweist (zwei Profilleisten für die äußere Rahmenstrebe und eine Profilleiste für die mittlere Rahmenstrebe). Alternativ können die Eckverbinderteile zur Ausbildung des Mittelverbinders so ausgebildet sein, dass drei jeweils an einer Profilleiste angeordnete Eckverbinderteile unterschiedlicher Rahmenbaugruppen zusammengesteckt werden können.A frame is also proposed which is assembled from a kit described above. The frame is intended in particular for forming an insect protection device, for which purpose an insect protection net/grid (possibly also pleated) that is included in the kit can be attached to the frame. For example, the insect screen may be provided for a window where the assembled frame has four frame braces (two vertical and two vertical). aligned horizontally). However, the frame can also be designed for an insect protection device for a door, for which purpose the assembled frame has, in addition to the outer frame struts, a center strut which, in the assembled state, is aligned in particular horizontally and connects the side frame struts of the insect protection door to one another, with a center connector connecting the outer frame struts with the center frame brace. In this case, the middle frame strut can be connected to the other frame struts via corresponding corner connector parts. To form the center strut, a center connector can consist of three corner connector parts that can be pivoted to one another, so that a frame assembly that has the profile strips of the center strut has three profile strips (two profile strips for the outer frame strut and one profile strip for the middle frame strut). Alternatively, the corner connector parts for forming the central connector can be designed in such a way that three corner connector parts of different frame assemblies, each arranged on a profile strip, can be plugged together.

Die Erfindung sowie das technische Umfeld werden im Folgenden anhand der Figuren beispielhaft erläutert. Es zeigen schematisch

- Figur 1:

- einen ersten Bausatz für einen ersten Rahmen,

- Figur 2:

- eine Rahmenbaugruppe des ersten Bausatzes während des Verschwenkens aus einer Ausgangsstellung,

- Figur 3:

- die vier Rahmenbaugruppen des ersten Bausatzes mit rechtwinklig zueinander angeordneten Profilleisten,

- Figur 4:

- einen aus dem ersten Bausatz zusammengesteckten ersten Rahmen,

- Figur 5:

- einen zweiten Bausatz für einen zweiten Rahmen,

- Figur 6:

- vier Rahmenbaugruppen des zweiten Bausatzes vor dem Zusammenstecken,

- Figur 7:

- einen aus dem zweiten Bausatz zusammengesteckten zweiten Rahmen,

- Figur 8

- einen dritten Bausatz für einen dritten Rahmen,

- Figur 9:

- eine Rahmenbaugruppe des dritten Bausatzes während des Verschwenkens aus der Ausgangsstellung,

- Figur 10:

- die beiden Rahmenbaugruppen des dritten Bausatzes und

- Figur 11:

- einen aus dem dritten Bausatz zusammengesteckten dritten Rahmen.

- Figure 1:

- a first kit for a first frame,

- Figure 2:

- a frame assembly of the first kit during pivoting from an initial position,

- Figure 3:

- the four frame assemblies of the first kit with profile strips arranged at right angles to one another,

- Figure 4:

- a first frame put together from the first kit,

- Figure 5:

- a second kit for a second frame,

- Figure 6:

- four frame assemblies of the second kit before plugging together,

- Figure 7:

- a second frame put together from the second kit,

- figure 8

- a third kit for a third frame,

- Figure 9:

- a frame assembly of the third kit during pivoting from the home position,

- Figure 10:

- the two frame assemblies of the third kit and

- Figure 11:

- a third frame put together from the third kit.

In

Wie aus den

In

In

In

Wie insbesondere aus

Nachdem beide Rahmenbaugruppen 3.1 und 3.2 in die rechtwinklige Stellung verschwenkt sind, können diese zueinander ausgerichtet werden, wie dies in

Aufgrund der Teleskopierbarkeit der Außenprofilleisten 4.1 und 4.3 zu den Innenprofilleisten 4.2 und 4.4 kann der in

- la, 1b, 1cla, 1b, 1c

- Bausatzkit

- 2a, 2b, 2c2a, 2b, 2c

- Rahmenframe

- 3.1, 3.2, 3.3, 3.43.1, 3.2, 3.3, 3.4

- Rahmenbaugruppeframe assembly

- 4.1, 4.34.1, 4.3

- Außenprofilleisteexternal profile bar

- 4.2, 4.44.2, 4.4

- Innenprofilleisteinterior molding

- 5.1, 5.2, 5.3, 5.45.1, 5.2, 5.3, 5.4

- Eckverbinderteilcorner connector part

- 66

- Schwenkachsepivot axis

- 77

- Rastverbindungsnap connection

Claims (14)

- A kit (1a, 1b, 1c) for a frame (2a, 2b, 2c), in particular for a frame of an insect protection device, having at least two frame assemblies (3.1, 3.2, 3.3, 3.4), wherein each frame assembly (3.1, 3.2, 3.3, 3.4) comprises- at least one profile strip (4.1, 4.2, 4.3, 4.4) and- at least one corner connector part (5.1, 5.2, 5.3, 5.4) arranged on each profile strip (4.1, 4.2), whereinthe profile strips (4.1, 4.2, 4.3, 4.4) and the corner connector parts (5.1, 5.2, 5.3, 5.4) of the frame assemblies (3.1, 3.2, 3.3, 3.4) are configured such that- the profile strips (4.1, 4.2, 4.3, 4.4) of all of the frame assemblies (3.1, 3.2, 3.3, 3.4) are or can be arranged parallel to one another in a starting position and- the frame assemblies (3.1, 3.2, 3.3, 3.4) can be plugged together to form a rectangular frame (2a, 2b, 2c) in which two profile strips (4.1, 4.2, 4.3, 4.4) are arranged in each case telescopically in one another, whereina first corner connector part (5.3) of a first frame assembly (3.1) and a second corner connector part (5.4) of a second frame assembly (3.2) are adapted to one another such that the first corner connector part (5.3) can be inserted into the second corner connector part (5.4).

- The kit (1a, 1b, 1c) according to Claim 1, wherein a profile strip and the corner connector part of a frame assembly are configured in one piece.

- The kit (1a, 1b, 1c) according to Claim 1, wherein the frame assemblies are preassembled, wherein the corner connector part (5.1, 5.2, 5.3, 5.4) is inserted with an insertion portion into the profile strip (4.1, 4.2, 4.3, 4.4).

- The kit according to one of the preceding claims, wherein the frame assemblies (3.1, 3.2, 3.3, 3.4) have in each case two profile strips (4.1, 4.2, 4.3, 4.4), wherein the two profile strips (4.1, 4.2, 4.3, 4.4) of a frame assembly are pivotable relative to one another, such that the two profile strips (4.1, 4.2, 4.3, 4.4) of the frame assembly (3.1, 3.2, 3.3, 3.4) are arranged parallel to one another in the starting position and are pivotable into a position at right-angles to one another before being plugged.

- The kit (1a, 1b, 1c) for a frame (2a, 2b, 2c), in particular for a frame of an insect protection device, having four frame assemblies (3.1, 3.2, 3.3, 3.4), wherein each frame assembly (3.1, 3.2, 3.3, 3.4) comprises- at least one profile strip (4.1, 4.2, 4.3, 4.4) and- at least one corner connector part (5.1, 5.2, 5.3, 5.4) arranged on each profile strip (4.1, 4.2), wherein

the profile strips (4.1, 4.2, 4.3, 4.4) and the corner connector parts (5.1, 5.2, 5.3, 5.4) of the frame assemblies (3.1, 3.2, 3.3, 3.4) are configured such that- the profile strips (4.1, 4.2, 4.3, 4.4) of all of the frame assemblies (3.1, 3.2, 3.3, 3.4) are or can be arranged parallel to one another in a starting position and- the frame assemblies (3.1, 3.2, 3.3, 3.4) can be plugged together to form a rectangular frame (2a, 2b, 2c) in which two profile strips (4.1, 4.2, 4.3, 4.4) are arranged in each case telescopically in one another, wherein the frame assemblies (3.1, 3.2, 3.3, 3.4) have in each case two profile strips (4.1, 4.2, 4.3, 4.4), wherein the two profile strips (4.1, 4.2, 4.3, 4.4) of a frame assembly are pivotable relative to one another, such that the two profile strips (4.1, 4.2, 4.3, 4.4) of the frame assembly (3.1, 3.2, 3.3, 3.4) are arranged parallel to one another in the starting position and before being plugged together are pivotable into a position at right-angles to one another and wherein the profile strips are configured as an inner profile strip (4.2, 4.4) and/or outer profile strip (4.1, 4.3), wherein in the right-angled position the inner profile strip (4.2, 4.4) of a first frame assembly (3.1) can be inserted into the outer profile strip (4.1, 4.3) of a second frame assembly (3.2) and wherein the frame assemblies are preassembled, wherein the corner connector part (5.1, 5.2, 5.3, 5.4) is inserted with an insertion portion into the profile strip (4.1, 4.2, 4.3, 4.4). - The kit (1a, 1c) according to Claim 4 or 5, wherein the two profile strips (4.1, 4.2, 4.3, 4.4) of a frame assembly (3.1, 3.2, 3.3, 3.4) are pivotable relative to one another about at least one pivot axis (6) and the pivot axes (6) of all of the frame assemblies (3.1, 3.2, 3.3, 3.4) having a pivot axis (6) are oriented parallel to one another in a final assembled position.

- The kit (1a, 1c) according to one of Claims 4 to 6, wherein the two profile strips (4.1, 4.2, 4.3, 4.4) of each frame assembly (3.1, 3.2, 3.3, 3.4) are arranged parallel and offset to one another in the starting position.

- The kit (1a, 1c) according to one of Claims 4 to 7, wherein the two profile strips are secured in the right-angled position by a fixing.

- The kit (1b, 1c) according to one of Claims 1 to 4, wherein the plug connection between the first corner connector part (5.3) and the second corner connector part (5.4) is secured by a fixing.

- The kit (1a, 1b, 1c) according to Claim 9, wherein the fixing is configured by a latching connection (7) configured on the first corner connector part (5.3) and the second corner connector part (5.4) or by an external fixing element, such as a screw, pin or cap.

- The kit (1b, 1c) according to one of Claims 9 or 10, which has four frame assemblies (3.1, 3.2, 3.3, 3.4) which have in each case on their two ends a corner connector part (5.3, 5.4), said corner connector parts being configured to produce a plug connection.

- The kit (1b) according to one of Claims 1 to 4, wherein the kit comprises two frame assemblies (3.1, 3.2) and the profile strips (4.1, 4.2, 4.3, 4.4) of each frame assembly (3.1, 3.2) are pivotable relative to one another and on their free ends in the starting position have corner connector parts (5.3, 5.4) which are configured to produce a plug connection with the corner connector parts of the other frame assembly (3.1, 3.2).

- The kit (1a, 1b, 1c) according to one of the preceding claims, wherein the at least one profile strip of a frame assembly comprises an inner profile strip (4.2, 4.4), an outer profile strip (4.1, 4.3) or an inner profile strip (4.2, 4.4) and an outer profile strip (4.1, 4.3).

- The kit (1a, 1b, 1c) according to one of the preceding claims, comprising a packaging in which the frame assemblies (3.1, 3.2, 3.3, 3.4) are arranged, wherein the profile strips (4.1, 4.2, 4.3, 4.4) of all of the frame assemblies (3.1, 3.2, 3.3, 3.4) are arranged parallel to one another.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP19215877.2A EP3835539B1 (en) | 2019-12-13 | 2019-12-13 | Kit for a frame |

| PCT/EP2020/085154 WO2021116137A1 (en) | 2019-12-13 | 2020-12-09 | Kit for a frame |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP19215877.2A EP3835539B1 (en) | 2019-12-13 | 2019-12-13 | Kit for a frame |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3835539A1 EP3835539A1 (en) | 2021-06-16 |

| EP3835539B1 true EP3835539B1 (en) | 2022-12-28 |

Family

ID=68916303

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19215877.2A Active EP3835539B1 (en) | 2019-12-13 | 2019-12-13 | Kit for a frame |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP3835539B1 (en) |

| WO (1) | WO2021116137A1 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2860457T3 (en) * | 2019-01-21 | 2021-10-05 | Buedenbender Arnd | Frame with profile connectors featuring swivel joint |

| DE102021134511A1 (en) | 2021-12-23 | 2023-06-29 | Arnd Büdenbender | Kit for a frame and profile connector |

Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2477443A1 (en) | 1980-03-05 | 1981-09-11 | Reith Charles | Tubular metallic framework with oval tubes - is assembled by metal end inserts to form 90 degree angles |

| EP0133145A2 (en) | 1983-07-26 | 1985-02-13 | Societe Industrielle Des Coussinets Sic | Method of mounting bearings with separated sleeve bearings and thrust plates |

| WO2005019588A1 (en) | 2003-08-18 | 2005-03-03 | Forster Rohr- & Profiltechnik Ag | Corner joint and method for producing a joint of this type |

| EP2128374A2 (en) | 2008-05-27 | 2009-12-02 | tesa SE | Self-actuated opening and size-adjustable frame for reversible attachment of a covering in a building opening |

| US20100238544A1 (en) | 2009-03-20 | 2010-09-23 | Skyline Displays, Inc. | Projection backwall apparatus and system |

| DE202011000289U1 (en) | 2011-02-09 | 2011-04-07 | Ruco Gmbh | Insect screens |

| DE102013100253A1 (en) | 2013-01-11 | 2014-07-31 | Eduard Hueck Gmbh & Co Kg | Corner connector |

| EP2878757A2 (en) | 2013-12-02 | 2015-06-03 | Bash-tec GmbH | Clamping frame for an insect screen or similar net-type tissue |

| DE102015015682A1 (en) | 2015-01-02 | 2016-07-07 | Erna Kronberger | Corner connector for special shapes |

| EP3078802A2 (en) | 2015-02-17 | 2016-10-12 | M.A.C.'s HOLDING GmbH | Insect protection frame system |

| DE202015104651U1 (en) | 2015-09-02 | 2016-12-05 | Arnd Büdenbender | Insect protection device with adapter profile strip |

| US20170265661A1 (en) | 2016-03-16 | 2017-09-21 | Quanex Homeshield Llc | Cornerlock for a Frame Assembly Including a Collar |

| DE202018105545U1 (en) | 2018-09-26 | 2019-10-30 | Arnd Büdenbender | Protective device with adapter profile strip |

| EP3683397A1 (en) | 2019-01-21 | 2020-07-22 | Büdenbender, Arnd | Frame with profile connectors comprising swivel joint |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4279288A (en) * | 1979-05-29 | 1981-07-21 | Lanier George G | Adjustable frame apparatus |

| DE102015116588B4 (en) | 2015-09-30 | 2019-08-01 | Arnd Büdenbender | Kit for a tenter |

| DE102015117643A1 (en) * | 2015-10-16 | 2017-04-20 | Windhager Handelsgesmbh | Frame element, profile part, terminal strip and protective grid |

-

2019

- 2019-12-13 EP EP19215877.2A patent/EP3835539B1/en active Active

-

2020

- 2020-12-09 WO PCT/EP2020/085154 patent/WO2021116137A1/en active Application Filing

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2477443A1 (en) | 1980-03-05 | 1981-09-11 | Reith Charles | Tubular metallic framework with oval tubes - is assembled by metal end inserts to form 90 degree angles |

| EP0133145A2 (en) | 1983-07-26 | 1985-02-13 | Societe Industrielle Des Coussinets Sic | Method of mounting bearings with separated sleeve bearings and thrust plates |

| WO2005019588A1 (en) | 2003-08-18 | 2005-03-03 | Forster Rohr- & Profiltechnik Ag | Corner joint and method for producing a joint of this type |

| EP2128374A2 (en) | 2008-05-27 | 2009-12-02 | tesa SE | Self-actuated opening and size-adjustable frame for reversible attachment of a covering in a building opening |

| US20100238544A1 (en) | 2009-03-20 | 2010-09-23 | Skyline Displays, Inc. | Projection backwall apparatus and system |

| DE202011000289U1 (en) | 2011-02-09 | 2011-04-07 | Ruco Gmbh | Insect screens |

| DE102013100253A1 (en) | 2013-01-11 | 2014-07-31 | Eduard Hueck Gmbh & Co Kg | Corner connector |

| EP2878757A2 (en) | 2013-12-02 | 2015-06-03 | Bash-tec GmbH | Clamping frame for an insect screen or similar net-type tissue |

| DE102015015682A1 (en) | 2015-01-02 | 2016-07-07 | Erna Kronberger | Corner connector for special shapes |

| EP3078802A2 (en) | 2015-02-17 | 2016-10-12 | M.A.C.'s HOLDING GmbH | Insect protection frame system |

| DE202015104651U1 (en) | 2015-09-02 | 2016-12-05 | Arnd Büdenbender | Insect protection device with adapter profile strip |

| US20170265661A1 (en) | 2016-03-16 | 2017-09-21 | Quanex Homeshield Llc | Cornerlock for a Frame Assembly Including a Collar |

| DE202018105545U1 (en) | 2018-09-26 | 2019-10-30 | Arnd Büdenbender | Protective device with adapter profile strip |

| EP3683397A1 (en) | 2019-01-21 | 2020-07-22 | Büdenbender, Arnd | Frame with profile connectors comprising swivel joint |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2021116137A1 (en) | 2021-06-17 |

| EP3835539A1 (en) | 2021-06-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3138990B1 (en) | Anti-insect device with adapter profile strip | |

| AT515135B1 (en) | Hinge, especially for a piece of furniture | |

| EP0789984A1 (en) | Frame for a switchgear cabinet | |

| EP3683397B1 (en) | Frame with profile connectors comprising swivel joint | |

| EP3835539B1 (en) | Kit for a frame | |

| WO2010031094A2 (en) | Moveable drawer with railing adjustment | |

| DE202014100431U1 (en) | Band arrangement with adjusting means | |

| EP3910156B1 (en) | Insect and / or pollen screen | |

| EP3690177B1 (en) | Profile connector with swivel joint | |

| EP4202174A2 (en) | Kit for a frame and profile connector for a frame | |

| DE102006042490B4 (en) | Device and method for attaching attachment elements to on-site frame systems, preferably for windows and doors | |

| DE102015116588B4 (en) | Kit for a tenter | |

| EP3875728B1 (en) | Profile connector assembly and frame comprising a profiled connector assembly | |

| EP3730310B1 (en) | Frame with rotary joints | |

| DE10295692B3 (en) | Telescopic spring unit with a locking device | |

| EP0773615A1 (en) | Switchgear cabinet for electrical installations | |

| EP3623568A1 (en) | Frame of a protection device | |

| WO2019015945A1 (en) | Shading device | |

| EP3183998B1 (en) | Drawer for a sink base unit | |

| AT520822A4 (en) | Drawer side wall | |

| EP3727091B1 (en) | Arrangement comprising a rail bar and a wall member of a drawer | |

| EP3563009B1 (en) | Screen connecting device for jointed connecting of screens and screen arrangement | |

| EP0442168B1 (en) | Hinge arrangement of an equipment cabinet door | |

| DE102017128373A1 (en) | Articulating device with a displacement and this integrating equipment | |

| EP2218864A2 (en) | Intake guide for a mounting in a roller blind box |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17P | Request for examination filed |

Effective date: 20200904 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20220718 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502019006627 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1540586 Country of ref document: AT Kind code of ref document: T Effective date: 20230115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502019006627 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| 26 | Opposition filed |

Opponent name: MACS HOLDING GMBH Effective date: 20230309 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230328 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20221228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230428 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230428 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20221228 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20231214 Year of fee payment: 5 |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |