EP3088331B1 - Capsule for beverages - Google Patents

Capsule for beverages Download PDFInfo

- Publication number

- EP3088331B1 EP3088331B1 EP15460025.8A EP15460025A EP3088331B1 EP 3088331 B1 EP3088331 B1 EP 3088331B1 EP 15460025 A EP15460025 A EP 15460025A EP 3088331 B1 EP3088331 B1 EP 3088331B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- separator

- casing

- capsule

- barrier

- punch

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 239000002775 capsule Substances 0.000 title claims description 55

- 235000013361 beverage Nutrition 0.000 title claims description 39

- 230000004888 barrier function Effects 0.000 claims description 34

- 238000002156 mixing Methods 0.000 claims description 20

- 239000007788 liquid Substances 0.000 claims description 15

- 239000000126 substance Substances 0.000 claims description 12

- 239000000203 mixture Substances 0.000 claims description 10

- 238000000034 method Methods 0.000 claims description 6

- 238000007865 diluting Methods 0.000 claims description 5

- 230000008569 process Effects 0.000 claims description 4

- 238000007789 sealing Methods 0.000 claims description 4

- 239000004615 ingredient Substances 0.000 description 11

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 7

- 239000012528 membrane Substances 0.000 description 6

- 239000000463 material Substances 0.000 description 4

- 238000005520 cutting process Methods 0.000 description 3

- 235000013305 food Nutrition 0.000 description 3

- 239000005030 aluminium foil Substances 0.000 description 2

- 238000009835 boiling Methods 0.000 description 2

- 238000004090 dissolution Methods 0.000 description 2

- 238000000605 extraction Methods 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 238000007373 indentation Methods 0.000 description 2

- 238000002360 preparation method Methods 0.000 description 2

- 238000004064 recycling Methods 0.000 description 2

- 230000009471 action Effects 0.000 description 1

- 230000001154 acute effect Effects 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 235000013334 alcoholic beverage Nutrition 0.000 description 1

- 235000013405 beer Nutrition 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 235000015115 caffè latte Nutrition 0.000 description 1

- 235000020303 café frappé Nutrition 0.000 description 1

- 235000015116 cappuccino Nutrition 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 235000019219 chocolate Nutrition 0.000 description 1

- 235000016213 coffee Nutrition 0.000 description 1

- 235000013353 coffee beverage Nutrition 0.000 description 1

- 235000020965 cold beverage Nutrition 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 235000011850 desserts Nutrition 0.000 description 1

- 238000010790 dilution Methods 0.000 description 1

- 239000012895 dilution Substances 0.000 description 1

- 235000015071 dressings Nutrition 0.000 description 1

- 235000011389 fruit/vegetable juice Nutrition 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 235000012171 hot beverage Nutrition 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 235000021056 liquid food Nutrition 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 238000009928 pasteurization Methods 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- 235000015067 sauces Nutrition 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 235000014347 soups Nutrition 0.000 description 1

- 235000013616 tea Nutrition 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/70—Containers, packaging elements or packages, specially adapted for particular articles or materials for materials not otherwise provided for

- B65D85/804—Disposable containers or packages with contents which are mixed, infused or dissolved in situ, i.e. without having been previously removed from the package

- B65D85/8043—Packages adapted to allow liquid to pass through the contents

- B65D85/8055—Means for influencing the liquid flow inside the package

Definitions

- An object of the invention is a capsule for beverages subjected to the processes of extracting, dissolving and diluting its content by injecting liquid under pressure into the capsule in an appliance for preparing beverages, comprising a casing containing such a substance closed with puncturable barriers at the top and the base, designed for the preparation of hot, cold or chilled beverages, liquid food and liquid additives to food, especially such drinks as cappuccino, coffee, chocolate, Latte Machiatto, Ice Frappe, soups, teas, juices, desserts, sauces/dressings, alcoholic drinks and beer.

- the appliance for extracting a food substance contained in a sealed cartridge and the method of extracting a food substance contained in a sealed cartridge known from the Polish Patent No. 196425 .

- the appliance has a hollow body with a chamber for inserting the cartridge, a water feeding duct running through the body and connected to the chamber and many puncturing elements distributed across the chamber. The puncturing elements puncture the cartridge in many separate places enabling water to flow into the cartridge and these are spaced across the chamber along the direction of water inflow.

- each puncturing element comprises a basic component that is connected to the body and protrudes into the chamber, and this basic component enters the cartridge at least partially forming in it the surface of water inflow inside the cartridge, and the basic component is a solid part with a closed cross-section while each puncturing member has a cutting face that cuts the basic component at an acute angle.

- the cross-section of the basic component narrows down gradually towards the cutting face at the " ⁇ " angle smaller than the " ⁇ " angle of the cutting face.

- the outer plastic circumferential protrusion is subject to plastic deformation by the action of the external heat source and its front wall is formed in such a manner that it is part of the side surface of a truncated cone with an obtuse vertical angle, with its vertex located in the axis of the casing, and the temperature of protrusion softening is lower than the boiling point of water while the temperature of its melting is higher than the boiling point of water.

- This container may be in the form of a capsule or bag containing at least one ingredient for preparing a beverage, and such a beverage is prepared by mixing liquid input to the capsule, while the capsule inside is divided into at least two separate chambers, the first and the second one, and each chamber contains a beverage ingredient or beverage ingredient mix, while the first chamber is adapted to release the ingredient or ingredient mix at a time lag versus the second chamber when the liquid is input inside the capsule to make the beverage.

- the capsule according to that invention is subjected to extraction by injecting liquid under pressure into the capsule in an appliance for preparing a beverage, and the capsule contains a substance for preparing the beverage in a sealed chamber and a means of opening the capsule applied, where the opening of the capsule permits the beverage to flow out as a results of the interaction of the opening means and the chamber wall under the influence of the liquid pressure increase in the chamber.

- a capsule for beverages known from the Polish Patent Description No.

- an appliance for preparing beverages comprising a casing containing such a substance closed with puncturable membranes at the top and the base, which is characterised in that there are at least two internal concentric chambers inside the casing sealed with the membrane at the top, fitted with a cap with a ring turned inside fitted with reinforcements spaced along its internal side, while at the base the cap has a ring turned outside fitted with passages that adhere to a spacing insert, and there is a frothing insert placed inside the area surrounded by the ring and fitted at the top with slots spaced around the ring perimeter and spacing mandrels and fitted at the base with concentric segmented rings of variable thickness and with a preferably centrally placed punch partly located in the outflow duct hole covered with the outflow membrane, where part of the casing base is rounded outwards within the outflow duct.

- the spacing insert has concentric rings on the inside, where there are indentations on the perimeter of the inner ring and passages on the rim of the outer ring, and there is a passage in the base of the spacing insert, while the rim of the spacing insert is clasp locked along its whole perimeter with a flange inside the casing.

- the frothing insert has a flexible sealing lip turned out along its perimeter.

- a capsule for beverages known from the Polish Patent Description No. 220172 subjected to extracting, dissolving and diluting its content by injecting liquid under pressure into the capsule in an appliance for preparing beverages, comprising a casting containing such a substance closed with puncturable membranes at the top and the base, which is characterized in that there is one internal chamber inside the casing which has a spacing insert in its lower part, and there is a frothing insert placed inside the area surrounded by the ring and fitted at the top with slots spaced around the ring perimeter and a row of spacing mandrels and fitted at the base with a row of concentric segmented rings of variable thickness and with a preferably centrally placed punch partly located in the outflow duct hole covered with the outflow membrane, where part of the casing base is rounded outwards within the outflow duct.

- the spacing insert is fitted with a passage and has concentric rings on the inside, where there is a row of indentations on the perimeter of the inner ring and the rim of the insert is clasp locked along its whole perimeter with a flange inside the casing.

- the flange In the locking area with the rim, the flange has the shape of a reversed letter "J".

- the frothing insert has a flexible sealing lip turned out along its perimeter.

- the purpose of the invention is to design a capsule for beverages that enables laminar outflow of the mixed ingredients and is made completely of a homogeneous material, and guarantees the complete emptying of its content.

- the capsule for beverages that comprises the casing sealed tightly with the upper barrier at the top and the lower barrier at the base, where there is a separator located in the casing with at least one hole and connected to the casing along its perimeter, and in the upper part of the capsule casing between the upper barrier and the separator, there is a substance subjected to the processes of extracting, dissolving and diluting its content by injecting liquid under pressure into it within the appliance for preparing beverages, and that contains a mixing unit located between the separator and the lower barrier which seals the outflow duct, through which the prepared content flows out, and the mixing unit is located inside the area surrounded by a centric ring fastened to the separator from the base and fitted with an undetachable punch, according to the invention is characterised in that there is a mixing unit guide in the separator seated

- the bush which is connected to the separator may or may not be detached.

- the advantage of the capsule according to the invention is that owing to the notch, specifically a radial one, made on the inner surface of the lower barrier, which, because of its separation into parts, additionally seals the outflow duct in its upper part with the outer surface of the punch base, thus ensuring the outflow of the mixed substance through the central hole in the punch only and enabling the laminar outflow of the mixed substance without it splashing onto the inner walls of the outflow duct, while the application of the additional bush enables the thorough mixing of the upper ingredients contained in the upper part of the capsule in a direction from the upper surface of the separator towards the upper barrier.

- the capsule is made of a homogeneous material this eliminates aluminium foils which are currently used and guarantees total recycling of the capsule.

- Fig. 1 - shows a side view of the capsule

- Fig. 2 - shows an axial section of the capsule

- Fig. 3 - shows an axial section of the capsule fitted with the bush

- Fig. 4 - shows a top view of the separator

- Fig. 5 - shows a base view of the separator

- Fig. 6 - shows an axial section of the separator

- Fig. 7 - shows a top view of the separator connected to the bush

- Fig. 8 - shows an axial section of the separator fitted with the connected bush which may be detached

- Fig. 9 - shows an axial section of the separator fitted with the undetachable connected bush

- Fig. 10 - shows a top view of the separator connected along its rim with the lower part of the capsule

- Fig. 11 shows a top view of the middle of the capsule without the separator and the mixing unit

- Fig. 12 - shows an axial section of the mixing unit

- Fig. 13 - shows a base view of the mixing unit

- Fig. 14 - shows a top view of the mixing unit

- Fig. 15 - shows an axial section of the capsule placed in the tray of the appliance for preparing beverages before emptying it

- Fig. 16 - shows an axial section of the capsule placed in the tray of the appliance for preparing beverages during emptying it

- FIG. 17 - shows an axial section of the capsule fitted with the bush and placed in the tray of the appliance for preparing beverages before emptying it

- Fig. 18 - shows an axial section of the capsule fitted with the bush and placed in the tray of the appliance for preparing beverages

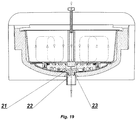

- Fig. 19 - shows an axial section of the capsule fitted with the bush and placed in the tray of the appliance for preparing beverages during emptying it.

- the capsule for beverages has the casing 1 , made of a homogeneous material, as are all capsule components, which is sealed with the upper barrier 2 at the top and with the lower barrier 3 at the base, especially of a circular shape, which act as tight closures of the separated capsule zones ( Fig. 2 ).

- the lower barrier 3 has at least one radial notch 45 from the centre of the casing 1 , and on splitting into parts it additionally seals the outflow duct 41 in its upper part with the outer surface of the punch 23 base 46, thus forcing the outflow of the prepared mix through the central hole 22 and preventing the uncontrolled outflow of the prepared mix along the inner surface 42 of the outflow duct 41 ( Fig. 2 , Fig. 11 - 12 ).

- the separator 4 there is a separator 4 inside the casing 1 fitted with the rim 5, which is connected by welds 6 to the outer ring-shaped surface 7 in the central part of the casing 1 ( Fig. 3 , Fig. 10 ).

- the separator 4 has at least one passage 12 inside the area 8 surrounded by the centric ring 9 consisting of segments 10 with gaps 11 between them, and the guide 13 placed in the geometric centre of the area 8 ( Fig. 5 ).

- the guide 13 is inserted in the cruciform hole 14 , which can have other geometric shapes, and this prevents the rotation of the mixing unit 15 inside the casing 1 ( Fig. 5 , Fig. 14 - 15 ).

- the cruciform hole 14 is made from the side of the surface 16 of the mixing unit 15 fitted with a row of spacing protrusions 17 and has arms 20 with outflow holes 21 at the ends placed in the walls 40 of the punch 23 base 46 ( Fig. 11 , Fig. 14 , Fig. 17 ).

- the outflow holes 21 are connected with the central hole 22 of the punch 23 that punches the lower barrier 3 , and after punching through the lower barrier 3 presses its torn parts along the inner notches 45 and on splitting into parts it additionally seals the outflow duct 41 in its upper part with the outer surface of the punch 23 base 46, thus forcing the outflow of the prepared mix through the central hole 22 and preventing the uncontrolled outflow of the prepared mix along the inner surface 42 of the outflow duct 41 ( Fig. 2 , Fig. 11 - 12 ).

- the generating line a of the punch 23 is longer than half the length d cut on the inside of the lower barrier 3 , and the height h of the punch is shorter than the height H of the casing 1 outflow duct 41 ( Fig. 3 ).

- a ring 29 with a lip 30 at its end comprising the protrusions 18 located between the holes 19, while the concentric rings 25 made of shaped segments 26 and holes 27 are seated on the side of the base 24 and may not be disconnected from it ( Fig. 12 , Fig. 13, Fig. 14 ).

- the option of the capsule for beverages has, between the upper barrier 2 and the surface 37 of the separator 4, a bush 35 fitted at the base with the openings 36 in the shape of holes or slots, and the said bush 35 supports the upper barrier 2 , which is significant for the process of pasteurization of the content in the upper part 39 ( Fig. 3 ).

- the openings 36 ensure the flow of the liquid under pressure delivered through the central hole 28 to the upper part 39 of the capsule 1 , and the said liquid dissolves/dilutes the content ( Fig. 3 , Fig. 19 ).

- the flow inside the upper part 39 of the capsule 1 is in the direction from the upper surface 37 of the separator 4 towards the upper barrier 2, and the outflow is through the passage 12 to the mixing unit 15 labyrinth and then to the outflow duct 41 ( Fig. 3 - 4 , Fig. 12 , Fig. 19 ).

- the bush 35 which is connected to the separator 4 ( Fig. 8 - 9 may or may not be detached.

- the capsule To empty the capsule of beverage ingredients it is placed in the removable tray 31, which is then locked inside the appliance for preparing beverages 32 used for preparing hot or cold beverages and by means of lifting the tray 31, the capsule is additionally sealed on its whole surface and thus the rounding 33 moves towards the punch 23 , which punches through the barrier 3 along at least one notch 45, and on splitting into parts it additionally seals the outflow duct 41 in its upper part with the outer surface of the punch 23 base 46, thus forcing the outflow of the prepared mix through the central hole 22 and preventing the uncontrolled outflow of the prepared mix along the inner surface 42 of the outflow duct 41 ( Fig. 11 - 12 , Fig. 15 - 16 ).

- the upper barrier 2 is punched through by the nozzle 34 fitted with the inner hole 38, through which cold or hot water is delivered under pressure into the capsule or into the hole 28 of the bush 35, causing the dissolution/dilution of the content in the upper part 39 of the capsule 1 and the outflow of the prepared mixed content through the holes 12, outflow holes 21, mixing unit 15 labyrinth, central hole 22 and the outflow duct 41 outside to a receiving vessel, namely a cup, a glass or another container ( Fig. 2 , Fig. 5 , Fig. 8 - 9 , Fig. 17 - 18 ).

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Apparatus For Making Beverages (AREA)

- Packging For Living Organisms, Food Or Medicinal Products That Are Sensitive To Environmental Conditiond (AREA)

- Tea And Coffee (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL412202A PL225608B1 (pl) | 2015-04-30 | 2015-04-30 | Kapsuła do napojów |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3088331A1 EP3088331A1 (en) | 2016-11-02 |

| EP3088331B1 true EP3088331B1 (en) | 2017-11-08 |

Family

ID=53510821

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP15460025.8A Not-in-force EP3088331B1 (en) | 2015-04-30 | 2015-06-24 | Capsule for beverages |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP3088331B1 (pl) |

| PL (1) | PL225608B1 (pl) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110589258A (zh) * | 2018-06-12 | 2019-12-20 | 广东美的生活电器制造有限公司 | 胶囊及其生产方法、饮品机及防止溢出的方法 |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT201600109774A1 (it) * | 2016-10-31 | 2018-05-01 | Gruppo Gimoka S R L | Capsula per la preparazione di bevande |

| ES2775058T3 (es) | 2016-02-23 | 2020-07-23 | Gruppo Gimoka S R L | Cápsula para producir bebidas |

| DE102016003516A1 (de) * | 2016-03-24 | 2017-09-28 | LigaLife GmbH & Co. KG | Kapsel für eine Erzeugung eines flüssigen Lebensmittels, Verfahren zum Erzeugen eines flüssigen Lebensmittels mit einer Kapsel, Vorrichtung zur Erzeugung eines flüssigen Lebensmittels, in die eine Kapsel in einen Aufnahmeraum einsetzbar ist, Verwenden einer Kapsel sowie System aufweisend eine Kapsel und eine Vorrichtung |

| CN107914313B (zh) * | 2017-11-14 | 2020-04-24 | 无锡鼎加弘思饮品科技有限公司 | 一种饮品胶囊冲孔加工装置及冲孔加工方法 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| PL105958B1 (pl) | 1977-03-03 | 1979-11-30 | Przed Projektowania I Realizac | Urzadzenie do wulkanizacji wyrobow gumowych |

| PL114679B1 (en) | 1977-10-06 | 1981-02-28 | Gni I Pi Obogascheniju Rud Tsv | Vibration apparatus for recovery of metals from their water solutions |

| PL131030B1 (en) | 1979-11-16 | 1984-09-29 | Przed Poszukiwan Nafty I Gazu | Filter for getting fluid minerals from boreholes |

| PL123573B1 (en) | 1979-12-06 | 1982-10-30 | Os Bad Rozwojowy Podstaw Techn | Apparatus for taking over and away previously oriented workpieces being machined on lengthwise turning single-spindle automatic lathes |

| IT1256690B (it) | 1992-03-04 | 1995-12-12 | Lavazza Luigi Spa | Capsula a perdere per l'uso nelle macchine per l'estrazione e la distribuzione di bevande calde. |

| ES2347158T3 (es) * | 2004-01-26 | 2010-10-26 | Tuttoespresso S.R.L. | Procedimiento y capsula para preparar bebidas. |

| ES2234445B1 (es) * | 2005-02-11 | 2006-10-01 | Francisco Navarro Alcantara | Recipiente para la elaboracion de bebidas calientes y procedimiento para la apertura automatica del mismo. |

| EP1785369A1 (en) | 2005-11-10 | 2007-05-16 | Nestec S.A. | Beverage ingredient containing capsule having several compartments |

| TR201202636U (tr) * | 2011-03-14 | 2012-10-22 | Cupsystem Company B.V. | Arap tipi kahveli bir içeceğin hazırlanması için sistem. |

| ITMI20120247A1 (it) * | 2012-02-20 | 2013-08-21 | Illycaffe Spa | Cartuccia per l'ottenimento di una bevanda. |

| ES2446641B1 (es) * | 2012-09-06 | 2015-02-03 | Francisco NAVARRO ALCÁNTARA | Contenedor para la preparación de una bebida bajo la presión de un fluido. |

-

2015

- 2015-04-30 PL PL412202A patent/PL225608B1/pl unknown

- 2015-06-24 EP EP15460025.8A patent/EP3088331B1/en not_active Not-in-force

Non-Patent Citations (1)

| Title |

|---|

| None * |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110589258A (zh) * | 2018-06-12 | 2019-12-20 | 广东美的生活电器制造有限公司 | 胶囊及其生产方法、饮品机及防止溢出的方法 |

| CN110589258B (zh) * | 2018-06-12 | 2021-05-25 | 广东美的生活电器制造有限公司 | 胶囊及其生产方法、饮品机及防止溢出的方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| PL225608B1 (pl) | 2017-04-28 |

| EP3088331A1 (en) | 2016-11-02 |

| PL412202A1 (pl) | 2016-11-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3088331B1 (en) | Capsule for beverages | |

| CN110015514B (zh) | 剂量容器和用于借助于剂量容器生产饮料的方法 | |

| RU2422346C2 (ru) | Капсула для экстракции напитка из порошкообразного вещества и пенообразующая перегородка для использования в капсуле | |

| EP2590876B1 (en) | A capsule for preparation of a food product from a food preparation machine | |

| EP2822877B1 (en) | Capsule for beverage | |

| EP2891615B1 (en) | Capsule for a beverage maker | |

| EP2330953B1 (en) | Method for preparing a food liquid contained in a capsule by centrifugation and system adapted for such method | |

| EP2091845B1 (en) | Cup for preparation of a liquid product | |

| CN109071102B (zh) | 封壳系统 | |

| HU225842B1 (en) | Capsule, method for preparing various beverage in the same machine and method for improving hygiene and reducing cross-contamination in the preparation of a baverage from a capsule | |

| EP2891614B1 (en) | Capsule for the preparation of a beverage and method for the manufacture of the capsule | |

| CN108883874A (zh) | 具有开口装置和一体阻隔层的封闭胶囊 | |

| JP2015531250A (ja) | 飲料の調製のためのカプセル、装置及び方法 | |

| EP3509966B1 (en) | Disposable capsule for dispensing machines of infused beverages | |

| US11174097B2 (en) | Capsule for the preparation of infusion or soluble beverages in low pressure extraction systems | |

| EP3088330A1 (en) | Capsule for beverages and beverage preparation method | |

| EP2891613B1 (en) | Capsule for producing a beverage | |

| CN105564843A (zh) | 饮料胶囊 | |

| EP2607269B1 (en) | Capsule and method for preparing drinks | |

| WO2016125195A1 (en) | Pre-packed charge of soluble edible powder material, for the use in machines for the preparation of beverages | |

| US20190322438A1 (en) | Cartridge and machine for multi-component beverage preparation | |

| CN108025863B (zh) | 单杯式容器、制造单杯式容器的方法、制造饮料的系统和方法 | |

| EP3722228A1 (en) | Capsule and method for preparing and dispensing a viscous drinkable food product | |

| PL219698B1 (pl) | Kapsuła do napojów | |

| PL220172B1 (pl) | Kapsuła do napojów |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| 17P | Request for examination filed |

Effective date: 20170110 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20170523 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 943923 Country of ref document: AT Kind code of ref document: T Effective date: 20171115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602015005877 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20171108 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 943923 Country of ref document: AT Kind code of ref document: T Effective date: 20171108 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180208 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180308 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180208 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602015005877 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20180809 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180630 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180624 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180624 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180630 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180630 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180624 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190624 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190624 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20150624 Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171108 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171108 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20230626 Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602015005877 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20250101 |