EP3045593A1 - Robinet de cuisine a bec pivotant - Google Patents

Robinet de cuisine a bec pivotant Download PDFInfo

- Publication number

- EP3045593A1 EP3045593A1 EP16151323.9A EP16151323A EP3045593A1 EP 3045593 A1 EP3045593 A1 EP 3045593A1 EP 16151323 A EP16151323 A EP 16151323A EP 3045593 A1 EP3045593 A1 EP 3045593A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- mouthpiece

- neck

- fitting

- axis

- rotation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03C—DOMESTIC PLUMBING INSTALLATIONS FOR FRESH WATER OR WASTE WATER; SINKS

- E03C1/00—Domestic plumbing installations for fresh water or waste water; Sinks

- E03C1/02—Plumbing installations for fresh water

- E03C1/04—Water-basin installations specially adapted to wash-basins or baths

- E03C1/0404—Constructional or functional features of the spout

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03C—DOMESTIC PLUMBING INSTALLATIONS FOR FRESH WATER OR WASTE WATER; SINKS

- E03C1/00—Domestic plumbing installations for fresh water or waste water; Sinks

- E03C1/02—Plumbing installations for fresh water

- E03C1/04—Water-basin installations specially adapted to wash-basins or baths

- E03C2001/0414—Water-basin installations specially adapted to wash-basins or baths allowing different orientations of the spout or the outlet nozzle

Definitions

- the invention relates to a fitting, in particular a kitchen fitting comprising a mouthpiece, on which an outlet for the discharge of water is provided. Further, the fitting has a base for mounting the fitting on a valve support, in particular a sink, a mounting unit for fixing the base to the fitting support and a tubular neck which is arranged between the base and the mouthpiece.

- Most known kitchen faucets are designed to include a pedestal which is mounted on the sink and which in particular comprises the mixer tap and the lever for adjusting the water pressure and the water temperature. Furthermore, such known kitchen fittings have a one-piece neck, which is rotatable relative to the base about its vertically extending axis of rotation.

- a disadvantage of such kitchen fittings is that the area to which the water can be blasted is limited to the circular path determined by the rotation of the neck. Thus, some areas of a sink can be cleaned only insufficiently over the water jet of the kitchen faucet.

- the fitting has a mouthpiece which is arranged on the end of the neck opposite the base.

- This mouthpiece is pivotable relative to the neck about a predetermined first axis of rotation. This pivoting ensures that the water jet emerging from the outlet opening of the mouthpiece can not only be radiated straight downwards but also laterally obliquely within the adjustment range of the mouthpiece, as is the case with known fittings.

- the water jet of the fitting can be directed to the largest possible area of the basin to which the fitting is attached.

- the fitting carrier is in particular a sink.

- the fitting comprises an assembly unit for fastening the fitting to the fitting carrier.

- the mounting unit for fixing the base to the sink can be arranged in particular fixed to the base.

- the mounting unit can also be designed as a separate unit, which can be connected via a fastening device with the base. As a result, the assembly is simplified.

- a lever is provided on the base, via which the temperature and / or the pressure of the water jet emerging from the outlet of the fitting can be set manually.

- a mixing valve is provided within the base, which is controlled accordingly via the lever.

- the mouthpiece is fastened to the neck via a fastening unit such that the mouthpiece is rotatable about the longitudinal axis of that portion of the neck to which it is attached. This ensures that the mouthpiece can be pivoted from the front side to the left or right when looking at the kitchen fitting.

- the longitudinal axis of the portion of the neck to which the mouthpiece is attached is thus the first axis of rotation.

- the fastening unit is in particular designed such that the mouthpiece is fastened to the neck such that the mouthpiece is not movable in the axial direction, ie in the direction of the longitudinal axis of the portion of the neck to which the mouthpiece is fastened. This prevents inadvertent removal of the mouthpiece from the neck.

- the mouthpiece is in particular tubular, so that water can flow through the mouthpiece as well as through the tubular neck.

- a bolt is provided at the end of the mouthpiece opposite the outlet, which is fastened to the inner surface of the mouthpiece and projects out of the mouthpiece.

- the bolt is in particular rotatably and fixedly secured to the mouthpiece.

- the protruding pin when the mouthpiece is attached to the neck, engages in particular in the end of the neck opposite the socket one.

- the bolt may also be fixedly secured to the end of the neck and the mouthpiece attached to the bolt.

- the bolt is thus in particular part of the above-described fastening unit.

- an axially extending passage opening is provided in the bolt. Through this passage, the water can pass from the neck into the mouthpiece.

- the passage opening is arranged for this purpose, in particular coaxially to the neck and the mouthpiece.

- At least one sealing ring for example an O-ring, is provided on the circumferential surface of the projecting region of the bolt.

- a plurality of sealing rings are provided.

- a sealing between the bolt and the inner wall of the neck is achieved via these sealing rings, so that the water can only pass through the passage opening of the bolt into the mouthpiece and can not escape from the interface between the neck and mouthpiece.

- a press fit is achieved by the sealing ring or the sealing rings, by which the mouthpiece is attached to the neck.

- a circumferentially extending groove is provided on the peripheral surface of the protruding part of the bolt. Further, in the portion of the neck to which the mouthpiece is fixed, there is provided a radial through hole located in the region of the groove. In the passage opening an engagement element is provided, which engages in the groove. The engagement of the engagement element in the groove on the one hand, the withdrawal of the mouthpiece from the neck, so moving in the axial direction of the mouthpiece prevented.

- a limitation of the pivotability of the mouthpiece about the first axis of rotation to a predetermined angular range is achieved by the stop of the engagement element at the ends of the groove in the longitudinal direction.

- the engagement element is in particular a screw, whereby an easy assembly and disassembly is achieved.

- the screw may be a grub screw or countersunk screw that can be fully countersunk within the neck so that it does not protrude and thus prevent injury when cleaning or operating the fitting.

- a split pin can also be provided instead of a screw.

- the mouthpiece is in particular pivotable relative to the neck from a zero position by a predetermined first angle in a first direction and by a predetermined second angle in a second direction opposite to the second direction.

- stops are provided in particular on the mouthpiece and / or the neck, which limit the pivoting accordingly.

- the first and the second angle are in particular the same size, so that the mouthpiece can be pivoted in the same direction from the zero position in both directions.

- the first and / or the second angle have in particular a value in the range between 30 ° and 70 °, preferably between 55 ° and 65 °.

- the mouthpiece can be moved relative to the neck by 60 ° in both directions from the zero position. Thus, the largest possible area is reached, to which the water jet can be directed.

- the zero position is that position in which the mouthpiece and the neck are aligned with each other. If you look at the fitting from the front, the mouthpiece and the neck are positioned in zero position in front of each other.

- the zero position is in particular the position in which the mouthpiece is arranged in such a way as it is always arranged in the case of commercial one-piece necks. In the zero position, in particular, the center axes of the tubular neck piece and the mouthpiece lie completely in one plane.

- the neck is in particular mounted relative to the base about a second axis of rotation rotatably mounted on the base.

- This second axis of rotation is in particular the longitudinal axis of that portion of the neck which is fixed to the base.

- the first and second axes of rotation lie in particular in one plane and intersect at one point.

- the second axis of rotation is in this case directed in particular orthogonal to the first axis of rotation.

- the first axis of rotation is particularly horizontal and the second axis of rotation arranged vertically.

- the neck has a straight first portion, a straight second portion, and an arcuate portion disposed between the first and second portions.

- the first section is in particular when mounted in accordance with the fitting vertical, the second section horizontally.

- the mouthpiece is mounted on the horizontal section.

- the mouthpiece itself is also bent in particular, so that the water is not radiated horizontally but directed downwards.

- the mouthpiece is in this case in particular bent at an angle between 60 ° and 90 °, preferably between 70 ° and 85 °, in particular by an angle of 75 ° or 90 °.

- FIG. 1 a side view of a kitchen fitting 10 in a first embodiment.

- the kitchen fitting 10 includes a base 12 which can be fixed by means of a mounting unit, not shown, to a dashboard, in particular a sink and in this case stands up on the top of the dashboard.

- a manually operable lever 14 is provided by the operation of the one hand, the temperature and on the other hand, the pressure of the water, which is discharged through the valve 12, can be adjusted.

- the fitting 10 comprises a neck 16 which is rotatably mounted on the base 12 about a second axis of rotation 18 corresponding to the arrow P2.

- the neck 16 is, in particular, a correspondingly bent tube, through the interior of which the water is passed.

- a mouthpiece 20 which is secured to the neck 16 so as to pivot about a first axis of rotation 22 relative to the neck 16, as shown in FIGS FIGS. 2 to 4 is shown.

- FIG. 2 a front view of the fitting 10 is shown in a first operating state, in which the mouthpiece 20 is arranged in a zero position relative to the neck 16.

- This zero position is the position that is also in FIG. 1 is shown and the position that usually takes the mouthpiece with non-adjustable one-piece fittings. In this zero position, the mouthpiece 20 and the neck 16 are aligned with each other.

- FIG. 3 a second operating state is shown in which the mouthpiece 20 is moved in accordance with the arrow P1 by an angle W1 in a first direction from the zero position.

- the valve is designed so that the mouthpiece can be deflected by 60 ° from the zero position.

- FIG. 4 a third operating state is shown, in which the mouthpiece 16 is pivoted by an angle W2 in a second direction opposite to the second direction from the zero position, wherein this angle W2 in particular represents 60 °.

- angles W1 and W2 are in particular the maximum possible adjustment angle, ie, the second or third operating state, as in the FIGS. 3 and 4 shown, the maximum pivotability of the mouthpiece 20 show.

- the maximum angle may also be greater or less than 60 °.

- the outlet 24 is provided for the outlet of the water.

- the pivoting of the mouthpiece 20 makes it possible, in particular, for the water not only to be radiated downwards, as is the case with conventional fittings in which the mouthpiece 20 is formed integrally with the neck 16 and thus always in the zero position, but also laterally from the body Armature 10 can be blasted off.

- FIG. 5 is a side view of a valve 100 according to a second embodiment shown.

- FIG. 6 shows a front view of this fitting 100, wherein the pivotability of the mouthpiece 20 is shown by the dashed lines.

- the first and the second embodiment differ in particular only by the shape of the base 12, whereas the neck 16 and the mouthpiece 20 are formed in particular the same.

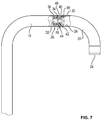

- FIG. 7 is a partially sectional view of the neck 16 and the mouthpiece 20 of the fittings 10, 100 of the first two embodiments shown.

- the transition region between the mouthpiece 20 and the neck 16 is cut free, so that the attachment of the mouthpiece 20 on the neck 16 is better recognizable.

- the mouthpiece 20 and the neck 16 are in particular two completely separate components.

- the mouthpiece 20 is rotatable about the first axis of rotation 22 via a fastening unit 26 and fixed immovably to the neck 16 in the axial direction, that is to say in the longitudinal direction of the first axis of rotation 22.

- a bolt 30 is attached to the inner wall 28 of the mouthpiece 20, which is arranged relative to the mouthpiece 22 in particular rotatable and stationary.

- a through-hole 32 is provided, through which the water from the neck 16 can flow into the mouthpiece 20.

- the bolt 30 protrudes from the end of the mouthpiece 20, which faces the neck 16, and thus protrudes into the neck 16 in the assembled state.

- two O-rings 36 are arranged, on the one hand, a seal of the mouthpiece 20 relative to the neck 16 and on the other a press fit is formed.

- O-rings 36 have the advantage that they do not prevent twistability of the mouthpiece 20 to the neck 16.

- more or less than two O-rings 36 in particular an O-ring 36 or three O-rings 36 may be provided.

- the bolt 30 has a shoulder 38 which abuts against a complementary stop 40 of the end portion of the neck 16 when the mouthpiece 20 is secured to the neck 16.

- a circumferentially extending groove 42 is provided in the peripheral surface 34 of the bolt 30, a circumferentially extending groove 42. This groove is formed such that it does not extend completely around the bolt 30, but covers only an angle of 120 °.

- a passage opening 44 is provided in the region of the groove 42, in which a grub screw 46 is arranged, which projects into the groove 42.

- visible gap 48 between the pin 30 and the wall of the neck 16 may be arranged in particular a plastic ring, which ensures a better rotatability of the bolt 30 to the neck 16.

- This ring also has a hole, in particular in the region of the through hole 44, through which the grub screw 46 can engage through into the groove 46.

- the grub screw 46 can also engage only in this additional ring, this ring then has on its inner surface a protruding element, which in turn engages in the groove 42.

- the mouthpiece 20 is in the in the FIGS. 1 to 7 shown forms such that it is bent by 90 °, so that the water jet is directed in the zero position straight down.

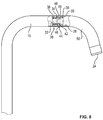

- FIG. 8 a third embodiment is shown in which a mouthpiece 50 is provided, which is bent by an angle of 75 °, so that the water is emitted slightly forward.

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Hydrology & Water Resources (AREA)

- Public Health (AREA)

- Water Supply & Treatment (AREA)

- Domestic Plumbing Installations (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE202015100178.9U DE202015100178U1 (de) | 2015-01-15 | 2015-01-15 | Küchenarmatur mit schwenkbarem Mundstück |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP3045593A1 true EP3045593A1 (fr) | 2016-07-20 |

Family

ID=52479001

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16151323.9A Withdrawn EP3045593A1 (fr) | 2015-01-15 | 2016-01-14 | Robinet de cuisine a bec pivotant |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP3045593A1 (fr) |

| CN (1) | CN205502144U (fr) |

| DE (1) | DE202015100178U1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4379759A1 (fr) | 2022-11-29 | 2024-06-05 | Delta Electronics (Thailand) Public Co., Ltd. | Ensemble transformateur et dispositif de conversion électrique |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108505586A (zh) * | 2018-03-02 | 2018-09-07 | 厦门建霖健康家居股份有限公司 | 一种厨房龙头 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1367721A (en) * | 1972-07-28 | 1974-09-25 | Imi Opella Ltd | Fluid flow control taps |

| DE3820837A1 (de) * | 1988-06-21 | 1990-01-04 | Wildfang Dieter Kg | Auslaufrohr fuer sanitaer-armaturen |

| DE4124764A1 (de) * | 1990-07-24 | 1992-01-30 | Walter Rauh | Standarmatur |

| DE3790241C2 (de) * | 1986-05-14 | 1996-05-02 | Masco Corp | Einhebel-Mischarmatur |

| DE19941820C1 (de) * | 1999-09-02 | 2001-02-08 | Hansa Metallwerke Ag | Sanitärarmatur |

-

2015

- 2015-01-15 DE DE202015100178.9U patent/DE202015100178U1/de not_active Expired - Lifetime

-

2016

- 2016-01-14 EP EP16151323.9A patent/EP3045593A1/fr not_active Withdrawn

- 2016-01-15 CN CN201620119889.XU patent/CN205502144U/zh not_active Expired - Fee Related

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1367721A (en) * | 1972-07-28 | 1974-09-25 | Imi Opella Ltd | Fluid flow control taps |

| DE3790241C2 (de) * | 1986-05-14 | 1996-05-02 | Masco Corp | Einhebel-Mischarmatur |

| DE3820837A1 (de) * | 1988-06-21 | 1990-01-04 | Wildfang Dieter Kg | Auslaufrohr fuer sanitaer-armaturen |

| DE4124764A1 (de) * | 1990-07-24 | 1992-01-30 | Walter Rauh | Standarmatur |

| DE19941820C1 (de) * | 1999-09-02 | 2001-02-08 | Hansa Metallwerke Ag | Sanitärarmatur |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4379759A1 (fr) | 2022-11-29 | 2024-06-05 | Delta Electronics (Thailand) Public Co., Ltd. | Ensemble transformateur et dispositif de conversion électrique |

Also Published As

| Publication number | Publication date |

|---|---|

| CN205502144U (zh) | 2016-08-24 |

| DE202015100178U1 (de) | 2015-02-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1707692B1 (fr) | Robinet pourvu d'un bec téléscopique | |

| EP0261320A2 (fr) | Pistolet de soupape pour appareil de nettoyage à haute pression | |

| EP0061561B1 (fr) | Mélangeur mural | |

| CH715798B1 (de) | Armaturenanordnung. | |

| EP3045593A1 (fr) | Robinet de cuisine a bec pivotant | |

| DE102015114327B3 (de) | Wasserarmatur, insbesondere für einen Wohnwagen, Caravan, Motorcaravan oder ein Boot | |

| DE202017107759U1 (de) | Sicherungsarmatur | |

| DE102019005946A1 (de) | Betätigungsgriff für eine Sanitärarmatur mit eingepresstem Verzahnungsadapter und Verfahren zur Montage eines solchen Betätigungsgriffs | |

| EP3914783B1 (fr) | Pièce de raccordement pour une armature | |

| EP1435480B1 (fr) | Robinetterie sanitaire | |

| EP0499716A1 (fr) | Robinet mélangeur à levier unique pour installations sanitaires | |

| EP0314823B1 (fr) | Soupape avec couvercle sans vis | |

| DE102014010130A1 (de) | Abdeckvorrichtung für ein Anschlussstück einer Wasserarmatur | |

| EP1838928B1 (fr) | Robinetterie sanitaire dotee d'un dispositif de raccordement servant a raccorder un corps de sortie d'eau a un element fonctionnel | |

| DE102013000030A1 (de) | Befestigungssystem für Einbaubrausen | |

| EP3171043B1 (fr) | Robinetterie de cuisine | |

| DE202005005219U1 (de) | Wandanschluß | |

| DE10357646B4 (de) | Wanddurchführung | |

| DE202004013395U1 (de) | Wasserauslaufarmatur | |

| DE102020105247A1 (de) | Wasserauslaufarmatur mit ausziehbarer Geschirrbrause | |

| EP4253674A1 (fr) | Interrupteur de conduit et système de rinçage équipé d'un tel interrupteur | |

| DE102020122954A1 (de) | Wasserauslaufarmatur mit ausziehbarer Geschirrbrause | |

| EP3519637A1 (fr) | Dispositif de sortie pouvant être monté sur une sortie d'eau | |

| DE102009012839A1 (de) | Betätigungsanordnung für Sanitärarmaturen | |

| DE10312863A1 (de) | Brausenanordnung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20170509 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20190801 |