EP3333112B1 - Load handling tool and hydraulic crane comprising such a load handling tool - Google Patents

Load handling tool and hydraulic crane comprising such a load handling tool Download PDFInfo

- Publication number

- EP3333112B1 EP3333112B1 EP16203102.5A EP16203102A EP3333112B1 EP 3333112 B1 EP3333112 B1 EP 3333112B1 EP 16203102 A EP16203102 A EP 16203102A EP 3333112 B1 EP3333112 B1 EP 3333112B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- locking

- bucket

- fold

- relation

- pivot arm

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66C—CRANES; LOAD-ENGAGING ELEMENTS OR DEVICES FOR CRANES, CAPSTANS, WINCHES, OR TACKLES

- B66C3/00—Load-engaging elements or devices attached to lifting or lowering gear of cranes or adapted for connection therewith and intended primarily for transmitting lifting forces to loose materials; Grabs

- B66C3/02—Bucket grabs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66C—CRANES; LOAD-ENGAGING ELEMENTS OR DEVICES FOR CRANES, CAPSTANS, WINCHES, OR TACKLES

- B66C3/00—Load-engaging elements or devices attached to lifting or lowering gear of cranes or adapted for connection therewith and intended primarily for transmitting lifting forces to loose materials; Grabs

- B66C3/14—Grabs opened or closed by driving motors thereon

Definitions

- the present invention relates to a load handling tool according to the preamble of claim 1.

- the invention also relates to a hydraulic crane comprising such a load handling tool.

- An ordinary lorry crane may be provided with a load handling tool mounted to an outer end of a crane boom in the form of a so-called outer boom, which is telescopically extensible and articulately connected to another crane boom in the form of a so-called inner boom, wherein the inner boom in its turn is articulately connected to a rotatable column of the crane.

- a load handling tool is previously known from EP 2 778 109 A1 .

- This previously known load handling tool has the form of a clam shell bucket with open shells and is intended to be mounted to a crane boom, wherein one of the bucket jaws of the clam shell bucket is provided with a recess for receiving a part of the crane boom in order to allow the crane boom and the clam shell bucket to assume a compact parking position.

- EP 2778 109 A1 is described in US 4023 848 A1 .

- the clam shell bucket disclosed in EP 2 778 109 A1 is particularly suitable for use with a so-called Z-type crane, which is a hydraulic lorry crane of the type illustrated in EP 1 475 345 A1 and US 4 183 712 A where inner and outer booms of the crane are foldable into a compact Z-shaped parking position when the crane is to be transported or stored.

- Z-type crane which is a hydraulic lorry crane of the type illustrated in EP 1 475 345 A1 and US 4 183 712 A where inner and outer booms of the crane are foldable into a compact Z-shaped parking position when the crane is to be transported or stored.

- the clam shell bucket has to be removed from the crane before the outer boom is moved from the working position to the parking position.

- the removal of the clam shell bucket from the outer boom constitutes an undesired time-consuming task for the crane operator and also implies that space on the lorry has to be occupied for storage of the removed clam shell bucket.

- the object of the present invention is to provide a solution to the above-mentioned problem.

- the load handling tool of the present invention comprises:

- the load handling tool of the present invention can be brought into a compact state by moving the bucket jaws to the fold-up storing position and it may be kept in this compact state under the effect of the actuating device acting on the pivot arms.

- a collapsible load handling tool of this type is suitable for use with a foldable knuckle boom crane of the above-mentioned type, wherein the load handling tool with the bucket jaws in the fold-up storing position may remain connected to the outer end of the outer boom when the outer boom is moved between the working position and the parking position, as explained in closer detail in the description following below.

- the invention also relates to a hydraulic crane having the features defined in claim 9.

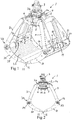

- a load handling tool 1 according to an embodiment of the present invention is illustrated in Fig 1-10 .

- the load handling tool 1 is to be attached to a crane boom, as illustrated in Fig 11 .

- the load handling tool 1 is designed as a clamshell bucket with open shells.

- the load handling tool 1 comprises a carrier head 2 and a rotator 3 mounted to the carrier head, wherein the carrier head 2 is configured to be connected to a crane boom via the rotator 3.

- the load handling tool 1 may be rotated in relation to the crane boom by means of the rotator 3.

- the load handling tool 1 further comprises first and second bucket jaws 10, 30 which are carried by the carrier head 2 and located opposite each other.

- the first bucket jaw 10 is pivotally connected to the carrier head 2 via a first pivot arm 11 and the second bucket jaw 30 is pivotally connected to the carrier head 2 via a second pivot arm 31, so as to allow the bucket jaws 10, 30 to be pivoted towards each other in order to grasp a load and away from each other in order to release a grasped load.

- Each bucket jaw 10, 30 has a leading edge 12, 32, wherein the leading edge 12 of the first bucket jaw 10 faces the leading edge 32 of the second bucket jaw 30.

- Each pivot arm 11, 31 has a first end 11a, 31a facing the carrier head 2 and an opposite second end 11b, 31b facing the associated bucket jaw 10, 30, wherein each pivot arm 11, 31 at its first end 11a, 31a is pivotally connected to the carrier head 2.

- the first pivot arm 11 is pivotable in relation to the carrier head 2 about a first pivot axis A1 (see Fig 2 ) and the second pivot arm 31 is pivotable in relation to the carrier head 2 about a second pivot axis A2, wherein the second pivot axis A2 is located at a distance from and extends in parallel with the first pivot axis A1.

- Each pivot arm 11, 31 is at its second end 11b, 31b articulately connected to the associated bucket jaw 10, 30 so as to allow the bucket jaw to be pivoted in relation to the pivot arm 11, 31 between a fold-down working position (see Figs 1-7 ) and a fold-up storing position (see Figs 8-10 ).

- the bucket jaws 10, 30 are configured to be located between the pivot arms 11, 31 and to rest against each other in the fold-up storing position, as illustrated in Figs 8 and 9 .

- the first bucket jaw 10 is pivotable in relation to the first pivot arm 11 about a third pivot axis A3 (see Fig 2 ), which extends in parallel with the above-mentioned first pivot axis A1, wherein the distance between the first and third pivot axes A1, A3 is larger than the distance between the third pivot axis A3 and the leading edge 12 of the first bucket jaw 10, to thereby allow the first bucket jaw 10 to be received between the first and second pivot arms 11, 31 when it is in the fold-up storing position.

- the second bucket jaw 30 is pivotable in relation to the second pivot arm 31 about a fourth pivot axis A4 (see Fig 2 ), which extends in parallel with the above-mentioned second pivot axis A2, wherein the distance between the second and fourth pivot axes A2, A4 is larger than the distance between the fourth pivot axis A4 and the leading edge 32 of the second bucket jaw 30, to thereby allow the second bucket jaw 30 to be received between the first and second pivot arms 11, 31 when it is in the fold-up storing position.

- a fourth pivot axis A4 see Fig 2

- each bucket jaw 10, 30 has a closed bottom surface 13, 33.

- one or more openings could be provided in the bottom surface 13, 33 of one or both bucket jaws.

- the load handling tool 1 comprises a first locking device 14 for locking the first bucket jaw 10 to the first pivot arm 11 in the fold-down working position, and a second locking device 34 for locking the second bucket jaw 30 to the second pivot arm 31 in the fold-down working position.

- the load handling tool 1 comprises an actuating device 4 for pivoting the pivot arms 11, 31 and thereby the bucket jaws 10, 30 in relation to the carrier head 2.

- the actuating device 4 is a hydraulic motor accommodated in the carrier head 2, for instance a hydraulic motor of the type described in closer detail in DE 202004013158 U1 or EP 1 541 771 B1 .

- the actuating device 4 comprises two rotatably driven pivot shafts which are rotatably mounted to the carrier head 2, each pivot shaft having two opposite shaft ends which project from the carrier head 2 on opposite sides thereof.

- the first pivot arm 11 is non-rotatably fixed to the opposite shaft ends 5 of a first one of the pivot shafts and the second pivot arm 31 is non-rotatably fixed to the opposite shaft ends 6 of the other pivot shaft.

- the actuating device may comprise one or two hydraulic cylinders for pivoting the pivot arms 11, 31 and thereby the bucket jaws 10, 30 in relation to the carrier head 2. Any other suitable type of actuating device may also be used for pivoting the pivot arms 11, 31 in relation to the carrier head 2.

- a load handling tool 1 according to an alternative embodiment is illustrated in Fig 25 .

- This load handling tool 1 comprises an actuating device 4' in the form of a hydraulic cylinder which is vertically arranged in the carrier head 2 and configured to act on the first and second pivot arms 11, 31 via a link mechanism 6 in order to pivot the pivot arms 11, 31 in relation to the carrier head 2.

- the load handling tool 1 illustrated in Fig 25 corresponds to the load handling tool illustrated in Figs 1-10 .

- the above-mentioned first locking device 14 comprises at least one locking member 15 which is moveable between an unlocking position (see Figs 6-8 ), in which the first bucket jaw 10 is free to pivot in relation to the first pivot arm 11 between the fold-down working position and the fold-up storing position, and a locking position (see Figs 1 , 3 and 4 ), in which the locking member 15 prevents the first bucket jaw 10 from pivoting in relation to the first pivot arm 11 from the fold-down working position towards the fold-up storing position.

- the first locking device 14 comprises two such locking members 15, which are slidably mounted to a cross-bar 16 on the first pivot arm 11 so as to be slidable along this cross-bar 16 between the locking position and the unlocking position.

- each locking member 15 comprises a shoulder 17a (see Fig 7 ) which is configured to be in contact with a corresponding shoulder 17b (see Fig 8 ) on the first bucket jaw 10 when the locking member 15 is in the locking position, as illustrated in Fig 4 , and thereby prevent the first bucket jaw 10 from pivoting in relation to the first pivot arm 11 towards the fold-up storing position.

- the shoulder 17a on the locking member is no longer in contact with the corresponding shoulder 17b on the first bucket jaw 10, as illustrated in Figs 7 and 8 , and the first bucket jaw is thereby allowed to pivot in relation to the first pivot arm 11 between the fold-down working position and the fold-up storing position.

- the above-mentioned second locking device 34 comprises at least one locking member 35 which is moveable between an unlocking position (see Figs 6 and 10 ), in which the second bucket jaw 30 is free to pivot in relation to the second pivot arm 31 between the fold-down working position and the fold-up storing position, and a locking position (see Fig 1 ), in which the locking member 35 prevents the second bucket jaw 30 from pivoting in relation to the second pivot arm 31 from the fold-down working position towards the fold-up storing position.

- the second locking device 34 comprises two such locking members 35, which are slidably mounted to a cross-bar 36 on the second pivot arm 31 so as to be slidable along this cross-bar 36 between the locking position and the unlocking position.

- the locking members 35 of the second locking device 34 have the same configuration and are operated in the same manner as the locking members 15 of the first locking device 14.

- each locking device 14, 34 comprises a handle 18, 38, by means of which the locking members 15, 35 of the locking device are moveable between the locking position and the unlocking position.

- the handle 18, 38 is connected to the associated locking members 15, 35 via a link mechanism 19, 39.

- the first and second locking devices 14, 34 may of course also be configured and operated in any other suitable manner.

- Each locking device 14, 34 may for instance comprise a hydraulically or electrically operated actuating unit for moving the locking members 15, 35 between the locking position and the unlocking position.

- Each bucket jaw 10, 30 is provided with at least one stop member 20, 40 (see Figs 1 , 5 , 8 and 10 ) which is configured to come into contact with a corresponding stop member 21, 41 on the associated pivot arm 11, 31 and thereby stop the pivotal movement of the bucket jaw 10, 30 in relation to the pivot arm 21, 31 when the bucket jaw 10, 30 has been pivoted in relation to the pivot arm 11, 31 from the fold-up storing position to the fold-down working position.

- each bucket jaw 10, 30 is provided with several such stop members 20, 40 distributed along the bucket jaw.

- the locking members 15, 35 are first moved from the locking position to the unlocking position.

- the load handling tool 1 With the leading edges 12, 32 of the first and second bucket jaws 10, 30 in contact with each other, the load handling tool 1 is thereafter lowered downwards against an upwardly protruding object so that the object will push the leading edges 12, 32 of the bucket jaws 10, 30 upwards in a pivoting movement in relation to the pivot arms 11, 31 about the third and fourth pivot axes A3, A4 until the leading edges 12, 32 assume a position above a horizontal plane across the third and fourth pivot axes A3, A4 and consequently point upwards.

- the final movement of the bucket jaws 10, 30 to the fold-up storing position is effected by means of the above-mentioned actuating device 4, which pivots the pivot arms 11, 31 towards each other and thereby pushes the bucket jaws 10, 30 towards each other so that the bucket jaws are forced to pivot further upwards in relation to the pivot arms 11, 31 in order to finally assume the fold-up storing position illustrated in Figs 8 and 9 .

- the bucket jaws 10, 30 are thereafter maintained in the fold-up storing position under the effect of the actuating device 4, which keeps the bucket jaws clamped between the pivot arms 11, 31 in the fold-up storing position.

- the load handling tool 1 could also be provided with a suitable locking device for keeping the bucket jaws 10, 30 locked in the fold-up storing position.

- the pivot arms 11, 31 are pivoted away from each other by means of the actuating device 4 so that the bucket jaws 10, 30 are allowed to pivot downwards in relation to the pivot arms 11, 31 under the effect of gravity, as illustrated in Figs 18g and 18h .

- the load handling tool 1 is provided with hydraulically or electrically operated actuating units for pivoting the bucket jaws 10, 30 in relation to the pivot arms 11, 31 between the fold-down working position and the fold-up storing position.

- a hydraulic crane 60 provided with a load handling tool 1 of the type described above is illustrated in Figs 11-24 .

- the illustrated crane 60 is mounted on a frame 61, which for instance may be connected to the chassis of a lorry.

- the frame 61 is provided with adjustable support legs 62 for supporting the crane 60.

- the crane 60 comprises:

- the outer boom 67 is telescopically extensible to enable an adjustment of the extension length thereof.

- the outer boom 67 comprises a base section 67a, through which the outer boom 67 is articulately connected to the inner boom 65, and several telescopic crane boom sections 67b which are carried by the base section 67a and displaceable in the longitudinal direction of the base section by means of hydraulic cylinders 69 for adjustment of the extension length of the outer boom 67.

- the illustrated crane 60 is a foldable knuckle boom crane, wherein the inner and outer booms 65, 67 of the crane are foldable into a compact parking position when the crane is to be transported or stored, as illustrated in Figs 12-14 .

- the telescopic crane boom sections 67b of the outer boom 67 are first retracted into the base section 67a of the outer boom, whereupon the outer boom 67 is folded downwards towards the inner boom 65 so as to assume a position essentially in parallel with the inner boom, as illustrated in Fig 18b .

- the inner boom 65 is folded downwards together with the outer boom 67 towards the frame 61 from the intermediate position illustrated in Fig 18b to the final parking position illustrated in Fig 12 .

- the inner and outer booms 65, 67 are moved in the opposite manner when they are to be moved from the parking position to the erected working position.

- the load handling tool 1 is mounted to the outer end of the outer boom 67.

- the bucket jaws 10, 30 of the load handling tool 1 has to be in the fold-up storing position and arranged in a suitable fixed position in relation to the outer boom 67.

- the crane 60 comprises a holding- and locking mechanism 70 (see Figs 15-17 ) for locking the load handling tool 1 to the second crane boom 67 with the first and second bucket jaws 10, 30 in the fold-up storing position and with the load handling tool 1 in a given fixed position in relation to and at the side of the outer boom 67.

- a holding- and locking mechanism 70 for locking the load handling tool 1 to the second crane boom 67 with the first and second bucket jaws 10, 30 in the fold-up storing position and with the load handling tool 1 in a given fixed position in relation to and at the side of the outer boom 67.

- the holding- and locking mechanism 70 comprises:

- first and third coupling members 72a, 72b have the form of hooks

- the second coupling member 22 has the form of a recess in the first bucket jaw 10

- the fourth coupling member 42 has the form of a recess in the second bucket jaw 30.

- the first coupling member 72a is insertable into the second coupling member 22

- the third coupling member 72b is insertable into the fourth coupling member 42.

- the holding- and locking mechanism 70 further comprises a base structure 74, which is fixed to the base section 67a of the outer boom 67, wherein the first and third coupling members 72a, 72b are fixed to and protrude from the base structure 74.

- the locking member 73 of the holding- and locking mechanism 70 has the form of a lever and is pivotally mounted to the base structure 74 through a joint 75 so as to be pivotable in relation to the base structure 74 about this joint 75 between its locking position and its unlocking position.

- the locking member 73 is provided with a protruding locking element 76 (see Figs 16 and 19 ), which is configured to be engaged with the second or fourth coupling member 22, 42 when the locking member 73 is in its locking position.

- the locking element 76 is located next to the third coupling member 72b and configured to be received in the forth coupling member 42 directly behind the third coupling member 72b when the third coupling member 72b is in engagement with the fourth coupling member 42 and the locking member 73 is in its locking position, to thereby prevent the fourth coupling member 42 from sliding in relation to the third coupling member 72b to a position in which the third coupling member 72b may be moved out of the fourth coupling member 42.

- the locking element 76 is located on a first side of the above-mentioned joint 75, wherein the centre of gravity of the locking member 73 is located on the opposite side of this joint 75 in order to allow the locking member 73 to be automatically moved between its locking position and its unlocking position by a rotating movement about the joint 75 under the effect of gravity and in dependence on the orientation in space of the locking member 73.

- the locking member 73 will act as a rocker arm and assume its locking position or its unlocking position in dependence on the orientation in space of the outer boom 67 and the base structure 74.

- a hook-shaped guide member 77 (see Figs 14-17 and 21 ) is provided on the base structure 74, wherein this guide member 77 is configured for contact with the load handling tool 1 in order to make sure that the load handling tool 1 will be correctly positioned in relation to the base structure 74 with the second and fourth coupling members 22, 42 on the bucket jaws 10, 30 of the load handling tool 1 located in front of the first and third coupling members 72a, 72b on the base structure 74.

- the hook-shaped guide member 77 is configured to engage with a part 11a of the first pivot arm 11, as illustrated in Figs 14 and 15 .

- the holding- and locking mechanism 70 keeps the load handling tool 1 fixed to the outer boom 67 in a position above the outer boom and at the side of the column 64 and the inner boom 65, as illustrated in Figs 12-14 , wherein the hook-shaped guide member 77 is in engagement with the first pivot arm 11, the first and third coupling members 72a, 72b on the base structure 74 are in engagement with the corresponding coupling members 22, 42 on the bucket jaws 10, 30 and the locking member 73 is in its locking position with the locking element 76 received in the fourth coupling member 42.

- the inner boom 65 is first pivoted in relation to the column 64 and lifted upwards from the position illustrated in Fig 12 to the position illustrated in Fig 18a and further on to the position illustrated in Fig 18b .

- the locking member 73 remains in its locking position and thereby prevents the load handling tool 1 from moving in relation to the outer boom 67.

- the outer boom is pivoted in relation to the inner boom 65 and lifted upwards from the position illustrated in Fig 18b to the position illustrated in Fig 18c and further on to the position illustrated in Fig 18d , wherein the locking member 73 is automatically pivoted under the effect of gravity from its locking position to its unlocking position, which implies that the locking element 76 no longer prevents the second and fourth coupling members 22, 42 on the bucket jaws 10, 30 from being released from the corresponding first and third coupling members 72a, 72b on the base structure 74.

- the second and fourth coupling members 22, 42 on the bucket jaws 10, 30 are released from the corresponding first and third coupling members 72a, 72b on the base structure 74 by a short extension of the outer boom 67.

- the load handling tool 1 may be released from the hook-shaped guide member 77 on the base structure 74 by a rotation of the load handling tool 1 by means of the rotator 3 from the position illustrated in Figs 18d and 20 to the position illustrated in Figs 18e and 23 .

- the load handling tool 1 is now hanging freely at the outer end of the outer boom 67, and the bucket jaws 10, 30 may be allowed to pivot downwards under the effect of gravity from the fold-up storing position to the fold-down working position by pivoting the pivot arms 11, 31 outwards away from each other, as illustrated in Figs 18g and 18h .

- the locking members 15, 35 of the first and second locking devices 14, 34 and moved from the unlocking position to the locking position in order to lock the bucket jaws 10, 30 to the pivot arms 11, 31 in the fold-down working position.

- the load handling tool 1 may be fixed to the outer boom 67 by means of the holding- and locking mechanism 70 and the crane 60 moved to the parking position by performing the steps illustrated in Figs 18a-18h in the opposite order.

- the holding- and locking mechanism 70 may of course also have any other suitable configuration than the one illustrated in the drawings.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Jib Cranes (AREA)

Description

- The present invention relates to a load handling tool according to the preamble of

claim 1. The invention also relates to a hydraulic crane comprising such a load handling tool. - An ordinary lorry crane may be provided with a load handling tool mounted to an outer end of a crane boom in the form of a so-called outer boom, which is telescopically extensible and articulately connected to another crane boom in the form of a so-called inner boom, wherein the inner boom in its turn is articulately connected to a rotatable column of the crane.

- A load handling tool according to the preamble of

claim 1 is previously known fromEP 2 778 109 A1EP 2778 109 A1 is described inUS 4023 848 A1 . The clam shell bucket disclosed inEP 2 778 109 A1EP 1 475 345 A1US 4 183 712 A - There also exists another conventional type of hydraulic lorry crane, in the following denominated foldable knuckle boom crane, where the outer boom, when moved into a parking position, is folded in the opposite direction in relation to the inner boom as compared to the outer boom of a Z-type crane. Such a foldable knuckle boom crane is for instance illustrated in

EP 0 360 071 A1EP 1 580 159 A1 - The object of the present invention is to provide a solution to the above-mentioned problem.

- According to the invention, this object is achieved by means of a load handling tool having the features defined in

claim 1. - The load handling tool of the present invention comprises:

- a carrier head configured for connection to a crane boom;

- first and second bucket jaws located opposite each other, the first bucket jaw being pivotally connected to the carrier head via a first pivot arm and the second bucket jaw being pivotally connected to the carrier head via a second pivot arm so as to allow the bucket jaws to be pivoted towards each other in order to grasp a load and away from each other in order to release a grasped load, each pivot arm having a first end facing the carrier head and an opposite second end, wherein each pivot arm at its first end is pivotally connected to the carrier head; and

- an actuating device for pivoting the pivot arms and thereby the bucket jaws in relation to the carrier head.

- The load handling tool of the present invention can be brought into a compact state by moving the bucket jaws to the fold-up storing position and it may be kept in this compact state under the effect of the actuating device acting on the pivot arms. A collapsible load handling tool of this type is suitable for use with a foldable knuckle boom crane of the above-mentioned type, wherein the load handling tool with the bucket jaws in the fold-up storing position may remain connected to the outer end of the outer boom when the outer boom is moved between the working position and the parking position, as explained in closer detail in the description following below.

- Further features of the load handling tool according to the present invention will appear from the description following below and the dependent claims.

- The invention also relates to a hydraulic crane having the features defined in claim 9.

- Further advantageous features of the hydraulic crane according to the present invention will appear from the description following below and the dependent claims.

- With reference to the appended drawings, a specific description of embodiments of the invention cited as examples follows below. In the drawings:

- Fig 1

- is a perspective view of a load handling tool according to a first embodiment of the present invention, as seen with bucket jaws of the load handling tool locked in a fold-down working position,

- Fig 2

- is a lateral view of the load handling tool of

Fig 1 with the bucket jaws locked in the fold-down working position, - Figs 3-5

- are partial views of the load handling tool of

Fig 1 with the bucket jaws locked in the fold-down working position, - Fig 6

- is a perspective view of the load handling tool of

Fig 1 , as seen with the bucket jaws unlocked in the fold-down working position, - Fig 7

- is a partial view of the load handling tool of

Fig 1 with the bucket jaws unlocked in the fold-down working position, - Fig 8

- is a perspective view of the load handling tool of

Fig 1 , as seen with the bucket jaws in a fold-up storing position, - Fig 9

- is a lateral view of the load handling tool of

Fig 1 with the bucket jaws in the fold-up storing position, - Fig 10

- is a partial view of the load handling tool of

Fig 1 with the bucket jaws in the fold-up storing position, - Fig 11

- is a frontal view of a hydraulic crane provided with a load handling tool of the type illustrated in

Figs 1-10 , - Fig 12

- is a frontal view of the hydraulic crane of

Fig 11 , as seen in a compact parking position, - Fig 13

- is a planar view from above of the hydraulic crane of

Fig 11 in the parking position, - Fig 14

- is a lateral view of the hydraulic crane of

Fig 11 in the parking position, - Fig 15

- is a partial view of the hydraulic crane of

Fig 11 in the parking position, - Figs 16 and 17

- are perspective views of a holding- and locking mechanism included in the hydraulic crane of

Fig 11 , - Figs 18a-18h

- are frontal views of the hydraulic crane of

Fig 11 , as seen at different stages during the movement of the crane from the parking position to an erected working position, - Fig 19

- is a partial view of the hydraulic crane in the position illustrated in

Fig 18c , - Figs 20-22

- are partial views of the hydraulic crane in the position illustrated in

Fig 18d , - Figs 23 and 24

- are partial views of the hydraulic crane in the position illustrated in

Fig 18e , and - Fig 25

- is a perspective view of a load handling tool according to a second embodiment of the invention, as seen with the bucket jaws in a fold-up storing position.

- A

load handling tool 1 according to an embodiment of the present invention is illustrated inFig 1-10 . Theload handling tool 1 is to be attached to a crane boom, as illustrated inFig 11 . In the illustrated example, theload handling tool 1 is designed as a clamshell bucket with open shells. - The

load handling tool 1 comprises acarrier head 2 and arotator 3 mounted to the carrier head, wherein thecarrier head 2 is configured to be connected to a crane boom via therotator 3. Theload handling tool 1 may be rotated in relation to the crane boom by means of therotator 3. Theload handling tool 1 further comprises first andsecond bucket jaws carrier head 2 and located opposite each other. Thefirst bucket jaw 10 is pivotally connected to thecarrier head 2 via afirst pivot arm 11 and thesecond bucket jaw 30 is pivotally connected to thecarrier head 2 via asecond pivot arm 31, so as to allow thebucket jaws bucket jaw leading edge edge 12 of thefirst bucket jaw 10 faces the leadingedge 32 of thesecond bucket jaw 30. - Each

pivot arm carrier head 2 and an oppositesecond end 11b, 31b facing the associatedbucket jaw pivot arm carrier head 2. Thefirst pivot arm 11 is pivotable in relation to thecarrier head 2 about a first pivot axis A1 (seeFig 2 ) and thesecond pivot arm 31 is pivotable in relation to thecarrier head 2 about a second pivot axis A2, wherein the second pivot axis A2 is located at a distance from and extends in parallel with the first pivot axis A1. - Each

pivot arm second end 11b, 31b articulately connected to the associatedbucket jaw pivot arm Figs 1-7 ) and a fold-up storing position (seeFigs 8-10 ). Thebucket jaws pivot arms Figs 8 and 9 . - The

first bucket jaw 10 is pivotable in relation to thefirst pivot arm 11 about a third pivot axis A3 (seeFig 2 ), which extends in parallel with the above-mentioned first pivot axis A1, wherein the distance between the first and third pivot axes A1, A3 is larger than the distance between the third pivot axis A3 and the leadingedge 12 of thefirst bucket jaw 10, to thereby allow thefirst bucket jaw 10 to be received between the first andsecond pivot arms - The

second bucket jaw 30 is pivotable in relation to thesecond pivot arm 31 about a fourth pivot axis A4 (seeFig 2 ), which extends in parallel with the above-mentioned second pivot axis A2, wherein the distance between the second and fourth pivot axes A2, A4 is larger than the distance between the fourth pivot axis A4 and the leadingedge 32 of thesecond bucket jaw 30, to thereby allow thesecond bucket jaw 30 to be received between the first andsecond pivot arms - In the illustrated embodiment, each

bucket jaw bottom surface bottom surface - The

load handling tool 1 comprises afirst locking device 14 for locking thefirst bucket jaw 10 to thefirst pivot arm 11 in the fold-down working position, and asecond locking device 34 for locking thesecond bucket jaw 30 to thesecond pivot arm 31 in the fold-down working position. - Furthermore, the

load handling tool 1 comprises anactuating device 4 for pivoting thepivot arms bucket jaws carrier head 2. In the embodiment illustrated inFigs 1-10 , theactuating device 4 is a hydraulic motor accommodated in thecarrier head 2, for instance a hydraulic motor of the type described in closer detail inDE 202004013158 U1 orEP 1 541 771 B1actuating device 4 comprises two rotatably driven pivot shafts which are rotatably mounted to thecarrier head 2, each pivot shaft having two opposite shaft ends which project from thecarrier head 2 on opposite sides thereof. Thefirst pivot arm 11 is non-rotatably fixed to the opposite shaft ends 5 of a first one of the pivot shafts and thesecond pivot arm 31 is non-rotatably fixed to the opposite shaft ends 6 of the other pivot shaft. As an alternative, the actuating device may comprise one or two hydraulic cylinders for pivoting thepivot arms bucket jaws carrier head 2. Any other suitable type of actuating device may also be used for pivoting thepivot arms carrier head 2. - A

load handling tool 1 according to an alternative embodiment is illustrated inFig 25 . Thisload handling tool 1 comprises an actuating device 4' in the form of a hydraulic cylinder which is vertically arranged in thecarrier head 2 and configured to act on the first andsecond pivot arms link mechanism 6 in order to pivot thepivot arms carrier head 2. As to the rest, theload handling tool 1 illustrated inFig 25 corresponds to the load handling tool illustrated inFigs 1-10 . - The above-mentioned

first locking device 14 comprises at least one lockingmember 15 which is moveable between an unlocking position (seeFigs 6-8 ), in which thefirst bucket jaw 10 is free to pivot in relation to thefirst pivot arm 11 between the fold-down working position and the fold-up storing position, and a locking position (seeFigs 1 ,3 and 4 ), in which the lockingmember 15 prevents thefirst bucket jaw 10 from pivoting in relation to thefirst pivot arm 11 from the fold-down working position towards the fold-up storing position. In the illustrated embodiment, thefirst locking device 14 comprises twosuch locking members 15, which are slidably mounted to a cross-bar 16 on thefirst pivot arm 11 so as to be slidable along this cross-bar 16 between the locking position and the unlocking position. In the illustrated example, each lockingmember 15 comprises ashoulder 17a (seeFig 7 ) which is configured to be in contact with a corresponding shoulder 17b (seeFig 8 ) on thefirst bucket jaw 10 when the lockingmember 15 is in the locking position, as illustrated inFig 4 , and thereby prevent thefirst bucket jaw 10 from pivoting in relation to thefirst pivot arm 11 towards the fold-up storing position. When the lockingmember 15 is in the unlocking position, theshoulder 17a on the locking member is no longer in contact with the corresponding shoulder 17b on thefirst bucket jaw 10, as illustrated inFigs 7 and 8 , and the first bucket jaw is thereby allowed to pivot in relation to thefirst pivot arm 11 between the fold-down working position and the fold-up storing position. - The above-mentioned

second locking device 34 comprises at least one lockingmember 35 which is moveable between an unlocking position (seeFigs 6 and10 ), in which thesecond bucket jaw 30 is free to pivot in relation to thesecond pivot arm 31 between the fold-down working position and the fold-up storing position, and a locking position (seeFig 1 ), in which the lockingmember 35 prevents thesecond bucket jaw 30 from pivoting in relation to thesecond pivot arm 31 from the fold-down working position towards the fold-up storing position. In the illustrated embodiment, thesecond locking device 34 comprises twosuch locking members 35, which are slidably mounted to a cross-bar 36 on thesecond pivot arm 31 so as to be slidable along this cross-bar 36 between the locking position and the unlocking position. The lockingmembers 35 of thesecond locking device 34 have the same configuration and are operated in the same manner as the lockingmembers 15 of thefirst locking device 14. - In the illustrated embodiment, each locking

device handle locking members handle members link mechanism - The first and

second locking devices device members - Each

bucket jaw stop member 20, 40 (seeFigs 1 ,5 ,8 and 10 ) which is configured to come into contact with acorresponding stop member pivot arm bucket jaw pivot arm bucket jaw pivot arm bucket jaw such stop members - When the

bucket jaws members edges second bucket jaws load handling tool 1 is thereafter lowered downwards against an upwardly protruding object so that the object will push theleading edges bucket jaws pivot arms leading edges bucket jaws actuating device 4, which pivots thepivot arms bucket jaws pivot arms Figs 8 and 9 . Thebucket jaws actuating device 4, which keeps the bucket jaws clamped between thepivot arms load handling tool 1 could also be provided with a suitable locking device for keeping thebucket jaws load handling tool 1 later on is to be used, thepivot arms actuating device 4 so that thebucket jaws pivot arms Figs 18g and 18h . - According to an alternative embodiment (not shown), the

load handling tool 1 is provided with hydraulically or electrically operated actuating units for pivoting thebucket jaws pivot arms - A

hydraulic crane 60 provided with aload handling tool 1 of the type described above is illustrated inFigs 11-24 . The illustratedcrane 60 is mounted on aframe 61, which for instance may be connected to the chassis of a lorry. Theframe 61 is provided withadjustable support legs 62 for supporting thecrane 60. Thecrane 60 comprises: - a

crane base 63, which is fixed to theframe 61; - a

column 64, which is rotatably mounted to thecrane base 63 so as to be rotatable in relation to the crane base about an essentially vertical axis of rotation A5 by means of an actuating device (not shown); - a liftable and lowerable

first crane boom 65, in the following denominated inner boom, which is articulately connected to thecolumn 64 in such a manner that it is pivotable in relation to the column about an essentially horizontal axis of rotation A6; - a first

hydraulic cylinder 66 for lifting and lowering theinner boom 65 in relation to thecolumn 64; - a liftable and lowerable

second crane boom 67, in the following denominated outer boom, which is articulately connected to theinner boom 65 in such a manner that it is pivotable in relation to the inner boom about an essentially horizontal axis of rotation A7; and - a second

hydraulic cylinder 68 for lifting and lowering of theouter boom 67 in relation to theinner boom 65. - The

outer boom 67 is telescopically extensible to enable an adjustment of the extension length thereof. Theouter boom 67 comprises abase section 67a, through which theouter boom 67 is articulately connected to theinner boom 65, and several telescopiccrane boom sections 67b which are carried by thebase section 67a and displaceable in the longitudinal direction of the base section by means ofhydraulic cylinders 69 for adjustment of the extension length of theouter boom 67. - The illustrated

crane 60 is a foldable knuckle boom crane, wherein the inner andouter booms Figs 12-14 . When the inner andouter booms Fig 11 , the telescopiccrane boom sections 67b of theouter boom 67 are first retracted into thebase section 67a of the outer boom, whereupon theouter boom 67 is folded downwards towards theinner boom 65 so as to assume a position essentially in parallel with the inner boom, as illustrated inFig 18b . Thereafter, theinner boom 65 is folded downwards together with theouter boom 67 towards theframe 61 from the intermediate position illustrated inFig 18b to the final parking position illustrated inFig 12 . The inner andouter booms - The

load handling tool 1 is mounted to the outer end of theouter boom 67. In order to prevent theload handling tool 1 from bumping into thecolumn 64 when the inner andouter booms bucket jaws load handling tool 1 has to be in the fold-up storing position and arranged in a suitable fixed position in relation to theouter boom 67. To make this possible, thecrane 60 comprises a holding- and locking mechanism 70 (seeFigs 15-17 ) for locking theload handling tool 1 to thesecond crane boom 67 with the first andsecond bucket jaws load handling tool 1 in a given fixed position in relation to and at the side of theouter boom 67. - In the illustrated embodiment, the holding- and

locking mechanism 70 comprises: - a first coupling member 72a (see

Figs 16, 17 and24 ), which is fixed to the outer boom and 67 configured for engagement with a corresponding second coupling member 22 (seeFigs 11 and24 ) on thefirst bucket jaw 10; - a

third coupling member 72b (seeFigs 16, 17 and24 ), which is fixed to theouter boom 67 and configured for engagement with a corresponding fourth coupling member 42 (seeFigs 11 and24 ) on thesecond bucket jaw 30; and - a locking member 73 (see

Figs 15-17 and19 ), which is moveable between a locking position (seeFig 15 ), in which the lockingmember 73 prevents the first andthird coupling members 72a, 72b from being disengaged from the correspondingcoupling members bucket jaws Fig 19 ), in which the lockingmember 73 allows the first coupling member 72a to be disengaged from thesecond coupling member 22 and thethird coupling member 72b to be disengaged from thefourth coupling member 42. - In the illustrated example, the first and

third coupling members 72a, 72b have the form of hooks, whereas thesecond coupling member 22 has the form of a recess in thefirst bucket jaw 10 and thefourth coupling member 42 has the form of a recess in thesecond bucket jaw 30. In this case, the first coupling member 72a is insertable into thesecond coupling member 22 and thethird coupling member 72b is insertable into thefourth coupling member 42. - The holding- and

locking mechanism 70 further comprises abase structure 74, which is fixed to thebase section 67a of theouter boom 67, wherein the first andthird coupling members 72a, 72b are fixed to and protrude from thebase structure 74. In the illustrated embodiment, the lockingmember 73 of the holding- andlocking mechanism 70 has the form of a lever and is pivotally mounted to thebase structure 74 through a joint 75 so as to be pivotable in relation to thebase structure 74 about this joint 75 between its locking position and its unlocking position. The lockingmember 73 is provided with a protruding locking element 76 (seeFigs 16 and19 ), which is configured to be engaged with the second orfourth coupling member member 73 is in its locking position. In the illustrated example, the lockingelement 76 is located next to thethird coupling member 72b and configured to be received in theforth coupling member 42 directly behind thethird coupling member 72b when thethird coupling member 72b is in engagement with thefourth coupling member 42 and the lockingmember 73 is in its locking position, to thereby prevent thefourth coupling member 42 from sliding in relation to thethird coupling member 72b to a position in which thethird coupling member 72b may be moved out of thefourth coupling member 42. The lockingelement 76 is located on a first side of the above-mentioned joint 75, wherein the centre of gravity of the lockingmember 73 is located on the opposite side of this joint 75 in order to allow the lockingmember 73 to be automatically moved between its locking position and its unlocking position by a rotating movement about the joint 75 under the effect of gravity and in dependence on the orientation in space of the lockingmember 73. Thus, the lockingmember 73 will act as a rocker arm and assume its locking position or its unlocking position in dependence on the orientation in space of theouter boom 67 and thebase structure 74. When theouter boom 67 and thebase structure 74 have such an orientation in space that the lockingelement 76 on the lockingmember 73 points upwards, the lockingmember 73 will assume its locking position with the lockingelement 76 forced outwards away from theouter boom 67, as illustrated inFig 15 . When theouter boom 67 and thebase structure 74 have such an orientation in space that the lockingelement 76 on the lockingmember 73 points downwards (seeFig 19 ), the lockingmember 73 will assume its unlocking position with the lockingelement 76 forced inwards towards theouter boom 67, as illustrated inFig 19 . - In the illustrated embodiment, a hook-shaped guide member 77 (see

Figs 14-17 and21 ) is provided on thebase structure 74, wherein thisguide member 77 is configured for contact with theload handling tool 1 in order to make sure that theload handling tool 1 will be correctly positioned in relation to thebase structure 74 with the second andfourth coupling members bucket jaws load handling tool 1 located in front of the first andthird coupling members 72a, 72b on thebase structure 74. The hook-shapedguide member 77 is configured to engage with a part 11a of thefirst pivot arm 11, as illustrated inFigs 14 and 15 . - When the

crane 60 is in the parking position, the holding- andlocking mechanism 70 keeps theload handling tool 1 fixed to theouter boom 67 in a position above the outer boom and at the side of thecolumn 64 and theinner boom 65, as illustrated inFigs 12-14 , wherein the hook-shapedguide member 77 is in engagement with thefirst pivot arm 11, the first andthird coupling members 72a, 72b on thebase structure 74 are in engagement with the correspondingcoupling members bucket jaws member 73 is in its locking position with the lockingelement 76 received in thefourth coupling member 42. When thecrane 60 is to be moved into the erected working position, theinner boom 65 is first pivoted in relation to thecolumn 64 and lifted upwards from the position illustrated inFig 12 to the position illustrated inFig 18a and further on to the position illustrated inFig 18b . When theouter boom 67 and theload handling tool 1 pivot together with theinner boom 65 from the position illustrated inFig 12 to the position illustrated inFig 18b , the lockingmember 73 remains in its locking position and thereby prevents theload handling tool 1 from moving in relation to theouter boom 67. In the next step, the outer boom is pivoted in relation to theinner boom 65 and lifted upwards from the position illustrated inFig 18b to the position illustrated inFig 18c and further on to the position illustrated inFig 18d , wherein the lockingmember 73 is automatically pivoted under the effect of gravity from its locking position to its unlocking position, which implies that the lockingelement 76 no longer prevents the second andfourth coupling members bucket jaws third coupling members 72a, 72b on thebase structure 74. With theouter boom 67 in the position illustrated inFig 18d , the second andfourth coupling members bucket jaws third coupling members 72a, 72b on thebase structure 74 by a short extension of theouter boom 67. Thereafter, theload handling tool 1 may be released from the hook-shapedguide member 77 on thebase structure 74 by a rotation of theload handling tool 1 by means of therotator 3 from the position illustrated inFigs 18d and20 to the position illustrated inFigs 18e and23 . Theload handling tool 1 is now hanging freely at the outer end of theouter boom 67, and thebucket jaws pivot arms Figs 18g and 18h . Finally, the lockingmembers second locking devices bucket jaws pivot arms - When the

bucket jaws load handling tool 1 may be fixed to theouter boom 67 by means of the holding- andlocking mechanism 70 and thecrane 60 moved to the parking position by performing the steps illustrated inFigs 18a-18h in the opposite order. - The holding- and

locking mechanism 70 may of course also have any other suitable configuration than the one illustrated in the drawings. - The invention is of course not in any way restricted to the embodiments described above. On the contrary, many possibilities to modifications thereof will be apparent to a person with ordinary skill in the art without departing from the basic idea of the invention such as defined in the appended claims.

Claims (15)

- A load handling tool to be attached to a crane boom, the load handling tool (1) comprising:- a carrier head (2) configured for connection to a crane boom;- first and second bucket jaws (10, 30) located opposite each other, the first bucket jaw (10) being pivotally connected to the carrier head (2) via a first pivot arm (11) and the second bucket jaw (30) being pivotally connected to the carrier head (2) via a second pivot arm (31) so as to allow the bucket jaws (10, 30) to be pivoted towards each other in order to grasp a load and away from each other in order to release a grasped load, each pivot arm (11, 31) having a first end (11a, 31a) facing the carrier head (2) and an opposite second end (11b, 31b), wherein each pivot arm (11, 31) at its first end (11a, 31a) is pivotally connected to the carrier head (2); and- an actuating device (4) for pivoting the pivot arms (11, 31) and thereby the bucket jaws (10, 30) in relation to the carrier head (2),characterized in:- that each pivot arm (11, 31) at its second end (11b, 31b) is articulately connected to the associated bucket jaw (10, 30) so as to allow the bucket jaw to be pivoted in relation to the pivot arm (11, 31) between a fold-down working position and a fold-up storing position, wherein the bucket jaws (10, 30) are configured to be located between the pivot arms (11, 31) and to rest against each other in the fold-up storing position; and- that the load handling tool (1) comprises a first locking device (14) for locking the first bucket jaw (10) to the first pivot arm (11) in the fold-down working position, and a second locking device (34) for locking the second bucket jaw (30) to the second pivot arm (31) in the fold-down working position.

- A load handling tool according to claim 1, characterized in:- that the first pivot arm (11) is pivotable in relation to the carrier head (2) about a first pivot axis (A1);- that the second pivot arm (31) is pivotable in relation to the carrier head (2) about a second pivot axis (A2), which extends in parallel with the first pivot axis (A1);- that the first bucket jaw (10) is pivotable in relation to the first pivot arm (11) about a third pivot axis (A3), which extends in parallel with the first pivot axis (A1), wherein the distance between the first and third pivot axes (A1, A3) is larger than the distance between the third pivot axis (A3) and the leading edge (12) of the first bucket jaw (10);- that the second bucket jaw (30) is pivotable in relation to the second pivot arm (31) about a fourth pivot axis (A4), which extends in parallel with the second pivot axis (A2), wherein the distance between the second and fourth pivot axes (A2, A4) is larger than the distance between the fourth pivot axis (A4) and the leading edge (32) of the second bucket jaw (30).

- A load handling tool according to claim 2, characterized in that the first pivot axis (A1) is located at a distance from the second pivot axis (A2).

- A load handling tool according to any of claims 1-3, characterized in:- that the first locking device (14) comprises at least one locking member (15) which is moveable between an unlocking position, in which the first bucket jaw (10) is free to pivot in relation to the first pivot arm (11) between the fold-down working position and the fold-up storing position, and a locking position, in which the locking member (15) prevents the first bucket jaw (10) from pivoting in relation to the first pivot arm (11) from the fold-down working position towards the fold-up storing position; and- that the second locking device (34) comprises at least one locking member (35) which is moveable between an unlocking position, in which the second bucket jaw (30) is free to pivot in relation to the second pivot arm (31) between the fold-down working position and the fold-up storing position, and a locking position, in which the locking member (35) prevents the second bucket jaw (30) from pivoting in relation to the second pivot arm (31) from the fold-down working position towards the fold-up storing position.

- A load handling tool according to claim 4, characterized in:- that the first locking device (14) comprises a handle (18), by means of which said at least one locking member (15) of the first locking device is moveable between the locking position and the unlocking position; and- that the second locking device (34) comprises a handle (38), by means of which said at least one locking member (35) of the second locking device is moveable between the locking position and the unlocking position.

- A load handling tool according to claim 4 or 5, characterized in:- that said locking member (15) of the first locking device (14) is slidably mounted to a bar (16) on the first pivot arm (11) so as to be slidable along this bar (16) between the locking position and the unlocking position; and- that said locking member (35) of the second locking device (34) is slidably mounted to a bar (36) on the second pivot arm (31) so as to be slidable along this bar (36) between the locking position and the unlocking position.

- A load handling tool according to any of claims 1-6, characterized in:- that the first bucket jaw (10) is provided with at least one stop member (20) which is configured to come into contact with a corresponding stop member (21) on the first pivot arm (11) and thereby stop the pivotal movement of the first bucket jaw (10) in relation to the first pivot arm (11) when the first bucket jaw (10) has been pivoted in relation to the first pivot arm (11) from the fold-up storing position to the fold-down working position; and- that the second bucket jaw (30) is provided with at least one stop member (40) which is configured to come into contact with a corresponding stop member (41) on the second pivot arm (31) and thereby stop the pivotal movement of the second bucket jaw (30) in relation to the second pivot arm (31) when the second bucket jaw (30) has been pivoted in relation to the second pivot arm (31) from the fold-up storing position to the fold-down working position.

- A load handling tool according to any of claims 1-7, characterized in that the load handling tool (1) is a clamshell bucket with open shells.

- A hydraulic crane comprising:- a crane base (63);- a column (64), which is rotatably mounted to the crane base (63) so as to be rotatable in relation to the crane base about an essentially vertical axis of rotation (A5);- a liftable and lowerable first crane boom (65), which is articulately connected to the column (64) so as to be pivotable in relation to the column about an essentially horizontal axis of rotation (A6); and- a liftable and lowerable second crane boom (67), which is articulately connected to the first crane boom (65) so as to be pivotable in relation to the first crane boom about an essentially horizontal axis of rotation (A7),characterized in that the crane (60) comprises a load handling tool (1) according to any of claims 1-8 mounted to an outer end of the second crane boom (67).

- A hydraulic crane according to claim 9, characterized in that the crane (60) comprises a holding- and locking mechanism (70) for locking the load handling tool (1) to the second crane boom (67) with the first and second bucket jaws (10, 30) in the fold-up storing position and with the load handling tool (1) in a given fixed position in relation to and at the side of the second crane boom (67).

- A hydraulic crane according to claim 10, characterized in that the holding- and locking mechanism (70) comprises:- a first coupling member (72a), which is fixed to the second crane boom (67) and configured for engagement with a corresponding second coupling member (22) on the first bucket jaw (10);- a third coupling member (72b), which is fixed to the second crane boom (67) and configured for engagement with a corresponding fourth coupling member (42) on the second bucket jaw (30); and- a locking member (73), which is moveable between a locking position, in which the locking member (73) prevents the first coupling member (72a) from being disengaged from the second coupling member (22) and the third coupling member (72b) from being disengaged from the fourth coupling member (42), and an unlocking position, in which the locking member (73) allows the first coupling member (72a) to be disengaged from the second coupling member (22) and the third coupling member (72b) to be disengaged from the fourth coupling member (42).

- A hydraulic crane according to claim 11, characterized in:- that the first coupling member (72a) has the form of a hook and the second coupling member (22) has the form of a recess, wherein the first coupling member (72a) is insertable into the second coupling member (22); and- that the third coupling member (72b) has the form of a hook and the fourth coupling member (42) has the form of a recess, wherein the third coupling member (72b) is insertable into the fourth coupling member (42).

- A hydraulic crane according to claim 12, characterized in:- that the holding- and locking mechanism (70) comprises a base structure (74), which is fixed to the second crane boom (67), wherein the first and third coupling members (72a, 72b) are fixed to the base structure (74); and- that the locking member (73) of the holding- and locking mechanism (70) has the form of a lever and is pivotally mounted to the base structure (74) through a joint (75) so as to be pivotable in relation to the base structure (74) about this joint (75) between its locking position and its unlocking position.

- A hydraulic crane according to claim 13, characterized in:- that the locking member (73) of the holding- and locking mechanism (70) is provided with a protruding locking element (76), which is configured to be engaged with the second or fourth coupling member (22, 42) when the locking member (73) is in its locking position; and- that the locking element (76) is located on a first side of said joint (75), wherein the centre of gravity of the locking member (73) is located on the opposite side of said joint (75) in order to allow the locking member (73) to be moved between its locking position and its unlocking position under the effect of gravity in dependence on the orientation in space of the second crane boom (67).

- A hydraulic crane according to claim 13 or 14, characterized in:- that the second crane boom (67) is telescopically extensible so as to enable an adjustment of the extension length thereof, wherein the second crane boom (67) comprises a base section (67a), through which the second crane boom (67) is articulately connected to the first crane boom (65), and one or more telescopic crane boom sections (67b) carried by the base section (67a); and- that the base structure (74) of the holding- and locking mechanism (70) is fixed to the base section (67a) of the second crane boom (67).

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DK16203102.5T DK3333112T3 (en) | 2016-12-09 | 2016-12-09 | Load handling tool and hydraulic crane with such a load handling tool |

| EP16203102.5A EP3333112B1 (en) | 2016-12-09 | 2016-12-09 | Load handling tool and hydraulic crane comprising such a load handling tool |

| PCT/EP2017/079827 WO2018104042A1 (en) | 2016-12-09 | 2017-11-21 | Load handling tool and hydraulic crane comprising such a load handling tool |

| CN201780075884.9A CN110121478B (en) | 2016-12-09 | 2017-11-21 | Load handling tool and hydraulic crane including such load handling tool |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP16203102.5A EP3333112B1 (en) | 2016-12-09 | 2016-12-09 | Load handling tool and hydraulic crane comprising such a load handling tool |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3333112A1 EP3333112A1 (en) | 2018-06-13 |

| EP3333112B1 true EP3333112B1 (en) | 2019-10-23 |

Family

ID=57539124

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16203102.5A Active EP3333112B1 (en) | 2016-12-09 | 2016-12-09 | Load handling tool and hydraulic crane comprising such a load handling tool |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP3333112B1 (en) |

| CN (1) | CN110121478B (en) |

| DK (1) | DK3333112T3 (en) |

| WO (1) | WO2018104042A1 (en) |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4023848A (en) * | 1976-01-05 | 1977-05-17 | J. I. Case Company | Log grapple |

| SE402903B (en) | 1976-12-10 | 1978-07-24 | Hiab Foco Ab | AT LOAD CRANES FOLDABLE CRANE ARM |

| JPS62249890A (en) * | 1986-04-22 | 1987-10-30 | 株式会社 中島鉄工所 | Lifting magnet with gripper |

| IT1225186B (en) | 1988-09-07 | 1990-11-02 | Guidetti Luigi A | LIFTING CRANE OF THE PERFECT TYPE FOR MOUNTING ON VEHICLES |

| FR2651220B1 (en) * | 1989-08-29 | 1991-11-29 | Koehl Jean Marie | RETRACTABLE ELECTRIC MAGNET. |

| SE521805C2 (en) * | 2002-04-22 | 2003-12-09 | Volvo Constr Equip Holding Se | Apparatus and method for gripping at least one elongate element and vehicles comprising the device |

| FI20030700A7 (en) | 2003-05-09 | 2004-11-10 | Loglift Oy Ab | Method for controlling a crane boom and equipment for implementing the method |

| DE20319227U1 (en) | 2003-12-11 | 2005-04-21 | Kinshofer Greiftechnik Gmbh & Co. Kg | Hydraulic rotary actuator for a gripper |

| EP1580159B1 (en) | 2004-03-23 | 2006-09-20 | Hiab Ab | Hose guide of a crane |

| DE202004013158U1 (en) | 2004-08-23 | 2006-01-12 | Kinshofer Greiftechnik Gmbh & Co. Kg | Hydraulic swivel drive for gripper, has grip arms with shafts that are parallel to one another and axially supported by hydrostatic axial bearing, where shafts are designed free of external bearing pressure supply |

| US7284718B2 (en) * | 2005-06-29 | 2007-10-23 | Genesis Attachments, Llc | Excavator demolition attachment with interchangeable jaw assemblies |

| DE202013002527U1 (en) | 2013-03-14 | 2014-06-16 | Kinshofer Gmbh | clamshell |

| GB2522420B (en) * | 2014-01-22 | 2018-09-05 | Caterpillar Work Tools Bv | Exchange system for implement of machine |

| GB2522690B (en) * | 2014-02-03 | 2016-12-14 | Caterpillar Work Tools Bv | Gripping device for machine |

-

2016

- 2016-12-09 EP EP16203102.5A patent/EP3333112B1/en active Active

- 2016-12-09 DK DK16203102.5T patent/DK3333112T3/en active

-

2017

- 2017-11-21 CN CN201780075884.9A patent/CN110121478B/en not_active Expired - Fee Related

- 2017-11-21 WO PCT/EP2017/079827 patent/WO2018104042A1/en not_active Ceased

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2018104042A1 (en) | 2018-06-14 |

| EP3333112A1 (en) | 2018-06-13 |

| CN110121478A (en) | 2019-08-13 |

| CN110121478B (en) | 2020-05-29 |

| DK3333112T3 (en) | 2020-01-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5725112A (en) | Crane | |

| US3968884A (en) | Storage means for jib for telescopic boom of mobile crane | |

| US9139402B2 (en) | Retractable load guide | |

| KR102630979B1 (en) | Ton bag lifting and cutting apparatus for self-driving device | |

| US11104559B2 (en) | Foldable personnel basket for a crane | |

| EP1788167A1 (en) | Collapsible platform | |

| US5402898A (en) | Crane having boom rest | |

| CA3016567C (en) | Foldable personnel basket for a crane | |

| US4067245A (en) | Lever transmission particularly for lifting means | |

| EP3333112B1 (en) | Load handling tool and hydraulic crane comprising such a load handling tool | |

| JP6013837B2 (en) | lift device | |

| JP3272721B2 (en) | Driving machine with articulated boom | |

| CN110552385A (en) | Locking mechanism for construction machine | |

| KR200458795Y1 (en) | Tongs for carrying mast of forklift | |

| CN111137795B (en) | Holding device for a load handling tool and hydraulic crane comprising such a holding device | |

| US4303165A (en) | Crane with telescopic jibs | |

| CN115123981B (en) | Working bucket assembly and working machine | |

| US3819059A (en) | Foldable cranes | |

| JP4683971B2 (en) | Jib connection structure of mobile crane | |

| JP3364186B2 (en) | Tread fixing device for construction machinery | |

| US8360707B2 (en) | Detachable implement handling apparatus for tractors | |

| JP3962698B2 (en) | Lamp device | |

| JP3640323B2 (en) | Crane jib overhang, storage method and apparatus | |

| JP2022183799A (en) | Tension rod holding structure and crane vehicle | |

| JPH0647440B2 (en) | Buckets for lifting equipment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20181115 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20190124 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: CARGOTEC PATENTER AB |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602016022844 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1193437 Country of ref document: AT Kind code of ref document: T Effective date: 20191115 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 Effective date: 20191217 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20191023 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200123 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200123 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200124 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200224 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602016022844 Country of ref document: DE |

|

| PG2D | Information on lapse in contracting state deleted |

Ref country code: IS |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200223 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20191231 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 |

|

| 26N | No opposition filed |

Effective date: 20200724 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191209 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191231 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191231 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 602016022844 Country of ref document: DE Representative=s name: MANITZ FINSTERWALD PATENT- UND RECHTSANWALTSPA, DE Ref country code: DE Ref legal event code: R081 Ref document number: 602016022844 Country of ref document: DE Owner name: HIAB AB, SE Free format text: FORMER OWNER: CARGOTEC PATENTER AB, LJUNGBY, SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20210513 AND 20210519 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: PC Ref document number: 1193437 Country of ref document: AT Kind code of ref document: T Owner name: HIAB AB, SE Effective date: 20210511 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20161209 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: UEP Ref document number: 1193437 Country of ref document: AT Kind code of ref document: T Effective date: 20191023 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191023 |

|