EP2843095A1 - Flat knitting machine having a yarn guide moving perpendicular to the pin bed - Google Patents

Flat knitting machine having a yarn guide moving perpendicular to the pin bed Download PDFInfo

- Publication number

- EP2843095A1 EP2843095A1 EP13182138.1A EP13182138A EP2843095A1 EP 2843095 A1 EP2843095 A1 EP 2843095A1 EP 13182138 A EP13182138 A EP 13182138A EP 2843095 A1 EP2843095 A1 EP 2843095A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- thread

- knitting machine

- flat knitting

- yarn guide

- machine according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000009940 knitting Methods 0.000 title claims abstract description 47

- 230000027455 binding Effects 0.000 claims description 7

- 238000009739 binding Methods 0.000 claims description 7

- 238000007747 plating Methods 0.000 claims description 5

- 239000004744 fabric Substances 0.000 description 5

- 238000010586 diagram Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 229920000742 Cotton Polymers 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000007664 blowing Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B39/00—Knitting processes, apparatus or machines not otherwise provided for

- D04B39/04—Knitting processes, apparatus or machines not otherwise provided for adapted for combined weft and warp knitting

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B1/00—Weft knitting processes for the production of fabrics or articles not dependent on the use of particular machines; Fabrics or articles defined by such processes

- D04B1/10—Patterned fabrics or articles

- D04B1/12—Patterned fabrics or articles characterised by thread material

- D04B1/123—Patterned fabrics or articles characterised by thread material with laid-in unlooped yarn, e.g. fleece fabrics

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B1/00—Weft knitting processes for the production of fabrics or articles not dependent on the use of particular machines; Fabrics or articles defined by such processes

- D04B1/10—Patterned fabrics or articles

- D04B1/12—Patterned fabrics or articles characterised by thread material

- D04B1/126—Patterned fabrics or articles characterised by thread material with colour pattern, e.g. intarsia fabrics

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B15/00—Details of, or auxiliary devices incorporated in, weft knitting machines, restricted to machines of this kind

- D04B15/38—Devices for supplying, feeding, or guiding threads to needles

- D04B15/54—Thread guides

- D04B15/56—Thread guides for flat-bed knitting machines

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B15/00—Details of, or auxiliary devices incorporated in, weft knitting machines, restricted to machines of this kind

- D04B15/38—Devices for supplying, feeding, or guiding threads to needles

- D04B15/54—Thread guides

- D04B15/56—Thread guides for flat-bed knitting machines

- D04B15/565—Associated thread-clamping or thread-severing devices

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B15/00—Details of, or auxiliary devices incorporated in, weft knitting machines, restricted to machines of this kind

- D04B15/66—Devices for determining or controlling patterns ; Programme-control arrangements

- D04B15/80—Devices for determining or controlling patterns ; Programme-control arrangements characterised by the thread guides used

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B7/00—Flat-bed knitting machines with independently-movable needles

- D04B7/14—Flat-bed knitting machines with independently-movable needles with provision for incorporating internal threads in laid-in fabrics

Definitions

- the invention relates to a flat knitting machine with at least one needle bed and a carriage movable over the needle bed and one or more yarn guides, which are movable along at least one yarn guide rail, wherein the yarn guide or are driven independently of the carriage.

- the yarn guides are not only movable along a yarn guide rail, but can also be raised by a linear movement or by pivoting out of the needle chamber, that is, be switched to a non-active position.

- the thread guides known machines can be moved so far only in Nadelbettenlnaturescardi and therefore perform only in a functional level either thread for a bond (weft, chain) or thread to knitting needles.

- the object of the present invention is to further develop a flat knitting machine in such a way that threads can be moved in several directions with the thread guide (s), thereby increasing the pattern variety of the machine.

- a flat knitting machine having at least one needle bed and a carriage movable over the needle bed and one or more yarn guides which are movable along at least one yarn guide rail, wherein the yarn guide or are driven independently of the carriage, which is characterized in that At least one yarn guide is also limited in the horizontal direction transversely to the longitudinal direction of the at least one needle bed movable.

- the at least one thread guide in expelled needles of the at least one needle bed in a course series warp, weft, plating or pile threads and any combinations thereof can be inserted. It is also possible, with the at least one yarn guide threads meander over several rows of knitting into expelled needles of at least one needle bed insert, that is to produce crosshairs.

- movements of the thread guide in the longitudinal direction of the at least one needle bed and, transversely thereto, one or more expelled needles can be partially or completely looped around with a thread.

- the at least one thread guide is movable in both directions transversely to the needle bed longitudinal direction.

- the at least one thread guide can be adjustable in height, i. be brought out of the needle room in an inactive position.

- the lateral movement of the thread guide or can be done in different ways.

- the at least one yarn guide rail is pivotally mounted about a horizontal axis. This means that all yarn guides guided on the rail can be swiveled simultaneously.

- the thread guide rail can move similar to the barre of a warp knitting machine combined into blocks thread guide together.

- a Fadenleitorgan the at least one yarn guide can be mounted eccentrically rotatable on a longitudinally along a yarn guide rail movable yarn guide box. This also makes it possible to realize a movement of the thread guide or, more precisely, its tip with the Fadenleitorgan transversely to the needle bed longitudinal direction.

- the thread guide rail is pivotable, so there is an additional degree of freedom for the movement of the thread guide or.

- the Fadenleitorgan be secured in a conventional manner via a cranked Faden embarkarm on the thread guide box, but now the Fadenterrorismarm is arranged pivotably about a vertical axis on the thread guide box.

- the thread guide can be a nut or a tube. In confined spaces and when different threads are to be inserted into adjacent needles, tubes are advantageous.

- a thread brake or clamp can be arranged on the at least one thread guide.

- the flat knitting machine also has at least one clamping-cutting device that can be moved along a yarn guide rail

- individual yarn guides can be equipped with a thread blowing device and blow in specific thread material together with the clamping cutting device, for example for feeding functional pockets in the knitted fabric.

- the invention also relates to the use of a flat knitting machine according to the invention for producing a knitted fabric having warp knitted bindings, with selectively or completely plated intarsia patterns or with standing threads, by partially or completely expelling needles of the at least one needle bed with a warp thread, a plating thread or a standing thread with the at least one thread guide be entwined.

- a flat knitting machine according to the invention for producing a knitted fabric having warp knitted bindings, with selectively or completely plated intarsia patterns or with standing threads, by partially or completely expelling needles of the at least one needle bed with a warp thread, a plating thread or a standing thread with the at least one thread guide be entwined.

- FIGS. 1a, b show a carriage 1 of an otherwise not shown flat knitting machine with lock systems 2, 3, which are movable via a not shown here front and rear needle bed of the flat knitting machine.

- Fig. 1a Between the carriage 1 and the Lock systems 2, 3 are in Fig. 1a arranged in a row next to each other a plurality of yarn guide rails 4, which are all pivotable about a longitudinal axis L in the direction of the double arrow 5.

- a corresponding pivoting movement of arranged on the yarn guide rails 4, not shown here thread guides transverse to the direction of movement of the carriage 1 is possible.

- the yarn guide rails 4 can be moved laterally in the direction of the double arrow 6. Also, this linear movement is transmitted to the movable in the thread guide rails 4 yarn guide.

- FIG. 1b The configuration shown differs from that shown Fig. 1a in that here the thread guide rails 4 'are arranged on a circular arc.

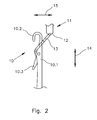

- Fig. 2 shows a knitting needle 10 and a yarn guide 11, of which essentially only one Fadenleitorgan 12 is shown in the form of a Faden administratnüsschen.

- the Fadenleitorgan 12 has a needle shaft 10.1 of the needle 10 between a needle hook 10.2 and a needle tongue 10.3 for closing the needle hook 10.2 looped with a thread 13.

- the Fadenleitorgan 12 is movable not only in the longitudinal direction of a needle bed, not shown here, in which the needle 10 is slidably mounted in the direction of the double arrow 14, wherein the longitudinal direction of the needle bed perpendicular to the plane.

- the thread guide member 12 must also be movable transversely to the longitudinal direction of the needle bed in the direction of the double arrow 15.

- the yarn guide 11 has its own, not shown here drive, so that its movement is independent of a carriage of the flat knitting machine whose knitting systems cause the movements of the needle 10 in the direction of the double arrow 14 via cam curves. A multiple looping around the needle 10 with the thread 13 is possible.

- the yarn guide 11 is thus particularly suitable for inserting additional threads such as plating threads, warp or weft threads and the like in a needle 10th

- FIG. 3 is the formation of a so-called open tricot binding clarified. Such bonds are previously produced only on warp knitting machines. Trikotitatien a knit or knitted fabric can be given a special elasticity.

- the figure shows on the left side from bottom to top the movement of a yarn guide FF1, which is symbolized as an arrow, via needles AI of a front needle bed V and via needles ai a rear needle bed H of a flat knitting machine,

- the yarn guide FF1 sets a thread 20 from left to right in the hook of the needle C of the front needle bed V. Then it is moved to behind the needle D in the direction of the needle bed V and places in line 2 from right to left the thread 20 in the hook of the needle D.

- the yarn guide FF1 is moved back to before the needle C. Thereafter, the steps of rows 1 and 2 are repeated in the following rows. Since the thread guide FF1 not only in Can be moved longitudinally of the needle beds V, H, but also across it, he can put the thread 20 around the shaft of the needles C and D, so that a secure thread insert is ensured, as on the right side of the Fig. 2 is clarified, showing the thread course.

- the thread 20 is a warp thread, which gives the fabric by its staggered integration in both directions a high elasticity.

- With the other needles of the two needle beds V, H can be made with one or more other threads a basic knit in any binding.

- a closed tricot weave can be made as in Fig. 4 is clarified.

- the yarn guide FF1 completely wraps around the needles C and D here.

- tricot binding is only one example of a possible application of a flat knitting machine according to the invention.

- pile threads or Plattierfaden can be inserted.

- Fig. 5a is a first variant of the deposit of two identical or different threads F1, F2 shown in a particular knit area, each with a thread guide.

- the first row shows the basic position of two thread guides FF1, FF2 longitudinally displaceable and transversely movable in a thread guide rail FS before the insertion of a thread into driven needles 33, 34.

- the thread guides FF1, FF2 have been moved to the right in the thread guide rail FS and thus the threads F1, F2 inserted in the needles 33, 34.

- the inserted threads F1, F2 are emulated, as shown in row 3.

- the in Fig. 5b is shown, three identical or different threads F1, F2, F3 with three different thread guides FF1, FF2, FF3 inserted completely into all needles 38.

- the needles 38 are expelled.

- the thread guides FF1, FF2, FF3 are formed in this variant as a tube thread guide.

- the yarn guides FF1, FF2, FF3 are first moved to the right and then to the rear to be able to securely insert the three different threads F1, F2, F3 in the hooks of the needles 38 can. Subsequently, the inserted threads F1 to F3 are knitted with a knitting system.

- Fig. 5c shows a thread insert, in which two thread guides FF1, FF2 are guided in a first yarn guide rail FS1.

- a second yarn guide rail FS2 is provided, in which a further yarn guide FF3 is guided, which inserts a thread in all the needles 39.

- the thread insert takes place in all needles 39 through the thread guide FF3.

- all threads are knitted in row 4 with a common knitting system.

- Fig. 5d is a further variant of a thread insert shown with a flat knitting machine according to the invention.

- There are three different thread guide rails FS1, FS2 and FS3 are provided here.

- FIG. 5e variant shown also three thread guide rails FS1, FS2, FS3 and four thread guides FF1, FF2, FF3 and FF4 are provided. All needles 51 are expelled. Then in line 2, the yarn guides FF1 and FF2 are moved to the right to insert a thread F1 or F2 in all the needles 51. Subsequently, additional threads F3 or F4 are inserted into selected needles (intarsia color fields) in the third row with additional thread guides FF3 and FF4. Subsequently, all the needles are combined with a knitting system, resulting in the image shown in row 4. The result is a real intarsia knit, which is plated in some areas.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Knitting Machines (AREA)

Abstract

Eine Flachstrickmaschine mit mindestens einem Nadelbett und einem über das Nadelbett bewegbaren Schlitten (1) sowie einem oder mehreren Fadenführern, die längs mindestens einer Fadenführerschiene (4) bewegbar sind, wobei der oder die Fadenführer unabhängig vom Schlitten (1) angetrieben sind und außerdem in horizontaler Richtung (5), (6) quer zur Längsrichtung des mindestens einen Nadelbetts begrenzt bewegbar sind.A flat knitting machine comprising at least one needle bed and a carriage (1) movable over the needle bed and one or more yarn guides movable along at least one yarn guide rail (4), the yarn guide (s) being driven independently of the carriage (1) and also horizontally Direction (5), (6) are movable transversely to the longitudinal direction of the at least one needle bed limited.

Description

Die Erfindung betrifft eine Flachstrickmaschine mit mindestens einem Nadelbett und einem über das Nadelbett bewegbaren Schlitten sowie einem oder mehreren Fadenführern, die längs mindestens einer Fadenführerschiene bewegbar sind, wobei der oder die Fadenführer unabhängig vom Schlitten angetrieben sind.The invention relates to a flat knitting machine with at least one needle bed and a carriage movable over the needle bed and one or more yarn guides, which are movable along at least one yarn guide rail, wherein the yarn guide or are driven independently of the carriage.

Gegenüber einer Mitnahme der Fadenführer durch den Schlitten der Flachstrickmaschine eröffnet ein autarker Antrieb der Fadenführer mehr Mustermöglichkeiten für die Gestricke und das Einsparen von Schlittenhüben, die bei durch den Schlitten angetriebenen Fadenführern häufig alleine zur korrekten Positionierung der Fadenführer notwendig sind und die Gesamtstrickzeit erhöhen.Compared with entrainment of the yarn guide by the carriage of the flat knitting machine opens a self-sufficient drive the yarn guide more pattern options for the knitted fabric and saving sled strokes, which are often necessary alone for correct positioning of the yarn guide in driven by the carriage yarn guides and increase the total knitting time.

Die Fadenführer sind nicht nur entlang einer Fadenführerschiene bewegbar, sondern können auch durch eine lineare Bewegung oder durch ein Schwenken aus dem Nadelraum angehoben werden, das heißt in eine nicht aktive Position geschaltet werden. In horizontaler Richtung können die Fadenführer bekannter Maschinen jedoch bisher nur in Nadelbettenlängsrichtung bewegt werden und daher nur in einer Funktionseben entweder Faden für eine Legebindung (Schuss, Kette) oder Faden zu strickenden Nadeln zuführen.The yarn guides are not only movable along a yarn guide rail, but can also be raised by a linear movement or by pivoting out of the needle chamber, that is, be switched to a non-active position. In the horizontal direction, however, the thread guides known machines can be moved so far only in Nadelbettenlängsrichtung and therefore perform only in a functional level either thread for a bond (weft, chain) or thread to knitting needles.

Die vorliegende Erfindung hat die Aufgabe, eine Flachstrickmaschine derart weiter zu entwickeln, dass mit dem oder den Fadenführern Fäden in mehreren Richtungen bewegt werden können und dadurch die Mustervielfalt der Maschine erhöht wird.The object of the present invention is to further develop a flat knitting machine in such a way that threads can be moved in several directions with the thread guide (s), thereby increasing the pattern variety of the machine.

Die Aufgabe wird gelöst durch eine Flachstrickmaschine mit mindestens einem Nadelbett und einem über das Nadelbett bewegbaren Schlitten sowie einem oder mehreren Fadenführern, die längs mindestens einer Fadenführerschiene bewegbar sind, wobei der oder die Fadenführer unabhängig vom Schlitten angetrieben sind, die dadurch gekennzeichnet ist, dass der mindestens eine Fadenführer außerdem in horizontaler Richtung quer zur Längsrichtung des mindestens einen Nadelbetts begrenzt bewegbar ist.The object is achieved by a flat knitting machine having at least one needle bed and a carriage movable over the needle bed and one or more yarn guides which are movable along at least one yarn guide rail, wherein the yarn guide or are driven independently of the carriage, which is characterized in that At least one yarn guide is also limited in the horizontal direction transversely to the longitudinal direction of the at least one needle bed movable.

Durch diese größere Bewegungsfreiheit des oder der Fadenführer sind neue Musterungsmöglichkeiten auf einer Flachstrickmaschine erzielbar, die bisher nur mit Spezialmaschinen wie Kettenwirkmaschinen oder Cotton-Maschinen herstellbar waren.Due to this greater freedom of movement of the thread guide or new Musterungsmöglichkeiten on a flat knitting machine can be achieved that were previously produced only with special machines such as warp knitting machines or cotton machines.

So können mit dem mindestens einen Fadenführer in ausgetriebene Nadeln des mindestens einen Nadelbetts in einer Maschenreihe Kett-, Schuss-, Plattier- oder Polfäden und beliebige Kombinationen davon einlegbar sein. Außerdem ist es möglich, mit dem mindestens einen Fadenführer Fäden mäanderförmig über mehrere Strickreihen hinweg in ausgetriebene Nadeln des mindestens einen Nadelbetts einzulegen, das heißt auch Fadenkreuzungen zu erzeugen.Thus, with the at least one thread guide in expelled needles of the at least one needle bed in a course series warp, weft, plating or pile threads and any combinations thereof can be inserted. It is also possible, with the at least one yarn guide threads meander over several rows of knitting into expelled needles of at least one needle bed insert, that is to produce crosshairs.

Weiter können mit dem mindestens einen Fadenführer durch Bewegungen des Fadenführers in Längsrichtung des mindestens einen Nadelbetts und quer dazu eine oder mehrere ausgetriebene Nadeln teilweise oder vollständig mit einem Faden umschlungen werden.Furthermore, with the at least one thread guide, movements of the thread guide in the longitudinal direction of the at least one needle bed and, transversely thereto, one or more expelled needles can be partially or completely looped around with a thread.

Dabei ist es von Vorteil, wenn der mindestens eine Fadenführer in beide Richtungen quer zur Nadelbettenlängsrichtung bewegbar ist. Außerdem kann auch bei der erfindungsgemäßen Flachstrickmaschine der mindestens eine Fadenführer in der Höhe verstellbar sein, d.h. aus dem Nadelsaum heraus in eine inaktive Position gebracht werden.It is advantageous if the at least one thread guide is movable in both directions transversely to the needle bed longitudinal direction. In addition, even with the flat knitting machine according to the invention, the at least one thread guide can be adjustable in height, i. be brought out of the needle room in an inactive position.

Die seitliche Bewegung des oder der Fadenführer kann auf unterschiedliche Weise erfolgen. Bei einer ersten Ausführungsform der Flachstrickmaschine ist die mindestens eine Fadenführerschiene um eine horizontale Achse schwenkbar gelagert. Damit sind alle auf der Schiene geführten Fadenführer gleichzeitig schwenkbar. Die Fadenführerschiene kann dabei ähnlich wie die Barre einer Kettenwirkmaschine zu Blöcken zusammengefasste Fadenführer gemeinsam bewegen.The lateral movement of the thread guide or can be done in different ways. In a first embodiment of the flat knitting machine, the at least one yarn guide rail is pivotally mounted about a horizontal axis. This means that all yarn guides guided on the rail can be swiveled simultaneously. The thread guide rail can move similar to the barre of a warp knitting machine combined into blocks thread guide together.

Alternativ oder zusätzlich kann ein Fadenleitorgan des mindestens einen Fadenführers exzentrisch drehbar an einem längs einer Fadenführerschiene bewegbaren Fadenführerkasten befestigt sein. Auch dadurch lässt sich eine Bewegung des Fadenführers oder, genauer gesagt, seiner Spitze mit dem Fadenleitorgan quer zur Nadelbettenlängsrichtung realisieren. Ist gleichzeitig die Fadenführerschiene schwenkbar, so entsteht ein zusätzlicher Freiheitsgrad für die Bewegung des oder der Fadenführer.Alternatively or additionally, a Fadenleitorgan the at least one yarn guide can be mounted eccentrically rotatable on a longitudinally along a yarn guide rail movable yarn guide box. This also makes it possible to realize a movement of the thread guide or, more precisely, its tip with the Fadenleitorgan transversely to the needle bed longitudinal direction. At the same time, the thread guide rail is pivotable, so there is an additional degree of freedom for the movement of the thread guide or.

Dabei kann das Fadenleitorgan in an sich bekannter Weise über einen abgekröpften Fadenführerarm am Fadenführerkasten befestigt sein, wobei jetzt der Fadenführerarm jedoch um eine vertikale Achse schwenkbar am Fadenführerkasten angeordnet ist.In this case, the Fadenleitorgan be secured in a conventional manner via a cranked Fadenführerarm on the thread guide box, but now the Fadenführerarm is arranged pivotably about a vertical axis on the thread guide box.

Das Fadenleitorgan kann ein Nüsschen oder ein Röhrchen sein. Bei beengten Platzverhältnissen und wenn in benachbarte Nadeln unterschiedliche Fäden eingelegt werden sollen, sind Röhrchen von Vorteil. Außerdem kann an dem mindestens einen Fadenführer auch eine Fadenbremse oder -klemme angeordnet sein.The thread guide can be a nut or a tube. In confined spaces and when different threads are to be inserted into adjacent needles, tubes are advantageous. In addition, a thread brake or clamp can be arranged on the at least one thread guide.

Wenn die Flachstrickmaschine zudem mindestens eine längs einer Fadenführerschiene bewegbare Klemm-Schneid-Einrichtung aufweist, können einzelne Fadenführer mit einer Fadenblaseinrichtung ausgestattet werden und zusammen mit der Klemm-Schneideinrichtung spezifisches Fadenmaterial einblasen, beispielsweise zum Auffüttern von Funktionstaschen im Gestrick.If the flat knitting machine also has at least one clamping-cutting device that can be moved along a yarn guide rail, individual yarn guides can be equipped with a thread blowing device and blow in specific thread material together with the clamping cutting device, for example for feeding functional pockets in the knitted fabric.

Die Erfindung betrifft außerdem die Verwendung einer erfindungsgemäßen Flachstrickmaschine zur Herstellung eines Gestricks mit Kettenwirkbindungen, mit selektiv oder vollständig plattierten Intarsiamustern oder mit Stehfäden, indem mit dem mindestens einen Fadenführer ausgetriebene Nadeln des mindestens einen Nadelbetts mit einem Kettfaden, einem Plattierfaden oder einem Stehfaden teilweise oder vollständig umschlungen werden. Nachfolgend werden verschiedene Anwendungen einer erfindungsgemäßen Strickmaschine mit Bezug auf die Zeichnung näher beschrieben.The invention also relates to the use of a flat knitting machine according to the invention for producing a knitted fabric having warp knitted bindings, with selectively or completely plated intarsia patterns or with standing threads, by partially or completely expelling needles of the at least one needle bed with a warp thread, a plating thread or a standing thread with the at least one thread guide be entwined. Hereinafter, various applications of a knitting machine according to the invention will be described in more detail with reference to the drawing.

Es zeigen:

- Fig. 1a, b

- schematische Stirnansichten eines Schlittens einer Flachstrickmaschine mit Fadenführerschienen;

- Fig. 2

- eine schematische Ansicht des Umwickelns einer Stricknadel mit einem Faden durch einen quer zur Nadelbettlängsrichtung beweglichen Fadenführer;

- Fig. 3

- ein Diagramm der Bewegung eines Fadenführers und einen Maschenverlauf zur Herstellung einer offenen Trikotbindung;

- Fig. 4

- eine Diagramm der Bewegung eines Fadenführers und einen Maschenverlauf zur Herstellung einer geschlossenen Trikotbindung;

- Fig. 5a - e

- schematische Darstellungen verschiedener Varianten der Fadeneinlage.

- Fig. 1a, b

- schematic end views of a carriage of a flat knitting machine with yarn guide rails;

- Fig. 2

- a schematic view of the wrapping a knitting needle with a thread through a transverse to the needle bed longitudinal direction yarn guide;

- Fig. 3

- a diagram of the movement of a yarn guide and a stitch course for the production of an open tricot binding;

- Fig. 4

- a diagram of the movement of a yarn guide and a stitch course for producing a closed tricot binding;

- Fig. 5a - e

- schematic representations of different variants of the thread insert.

Die

Zusätzlich zu einer Schwenkbewegung können die Fadenführerschienen 4 auch in Richtung des Doppelpfeils 6 seitlich verschoben werden. Auch diese lineare Bewegung wird auf die in den Fadenführerschienen 4 bewegbaren Fadenführer übertragen.In addition to a pivoting movement, the

Die in

Das Fadenleitorgan 12 muss auch quer zur Längsrichtung des Nadelbetts in Richtung des Doppelpfeils 15 bewegbar sein. Der Fadenführer 11 weist dazu einen eigenen, hier nicht näher dargestellten Antrieb auf, sodass seine Bewegung unabhängig von einem Schlitten der Flachstrickmaschine ist, dessen Stricksysteme über Schlosskurven die Bewegungen der Nadel 10 in Richtung des Doppelpfeils 14 bewirken. Auch ein mehrfaches Umschlingen der Nadel 10 mit dem Faden 13 ist möglich. Der Fadenführer 11 eignet sich damit insbesondere zum Einlegen von Zusatzfäden wie Plattierfäden, Kett- oder Schussfäden und dergleichen in eine Nadel 10.The

In

Die Figur zeigt auf der linken Seite von unten nach oben die Bewegung eines Fadenführers FF1, der als Pfeil symbolisiert ist, über Nadeln A-I eines vorderen Nadelbetts V und über Nadeln a-i eines hinteren Nadelbetts H einer Flachstrickmaschine, In Reihe 1 legt der Fadenführer FF1 einen Faden 20 von links nach rechts in den Haken der Nadel C des vorderen Nadelbetts V. Danach wird er bis hinter die Nadel D in Richtung des Nadelbetts V bewegt und legt in Reihe 2 von rechts nach links den Faden 20 in den Haken der Nadel D.The figure shows on the left side from bottom to top the movement of a yarn guide FF1, which is symbolized as an arrow, via needles AI of a front needle bed V and via needles ai a rear needle bed H of a flat knitting machine, In

Anschließend wird der Fadenführer FF1 zurück bis vor die Nadel C bewegt. Danach wiederholen sich die Schritte der Reihen 1 und 2 in den folgenden Reihen. Da der Fadenführer FF1 nicht nur in Längsrichtung der Nadelbetten V, H bewegbar ist, sondern auch quer dazu, kann er den Faden 20 um den Schaft der Nadeln C und D herumlegen, sodass eine sichere Fadeneinlage gewährleistet ist, wie auf der rechten Seite der

In ähnlicher Weise kann auch eine geschlossene Trikotbindung hergestellt werden, wie in

Die Herstellung einer Trikotbindung ist nur ein Beispiel einer möglichen Anwendung einer erfindungsgemäßen Flachstrickmaschine. Anstelle von Kettfäden können auch Schussfäden, Polfäden oder Plattierfaden eingelegt werden.The production of a tricot binding is only one example of a possible application of a flat knitting machine according to the invention. Instead of warp threads and weft threads, pile threads or Plattierfaden can be inserted.

In

In der zweiten Variante, die in

In

In der Schiene FS1 sind zwei Fadenführer FF1 und FF2 verschiebbar gelagert. Sie legen in Reihe 2 in einer Bewegung nach rechts jeweils einen Faden F1 und F2 in ausgetriebene Nadeln 45, 46 ein. Anschließend werden diese Nadeln 45, 46 mit einem ersten Stricksystem kuliert. Danach werden in Reihe 3 andere Nadelgruppen 47, 48 ausgetrieben und in diese Nadeln 47, 48 mit einem in der Schiene FS2 geführten Fadenführer FF3 ein Faden F3 eingelegt und mit einem zweiten Stricksystem kuliert. In der vierten Reihe werden weitere Nadelgruppen 49, 50 ausgetrieben und in diese Nadeln mit einem vierten Fadenführer FF4 ein weiterer Faden F4 eingelegt und mit einem weiteren Stricksystem kuliert. In Reihe 5 ist der Endzustand nach dem Kulieren aller Nadeln gezeigt.In the rail FS1 two yarn guides FF1 and FF2 are slidably mounted. In

Bei der in

Claims (12)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP13182138.1A EP2843095A1 (en) | 2013-08-29 | 2013-08-29 | Flat knitting machine having a yarn guide moving perpendicular to the pin bed |

| CN201410433642.0A CN104420069B (en) | 2013-08-29 | 2014-08-29 | Flat knitting machine with yarn guides movable transversely to the needle bed |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP13182138.1A EP2843095A1 (en) | 2013-08-29 | 2013-08-29 | Flat knitting machine having a yarn guide moving perpendicular to the pin bed |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP2843095A1 true EP2843095A1 (en) | 2015-03-04 |

Family

ID=49054416

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP13182138.1A Ceased EP2843095A1 (en) | 2013-08-29 | 2013-08-29 | Flat knitting machine having a yarn guide moving perpendicular to the pin bed |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP2843095A1 (en) |

| CN (1) | CN104420069B (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102016112585A1 (en) * | 2016-07-08 | 2018-01-11 | H. Stoll Ag & Co. Kg | Method for producing a knitted fabric with standing thread |

| CN114232187A (en) * | 2020-09-08 | 2022-03-25 | 阿迪达斯股份公司 | Article comprising knitted element |

| EP4019682A1 (en) | 2020-12-23 | 2022-06-29 | KARL MAYER STOLL R&D GmbH | Knitting machine with at least one yarn guide |

| EP4019683A1 (en) | 2020-12-23 | 2022-06-29 | KARL MAYER STOLL R&D GmbH | Knitting machine with at least one yarn guide for feeding one or more separate yarns |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105256455B (en) * | 2015-09-14 | 2017-03-08 | 宁波慈星股份有限公司 | A kind of lead method |

| EP3786327B1 (en) | 2017-03-31 | 2022-02-23 | Nike Innovate C.V. | Knitting feeder with a cutting device |

| CN109468744B (en) * | 2018-12-04 | 2020-07-10 | 武汉纺织大学 | Warp-weft composite knitting system and knitting method thereof |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5615562A (en) * | 1992-07-08 | 1997-04-01 | Tecnit-Technische Textilien Und Systeme Gmbh | Apparatus for production of weave-knit material |

| DE69503831T2 (en) * | 1994-05-02 | 1999-04-08 | Shima Seiki Mfg. Ltd., Wakayama | Knitting yarn feed device for a flat knitting machine |

| EP1959041A1 (en) * | 2005-11-17 | 2008-08-20 | Shima Seiki Manufacturing Limited | Method and device for cutting/holding warp of weft knitting machine |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5415501B2 (en) * | 2011-09-22 | 2014-02-12 | 佰龍機械廠股▲ふん▼有限公司 | Yarn feeder for flat knitting machine |

-

2013

- 2013-08-29 EP EP13182138.1A patent/EP2843095A1/en not_active Ceased

-

2014

- 2014-08-29 CN CN201410433642.0A patent/CN104420069B/en active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5615562A (en) * | 1992-07-08 | 1997-04-01 | Tecnit-Technische Textilien Und Systeme Gmbh | Apparatus for production of weave-knit material |

| DE69503831T2 (en) * | 1994-05-02 | 1999-04-08 | Shima Seiki Mfg. Ltd., Wakayama | Knitting yarn feed device for a flat knitting machine |

| EP1959041A1 (en) * | 2005-11-17 | 2008-08-20 | Shima Seiki Manufacturing Limited | Method and device for cutting/holding warp of weft knitting machine |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102016112585A1 (en) * | 2016-07-08 | 2018-01-11 | H. Stoll Ag & Co. Kg | Method for producing a knitted fabric with standing thread |

| CN107587248A (en) * | 2016-07-08 | 2018-01-16 | H.斯托尔股份两合公司 | Method for manufacturing the braid with warp thread |

| CN107587248B (en) * | 2016-07-08 | 2019-06-18 | H.斯托尔股份两合公司 | For manufacturing the method for having the braided fabric of warp thread |

| US10323344B2 (en) | 2016-07-08 | 2019-06-18 | H. Stoll Ag & Co. Kg | Method for manufacturing a knitted fabric comprising a vertical yarn filament |

| DE102016112585B4 (en) | 2016-07-08 | 2019-10-24 | H. Stoll Ag & Co. Kg | Method for producing a knitted fabric with standing thread |

| CN114232187A (en) * | 2020-09-08 | 2022-03-25 | 阿迪达斯股份公司 | Article comprising knitted element |

| EP3964615A3 (en) * | 2020-09-08 | 2022-06-08 | adidas AG | Article comprising a knit element with threads knitted together and diverging |

| CN114232187B (en) * | 2020-09-08 | 2023-11-03 | 阿迪达斯股份公司 | Article comprising knit element and method of forming the same |

| US11821117B2 (en) | 2020-09-08 | 2023-11-21 | Adidas Ag | Article comprising a knit element |

| EP4019682A1 (en) | 2020-12-23 | 2022-06-29 | KARL MAYER STOLL R&D GmbH | Knitting machine with at least one yarn guide |

| EP4019683A1 (en) | 2020-12-23 | 2022-06-29 | KARL MAYER STOLL R&D GmbH | Knitting machine with at least one yarn guide for feeding one or more separate yarns |

Also Published As

| Publication number | Publication date |

|---|---|

| CN104420069B (en) | 2017-04-26 |

| CN104420069A (en) | 2015-03-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2843095A1 (en) | Flat knitting machine having a yarn guide moving perpendicular to the pin bed | |

| EP3034665B1 (en) | Flat knitting machine with stitch pressing means | |

| EP2664701B1 (en) | Method for producing a knitted fabric with at least one float thread and fabric obtained therefrom | |

| CH623213A5 (en) | ||

| EP2336412B1 (en) | Float needle for a gallon crocheting machine | |

| EP0616064B1 (en) | Method for making a thread securing knot on a flat bed knitting machine, knitting including a securing knot and use of a flat knitting machine for making the knot | |

| EP0338194B1 (en) | Method for manufacturing intarsia knitwear, and flat-bed knitting machine for carrying out this method | |

| DE1919268C3 (en) | Needle plate for tufting machines or the like | |

| DE102010017946B4 (en) | Lock system for a flat knitting machine | |

| EP3276062B1 (en) | Warp knitting machine and method for producing a warp knitted item | |

| DE102010010892B4 (en) | Method of making a knit and flat knitting machine | |

| EP2141271A1 (en) | Knitted fabric take-down device | |

| EP1914335B1 (en) | Method of producing a knitwear with cable-stitch pattern | |

| DE102011108702B4 (en) | Process for producing a knitted fabric with decorative stitches and knitted fabric | |

| DE2027102A1 (en) | Knitted woven goods | |

| DE19954477A1 (en) | Method and device for transferring stitches on a knitting machine | |

| EP1347088B1 (en) | Flat knitting machine with adjustable sinkers | |

| DE4301242A1 (en) | Method and device for producing textile spacer fabrics | |

| EP1522618A1 (en) | Sinker of a flat knitting machine | |

| DE102010017948B4 (en) | Lock system for a flat knitting machine | |

| EP0179072B1 (en) | Process for manufacturing a patterned warp-knitted material and a warp knitting machine for its use | |

| DE69815266T2 (en) | A widening method for a rib knitwear and a rib knitwear widened by this method | |

| EP4261333B1 (en) | Flat knitting machine and method for the production of double plated knitwear, especially fine knitwear | |

| DE2040193A1 (en) | Right / right warp knitted fabric with mechanically inserted weft threads and its manufacturing process | |

| EP2666896A1 (en) | Flat knitting machine with cutting elements |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 17P | Request for examination filed |

Effective date: 20130829 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| R17P | Request for examination filed (corrected) |

Effective date: 20150831 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: H. STOLL AG & CO. KG |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20180618 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| APBK | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNE |

|

| APBN | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2E |

|

| APBR | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3E |

|

| RAP3 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: KARL MAYER STOLL R&D GMBH |

|

| APAF | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNE |

|

| APBT | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9E |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN REFUSED |

|

| 18R | Application refused |

Effective date: 20231017 |