EP2655834B1 - Orifice d'injection pour une centrale thermique à vapeur - Google Patents

Orifice d'injection pour une centrale thermique à vapeur Download PDFInfo

- Publication number

- EP2655834B1 EP2655834B1 EP12704399.0A EP12704399A EP2655834B1 EP 2655834 B1 EP2655834 B1 EP 2655834B1 EP 12704399 A EP12704399 A EP 12704399A EP 2655834 B1 EP2655834 B1 EP 2655834B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- injection

- injection line

- line

- aperture

- steam

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 238000002347 injection Methods 0.000 title claims description 132

- 239000007924 injection Substances 0.000 title claims description 132

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 30

- 238000000034 method Methods 0.000 claims description 8

- 238000001816 cooling Methods 0.000 claims description 3

- 230000001105 regulatory effect Effects 0.000 claims 4

- 238000011161 development Methods 0.000 description 5

- 230000018109 developmental process Effects 0.000 description 5

- 239000000498 cooling water Substances 0.000 description 2

- 230000003628 erosive effect Effects 0.000 description 2

- 230000007423 decrease Effects 0.000 description 1

- 230000009977 dual effect Effects 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 230000003716 rejuvenation Effects 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01K—STEAM ENGINE PLANTS; STEAM ACCUMULATORS; ENGINE PLANTS NOT OTHERWISE PROVIDED FOR; ENGINES USING SPECIAL WORKING FLUIDS OR CYCLES

- F01K9/00—Plants characterised by condensers arranged or modified to co-operate with the engines

- F01K9/04—Plants characterised by condensers arranged or modified to co-operate with the engines with dump valves to by-pass stages

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28C—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA COME INTO DIRECT CONTACT WITHOUT CHEMICAL INTERACTION

- F28C3/00—Other direct-contact heat-exchange apparatus

- F28C3/06—Other direct-contact heat-exchange apparatus the heat-exchange media being a liquid and a gas or vapour

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/30—Injector mixers

- B01F25/31—Injector mixers in conduits or tubes through which the main component flows

- B01F25/313—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit

- B01F25/3133—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit characterised by the specific design of the injector

- B01F25/31332—Ring, torus, toroidal or coiled configurations

Definitions

- the invention relates to an injection orifice for mixing water and steam in a pipeline, wherein means for injecting water are provided in the injection orifice. Furthermore, the invention relates to a method for cooling a vapor, wherein the vapor flows through an injection orifice.

- steam turbines are fluidly connected via comparatively complicated pipelines to a steam generator.

- hot steam is generated, which is usually led to a high-pressure or medium-pressure turbine section.

- the steam generated by the steam generator flows directly to the high-pressure or medium-pressure turbine section.

- the steam must not necessarily flow directly to the turbine, but must be diverted to the condenser.

- the condenser the steam is converted back into water.

- diverter stations are used in these power plants described above, whose task is to direct the steam coming from the steam generator completely or partially directly into the condenser.

- the bypass station is used in addition to the regular continuous operation during the so-called start-up or shutdown.

- a diverter station displays the document WO2010 / 034659A2 .

- the steam is conducted via the bypass station to the condenser, the steam is passed via a diverter valve and a short pipe to an injection orifice. After flowing through the bypass valve, the short pipe and the injection orifice, the pressure of the steam decreases.

- the steam is cooled to be controlled with the condenser to a tuned level.

- the single-stage injection orifice is for a maximum injection quantity designed for water. Under unfavorable circumstances, this can lead to a poor mixing of the steam with the water in the partial load operation of the bypass station, when comparatively little cooling water is required. This could lead to erosion and temperature problems in the downstream condenser.

- the invention begins, whose task is to provide a way to optimally adapt the steam parameters, especially to be able to adapt to load cases.

- an injection orifice for mixing water and steam in a pipeline according to claim 1, wherein in the aperture a first injection line and a second injection line for injection of water is formed in an injection orifice flow channel, wherein the injection orifice flow channel through a inside injection port flow surface is formed on the injection orifice and the second injection line is arranged in the flow direction after the first injection line.

- the object is achieved by a method for cooling a vapor according to claim 9, wherein the steam flows through an injection orifice, wherein water is injected into the steam via a first injection line and a second injection line.

- the invention is based on the idea that in addition to a singular injection known in the prior art, a dual injection with two injection lines to a better Mixing of the water with the steam leads. This tunes the steam parameters better to the level of the condenser.

- the injection via the first injection line and the second injection line takes place in two stages. This means that 0% - 60% of the injection takes place in the first injection line during a start-up process in which not the full amount of water is needed via a control. For example, in load shedding, etc., the second stage is additionally turned on so that the second stage represented by the second injection pipe realizes the remaining capacity of 60% -100%.

- the modified and inventive injection orifice can not only inject sufficient cooling water mass flow at 100% load, but also ensure a part-load operation of Dampfumleitstation better mixing of the water with the steam.

- the injection port flow-side surface of the injection port on the inside is designed as a Laval nozzle. This basically means that the flow cross-section first tapers and then increases. As a result, the pressure distribution in the injection orifice is optimized.

- the injection orifice is substantially rotationally symmetrical to a rotational symmetry axis and the first injection line is arranged at an angle ⁇ 1 with respect to the injection orifice flow surface, wherein the second injection line is arranged at an angle ⁇ 2 with respect to the injection orifice flow surface, the angles ⁇ 1 and ⁇ 2 can assume values between 10 ° and 80 °.

- Optimum mixing of the steam jet with the water injection jet is possible if the two flow directions (of the steam jet and the water injection jet) are not disposed at an obtuse angle. It would be better to mix at an angle between 10 ° and 80 °. Further advantageous angles are in the range of 20 ° to 70 ° and between 30 ° and 60 °.

- angles ⁇ 1 and ⁇ 2 are substantially identical.

- the first injection line and the second injection line can be connected to a common injection line.

- one valve can be used in the first injection line and in the second injection line.

- a control valve shall be taken into account.

- the first injection line and the second injection line are fluidically connected via a common injection line.

- the second injection line is initially blocked via the valve, so that water can be injected only via the first injection line.

- the second control valve is opened so that it is possible to let up to 100% of the water injection amount flow into the injection orifice, thereby enabling better mixing with the steam jet.

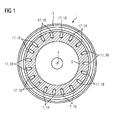

- the FIG. 1 shows a view of an injection orifice 1 seen in a flow direction 2.

- the flow direction 2 in this case shows perpendicular to the plane.

- the injection orifice 1 is arranged within a pipeline 3, this pipeline 3 being arranged in a bypass station in a steam power plant or in a gas turbine power plant. Through this pipe 3 flows a vapor which has been generated in a steam generator.

- the injection orifice 1 is formed substantially rotationally symmetrical to a rotational symmetry axis 4.

- the injection orifice 1 has, within the pipeline 3, an injection orifice flow surface 5 which serves as what is shown in FIG FIG. 2 it can be seen, Laval nozzle is formed.

- the FIG. 2 shows a cross-sectional view of the injection orifice 1.

- the injection orifice 1 is substantially characterized in that the injection orifice flow surface 5 is similar to a Laval nozzle.

- the Laval nozzle in a first region 6 has a comparatively large flow cross-section.

- the first region 6 is adjoined by a tapering region 7, in which the flow cross section is reduced.

- a continuous region 8 adjoins, in which the flow channel is continuously expanded.

- a first injection line 9 and a second injection line 10 are arranged.

- the first region 6, the tapering region 7 and the continuous region 8 are viewed in the flow direction 2, arranged one behind the other.

- the first injection line 9 is inclined at an angle ⁇ 1 , which is substantially opposite the injection orifice flow surface 5 is arranged.

- the second injection line 10 is formed at an angle ⁇ 2 with respect to the inflow-flow surface 5.

- the angle ⁇ 1 can assume values between 10 ° - 80 °, 20 ° - 70 °, 30 ° - 60 °.

- the angle ⁇ 2 can assume values between 10 ° - 80 °, 20 ° - 70 ° and 30 ° - 60 °.

- the angles ⁇ 1 and ⁇ 2 may be substantially identical.

- the first injection line 9 opens into a first supply line 11.

- the second injection line 10 opens into a second supply line 12.

- a control valve 13 is arranged in the first supply line 11.

- a control valve 14 is arranged in the second supply line 12.

- the first supply line 11 and the second supply line 12 open into a common injection line 15.

- a measuring device 16 is arranged, which determines the flow rate.

- the second injection line 10 is arranged in the flow direction 2 after the first injection line 9.

- control valve 14 is initially closed, so that no water is flowed into the steam jet via the second injection line 2. If a water capacity of 0% - 60% is required in the steam jet, the control valve 13 is opened, wherein a control regulates the flow rate in the first injection line 9 in the steam jet.

- the control valve 14 is opened, so that a capacity of up to 100% in the steam jet is possible. Therefore, in the second injection pipe 10, the capacity of 60% - 100% is adopted.

- first bore 17 in the injection orifice 1 is arranged between the first injection line 9 and the first supply line 11.

- second bore 18 in the injection orifice 1 is arranged between the second injection line 10 and the second supply line 12.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Nozzles (AREA)

- Control Of Turbines (AREA)

Claims (11)

- Orifice ( 1 ) d'injection pour mélanger de l'eau et de la vapeur dans une canalisation ( 3 ),

dans lequel la vapeur passe dans un sens ( 2 ) d'écoulement, dans lequel il est formé dans l'orifice ( 1 ) d'injection un premier conduit ( 9 ) d'injection et un deuxième conduit ( 10 ) d'injection pour l'injection d'eau dans un canal d'écoulement d'orifice d'injection,

dans lequel le canal d'écoulement d'orifice d'injection est formé par une surface ( 5 ) d'orifice d'injection du côté intérieur sur l'orifice ( 1 ) d'injection,

caractérisé en ce que

le deuxième conduit ( 10 ) d'injection est disposé dans le sens d'écoulement en aval du premier conduit ( 9 ) d'injection,

dans lequel le premier conduit ( 9 ) d'injection débouche dans un premier conduit ( 11 ) d'admission, dans lequel est monté un robinet ( 13 ) de réglage,

dans lequel le deuxième conduit ( 10 ) d'injection débouche dans un deuxième conduit ( 12 ) d'admission, dans lequel est monté un robinet ( 14 ) de commande,

dans lequel le robinet ( 14 ) de commande et le robinet ( 13 ) de réglage sont constitués de manière à ce que, pendant le fonctionnement, il ne passe d'abord pas de vapeur par le deuxième conduit ( 2 ) d'injection. - Orifice ( 1 ) d'injection suivant la revendication 1,

dans lequel le robinet ( 13 ) de réglage est constitué de manière à ce que, si la capacité d'eau dont on a besoin va de 0 % à 60 %, le robinet ( 13 ) de réglage est ouvert et règle une régulation du débit dans le premier conduit ( 9 ) d'injection. - Orifice ( 1 ) d'injection suivant la revendication 2,

dans lequel le robinet ( 14 ) de commande est constitué de manière à ce que, si l'on a besoin d'une capacité d'eau allant jusqu'à 100 %, le robinet ( 14 ) de commande est ouvert. - Orifice ( 1 ) d'injection suivant l'une des revendications précédentes,

dans lequel la surface ( 5 ) d'écoulement d'orifice d'injection du côté intérieur est constituée sous la forme d'une tuyère Laval. - Orifice ( 1 ) d'injection suivant l'une des revendications précédentes,

dans lequel le canal d'écoulement d'orifice d'injection se rétrécit d'abord dans un sens ( 2 ) d'écoulement de la vapeur entrante et ensuite s'élargit. - Orifice ( 1 ) d'injection suivant l'une des revendications précédentes,

dans lequel l'orifice ( 1 ) d'injection est sensiblement de révolution par rapport à un axe ( 4 ) de révolution et le premier conduit ( 9 ) d'injection fait un angle α1 par rapport à la surface ( 5 ) d'écoulement d'orifice d'injection,

le deuxième conduit ( 10 ) d'injection fait un angle α2 par rapport à la surface ( 5 ) d'écoulement d'orifice d'injection,

α1 et α2 pouvant prendre des valeurs comprises entre 10° et 80°. - Orifice ( 1 ) d'injection suivant la revendication 6, dans lequel α1 et α2 sont sensiblement pareils.

- Orifice ( 1 ) d'injection suivant l'une des revendications précédentes,

dans lequel le premier conduit ( 9 ) d'injection et le deuxième conduit ( 10 ) d'injection peuvent communiquer avec un conduit ( 15 ) d'injection commun. - Procédé de refroidissement d'une vapeur,

dans lequel la vapeur passe dans un orifice ( 1 ) d'injection,

dans lequel on injecte de l'eau dans la vapeur par un premier conduit ( 9 ) d'injection et par un deuxième conduit ( 10 ) d'injection ( 10 ),

dans lequel on ferme d'abord le deuxième conduit ( 10 ) d'injection et on n'injecte de l'eau que par le premier conduit ( 9 ) d'injection,

dans lequel on relie fluidiquement le premier conduit ( 9 ) d'injection et le deuxième conduit ( 10 ) d'injection avec un conduit ( 15 ) d'injection commun et

dans lequel le premier conduit ( 9 ) d'injection injecte dans la vapeur de 0 % à 60 % de la capacité de l'eau pouvant passer dans le conduit ( 5 ) d'injection commun. - Procédé suivant la revendication 9,

dans lequel le deuxième conduit ( 10 ) d'injection injecte dans la vapeur les 60 % à 100 % restants de la capacité de l'eau pouvant passer dans le conduit commun d'injection. - Procédé suivant l'une des revendications 9 à 10,

dans lequel on monte dans le premier conduit ( 9 ) d'injection un premier robinet ( 13 ) et dans le deuxième conduit ( 10 ) d'injection un deuxième robinet ( 14 ).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP12704399.0A EP2655834B1 (fr) | 2011-03-14 | 2012-02-09 | Orifice d'injection pour une centrale thermique à vapeur |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP11158049A EP2500549A1 (fr) | 2011-03-14 | 2011-03-14 | Ecran d'injection pour une centrale à vapeur |

| PCT/EP2012/052192 WO2012123194A1 (fr) | 2011-03-14 | 2012-02-09 | Orifice d'injection pour une centrale thermique à vapeur |

| EP12704399.0A EP2655834B1 (fr) | 2011-03-14 | 2012-02-09 | Orifice d'injection pour une centrale thermique à vapeur |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2655834A1 EP2655834A1 (fr) | 2013-10-30 |

| EP2655834B1 true EP2655834B1 (fr) | 2015-10-28 |

Family

ID=44357958

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP11158049A Withdrawn EP2500549A1 (fr) | 2011-03-14 | 2011-03-14 | Ecran d'injection pour une centrale à vapeur |

| EP12704399.0A Not-in-force EP2655834B1 (fr) | 2011-03-14 | 2012-02-09 | Orifice d'injection pour une centrale thermique à vapeur |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP11158049A Withdrawn EP2500549A1 (fr) | 2011-03-14 | 2011-03-14 | Ecran d'injection pour une centrale à vapeur |

Country Status (3)

| Country | Link |

|---|---|

| EP (2) | EP2500549A1 (fr) |

| CN (1) | CN103443420B (fr) |

| WO (1) | WO2012123194A1 (fr) |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4372125A (en) * | 1980-12-22 | 1983-02-08 | General Electric Company | Turbine bypass desuperheater control system |

| JPS595811A (ja) * | 1982-07-01 | 1984-01-12 | Toshiba Corp | 低圧タ−ビンバイパス装置 |

| DE3240453A1 (de) * | 1982-11-02 | 1984-05-03 | Kraftwerk Union AG, 4330 Mülheim | Dampfturbinenkondensator mit mindestens einer in den dampfdom einmuendenden umleitdampfeinfuehrung |

| CN86207574U (zh) * | 1986-10-13 | 1987-08-19 | 长春市盐城科技开发咨询处 | 喷管式汽水混合加热器 |

| EP2213847A1 (fr) * | 2008-09-24 | 2010-08-04 | Siemens Aktiengesellschaft | Centrale à vapeur destinée à la production d'énergie électrique |

-

2011

- 2011-03-14 EP EP11158049A patent/EP2500549A1/fr not_active Withdrawn

-

2012

- 2012-02-09 EP EP12704399.0A patent/EP2655834B1/fr not_active Not-in-force

- 2012-02-09 CN CN201280013635.4A patent/CN103443420B/zh not_active Expired - Fee Related

- 2012-02-09 WO PCT/EP2012/052192 patent/WO2012123194A1/fr active Application Filing

Also Published As

| Publication number | Publication date |

|---|---|

| EP2655834A1 (fr) | 2013-10-30 |

| EP2500549A1 (fr) | 2012-09-19 |

| CN103443420B (zh) | 2016-05-18 |

| WO2012123194A1 (fr) | 2012-09-20 |

| CN103443420A (zh) | 2013-12-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102008029941B4 (de) | Dampfkraftanlage und Verfahren zur Regelung der Leistung einer Dampfkraftanlage | |

| DE102006045034A1 (de) | Wassergekühlte Konstanttemperatur-Flüssigkeitszirkuliervorrichtung und Verfahren zur Steuerung der Temperatur der zirkulierenden Flüssigkeit | |

| DE102011011123B4 (de) | Dampfanlage und Verfahren zum Konfigurieren der Dampfanlage | |

| WO2008104465A2 (fr) | Procédé de fonctionnement d'une turbine à vapeur à plusieurs étages | |

| EP2726785A1 (fr) | Conduit de dérivation de vapeur | |

| EP3049639B1 (fr) | Turbine à gaz comportant une conduite de dérivation pour un meilleur nettoyage de conduite de carburant et procédé de nettoyage d'une turbine à gaz | |

| EP2918793A1 (fr) | Concept de réglage pour la production de chauffage à distance dans une centrale à vapeur | |

| EP2655834B1 (fr) | Orifice d'injection pour une centrale thermique à vapeur | |

| EP3643396B1 (fr) | Dispositif de mélange de fluides fonctionnant en continu et respirant du fluide et son procédé de fonctionnement | |

| WO2014048742A2 (fr) | Système de turbines à gaz et à vapeur à dégazeur de flux partiel d'eau d'alimentation | |

| WO2015011006A2 (fr) | Condenseur de turbine pour une turbine à vapeur | |

| DE3919074A1 (de) | Reinstwasserversorgungssystem | |

| WO2013020829A1 (fr) | Station de dérivation de vapeur | |

| EP1784558A1 (fr) | Turbine à vapeur | |

| DE102010007662A1 (de) | Geothermieverteiler | |

| EP2918796A1 (fr) | Centrale à vapeur dotée d'un générateur de vapeur comprenant une armature de maintien de pression à tambour | |

| WO2015135791A1 (fr) | Groupe vapeur équipé d'un conduit de vapeur de fuite de broche | |

| DE102006009558A1 (de) | Speisepumpenantriebsturbine | |

| EP3296506A1 (fr) | Dispositif d'amenée de débit massique supplémentaire dans un débit massique principal | |

| WO2023036570A1 (fr) | Dispositif et procédé pour la recirculation de gaz anodique dans un circuit anodique d'un système de pile à combustible, et système de pile à combustible | |

| DE102021212308A1 (de) | Vorrichtung und Betriebsverfahren zur Rezirkulation von Anodengas in einem Anodenkreis eines Brennstoffzellensystems, Brennstoffzellensystem | |

| WO2023036569A1 (fr) | Dispositif et procédé de recirculation de gaz anodique dans un circuit anodique d'un système de pile à combustible, et système de pile à combustible | |

| EP3109420A1 (fr) | Procédé de refroidissement d'une turbomachine | |

| EP3591175A1 (fr) | Canal d'évacuation d'une turbine à vapeur | |

| EP2737196A1 (fr) | Orifices d'étranglement optimisés en termes de cavitation |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20130722 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| 17Q | First examination report despatched |

Effective date: 20140423 |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F01D 19/00 20060101ALI20150408BHEP Ipc: F28C 3/06 20060101ALI20150408BHEP Ipc: F02C 7/141 20060101AFI20150408BHEP Ipc: F01K 9/04 20060101ALI20150408BHEP Ipc: B01F 5/04 20060101ALI20150408BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20150521 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 758083 Country of ref document: AT Kind code of ref document: T Effective date: 20151115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502012005087 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: SIEMENS SCHWEIZ AG, CH |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20151028 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160128 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160228 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CZ Payment date: 20160208 Year of fee payment: 5 Ref country code: IT Payment date: 20160225 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160129 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160229 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160229 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20160212 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20160502 Year of fee payment: 5 Ref country code: DE Payment date: 20160420 Year of fee payment: 5 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502012005087 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160209 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 |

|

| 26N | No opposition filed |

Effective date: 20160729 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20160209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160209 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502012005087 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170209 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170228 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170228 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20171031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170228 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170209 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 758083 Country of ref document: AT Kind code of ref document: T Effective date: 20170209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170209 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20120209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151028 |