EP2841758B1 - Arrangement comprising a housing part of an internal combustion engine, a fuel injector and a clamping bracket - Google Patents

Arrangement comprising a housing part of an internal combustion engine, a fuel injector and a clamping bracket Download PDFInfo

- Publication number

- EP2841758B1 EP2841758B1 EP13709135.1A EP13709135A EP2841758B1 EP 2841758 B1 EP2841758 B1 EP 2841758B1 EP 13709135 A EP13709135 A EP 13709135A EP 2841758 B1 EP2841758 B1 EP 2841758B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- fuel injector

- housing part

- injector

- bore

- plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 239000000446 fuel Substances 0.000 title claims description 47

- 238000002485 combustion reaction Methods 0.000 title claims description 16

- 210000000078 claw Anatomy 0.000 description 24

- 238000007789 sealing Methods 0.000 description 12

- 238000004519 manufacturing process Methods 0.000 description 3

- 230000005540 biological transmission Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M61/00—Fuel-injectors not provided for in groups F02M39/00 - F02M57/00 or F02M67/00

- F02M61/14—Arrangements of injectors with respect to engines; Mounting of injectors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M61/00—Fuel-injectors not provided for in groups F02M39/00 - F02M57/00 or F02M67/00

- F02M61/16—Details not provided for in, or of interest apart from, the apparatus of groups F02M61/02 - F02M61/14

- F02M61/168—Assembling; Disassembling; Manufacturing; Adjusting

Definitions

- the invention relates to an arrangement comprising a housing part of an internal combustion engine having a bore, a in the bore of the housing part at least partially received fuel injector and a clamping claw, the fuel injector is biased in the direction of its longitudinal axis A against the housing part on their Pratzkraft. Furthermore, the invention relates to a fuel injector for such an arrangement as well as the use of a clamping claw for fixing a fuel injector to a housing part of an internal combustion engine.

- a fuel injector for internal combustion engines which has a housing which comprises at least two each a pressure chamber enclosing the high-pressure body, which lie against each other via abutment surfaces and are clamped by means of a clamping device.

- a clamping device In order to ensure a high-pressure-tight connection of the high-pressure body, it is proposed in this document to provide at least one contact surface with a biting edge.

- the biting edge is intended to cause a particularly favorable surface pressure distribution in the region of the high-pressure seal when clamping the high-pressure body against each other by means of a clamping nut, with the biting edge digging into the end face of the respective other body.

- the clamping nut has an internal thread and the housing has a corresponding external thread.

- an injector for injecting fuel into combustion chambers of internal combustion engines which can be fixed by means of a clamping claw on a housing part of an internal combustion engine.

- the injector is inserted into a bore of the housing part and held in the bore by the force of the clamping claw.

- the present invention seeks to simplify an arrangement comprising a housing part having a bore, a fuel injector at least partially received in the bore and a clamping claw for fixing the fuel injector on the housing part.

- the proposed arrangement comprises a housing part of an internal combustion engine having a bore, a in the bore of the housing part at least partially received fuel injector and a clamping claw, the fuel injector in the direction of its longitudinal axis A can be prestressed against the housing part by their Pratzkraft.

- the fuel injector is supported directly or indirectly on the housing part and the Pratzkraft the Spannpratze causes a high-pressure-tight connection of at least one plate-shaped component of the fuel injector with a nozzle body and / or a holding body of the fuel injector.

- the clawing force of the clamping claw is therefore not only used to fix the injector on the housing part, but also as a sealing force in order to realize a high-pressure-tight connection of at least one first component with a second component of the injector.

- the use of a nozzle retaining nut and / or a valve clamping screw is unnecessary, via the screw connection to the injector, an axial force can be generated, which is usually the required high-pressure density Connection of the components causes.

- the production of the fuel injector is simplified, so that the production costs decrease. For one thing, the number of components is reduced, on the other hand, the structure of the components is simplified because at least one thread is eliminated. Furthermore, a factory leakage test can be omitted.

- the clamping claw By acting in the longitudinal direction of the injector Pratzkraft the clamping claw can be effected in the region of at least one sealing point depending on the specific configuration of the support of the injector on the housing part a high-pressure-tight seal. It is important to form sealing points in the area of the contact surfaces of two adjacent components.

- the one component is supported directly or indirectly on the housing part of the internal combustion engine and the other component is acted upon directly or indirectly by the Pratzkraft of the clamping claw.

- the clamping claw acts together with the housing part of the internal combustion engine for generating the clawing force serving as sealing force.

- the clamping claw is screwed by means of a fastening screw in the housing part.

- the bore of the housing part on an obliquely, in particular radially, with respect to the longitudinal axis A of the injector extending support surface for the axial support of the fuel injector.

- the support surface is further preferably annular. It can also be formed by a radially extending shoulder or a cone-shaped portion of the bore. This has the advantage that a uniform application of force is guaranteed.

- the injector can also be supported outside the bore on the housing part.

- the housing part the obliquely, in particular radially, with respect to the longitudinal axis A of the injector extending support surface - and that outside the bore - on.

- the support surface the above applies.

- At least one plate-shaped component is a throttle plate and / or a valve plate.

- the Pratzkraft the clamping claw is then preferably the high-pressure-tight connection of the throttle plate with the valve plate and / or with a nozzle body, which usually rests on the side facing away from the valve plate of the throttle plate.

- the clawing force of the clamping claw of the high-pressure-tight connection of the valve plate can be used with a holding body, which usually rests on the side of the valve plate facing away from the throttle plate.

- a holding body which usually rests on the side of the valve plate facing away from the throttle plate.

- the injector is preferably supported on the housing part of the internal combustion engine via the nozzle body.

- the nozzle body may have a radial shoulder over which it rests directly or indirectly on a support surface of the housing part.

- the support surface is preferably designed as an annular surface and preferably formed within the bore, in which the injector is at least partially received.

- the bore may be formed as a stepped bore in order to realize the annular surface.

- the further proposed for an inventive arrangement fuel injector is characterized in that it comprises a holding device for temporary or permanent connection of at least one plate-shaped component of the fuel injector with a nozzle body and / or a holding body of the fuel injector.

- the holding device is preferably detachably connectable to the fuel injector. In this way - at least during transport, ie before the determination of the injector on the housing part of the internal combustion engine - a connection of the components are effected, which is not initially high pressure-tight. Because this requires the Pratzkraft the Spannpratze.

- the task of the holding device is essentially to connect the individual components captive.

- the holding device Before the insertion of the injector into the bore of the housing part, the holding device is advantageously removed, since the injector without such a holding device has a smaller space requirement. If the injector is supported on the outside of the housing part, the holding device can also remain permanently connected to the injector and the support of the injector on the housing part can be made indirectly via the holding device. The holding device can serve in this way the radial positional fixation of the injector or individual components of the injector. If the injector is at least partially inserted into a bore of the housing part, preferably the bore serves for the radial support.

- the holding device comprises at least one sleeve, a clip, a bracket or the like. Both the bracket and the bracket allow a releasable connection of the holding device with the injector.

- the holding device has at least one latching element which can be brought into engagement with a recess of at least one plate-shaped component, the nozzle body and / or the holding body.

- the recess is preferably formed on the outer peripheral side of a component of the injector, preferably in the form of a circumferential groove or a circumferential paragraph.

- a clamping claw for fixing a fuel injector on a housing part of an internal combustion engine wherein the fuel injector is at least partially received in a bore of a housing part and supported directly or indirectly on the housing part, wherein the Pratzkraft the clamping claw for high-pressure-tight connection of at least one plate-shaped component the fuel injector is used with a nozzle body and / or a holding body of the fuel injector.

- the use of the clawing force of the clamping claw as a sealing force allows a nozzle tension-free design of the fuel injector. In this way, the configuration of the injector can be simplified and at the same time a high-pressure-tight connection of the components of the injector can be achieved. By eliminating the nozzle retaining nut, the production costs can be reduced at the same time.

- FIG. 1 An inventive arrangement is exemplary of the Fig. 1 refer to.

- the illustrated arrangement comprises a fuel injector 3, which is received in a bore 2 of a housing part 1 of an internal combustion engine and fixed by means of a clamping claw 4 on the housing part 1.

- the clamping claw 4 is attached thereto by means of a fastening screw 14 on the housing part 1.

- the clamping claw 4 exerts an axial force, the so-called Pratzkraft, on the injector 3, which presses the injector 3 against serving as a support surface 9 paragraph of the bore 2.

- individual components of the injector 3, namely a nozzle body 7, a throttle plate 5, a valve plate 6 and a holding body 8, axially biased against each other.

- the bias in the axial direction causes the components are connected to each other high pressure tight in the range of sealing points 13, since the Pratzkraft the clamping claw 4 due to a non-existing nozzle lock nut also serves as a sealing force.

- Another sealing point 13, which is sealed high-pressure-tight over the Pratzkraft the clamping claw 4 is formed between the nozzle body 7 and the support surface 9 of the housing part 1.

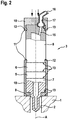

- FIG. 2 An inventive fuel injector is exemplary of Fig. 2 refer to.

- the fuel injector 3 has no nozzle retaining nut, so that other means for axially biasing a nozzle body 7, a throttle plate 5, a valve plate 6 and a holding body 8 are provided against each other.

- These means comprise a plurality of holding devices 10, which are sleeve-shaped or clip-like.

- the clip-type holding devices 10 encompass a component arrangement consisting of nozzle body 7, throttle plate 5, valve plate 6 and holding body 8, so that they ensure cohesion of the component arrangement.

- the clamps are provided on both sides with latching elements 11, which engage in a recess 12 of the injector 3 designed as a circumferential groove or engage behind a shoulder of the injector 3, so that a positive connection is effected in each case.

- a sleeve-shaped or pot-shaped holding device 10 is placed on the nozzle body 7 facing away from the end of the injector 3. Due to the cup shape of the holding device 10 is at the same time a contact surface for the plant of the clamping claw (in Fig. 2 not shown) created on the injector 3.

- the holding device 10 thus serves at the same time as a force transmission member, which the Pratzkraft (see arrows) on the fuel injector 3 transmits.

- the sleeve-shaped or cup-shaped holding device 10 also has a latching element 11, which in the present case has the shape of a radially inwardly extending collar, which is in engagement with a recess 12 designed as a circumferential groove 12 of the injector. Furthermore, the pot-shaped holding device 10 has a bore 17 for carrying out a feed line 16, which is connected to an inlet channel 15 of the injector 3.

- the bore 17 is in the present case designed as a stepped bore, so that over the stage a positive connection with the likewise step-shaped supply line 16 can be produced. In this way, a high pressure-tight connection of the feed line 16 to the inlet channel 15 can be effected via the Pratzkraft (see arrows).

- the connection area thus represents a further sealing point 13.

Description

Die Erfindung betrifft eine Anordnung umfassend ein Gehäuseteil einer Brennkraftmaschine mit einer Bohrung, einen in der Bohrung des Gehäuseteils zumindest teilweise aufgenommenen Kraftstoffinjektor sowie eine Spannpratze, über deren Pratzkraft der Kraftstoffinjektor in Richtung seiner Längsachse A gegen das Gehäuseteil vorgespannt ist. Ferner betrifft die Erfindung einen Kraftstoffinjektor für eine solche Anordnung sowie die Verwendung einer Spannpratze zur Festlegung eines Kraftstoffinjektors an einem Gehäuseteil einer Brennkraftmaschine.The invention relates to an arrangement comprising a housing part of an internal combustion engine having a bore, a in the bore of the housing part at least partially received fuel injector and a clamping claw, the fuel injector is biased in the direction of its longitudinal axis A against the housing part on their Pratzkraft. Furthermore, the invention relates to a fuel injector for such an arrangement as well as the use of a clamping claw for fixing a fuel injector to a housing part of an internal combustion engine.

Aus der

Aus der

Ausgehend von dem vorstehend genannten Stand der Technik liegt der vorliegenden Erfindung die Aufgabe zugrunde, eine Anordnung umfassend ein Gehäuseteil mit einer Bohrung, einem in der Bohrung zumindest teilweise aufgenommenen Kraftstoffinjektor und eine Spannpratze zur Festlegung des Kraftstoffinjektors am Gehäuseteil einfacher zu gestalten.Based on the above-mentioned prior art, the present invention seeks to simplify an arrangement comprising a housing part having a bore, a fuel injector at least partially received in the bore and a clamping claw for fixing the fuel injector on the housing part.

Zur Lösung der Aufgabe wird eine Anordnung mit den Merkmalen des Anspruchs 1 sowie ein Kraftstoffinjektor für eine solche Anordnung mit den Merkmalen des Anspruchs 4 vorgeschlagen. Vorteilhafte Weiterbildungen der Erfindung sind den jeweiligen Unteransprüchen zu entnehmen. Des Weiteren wird eine neue Verwendung für eine Spannpratze vorgeschlagen.To solve the problem, an arrangement with the features of claim 1 and a fuel injector for such an arrangement with the features of

Die vorgeschlagene Anordnung umfasst ein Gehäuseteil einer Brennkraftmaschine mit einer Bohrung, einen in der Bohrung des Gehäuseteils zumindest teilweise aufgenommenen Kraftstoffinjektor sowie eine Spannpratze, über deren Pratzkraft der Kraftstoffinjektor in Richtung seiner Längsachse A gegen das Gehäuseteil vorspannbar ist. Erfindungsgemäß ist der Kraftstoffinjektor unmittelbar oder mittelbar am Gehäuseteil abgestützt und die Pratzkraft der Spannpratze bewirkt eine hochdruckdichte Verbindung wenigstens eines plattenförmigen Bauteils des Kraftstoffinjektors mit einem Düsenkörper und/oder einem Haltekörper des Kraftstoffinjektors. Vorliegend wird die Pratzkraft der Spannpratze demnach nicht nur zur Festlegung des Injektors am Gehäuseteil, sondern ferner als Dichtkraft genutzt, um eine hochdruckdichte Verbindung wenigstens eines ersten Bauteils mit einem zweiten Bauteil des Injektors zu realisieren. Durch die Nutzung der Pratzkraft als Dichtkraft ist der Einsatz einer Düsenspannmutter und/oder einer Ventilspannschraube entbehrlich, über deren Schraubverbindung mit dem Injektor eine Axialkraft erzeugbar ist, welche üblicherweise die erforderliche hochdruckdichte Verbindung der Bauteile bewirkt. Mit Wegfall der Düsenspannmutter und/oder der Ventilspannschraube wird die Fertigung des Kraftstoffinjektors vereinfacht, so dass die Fertigungskosten sinken. Denn zum Einen wird die Anzahl der Bauteile reduziert, zum Anderen wird der Aufbau der Bauteile vereinfacht, da wenigstens ein Gewinde wegfällt. Des Weiteren kann eine werkseitige Dichtheitsprüfung entfallen.The proposed arrangement comprises a housing part of an internal combustion engine having a bore, a in the bore of the housing part at least partially received fuel injector and a clamping claw, the fuel injector in the direction of its longitudinal axis A can be prestressed against the housing part by their Pratzkraft. According to the fuel injector is supported directly or indirectly on the housing part and the Pratzkraft the Spannpratze causes a high-pressure-tight connection of at least one plate-shaped component of the fuel injector with a nozzle body and / or a holding body of the fuel injector. In the present case, the clawing force of the clamping claw is therefore not only used to fix the injector on the housing part, but also as a sealing force in order to realize a high-pressure-tight connection of at least one first component with a second component of the injector. By using the Pratzkraft as sealing force, the use of a nozzle retaining nut and / or a valve clamping screw is unnecessary, via the screw connection to the injector, an axial force can be generated, which is usually the required high-pressure density Connection of the components causes. With the elimination of the nozzle retaining nut and / or the valve clamping screw, the production of the fuel injector is simplified, so that the production costs decrease. For one thing, the number of components is reduced, on the other hand, the structure of the components is simplified because at least one thread is eliminated. Furthermore, a factory leakage test can be omitted.

Über die in Längsrichtung des Injektors wirkende Pratzkraft der Spannpratze kann in Abhängigkeit von der konkreten Ausgestaltung der Abstützung des Injektors am Gehäuseteil eine hochdruckdichte Abdichtung im Bereich wenigstens einer Dichtstelle bewirkt werden. Dichtstellen gilt es insbesondere im Bereich der Anlageflächen zweier aneinander liegender Bauteile auszubilden. Hierzu ist das eine Bauteil unmittelbar oder mittelbar am Gehäuseteil der Brennkraftmaschine abgestützt und das andere Bauteil unmittelbar oder mittelbar von der Pratzkraft der Spannpratze beaufschlagt. Die Spannpratze wirkt demnach zur Erzeugung der als Dichtkraft dienenden Pratzkraft mit dem Gehäuseteil der Brennkraftmaschine zusammen. Vorzugsweise wird hierzu die Spannpratze mittels einer Befestigungsschraube im Gehäuseteil verschraubt.By acting in the longitudinal direction of the injector Pratzkraft the clamping claw can be effected in the region of at least one sealing point depending on the specific configuration of the support of the injector on the housing part a high-pressure-tight seal. It is important to form sealing points in the area of the contact surfaces of two adjacent components. For this purpose, the one component is supported directly or indirectly on the housing part of the internal combustion engine and the other component is acted upon directly or indirectly by the Pratzkraft of the clamping claw. Accordingly, the clamping claw acts together with the housing part of the internal combustion engine for generating the clawing force serving as sealing force. Preferably, for this purpose, the clamping claw is screwed by means of a fastening screw in the housing part.

Gemäß einer bevorzugten Ausführungsform der Erfindung weist die Bohrung des Gehäuseteils eine schräg, insbesondere radial, in Bezug auf die Längsachse A des Injektors verlaufende Stützfläche zur axialen Abstützung des Kraftstoffinjektors auf. Innerhalb der Bohrung ist die Stützfläche weiterhin bevorzugt ringförmig ausgebildet. Sie kann darüber hinaus durch einen radial verlaufenden Absatz oder einen konusförmigen Abschnitt der Bohrung gebildet werden. Dies hat den Vorteil, dass eine gleichmäßige Krafteinleitung gewährleistet ist.According to a preferred embodiment of the invention, the bore of the housing part on an obliquely, in particular radially, with respect to the longitudinal axis A of the injector extending support surface for the axial support of the fuel injector. Within the bore, the support surface is further preferably annular. It can also be formed by a radially extending shoulder or a cone-shaped portion of the bore. This has the advantage that a uniform application of force is guaranteed.

Alternativ oder ergänzend kann der Injektor auch außerhalb der Bohrung am Gehäuseteil abgestützt sein. In diesem Fall weist das Gehäuseteil die schräg, insbesondere radial, in Bezug auf die Längsachse A des Injektors verlaufende Stützfläche - und zwar außerhalb der Bohrung - auf. Hinsichtlich der bevorzugten Ausgestaltung der Stützfläche gilt das zuvor Gesagte.Alternatively or additionally, the injector can also be supported outside the bore on the housing part. In this case, the housing part, the obliquely, in particular radially, with respect to the longitudinal axis A of the injector extending support surface - and that outside the bore - on. With regard to the preferred embodiment of the support surface, the above applies.

Des Weiteren wird vorgeschlagen, dass wenigstens ein plattenförmiges Bauteil eine Drosselplatte und/oder eine Ventilplatte ist. Die Pratzkraft der Spannpratze dient dann bevorzugt der hochdruckdichten Verbindung der Drosselplatte mit der Ventilplatte und/oder mit einem Düsenkörper, welcher üblicherweise auf der der Ventilplatte abgewandten Seite der Drosselplatte anliegt. Alternativ oder ergänzend kann die Pratzkraft der Spannpratze der hochdruckdichten Verbindung der Ventilplatte mit einem Haltekörper dienen, welcher üblicherweise auf der der Drosselplatte abgewandten Seite der Ventilplatte anliegt. Zwischen den Bauteilen werden somit mindestens drei Dichtstellen ausgebildet, welche über die Pratzkraft der Spannpratze hochdruckdicht abgedichtet werden können. Sofern im Bereich aller drei Dichtstellen eine hochdruckdichte Verbindung der Bauteile miteinander bewirkt werden soll, ist der Injektor vorzugsweise über den Düsenkörper am Gehäuseteil der Brennkraftmaschine abgestützt. Hierzu kann der Düsenkörper einen radialen Absatz aufweisen, über welchen er unmittelbar oder mittelbar an einer Stützfläche des Gehäuseteils anliegt. Die Stützfläche ist vorzugsweise als Ringfläche ausgebildet und bevorzugt innerhalb der Bohrung ausgebildet, in welcher der Injektor zumindest teilweise aufgenommen ist. Beispielsweise kann die Bohrung als Stufenbohrung ausgebildet sein, um die Ringfläche zu verwirklichen.Furthermore, it is proposed that at least one plate-shaped component is a throttle plate and / or a valve plate. The Pratzkraft the clamping claw is then preferably the high-pressure-tight connection of the throttle plate with the valve plate and / or with a nozzle body, which usually rests on the side facing away from the valve plate of the throttle plate. Alternatively or additionally, the clawing force of the clamping claw of the high-pressure-tight connection of the valve plate can be used with a holding body, which usually rests on the side of the valve plate facing away from the throttle plate. Between the components thus at least three sealing points are formed, which can be sealed high pressure-tight over the Pratzkraft of the clamping claw. If a high-pressure-tight connection of the components is to be effected in the region of all three sealing points, the injector is preferably supported on the housing part of the internal combustion engine via the nozzle body. For this purpose, the nozzle body may have a radial shoulder over which it rests directly or indirectly on a support surface of the housing part. The support surface is preferably designed as an annular surface and preferably formed within the bore, in which the injector is at least partially received. For example, the bore may be formed as a stepped bore in order to realize the annular surface.

Der des Weiteren für eine erfindungsgemäße Anordnung vorgeschlagene Kraftstoffinjektor zeichnet sich dadurch aus, dass er zur temporären oder dauerhaften Verbindung wenigstens eines plattenförmigen Bauteils des Kraftstoffinjektors mit einem Düsenkörper und/oder einem Haltekörper des Kraftstoffinjektors eine Haltevorrichtung umfasst. Die Haltevorrichtung ist vorzugsweise lösbar mit dem Kraftstoffinjektor verbindbar. Auf diese Weise kann - zumindest während des Transports, d.h. vor der Festlegung des Injektors am Gehäuseteil der Brennkraftmaschine - eine Verbindung der Bauteile bewirkt werden, welche zunächst nicht hochdruckdicht ist. Denn hierzu bedarf es der Pratzkraft der Spannpratze. Die Aufgabe der Haltevorrichtung besteht im Wesentlichen darin, die einzelnen Bauteile verliersicher zu verbinden. Vor dem Einsetzen des Injektors in die Bohrung des Gehäuseteils wird die Haltevorrichtung vorteilhafterweise abgenommen, da der Injektor ohne eine solche Haltevorrichtung einen geringeren Bauraumbedarf besitzt. Sofern der Injektor außen am Gehäuseteil abgestützt ist, kann die Haltevorrichtung auch dauerhaft mit dem Injektor verbunden bleiben und die Abstützung des Injektors am Gehäuseteil mittelbar über die Haltevorrichtung erfolgen. Die Haltevorrichtung kann auf diese Weise der radialen Lagefixierung des Injektors bzw. einzelner Bauteile des Injektors dienen. Wird der Injektor zumindest teilweise in eine Bohrung des Gehäuseteils eingesetzt, dient vorzugsweise die Bohrung der radialen Abstützung.The further proposed for an inventive arrangement fuel injector is characterized in that it comprises a holding device for temporary or permanent connection of at least one plate-shaped component of the fuel injector with a nozzle body and / or a holding body of the fuel injector. The holding device is preferably detachably connectable to the fuel injector. In this way - at least during transport, ie before the determination of the injector on the housing part of the internal combustion engine - a connection of the components are effected, which is not initially high pressure-tight. Because this requires the Pratzkraft the Spannpratze. The task of the holding device is essentially to connect the individual components captive. Before the insertion of the injector into the bore of the housing part, the holding device is advantageously removed, since the injector without such a holding device has a smaller space requirement. If the injector is supported on the outside of the housing part, the holding device can also remain permanently connected to the injector and the support of the injector on the housing part can be made indirectly via the holding device. The holding device can serve in this way the radial positional fixation of the injector or individual components of the injector. If the injector is at least partially inserted into a bore of the housing part, preferably the bore serves for the radial support.

Gemäß einer Weiterbildung der Erfindung umfasst die Haltevorrichtung wenigstens eine Hülse, eine Klammer, einen Bügel oder dergleichen. Sowohl die Klammer als auch der Bügel ermöglichen eine lösbare Verbindung der Haltevorrichtung mit dem Injektor. Alternativ oder ergänzend kann vorgesehen sein, dass die Haltevorrichtung wenigstens ein Rastelement aufweist, das in Eingriff mit einer Ausnehmung wenigstens eines plattenförmigen Bauteils, des Düsenkörpers und/oder des Haltekörpers bringbar ist. Die Ausnehmung ist vorzugsweise außenumfangseitig an einem Bauteil des Injektors ausgebildet, vorzugsweise in Form einer Umfangsnut oder eines umlaufenden Absatzes. Über das in Eingriff mit dieser Ausnehmung stehende Rastelement kann demnach ein in axialer Richtung wirksamer Formschluss werden.According to one embodiment of the invention, the holding device comprises at least one sleeve, a clip, a bracket or the like. Both the bracket and the bracket allow a releasable connection of the holding device with the injector. Alternatively or additionally, it may be provided that the holding device has at least one latching element which can be brought into engagement with a recess of at least one plate-shaped component, the nozzle body and / or the holding body. The recess is preferably formed on the outer peripheral side of a component of the injector, preferably in the form of a circumferential groove or a circumferential paragraph. By means of the latching element engaged with this recess, it is accordingly possible to have an effective positive connection in the axial direction.

Des Weiteren wird die Verwendung einer Spannpratze zur Festlegung eines Kraftstoffinjektors an einem Gehäuseteil einer Brennkraftmaschine beansprucht, wobei der Kraftstoffinjektor zumindest teilweise in einer Bohrung eines Gehäuseteils aufgenommen und unmittelbar oder mittelbar am Gehäuseteil abgestützt ist, wobei die Pratzkraft der Spannpratze zur hochdruckdichten Verbindung wenigstens eines plattenförmigen Bauteils des Kraftstoffinjektors mit einem Düsenkörper und/oder einem Haltekörper des Kraftstoffinjektors eingesetzt wird. Die Verwendung der Pratzkraft der Spannpratze als Dichtkraft ermöglicht eine düsenspannmutterfreie Ausführung des Kraftstoffinjektors. Auf diese Weise kann die Ausgestaltung des Injektors vereinfacht und zugleich eine hochdruckdichte Verbindung der Bauteile des Injektors erreicht werden. Durch den Wegfall der Düsenspannmutter können zugleich die Fertigungskosten gesenkt werden.Furthermore, the use of a clamping claw for fixing a fuel injector on a housing part of an internal combustion engine is claimed, wherein the fuel injector is at least partially received in a bore of a housing part and supported directly or indirectly on the housing part, wherein the Pratzkraft the clamping claw for high-pressure-tight connection of at least one plate-shaped component the fuel injector is used with a nozzle body and / or a holding body of the fuel injector. The use of the clawing force of the clamping claw as a sealing force allows a nozzle tension-free design of the fuel injector. In this way, the configuration of the injector can be simplified and at the same time a high-pressure-tight connection of the components of the injector can be achieved. By eliminating the nozzle retaining nut, the production costs can be reduced at the same time.

Bevorzugte Ausführungsformen der Erfindung werden nachfolgend anhand der beigefügten Zeichnungen näher erläutert. Diese zeigen:

- Fig. 1

- einen schematischen Längsschnitt durch eine erfindungsgemäße Anordnung und

- Fig. 2

- einen schematischen Längsschnitt durch einen erfindungsgemäßen Kraftstoffinjektor.

- Fig. 1

- a schematic longitudinal section through an inventive arrangement and

- Fig. 2

- a schematic longitudinal section through a fuel injector according to the invention.

Eine erfindungsgemäße Anordnung ist beispielshaft der

Ein erfindungsgemäßer Kraftstoffinjektor ist beispielhaft der

Claims (6)

- Arrangement comprising a housing part (1) of an internal combustion engine having a bore (2), comprising a fuel injector (3) at least partially received in the bore (2) of the housing part (1), and comprising a clamping bracket (4), by way of the bracket force of which the fuel injector (3) is preloaded in the direction of its longitudinal axis (A) against the housing part (1), characterized in that the fuel injector (3) is supported directly or indirectly on the housing part (1) and the bracket force of the clamping bracket (4) gives rise to a high-pressure-tight connection of at least one plate-shaped component (5, 6) of the fuel injector (3) to a nozzle body (7) and/or a holding body (8) of the fuel injector (3).

- Arrangement according to Claim 1,

characterized in that the bore (2) of the housing part (1) and/or the housing part (1) has a support surface (9), which runs obliquely, in particular radially, relative to the longitudinal axis (A), for the axial support of the fuel injector (3). - Arrangement according to Claim 1 or 2, characterized in that at least one plate-shaped component (5, 6) is a throttle plate (5) and/or a valve plate (6).

- Fuel injector for an arrangement according to one of the preceding claims,

characterized in that, for the temporary or permanent connection of at least one plate-shaped component (5, 6) of the fuel injector (3) to a nozzle body (7) and/or to a holding body (8) of the fuel injector (3), the fuel injector (3) comprises a holding device (10) which is preferably detachably connectable to the fuel injector (3). - Fuel injector according to Claim 4,

characterized in that the holding device (10) comprises at least a sleeve, a clamp, a clip or the like and/or has at least one detent element (11), which can be placed in engagement with a recess (12) of at least one plate-shaped component (5, 6), of the nozzle body (7) and/or of the holding body (8). - Use of a clamping bracket (4) for fixing a fuel injector (3) to a housing part (1) of an internal combustion engine, wherein the fuel injector (3) is at least partially received in a bore (2) of the housing part (1) and is supported directly or indirectly on the housing part (1), wherein the bracket force of the clamping bracket (4) is used to realize the high-pressure-tight connection of at least one plate-shaped component (5, 6) of the fuel injector (3) to a nozzle body (7) and/or to a holding body (8) of the fuel injector (3).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE201210205701 DE102012205701A1 (en) | 2012-04-05 | 2012-04-05 | Arrangement comprising a housing part of an internal combustion engine, a fuel injector and a clamping claw |

| PCT/EP2013/055276 WO2013149799A1 (en) | 2012-04-05 | 2013-03-14 | Arrangement comprising a housing part of an internal combustion engine, a fuel injector and a clamping bracket |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2841758A1 EP2841758A1 (en) | 2015-03-04 |

| EP2841758B1 true EP2841758B1 (en) | 2016-05-18 |

Family

ID=47878069

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP13709135.1A Not-in-force EP2841758B1 (en) | 2012-04-05 | 2013-03-14 | Arrangement comprising a housing part of an internal combustion engine, a fuel injector and a clamping bracket |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP2841758B1 (en) |

| CN (1) | CN104603446B (en) |

| DE (1) | DE102012205701A1 (en) |

| IN (1) | IN2014DN07380A (en) |

| WO (1) | WO2013149799A1 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102012208075A1 (en) * | 2012-05-15 | 2013-11-21 | Man Diesel & Turbo Se | Injector for a fuel supply system of an internal combustion engine and fuel supply system |

| DE102013018177B4 (en) * | 2013-11-29 | 2016-01-28 | L'orange Gmbh | Fuel injector module and fuel injector and test arrangement with it |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19705227A1 (en) * | 1997-02-12 | 1998-08-13 | Bosch Gmbh Robert | High pressure fuel injector |

| CN101176905B (en) * | 2003-12-22 | 2011-11-09 | 本田技研工业株式会社 | Method of forming member, valve guide and method of forming the same and method of forming tubular member |

| DE202006002663U1 (en) | 2006-02-20 | 2006-04-13 | Robert Bosch Gmbh | Fuel injector for internal combustion engines |

| DE102007008146A1 (en) | 2007-02-19 | 2008-08-21 | Robert Bosch Gmbh | Injector with additional body |

| DE102011078387A1 (en) * | 2011-06-30 | 2013-01-03 | Robert Bosch Gmbh | fuel injector |

-

2012

- 2012-04-05 DE DE201210205701 patent/DE102012205701A1/en not_active Withdrawn

-

2013

- 2013-03-14 CN CN201380018468.7A patent/CN104603446B/en not_active Expired - Fee Related

- 2013-03-14 EP EP13709135.1A patent/EP2841758B1/en not_active Not-in-force

- 2013-03-14 IN IN7380DEN2014 patent/IN2014DN07380A/en unknown

- 2013-03-14 WO PCT/EP2013/055276 patent/WO2013149799A1/en active Application Filing

Also Published As

| Publication number | Publication date |

|---|---|

| CN104603446A (en) | 2015-05-06 |

| WO2013149799A1 (en) | 2013-10-10 |

| CN104603446B (en) | 2018-04-24 |

| EP2841758A1 (en) | 2015-03-04 |

| DE102012205701A1 (en) | 2013-10-10 |

| IN2014DN07380A (en) | 2015-04-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102013205340B3 (en) | Wheel bearing unit of vehicle axle, has bearing hub which is associated with resilient expansion sleeve cooperating with joint bell, and supply port is provided for releasing clamping screw to tooth in gap position of front serrations | |

| AT522050B1 (en) | LIQUID-COOLED COMBUSTION MACHINE | |

| EP2841756B1 (en) | Holder for securing a component to an internal combustion engine | |

| EP2321521B1 (en) | Fuel injection valve for arrangement in a combustion chamber of an internal combustion engine | |

| DE19857485A1 (en) | Assembly device for assembling and disassembling a fuel injector | |

| EP2841758B1 (en) | Arrangement comprising a housing part of an internal combustion engine, a fuel injector and a clamping bracket | |

| EP2636911A1 (en) | Mounting assembly | |

| DE10256668A1 (en) | support element | |

| DE102016225706A1 (en) | Valve for metering a fluid | |

| EP2905461B1 (en) | Fuel injection system with a fuel conveying component, a fuel injector and a holder | |

| EP2664782A1 (en) | Injector for a fuel supply system of a combustion engine and fuel supply system | |

| DE102011088293B4 (en) | Claw for holding an injector | |

| AT510318A1 (en) | CENTERING DEVICE FOR A FUEL INJECTION NOZZLE | |

| DE102005024044A1 (en) | Injector fastening device for internal combustion engine, has clamping units with which radial clamping forces are generatable, where clamping forces act in perpendicular plane in direction of longitudinal axis of injector | |

| DE19807819C1 (en) | Motor fuel injector | |

| WO2008058799A1 (en) | Fuel injector | |

| DE102013200922A1 (en) | Suspension apparatus for fuel injection system of internal combustion engine, has fuel injection valve with fuel nozzle that is supported on annular element and elastically deformable element along axis of receiving space of connector | |

| EP2702379B1 (en) | Apparatus for detecting a pressure, in particular a combustion space pressure of an internal combustion engine | |

| DE102016220395A1 (en) | Sealing ring for an injection valve | |

| DE102016201600B4 (en) | High-pressure fuel pump and fuel injection system | |

| DE102021203668A1 (en) | High-pressure pump for a fuel injection system | |

| DE102021202697A1 (en) | High-pressure accumulator line for a fuel injection system, fuel injection system and use of a throttle element in a high-pressure accumulator line | |

| DE102014207586A1 (en) | Connecting piece for a high-pressure pump in a fuel injection system and high-pressure pump with such a connecting piece | |

| EP1427936A1 (en) | Device for fixing injectors on a cylinder head | |

| DE102020215380A1 (en) | Adapter device, fluid line device and fuel injection system for a vehicle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20141105 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160215 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN Ref country code: AT Ref legal event code: REF Ref document number: 800710 Country of ref document: AT Kind code of ref document: T Effective date: 20160615 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502013003035 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20160518 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160818 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160919 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160819 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502013003035 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20170221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20170314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170314 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170314 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170331 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170331 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170331 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20190326 Year of fee payment: 7 Ref country code: IT Payment date: 20190321 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 800710 Country of ref document: AT Kind code of ref document: T Effective date: 20180314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20130314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160518 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160918 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200314 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20220525 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502013003035 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20231003 |