EP3029162B1 - Method for the heat treatment of a manganese steel product - Google Patents

Method for the heat treatment of a manganese steel product Download PDFInfo

- Publication number

- EP3029162B1 EP3029162B1 EP14195644.1A EP14195644A EP3029162B1 EP 3029162 B1 EP3029162 B1 EP 3029162B1 EP 14195644 A EP14195644 A EP 14195644A EP 3029162 B1 EP3029162 B1 EP 3029162B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- weight

- steel product

- range

- holding

- steel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims description 26

- 229910000617 Mangalloy Inorganic materials 0.000 title claims description 12

- 238000010438 heat treatment Methods 0.000 title claims description 10

- 229910000831 Steel Inorganic materials 0.000 claims description 111

- 239000010959 steel Substances 0.000 claims description 111

- 239000011572 manganese Substances 0.000 claims description 35

- 238000001816 cooling Methods 0.000 claims description 34

- 229910045601 alloy Inorganic materials 0.000 claims description 26

- 239000000956 alloy Substances 0.000 claims description 26

- 229910052748 manganese Inorganic materials 0.000 claims description 23

- PWHULOQIROXLJO-UHFFFAOYSA-N Manganese Chemical compound [Mn] PWHULOQIROXLJO-UHFFFAOYSA-N 0.000 claims description 13

- 229910052799 carbon Inorganic materials 0.000 claims description 10

- 238000004519 manufacturing process Methods 0.000 claims description 10

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 9

- 230000008569 process Effects 0.000 claims description 9

- 238000000137 annealing Methods 0.000 claims description 6

- 230000007423 decrease Effects 0.000 claims description 2

- 239000000047 product Substances 0.000 description 86

- 229910000734 martensite Inorganic materials 0.000 description 19

- 229910001566 austenite Inorganic materials 0.000 description 18

- 229910000851 Alloy steel Inorganic materials 0.000 description 13

- 229910001563 bainite Inorganic materials 0.000 description 12

- 239000000203 mixture Substances 0.000 description 11

- 229910000859 α-Fe Inorganic materials 0.000 description 10

- 229910052782 aluminium Inorganic materials 0.000 description 7

- XEEYBQQBJWHFJM-UHFFFAOYSA-N iron Substances [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 7

- 239000000463 material Substances 0.000 description 7

- 229910052710 silicon Inorganic materials 0.000 description 7

- 230000009466 transformation Effects 0.000 description 7

- 230000000717 retained effect Effects 0.000 description 6

- 239000011159 matrix material Substances 0.000 description 5

- 238000010586 diagram Methods 0.000 description 4

- 238000013459 approach Methods 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 3

- 239000010949 copper Substances 0.000 description 3

- 239000000155 melt Substances 0.000 description 3

- 230000008092 positive effect Effects 0.000 description 3

- 238000007669 thermal treatment Methods 0.000 description 3

- 230000009286 beneficial effect Effects 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 238000005097 cold rolling Methods 0.000 description 2

- 239000000470 constituent Substances 0.000 description 2

- 229910052738 indium Inorganic materials 0.000 description 2

- 229910052742 iron Inorganic materials 0.000 description 2

- 238000005496 tempering Methods 0.000 description 2

- SDGKUVSVPIIUCF-UHFFFAOYSA-N 2,6-dimethylpiperidine Chemical compound CC1CCCC(C)N1 SDGKUVSVPIIUCF-UHFFFAOYSA-N 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 229910005347 FeSi Inorganic materials 0.000 description 1

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 description 1

- 229910004298 SiO 2 Inorganic materials 0.000 description 1

- 229910001035 Soft ferrite Inorganic materials 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 238000005275 alloying Methods 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 229910052729 chemical element Inorganic materials 0.000 description 1

- 239000010960 cold rolled steel Substances 0.000 description 1

- 239000012809 cooling fluid Substances 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000001887 electron backscatter diffraction Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 239000013067 intermediate product Substances 0.000 description 1

- 238000011835 investigation Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000002105 nanoparticle Substances 0.000 description 1

- 230000007935 neutral effect Effects 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 229910001562 pearlite Inorganic materials 0.000 description 1

- 229910052698 phosphorus Inorganic materials 0.000 description 1

- 239000011574 phosphorus Substances 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 238000005728 strengthening Methods 0.000 description 1

- 238000000844 transformation Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/005—Heat treatment of ferrous alloys containing Mn

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/18—Hardening; Quenching with or without subsequent tempering

- C21D1/185—Hardening; Quenching with or without subsequent tempering from an intercritical temperature

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/26—Methods of annealing

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/002—Ferrous alloys, e.g. steel alloys containing In, Mg, or other elements not provided for in one single group C22C38/001 - C22C38/60

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/06—Ferrous alloys, e.g. steel alloys containing aluminium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/16—Ferrous alloys, e.g. steel alloys containing copper

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/001—Austenite

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/002—Bainite

Definitions

- the present invention relates to a method of heat treating a manganese steel product, also referred to herein as a mid-manganese steel product. It is also a special alloy of a manganese steel product that can be heat treated by a special process.

- High-strength steel alloys are known as a material for the production of spring plates for motor vehicle struts and methods for their production. Depending on the steel alloy, blanks are used cold or warm formed to the spring plate and hardened in liquid or in air.

- steel products may include ferrite, pearlite, retained austenite, annealed martensite phases, martensite phases, and bainite microstructures form.

- the properties of steel alloys depend, among other things, on the proportions of the different phases, microstructures and their structural arrangement in microscopic observation.

- each of these phases and microstructures has different properties.

- the steel alloys comprising several such phases and microstructures may therefore have significantly different mechanical properties.

- IF steel deep-drawing steels

- IF stands for "interstitial-free”

- this IF steel has only a low content of alloying elements embedded in interstitial sites.

- Mn manganese

- the manganese content in% by weight is often in the range between 2.5 and 12%. Therefore, they are so-called medium-manganese steels, which are also referred to as medium-manganese steels.

- Such medium-manganese steels are typically characterized by a microstructure consisting of a ferritic, martensite and austenite matrix. In this matrix, as the second or third phase, predominantly austenite is incorporated at the grain boundaries. Austenite has a strengthening effect.

- the proportion of martensite in medium-manganese steels is usually at most 80-90 vol.%. Due to this ambivalent microstructure combination, the medium-manganese steel has a relatively low yield strength with a high tensile strength, which is favorable for the forming process.

- Fig. 1 is a classical, highly schematic diagram shown in which the elongation at break (called elongation) in percent (also called ductility) is plotted on the tensile strength in MPa.

- the tensile strength in MPa allows a statement about the lower yield strength of a material.

- the diagram of Fig. 1 gives an overview of the strength classes of currently used steel materials. In general, the following statement applies: the higher the yield strength of a steel alloy, the lower the elongation at break of this alloy. In simple terms, it can be said that the elongation at break decreases with increasing tensile strength and vice versa. It must therefore be found for each application, an optimal compromise between the elongation at break and the tensile strength.

- Fig. 1 statements can be made about the relationship between the strength and the forming capacity of different steel materials.

- the range denoted by reference numeral 1 includes medium-manganese steels having an Mn content of between 3 and 7 wt.% And a carbon content of between 0.05 and 0.1 wt.%.

- medium-manganese steels are expensive to produce because they undergo a 2-step heat treatment.

- these steels are e.g. alloyed with manganese to get a martensitic phase.

- a medium manganese steel with a high tensile strength of e.g. 1200 MPa typically has an elongation of only between 2 and 8%.

- TRIP steels are designated by the reference numeral 2 and the so-called HD steels bear the reference numeral 3.

- TRIP stands in English for "TRANSformation Induced Plasticity”.

- HD stands for High Ductility.

- AHSS HD Advanced High-Strength Steels High Ductility

- AHSS HD steels have, for example, a medium manganese content in the range between 1.2 and 3.5 wt.% And a carbon content (C), which is between 0.05 and 0.25 wt.%.

- the steel products of the invention should have a tensile strength R m (also called minimum strength) which is significantly greater than 1200 MPa.

- R m also called minimum strength

- the tensile strength should be even greater than 1400 MPa.

- the minimum elongation at break (A 80 ) should be 10% - 20%.

- the steel products of the invention should enable workability in the deep drawing process.

- a combination of process and alloy concepts provides a multi-phase steel product having an ultrafine microstructure and good machinability.

- the alloy of the steel products of the invention has an average manganese content, which means that the manganese content is in the range of 3.5% by weight ⁇ Mn ⁇ 6% by weight.

- the manganese content in all embodiments is in the range of 4 wt% ⁇ Mn ⁇ 6 wt%.

- the multiphase steel products of the invention form a heterogeneous system or a heterogeneous structure.

- the steel products of the invention preferably have, according to the invention, a microstructure comprising austenite, bainite and martensite and a significantly reduced proportion of ferrite.

- the ferrite phase is relatively soft compared to the bainite phase. Replacing the soft ferrite phase or matrix with a stronger and finer (nano-sized) bainite phase makes it possible to provide a steel product that has outstanding properties. Above all, the replacement of the ferrite phase or matrix by bainite leads to a significant increase in the hole expansion properties.

- the steel products of the invention preferably have in all embodiments a proportion of a bainitic microstructure which is substantially greater than 5% by volume of the steel product. More preferably, the proportion of the bainitic microstructure is in the range of 10 to 80 vol.%. A proportion of the bainitic microstructure in the range from 20 to 40% by volume has proven to be particularly suitable.

- the bainitic microstructure is characterized in that it has a very fine structure and that it comprises little or no carbide.

- the retained austenite content is preferably significantly less than 30% by volume in all embodiments. Preferred embodiments are those in which the retained austenite content is less than 10% by volume.

- the steel products of the invention preferably have at least proportionally microstructures or areas with an austenitic microstructure.

- the proportion of the austenitic microstructure is preferably in the range of 5 to 20% by volume of the steel product in all embodiments.

- the steel products of the invention preferably have proportionally austenite grains which are isotropic (ie independent of the direction) are distributed in the structure of the steel products.

- the volume fraction of the austenite grains is preferably less than 5% in all embodiments.

- the size of the austenite grains is preferably less than 1 ⁇ m in all embodiments.

- the steel products of the invention preferably have in all embodiments a level of martensite that is lower than other steel alloys whose tensile strength is in the range above 1000 MPa.

- the martensite content is usually 80-90% vol.% In prior art high tensile steel alloys. Although this low martensite content can be expected negative influences, the mechanical properties and the deep drawability of the steel product according to the invention are unexpectedly good.

- the tensile strength R m of the steel products according to the invention in the region of 1400 MPa is significantly higher than the tensile strength which a steel alloy with conventionally large martensite content can offer.

- the microstructure of the steel products according to the invention is characterized in that the comparatively low martensite content is in the form of lath-shaped martensite. It turns out that these fine martensitic battens have a positive effect on the tensile strength of the invention.

- the steel products of the invention have proportionally microstructures or areas with ferrite.

- the proportion of these microstructures or regions is preferably in the range below 50% by volume of the steel product in all embodiments.

- the volume fraction of the ferrite phase is between 15 and 30%, wherein the ferrite phase forms a KRZ lattice (KRZ stands for cubic-body-centered) and has a low dislocation density.

- the grains of the ferrite phase usually have a slightly anisotropic expansion.

- the alloy of the steel products comprises Al and Si components.

- the proportion of Al plus Si is preferably in the range ⁇ 4 wt.% In all embodiments.

- the following condition holds: Al + Si ⁇ 3% by weight.

- the addition of specifically Al and Si in said weight percent range unexpectedly leads to an improvement in the tensile strength and at the same time to an increased elongation at break.

- the addition of Al and Si leads to the promotion of bainite formation.

- the bainite microstructure has, as already mentioned, a significant influence on the positive properties of the alloy of the steel products.

- Al and Si also serves to suppress carbide formation in bainite, which further improves the positive properties of the alloy.

- the proportions of Al and Si can also be defined more precisely in all embodiments as follows: Si ⁇ 0.5% by weight and Al ⁇ 3% by weight.

- the alloy of the steel products preferably comprises Al and Si fractions according to the following formula: Si + Al ⁇ 1% by weight.

- the alloy of the steel products preferably comprises a phosphorus component.

- the proportion of P is preferably ⁇ 0.03 wt% in all embodiments.

- the alloy of the steel products preferably comprises a copper portion.

- the proportion of Cu is preferably ⁇ 0.1% by weight in all embodiments.

- the steel products of the invention preferably comprise, according to the invention, at least proportionally a small amount of Nb so as to reduce the Ms temperature.

- M S denotes the martensite start temperature.

- the proportion of Nb is preferably less than 0.4 in all embodiments Wt.%.

- the steel products of the invention preferably have at least proportionally a small amount of Ti according to the invention.

- the proportion of Ti is preferably less than 0.2% by weight in all embodiments.

- the steel products of the invention preferably have a small proportion of V according to the invention, at least proportionally.

- the proportion of V in all embodiments is preferably less than 0.1% by weight.

- the described structure of the steel products with the indicated weight percentages is achieved by a special temperature treatment, which leads to controlled transformations and microstructures in the multiphase steel product.

- This temperature treatment is referred to herein as en-bloc temperature treatment because it involves only a single continuous treatment process. That is, the en-bloc thermal treatment of the invention has no break or break after which the steel product would have to be reheated.

- ART stands for "austenite reverted transformation”.

- the described alloys surprisingly lead to steel products having the desired properties, although they undergo only an en bloc thermal treatment with the process steps according to claim 1.

- This special form of en-bloc temperature treatment has a significant influence on the formation of the specific ultrafine structure (s) of the steel product.

- the microstructure or the microstructure of the steel product is specifically controlled and defined by a special and efficient form of en-bloc temperature treatment.

- the en-bloc thermal treatment comprises a rapid heating phase up to a first holding temperature which is in the range of 820 ° C ⁇ 20 ° C.

- a first holding temperature at about 810 ° C.

- a rapid cooling phase occurs.

- a second holding temperature is reached and there is an intermediate holding phase (second holding period) in the range of this second holding temperature.

- the second holding temperature is in the range between 350 ° C and 450 ° C.

- the second holding temperature is in all embodiments in the range between 380 ° C and 450 ° C.

- the rapid cooling phase preferably has a cooling rate greater than -30 K / sec in all embodiments. Cooling rates which are greater than -50 K / sec are particularly preferred. These rapid cooling rates have a beneficial effect on the microstructure of the steel product of the invention.

- the en-bloc temperature treatment of the invention serves to avoid the negative influences of the martensitic or ferritic matrix and at the same time to produce a new microstructure with the desired properties.

- the first intermediate holding phase preferably has a maximum duration of 5 minutes in all embodiments.

- the second intermediate holding phase preferably has a maximum duration of 10 minutes in all embodiments.

- the first holding period is shorter than the second holding period.

- the fine, batten-shaped bainite has been shown to improve the strength of the steel products of the invention.

- the steel products of the invention have bainitic slats that have a width between 20 and 200 nm and a typical length in the range of 1 ⁇ m to 4 ⁇ m.

- These bainitic laths also referred to here as nano-fine laths, form due to the special en-bloc temperature treatment.

- the high dislocation density ferritic phases play an important role in improving the elongation and formability of the steel products of the invention.

- the invention is used to provide cold rolled steel products in the form of cold rolled flat products (e.g., coils).

- the invention can also be used to e.g. To produce thin sheets or wire and wire products.

- the invention has, inter alia, the advantage that no ART heat treatment is needed.

- ART stands for "Austenite Reverted Transformation”.

- the invention relates to ultrafine multiphase medium-manganese steel products comprising martensite, ferrite and retained austenite regions or phases, and optionally also bainite microstructures.

- the steel products of Invention are characterized by a special structure constellation, which is also referred to as a multi-phase structure.

- steel (intermediate) products are sometimes referred to when it comes to emphasizing that it is not about the finished steel product but about a preliminary or intermediate product in a multi-stage production process.

- the starting point for such production processes is usually a melt.

- the following is an indication of the alloy composition of the melt, since on this side of the manufacturing process it is possible to influence the alloy composition relatively precisely (for example by attacking constituents such as silicon).

- the alloy composition of the steel product usually deviates only insignificantly from the alloy composition of the melt.

- phase is defined inter alia by its composition of proportions of the components, enthalpy content and volume. Different phases are separated in the steel product by phase boundaries.

- the “components” or “constituents” of the phases can be either chemical elements (such as Mn, Ni, Al, Fe, C, etc.) or neutral, molecular aggregates (such as FeSi, Fe 3 C, SiO 2 , etc.). ) or charged, molecular aggregates (such as Fe 2+ , Fe 3+ , etc.).

- Quantities or proportions are here largely in weight percent (short wt.%) Made, unless otherwise stated. If information is provided on the composition of the alloy, or the steel product, then the composition comprises in addition to the explicitly listed materials or materials as the basic iron (Fe) and so-called unavoidable impurities that always occur in the molten bath and also in the resulting steel product demonstrate. All% by weight must always be supplemented to 100% by weight and all% by volume must always be completed to 100% of the total volume.

- the medium-manganese steel products of the invention all have a manganese content which is in the range of 3.5 and 6 wt.%, The stated limits being within the range thereof, i. the manganese content is in the range of 3.5% by weight ⁇ Mn ⁇ 6% by weight.

- the manganese content in all embodiments is preferably in the range 4% by weight ⁇ Mn ⁇ 6% by weight.

- the carbon content C in the following range is 0.02 ⁇ C ⁇ 0.35 wt%.

- a starting amount of iron has a carbon content C in the range of 0.02 ⁇ C ⁇ 0.35 wt%, and a manganese content Mn in the range of 3.5 wt% ⁇ Mn ⁇ 6 wt. % added.

- the corresponding procedure is well known.

- en-bloc temperature treatment As part of the further processing of the alloy thus obtained, follows a particularly efficient annealing process (called en-bloc temperature treatment).

- en-bloc is used here to emphasize that, unlike many alternative approaches, no two-fold annealing or tempering is required.

- the first intermediate holding phase H1 preferably has a maximum duration of 5 minutes in all embodiments.

- the second intermediate holding phase H2 preferably has a maximum duration of 10 minutes in all embodiments.

- the first cooling A1 can be carried out in all embodiments in an air stream or using a cooling fluid.

- the second cooling A2 can be carried out in all embodiments in an air stream.

- the steel product of the invention may also be placed in a separate environment (e.g., an incandescent unit) to be held there for a while longer (e.g., at 300 to 450 ° C). In this case, the time 52 is extended accordingly.

- the rapid cooling phase A1 preferably has a cooling rate greater than -30 K / sec in all embodiments. Cooling rates A1 which are greater than -50 K / sec are particularly preferred. These rapid cooling rates have a beneficial effect on the microstructure of the steel product of the invention.

- the faster first cooling A1 occurs at a cooling rate higher than the cooling rate of the slower second cooling A2.

- the second cooling takes place along an asymptotic curve A2 *, which is the asymptote Asy (see Fig. 2 ) approaches.

- the steel product coils are left to self-cool so that they can continue to cool on their own.

- steel products which comprise a proportion of a bainitic microstructure which is greater than 5% by weight of the steel product, the fraction of the bainitic microstructure preferably being in the range from 10 to 70% by volume of the steel product. Particularly preferably, the proportion of the microstructure is in the range from 20 to 40% by volume.

- steel products which comprise a retained austenite content of less than 30% by volume of the steel product, the retained austenite content preferably being less than 10% by volume of the steel product.

- steel products which comprise a volume fraction of austenite grains, which is preferably less than 5% of the total volume of the steel product.

- These austenite grains preferably have a maximum size smaller than 1 ⁇ m.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Heat Treatment Of Sheet Steel (AREA)

- Heat Treatment Of Steel (AREA)

Description

Die vorliegende Erfindung bezieht sich auf ein Verfahren zum Wärmebehandeln eines Mangan-Stahlprodukts, das hier auch als Mittel-Mangan-Stahlprodukt bezeichnet wird. Es geht auch um eine spezielle Legierung eines Mangan-Stahlprodukts, das im Rahmen eines speziellen Verfahrens wärmebehandelt werden kann.The present invention relates to a method of heat treating a manganese steel product, also referred to herein as a mid-manganese steel product. It is also a special alloy of a manganese steel product that can be heat treated by a special process.

Sowohl die Zusammensetzung, respektive Legierung, als auch die Wärmebehandlung im Herstellungsprozess haben einen deutlichen Einfluss auf die Eigenschaften von Stahlprodukten.Both the composition, respectively alloy, and the heat treatment in the manufacturing process have a significant influence on the properties of steel products.

Es ist bekannt, dass im Rahmen einer Wärmebehandlung das Aufwärmen, Halten und Abkühlen einen Einfluss auf das endgültige Gefüge eines Stahlprodukts haben kann. Weiterhin spielt, wie bereits angedeutet, natürlich auch die Legierungszusammensetzung des Stahlprodukts eine grosse Rolle. Die thermodynamischen und werkstofftechnischen Zusammenhänge in legierten Stählen sind sehr komplex und hängen von vielen Parametern ab.It is known that in the course of a heat treatment, the warm-up, holding and cooling can have an influence on the final structure of a steel product. Furthermore, as already indicated, of course, the alloy composition of the steel product also plays a major role. The thermodynamic and materials-related relationships in alloyed steels are very complex and depend on many parameters.

Aus dem Dokument

Es hat sich gezeigt, dass sich durch eine Kombination verschiedener Phasen und Mikrostrukturen im Gefüge eines Stahlprodukts die mechanischen Eigenschaften und die Verformbarkeit beeinflussen lassen.It has been shown that a combination of different phases and microstructures in the microstructure of a steel product can influence the mechanical properties and the deformability.

Je nach Zusammensetzung und Wärmebehandlung können sich in Stahlprodukten unter anderem Ferrit-, Pearlit-, Restaustenit- (auch als "retained austenite" bekannt), angelassene Martensit-Phasen (auch als "tempered martensite" bekannt), Martensit-Phasen und Bainit-Mikrostrukturen ausbilden. Die Eigenschaften von Stahl-Legierungen hängen unter anderem von den Anteilen der verschiedenen Phasen, Mikrostrukturen und von deren struktureller Anordnung in der mikroskopischen Betrachtung ab.Depending on the composition and heat treatment, steel products may include ferrite, pearlite, retained austenite, annealed martensite phases, martensite phases, and bainite microstructures form. The properties of steel alloys depend, among other things, on the proportions of the different phases, microstructures and their structural arrangement in microscopic observation.

Jede dieser Phasen und Mikrostrukturen hat andere Eigenschaften. Die Stahl-Legierungen, die mehrere solcher Phasen und Mikrostrukturen aufweisen, können daher deutlich unterschiedliche mechanische Eigenschaften haben.Each of these phases and microstructures has different properties. The steel alloys comprising several such phases and microstructures may therefore have significantly different mechanical properties.

Je nach spezifischem Anforderungsprofil, kommen zum Beispiel im Automobilbau unterschiedliche Stähle zum Einsatz. Vor mehreren Jahrzehnten wurden im Automobilsektor für den Karosseriebau meist Tiefziehstähle (z.B. IF-Stahl) verwendet, die zwar ein gutes Verformungsvermögen, aber nur eine geringe Festigkeit im Bereich von 120 - 400 N/mm2 aufwiesen. IF steht für "interstitial-free", d.h. dieser IF-Stahl hat nur einen geringen Gehalt an Legierungselementen, die auf Zwischengitterplätzen eingelagert sind.Depending on the specific requirement profile, different steels are used, for example, in the automotive industry. Several decades ago, in the automotive sector, deep-drawing steels (eg IF steel) were mostly used for bodywork. They had good deformability but low strength in the range of 120-400 N / mm 2 . IF stands for "interstitial-free", ie this IF steel has only a low content of alloying elements embedded in interstitial sites.

Eine bedeutende Komponente heutiger Stahl-Legierungen ist Mangan (Mn). Der Mangan-Anteil in Gew.% liegt dabei häufig im Bereich zwischen 2,5 und 12%. Es handelt sich daher um sogenannte Mittel-Mangan-Stähle, die auch als Medium-Mangan-Stähle bezeichnet werden. Solche Medium-Mangan-Stähle zeichnen sich typischerweise durch ein Gefüge aus, das aus einer ferritischen, Martensit- und Austenit-Matrix besteht. In diese Matrix ist als zweite oder dritte Phase überwiegend Austenit an den Korngrenzen eingelagert. Das Austenit hat eine festigkeitssteigernde Wirkung. Der Anteil an Martensit liegt bei Medium-Mangan-Stählen gewöhnlich bei maximal 80-90 Vol.%. Durch diese ambivalente Gefügekombination weist der Medium-Mangan-Stahl eine relativ niedrige und somit für den Umformprozess günstige Streckgrenze mit einer hohen Zugfestigkeit auf.An important component of today's steel alloys is manganese (Mn). The manganese content in% by weight is often in the range between 2.5 and 12%. Therefore, they are so-called medium-manganese steels, which are also referred to as medium-manganese steels. Such medium-manganese steels are typically characterized by a microstructure consisting of a ferritic, martensite and austenite matrix. In this matrix, as the second or third phase, predominantly austenite is incorporated at the grain boundaries. Austenite has a strengthening effect. The proportion of martensite in medium-manganese steels is usually at most 80-90 vol.%. Due to this ambivalent microstructure combination, the medium-manganese steel has a relatively low yield strength with a high tensile strength, which is favorable for the forming process.

In

In dem Bereich, der mit dem Bezugszeichen 1 bezeichnet ist, sind die bereits erwähnten Medium-Mangan-Stähle schematisch zusammengefasst. Der mit Bezugszeichen 1 bezeichnet Bereich umfasst Medium-Mangan-Stähle mit einem Mn-Anteil zwischen 3 und 7 Gew.% und mit einem Kohlenstoff-Anteil zwischen 0,05 und 0,1 Gew.%.In the area designated by the

Konventionelle Medium-Mangan-Stähle sind aufwendig zu produzieren, da sie eine 2-Schritt-Wärmebehandlung unterzogen werden. Um bei den Medium-Mangan-Stählen die Zugfestigkeit zu erhöhen (z.B. von ca. 950 MPa auf 1250 MPa), werden diese Stähle z.B. mit Mangan legiert, um eine martensitische Phase zu bekommen. Leider muss man aber gleichzeitig eine deutlich reduzierte Dehnbarkeit in Kauf nehmen. Ein Medium-Mangan-Stahl mit einer großen Zugfestigkeit von z.B. 1200 MPa hat typischerweise eine Dehnung, die nur zwischen 2 und 8% liegt.Conventional medium-manganese steels are expensive to produce because they undergo a 2-step heat treatment. In order to increase the tensile strength of medium-manganese steels (e.g., from about 950 MPa to 1250 MPa), these steels are e.g. alloyed with manganese to get a martensitic phase. Unfortunately, at the same time, you have to accept a significantly reduced stretchability. A medium manganese steel with a high tensile strength of e.g. 1200 MPa typically has an elongation of only between 2 and 8%.

Die TRIP Stähle sind mit dem Bezugszeichen 2 bezeichnet und die sogenannten HD Stähle tragen das Bezugszeichen 3. TRIP steht im Englischen für "TRansformation Induced Plasticity". HD steht für High Ductility.The TRIP steels are designated by the

Im Automobilsektor arbeitet man mit einer ganzen Reihe unterschiedlicher Stahllegierungen, die jeweils speziell für ihr jeweiliges Einsatzgebiet am Fahrzeug optimiert wurden. Bei Innen- und Außenpanelen, strukturellen Teilen und Stoßfängern kommen Legierungen zum Einsatz, die eine gute Energieabsorption aufweisen. Stahlpanele für die Außenhaut eines Fahrzeugs sind relativ "weich" und haben beispielsweise eine Streckgrenze unterhalb von 140 MPa. Solche Legierungen haben eine geringere Zugfestigkeit und eine höhere Bruchdehnung. Die Stahllegierungen von Stoßfängern haben beispielsweise eine Bruchdehnung im Bereich zwischen 600 und 1000 MPa. Hierfür eignen sich zum Beispiel die TRIP Stähle (Bezugszeichen 2 in

Bei Stahlbarrieren (z.B. für den Seitenaufprallschutz), die bei einem Unfall das Eindringen von Fahrzeugteilen verhindern sollen, werden Stahllegierungen eingesetzt, die eine hohe Zugfestigkeit von meist mehr als 1000 MPa aufweisen. Hier eignet sich beispielweise die neue Generation von höherfesten AHSS HD Stählen. AHSS HD steht im Englischen für "Advanced High-Strength Steels High Ductility".In the case of steel barriers (for example, for side impact protection), which are intended to prevent the intrusion of vehicle parts in the event of an accident, steel alloys are used which have a high tensile strength, usually greater than 1000 MPa. Here, for example, the new generation of higher-strength AHSS HD steels is suitable. AHSS HD stands for "Advanced High-Strength Steels High Ductility".

Diese AHSS HD Stähle haben beispielsweise einen Medium-Mangan-Anteil im Bereich zwischen 1,2und 3,5 Gew.% und einen Kohlenstoffanteil (C), der zwischen 0,05 und 0,25 Gew.% liegt.These AHSS HD steels have, for example, a medium manganese content in the range between 1.2 and 3.5 wt.% And a carbon content (C), which is between 0.05 and 0.25 wt.%.

Es ist andeutungsweise anhand der einleitenden Erklärungen zu erkennen, dass die Zusammenhänge sehr komplex sind und dass man oft vorteilhafte Eigenschaften auf der einen Seite nur erzielen kann, wenn man auf der anderen Seite Abstriche macht.It can be seen from the introductory explanations that the connections are very complex and that one can often only achieve advantageous properties on the one hand, if one cuts back on the other.

Vor allem können bei modernen Stahlprodukten der 3. Generation beim Umformen Probleme auftreten. Unter anderem wird es als nachteilig angesehen, dass Martensit-haltige Stähle beim Kaltwalzen relativ hohe Walzkräfte erfordern. Ausserdem können sich in Martensit-haltigen Stählen beim Kaltwalzen Risse bilden.Above all, problems can occur with modern steel products of the 3rd generation during forming. Among other things, it is considered disadvantageous that martensite-containing steels require relatively high rolling forces during cold rolling. In addition, cracks can form in martensite-containing steels during cold rolling.

Es bestätigt sich immer wieder die Einschätzung von Experten, die betonen, dass man bei Stahllegierungen, die eine hohe Zugfestigkeit aufweisen, auf eine brauchbare Bruchdehnung verzichten muss.Again and again, it is confirmed by the experts who emphasize that for steel alloys which have a high tensile strength, it is necessary to forego a usable elongation at break.

Es stellt sich daher die Aufgabe, ein Verfahren zum Vergüten (Wärmebehandeln) sowie entsprechend hergestellte Stahlprodukte zu schaffen, die eine hohe Zugfestigkeit haben und deren Bruchdehnung geeignet ist für den Einsatz im Automobilsektor und in anderen Bereichen, in denen das Umformvermögen der Stahlprodukte wichtig ist.It is therefore an object to provide a method for tempering (heat treatment) and correspondingly produced steel products, which have a high tensile strength and the elongation at break is suitable for use in the automotive sector and in other areas in which the formability of the steel products is important.

Vorzugsweise sollen die Stahlprodukte der Erfindung eine Zugfestigkeit Rm (auch Mindestfestigkeit genannt) haben, die deutlich grösser ist als 1200 MPa. Vorzugsweise soll die Zugfestigkeit sogar grösser sein als 1400 MPa. Die Mindestbruchdehnung (A80) soll 10% - 20% betragen.Preferably, the steel products of the invention should have a tensile strength R m (also called minimum strength) which is significantly greater than 1200 MPa. Preferably, the tensile strength should be even greater than 1400 MPa. The minimum elongation at break (A 80 ) should be 10% - 20%.

Vorzugsweise sollen die Stahlprodukte der Erfindung eine Bearbeitbarkeit im Tiefziehverfahren ermöglichen.Preferably, the steel products of the invention should enable workability in the deep drawing process.

Gemäss Erfindung wird durch eine Kombination von Verfahrens- und Legierungskonzepten ein Multiphasen-Stahlprodukt mit einem ultrafeinen Gefüge und mit guter maschineller Umformbarkeit bereitgestellt.According to the invention, a combination of process and alloy concepts provides a multi-phase steel product having an ultrafine microstructure and good machinability.

Die Legierung der Stahlprodukte der Erfindung weist gemäss Erfindung einen mittleren Mangangehalt auf, was bedeutet, dass der Mangananteil im Bereich 3,5 Gew.% ≤ Mn ≤ 6 Gew.% liegt. Vorzugsweise liegt der Mangananteil bei allen Ausführungsformen im Bereich von 4 Gew.% ≤ Mn ≤ 6 Gew.%.According to the invention, the alloy of the steel products of the invention has an average manganese content, which means that the manganese content is in the range of 3.5% by weight ≦ Mn ≦ 6% by weight. Preferably, the manganese content in all embodiments is in the range of 4 wt% ≤ Mn ≤ 6 wt%.

Die Multiphasen-Stahlprodukte der Erfindung bilden ein heterogenes System bzw. ein heterogenes Gefüge.The multiphase steel products of the invention form a heterogeneous system or a heterogeneous structure.

Um die Zusammenhänge zu verstehen und um eine geeignete Legierung sowie ein spezielles Verfahren zur Temperatubehandlung bereitstellen zu können, wurden zahlreiche Proben Röntgen-Untersuchungen, TEM-Untersuchungen, EBSD-Untersuchungen und auch lichtmikroskopischen Untersuchungen unterzogen.In order to understand the correlations and to be able to provide a suitable alloy as well as a special method for the treatment of temperature, numerous samples were subjected to X-ray examinations, TEM examinations, EBSD investigations and also subjected to light microscopic examinations.

Die Stahlprodukte der Erfindung weisen gemäß Erfindung vorzugsweise eine Mikrostruktur auf, die Austenit, Bainit sowie Martensit und einen deutlich reduzierten Anteil an Ferrit umfasst. Die Ferrit-Phase ist im Vergleich zur Bainit-Phase relativ weich. Das Ersetzen der weichen Ferrit-Phase oder -Matrix durch eine stärkere und feinere (nano-grosse) Bainit-Phase, ermöglicht es ein Stahlprodukte bereit zu stellen, das herausragende Eigenschaften hat. Vor allem führt das Ersetzen der Ferrit-Phase oder -Matrix durch Bainit zu einer deutlichen Erhöhung der Lochausdehnungseigenschaften.The steel products of the invention preferably have, according to the invention, a microstructure comprising austenite, bainite and martensite and a significantly reduced proportion of ferrite. The ferrite phase is relatively soft compared to the bainite phase. Replacing the soft ferrite phase or matrix with a stronger and finer (nano-sized) bainite phase makes it possible to provide a steel product that has outstanding properties. Above all, the replacement of the ferrite phase or matrix by bainite leads to a significant increase in the hole expansion properties.

Die Stahlprodukte der Erfindung weisen gemäß Erfindung vorzugsweise bei allen Ausführungsformen einen Anteil einer bainitischen Mikrostruktur auf, der wesentlich grösser ist als 5 Vol.% des Stahlprodukts. Besonders vorzugsweise liegt der Anteil der bainitischen Mikrostruktur im Bereich von 10 bis 80 Vol.%. Ganz besonders bewährt hat sich ein Anteil der bainitischen Mikrostruktur im Bereich von 20 bis 40 Vol.%.The steel products of the invention preferably have in all embodiments a proportion of a bainitic microstructure which is substantially greater than 5% by volume of the steel product. More preferably, the proportion of the bainitic microstructure is in the range of 10 to 80 vol.%. A proportion of the bainitic microstructure in the range from 20 to 40% by volume has proven to be particularly suitable.

Besonders vorzugsweise zeichnet sich die bainitische Mikrostruktur dadurch aus, dass sie eine sehr feine Struktur hat und dass sie kein oder nur wenig Karbid umfasst.Particularly preferably, the bainitic microstructure is characterized in that it has a very fine structure and that it comprises little or no carbide.

Der Restaustenit-Anteil beträgt bei allen Ausführungsformen vorzugsweise deutlich weniger als 30 Vol.%. Bevorzugt sind Ausführungsformen, bei denen der Restaustenit-Anteil weniger als 10 Vol.% beträgt.The retained austenite content is preferably significantly less than 30% by volume in all embodiments. Preferred embodiments are those in which the retained austenite content is less than 10% by volume.

Die Stahlprodukte der Erfindung weisen gemäss Erfindung vorzugsweise mindestens anteilsmäßig Gefüge oder Bereiche mit austenitischer Mikrostruktur auf. Der Anteil der austenitischen Mikrostruktur liegt vorzugsweise bei allen Ausführungsformen im Bereich von 5 bis 20 Vol.% des Stahlprodukts.According to the invention, the steel products of the invention preferably have at least proportionally microstructures or areas with an austenitic microstructure. The proportion of the austenitic microstructure is preferably in the range of 5 to 20% by volume of the steel product in all embodiments.

Die Stahlprodukte der Erfindung weisen gemäß Erfindung vorzugsweise anteilsmäßig Austenitkörner auf, die isotrop (d.h. unabhängig von der Richtung) im Gefüge der Stahlprodukte verteilt sind. Der Volumenanteil der Austenitkörner beträgt vorzugsweise bei allen Ausführungsformen weniger als 5%. Die Größe der Austenitkörner beträgt vorzugsweise bei allen Ausführungsformen weniger als 1 µm.According to the invention, the steel products of the invention preferably have proportionally austenite grains which are isotropic (ie independent of the direction) are distributed in the structure of the steel products. The volume fraction of the austenite grains is preferably less than 5% in all embodiments. The size of the austenite grains is preferably less than 1 μm in all embodiments.

Die Stahlprodukte der Erfindung weisen gemäß Erfindung vorzugsweise bei allen Ausführungsformen einen Anteil an Martensit auf, der niedriger ist als bei anderen Stahllegierungen, deren Zugfestigkeit im Bereich oberhalb von 1000 MPa liegt. Der Martensitanteil liegt gewöhnlich bei vorbekannten hoch zugfesten Stahllegierungen bei 80 - 90% Vol.%. Obwohl dieser niedrige Martensit-Anteil negative Einflüsse erwarten lässt, sind die mechanischen Eigenschaften und die Tiefziehbarkeit des erfindungsgemäßen Stahlprodukts unerwartet gut. Die Zugfestigkeit Rm der erfindungsgemässen Stahlprodukte im Bereich von 1400 MPa ist deutlich höher als die Zugfestigkeit, die eine Stahllegierung mit konventionell grossem Martensitanteil bieten kann.The steel products of the invention preferably have in all embodiments a level of martensite that is lower than other steel alloys whose tensile strength is in the range above 1000 MPa. The martensite content is usually 80-90% vol.% In prior art high tensile steel alloys. Although this low martensite content can be expected negative influences, the mechanical properties and the deep drawability of the steel product according to the invention are unexpectedly good. The tensile strength R m of the steel products according to the invention in the region of 1400 MPa is significantly higher than the tensile strength which a steel alloy with conventionally large martensite content can offer.

Die Mikrostruktur der erfindungsgemässen Stahlprodukte zeichnet sich dadurch aus, dass der vergleichbar geringe Martensitanteil sich in Form von lattenförmigem Martensit darstellt. Es zeigt sich, dass sich diese feinen martensitischen Latten positiv auf die Zugfestigkeit der Erfindung auswirken.The microstructure of the steel products according to the invention is characterized in that the comparatively low martensite content is in the form of lath-shaped martensite. It turns out that these fine martensitic battens have a positive effect on the tensile strength of the invention.

Die Stahlprodukte der Erfindung weisen gemäß Erfindung anteilsmäßig Gefüge oder Bereiche mit Ferrit auf. Der Anteil dieser Gefüge oder Bereiche liegt vorzugsweise bei allen Ausführungsformen im Bereich unterhalb von 50 Vol.% des Stahlprodukts. Der Volumenanteil der Ferritphase beträgt zwischen 15 und 30%, wobei die Ferritphase ein KRZ-Gitter (KRZ steht für kubisch-raumzentriert) bildet und eine geringe Versetzungsdichte aufweist. Die Körner der Ferritphase weisen meist eine leicht anisotrope Ausdehnung auf.According to the invention, the steel products of the invention have proportionally microstructures or areas with ferrite. The proportion of these microstructures or regions is preferably in the range below 50% by volume of the steel product in all embodiments. The volume fraction of the ferrite phase is between 15 and 30%, wherein the ferrite phase forms a KRZ lattice (KRZ stands for cubic-body-centered) and has a low dislocation density. The grains of the ferrite phase usually have a slightly anisotropic expansion.

Der Kohlenstoffanteil der Stahlprodukte der Erfindung ist generell eher niedrig. D.h. der Kohlenstoffanteil liegt bei der Erfindung im Bereich 0,02 Gew.% ≤ C ≤ 0,35 Gew.%. Besonders bevorzugt sind Ausführungsformen, bei denen der Kohlenstoffanteil im einem der folgenden Bereiche liegt

- a. 0,05 ≤ C ≤ 0,22 Gew.%, oder

- b. 0,09 ≤ C ≤ 0,18 Gew.%.

- a. 0.05 ≤ C ≤ 0.22 wt.%, Or

- b. 0.09 ≤ C ≤ 0.18 wt%.

Gemäss Erfindung umfasst die Legierung der Stahlprodukte Al- und Si-Anteile. Der Anteil von Al plus Si ist vorzugsweise bei allen Ausführungsformen im Bereich ≤ 4 Gew.%. Vorzugsweise gilt die folgende Bedingung: Al + Si < 3 Gew.%. Die Zugabe speziell von Al und Si im genannten Gewichtsprozentbereich führt unerwarteter Weise zu einer Verbesserung der Zugfestigkeit und gleichzeitig zu einer erhöhten Bruchdehnung. Das Beimengen von Al und Si führt unter anderem dazu, dass die Bainit-Bildung gefördert wird. Die Bainit-Mikrostruktur hat, wie bereits erwähnt, einen deutlichen Einfluss auf die positiven Eigenschaften der Legierung der Stahlprodukte. Al und Si dient auch dazu die Karbid-Bildung im Bainit zu unterdrücken, was die positiven Eigenschaften der Legierung weiter verbessert.According to the invention, the alloy of the steel products comprises Al and Si components. The proportion of Al plus Si is preferably in the range ≤ 4 wt.% In all embodiments. Preferably, the following condition holds: Al + Si <3% by weight. The addition of specifically Al and Si in said weight percent range unexpectedly leads to an improvement in the tensile strength and at the same time to an increased elongation at break. The addition of Al and Si, among other things, leads to the promotion of bainite formation. The bainite microstructure has, as already mentioned, a significant influence on the positive properties of the alloy of the steel products. Al and Si also serves to suppress carbide formation in bainite, which further improves the positive properties of the alloy.

Der Anteil von Al und von Si kann bei allen Ausführungsformen auch wie folgt genauer definiert werden: Si ≤ 0,5 Gew.% und Al ≤ 3 Gew.%.The proportions of Al and Si can also be defined more precisely in all embodiments as follows: Si ≦ 0.5% by weight and Al ≦ 3% by weight.

Gemäss Erfindung umfasst die Legierung der Stahlprodukte vorzugsweise Al- und Si- Anteile gemäss der folgenden Formel: Si + Al ≤ 1 Gew.%.According to the invention, the alloy of the steel products preferably comprises Al and Si fractions according to the following formula: Si + Al ≦ 1% by weight.

Gemäss Erfindung umfasst die Legierung der Stahlprodukte vorzugsweise einen Phosphor-Anteil. Der Anteil von P ist vorzugsweise bei allen Ausführungsformen ≤ 0,03 Gew.%.According to the invention, the alloy of the steel products preferably comprises a phosphorus component. The proportion of P is preferably ≦ 0.03 wt% in all embodiments.

Gemäss Erfindung umfasst die Legierung der Stahlprodukte vorzugsweise einen Kupfer-Anteil. Der Anteil von Cu ist vorzugsweise bei allen Ausführungsformen ≤ 0,1 Gew.%.According to the invention, the alloy of the steel products preferably comprises a copper portion. The proportion of Cu is preferably ≦ 0.1% by weight in all embodiments.

Die Stahlprodukte der Erfindung weisen gemäß Erfindung vorzugsweise mindestens anteilsmäßig einen kleinen Anteil an Nb auf, um so die Ms-Temperatur zu reduzieren. MS bezeichnet die Martensitstarttemperatur. Der Anteil an Nb beträgt bei allen Ausführungsformen vorzugsweise weniger als 0,4 Gew.%. Auf diesem Wege kann die bainitische Umwandlung in einem industriellen Herstellprozess kontrolliert werden. Diese bainitische Umwandlung findet bei der erfindungsgemässen Temperaturbehandlung hauptsächlich während einer Phase des sogenannten zweiten Haltens und während des darauffolgenden zweiten Abkühlens statt.The steel products of the invention preferably comprise, according to the invention, at least proportionally a small amount of Nb so as to reduce the Ms temperature. M S denotes the martensite start temperature. The proportion of Nb is preferably less than 0.4 in all embodiments Wt.%. In this way, the bainitic transformation can be controlled in an industrial manufacturing process. This bainitic transformation takes place in the inventive temperature treatment mainly during a phase of the so-called second holding and during the subsequent second cooling.

Die Stahlprodukte der Erfindung weisen gemäß Erfindung vorzugsweise mindestens anteilsmäßig einen kleinen Anteil an Ti auf. Der Anteil an Ti beträgt bei allen Ausführungsformen vorzugsweise weniger als 0,2 Gew.%.The steel products of the invention preferably have at least proportionally a small amount of Ti according to the invention. The proportion of Ti is preferably less than 0.2% by weight in all embodiments.

Die Stahlprodukte der Erfindung weisen gemäß Erfindung vorzugsweise mindestens anteilsmäßig einen kleinen Anteil an V auf. Der Anteil an V beträgt bei allen Ausführungsformen vorzugsweise weniger als 0,1 Gew.%.The steel products of the invention preferably have a small proportion of V according to the invention, at least proportionally. The proportion of V in all embodiments is preferably less than 0.1% by weight.

Das beschriebene Gefüge der Stahlprodukte mit den angegebenen Gewichtsprozenten wird durch eine spezielle Temperaturbehandlung erreicht, die zu kontrollierten Umwandlungen und Gefügeausbildungen im Multiphasen-Stahlprodukt führt. Diese Temperaturbehandlung wird hier als en-bloc Temperaturbehandlung bezeichnet, da sie lediglich einen einzigen kontinuierlich ablaufenden Behandlungprozess umfasst. D.h., die en-bloc Temperaturbehandlung der Erfindung weist keine Unterbrechung oder Pause auf, nach der das Stahlprodukt erneut erwärmt werden müsste.The described structure of the steel products with the indicated weight percentages is achieved by a special temperature treatment, which leads to controlled transformations and microstructures in the multiphase steel product. This temperature treatment is referred to herein as en-bloc temperature treatment because it involves only a single continuous treatment process. That is, the en-bloc thermal treatment of the invention has no break or break after which the steel product would have to be reheated.

Die Erfindung braucht somit keine konventionelle ART-Annealing Behandlung. ART steht für "austenite reverted transformation".The invention thus does not require a conventional ART annealing treatment. ART stands for "austenite reverted transformation".

Die beschriebenen Legierungen führen überraschenderweise zu Stahlprodukten mit den gewünschten Eigenschaften, obwohl sie nur einer en-bloc Temperaturbehandlung mit den Verfahrensschritten nach Patentanspruch 1 unterzogen werden. Diese spezielle Form der en-bloc Temperaturbehandlung hat einen deutlichen Einfluss auf die Ausbildung der spezifischen ultrafeinen Struktur(en) des Stahlprodukts.The described alloys surprisingly lead to steel products having the desired properties, although they undergo only an en bloc thermal treatment with the process steps according to

Gemäss Erfindung wird das Gefüge, respektive die Mikrostruktur des Stahlprodukts gezielt durch eine spezielle und effiziente Form der en-bloc Temperaturbehandlung gesteuert und festgelegt.According to the invention, the microstructure or the microstructure of the steel product is specifically controlled and defined by a special and efficient form of en-bloc temperature treatment.

Vorzugsweise umfasst die en-bloc Temperaturbehandlung eine Phase des schnellen Erwärmens bis zu einer ersten Haltetemperatur, die im Bereich um 820 °C ±20 °C liegt. Besonders bewährt hat sich eine erste Haltetemperatur bei ca. 810 °C. Nachdem das Stahlprodukt im Bereich der ersten Haltetemperatur für eine erste Zeitdauer (erste Haltedauer) gehalten wurde, erfolgt eine Phase des schnellen Abkühlens. Bei diesem schnellen Abkühlen wird eine zweite Haltetemperatur erreicht und es folgt eine zwischenzeitliche Haltephase (zweite Haltedauer) im Bereich dieser zweiten Haltetemperatur. Die zweite Haltetemperatur liegt im Bereich zwischen 350 °C und 450 °C. Vorzugsweise liegt die zweite Haltetemperatur bei allen Ausführungsformen im Bereich zwischen 380 °C und 450 °C. Nachdem das Stahlprodukt im Bereich der zweiten Haltetemperatur für eine zweite Zeitdauer gehalten wurde, erfolgt eine weitere Phase des schnellen Abkühlens.Preferably, the en-bloc thermal treatment comprises a rapid heating phase up to a first holding temperature which is in the range of 820 ° C ± 20 ° C. Has proven particularly useful a first holding temperature at about 810 ° C. After the steel product has been held in the range of the first holding temperature for a first period of time (first holding period), a rapid cooling phase occurs. In this rapid cooling, a second holding temperature is reached and there is an intermediate holding phase (second holding period) in the range of this second holding temperature. The second holding temperature is in the range between 350 ° C and 450 ° C. Preferably, the second holding temperature is in all embodiments in the range between 380 ° C and 450 ° C. After the steel product has been held in the range of the second holding temperature for a second period of time, another phase of rapid cooling takes place.

Die Phase des schnellen Abkühlens hat vorzugsweise bei allen Ausführungsformen eine Abkühlrate, die grösser ist als -30K/sec. Besonders bevorzugt sind Abkühlraten, die grösser sind als -50K/sec. Diese schnellen Abkühlraten haben eine vorteilhaften Einfluss auf die Mikrostruktur des Stahlprodukts der Erfindung.The rapid cooling phase preferably has a cooling rate greater than -30 K / sec in all embodiments. Cooling rates which are greater than -50 K / sec are particularly preferred. These rapid cooling rates have a beneficial effect on the microstructure of the steel product of the invention.

Die en-bloc Temperaturbehandlung der Erfindung dient dazu die negativen Einflüsse der martensitischen oder ferritischen Matrix zu vermeiden und gleichzeitig eine neue Mikrostruktur mit den angestrebten Eigenschaften herzustellen.The en-bloc temperature treatment of the invention serves to avoid the negative influences of the martensitic or ferritic matrix and at the same time to produce a new microstructure with the desired properties.

Die erste zwischenzeitliche Haltephase hat vorzugsweise bei allen Ausführungsformen eine Dauer von maximal 5 Minuten.The first intermediate holding phase preferably has a maximum duration of 5 minutes in all embodiments.

Die zweite zwischenzeitliche Haltephase hat vorzugsweise bei allen Ausführungsformen eine Dauer von maximal 10 Minuten.The second intermediate holding phase preferably has a maximum duration of 10 minutes in all embodiments.

Vorzugsweise ist die erste Haltedauer kürzer als die zweite Haltedauer.Preferably, the first holding period is shorter than the second holding period.

Durch das Halten im Bereich der zweiten Haltetemperatur im genannten Temperaturfenster und während des anschliessenden schnellen Abkühlens, kann gezielt eine bainitische Umwandlung stattfinden.By holding in the range of the second holding temperature in said temperature window and during the subsequent rapid cooling, a bainitic transformation can take place deliberately.

Die Mikrostruktur des Stahlprodukte zeichnet sich dadurch aus, dass sie vorzugsweise umfasst:

- feines, lattenförmiges Bainit,

- ferritische Phasen mit einer hohen Versetzungsdichte.

- fine, batten-shaped bainite,

- ferritic phases with a high dislocation density.

Das feine, lattenförmige Bainit trägt nachweislich dazu bei die Festigkeit der Stahlprodukte der Erfindung zu verbessern.The fine, batten-shaped bainite has been shown to improve the strength of the steel products of the invention.

Die Stahlprodukte der Erfindung weisen bainitische Latten auf, die eine Breite zwischen 20 und 200nm und eine typische Länge im Bereich von 1 µm bis 4 µm haben. Diese bainitischen Latten, die hier auch als nanofeine Latten bezeichnet werden, bilden sich aufgrund der speziellen en-bloc Temperaturbehandlung.The steel products of the invention have bainitic slats that have a width between 20 and 200 nm and a typical length in the range of 1 μm to 4 μm. These bainitic laths, also referred to here as nano-fine laths, form due to the special en-bloc temperature treatment.

Die ferritischen Phasen mit hoher Versetzungsdichte spielen eine bedeutende Rolle, da sie die Dehnung und Umformbarkeit der Stahlprodukte der Erfindung verbessern.The high dislocation density ferritic phases play an important role in improving the elongation and formability of the steel products of the invention.

Aufgrund der speziell entwickelten Legierungszusammensetzung und der genau aufeinander abgestimmten Gefügeanteile von Austenit, Bainit und Martensit oder Ferrit, werden besonders gute Eigenschaften erzielt und gleichzeitig liegt das Umformvermögen der Stahlprodukte in einem maschinell handhabbaren Bereich.Due to the specially developed alloy composition and the precisely coordinated microstructures of austenite, bainite and martensite or ferrite, particularly good properties are achieved and at the same time the forming capacity of the steel products lies in a machinable range.

Vorzugsweise wird die Erfindung eingesetzt, um Kaltband-Stahlprodukte in Form von kaltgewalztem Flachzeug (z.B. Coils) bereit zu stellen. Die Erfindung kann auch eingesetzt werden, um z.B. Feinbleche oder auch Draht und Drahtprodukte herzustellen.Preferably, the invention is used to provide cold rolled steel products in the form of cold rolled flat products (e.g., coils). The invention can also be used to e.g. To produce thin sheets or wire and wire products.

Es ist ein Vorteil des Verfahrens der Erfindung, dass es im Vergleich zu vielen anderen Verfahrensansätzen wenig energieaufwändig, schneller und kostengünstiger ist.It is an advantage of the method of the invention that it is less energy consuming, faster and less expensive compared to many other approaches.

Die Erfindung hat unter anderem den Vorteil, dass keine ART-Wärmebehandlung benötigt wird. ART steht für "Austenite Reverted Transformation".The invention has, inter alia, the advantage that no ART heat treatment is needed. ART stands for "Austenite Reverted Transformation".

Weitere vorteilhafte Ausgestaltungen der Erfindung bilden die Gegenstände der abhängigen Ansprüche.Further advantageous embodiments of the invention form the subject of the dependent claims.

Ausführungsbeispiele der Erfindung werden im Folgenden unter Bezugnahme auf die Zeichnungen näher beschrieben.

- FIG. 1

- zeigt ein stark schematisiertes Diagramm, bei dem die Bruchdehnung in Prozent über die Zugfestigkeit in MPa für verschiedene Stähle aufgetragen ist;

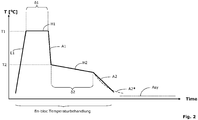

- FIG. 2

- zeigt ein schematisiertes Diagramm der einmaligen Temperaturbehandlung, das im Rahmen der Herstellung eines Stahlprodukts der Erfindung zum Einsatz kommt.

- FIG. 1

- shows a highly schematic diagram in which the percent elongation at break is plotted against the tensile strength in MPa for various steels;

- FIG. 2

- shows a schematic diagram of the one-time temperature treatment, which is used in the production of a steel product of the invention.

Gemäß Erfindung geht es um ultrafeine Multiphasen Medium-Mangan-Stahlprodukte, die Martensit-, Ferrit- und Restaustenit-Bereiche oder Phasen, sowie optional auch Bainit-Mikrostrukturen umfassen. D.h. die Stahlprodukte der Erfindung zeichnen sich durch eine spezielle Gefügekonstellation aus, die auch als Multiphasen-Gefüge bezeichnet wird.The invention relates to ultrafine multiphase medium-manganese steel products comprising martensite, ferrite and retained austenite regions or phases, and optionally also bainite microstructures. Ie the steel products of Invention are characterized by a special structure constellation, which is also referred to as a multi-phase structure.

Teilweise ist im Folgenden von Stahl(zwischen)produkten die Rede, wenn es darum geht zu betonen, dass es nicht um das fertige Stahlprodukt sondern um ein Vor- oder Zwischenprodukt in einem mehrstufigen Fertigungsprozess geht. Ausgangspunkt für solche Fertigungsprozesse ist meist eine Schmelze. Im Folgenden wird die Legierungszusammensetzung der Schmelze angegeben, da man auf dieser Seite des Fertigungsprozesses relativ genau auf die Legierungszusammensetzung Einfluss nehmen kann (z.B. durch Zuchargieren von Bestandteilen, wie Silizium). Die Legierungszusammensetzung des Stahlprodukts weicht im Normalfall nur unwesentlich von der Legierungszusammensetzung der Schmelze ab.In the following, steel (intermediate) products are sometimes referred to when it comes to emphasizing that it is not about the finished steel product but about a preliminary or intermediate product in a multi-stage production process. The starting point for such production processes is usually a melt. The following is an indication of the alloy composition of the melt, since on this side of the manufacturing process it is possible to influence the alloy composition relatively precisely (for example by attacking constituents such as silicon). The alloy composition of the steel product usually deviates only insignificantly from the alloy composition of the melt.

Der Begriff "Phase" wird unter anderem durch seine Zusammensetzung aus Anteilen der Komponenten, Enthalpiegehalt und Volumen definiert. Unterschiedliche Phasen sind im Stahlprodukt durch Phasengrenzen voneinander getrennt.The term "phase" is defined inter alia by its composition of proportions of the components, enthalpy content and volume. Different phases are separated in the steel product by phase boundaries.

Die "Komponenten" oder "Konstituenten" der Phasen können entweder chemische Elemente (wie Mn, Ni, Al, Fe, C, ... usw.) oder neutrale, molekülartige Aggregate (wie FeSi, Fe3C, SiO2, usw.) oder geladene, molekülartige Aggregate (wie Fe2+, Fe3+, usw.) sein.The "components" or "constituents" of the phases can be either chemical elements (such as Mn, Ni, Al, Fe, C, etc.) or neutral, molecular aggregates (such as FeSi, Fe 3 C, SiO 2 , etc.). ) or charged, molecular aggregates (such as Fe 2+ , Fe 3+ , etc.).

Mengen oder Anteilsangaben werden hier grossteils in Gewichtsprozent (kurz Gew.%) gemacht, soweit nichts anderes erwähnt ist. Wenn Angaben zur Zusammensetzung der Legierung, respektive des Stahlprodukts gemacht werden, dann umfasst die Zusammensetzung neben den explizit aufgelisteten Materialien bzw. Stoffen als Grundstoff Eisen (Fe) und sogenannte unvermeidbare Verunreinigungen, die immer im Schmelzbad auftreten und die sich auch in dem daraus entstehenden Stahlprodukt zeigen. Alle Gew.%-Angaben sind also stets auf 100 Gew.% zu ergänzen und alle Vol.%-Angaben sind stets auf 100 % des Gesamtvolumens zu ergänzen.Quantities or proportions are here largely in weight percent (short wt.%) Made, unless otherwise stated. If information is provided on the composition of the alloy, or the steel product, then the composition comprises in addition to the explicitly listed materials or materials as the basic iron (Fe) and so-called unavoidable impurities that always occur in the molten bath and also in the resulting steel product demonstrate. All% by weight must always be supplemented to 100% by weight and all% by volume must always be completed to 100% of the total volume.

Die Medium-Mangan-Stahlprodukte der Erfindung haben alle einen Mangangehalt, der im Bereich von 3,5 und 6 Gew.% liegt, wobei die angegebenen Grenzen zu dem Bereich dazu gehören, d.h. der Mangananteil liegt im Bereich 3,5 Gew.% ≤ Mn ≤ 6 Gew.%. Vorzugsweise liegt der Mangananteil bei allen Ausführungsformen liegt im Bereich 4 Gew.% ≤ Mn ≤ 6 Gew.%.The medium-manganese steel products of the invention all have a manganese content which is in the range of 3.5 and 6 wt.%, The stated limits being within the range thereof, i. the manganese content is in the range of 3.5% by weight ≦ Mn ≦ 6% by weight. The manganese content in all embodiments is preferably in the

Ausserdem liegt der Kohlenstoffanteil C im folgenden Bereich 0,02 ≤ C ≤ 0,35 Gew.%.In addition, the carbon content C in the following range is 0.02 ≦ C ≦ 0.35 wt%.

Beim Herstellen eines Mangan-Stahlprodukts werden unter anderem die folgenden Schritte ausgeführt, wobei diese Schritte nicht unbedingt unmittelbar aufeinander folgen müssen.When manufacturing a manganese steel product, among other things, the following steps are performed, but these steps may not necessarily follow each other immediately.

Im Rahmen des Bereitstellens der erfindungsgemässen Legierung wird einer Ausgangsmenge an Eisen ein Kohlenstoffanteil C im folgenden Bereich 0,02 ≤ C ≤ 0,35 Gew.%, und ein Mangananteil Mn im folgenden Bereich 3,5 Gew.% ≤ Mn ≤ 6 Gew.% hinzugefügt. Die entsprechende Vorgehensweise ist hinlänglich bekannt.In the course of providing the alloy of the present invention, a starting amount of iron has a carbon content C in the range of 0.02 ≦ C ≦ 0.35 wt%, and a manganese content Mn in the range of 3.5 wt% ≦ Mn ≦ 6 wt. % added. The corresponding procedure is well known.

Im Rahmen der Weiterbearbeitung der so gewonnen Legierung, folgt ein besonders effizientes Glühverfahren (en-bloc Temperaturbehandlung genannt). Das Wort en-bloc wird hier verwendet, um zu betonen, dass im Gegensatz zu zahlreichen alternativen Ansätzen kein zweimaliges Glühen oder Temperaturbehandeln erforderlich ist.As part of the further processing of the alloy thus obtained, follows a particularly efficient annealing process (called en-bloc temperature treatment). The word en-bloc is used here to emphasize that, unlike many alternative approaches, no two-fold annealing or tempering is required.

Beim Durchführen des en-bloc Glühverfahrens werden die folgenden Teilschritte ausgeführt (in diesem Zusammenhang wird auf die

- ∘ Erwärmen E1 des Stahl(zwischen)produkts auf eine erste Haltetemperatur T1, die im Bereich von 820 °C ±20°C liegt,

- ∘ Erstes Halten H1 des Stahl(zwischen)produkts während einer ersten Haltedauer 51 auf der ersten Haltetemperatur T1,

- ∘ Schnelles erstes Abkühlen A1 des Stahl(zwischen)produkts auf eine zweite Haltetemperatur T2, die im Bereich zwischen 350 °C und 450 °C liegt,

- ∘ Zweites Halten H2 des Stahl(zwischen)produkts während einer zweiten Haltedauer 52 im Bereich der zweiten Haltetemperatur T2,

- ∘ Durchführen eines langsamen zweiten Abkühlens A2.

- E heating E1 of the steel (intermediate) product to a first holding temperature T1, which is in the range of 820 ° C ± 20 ° C,

- ∘ first holding H1 of the steel (intermediate) product during a

first holding period 51 at the first holding temperature T1, - ∘ Fast first cooling A1 of the steel (intermediate) product to a second holding temperature T2, which lies in the range between 350 ° C and 450 ° C,

- Second holding H2 of the steel (between) product during a

second holding period 52 in the region of the second holding temperature T2, - ∘ Perform a slow second cooling A2.

Die erste zwischenzeitliche Haltephase H1 hat vorzugsweise bei allen Ausführungsformen eine Dauer von maximal 5 Minuten. Die zweite zwischenzeitliche Haltephase H2 hat vorzugsweise bei allen Ausführungsformen eine Dauer von maximal 10 Minuten.The first intermediate holding phase H1 preferably has a maximum duration of 5 minutes in all embodiments. The second intermediate holding phase H2 preferably has a maximum duration of 10 minutes in all embodiments.

Besonders bevorzugt sind Ausführungsformen, bei denen gilt: δ1 + 52 < 15 min und 51 < 52.Particular preference is given to embodiments in which δ1 + 52 <15 min and 51 <52.

Das erste Abkühlen A1 kann bei allen Ausführungsformen in einem Luftstrom oder unter Einsatz eines Kühlfluids erfolgen. Das zweite Abkühlen A2 kann bei allen Ausführungsformen in einem Luftstrom erfolgen. Das Stahlprodukt der Erfindung kann aber auch in ein separates Umfeld (z.B. in ein Glühaggregat) gebracht werden, um dort eine Weile länger gehalten zu werden (z.B. bei 300 bis 450 °C). In diesem Fall verlängert sich die Zeit 52 entsprechend.The first cooling A1 can be carried out in all embodiments in an air stream or using a cooling fluid. The second cooling A2 can be carried out in all embodiments in an air stream. However, the steel product of the invention may also be placed in a separate environment (e.g., an incandescent unit) to be held there for a while longer (e.g., at 300 to 450 ° C). In this case, the

Die Phase des schnellen Abkühlens A1 hat vorzugsweise bei allen Ausführungsformen eine Abkühlrate, die grösser ist als -30K/sec. Besonders bevorzugt sind Abkühlraten A1, die grösser sind als -50K/sec. Diese schnellen Abkühlraten haben eine vorteilhaften Einfluss auf die Mikrostruktur des Stahlprodukts der Erfindung.The rapid cooling phase A1 preferably has a cooling rate greater than -30 K / sec in all embodiments. Cooling rates A1 which are greater than -50 K / sec are particularly preferred. These rapid cooling rates have a beneficial effect on the microstructure of the steel product of the invention.

Der

Gemäss Erfindung sind Stahlprodukte bevorzugt, die anteilsmässig die folgenden Beimengungen umfassen:

- ∘ Al- plus Si -Anteile ≤ 4 Gew.%, und/oder

- ∘ Nb-

Anteil ≤ - ∘ Ti-

Anteil ≤ - ∘ V-

Anteil ≤ - ∘ P-

Anteil ≤ 0,03 Gew.%, und/oder - ∘ Cu-

Anteil ≤

- ∘ Al plus Si contents ≤ 4 wt.%, And / or

- ∘ Nb content ≦ 0.4% by weight, and / or

- Ti content ≤ 0.2 wt.%, And / or

- ∘ V content ≤ 0.1% by weight, and / or

- ∘ P content ≤ 0.03 wt.%, And / or

- ∘ Cu content ≤ 0.1% by weight.

Gemäss Erfindung sind Stahlprodukte bevorzugt, die einen Anteil einer bainitischen Mikrostruktur umfassen, der grösser ist als 5 Gew.% des Stahlprodukts, wobei der Anteil der bainitischen Mikrostruktur vorzugsweise im Bereich von 10 bis 70 Vol.% des Stahlprodukts liegt. Besonders vorzugsweise liegt der Anteil der Mikrostruktur im Bereich von 20 bis 40 Vol.%According to the invention, preference is given to steel products which comprise a proportion of a bainitic microstructure which is greater than 5% by weight of the steel product, the fraction of the bainitic microstructure preferably being in the range from 10 to 70% by volume of the steel product. Particularly preferably, the proportion of the microstructure is in the range from 20 to 40% by volume.

Gemäss Erfindung sind Stahlprodukte bevorzugt, die einen Restaustenit-Anteil umfassen, der weniger als 30 Vol.% des Stahlprodukts beträgt, wobei der Restaustenit-Anteil vorzugsweise weniger als 10 Vol.% des Stahlprodukts beträgt.According to the invention, steel products are preferred which comprise a retained austenite content of less than 30% by volume of the steel product, the retained austenite content preferably being less than 10% by volume of the steel product.

Gemäss Erfindung sind Stahlprodukte bevorzugt, die einen Anteil einer austenitischen Mikrostruktur aufweisen, der im Bereich von 5 bis 20 Vol.% des Stahlprodukts liegt, insbesondere von 2 bis 10 Vol.%.According to the invention, preference is given to steel products which have a proportion of an austenitic microstructure which is in the range from 5 to 20% by volume of the steel product, in particular from 2 to 10% by volume.

Gemäss Erfindung sind Stahlprodukte bevorzugt, die einen Volumenanteil von Austenitkörnern umfassen, der vorzugsweise bei weniger als 5% des Gesamtvolumens des Stahlprodukts beträgt. Diese Austenitkörner weisen vorzugsweise eine Maximalgröße auf, die kleiner ist als 1 µm.

Claims (8)

- A method for producing a manganese steel product, the method comprising the following steps:- providing an alloy withwherein the method is characterized by the following steps:∘ a carbon content (C) in the following range 0.02 ≤ C ≤ 0.35% by weight, and∘ a manganese content (Mn) in the following range of 3.5% by weight ≤ Mn ≤ 6 % by weight,- carrying out an en-bloc annealing process with the following substeps, wherein the en-bloc annealing process is a continuously conducted temperature treatment without interruption, after which the steel product must be reheated:∘ heating (E1) the steel product to a first holding temperature (T1) which is in the range of 820°C ± 20°C,∘ first holding (H1) of the steel product during a first holding period (δ1) at the first holding temperature (T1),∘ faster first cooling (A1) of the steel product to a second holding temperature (T2) which is in the range between 350°C and 450°C,∘ second holding (H2) of the steel product during a second holding period (δ2) in the range of the second holding temperature (T2),∘ performing a slower second cooling (A2), wherein the faster first cooling (A1) is performed at a cooling rate higher than the cooling rate of the slower second cooling (A2).