EP2709495B1 - Beverage glass and beverage glass assembly - Google Patents

Beverage glass and beverage glass assembly Download PDFInfo

- Publication number

- EP2709495B1 EP2709495B1 EP12785980.9A EP12785980A EP2709495B1 EP 2709495 B1 EP2709495 B1 EP 2709495B1 EP 12785980 A EP12785980 A EP 12785980A EP 2709495 B1 EP2709495 B1 EP 2709495B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rim

- base

- assembly

- beverage container

- side wall

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 235000013361 beverage Nutrition 0.000 title claims description 110

- 239000011521 glass Substances 0.000 title description 13

- 239000000463 material Substances 0.000 claims description 23

- 239000007788 liquid Substances 0.000 claims description 4

- 239000000853 adhesive Substances 0.000 description 12

- 230000001070 adhesive effect Effects 0.000 description 12

- 239000011324 bead Substances 0.000 description 11

- 235000014101 wine Nutrition 0.000 description 10

- 230000035622 drinking Effects 0.000 description 5

- 239000007787 solid Substances 0.000 description 5

- 230000000712 assembly Effects 0.000 description 3

- 238000000429 assembly Methods 0.000 description 3

- 238000002788 crimping Methods 0.000 description 2

- 235000013305 food Nutrition 0.000 description 2

- 239000010410 layer Substances 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 239000012790 adhesive layer Substances 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- 230000003190 augmentative effect Effects 0.000 description 1

- 235000013405 beer Nutrition 0.000 description 1

- -1 but not limited to Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 239000000796 flavoring agent Substances 0.000 description 1

- 235000019634 flavors Nutrition 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 235000011389 fruit/vegetable juice Nutrition 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000013011 mating Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 239000003566 sealing material Substances 0.000 description 1

- 235000021055 solid food Nutrition 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D21/00—Nestable, stackable or joinable containers; Containers of variable capacity

- B65D21/02—Containers specially shaped, or provided with fittings or attachments, to facilitate nesting, stacking, or joining together

- B65D21/0209—Containers specially shaped, or provided with fittings or attachments, to facilitate nesting, stacking, or joining together stackable or joined together one-upon-the-other in the upright or upside-down position

- B65D21/0213—Containers presenting a continuous stacking profile along the upper or lower edge of at least two opposite side walls

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47G—HOUSEHOLD OR TABLE EQUIPMENT

- A47G19/00—Table service

- A47G19/22—Drinking vessels or saucers used for table service

- A47G19/2205—Drinking glasses or vessels

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47G—HOUSEHOLD OR TABLE EQUIPMENT

- A47G19/00—Table service

- A47G19/22—Drinking vessels or saucers used for table service

- A47G19/2205—Drinking glasses or vessels

- A47G19/2255—Details related to the connection between the liquid containing part and the supporting part

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D21/00—Nestable, stackable or joinable containers; Containers of variable capacity

- B65D21/02—Containers specially shaped, or provided with fittings or attachments, to facilitate nesting, stacking, or joining together

- B65D21/0201—Containers specially shaped, or provided with fittings or attachments, to facilitate nesting, stacking, or joining together stackable or joined together side-by-side

- B65D21/0204—Containers specially shaped, or provided with fittings or attachments, to facilitate nesting, stacking, or joining together stackable or joined together side-by-side and joined together by interconnecting formations forming part of the container, e.g. dove-tail, snap connections, hook elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D21/00—Nestable, stackable or joinable containers; Containers of variable capacity

- B65D21/02—Containers specially shaped, or provided with fittings or attachments, to facilitate nesting, stacking, or joining together

- B65D21/0209—Containers specially shaped, or provided with fittings or attachments, to facilitate nesting, stacking, or joining together stackable or joined together one-upon-the-other in the upright or upside-down position

- B65D21/0217—Containers with a closure presenting stacking elements

- B65D21/0222—Containers with a closure presenting stacking elements the closure and the bottom presenting co-operating peripheral ribs and grooves

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/70—Containers, packaging elements or packages, specially adapted for particular articles or materials for materials not otherwise provided for

- B65D85/72—Containers, packaging elements or packages, specially adapted for particular articles or materials for materials not otherwise provided for for edible or potable liquids, semiliquids, or plastic or pasty materials

Definitions

- the present invention is directed to a beverage container such as a wine glass that can be sealed with a seal or lid that can be removed prior to consumption.

- the present invention also relates to assemblies of multiple beverage containers in a direct connected, attached configuration.

- Beverages are commonly sold to consumers in containers such as glass or plastic bottles, aluminum or steel cans, cardboard or plastic cartons; or devices that include bladders containing the beverage.

- the beverage contained therein can be transferred to a suitable drinking glass composed of a suitable material including but not limited to glass, plastic, or the like for consumption.

- users prefer drinking beverages from individual serving containers such as cans, juice bottles and the like.

- many consumers prefer drinking certain types of beverages from glasses having wide mouths to enhance the aroma and, therefore, the flavor of the beverage.

- DE 296 22 585 U1 discloses an assembly of containers connected together by screw threads to resemble a single, large bottle.

- the present invention regards a beverage container assembly according to claim 1.

- a beverage container 10 includes a beverage vessel body 12 and a removable lid 14 sealingly affixed to the beverage vessel body 12.

- the beverage vessel body 12 can be constructed of any suitable material.

- the beverage vessel body 12 can be made of a suitable moldable polymeric material. Where desired or required, the material can be transparent.

- the material employed can be any material that is suitable for use with food stuffs. The material can be one that is dimensionally stable, but can provide minor deformation in specific applications. In applications where the beverage container 10 contains wine, the beverage vessel body 12 can be composed of a suitable transparent polymeric material.

- the lid 14 can be made of any suitable material including, but not limited to, foil, plastic and the like.

- the material employed in the lid 14 can be made of a material that is the same or different from the material of the vessel body 12. In some applications, it is contemplated that the material employed in the lid 14 will be more deformable than that employed in the vessel body 12 and will be able to conform to suitable dimensional contours by crimping or the like.

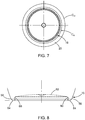

- the beverage vessel body 12 includes a base 16 that has a circumference C B as measured at the outer perimeter of a surface contacting region that has of a first defined value (see FIG. 7 ).

- the beverage vessel body 12 also has a side wall 20 that terminates at a rim 22.

- the side wall 20 and base 16 define an interior chamber of a specified volume. As such, the side wall 20 will have a suitable height H.

- the side wall 20 also has a side wall median M as shown in FIG. 2 .

- the side wall 20 has a curvilinear outer contour that creates at least one outwardly protecting bulbous region 24 that extends beyond the perimeter created by the base 16.

- the side wall 20 has an inwardly tapering region 26 immediately above bulbous region 24 as shown in FIG. 2 . Tapering region 26 terminates at rim 22, the geometry of which will be described in greater detail subsequently.

- the side wall 20 has bulbous region 24 located below the side wall height median M. Bulbous region 24 has a circumference C W greater than the circumference C B of base 16 as shown in FIG. 7 .

- the side wall 20 curves upward from base 16 to the circumference maxima at C W .

- Circumference maxima at C W can be any percentage greater than that of the circumference C B of base 16. In certain embodiments, it is contemplated that the circumference maxima C W can be between 10 and 50% greater than the circumference C B of base 16.

- the side wall 20 has an inwardly tapering region 26 between the bulbous region 24 and the rim 22.

- the rim 22 has a circumference maxima C R equal to or less than the circumference C B of the base 16.

- the outer circumference or circumference maxima C R of the rim 22 will be between 0 and 15% less than the circumference C B of base 16.

- the maximum circumference C W of side wall 20 will be between 5% and 50% greater than the circumference C B of base 16.

- side wall 20 can have a suitable inner face 28 opposed to a curvilinear outer face 30.

- the inner and outer faces will be parallel.

- the internal chamber defined in vessel body 12 will have greater volume in the regions below the median M.

- the internal volume of the vessel body 12 contained in the internal chamber generally will be suitable to contain a suitable beverage serving.

- the vessel body 12 will be proportioned in a manner that provides the suitable volume.

- the base 16 will have a cross-sectional diameter between 5.1 and 10.2 cm (2 and 4 inches).

- the outer diameter of rim 22 will be sufficient to permit releasable engagement between rim 22 of one container 10 and base 16 of a second container.

- the inner diameter of the rim 22 will be sufficient to permit the beverage to be consumed from the vessel body 12.

- the maximum diameter of side wall 20 in the bulbous region 24 can be between 0.6cm and 2.5cm (1/4 inch and 1 inch) greater than the diameter of base 16.

- the total height of the beverage container will be one that approximates the height of a 177ml (6 oz.) beverage glass in certain applications.

- Rim 22 is contiguously joined to the upper region of side wall 20. As depicted in FIGS. 5-6 , rim 22 includes a body 32 with a lip 34 projecting axially outward therefrom to a defined distance. In the embodiment depicted in the drawing figures, the lip 34 extends to provide an outer surface that can be received in a suitable orifice defined in the base 16 of a corresponding beverage vessel. In certain embodiments, the outer diameter of rim 22 is essentially equal to an inner diameter defined by base 16. The rim 22 also has an upwardly oriented surface that can include at least one upwardly oriented surface or bead 36 projecting therefrom.

- Rim 22 is configured to be placed in mating contact with the lid 14 in a manner that facilitates establishment of a removed seal.

- Lid 14 can contact rim 22 in any suitable manner.

- the lid 14 is configured with a suitable edge region that is affixed to the rim 22 to maintain the beverage inside that vessel body 12.

- the lid 14 can be attached to the rim 22 in any suitable manner including, but not limited to, crimping adhesives and the like.

- the suitable adhesive material will be one that is suitable for use with food stuffs.

- the adhesive material can be present as a layer, bead, or other structure that is interposed between the rim 22 and the interior facing side of lid 14. Where desired or required, the interposed adhesive can be positioned such that it contacts all or a portion of the upper surface of rim 22, such as bead 36.

- the lid 14 can have any suitable configuration to sealingly engage the rim 14 and span the opening defined in the vessel body 12.

- the lid 14 can be a thin planar member that can conform to and cover the defined opening.

- the lid 14 can be made of a foil-like material that has a tab that extends beyond the bead so that a user can grasp the tab and remove the lid 14. When in sealing engagement, the lid 14 can deflect inward into the opening defined in the vessel body 12.

- the lid 14 can have a suitable peripheral region proximate to its outer edge that can be configured to conform to at least a portion of the rim 22.

- the desired beverage can be sealed in the vessel body 12 by lid 14.

- the volume of beverage will be such that the height of the beverage comes to a suitable fill line F.

- the vessel body is composed of a suitable transparent polymeric material, the beverage will be visible through the vessel body 12. Note that besides liquids, the vessel body 12 can contain other types of objects, such as solid foods.

- the rim 22 can have any configuration that will facilitate sealing engagement between the lid 14 and the vessel body 12.

- the rim 22 can include a generally vertical neck portion with a bead present at an end thereof.

- the rim 22 can be configured with a plurality of steps 40, 42 positioned on interiorly and exteriorly oriented surfaces relative to bead 36. It is contemplated that adhesives or other sealing material can be interposed between the interiorly oriented steps 40, 42 and lid 14.

- adhesives or other sealing material can be interposed between the interiorly oriented steps 40, 42 and lid 14.

- the term "adhere" is taken to include connection facilitated by direct rim-to-lid adhesion as well as interposition of a suitable adhesive layer between the rim 22 and the lid 14.

- the adhesive line can be deployed so as to contact the bead 36 of rim 22 and, if desired, the adhesive can be disposed such that the adhesive contacts multiple planar surfaces defined in the inwardly oriented surface of the rim 22.

- lid 14 it is also within the purview of this disclosure to configure lid 14 to conform to one or more of the geometric ridges and/or shelves defined in the upper surface of the rim 22. Conformance can be accomplished during manufacture of lid 14 or during attachment of lid 14 to associated rim 22. Conformance fitting may be augmented by adhesives where desired or required.

- the rim 22 has at least one shoulder 38 radially interior of the bead 36.

- the shoulder 38 is has a maximum height or peak below bead 36.

- Shelf 40 is located radially interior to shoulder 38 and is positioned contiguous thereto. Shelf 40 terminates in a downwardly projecting upper portion of inner wall 28.

- the rim 22 can have suitable outer geometric details.

- the rim 22 has a shoulder 42 radially outward of bead 36 and positioned below the bead 36.

- a shelf 44 is positioned radially outward of and below the shoulder 42 and is contiguously joined to it. The contours of the various shelves 40, 44 and shoulders 38, 42 will be sufficient to permit contact with lid 14, but will be small enough to permit an enjoyable drinking experience.

- lid 14 While an adhesive attachment between the lid 14 and the associated rim 22 has been previously described, other types of attachment are possible.

- an outer edge of the lid 14 could be crimped like a beer bottle cap so as to engage an exterior side of the rim 22.

- Another possibility is to slightly melt the top layer of the rim 22 and/or the bottom of the lid 14 prior to placing the lid 14 thereon so that a seal is formed between the lid 14 and rim 22.

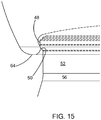

- the outer edge 46 of shelf 44 defines a downwardly extending wall region 48 that terminates in an inwardly curved lower region 50.

- the inwardly curved lower region 50 terminates in a cylindrical band portion 52 that is interposed between the rim 22 and the uppermost portion of side wall 20.

- Side wall 20 and cylindrical band portion 52 can be contiguous to one another or can have a suitable intermediate region 54 interposed between them.

- an inwardly tapered is interposed between the intermediate region 54 inwardly curved lower region 50 and the cylindrical band portion 52.

- the vessel body 12 can also include a transitional region 55 interposed between band portion 52 and the upper region of side wall 20.

- the base 16 of vessel body 12 can be configured to releasably engage with rim 22 of a similarly configured beverage vessel 10.

- the base 16 includes at least one arm member 56 having an outwardly oriented side 58 contiguously connected to the lower region of the side wall 20 at a location on vessel body 12 opposed to the rim 22.

- the arm member 56 defines an inwardly oriented detent 60 generally opposed to outwardly oriented side 58 that terminates in bottom wall (shown in phantom in FIGS. 8 and 9 ).

- the size, number and positioning of arm member(s) 56 is sufficient to releasably engage the rim 22 of a corresponding beverage container 10.

- the device has one arm member 56 that extends continuously around the circumference of the base 16 and defines a surface contacting region 64.

- the detent 60 can have any suitable internal wall configuration sufficient to receive and maintain at least a portion of rim 22 of an associated beverage device 10 in engaged relationship.

- the internal wall of detent 60 has a concave configuration that can releasably engage the corresponding rim 22.

- the inner wall of detent 60 contacts the shoulder 50 associated with rim 22.

- the arm member 56 can be either of solid or hollow construction depending on the specific application.

- arm member 56 is a continuous solid circular body contiguously positioned relative to side wall 20 and bottom surface 62. Without being bound to any theory, it is believed that the solid continuous arm member 56 provides stability to the associated vessel body 12. It is further believed that solid continuous arm member 56, when employed with solid rim 22 as further associated with curve linear side wall 20 provides a structurally robust beverage container 10.

- the bottom surface 62 (shown in phantom in FIGS. 2 , 8 and 9 ) can have any suitable geometric configuration.

- the bottom surface 62 has an inwardly curved geometry having a lowest region proximate to arm member 56 and a maximum inwardly oriented point proximate to the radial center of the device 10.

- the arc defined by curved bottom surface 62 is between 1 degree and 30 degrees from planar.

- Engagement between rim 22 and the arm member 56 generally occurs at a junction point located at a lower portion of detent 60 and rounded shoulder region 50 of the respective elements.

- an interior side surface of the base 16 of one beverage container 10 of FIGS. 1-9 can be altered to have a threaded pattern 80 that is threadedly engaged by a threaded pattern 82 formed on an exterior surface of the rim 22' of another beverage container 10' as shown in FIG. 10 .

- the beverage containers 10 and 10' are screwed onto one another.

- the attachment scheme can be reversed where the threaded pattern 80 is formed on an exterior surface of the base 16 and the threaded pattern 82 is formed on an interior surface of the rim 22', the base 16 dimensioned so that the threaded patterns can engage one another.

- the bases and rims of each of the beverage containers 10, 10' of FIGS. 1-9 can be altered to include the threaded engagement disclosed above.

- FIG. 11 Another possible attachment scenario is shown in FIG. 11 .

- the base 16 of FIGS. 1-9 is altered so an interior surface 84 of a lower portion of the side wall 20 defines a vertical surface.

- a bottom surface 62 is formed above the bottom edge 86 of the interior surface.

- a channel 88 is formed in the interior surface 84, wherein one end 90 of the channel 88 is formed at the bottom edge 86 so that access to the channel 88 at the bottom edge 86 is possible.

- the channel 88 rises at an angle from the bottom edge 86 and then levels off at another end 92. Before leveling off, the channel 88 includes a protrusion 94.

- the channel 88 and protrusion 94 are dimensioned and structured so that when a nub 96 formed on the rim 22 of another container moves along the channel 88, the nub 96 is trapped in end 92 after the nub 96 passes the protrusion 94.

- attachment of the rim 22 of one container to the base 16 of another container is accomplished by inserting the rim 22 of one container within the interior surface 84 of another container.

- the two containers are rotated relative to one another in a first direction until a nub 96 on the rim 22 of one container is inserted into the channel 88 f the other container and passes the protrusion 94.

- the containers are effectively locked to one another until relative rotation between the two containers is performed in a direction opposite to the first direction. If sufficient torque is applied, the nub 96 will pass the protrusion 94 and be fed to the bottom edge of the container where the rim 22 can be released.

- FIGS. 12a-b Another possible attachment scenario is shown in FIGS. 12a-b .

- the base 16 of FIGS. 1-9 is altered so that lower portion at the bottom edge extends approximately 180° so as to be C-shaped.

- the lid 22' of one container is slid into the detent 60 until the rim 22' reaches the rear portion 98 of the base 16.

- the rim 22' and the base 16 are locked to one another by using a channel and nub system similar to that described with respect to FIG. 11 .

- the structure of the channel formed in the interior of the side wall where the detent 60 is present is basically the same as that described with respect to the channel 88 of FIG. 11 .

- One difference is that unlike protrusion 94 of FIG.

- the protrusion is formed in the side of the channel 88 and not the bottom as shown in FIG. 11 .

- locking between the rim 22' and the base 16 is accomplished by sliding the rim 22' into the detent 60 and then twisting the rim 22' and base 16 relative to one another until a nub formed in the rim 22' slides into the channel and rises up the channel until it moves over the protrusion into an end portion of the channel where the rim 22' and base 16 are locked. Twisting in the opposite direction with sufficient torque will release the nub from the channel in the manner similar to that described previously with respect to FIG. 11 .

- the present disclosure contemplates an assembly of beverage containers such as those previously described the assembly including at least two beverage containers each having a vessel body 12 and a lid 14.

- An example of such an assembly when the beverage containers of FIGS. 1-9 are used is shown in FIGS. 13-15 .

- Each beverage container 10 has a serving of a given beverage located in a sealed chamber defined in the vessel body 12.

- the serving size can be a predetermined amount. In applications were the beverage container 10 is configured to contain wine, the serving size can be between 2 oz. and 6 oz. by way of example.

- the assembly 200 as depicted in FIGS.

- the base 16 of at least one first beverage container 10 releasably engages the rim 22' of a second beverage container 10' such that a lid 14' of the second beverage container 10' is interposed between the respective rim 22' and base 16.

- the beverage container at the top of the stack may include a plastic cap to cover the lid.

- the assembly 200 can be composed of any number of beverage containers 10, 10'. Certain assemblies can be composed of even multiples of beverage containers with assemblies of two and four being typical in certain applications.

- the assembly 200 of FIGS. 13-15 can further include an outer covering member. Non-limiting examples of outer covering include boxes and shrink wrap and the like.

- FIGS. 16-19 An example of a possible outer covering is shown in FIGS. 16-19 .

- the outer covering 300 is made of a flexible, plastic material, such as PET, that has an opening at both ends thereof.

- the assembly 200 of FIGS. 13-15 is inserted bottom end first through the opening so that the covering 300 and assembly 200 define a covered assembly of beverage containers 302.

- the covering 300 and assembly combination are placed in a steam tunnel or the like, which results in the covering shrinking and taking on the shape of the assembly of beverage containers

- the material takes on the exterior shape of the assembly 200 along the sides.

- an annular ring may be formed around the outer edge of the plastic cap attached to the lid 14 and rim 22.

- an annular portion 306 is centered about the center of the base 16.

- the covering 300 may contain various features.

- the covering 300 may include an opening 308 so that an observer can determine the contents within the covering 300.

- the covering 300 may include an opening device 310 that includes an area that extends along the length of the assembly 302 and the area is so weakened that when a user pulls on a tab area 308 at the top and along the length of the opening device the area breaks apart to reveal the beverage containers therein.

- the area includes two parallel lines of holes, wherein each hole 312 is approximately 1 mm in diameter and there are about 7 holes per every centimeter along the length of the area. The lines of holes are separated from one another by approximately 8 mm. When the tab area 308 is pulled downward, the material along one of the lines of holes and between the holes of that line is broken apart. The same process occurs with the other line of holes so that a slit -like opening is formed between the lines of holes.

- the beverage containers 10, 10' etc. can be dimensioned to approximate the height and maximum width dimensions of a standard wine bottle.

- an assembly 200 of four beverage containers 10, 10', 10", 10'" positioned in stacked end-to-end relationship will have the approximate height of a standard wine bottle.

- the assembly can contain four servings of the same or different wines.

- Each container can be accessed by removing the respective lid.

- the contents can be consumed from the opened beverage container which can be used as a drinking glass.

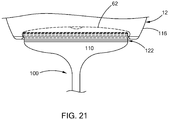

- FIGS. 20 and 21 One non-limiting example of a suitable accessory to be engaged by the beverage container 10 of FIGS. 1-9 is wine glass support 100 depicted in FIGS. 20 and 21 .

- Wine glass support 100 includes a suitable head 110, base 112 and stem 114 interposed between head 110 and base 112. Head 110 is configured to releasably engage a suitably configured base 16 of beverage container 10.

- head 110 of wine glass support 100 includes a suitable rim 122 configured to matingly contact arm member(s) 56.

- rim 122 is matingly received in the orifice defined by continuous circular arm member 56 in the manner described previously.

- Other accessories are contemplated, including but not limited to Pilsner stems as well as plate members and the like.

- the support 100 can be attached when desired. Typically the support 100 will be attached to base 16 of beverage container 10 prior to removal of lid 14.

- the container 10 of FIGS. 1-15 are adapted to include one or more connecting members 402 on the side wall 20.

- Such connecting members 402 are adapted to engage with engagement members 404 of another container 10'.

- connecting member 402 would be a male member of a snap and attachment member 404 would be a corresponding female member of the snap.

- other engagement structures for members 402 and 404 are possible.

- FIG. 23 Another pattern would be to connect each container 10 side-to-side along a line using members 402 and 404 as shown in FIG. 24 . If one of the unattached sides had a sufficient shape, such as a flat surface, the entire line of attached containers could be rotated so that the previously mentioned unattached side was placed on a surface so that the line of containers extended vertically from that surface so as to define a stack similar to those shown in FIGS. 13 and 14 .

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Details Of Rigid Or Semi-Rigid Containers (AREA)

- Packages (AREA)

- Table Devices Or Equipment (AREA)

- Closures For Containers (AREA)

- Stackable Containers (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/111,454 US8807340B2 (en) | 2011-05-19 | 2011-05-19 | Beverage glass and beverage glass assembly |

| US29/411,983 USD674236S1 (en) | 2011-05-19 | 2012-01-27 | Wine glass container device |

| PCT/US2012/038380 WO2012158937A1 (en) | 2011-05-19 | 2012-05-17 | Beverage glass and beverage glass assembly |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2709495A1 EP2709495A1 (en) | 2014-03-26 |

| EP2709495A4 EP2709495A4 (en) | 2015-03-11 |

| EP2709495B1 true EP2709495B1 (en) | 2018-11-07 |

Family

ID=47177344

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12785980.9A Not-in-force EP2709495B1 (en) | 2011-05-19 | 2012-05-17 | Beverage glass and beverage glass assembly |

Country Status (11)

| Country | Link |

|---|---|

| US (3) | USD674236S1 (enExample) |

| EP (1) | EP2709495B1 (enExample) |

| JP (1) | JP6161166B2 (enExample) |

| KR (1) | KR102016771B1 (enExample) |

| CN (1) | CN103687516B (enExample) |

| AU (3) | AU2012255255B2 (enExample) |

| BR (1) | BR112013029782A2 (enExample) |

| CA (1) | CA2836563C (enExample) |

| MX (1) | MX341746B (enExample) |

| WO (1) | WO2012158937A1 (enExample) |

| ZA (1) | ZA201308694B (enExample) |

Families Citing this family (37)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10604296B2 (en) | 2010-04-19 | 2020-03-31 | Merrilee Kick | Container |

| US8807340B2 (en) | 2011-05-19 | 2014-08-19 | Stacked Wines, Llc | Beverage glass and beverage glass assembly |

| US10336496B2 (en) | 2011-05-19 | 2019-07-02 | Stacked Wines Llc | Beverage glass and beverage glass assembly |

| US20130206781A1 (en) * | 2011-08-15 | 2013-08-15 | Michelle MacCormick | Method of wrapping a glass and the wrapped glass produced |

| NZ701854A (en) | 2012-05-25 | 2016-09-30 | Zipz Inc | Single serve beverage container |

| DE102012019220A1 (de) * | 2012-08-14 | 2014-02-20 | Hipp & Co | Sterilisierbecher insbesondere für Babynahrung |

| USD718576S1 (en) * | 2013-03-08 | 2014-12-02 | Zalto Glas GmbH | Drinking glass |

| USD710649S1 (en) * | 2013-04-24 | 2014-08-12 | Steven Kihl | Wine aerator |

| DE102014102306B4 (de) | 2013-07-02 | 2015-03-12 | Silgan Holdings Inc. | Behälter mit reduzierter Halshöhe zum Verschließen mit einem Verschlussdeckel und Verfahren zum Verschließen |

| DE102014104344B3 (de) * | 2013-07-02 | 2014-10-02 | Silgan Holdings Inc. | PT-Verschlussdeckel, Verfahren zum Verschließen und Verschlusseinheit aus Deckel und Gefäß |

| USD717604S1 (en) * | 2013-09-04 | 2014-11-18 | Jason E. Klinge | Drinking glass |

| USD743210S1 (en) * | 2013-09-21 | 2015-11-17 | Rie Yasui | Drinking vessel |

| USD754544S1 (en) * | 2014-02-12 | 2016-04-26 | Beech-Nut Nutrition Company | Baby food container |

| USD760028S1 (en) * | 2014-02-17 | 2016-06-28 | Bormioli Luigi S.P.A. | Goblet |

| USD739735S1 (en) * | 2014-03-06 | 2015-09-29 | Beech-Nut Nutrition Company | Baby food container |

| USD756713S1 (en) | 2014-03-24 | 2016-05-24 | Zipz, Inc. | Beverage container |

| USD756789S1 (en) * | 2014-03-26 | 2016-05-24 | Beech-Nut Nutrition Company | Baby food container |

| USD760593S1 (en) * | 2014-03-28 | 2016-07-05 | Zipz, Inc. | Beverage container |

| CA158649S (en) * | 2014-04-09 | 2015-05-21 | Philips Electronics Ltd | Drinking cup |

| CA158629S (en) * | 2014-04-09 | 2015-05-21 | Philips Electronics Ltd | Drinking cup |

| USD760601S1 (en) | 2014-08-04 | 2016-07-05 | Duet Bottle Company, LLC | Double-ended bottle |

| USD752840S1 (en) * | 2014-11-26 | 2016-03-29 | Flextank, Inc. | Wine container |

| USD815531S1 (en) * | 2015-03-04 | 2018-04-17 | The Clorox Company | Wipes dispenser container |

| USD770301S1 (en) * | 2015-04-08 | 2016-11-01 | John Thomas Goserud | Stacked golfballs secured by transparent film to a flat base |

| US20190127114A1 (en) * | 2016-03-10 | 2019-05-02 | Ripshot Enterprises Corporation | Disposable shot glass with peel-off lid |

| KR101888109B1 (ko) * | 2016-03-10 | 2018-08-13 | 델몬트 후레쉬 프러듀스 인터내셔널,인크. | 과일 용기 |

| WO2018161111A1 (en) * | 2017-03-05 | 2018-09-13 | Candice Rogers | A bottle convertible to a glass |

| USD838541S1 (en) * | 2017-09-23 | 2019-01-22 | Frank Carter, IV | Wine aerator |

| USD902043S1 (en) * | 2019-02-01 | 2020-11-17 | Société des Produits Nestlé S.A. | Container |

| USD914508S1 (en) * | 2019-07-15 | 2021-03-30 | Rubbermaid Incorporated | Jar |

| USD926040S1 (en) * | 2019-07-15 | 2021-07-27 | Rubbermaid Incorporated | Jar |

| USD922251S1 (en) * | 2019-10-07 | 2021-06-15 | II Steven Leslie Rands | Rotating wine glass art display |

| USD889968S1 (en) * | 2019-10-09 | 2020-07-14 | Owens-Brockway Glass Container Inc. | Container |

| USD1013512S1 (en) | 2019-10-10 | 2024-02-06 | Merrilee Kick | Container |

| USD964807S1 (en) | 2020-10-21 | 2022-09-27 | Brian Carr | Double wall wine glass |

| US11975889B2 (en) | 2021-09-02 | 2024-05-07 | Merrilee Kick | Container apparatus |

| USD1036994S1 (en) * | 2022-04-29 | 2024-07-30 | Lavian Ltd. | Bottle cap grip |

Family Cites Families (47)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2747387A (en) * | 1953-02-06 | 1956-05-29 | Harry H Hart | Double cup |

| US2738891A (en) | 1953-03-02 | 1956-03-20 | Ball Brothers Co Inc | Stackable jars |

| FR84721E (fr) * | 1963-08-03 | 1965-04-02 | Procédé de fabrication d'objets en verre à embase ou pied, et objets obtenus | |

| US3482731A (en) | 1968-04-25 | 1969-12-09 | United States Steel Corp | Sectional drinking goblet |

| US3684123A (en) * | 1970-08-10 | 1972-08-15 | Aladdin Ind Inc | Stacked insulated cups |

| AU534706B2 (en) * | 1980-03-12 | 1984-02-09 | Mead Corporation, The | Carrier pack |

| FR2554786A1 (fr) * | 1983-11-15 | 1985-05-17 | Kimmel Marcel | Procede de fabrication d'emballages en forme de pot pour produits alimentaires et emballages ainsi realises |

| US4685565A (en) * | 1986-01-24 | 1987-08-11 | Michael Sparling | Interconnectable beverage container system |

| US4679699A (en) * | 1986-05-22 | 1987-07-14 | Rexcel, Inc. | Sealing lid and container |

| US4848579A (en) * | 1987-05-27 | 1989-07-18 | Nabisco Brands, Inc. | Food container |

| JPH0366833U (enExample) * | 1989-10-27 | 1991-06-28 | ||

| JPH0397064U (enExample) * | 1990-01-19 | 1991-10-04 | ||

| USD347763S (en) * | 1993-03-17 | 1994-06-14 | Arrow Plastic Manufacturing Company | Drinking cup |

| USD404256S (en) * | 1994-12-07 | 1999-01-19 | Heineken Technical Services, B.V. | Beverage container |

| USD368311S (en) * | 1995-06-27 | 1996-03-26 | Allan Cockram | Baby bottle |

| US5860527A (en) | 1996-10-18 | 1999-01-19 | Menasha Corporation | Plastic tote box improvements |

| DE29622585U1 (de) * | 1996-12-31 | 1998-04-23 | Striebel, Christhard, 70569 Stuttgart | Flasche zur Aufnahme von Flüssigkeiten, insbesondere Getränke |

| USD409444S (en) * | 1997-02-21 | 1999-05-11 | Dieter Pelz | Drinking glass |

| JP2000153841A (ja) * | 1998-11-20 | 2000-06-06 | System Art:Kk | 飲料容器 |

| US6065603A (en) | 1999-01-08 | 2000-05-23 | Newell Operating Company | Stackable glass tumblers |

| USD479436S1 (en) * | 2001-10-24 | 2003-09-09 | Stor Inter, S.L. | Glass |

| MXPA04009099A (es) * | 2002-03-20 | 2005-07-13 | Graham Packaging Co | Contenedor con base apilable. |

| USD484361S1 (en) | 2003-09-04 | 2003-12-30 | Jehyun Jeung | Stackable cup |

| US7886924B2 (en) | 2003-11-05 | 2011-02-15 | By The Glass, Llc | Wine glass |

| US8567635B2 (en) | 2003-11-05 | 2013-10-29 | By The Glass, Llc | Wine glass |

| US20070119726A1 (en) | 2004-11-01 | 2007-05-31 | Willat | Wine glass |

| AU2004289219B2 (en) | 2003-11-05 | 2010-02-04 | Govino, Llc | Wine glass |

| US9414699B2 (en) | 2004-09-13 | 2016-08-16 | Dominic John Wing | Beverage container with removable top |

| US20070012693A1 (en) * | 2005-06-03 | 2007-01-18 | Kummer William J | Interlocking Assembly of Containers, Closures, Holding Apparatus and Methodology |

| US20070158225A1 (en) * | 2006-01-09 | 2007-07-12 | Rexam Beverage Can Co. | Multi-pack container arrangements |

| USD540621S1 (en) * | 2006-02-24 | 2007-04-17 | Pacific Market International, Llc | Snowman tumbler |

| US20080023347A1 (en) | 2006-07-28 | 2008-01-31 | Mystique Brands, Llc | Pre-filled cocktail glass and packaging |

| US20080023348A1 (en) | 2006-07-28 | 2008-01-31 | Mystique Brands, Llc | Liquid seal arrangement for use in a pre-filled cocktail glass |

| US7780029B2 (en) * | 2006-10-04 | 2010-08-24 | Carol Peterman | Stackable container systems |

| USD578827S1 (en) * | 2006-10-19 | 2008-10-21 | Italesse Srl | Glass |

| USD569189S1 (en) * | 2007-01-18 | 2008-05-20 | Bbc Brands, Llc | Glass |

| USD595096S1 (en) * | 2007-10-29 | 2009-06-30 | Slay Thomas A | Wine glass insulator |

| USD577547S1 (en) | 2007-11-01 | 2008-09-30 | By The Glass, Llc | Wine glass |

| US20100025351A1 (en) * | 2008-04-16 | 2010-02-04 | Jesse James Fowler | Inter-locking stacking segment jar |

| CN201317492Y (zh) * | 2008-10-27 | 2009-09-30 | 陈克敏 | 一种可相互组合的饮料瓶 |

| US8967416B2 (en) * | 2009-01-09 | 2015-03-03 | Rubbermaid Incorporated | Food storage container and container system |

| EP2408688B1 (fr) * | 2009-03-16 | 2013-01-09 | 1/4 Vin | Verre à vin, procédé de conditionnement du vin, et conteneur de vin |

| US20100314274A1 (en) | 2009-06-16 | 2010-12-16 | Nottingham Spirk Partners Llc | Multiple sealed beverage vessels in a case |

| USD644938S1 (en) | 2009-10-05 | 2011-09-13 | Nottingham Spirk | Pre-filled wine glasses stacked in a package |

| US9227772B2 (en) | 2009-12-03 | 2016-01-05 | Govino, Llc | Combined wine glass and wine bottle package |

| US20110174763A1 (en) | 2010-01-21 | 2011-07-21 | Kennedy Timothy J | Two piece wine glass and protective case |

| USD640900S1 (en) * | 2010-11-04 | 2011-07-05 | W.I.N.O.S., Inc. | Wine glass insulator |

-

2012

- 2012-01-27 US US29/411,983 patent/USD674236S1/en active Active

- 2012-05-17 BR BR112013029782A patent/BR112013029782A2/pt not_active IP Right Cessation

- 2012-05-17 WO PCT/US2012/038380 patent/WO2012158937A1/en not_active Ceased

- 2012-05-17 CN CN201280035501.2A patent/CN103687516B/zh not_active Expired - Fee Related

- 2012-05-17 KR KR1020137033801A patent/KR102016771B1/ko not_active Expired - Fee Related

- 2012-05-17 AU AU2012255255A patent/AU2012255255B2/en not_active Ceased

- 2012-05-17 JP JP2014511543A patent/JP6161166B2/ja not_active Expired - Fee Related

- 2012-05-17 MX MX2013013519A patent/MX341746B/es active IP Right Grant

- 2012-05-17 EP EP12785980.9A patent/EP2709495B1/en not_active Not-in-force

- 2012-05-17 CA CA2836563A patent/CA2836563C/en not_active Expired - Fee Related

- 2012-06-01 US US29/423,578 patent/USD674238S1/en active Active

- 2012-06-01 US US29/423,581 patent/USD674243S1/en active Active

-

2013

- 2013-11-20 ZA ZA2013/08694A patent/ZA201308694B/en unknown

-

2017

- 2017-11-13 AU AU2017258987A patent/AU2017258987A1/en not_active Abandoned

-

2019

- 2019-11-07 AU AU2019261765A patent/AU2019261765A1/en not_active Abandoned

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| MX2013013519A (es) | 2014-07-14 |

| WO2012158937A1 (en) | 2012-11-22 |

| JP2014517794A (ja) | 2014-07-24 |

| JP6161166B2 (ja) | 2017-07-12 |

| KR102016771B1 (ko) | 2019-10-21 |

| AU2012255255B2 (en) | 2017-12-14 |

| AU2012255255A2 (en) | 2014-01-16 |

| CA2836563A1 (en) | 2012-11-22 |

| CN103687516B (zh) | 2016-11-02 |

| BR112013029782A2 (pt) | 2019-09-24 |

| EP2709495A4 (en) | 2015-03-11 |

| WO2012158937A4 (en) | 2013-01-03 |

| CA2836563C (en) | 2016-06-21 |

| EP2709495A1 (en) | 2014-03-26 |

| USD674238S1 (en) | 2013-01-15 |

| AU2012255255A9 (en) | 2017-12-07 |

| AU2017258987A1 (en) | 2017-11-30 |

| AU2017258987A2 (en) | 2017-12-14 |

| ZA201308694B (en) | 2015-02-25 |

| MX341746B (es) | 2016-08-31 |

| AU2012255255A1 (en) | 2014-01-09 |

| USD674236S1 (en) | 2013-01-15 |

| KR20140050612A (ko) | 2014-04-29 |

| AU2019261765A1 (en) | 2019-11-28 |

| USD674243S1 (en) | 2013-01-15 |

| CN103687516A (zh) | 2014-03-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2709495B1 (en) | Beverage glass and beverage glass assembly | |

| US10336496B2 (en) | Beverage glass and beverage glass assembly | |

| US20180134447A1 (en) | Container with and container assembly with engagable cap | |

| US8807340B2 (en) | Beverage glass and beverage glass assembly | |

| US8313001B1 (en) | Container closure with stored scoop | |

| US8336732B1 (en) | Container with an integral lid retained onto the top of the sidewall of the container by a living hinge, the container used to retain hot liquids, the container having a thermal barrier incorporated into the exterior surface of the container | |

| US20010022304A1 (en) | Container | |

| US20130075356A1 (en) | Single serving beverage vessel with a resealable lid | |

| WO2009098590A1 (en) | Pocket-sized container | |

| CA2697646A1 (en) | Supportable pressurizable container having a bottom for receiving a dip tube and base cup therefor | |

| US10172487B2 (en) | Stemmed glass and stemmed glass set | |

| US20190256260A1 (en) | Container adapter lids | |

| US20050211713A1 (en) | Disposable container with deformable brim | |

| US11174087B2 (en) | Drinking glass and combination of a beverage bottle and a drinking glass | |

| WO2006083606A2 (en) | Easy open container closure | |

| US20070029325A1 (en) | Covered containers and related dispensing systems | |

| US20190357713A1 (en) | Container with coaster | |

| US20090139954A1 (en) | Closure With Improved Tamper-Evident Band | |

| JP2010528943A (ja) | 飲料容器閉鎖部材 | |

| CA2539528C (en) | Disposable container with deformable brim and lid therefor | |

| GB2539025A (en) | Drink receptacle | |

| US10934057B2 (en) | Aseptic screw-cap assembly | |

| RU54902U1 (ru) | Бутылка | |

| EP1254847A1 (en) | A container |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20131218 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: STACKED WINES, LLC |

|

| A4 | Supplementary search report drawn up and despatched |

Effective date: 20150211 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: A47G 19/22 20060101AFI20150205BHEP Ipc: B65D 21/02 20060101ALI20150205BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B65D 21/02 20060101ALI20180222BHEP Ipc: A47G 19/22 20060101AFI20180222BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20180323 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTC | Intention to grant announced (deleted) | ||

| INTG | Intention to grant announced |

Effective date: 20180606 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 1061083 Country of ref document: AT Kind code of ref document: T Effective date: 20181115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602012053229 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 1061083 Country of ref document: AT Kind code of ref document: T Effective date: 20181107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190207 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190207 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190307 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190307 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190208 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20190508 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20190524 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602012053229 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20190521 Year of fee payment: 8 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20190808 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20190524 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190531 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190531 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190531 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602012053229 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20200601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200601 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20200517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200531 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20120517 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181107 |