EP2823364B1 - Federhaus - Google Patents

Federhaus Download PDFInfo

- Publication number

- EP2823364B1 EP2823364B1 EP13710338.8A EP13710338A EP2823364B1 EP 2823364 B1 EP2823364 B1 EP 2823364B1 EP 13710338 A EP13710338 A EP 13710338A EP 2823364 B1 EP2823364 B1 EP 2823364B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- drum

- hub

- barrel

- barrel according

- timepiece

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B1/00—Driving mechanisms

- G04B1/10—Driving mechanisms with mainspring

- G04B1/16—Barrels; Arbors; Barrel axles

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B1/00—Driving mechanisms

- G04B1/10—Driving mechanisms with mainspring

- G04B1/12—Driving mechanisms with mainspring with several mainsprings

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B1/00—Driving mechanisms

- G04B1/10—Driving mechanisms with mainspring

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B1/00—Driving mechanisms

- G04B1/10—Driving mechanisms with mainspring

- G04B1/16—Barrels; Arbors; Barrel axles

- G04B1/165—Spring cylinder with friction transmission to the gearing (especially for Roskopf clockworks)

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B1/00—Driving mechanisms

- G04B1/10—Driving mechanisms with mainspring

- G04B1/18—Constructions for connecting the ends of the mainsprings with the barrel or the arbor

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B1/00—Driving mechanisms

- G04B1/10—Driving mechanisms with mainspring

- G04B1/18—Constructions for connecting the ends of the mainsprings with the barrel or the arbor

- G04B1/185—Friction clutch between spring and spring cylinder

-

- G—PHYSICS

- G04—HOROLOGY

- G04B—MECHANICALLY-DRIVEN CLOCKS OR WATCHES; MECHANICAL PARTS OF CLOCKS OR WATCHES IN GENERAL; TIME PIECES USING THE POSITION OF THE SUN, MOON OR STARS

- G04B1/00—Driving mechanisms

- G04B1/10—Driving mechanisms with mainspring

- G04B1/18—Constructions for connecting the ends of the mainsprings with the barrel or the arbor

- G04B1/20—Protecting arrangements against rupture or overwinding of the mainspring located in the barrel or attached to the barrel

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49579—Watch or clock making

Definitions

- Each compartment contains a spirally wound spring whose first inner end cooperates with the first and second hubs respectively and whose second end cooperates with the drum.

- the present invention aims to provide an alternative and advantageous construction, to improve the energy performance of a cylinder in a limited space.

- the invention relates to a barrel and a timepiece and its mounting method as defined in the claims.

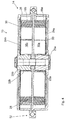

- FIG. 1 a timepiece cylinder 10 illustrating the invention.

- This barrel 10 comprises a drum 14 which defines two compartments 16a, 16b superimposed with reference to the geometric axis of the barrel and each containing a spring 18a, 18b wound in a spiral.

- the barrel comprises a first and a second tubular hubs, separated.

- the first hub 22a is secured to a first cover 24a.

- the first hub 22a is housed at least partially in the first compartment 16a, said lower with reference to the figure 1

- the second hub 22b is secured of a second cover 24b, and is housed at least partially in the second compartment 16b, said upper with reference to the figure 1 .

- Each of the springs 18b, 18a is spirally wound. Their inner end cooperates respectively with a hook which are provided with the first and second hubs and their outer end cooperates with the drum 14.

- the compartments are open on the side of the lids.

- cover is meant the element that covers or even closes a compartment of the drum.

- the first 24a and second 24b covers are free with reference to the drum 14 and are separated from the drum by a gap 30.

- the covers 24a and 24b are each provided with a peripheral toothing while the drum 14 is free of teeth. One of these teeth is used to arm the springs, while the other is used as PTO, to supply energy to a finishing gear of a timepiece in which is mounted the cylinder according to the invention .

- the skilled person can choose to use one or other of the lids for winding or for supply energy.

- covers 24a, 24b are independent of the drum 14, there may be a drum 14 of diameter greater than that of one or both covers 24a, 24b, which increases the number of turns of the springs. 18a, 18b and therefore, the power reserve available.

- the covers may be supported, each on a shoulder 25a, 25b that respectively comprise the hubs 22a and 22b.

- the drum 14 comprises a cylindrical wall 26 and a flat wall 28, projecting with reference to the cylindrical wall 26.

- the flat wall 28 is disposed substantially at mid-height of the cylindrical wall 26 and delimits the compartments 16a, 16b.

- the cylindrical wall 26 and the flat wall 28 are integrally formed.

- the plane wall 28 defines, at its center, an opening 28a positioned and dimensioned so as to substantially extend a channel formed by the hubs 22a and 22b. At the opening 28a, the flat wall may have an extra thickness to position the hubs in height. Between the lower hubs 22a and 22b and the walls of the drum 14, compartments 16a and 16b are thus defined.

- compartments 16a, 16b take place, respectively, the first spiral spring 18a and the second spiral spring 18b.

- the inner end cooperates with the lower hub 22a or the upper hub 22b, via the hooks mentioned above.

- the outer end of the springs 18a, 18b cooperates with the cylindrical wall 26 of the drum 14.

- the skilled person may consider making a fixed or sliding cooperation, of a type known in the field of barrels.

- the two springs 18a, 18b are mounted so that the spirals they describe are in opposite directions.

- the two springs of the barrel 10 being interconnected via the cylindrical wall 26 of the drum 14, they are thus arranged in series.

- At least one of the covers is provided on its face facing the compartments with an anti-friction coating 50.

- the two covers are thus provided with such antifriction coating 50.

- the flat wall 28 may be provided on at least one of its faces facing the compartments, preferably on both sides, an anti-friction coating.

- the friction coating can be achieved by a washer fixed to the cover 24a, 24b or to the flat wall 28.

- the washer can be glued or deposited on the cover or on the flat wall.

- a housing can be provided in the covers and / or in the flat wall, to accommodate the coating.

- the antifriction coating may be made of a material selected from PTFE (polytetrafluoroethylene), or DLC (diamond like carbon), or silicon, or in another hard material within the reach of the skilled person.

- PTFE polytetrafluoroethylene

- DLC diamond like carbon

- silicon silicon

- the barrel 10 according to the invention does not have a pivot, in the usual sense of the term in terms of timepieces.

- the barrels of the state of the art comprise an axis on which is mounted the inner end of the spring.

- the ends of the axis define pivots which pivot in bearings of the frame of the timepiece in which the barrel is mounted.

- the hubs and the drum pivot on a fixed shaft which takes place in the channel defined by the hubs 22a and 22b and by the central opening 28a of the flat wall.

- the shaft 20 is arranged in the frame of the timepiece.

- the barrel as defined by the present invention forms a functional whole constituted by the hubs 22a and 22b, the drum 14 and the springs 18a and 18b. According to this definition, the barrel pivots on the shaft 20 which is associated with it.

- the shaft 20 serves to guide the barrel in rotation, without defining a pivot relative to the frame of the timepiece.

- the shaft 20 may advantageously comprise bearing surfaces 20a, 20b for positioning in height, that is to say along the axis of the shaft, the hubs 22a and 22b and the drum 14.

- the shaft also participates in defining means for axial positioning of the barrel, to maintain the relative positioning of the components of the barrel.

- the shaft 20 can receive a screw 34 or a nut, clamped against a third bearing 20c of the shaft. It will be noted that the axial positioning means do not force the hubs against each other and leave them free to rotate.

- the shaft 20 is provided to be assembled on the timepiece independently of the constituents of the barrel.

- the shaft participates in both the axial positioning means and the rotating guide means.

- the shaft can thus receive a bearing screw 34 or a nut holding the hubs and the drum axially.

- the shaft is intended to be free and independent from the plate and defines only the axial positioning means.

- the means for guiding the drum in rotation is a bearing 52 acting at the periphery of the drum.

- the bearing serves as an interface between the drum and the frame of the timepiece and allows to suspend the barrel without the use of a bridge. External rollers could also be used to pivot the drum.

- the lower hub 22a serves as a rotational guide for the upper hub 22b.

- the lower hub 22a can advantageously participate in the axial positioning means, receiving, at its end, a nut or a bearing screw 34.

- the lower hub forms a tube that can be positioned on a fixed shaft integral with the timepiece.

- the barrel can thus form an independent, functional assembly, without pivot or axis of rotation, which can be assembled independently of the timepiece and then be mounted on the axis, previously fixed to the timepiece.

- the springs can be connected to their respective hub by rotating each of the hubs until its hook cooperates with the inner end of the spring.

- the proposed constructions are advantageously simple in that they comprise a small number of parts and a small footprint. Both springs can be mounted independently of each other, which also facilitates assembly operations.

- This return can, for example, be the average wheel of the movement.

- springs used either springs of the automatic winding type, that is to say allowing a limitation of the arming, or springs of the manual winding type, cooperating rigidly with the drum 14.

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Springs (AREA)

- Electric Clocks (AREA)

- Electromechanical Clocks (AREA)

- Measurement Of Unknown Time Intervals (AREA)

- Details Of Rigid Or Semi-Rigid Containers (AREA)

Claims (16)

- Federhaus einer Uhr, umfassend:- eine Trommel (14), die ein erstes (16a) und ein zweites (16b) Abteil definiert, die übereinanderliegen,- eine erste rohrförmige Nabe (22a), die mit einem ersten Deckel (24a) fest verbunden und zumindest teilweise im ersten Abteil untergebracht ist,- eine zweite rohrförmige Nabe (22b), die mit einem zweiten Deckel (24b) fest verbunden ist, der zumindest teilweise im zweiten Abteil untergebracht ist,wobei jedes Abteil eine spiralig eingerollte Feder (18a, 18b) enthält, von der ein erstes inneres Ende jeweils mit der ersten und der zweiten Nabe zusammenwirkt und deren zweites Ende mit der Trommel (14) zusammenwirkt,

wobei die Abteile deckelseitig offen sind und der erste und zweite Deckel in Bezug auf die Trommel (14) frei sind und jeweils mit einer peripheren Zahnung ausgestattet sind, wogegen die Trommel (14) zahnungsfrei ist. - Federhaus nach Anspruch 1, dadurch gekennzeichnet, dass das Federhaus als solches keinen Zapfen umfasst, der bestimmt ist, auf einer Werkplatte einer Uhr zu drehen.

- Federhaus nach Anspruch 1, dadurch gekennzeichnet, dass zumindest einer des ersten und zweiten Deckels auf seiner gegenüberliegenden Seite des jeweiligen ersten oder zweiten Abteils mit einer Antifriktionsbeschichtung (50) ausgestattet ist.

- Federhaus nach einem der vorangehenden Ansprüche, dadurch gekennzeichnet, dass die Trommel (14) eine zylindrische Wand (26) und eine ebene Wand (28) aufweist, die sich in Bezug auf die zylindrische Wand (26) hervorstehend erstreckt, wobei die ebene Wand (28) die Abteile begrenzt.

- Federhaus nach Anspruch 4, dadurch gekennzeichnet, dass die ebene Wand (28) auf zumindest einer ihrer Seiten, die sich gegenüber dem ersten oder zweiten Abteils befinden, mit einer Antifriktionsbeschichtung (50) ausgestattet ist.

- Federhaus nach Anspruch 4 oder Anspruch 5, dadurch gekennzeichnet, dass die zylindrische Wand (26) und die ebene Wand (28) einstückig sind.

- Federhaus nach einem der Ansprüche 3 bis 6, dadurch gekennzeichnet, dass die Antifriktionsbeschichtung mittels einer Unterlagscheibe hergestellt ist, die am Deckel oder an der ebenen Wand befestigt ist.

- Federhaus nach einem der Ansprüche 3 bis 7, dadurch gekennzeichnet, dass die Antifriktionsbeschichtung (50) aus einem Werkstoff hergestellt ist, die aus dem PTFE oder dem DLC oder dem Silizium ausgewählt ist.

- Federhaus nach einem der Ansprüche 3 bis 8, dadurch gekennzeichnet, dass die Antifriktionsbeschichtung, mit welcher der Deckel ausgestattet ist, durch in den Deckel eingearbeitete Öffnungen zu sehen ist.

- Federhaus nach einem der vorangehenden Ansprüche, dadurch gekennzeichnet, dass die erste und zweite Nabe mit Axialpositionierungsmitteln positioniert sind, welche die eine in Bezug zur anderen positionieren.

- Federhaus nach Anspruch 10, dadurch gekennzeichnet, dass die erste Nabe (22a) im ersten (16a) und im zweiten (16b) Abteil untergebracht ist und dass die zweite Nabe (22b) auf der ersten Nabe (22a) gedreht ist, wobei die Axialpositionierungsmittel ausgebildet sind, um mit der ersten Nabe (22a) zusammenzuwirken.

- Federhaus nach einem der vorangehenden Ansprüche, dadurch gekennzeichnet, dass es einer Rotationsführungswelle (20) zugeordnet ist, wobei die Welle bestimmt ist, fest zu sein.

- Uhr, umfassend ein Federhaus nach Anspruch 10 und ein Rotationsführungsmittel der Trommel (14).

- Uhr nach Anspruch 13, dadurch gekennzeichnet, dass das Rotationsführungsmittel der Trommel derart ausgebildet ist, dass es auf die Peripherie der Trommel wirkt, wobei das Federhaus aufgehängt ist.

- Uhr nach Anspruch 13, dadurch gekennzeichnet, dass das Rotationsführungsmittel eine mit dem Gestell der Uhr fest verbundene Welle ist und dass die Welle an den Axialpositionierungsmitteln des Federhauses beteiligt ist.

- Montageverfahren einer Uhr nach Anspruch 15, dadurch gekennzeichnet, dass es die folgenden Schritte aufweist:- Montieren der ersten Nabe (22a) auf die Welle (20),- Montieren der den Federn (18b, 18a) zugeordneten Trommel (14) auf die erste Nabe (22a),- Verbinden der ersten Feder (18a) mit der ersten Nabe (22a),- Montieren der zweiten Nabe (22b) auf die Welle,- Verbinden der zweiten Feder (18b) mit der zweiten Nabe (22b),- Positionieren der Axialpositionierungsmittel auf der Welle (20).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH00340/12A CH706214B1 (fr) | 2012-03-09 | 2012-03-09 | Barillet de pièce d'horlogerie. |

| PCT/EP2013/054765 WO2013132076A1 (fr) | 2012-03-09 | 2013-03-08 | Barillet |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2823364A1 EP2823364A1 (de) | 2015-01-14 |

| EP2823364B1 true EP2823364B1 (de) | 2016-05-25 |

Family

ID=47901045

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP13710338.8A Not-in-force EP2823364B1 (de) | 2012-03-09 | 2013-03-08 | Federhaus |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US9335738B2 (de) |

| EP (1) | EP2823364B1 (de) |

| JP (1) | JP6072837B2 (de) |

| CN (1) | CN104220939B (de) |

| CH (1) | CH706214B1 (de) |

| HK (1) | HK1204100A1 (de) |

| WO (1) | WO2013132076A1 (de) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101952460A (zh) | 2007-11-20 | 2011-01-19 | 奥林巴斯株式会社 | 用于制备粪便样品的方法、制备粪便样品用溶液和采集粪便用试剂盒 |

| CN108196438B (zh) * | 2012-04-04 | 2020-09-08 | 劳力士有限公司 | 轴、发条及包括轴和发条的发条盒、钟表机芯、腕表和表 |

| EP2887150A1 (de) * | 2013-12-20 | 2015-06-24 | ETA SA Manufacture Horlogère Suisse | Optimiertes Federgehäuse einer Uhr |

| EP2952979B1 (de) * | 2014-06-03 | 2017-03-01 | Nivarox-FAR S.A. | Uhrkomponente aus fotostrukturierbarem glas |

| EP3208666B1 (de) * | 2016-02-19 | 2018-11-21 | Blancpain SA | Uhrenrad mit spielnachstellung |

| CH712308A1 (fr) * | 2016-03-30 | 2017-10-13 | Officine Panerai Ag | Système de barillet autolubrifié pour pièce d'horlogerie. |

| CN107817670A (zh) * | 2016-09-13 | 2018-03-20 | 天津海鸥表业集团有限公司 | 一种双发条手表原动组件 |

| DE102016122936B4 (de) * | 2016-11-28 | 2018-11-08 | Lange Uhren Gmbh | Federhaus für eine Uhr |

| EP3654109B1 (de) * | 2018-11-13 | 2021-03-31 | Patek Philippe SA Genève | Uhr, die zwei energiequellen besitzt |

| CN109579662A (zh) * | 2019-01-28 | 2019-04-05 | 汉中万目仪电有限责任公司 | 杯底规 |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US249845A (en) * | 1881-11-22 | Strike-spring for eight-day clocks | ||

| US410327A (en) * | 1889-09-03 | meylan | ||

| BE567865A (de) * | ||||

| GB103121A (de) * | 1915-12-31 | 1918-05-02 | Wuthrich Edouard | |

| CH90009A (fr) * | 1917-10-18 | 1921-07-16 | Victor Talking Machine Co | Moteur à ressort multiple. |

| GB147339A (en) * | 1919-12-16 | 1920-07-22 | Thomas Frederick Redington | Improvements in spring-driven mechanism |

| US1796374A (en) * | 1930-02-13 | 1931-03-17 | Albert F Kendle | Mainspring barrel |

| CH1147874A4 (de) * | 1974-08-22 | 1977-05-13 | ||

| JPS5194389U (de) * | 1975-01-28 | 1976-07-29 | ||

| IT1074807B (it) * | 1976-02-18 | 1985-04-20 | Bouchet Lassale Sa | Dispositivo di imperniamento per bariletto d'orologio |

| ATE390651T1 (de) * | 2000-01-06 | 2008-04-15 | Chopard Manufacture Sa | Antriebsvorrichtung für uhrwerk mit grosser gangreserve |

| DE10357228A1 (de) * | 2003-12-08 | 2005-07-07 | Lange Uhren Gmbh | Federhausvorrichtung |

| EP1582943B1 (de) * | 2004-04-01 | 2008-09-03 | Richemont International S.A. | Uhrwerk mit mehreren Federhäusern |

| CN201116972Y (zh) * | 2007-08-28 | 2008-09-17 | 天津海鸥表业集团有限公司 | 手表串联式原动机构 |

| EP2060957A1 (de) * | 2007-11-16 | 2009-05-20 | ETA SA Manufacture Horlogère Suisse | Motorelement mit federn für uhrwerk |

| CN201181396Y (zh) * | 2008-03-31 | 2009-01-14 | 天津海鸥表业集团有限公司 | 手表同轴双层条盒联动机构 |

| CH699988A2 (fr) * | 2008-11-28 | 2010-05-31 | Patek Philippe Sa Geneve | Organe moteur pour mouvement horloger. |

| CH702856A2 (fr) * | 2010-03-22 | 2011-09-30 | Patek Philippe Sa Geneve | Mouvement de montre. |

| CH704249B1 (fr) * | 2010-12-20 | 2015-02-27 | Elsbeth Roesner | Organe moteur pour mouvement horloger. |

| CH706641A2 (fr) * | 2012-06-22 | 2013-12-31 | Cartier Creation Studio Sa | Organe moteur pour mouvement d'horlogerie. |

-

2012

- 2012-03-09 CH CH00340/12A patent/CH706214B1/fr unknown

-

2013

- 2013-03-08 JP JP2014560400A patent/JP6072837B2/ja not_active Expired - Fee Related

- 2013-03-08 US US14/383,635 patent/US9335738B2/en active Active

- 2013-03-08 EP EP13710338.8A patent/EP2823364B1/de not_active Not-in-force

- 2013-03-08 WO PCT/EP2013/054765 patent/WO2013132076A1/fr active Application Filing

- 2013-03-08 CN CN201380012942.5A patent/CN104220939B/zh not_active Expired - Fee Related

-

2015

- 2015-05-06 HK HK15104318.0A patent/HK1204100A1/zh not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| CN104220939A (zh) | 2014-12-17 |

| CH706214B1 (fr) | 2016-09-30 |

| HK1204100A1 (zh) | 2015-11-06 |

| CN104220939B (zh) | 2016-10-12 |

| US9335738B2 (en) | 2016-05-10 |

| CH706214A1 (fr) | 2013-09-13 |

| JP2015509600A (ja) | 2015-03-30 |

| WO2013132076A1 (fr) | 2013-09-12 |

| JP6072837B2 (ja) | 2017-02-01 |

| US20150138932A1 (en) | 2015-05-21 |

| EP2823364A1 (de) | 2015-01-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2823364B1 (de) | Federhaus | |

| EP2080066B1 (de) | Uhr | |

| EP2212749B1 (de) | Federdruck-antriebsglied für ein uhrwerk | |

| EP2437125B1 (de) | Uhr | |

| EP2255257A1 (de) | Schwenkelement | |

| WO2005096104A1 (fr) | Mouvement de montre comportant plusieurs barillets | |

| EP3106927B1 (de) | Gangreserveanzeige für uhr | |

| EP2264551B1 (de) | Differentialzahnradgetriebe für Uhrwerk | |

| WO2004070478A2 (fr) | Masse oscillante | |

| EP2725433A1 (de) | Bewegliches Tourbillon mit beweglicher Unruh für Uhrwerk | |

| EP3889688B1 (de) | Antriebsorgan für uhr | |

| EP2564276B1 (de) | Uhr | |

| EP2466393B1 (de) | Feder eines Federhauses, das eine solche Feder umfasst | |

| EP2869139B1 (de) | Tourbillonmechanismus | |

| EP3066527B1 (de) | Warnsignalsystem | |

| EP2869134B1 (de) | Federhaussystem für Uhr | |

| EP3761122B1 (de) | Drehteil für uhrhemmung, entsprechender hemmungsmechanismus und entsprechendes uhrenteil | |

| EP2757425A2 (de) | Uhr, die eine Anzeige der Gangreserve über polarisierte Organe umfasst, die eine variable relative Ausrichtung haben | |

| EP3112949B1 (de) | Mechanische energiequelle für uhrwerk | |

| WO2010108884A1 (fr) | Balancier a inertie reglable | |

| CH714303A1 (fr) | Système décoratif pour pièce d'horlogerie ou de bijouterie. | |

| EP3470932A1 (de) | Oszillator für uhrwerk | |

| CH710636B1 (fr) | Mécanisme de remontage à engrenage planétaire sphérique pour mouvement horloger. | |

| EP3974913A1 (de) | Federgehäuse für uhr | |

| WO2008003735A2 (fr) | Montre automatique |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20141009 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: DE Ref document number: 1204100 Country of ref document: HK |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: G04B 1/12 20060101AFI20151030BHEP Ipc: G04B 1/16 20060101ALI20151030BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20151207 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH Ref country code: AT Ref legal event code: REF Ref document number: 802791 Country of ref document: AT Kind code of ref document: T Effective date: 20160615 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602013007929 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: GLN S.A., CH |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160825 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 802791 Country of ref document: AT Kind code of ref document: T Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160926 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160826 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: SOWIND S.A., CH Free format text: FORMER OWNER: SOWIND S.A., CH |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: GR Ref document number: 1204100 Country of ref document: HK |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602013007929 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20170228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170308 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170331 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20180327 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170331 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20180326 Year of fee payment: 6 Ref country code: IT Payment date: 20180322 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180328 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: BOVARD SA NEUCHATEL CONSEILS EN PROPRIETE INTE, CH |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20130308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20190404 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602013007929 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190308 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160925 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200331 |