EP2899323B1 - Slotted pipe with fire seal drainage system and its use - Google Patents

Slotted pipe with fire seal drainage system and its use Download PDFInfo

- Publication number

- EP2899323B1 EP2899323B1 EP14002805.1A EP14002805A EP2899323B1 EP 2899323 B1 EP2899323 B1 EP 2899323B1 EP 14002805 A EP14002805 A EP 14002805A EP 2899323 B1 EP2899323 B1 EP 2899323B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- flap

- slotted pipe

- pivoting

- liquid

- slotted

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03F—SEWERS; CESSPOOLS

- E03F3/00—Sewer pipe-line systems

- E03F3/04—Pipes or fittings specially adapted to sewers

- E03F3/046—Open sewage channels

Definitions

- the invention relates to the construction of drainage system formed by slotted pipes, wherein at least one slotted pipe has a fireproof seal that prevents the spread of fire in a concrete precast slotted pipe system used to drain water from paved roads.

- the first objective is to prevent flame spreading in the drainage system of the slotted pipes whilst maintaining the same height of the fireproof seal element as other elements of the system.

- the second objective is to eliminate the need to keep water in a part of the system, thus ensuring system reliability.

- the third objective is to provide greater hydraulic purity of the solutions by eliminating unnecessary hydraulic losses and clogging due to settling of impurities.

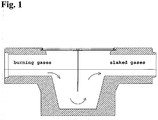

- the basic concept of the invention is the use of fire seals in the slotted pipe systems, an element externally dimensionally identical to the slotted pipe, but without a slot and with damming of the internal flow profile via a dry pivoting flap, or by two or more flaps. Flaps create two or more fireproof areas with a lack of oxygen intake, and thereby the ability to extinguish the fire whilst cooling the burning liquid and prevent evaporation of burning gases from the fluid flowing through.

- the flap is pivotally connected to the element at the top of the flow profile. The swivel movement of the flap is preferably at a limited angle of a maximum of 79° in the direction of the gradient of the liquid flow.

- the flap is directly attached to the wall of the upper part of the flow profile, or via another fastening element, which mediates the connection between the flap and the inner wall of the slotted pipe.

- the flap prevents the direct transfer of hot burning gases from the area in front of the flap into the space behind the flap, even preventing flame flashing using flap plug-segments.

- the effect of flame flashing in the early stage of flame spreading, which normally accompanies flame spreading in closed pipe systems, wherein the expansion of burning gas causes an increase in pressure in the pipes, does not occur in slotted pipes due to the opening of the inlet slots in all system elements, except the element with fireproof seal.

- This slot also leads to smooth and easy pressure equalization between the flow profile with fireproof seal with the burning liquid and the surrounding environment.

- the weight of the pivoting flap with optional weight is created so that the resulting pressure acting on the valve was not able, at different gradients of the slotted pipe, to overcome the force of gravity ensuring the sealing of the flap with an installed counterweight.

- the flap fills the entire space of the flow profile.

- the initial position of the flap is in a vertical position, see e.g. Fig. 11 , although it is possible that the initial position of the flap is limited by a certain angle, see Fig. 12 , or it is expanded against the direction of the flow of the liquid, see Fig. 13 ; such a design typically requires the creation of recesses in the lower inner wall of the slotted pipe.

- the flow profile can thus be closed from a variety of positions, of which the above figures are proof.

- the bottom edge of the flap is thus constantly in contact with the liquid, which is ensured by the actual weight of the flap with counterweight and acting force of gravity. Flashing of flames on the sides of the flap is prevented by the sliding segments of the flap. This ensures that the flap will not be opened more and the flame will not spread behind the flap on the side of the outlet, even when the ignition of flammable fluid in the system, not even if the flammable liquids are ignited in the system. This is due to the fact that as specified above, the weight of the flap along with the ventilation of the slotted pipe system through openings, through which liquid flows into the system, does not allow for such a an increase in pressure in the slotted pipe that would open the flap above the liquid level.

- the profile of the pipe of the fireproof seal is in a vertical position from the location of the flap, and in the area behind the flap, in the direction of its opening, in the shape of a rectangle or square, and that the tightness of all of the outer edges of the flap in contact with the inner walls of the slotted pipe is maintained.

- the space in which the flap moves, must, in any of its swings copy the edges of the flap, with the exception of the bottom edge, which copies the lower edge of the flap only when the flap is in a vertical position.

- this is achieved through a mutual combination of minimizing the thickness of the gap between the pivoting flap and the inner wall of the pipe and maximizing the length of the gap.

- the flap has balancing elements for fine tuning of the swing operation depending on the expected environmental conditions.

- the flap operates completely independently only through the effect of the horizontal forces caused by increasing and decreasing the flow rate of the liquid and the gravitational forces of the earth. This ensures the smooth closing and opening of the flap.

- the drainage system of the slotted pipes with fireproof seal can be manufactured as single-flap and dual-flap, i.e. with a locking flap placed behind the first flap in the direction of the flow of the liquid, or multi-flap, i.e. made up of several flaps, fitted into one or more slotted pipes.

- the drainage system of the slotted pipes contains at least one element - a slotted pipe - which contains at least one fireproof seal as described above.

- each pivoting flap may be supplemented by other appropriate measures that increase safety. Examples include tightening their sides, additional sidewalls extending the route of burning gases, thereby cooling the gas mixture below the combustion temperature. These sidewalls are conveniently placed vertically to the side profile of the pivoting flap and must allow for the free movement of the flap, and they replicate the side walls of the interior space of the slotted pipe.

- the possible shape of the sidewalls should allow for the largest possible area adjacent to the walls of the slotted pipe while maintaining the required momentum of the flap and tilt angle.

- a suitable shape of the sidewalls would be a circle or ellipse, where the side edge of the flap passes through their centre, or a lozenge, where the side edge of the flap is placed vertically to its diagonal. In any case, the sidewall should not restrict the flap with regard to its desired rotation.

- the system or its individual elements - slotted pipe - may be equipped with a service opening in the area in front of the flap, behind the flap or above the flap.

- the length of the fireproof seal element may be modified, i.e. manufactured in various lengths ranging from 50 cm to 20 m.

- Slotted pipe 1 of the sewage drainage system is fitted with a fireproof seal made up of a pivoting flap 2 , which is affixed pivotally to the upper inner wall 11 of the slotted pipe 1 by means of a rotary connection 21 so that it permits liquid flow into the slotted pipe 1 , and depending on the speed and the amount of liquid, this creates pressure on the flap 2 , which, as a consequence of the force exerted by the liquid and gravity pivots the flap 2 in the direction of the liquid flow.

- the flap prevents the burning gas from proceeding further in the direction of the liquid flow above its surface.

- the flap 2 in a vertical position and at any of its rotations, fills the overall space above the liquid so that it adjoins to the internal walls of the slotted pipe 1 . If liquid is present, the flap 2 is at least continuously partially immersed in the liquid so that it does not pass the burning gases in the direction of the liquid flow.

- the slotted pipe 1 of the sewage drainage system according to example 1 further contains a service opening 3 , which is created behind a rotary joint 21 in the direction of the flow of the liquid.

- the slotted pipe 1 of the sewage drainage system according to example 1 contains two fireproof seals in the form of the flaps 2 according to example 1.

- the invention is useful for preventing spreading of fire in a slotted pipe sewage system. Individual fire seals divide the system into fire sections. Normally, the length is around 50 m, depending on the projected length of fire hoses.

- the invention is mainly applicable in highway tunnels, airports and industrial plants where it is necessary to prevent the free spreading of a fire through the system in case of fire.

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Hydrology & Water Resources (AREA)

- Public Health (AREA)

- Water Supply & Treatment (AREA)

- Pipe Accessories (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL14002805T PL2899323T3 (pl) | 2014-01-24 | 2014-08-12 | Rura szczelinowa z systemem ochrony przeciwpożarowej i jej zastosowanie |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CZ2014-57A CZ306259B6 (cs) | 2014-01-24 | 2014-01-24 | Štěrbinová trouba s protipožárním uzávěrem odvodňovacího systému a jeho použití |

| CZ2014029131 | 2014-01-24 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2899323A1 EP2899323A1 (en) | 2015-07-29 |

| EP2899323B1 true EP2899323B1 (en) | 2017-05-31 |

Family

ID=53838112

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP14002805.1A Active EP2899323B1 (en) | 2014-01-24 | 2014-08-12 | Slotted pipe with fire seal drainage system and its use |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP2899323B1 (pl) |

| CZ (1) | CZ306259B6 (pl) |

| PL (1) | PL2899323T3 (pl) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109295869B (zh) * | 2018-10-23 | 2021-05-28 | 上海市基础工程集团有限公司 | 水域工况下大断面箱涵改排接口装置及方法 |

| GB2589823B (en) * | 2019-09-23 | 2022-01-19 | Alumasc Building Products Ltd | Modular conduit-connector apparatus |

| CN112057783A (zh) * | 2020-08-06 | 2020-12-11 | 常州大学 | 一种工业管道支管防爆阻火装置 |

| EP4506517A1 (de) | 2023-08-07 | 2025-02-12 | Hauraton GmbH & Co. KG | Verschlussvorrichtung für einen rinnenstrang |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3032734B2 (ja) * | 1997-07-30 | 2000-04-17 | 神戸樹脂工業株式会社 | 耐火材被覆管継手 |

| JP3137932B2 (ja) * | 1997-09-10 | 2001-02-26 | 神戸樹脂工業株式会社 | 耐火性被覆管及びその製造方法とその製造装置 |

| DE10016099A1 (de) * | 2000-03-17 | 2001-09-20 | Rinninger Hans & Sohn | Schacht |

| CZ14467U1 (cs) * | 2004-03-26 | 2004-06-21 | Csábetonźás@Ár@Áo | Bezpečnostníštěrbinová trouba |

| DE202007008019U1 (de) * | 2007-06-05 | 2008-10-16 | Raimund Höllein Carolinenhütte GmbH | Entwässerungssystem |

| IT1391720B1 (it) * | 2008-11-20 | 2012-01-27 | Futura Spa | Circuito idraulico per il deflusso di acqua da una galleria, in particolare acqua di un impianto antincendio |

| DE202011052123U1 (de) * | 2011-11-28 | 2012-01-16 | Aco Severin Ahlmann Gmbh & Co. Kg | Entwässerungsschacht für einen Tunnel |

-

2014

- 2014-01-24 CZ CZ2014-57A patent/CZ306259B6/cs unknown

- 2014-08-12 PL PL14002805T patent/PL2899323T3/pl unknown

- 2014-08-12 EP EP14002805.1A patent/EP2899323B1/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| EP2899323A1 (en) | 2015-07-29 |

| CZ201457A3 (cs) | 2015-08-05 |

| CZ306259B6 (cs) | 2016-11-02 |

| PL2899323T3 (pl) | 2018-10-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2899323B1 (en) | Slotted pipe with fire seal drainage system and its use | |

| EP2257691B1 (en) | Automatic flooding protection for underground ventilation ducts | |

| JP6574657B2 (ja) | 雨水排水貯留設備 | |

| KR101558528B1 (ko) | 소화 기능이 구비된 샌드위치패널 및 이를 이용한 건축벽체 | |

| CN106480905B (zh) | 一种综合管廊 | |

| CN109667520A (zh) | 一种用于消防通道的门结构 | |

| US3338254A (en) | Safety gas connection assembly | |

| KR102541030B1 (ko) | 방화댐퍼가 구비된 에어덕트용 수직관 | |

| KR20010012931A (ko) | 유체로 구동가능한 차단장치 | |

| FI86452B (fi) | FOERFARANDE OCH ANLAEGGNING FOER ATT HAOLLA EN SLUSS OEPPEN. SIIRRETTY PAEIVAEMAEAERAE-FOERSKJUTET DATUM 14 ç 11.04.91. | |

| CN112648001B (zh) | 一种北方用隧道消防设施 | |

| CN110374658B (zh) | 隧道活动式倾斜顶棚排烟系统及方法 | |

| CZ26992U1 (cs) | Štěrbinová trouba s protipožárním uzávěrem odvodňovacího systému | |

| HUE034981T2 (en) | Slotted water drainage system and application | |

| PT2537562E (pt) | Obturador de evacuação de fumo | |

| KR101937863B1 (ko) | 우수한 배수성과 지반의 안전성을 보장하는 보도블록 | |

| KR101017404B1 (ko) | 복개천 방류부 개폐 장치 | |

| CN209324419U (zh) | 一种矿山井下防水闸门硐室排水沟止水装置 | |

| Petrichenko et al. | The Double-Layer Nonstationary Heat Conduction Measures to Prevent the Formation Ice-Dams on the Roof | |

| CN223649287U (zh) | 锅炉烟囱冷凝水排放装置及锅炉排烟组件 | |

| RU2467138C2 (ru) | Способ предотвращения образования наледей и сосулек на чердачных крышах | |

| CN215715110U (zh) | 一种排水洞出口的跌水布置结构 | |

| KR102263762B1 (ko) | 결로 방지 구조물이 설치된 단열 밸브실 | |

| JP2003021372A (ja) | 戸建て住宅の空調設備 | |

| ES2270716B1 (es) | Instalacion para aislamiento asistido natural para auto salvaguardar personas en caso de incendio. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20140812 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| 17P | Request for examination filed |

Effective date: 20160107 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20161116 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 897612 Country of ref document: AT Kind code of ref document: T Effective date: 20170615 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602014010172 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: HR Ref legal event code: TUEP Ref document number: P20171307T Country of ref document: HR |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20170531 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 897612 Country of ref document: AT Kind code of ref document: T Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170831 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170901 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170930 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170831 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| REG | Reference to a national code |

Ref country code: HR Ref legal event code: OTEP Ref document number: P20171307T Country of ref document: HR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602014010172 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: T3 Ref document number: E 25913 Country of ref document: SK |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170831 Ref country code: HU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170813 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170831 |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E034981 Country of ref document: HU |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170831 |

|

| 26N | No opposition filed |

Effective date: 20180301 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20180430 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180220 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170812 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180301 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170812 |

|

| REG | Reference to a national code |

Ref country code: HR Ref legal event code: RESP Ref document number: P20171307T Country of ref document: HR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170831 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170812 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180812 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170813 |

|

| PGRI | Patent reinstated in contracting state [announced from national office to epo] |

Ref country code: HU Effective date: 20190205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180812 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20220131 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230812 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220812 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: RO Payment date: 20250807 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SK Payment date: 20250820 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: HC9C Owner name: CS-BETON S.R.O., CZ |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: HU Payment date: 20251013 Year of fee payment: 12 |