EP3665415B1 - Safety system for a pressure vessel - Google Patents

Safety system for a pressure vessel Download PDFInfo

- Publication number

- EP3665415B1 EP3665415B1 EP18758832.2A EP18758832A EP3665415B1 EP 3665415 B1 EP3665415 B1 EP 3665415B1 EP 18758832 A EP18758832 A EP 18758832A EP 3665415 B1 EP3665415 B1 EP 3665415B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- valve

- gas

- connection

- pressure accumulator

- safety

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C13/00—Details of vessels or of the filling or discharging of vessels

- F17C13/04—Arrangement or mounting of valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B20/00—Safety arrangements for fluid actuator systems; Applications of safety devices in fluid actuator systems; Emergency measures for fluid actuator systems

- F15B20/007—Overload

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B1/00—Installations or systems with accumulators; Supply reservoir or sump assemblies

- F15B1/02—Installations or systems with accumulators

- F15B1/04—Accumulators

- F15B1/08—Accumulators using a gas cushion; Gas charging devices; Indicators or floats therefor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B20/00—Safety arrangements for fluid actuator systems; Applications of safety devices in fluid actuator systems; Emergency measures for fluid actuator systems

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B21/00—Common features of fluid actuator systems; Fluid-pressure actuator systems or details thereof, not covered by any other group of this subclass

- F15B21/005—Filling or draining of fluid systems

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/40—Flow control

- F15B2211/41—Flow control characterised by the positions of the valve element

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/40—Flow control

- F15B2211/41—Flow control characterised by the positions of the valve element

- F15B2211/411—Flow control characterised by the positions of the valve element the positions being discrete

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/40—Flow control

- F15B2211/42—Flow control characterised by the type of actuation

- F15B2211/421—Flow control characterised by the type of actuation mechanically

- F15B2211/423—Flow control characterised by the type of actuation mechanically manually, e.g. by using a lever or pedal

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/50—Pressure control

- F15B2211/505—Pressure control characterised by the type of pressure control means

- F15B2211/50509—Pressure control characterised by the type of pressure control means the pressure control means controlling a pressure upstream of the pressure control means

- F15B2211/50518—Pressure control characterised by the type of pressure control means the pressure control means controlling a pressure upstream of the pressure control means using pressure relief valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/80—Other types of control related to particular problems or conditions

- F15B2211/875—Control measures for coping with failures

- F15B2211/8757—Control measures for coping with failures using redundant components or assemblies

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C2205/00—Vessel construction, in particular mounting arrangements, attachments or identifications means

- F17C2205/03—Fluid connections, filters, valves, closure means or other attachments

- F17C2205/0302—Fittings, valves, filters, or components in connection with the gas storage device

- F17C2205/0323—Valves

- F17C2205/0329—Valves manually actuated

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C2205/00—Vessel construction, in particular mounting arrangements, attachments or identifications means

- F17C2205/03—Fluid connections, filters, valves, closure means or other attachments

- F17C2205/0302—Fittings, valves, filters, or components in connection with the gas storage device

- F17C2205/0323—Valves

- F17C2205/0332—Safety valves or pressure relief valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C2205/00—Vessel construction, in particular mounting arrangements, attachments or identifications means

- F17C2205/03—Fluid connections, filters, valves, closure means or other attachments

- F17C2205/0302—Fittings, valves, filters, or components in connection with the gas storage device

- F17C2205/0382—Constructional details of valves, regulators

- F17C2205/0385—Constructional details of valves, regulators in blocks or units

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C2221/00—Handled fluid, in particular type of fluid

- F17C2221/01—Pure fluids

- F17C2221/014—Nitrogen

Definitions

- the invention relates to a security system having the features in the preamble of claim 1.

- a safety system of this type is used in various hydraulic supply systems and is known, for example, from the "Storage Technology" product catalogue, No. D 3.553.4/03.16 from HYDAC INTERNATIONAL.

- the well-known solution is used for filling and testing hydraulic accumulator systems with a so-called back-up version.

- the known valve block has various fluid connections, in particular for connecting a filling and testing device, a manometer, downstream nitrogen bottles, a pressure accumulator in the form of a hydraulic accumulator and at least one gas safety valve.

- the hydraulic accumulator preferably in the form of a piston accumulator, is permanently connected with its gas side to the gas safety valve.

- the liquid side of the hydraulic accumulator which is separated from the gas side by a separating element such as a longitudinally movable separating piston in an accumulator housing, is connected to a hydraulic supply system, for example in the form of a conventional hydraulic working circuit. Furthermore, a shut-off valve is present in the valve block, which in its open position the fluid path between the possibly connected, downstream Releases nitrogen bottles and the hydraulic accumulator for a gas-carrying connection with the nitrogen gas and blocks this fluid path in its closed position.

- a shut-off valve is present in the valve block, which in its open position the fluid path between the possibly connected, downstream Releases nitrogen bottles and the hydraulic accumulator for a gas-carrying connection with the nitrogen gas and blocks this fluid path in its closed position.

- the EP 2 857 727 A1 describes a safety system with the features in the preamble of claim 1 with a valve block to which at least one gas safety valve is connected in a detachable manner, with at least one controllable valve in or on the valve block and with at least one pressure accumulator accommodating a gaseous pressure medium, which is attached to the valve block in is also connected in a removable manner, with a gas-carrying connection running at least in sections within the valve block between the respectively connected pressure accumulator and the respectively connected gas safety valve being able to be blocked or released by means of the valve.

- the object of the invention is to create a security system with improved functionality and for saving resources.

- a safety device which includes the controllable valve, ensures that the gas-carrying connection to the respectively connected pressure accumulator is interrupted in order to remove a gas safety valve from the valve block and the connection leading to at least one other gas safety valve is maintained in such a way that a permanent gas-carrying connection is established between this respective pressure accumulator and this respective other gas safety valve during the changing process of the one gas safety valve and its renewed commissioning.

- a gas-carrying connection running at least in sections within the valve block between the respectively connected pressure accumulator and the respectively connected gas safety valve can be blocked or released by means of the valve, a particularly high level of safety is achieved.

- the respective gas safety valve can be opened if necessary remove from the valve block, provided that the associated valve in or on the valve block is brought into its closed position and to this extent is safely decoupled on the gas side from the respectively connected pressure accumulator, which consists of a hydraulic accumulator or a gas accumulator, such as a nitrogen bottle or another, at least partially gas-carrying pressure vessel, such as a storage tank or the like.

- the safety system according to the invention opens up the possibility of shutting off the gas safety valve connected to the valve block of the safety system via an associated, controllable valve, without suffering significant gas losses on the part of the respective pressure accumulator system connected to the valve block and without hydraulic system parts having to be depressurized.

- Pressure accumulators within the meaning of the invention include all containers suitable and used for holding a fluid, in particular a gas, such as pressure containers, hydraulic accumulators, gas cylinders, in particular nitrogen cylinders, and the like. It goes without saying that the pressure accumulator used in the safety system according to the invention is not restricted to the language definitions customary in individual areas.

- the respective accumulator is a pressure vessel that exclusively is filled or can be filled with the gaseous pressure medium, such as a nitrogen cylinder or a hydraulic accumulator, in particular in the form of a bellows, membrane, accumulator or piston, the separating element of which, accommodated in an accumulator housing, separates a gas side from a liquid side.

- the gaseous pressure medium such as a nitrogen cylinder or a hydraulic accumulator, in particular in the form of a bellows, membrane, accumulator or piston, the separating element of which, accommodated in an accumulator housing, separates a gas side from a liquid side.

- the safety system ensures in particular that during commissioning and continuous operation of a hydraulic supply system, the gas safety valve, which is set to a maximum response pressure, is permanently in contact with the gas side of the pressure accumulator connected from its liquid side to a hydraulic system or plant, for example in the form of a hydraulic accumulator remains connected.

- the gas safety valve which is set to a maximum response pressure

- the gas safety valve can be removed from the valve block for cleaning and/or maintenance purposes, while the other gas safety valve remaining on the valve block continues to perform the described safety function for the hydraulic supply system and its system parts.

- Such gas safety valves are regularly formed from pressure-limiting valves whose gas outlet side leading to the environment is covered by a mesh grid or a sieve in order to possibly in the In the event of safety, people in the vicinity are to be protected from the high-pressure discharged compressed gas.

- the safety device is based on a mechanical locking concept, a mechanical control concept, an electrical monitoring concept or a chip-controlled actuation concept for the controllable valve in each case. Due to the design of the safety device that meets the requirements and is adapted to the respective application, a safe shut-off of the pressure accumulator is ensured during operation with little susceptibility to faults and errors, for example before removing an associated gas safety valve.

- Mechanical concepts for locking or valve control offer the advantage of high robustness and low maintenance.

- An electrical or chip-controlled concept for the monitoring or the actuation offers the advantage of a small installation space requirement and the possibility of remote monitoring when using a corresponding data transmission.

- two ball valves which can preferably be actuated by hand, are provided for the implementation of the mechanical locking concept, which are each connected to an assignable gas safety valve and carry the control discs, which in the mutually locked state ensure that a ball valve its open position connects the associated gas safety valve to the pressure accumulator via a gas-carrying connection and the other ball valve in its blocking position for removing the associated gas safety valve from the valve block, for example for replacement or maintenance purposes, blocks another associated connection to the respective pressure accumulator.

- the control discs are an integral part of a mechanical locking mechanism for the actuation elements of the ball valves and are preferably arranged on an outside of the valve block. As soon as a ball valve is blocked to remove the associated gas safety valve, the associated control disk is locked with at least one control disk of another gas safety valve in such a way that the other gas safety valve is blocked and securely held in the open, operationally safe position. Thus, when a gas safety valve is removed and removed, at least one functional additional gas safety valve is connected to the valve block in its open position, which then exclusively performs the safety function.

- two hand levers of the ball valves can be used to actuate one of the control disks in the direction of a closed position of the ball valve, which has a cutout on the outer circumference which corresponds to a correspondingly designed cutout on the outer circumference of the other control disc cooperates in that a rotational movement of the respective ball valve is enabled or blocked by means of the associated hand lever.

- the respective section particularly preferably has an arcuate contour with a curvature comparable to the outer circumference of the control disk.

- the respective other control disk engages in such a shaped cutout in such a way that the associated hand lever is blocked in the selected position and an unintentional or intentional changing of this position is not possible.

- the gas safety valves have a cylindrical basic shape and are arranged on the underside of the valve block.

- the hand levers for actuating the associated ball valves are preferably arranged on a side of the valve block that is accessible to an operator, with a vertical direction generally being the open position and a horizontal one being the open position Direction indicates the closed position of the associated ball valve.

- the cutouts in adjacent hand levers are particularly preferably arranged in such a way that when the two hand levers are in the open position, the cutouts are arranged adjacent and opposite one another in such a way that when one hand lever is moved into the closed position, the associated control disk fits into the cutout on the other control disk of the other hand lever is moved in and thereby also blocking their movement into the closed position.

- Two or more gas safety valves are preferably arranged next to one another, forming a row, on the valve block. Accordingly, two or more hand levers with associated control disks are arranged next to one another, forming a row, on the side of the valve block.

- control disc interacts with a limit stop on the valve block in such a way that the hand lever can be pivoted from an opening direction parallel to the longitudinal direction of the respective gas safety valve by 90° into a blocking position transverse to this longitudinal alignment and vice versa. This results in the advantage of error-free operation when pivoting the respective hand lever into one of its positions.

- a 3-way ball valve is used as a controllable valve for the implementation of the mechanical control concept, which in its one switching position connects a gas safety valve via a connection to the pressure accumulator in a gas-carrying manner and another gas safety valve by blocking an associated other Connection decoupled from the accumulator, in a further switching position the other gas safety valve connected via the other connection to the accumulator gas-carrying and a gas safety valve through Lock the one connection is decoupled.

- two separate ball valves for the two gas safety valves can be omitted. Regardless of the switching position of the 3-way ball valve, a gas safety valve is then connected to the pressure accumulator and a gas safety valve is separated from it, so that at least one gas safety valve always assumes the safety function for the pressure accumulator.

- the position of the controllable valve is monitored by means of a sensor system with regard to its open and/or closed position, and operation of the hydraulic supply system is only made possible by a higher-level controller if when the sensors determine and transmit to the controller that the respective gas-carrying connection between the gas safety valve and the pressure accumulator is actually released via the controllable valve.

- a higher-level controller if when the sensors determine and transmit to the controller that the respective gas-carrying connection between the gas safety valve and the pressure accumulator is actually released via the controllable valve.

- a control chip is provided for the realization of the chip-controlled actuation concept, which is used on the control of the hydraulic supply system and enables its operation in the first place, but when it is removed the supply system is shut down and when it is used on the controllable valve the assignable gas safety valve then on the gas side from the pressure accumulator by blocking the associated connection decoupled.

- operation of the hydraulic supply system is only possible if the control chip releases the gas safety valve back into its open position after removal and this chip is reinserted in the control system to enable operation of the connected hydraulic system again.

- valve block has at least one additional supply connection, via which at least one additional pressure accumulator, preferably a gas pressure accumulator, can be connected, which, in its open position, is connected to the respective pressure accumulator to carry gas, preferably to the gas side, via a check valve arranged within the valve block connected to a hydraulic accumulator.

- gas can then be taken from the gas supply of the storage bottle via the additional supply connection and routed to the gas side of the hydraulic accumulator in order to increase the working capacity of this hydraulic accumulator in this way.

- valve block has at least one additional connection point to which a filling and testing device can be connected, which is connected directly to the pressure accumulator via a filling and testing connection in the valve block, preferably connected to the gas side of a hydraulic accumulator in the form of a piston accumulator , Is, and that this filling and testing connection is connected to a further connection between the respective further pressure accumulator and the pressure accumulator via a non-return valve which opens in the direction of the respective controllable valve.

- Properties of the gas such as temperature and pressure of the gas volume, can be monitored and recorded via the filling and testing device.

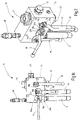

- Figures 1a to 1c each show a side view of a valve block 10, on the underside of which a first gas safety valve 12 and a second gas safety valve 14 are arranged.

- the gas safety valves 12, 14 are each fitted with a plug of a ball valve 50, 52 (see Fig. Figure 3a , b) assigned.

- the chicks of the ball valves 50, 52 are arranged separately from one another via a first hand lever 16 and a second hand lever 18 between an open switch position and a closed switch position and can be switched back and forth.

- switching position of the two hand levers 16, 18, these are each in the vertical direction, parallel to the cylindrical gas safety valves 12, 14, aligned and therefore shown in their open switching position.

- the associated hand lever 16 or 18 In the closed switch position, the associated hand lever 16 or 18 is aligned horizontally, as in Fig. 1b for the second hand lever 18 and in 1c shown for the first hand lever 16. While the hand lever 16 is designed to run straight, the other hand lever 18 is cranked so that it can be swiveled over the hand lever 16 if necessary (see Fig. 2 ).

- the connection to the gas side 45 is one in the Figures 1a to 1c not shown pressure accumulator 42 (see Figure 3a and 3b ) separated via the associated ball valve 50 or 52 and the removal of the associated gas safety valve 12 or 14 is possible in a safe manner, which will be explained in more detail below.

- a third hand lever 20 is arranged on the outside of the valve block 10, via which a plug of a further third ball valve 54 (see Fig. Figure 3a , b) is operable.

- the connection 22 is in the direction of the Figures 1a, b , c and 2 arranged on the underside of the cuboid valve block 10.

- a filling and testing connection point 24 for a gas-side filling and testing device not shown in detail

- a pressure connection 26 for a connection of the pressure accumulator 42.

- a measuring device 28 in the form of an electrical pressure transducer is also provided on the upper side of the valve block 10 .

- the side surface of the valve block 10 shown on the right is a pressure gauge connection 34 for a pressure gauge 44 (see Fig. 3a to 6 ) educated.

- the first and the second hand lever 16, 18 are each connected to a circular control disk 30a, 30b, which are each arranged coaxially to the axis of rotation of the associated hand lever 16, 18 on the front face of the valve block 10.

- the third hand lever 20 has a conventional disk 30c for rotation limitation.

- the ring-shaped control discs 30a, 30b for the hand levers 16, 18 each have a segmented and concave cutout 32a, 32b with an arcuate contour.

- the two cutouts 32a, 32b are arranged opposite one another.

- the design and arrangement of the cutouts 32a, 32b is selected such that when the second hand lever 18 is moved clockwise into the closed switch position, comparable to the representation according to FIG Fig. 1b , the second control disk 30b is positively moved on the outer circumference with its outer contour, which is convex to this extent, into the first, concave recess 32a on the first control disk 30a of the first hand lever 16 .

- the first hand lever 16 is mechanically locked in the open, vertical switch position shown by the control disks 30a, 30b.

- the first control disk 30a with its convex or arcuate outer circumference is moved clockwise into the closed switch position when the first hand lever 16 is moved, as in FIG 1c shown, moved into the second, concave cutout 32b on the second control disk 30b and accordingly the second hand lever 18 in the 1c securely locked in the open, vertical switching position shown.

- Two stop limits 15a, 15b protruding like pins are also provided on the valve block 10, each of which defines the rotational movement of the associated hand lever 16, 18 by 90° into the open and the closed switching position and are formed adjacent to the cutout 32a, 32b of the respective control disk 30a, 30b Stop lugs interact.

- the pertinent limit stop is common with ball valves, so that this is not discussed in detail; in particular, individual details have been omitted from the figures for the sake of clarity.

- a stop limiter 15c for a lug formed on the control disk 30c is also shown, which limits the corresponding rotational movement of the third hand lever 20.

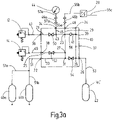

- Figure 3a shows a hydraulic circuit diagram for a first exemplary embodiment of the valve block 10 with a first valve connection 36 (see Fig. 1a ) for the first gas safety valve 12 and a second valve connection 38 (see Fig. 1b ) for the second gas safety valve 14.

- Two additional pressure accumulators 40a, 40b designed as gas accumulators in the form of conventional nitrogen refill bottles, are connected to the valve block 10 at the supply connection 22, for example.

- a pressure reservoir 42 also connected to the pressure port 26 , designed as a pressure vessel in the form of a nitrogen bottle that is filled exclusively with a gaseous pressure medium.

- the manometer 44 is connected to the manometer connection 34 and the measuring device 28 is connected to a measuring connection 48 .

- the pressure gauge 44 and the measuring device 28 of conventional design are connected to the associated connections 34 and 48 on the valve block 10 via quick-acting couplings 46a, 46b to carry fluid and pressure.

- the pressure accumulator 42 can be filled with nitrogen from the reloading cylinders 40a, 40b. The filled reservoir 42 can then be removed from the valve block 10 and a new reservoir 42 can be filled again.

- a supply network (not shown) could also take the place of the individual storage bottles 40a, 40b, from which the storage 42 can then be filled.

- a pressure accumulator 42 in the form of a gas storage bottle shown as an example, a large number of such gas-carrying storage systems can also be connected to the connection 26 of the valve block 10 (not shown).

- valve block 10 In the valve block 10 are several interconnected fluid connections between the first valve port 36, the second valve port 38, the supply port 22, the pressure port 26, the Filling and test connection point 24, the measuring connection 48 and the pressure gauge connection 34 are formed.

- the connections are made as bores in the valve block 10 made of a metal material.

- a first connecting section 21 leads from the first valve port 36 to a first crossing point 23, and a second connecting section 25 leads from the second valve port 38 to a second crossing point 27.

- the first crossing point 23 and the second crossing point 27 are arranged in a third connecting section 29, which extends from the measuring port 48 runs to a third crossing point 31 inside the valve block 10 .

- a fourth connection section 33 runs from the supply connection 22 to the pressure connection 26.

- the third crossing point 31 and a fourth crossing point 35 are arranged.

- the fourth crossing point 35 is the end of a filling and testing connection 37 beginning at the filling and testing connection point 24.

- a fifth crossing point 39 is arranged in the filling and testing connection 37, which represents the end of a fifth connection section 41 beginning at the first crossing point 23.

- a sixth crossing point 43 is arranged in the first connecting section 21 between the first valve connection 36 and the first crossing point 22 , which represents the end of a sixth connecting section 45 beginning at the manometer connection 34 .

- first line section 47 between the first gas safety valve 12 and the first valve port 36

- second line section 49 between the second gas safety valve 14 and the second valve port 38

- third line sections 51, 51a, 51b between the other pressure accumulators 40a, 40b and the supply port 22

- fourth line section 53 between the pressure accumulator or gas storage bottle 42 and the pressure connection 26

- fifth line sections 55a, 55b, 55c between the measuring device 28 and the measuring connection 48 and continuing from the measuring device 28 and sixth line sections 57a, 57b between the pressure gauge 44 and the pressure gauge connection 34 are present.

- the first ball valve 50 is arranged in the first connecting section 21 and the second ball valve 52 is arranged in the second connecting section 25.

- the third ball valve 54 is arranged between the third 31 and fourth crossing point 35, and a check valve 56 is connected parallel to this in the fifth connecting section 41 between the first 23 and fifth crossing point 39, which valve opens in the direction of the first crossing point 23 .

- the individual ball valves 50, 52, 54 are actuated individually by hand via the associated hand levers 16, 18, 20. From the fourth crossing point 35 arranged adjacent to the pressure connection 26, the filling and testing connection 37 leads directly to the filling and testing connection point 24.

- Figure 3b is essentially identical to Figure 3a and differs from this solution shown in that instead of a gas storage bottle 42 designed as a pressure container, a pressure accumulator 42 designed as a hydraulic accumulator in the form of a piston accumulator is connected to the pressure connection 26 of the valve block 10 .

- a pressure accumulator 42 designed as a hydraulic accumulator in the form of a piston accumulator is connected to the pressure connection 26 of the valve block 10 .

- a hydraulic supply system 43 is connected as an example, regularly consisting of a hydraulic working circuit, such as a motor-pump unit, a storage tank, hydraulic consumers, control and monitoring devices, etc. (not shown).

- This safety function is also implemented when the other pressure accumulators 40a, 40b are separated on the gas side from the gas side 45 of the pressure accumulator 42 by closing the other third ball valve 54.

- the pressure is equalized via the non-return valve 56, which opens in the direction of the two gas safety valves 12, 14 and to this extent the associated, working gas regularly leading in the form of nitrogen gas, releases connections in the valve block 10 for the purpose of pressure reduction.

- the piston 49 of the pressure accumulator 42 designed as a piston accumulator separates the gas side 45 from the liquid side 47, which leads to the supply system 43.

- the inside 4 shown circuit diagram for a second embodiment of the security system differs from that in the Figure 3a and 3b shown first embodiment in that instead of the two ball valves 50, 52 only a 3-way ball valve 58 in the connections from the gas safety valves 12, 14 to the respective pressure accumulator 42 is arranged is. Due to the arrangement of the 3-way ball valve 58, the wiring of the connections in the valve block 10 is modified in such a way that the first connection section 21 and the second connection section 25 each end at the ball valve 58 and from this a common connection section 59 to a common crossing point 61 in the third Connecting section 29 leads.

- the pressure gauge 44 is also connected to the third connection portion 29 via the sixth connection portion 45 .

- the wiring of the fourth connection section 33, the fifth connection section 41 and the filling and test connection 37 are unchanged.

- the pressure accumulators 40a, 40b, 42 are in 4 not shown for the sake of simplicity.

- the bottles 40a, 40b also do not necessarily have to be connected to the connection 22, which then has to be closed if it is unoccupied.

- the safety functions with the two gas safety valves 12, 14 and the associated ball valves 50, 52 are also reduced if only one corresponding pressure accumulator 42 is connected to the connection 26 of the valve block 10.

- the circuit diagram shown in the form of a hydraulic circuit diagram for a third exemplary embodiment of the safety system includes a first monitoring device 60 in the first connecting section 21 for electrically or electronically monitoring one connection from the first gas safety valve 12 to the pressure accumulator 42 and a second comparable monitoring device 62 in the second connecting section 25 for monitoring the other connection from the second gas safety valve 14 to the pressure accumulator 42 at connections 3, 2 of the 3-way ball valve 58 is formed. Otherwise, the representation corresponds to figure 5 essentially the representation according to the 4 .

- FIG. 6 circuit diagram for an embodiment of a safety system, which is not part of the invention, only one gas safety valve 12 is provided and only one monitoring device 60, as presented above, in the first connection section 21 for monitoring the one connection from the gas safety valve 12 to the pressure accumulator 42 on the associated ball valve 50 present.

- This monitoring device 60 can optionally monitor the open and/or closed position of the ball valve 50 electrically or electronically.

- the representation of 6 differs from that in the Figure 3a and 3b shown first embodiment in particular that the second gas safety valve 14, the second line section 49, the second valve port 38, the second connecting portion 25 together with the second crossing point 27 and the second ball valve 52 are omitted.

- a redundant mechanical locking or valve control concept is implemented in the exemplary embodiments of the safety system shown.

- the two associated 2-way ball valves 50, 52 can be mutually blocked in the direction of their respective horizontal closed position via the control disks 30a, 30b, so that only one ball valve 50 or 52 can reach its blocked position at a time, which means that the gas-carrying safety function is always only one of the two connected gas safety valves 12 or 14 overrides.

- the valve control concept according to the 4 operator guidance is achieved in the sense that, regardless of the operator's will, at least as seen from the valve position of the valve 58, a gas safety valve 12, 14 is always kept in its safety function.

- an electrical or electronic monitoring concept is implemented via at least one monitoring device 60, 62 on the 3-way ball valve 58 or on a ball valve 50. It is understood that combinations of such a monitoring concept according to the Figures 5 and 6 with a mechanical locking or valve control concept according to the Figure 3a , 3b and 4 can be combined with one another on the valve block 10 for reasons of redundancy.

- the blocking of the gas connection from the gas safety valve 12, 14 to the respective pressure accumulator 42 can be monitored via at least one monitoring device 60, 62, with the monitoring device 60, 62 generating a corresponding control and/or monitoring signal for a higher-level control device (not shown). can.

- the active replacement of a gas safety valve 12, 14 can be monitored manually on the valve block 10 and the valves 50, 52, 58 can be brought into the open or closed switching position as required.

- the gas side 45 of the respective pressure accumulator 42 can be checked via a filling and testing device 28 (not shown) to be connected to the filling and testing connection point 24 and optionally refillable.

- the third ball valve 54 remains open so that the working gas from the gas supply of the other pressure accumulators 40a, 40b can flow via the third line sections 51, 51a, 51b to can flow to the supply port 22, further via the fourth connecting section 33 to the pressure port 26 and further via the fourth line section 53 to the pressure accumulator 42 if necessary.

- the associated pressure profile can be monitored via the pressure gauge 44 connected to the pressure gauge connection 34 .

- the pressure in the safety system can be monitored electrically via the pressure transducer 28 . If the gas supply in the respective additional pressure accumulator 40a, 40b also has to be filled up, assuming that the additional pressure accumulators 40a, 40b are also connected to the valve block 10 via the connection point 22, this happens simultaneously with the gas side 45 of the respective pressure accumulator when the ball valve 54 is open 42 and, if necessary, with the ball valve 54 closed via the non-return valve 56. The relevant filling via the connection point 24 then continues until the pressure equilibrium established between the further pressure accumulators 40a, 40b, the refilling device at the connection point 24 and the respective pressure accumulator 42 the check valve 56 increasingly reaches its closed position.

- FIG. 7a and 7b An alternative embodiment of the security system is in the Figure 7a and 7b shown, the system according to Figure 7a is not part of the invention.

- the valve block 10 is compared to that in the Figures 1a to 1c shown embodiment designed comparatively small and encloses one in the perspective view of Figure 7a and 7b not shown 3-way ball valve.

- the ball valve can be actuated between its switch positions via a hand lever 16 rotatably arranged on the valve block 10 .

- the valve block 10 with the components arranged thereon forms a separate structural unit which is arranged on an end face 64 of a pressure accumulator 42 .

- a connecting piece 66 bent at right angles is inserted into a passage opening on the end face 64 , the valve block 10 being firmly connected to the connecting piece 66 .

- a gas safety valve 12 and a bursting disk 68 are arranged on the valve block 10 .

- the gas safety valve 12 and the bursting disc 68 are aligned horizontally and are arranged on opposite sides of the valve block 10 .

- the bursting disk 68 has the function that when the gas safety valve 12 is connected, this is kept free from damage in the event of excessive pressure loads due to the rupturing of the bursting disk 68 .

- a gas-carrying connection between the gas safety valve 12 and the pressure accumulator 42 can be blocked or released via the 3-way ball valve arranged in the valve block 10 .

- the 3-way ball valve has an L or T bore, with the central connection leading to the pressure accumulator 42 and the gas safety valve 12 and/or the bursting disc 68 being attached to the other connections.

- the second variant of the safety system shown differs from that in Figure 7a

- the first variant shown is that instead of the bursting disc 68 a second gas safety valve 14 is arranged on the valve block 10 .

- This has the advantage that when removing one of the two gas safety valves 12, 14 by the respective other gas safety valves 14, 12 remaining on the valve block 10 ensure a continuous safety function.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Filling Or Discharging Of Gas Storage Vessels (AREA)

- Fluid-Pressure Circuits (AREA)

- Supply Devices, Intensifiers, Converters, And Telemotors (AREA)

Description

Die Erfindung betrifft ein Sicherheitssystem mit den Merkmalen im Oberbegriff von Anspruch 1.The invention relates to a security system having the features in the preamble of

Ein derartiges Sicherheitssystem findet in unterschiedlichen hydraulischen Versorgungssystemen Anwendung und ist beispielsweise aus dem Produktkatalog "Speichertechnik" mit der Nr. D 3.553.4/03.16 der Firma HYDAC INTERNATIONAL bekannt. Die bekannte Lösung dient dem Befüllen und Prüfen von Hydro-Speicheranlagen mit sog. Nachschaltausführung. Hierzu weist der bekannte Ventilblock verschiedene Fluidanschlüsse auf, insbesondere für den Anschluss einer Füll- und Prüfeinrichtung, eines Manometers, von nachgeschalteten Stickstoffflaschen, eines Druckspeichers in Form eines Hydrospeichers sowie mindestens eines Gassicherheitsventils. Im Betrieb des Ventilblocks ist der Hydrospeicher, vorzugsweise in Form eines Kolbenspeichers, mit seiner Gasseite mit dem Gassicherheitsventil permanent verbunden. Die Flüssigkeitsseite des Hydrospeichers, die über ein Trennelement, wie einem in einem Speichergehäuse längsverfahrbar geführten Trennkolben, von der Gasseite separiert ist, ist an ein hydraulisches Versorgungssystem, beispielsweise in Form eines üblichen hydraulischen Arbeitskreises, angeschlossen. Ferner ist in dem Ventilblock ein Absperrventil vorhanden, das in seiner geöffneten Stellung den Fluidweg zwischen den möglicherweise angeschlossenen, nachgeschalteten Stickstoffflaschen und dem Hydrospeicher für eine gasführende Verbindung mit dem Stickstoffgas freigibt und das in seiner geschlossenen Stellung diesen Fluidweg sperrt.A safety system of this type is used in various hydraulic supply systems and is known, for example, from the "Storage Technology" product catalogue, No. D 3.553.4/03.16 from HYDAC INTERNATIONAL. The well-known solution is used for filling and testing hydraulic accumulator systems with a so-called back-up version. For this purpose, the known valve block has various fluid connections, in particular for connecting a filling and testing device, a manometer, downstream nitrogen bottles, a pressure accumulator in the form of a hydraulic accumulator and at least one gas safety valve. During operation of the valve block, the hydraulic accumulator, preferably in the form of a piston accumulator, is permanently connected with its gas side to the gas safety valve. The liquid side of the hydraulic accumulator, which is separated from the gas side by a separating element such as a longitudinally movable separating piston in an accumulator housing, is connected to a hydraulic supply system, for example in the form of a conventional hydraulic working circuit. Furthermore, a shut-off valve is present in the valve block, which in its open position the fluid path between the possibly connected, downstream Releases nitrogen bottles and the hydraulic accumulator for a gas-carrying connection with the nitrogen gas and blocks this fluid path in its closed position.

Bei Abnahme des jeweiligen Gassicherheitsventils vom Ventilblock, beispielsweise im Rahmen von Wartungs- oder Reparaturarbeiten, ist dann stets das gesamte, unter einem Betriebsdruck stehende Arbeitsgas aus dem Sicherheitssystem abzulassen, wobei der jeweils angeschlossene Hydrospeicher und/oder die jeweils angeschlossenen Stickstoffflaschen zu schließen sind und zumindest Teile einer angeschlossenen Hydraulikanlage müssen entsprechend drucklos gemacht werden. Bei anschließender Wiederinbetriebnahme des Sicherheitssystems samt jeweils zugehörigem Gassicherheitsventil und entsprechend angeschlossenen Druckspeichern sind die vorstehend angesprochenen Stilllegungsschritte wieder rückgängig zu machen.When the respective gas safety valve is removed from the valve block, for example as part of maintenance or repair work, the entire working gas that is under an operating pressure must then always be released from the safety system, with the respectively connected hydraulic accumulator and/or the respectively connected nitrogen bottles being closed and at least Parts of a connected hydraulic system must be depressurized accordingly. When the safety system is subsequently restarted, together with the associated gas safety valve and the correspondingly connected pressure accumulators, the decommissioning steps mentioned above must be reversed.

Die

Weitere Sicherheitssysteme gehen aus der

Ausgehend von diesem Stand der Technik stellt sich die Erfindung die Aufgabe, ein Sicherheitssystem mit verbesserter Funktionalität und zur Ressourcenschonung zu schaffen.Proceeding from this state of the art, the object of the invention is to create a security system with improved functionality and for saving resources.

Eine dahingehende Aufgabe löst ein Sicherheitssystem mit den Merkmalen des Patentanspruchs 1 in seiner Gesamtheit. Vorteilhafte Ausgestaltungen der Erfindung sind Gegenstand der Unteransprüche.A security system with the features of

Gemäß dem Kennzeichen von Anspruch 1 ist vorgesehen, dass an den Ventilblock mindestens zwei Gassicherheitsventile angeschlossen sind, und dass mittels einer Sicherheitseinrichtung, die das ansteuerbare Ventil umfasst, gewährleistet ist, dass zum Abnehmen eines Gassicherheitsventils vom Ventilblock die gasführende Verbindung zum jeweils angeschlossenen Druckspeicher unterbrochen ist und die zu mindestens einem anderen Gassicherheitsventil führende Verbindung derart aufrechterhalten bleibt, dass eine permanente gasführende Verbindung zwischen diesem jeweiligen Druckspeicher und diesem jeweils anderen Gassicherheitsventil während des Wechselvorgangs des einen Gassicherheitsventils und dessen erneuter Inbetriebnahme hergestellt ist.According to the characterizing part of

Dergestalt lässt sich der Betrieb einer hydraulischen, zumindest teilweise gasführenden Anlage aufrecht erhalten, auch wenn ein Gassicherheitsventil vom Ventilblock abgenommen ist, da das am Ventilblock sicherheitshalber verbleibende eine Gassicherheitsventil die angesprochenen Sicherheitsfunktionen vollständig übernimmt.In this way, the operation of a hydraulic, at least partially gas-carrying system can be maintained even if a gas safety valve has been removed from the valve block, since the one gas safety valve remaining on the valve block for safety's sake completely takes over the safety functions mentioned.

Dadurch, dass eine zumindest abschnittsweise innerhalb des Ventilblocks verlaufende gasführende Verbindung zwischen dem jeweils angeschlossenen Druckspeicher und dem jeweils angeschlossenen Gassicherheitsventil mittels des Ventils sperr- oder freigebbar ist, ist eine besonders hohe Sicherheit erreicht. Das jeweilige Gassicherheitsventil lässt sich im Bedarfsfall vom Ventilblock abnehmen, sofern das zugehörige Ventil im oder am Ventilblock in seine Sperrstellung gebracht und insoweit mit Sicherheit von dem jeweils angeschlossenen Druckspeicher gasseitig entkoppelt ist, der aus einem Hydrospeicher oder einem Gasspeicher, wie einer Stickstoffflasche oder einem sonstigen, zumindest teilweise gasführenden Druckbehälter, wie einem Vorratstank oder dergleichen, gebildet ist.Because a gas-carrying connection running at least in sections within the valve block between the respectively connected pressure accumulator and the respectively connected gas safety valve can be blocked or released by means of the valve, a particularly high level of safety is achieved. The respective gas safety valve can be opened if necessary remove from the valve block, provided that the associated valve in or on the valve block is brought into its closed position and to this extent is safely decoupled on the gas side from the respectively connected pressure accumulator, which consists of a hydraulic accumulator or a gas accumulator, such as a nitrogen bottle or another, at least partially gas-carrying pressure vessel, such as a storage tank or the like.

Das erfindungsgemäße Sicherheitssystem eröffnet die Möglichkeit, das am Ventilblock des Sicherheitssystems angeschlossene Gassicherheitsventil über ein zugeordnetes, ansteuerbares Ventil abzusperren, ohne dabei wesentliche Gasverluste auf Seiten der jeweiligen am Ventilblock angeschlossenen Druckspeicheranlage zu erleiden und ohne dass hydraulische Anlageteile drucklos zu machen wären.The safety system according to the invention opens up the possibility of shutting off the gas safety valve connected to the valve block of the safety system via an associated, controllable valve, without suffering significant gas losses on the part of the respective pressure accumulator system connected to the valve block and without hydraulic system parts having to be depressurized.

Die bei Reparatur- und/oder Wartungsarbeiten erforderliche Abnahme eines Gassicherheitsventils vom Ventilblock des Sicherheitssystems lässt sich schnell sowie kostengünstig durchführen und zeitlich aufwändige Entleer- und Befüllvorgänge auf der Gasseite einer insoweit angeschlossenen Anlage mit dem jeweiligen Druckspeicher können entfallen, was insoweit Ressourcen schonend ist. Dies hat so keine Entsprechung im Stand der Technik.The removal of a gas safety valve from the valve block of the safety system, which is required for repair and/or maintenance work, can be carried out quickly and inexpensively, and time-consuming emptying and filling processes on the gas side of a system connected in this way with the respective pressure accumulator can be eliminated, which is resource-saving in this respect. This has no equivalent in the prior art.

Druckspeicher im Sinne der Erfindung umfassen sämtliche zur Aufnahme eines Fluids, insbesondere eines Gases, geeigneten und eingesetzten Behältnisse, wie Druckbehältnisse, Hydrospeicher, Gasflaschen, insbesondere Stickstoffflaschen, und dergleichen. Es versteht sich, dass der im erfindungsgemäßen Sicherheitssystem eingesetzte Druckspeicher nicht auf die in einzelnen Bereichen üblichen Sprachdefinitionen eingeschränkt ist.Pressure accumulators within the meaning of the invention include all containers suitable and used for holding a fluid, in particular a gas, such as pressure containers, hydraulic accumulators, gas cylinders, in particular nitrogen cylinders, and the like. It goes without saying that the pressure accumulator used in the safety system according to the invention is not restricted to the language definitions customary in individual areas.

Bei einer bevorzugten Ausführungsform des erfindungsgemäßen Sicherheitssystems ist der jeweilige Druckspeicher ein Druckbehälter, der ausschließlich mit dem gasförmigen Druckmedium befüllt oder befüllbar ist, wie eine Stickstoffflasche oder ein Hydrospeicher, insbesondere in Balg-, Membran-, Speicher- oder Kolbenausführung, dessen in einem Speichergehäuse aufgenommenes Trennglied eine Gasseite von einer Flüssigkeitsseite trennt. Dergestalt lassen sich mit nur einem Sicherheitssystem auch verschiedene Arten von Druckspeichern, die nur an einen Ventilblock angeschlossen sind, sicher beherrschen, was regelmäßig der Fall ist, wenn auf einer Seite des Ventilblocks mindestens ein Hydrospeicher als Druckspeicher an eine hydraulische Anlage angeschlossen ist und auf derselben oder einer anderen Seite des Ventilblocks zusätzliche Stickstoffflaschen als Vorrats- oder Nachschaltflaschen angeschlossen sind, die bei hergestellter Fluidversorgung den Hydrospeicher auf seiner Gasseite auch im Betrieb desselben nachladen oder dessen Vorspannung auf seiner Gasseite im Betrieb erhöhen können.In a preferred embodiment of the security system according to the invention, the respective accumulator is a pressure vessel that exclusively is filled or can be filled with the gaseous pressure medium, such as a nitrogen cylinder or a hydraulic accumulator, in particular in the form of a bellows, membrane, accumulator or piston, the separating element of which, accommodated in an accumulator housing, separates a gas side from a liquid side. In this way, different types of pressure accumulators that are only connected to one valve block can also be safely controlled with just one safety system, which is regularly the case when at least one hydraulic accumulator is connected as a pressure accumulator to a hydraulic system on one side of the valve block and on the same or another side of the valve block, additional nitrogen cylinders are connected as storage or back-up cylinders, which can reload the hydraulic accumulator on its gas side even during operation of the hydraulic accumulator when the fluid supply is established or increase its preload on its gas side during operation.

Mit dem erfindungsgemäßen Sicherheitssystem ist insbesondere gewährleistet, dass bei einer Inbetriebnahme und beim fortlaufenden Betrieb eines hydraulischen Versorgungssystems in jedem Fall das auf einen maximalen Ansprechdruck eingestellte Gassicherheitsventil permanent mit der Gasseite des von seiner Flüssigkeitsseite her an ein hydraulisches System oder eine Anlage angeschlossenen Druckspeichers beispielsweise in Form eines Hydrospeichers verbunden bleibt. Insbesondere bei mehrfach am Ventilblock eingesetzten Gassicherheitsventilen lässt sich zu Reinigungsund/oder Wartungszwecken eines solchen Gassicherheitsventils dieses vom Ventilblock abnehmen, während das jeweils andere, am Ventilblock verbleibende Gassicherheitsventil die beschriebene Sicherheitsfunktion für das hydraulische Versorgungssystem nebst seinen Anlageteilen weiter wahrnimmt. Regelmäßig sind solche Gassicherheitsventile aus Druckbegrenzungsventilen gebildet, deren zur Umgebung führende Gasaustrittsseite von einem Netzgitter oder einem Sieb abgedeckt ist, um etwaig in der Nähe sich aufhaltende Personen im Sicherheitsfall von dem abströmenden Druckgas hohen Druckes zu schützen.The safety system according to the invention ensures in particular that during commissioning and continuous operation of a hydraulic supply system, the gas safety valve, which is set to a maximum response pressure, is permanently in contact with the gas side of the pressure accumulator connected from its liquid side to a hydraulic system or plant, for example in the form of a hydraulic accumulator remains connected. In particular in the case of gas safety valves used several times on the valve block, such a gas safety valve can be removed from the valve block for cleaning and/or maintenance purposes, while the other gas safety valve remaining on the valve block continues to perform the described safety function for the hydraulic supply system and its system parts. Such gas safety valves are regularly formed from pressure-limiting valves whose gas outlet side leading to the environment is covered by a mesh grid or a sieve in order to possibly in the In the event of safety, people in the vicinity are to be protected from the high-pressure discharged compressed gas.

Bei einer bevorzugten Ausführungsform des erfindungsgemäßen Sicherheitssystems liegt der Sicherheitseinrichtung ein mechanisches Verriegelungskonzept, ein mechanisches Steuerkonzept, ein elektrisches Überwachungskonzept oder ein chipgesteuertes Betätigungskonzept für das jeweils ansteuerbare Ventil zugrunde. Durch die anforderungsgerechte, an die jeweilige Anwendung angepasste Ausgestaltung der Sicherheitseinrichtung ist im laufenden Betrieb bei geringer Stör- und Fehleranfälligkeit eine sichere Absperrung des Druckspeichers beispielsweise vor Abnahme eines zugehörigen Gassicherheitsventils gewährleistet. Mechanische Konzepte für die Verriegelung oder die Ventilsteuerung bieten den Vorteil einer hohen Robustheit sowie einer geringen Wartungsintensität. Ein elektrisches oder chipgesteuertes Konzept für die Überwachung oder die Betätigung bietet den Vorteil eines geringen Bauraumerfordernisses sowie die Möglichkeit einer Fernüberwachung bei Einsatz einer entsprechenden Datenübertragung.In a preferred embodiment of the safety system according to the invention, the safety device is based on a mechanical locking concept, a mechanical control concept, an electrical monitoring concept or a chip-controlled actuation concept for the controllable valve in each case. Due to the design of the safety device that meets the requirements and is adapted to the respective application, a safe shut-off of the pressure accumulator is ensured during operation with little susceptibility to faults and errors, for example before removing an associated gas safety valve. Mechanical concepts for locking or valve control offer the advantage of high robustness and low maintenance. An electrical or chip-controlled concept for the monitoring or the actuation offers the advantage of a small installation space requirement and the possibility of remote monitoring when using a corresponding data transmission.

Bei einer weiteren bevorzugten Ausführungsform des erfindungsgemäßen Sicherheitssystems sind für die Realisierung des mechanischen Verriegelungskonzepts zwei, vorzugsweise von Hand betätigbare, Kugelhähne vorgesehen, die jeweils an ein zuordenbares Gassicherheitsventil gasführend angeschlossen sind und die Steuerscheiben tragen, die im gegenseitig verriegelten Zustand sicherstellen, dass ein Kugelhahn in seiner geöffneten Stellung das zugehörige Gassicherheitsventil mit dem Druckspeicher über eine Verbindung gasführend verbindet und der andere Kugelhahn in seiner Sperrstellung für ein Entfernen des zugehörigen Gassicherheitsventils, beispielsweise zu Austausch- oder Wartungszwecken, vom Ventilblock eine zugehörige andere Verbindung zum jeweiligen Druckspeicher sperrt.In a further preferred embodiment of the safety system according to the invention, two ball valves, which can preferably be actuated by hand, are provided for the implementation of the mechanical locking concept, which are each connected to an assignable gas safety valve and carry the control discs, which in the mutually locked state ensure that a ball valve its open position connects the associated gas safety valve to the pressure accumulator via a gas-carrying connection and the other ball valve in its blocking position for removing the associated gas safety valve from the valve block, for example for replacement or maintenance purposes, blocks another associated connection to the respective pressure accumulator.

Die Steuerscheiben sind integraler Bestandteil einer mechanischen Verriegelung der Betätigungselemente der Kugelhähne und vorzugsweise an einer Außenseite des Ventilblocks angeordnet. Sobald ein Kugelhahn gesperrt wird zur Abnahme des zugehörigen Gassicherheitsventils, wird die zugehörige Steuerscheibe derart mit zumindest einer Steuerscheibe eines weiteren Gassicherheitsventils verriegelt, dass das weitere Gassicherheitsventil in der geöffneten, betriebssicheren Stellung blockiert und sicher gehalten ist. Somit ist bei Abnahme und Entfernen eines Gassicherheitsventils mindestens ein funktionstüchtiges weiteres Gassicherheitsventil an den Ventilblock in seiner Offenstellung angeschlossen, das dann ausschließlich die Sicherheitsfunktion wahrnimmt.The control discs are an integral part of a mechanical locking mechanism for the actuation elements of the ball valves and are preferably arranged on an outside of the valve block. As soon as a ball valve is blocked to remove the associated gas safety valve, the associated control disk is locked with at least one control disk of another gas safety valve in such a way that the other gas safety valve is blocked and securely held in the open, operationally safe position. Thus, when a gas safety valve is removed and removed, at least one functional additional gas safety valve is connected to the valve block in its open position, which then exclusively performs the safety function.

Bei einer weiteren bevorzugten Ausführungsform der Erfindung ist mittels zweier Handhebel der Kugelhähne, ausgehend von einer gemeinsamen Öffnungsrichtung, je eine der Steuerscheiben in Richtung einer Schließstellung des Kugelhahns betätigbar, die außenumfangsseitig einen Ausschnitt aufweist, der mit einem korrespondierend ausgebildeten Ausschnitt am Außenumfang der anderen Steuerscheibe derart zusammenwirkt, dass eine Drehbewegung des jeweiligen Kugelhahns mittels des zugeordneten Handhebels ermöglicht oder blockiert ist. Besonders bevorzugt weist der jeweilige Ausschnitt eine bogenförmige Kontur mit einer Krümmung vergleichbar dem Außenumfang der Steuerscheibe auf. In einen derart geformten Ausschnitt greift die jeweils andere Steuerscheibe derart ein, dass der zugehörige Handhebel in der gewählten Stellung blockiert und ein unbeabsichtigtes oder gewolltes Ändern dieser Stellung nicht möglich ist.In a further preferred embodiment of the invention, two hand levers of the ball valves, starting from a common opening direction, can be used to actuate one of the control disks in the direction of a closed position of the ball valve, which has a cutout on the outer circumference which corresponds to a correspondingly designed cutout on the outer circumference of the other control disc cooperates in that a rotational movement of the respective ball valve is enabled or blocked by means of the associated hand lever. The respective section particularly preferably has an arcuate contour with a curvature comparable to the outer circumference of the control disk. The respective other control disk engages in such a shaped cutout in such a way that the associated hand lever is blocked in the selected position and an unintentional or intentional changing of this position is not possible.

Die Gassicherheitsventile weisen eine zylindrische Grundform auf und sind an einer Unterseite des Ventilblocks angeordnet. Die Handhebel zur Betätigung der zugehörigen Kugelventile sind vorzugsweise an einer für eine Bedienperson zugänglichen Seite des Ventilblocks angeordnet, wobei in der Regel eine senkrechte Richtung die Öffnungsstellung und eine waagerechte Richtung die Schließstellung des zugehörigen Kugelhahns anzeigt. Besonders bevorzugt sind die Ausschnitte bei benachbarten Handhebeln derart angeordnet, dass in der Öffnungsstellung der beiden Handhebel die Ausschnitte benachbart und gegenüberliegend derart zueinander angeordnet sind, dass bei Bewegung des einen Handhebels in die Schließstellung die zugehörige Steuerscheibe in den Ausschnitt an der anderen Steuerscheibe des anderen Handhebels hinein bewegt wird und dabei deren Bewegung gleichfalls in die Schließstellung blockiert.The gas safety valves have a cylindrical basic shape and are arranged on the underside of the valve block. The hand levers for actuating the associated ball valves are preferably arranged on a side of the valve block that is accessible to an operator, with a vertical direction generally being the open position and a horizontal one being the open position Direction indicates the closed position of the associated ball valve. The cutouts in adjacent hand levers are particularly preferably arranged in such a way that when the two hand levers are in the open position, the cutouts are arranged adjacent and opposite one another in such a way that when one hand lever is moved into the closed position, the associated control disk fits into the cutout on the other control disk of the other hand lever is moved in and thereby also blocking their movement into the closed position.

Vorzugsweise sind zwei oder mehr Gassicherheitsventile nebeneinander, eine Reihe bildend, am Ventilblock angeordnet. Dementsprechend sind zwei bzw. mehr Handhebel mit zugehörigen Steuerscheiben nebeneinander, eine Reihe bildend, an der Seite des Ventilblocks angeordnet.Two or more gas safety valves are preferably arranged next to one another, forming a row, on the valve block. Accordingly, two or more hand levers with associated control disks are arranged next to one another, forming a row, on the side of the valve block.

Weiter ist vorteilhaft, dass die Steuerscheibe mit einer Anschlagbegrenzung am Ventilblock derart zusammenwirkt, dass der Handhebel aus einer Öffnungsrichtung parallel zu der Längsrichtung des jeweiligen Gassicherheitsventils um 90° in eine Sperrstellung quer zu dieser Längsausrichtung und umgekehrt verschwenkbar ist. Hieraus ergibt sich der Vorteil einer fehlerfreien Bedienung beim Verschwenken des jeweiligen Handhebels in eine seiner Stellungen.It is also advantageous that the control disc interacts with a limit stop on the valve block in such a way that the hand lever can be pivoted from an opening direction parallel to the longitudinal direction of the respective gas safety valve by 90° into a blocking position transverse to this longitudinal alignment and vice versa. This results in the advantage of error-free operation when pivoting the respective hand lever into one of its positions.

Bei einer weiteren bevorzugten Ausführungsform des erfindungsgemäßen Sicherheitssystems ist für die Realisierung des mechanischen Steuerkonzepts als steuerbares Ventil ein 3-Wege-Kugelhahn eingesetzt, der in seiner einen Schaltstellung ein Gassicherheitsventil über eine Verbindung mit dem Druckspeicher gasführend verbindet und ein anderes Gassicherheitsventil durch Sperren einer zugehörigen anderen Verbindung vom Druckspeicher entkoppelt, wobei in einer weiteren Schaltstellung das andere Gassicherheitsventil über die andere Verbindung mit dem Druckspeicher gasführend verbunden und das eine Gassicherheitsventil durch Sperren der einen Verbindung entkoppelt ist. Durch den Einsatz nur eines 3-Wege-Kugelhahns können zwei separate Kugelhähne für die beiden Gassicherheitsventile entfallen. Unabhängig von der Schaltstellung des 3-Wege-Kugelhahns ist dann aber ein Gassicherheitsventil an den Druckspeicher angeschlossen und ein Gassicherheitsventil hiervon getrennt, so dass zumindest immer ein Gassicherheitsventil die Sicherheitsfunktion für den Druckspeicher übernimmt.In a further preferred embodiment of the safety system according to the invention, a 3-way ball valve is used as a controllable valve for the implementation of the mechanical control concept, which in its one switching position connects a gas safety valve via a connection to the pressure accumulator in a gas-carrying manner and another gas safety valve by blocking an associated other Connection decoupled from the accumulator, in a further switching position the other gas safety valve connected via the other connection to the accumulator gas-carrying and a gas safety valve through Lock the one connection is decoupled. By using only one 3-way ball valve, two separate ball valves for the two gas safety valves can be omitted. Regardless of the switching position of the 3-way ball valve, a gas safety valve is then connected to the pressure accumulator and a gas safety valve is separated from it, so that at least one gas safety valve always assumes the safety function for the pressure accumulator.

Bei einer weiteren bevorzugten Ausführungsform des erfindungsgemäßen Sicherheitssystems ist für die Realisierung des elektrischen Überwachungskonzepts mittels einer Sensorik die Position des jeweils ansteuerbaren Ventils auf seine Öffnungs- und/oder Schließstellung hin überwacht, und ein Betrieb des hydraulischen Versorgungssystems wird von einer übergeordneten Steuerung erst dann ermöglicht, wenn die Sensorik feststellt und an die Steuerung übermittelt, dass die jeweilige gasführende Verbindung zwischen Gassicherheitsventil und Druckspeicher über das steuerbare Ventil tatsächlich freigegeben ist. Hieraus ergibt sich der Vorteil, dass ein Öffnen oder Sperren der gasführenden Verbindung "automatisch" feststellbar ist. Mittels einer zusätzlichen optischen Anzeige, beispielsweise an einer Außenseite des Ventilblocks angebracht, kann einer Bedienperson die Freigabe zur Abnahme des Gassicherheitsventils angezeigt werden, wenn das andere Gassicherheitsventil die Sicherheitsfunktion wahrnimmt.In a further preferred embodiment of the safety system according to the invention, for the implementation of the electrical monitoring concept, the position of the controllable valve is monitored by means of a sensor system with regard to its open and/or closed position, and operation of the hydraulic supply system is only made possible by a higher-level controller if when the sensors determine and transmit to the controller that the respective gas-carrying connection between the gas safety valve and the pressure accumulator is actually released via the controllable valve. This results in the advantage that an opening or blocking of the gas-carrying connection can be detected "automatically". By means of an additional optical display, for example attached to an outside of the valve block, an operator can be shown the release to remove the gas safety valve when the other gas safety valve performs the safety function.

Bei einer weiteren bevorzugten Ausführungsform des erfindungsgemäßen Sicherheitssystems ist für die Realisierung des chipgesteuerten Betätigungskonzepts ein Steuerchip vorgesehen, der an der Steuerung des hydraulischen Versorgungssystems eingesetzt deren Betrieb erst ermöglicht, bei dessen Entfernen das Versorgungssystem aber stillsetzt und bei dessen Einsatz am steuerbaren Ventil das jeweils zuordenbare Gassicherheitsventil dann gasseitig vom Druckspeicher durch Sperren der zugehörigen Verbindung entkoppelt. Umgekehrt ist ein Betrieb des hydraulischen Versorgungssystems erst möglich, wenn der Steuerchip nach Entnahme das Gassicherheitsventil wieder in seine Öffnungsstellung freigibt und dieser Chip an der Steuerung erneut eingesetzt den Betrieb der angeschlossenen hydraulischen Anlage wieder ermöglicht.In a further preferred embodiment of the safety system according to the invention, a control chip is provided for the realization of the chip-controlled actuation concept, which is used on the control of the hydraulic supply system and enables its operation in the first place, but when it is removed the supply system is shut down and when it is used on the controllable valve the assignable gas safety valve then on the gas side from the pressure accumulator by blocking the associated connection decoupled. Conversely, operation of the hydraulic supply system is only possible if the control chip releases the gas safety valve back into its open position after removal and this chip is reinserted in the control system to enable operation of the connected hydraulic system again.

Weiter ist vorteilhaft, dass der Ventilblock mindestens einen weiteren Versorgungsanschluss aufweist, über den mindestens ein weiterer Druckspeicher, vorzugsweise ein Gasdruckspeicher, anschließbar ist, der über ein innerhalb des Ventilblocks angeordnetes Sperrventil in seiner geöffneten Stellung mit dem jeweiligen Druckspeicher gasführend verbunden, vorzugsweise an die Gasseite eines Hydrospeichers angeschlossen, ist. Über den weiteren Versorgungsanschluss kann dann insbesondere Gas aus dem Gasvorrat der Speicherflasche entnommen und auf die Gasseite des Hydrospeichers geleitet werden, um dergestalt das Arbeitsvermögen dieses Hydrospeichers zu erhöhen.It is also advantageous that the valve block has at least one additional supply connection, via which at least one additional pressure accumulator, preferably a gas pressure accumulator, can be connected, which, in its open position, is connected to the respective pressure accumulator to carry gas, preferably to the gas side, via a check valve arranged within the valve block connected to a hydraulic accumulator. In particular, gas can then be taken from the gas supply of the storage bottle via the additional supply connection and routed to the gas side of the hydraulic accumulator in order to increase the working capacity of this hydraulic accumulator in this way.

Weiter ist vorteilhaft, dass der Ventilblock zumindest eine weitere Anschlussstelle aufweist, an die eine Füll- und Prüfeinrichtung anschließbar ist, die über eine Füll- und Prüfverbindung im Ventilblock direkt mit dem Druckspeicher gasführend verbunden, vorzugsweise an die Gasseite eines Hydrospeichers in Form eines Kolbenspeichers angeschlossen, ist, und dass diese Füll- und Prüfverbindung über ein Rückschlagventil, das in Richtung des jeweiligen steuerbaren Ventils öffnet, an eine weitere Verbindung zwischen dem jeweiligen weiteren Druckspeicher und dem Druckspeicher angeschlossen ist. Über die Füll- und Prüfeinrichtung sind Eigenschaften des Gases, wie Temperatur und Druck des Gasvolumens, überwach- und erfassbar.It is also advantageous that the valve block has at least one additional connection point to which a filling and testing device can be connected, which is connected directly to the pressure accumulator via a filling and testing connection in the valve block, preferably connected to the gas side of a hydraulic accumulator in the form of a piston accumulator , Is, and that this filling and testing connection is connected to a further connection between the respective further pressure accumulator and the pressure accumulator via a non-return valve which opens in the direction of the respective controllable valve. Properties of the gas, such as temperature and pressure of the gas volume, can be monitored and recorded via the filling and testing device.

Ist an den vorstehend bezeichneten Hydrospeicher auf seiner Flüssigkeitsseite in üblicher Weise ein hydraulisches Versorgungssystem angeschlossen, ist mit dem erfindungsgemäßen Sicherheitssystem gewährleistet, dass im Fall einer Betriebsstörung, wie sie auch durch einen Brand verursacht sein kann, es nicht ungewollt zu einer Druckerhöhung auf der Gasseite des Hydrospeichers kommen kann, da über die geöffnete Ventileinrichtung, respektive den in Öffnungsstellung befindlichen Kugelhahn sichergestellt ist, dass bei Überschreiten eines Maximaldrucks auf den das jeweilige Gassicherheitsventil eingestellt ist, Gas mit höherem Druck auf der Hydrospeicherseite in die Umgebung direkt entweichen kann. Dergestalt wird auch ein zu hoher Druck auf der Flüssigkeitsseite des Hydrospeichers und auf Seiten des Versorgungssystems, der zum Bersten von Anlageteilen führen könnte, unmittelbar abgebaut, so dass eine Gefährdung von Bedienpersonen an den Anlageteilen des Versorgungssystems ausgeschlossen ist. Das Sicherheitssystem gewährleistet dabei weiter, dass manuelle Fehlbedienungen, die zu einer ungewollten Stilllegung der Funktion des Gassicherheitsventils führen könnten, ausgeschlossen sind.If a hydraulic supply system is connected to the fluid side of the hydraulic accumulator described above in the usual way, With the safety system according to the invention, it is ensured that in the event of a malfunction, such as can be caused by a fire, there cannot be an unintentional increase in pressure on the gas side of the hydraulic accumulator, since this is ensured by the open valve device or the ball valve in the open position is that if a maximum pressure to which the respective gas safety valve is set is exceeded, gas with a higher pressure on the hydraulic accumulator side can escape directly into the environment. In this way, too high a pressure on the liquid side of the hydraulic accumulator and on the side of the supply system, which could lead to the bursting of parts of the system, is reduced immediately, so that there is no danger to operators on the parts of the supply system. The safety system also ensures that incorrect manual operation, which could lead to an unintentional shutdown of the function of the gas safety valve, is ruled out.

Weitere Vorteile und Merkmale der Erfindung ergeben sich aus den Figuren und der nachfolgenden Beschreibung der Zeichnung. Die vorstehend genannten und die weiter angeführten Merkmale können erfindungsgemäß jeweils einzeln oder in beliebigen Kombinationen an einem erfindungsgemäßen Sicherheitssystem realisiert sein. Die in den Figuren gezeigten Merkmale sind rein schematisch und nicht maßstäblich zu verstehen. Es zeigen:

- Fig. 1a bis 1c

- jeweils eine Seitenansicht auf ein Ausführungsbeispiel eines Ventilblocks eines Sicherheitssystems mit unterschiedlichen Betätigungsstellungen von einzelnen Gassicherheitsventilen zugeordneten Handhebeln;

- Fig. 2

- eine perspektivische Ansicht des Ventilblocks aus

Fig. 1b ; - Fig. 3a und 3b

- jeweils einen Schaltplan für ein erstes Ausführungsbeispiel des erfindungsgemäßen Sicherheitssystems;

- Fig. 4