EP2638537B1 - Method and apparatus for joint motion simulation - Google Patents

Method and apparatus for joint motion simulation Download PDFInfo

- Publication number

- EP2638537B1 EP2638537B1 EP11784916.6A EP11784916A EP2638537B1 EP 2638537 B1 EP2638537 B1 EP 2638537B1 EP 11784916 A EP11784916 A EP 11784916A EP 2638537 B1 EP2638537 B1 EP 2638537B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rotation

- actuators

- axis

- mount

- lower mount

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000033001 locomotion Effects 0.000 title claims description 44

- 238000000034 method Methods 0.000 title claims description 10

- 238000004088 simulation Methods 0.000 title description 7

- 238000013519 translation Methods 0.000 claims description 29

- 238000006073 displacement reaction Methods 0.000 claims description 24

- 230000014616 translation Effects 0.000 description 23

- 239000013598 vector Substances 0.000 description 17

- 239000012530 fluid Substances 0.000 description 10

- 238000012360 testing method Methods 0.000 description 8

- 238000013461 design Methods 0.000 description 7

- 238000004458 analytical method Methods 0.000 description 6

- 230000002706 hydrostatic effect Effects 0.000 description 5

- 239000007943 implant Substances 0.000 description 5

- 210000003127 knee Anatomy 0.000 description 5

- 238000005259 measurement Methods 0.000 description 5

- 230000001133 acceleration Effects 0.000 description 4

- 210000004872 soft tissue Anatomy 0.000 description 4

- 239000004698 Polyethylene Substances 0.000 description 3

- -1 polyethylene Polymers 0.000 description 3

- 229920000573 polyethylene Polymers 0.000 description 3

- 241001605719 Appias drusilla Species 0.000 description 2

- 208000037408 Device failure Diseases 0.000 description 2

- 230000005355 Hall effect Effects 0.000 description 2

- 241001227561 Valgus Species 0.000 description 2

- 241000469816 Varus Species 0.000 description 2

- 230000009471 action Effects 0.000 description 2

- 238000013459 approach Methods 0.000 description 2

- 238000004364 calculation method Methods 0.000 description 2

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 238000002955 isolation Methods 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 230000009466 transformation Effects 0.000 description 2

- 210000004027 cell Anatomy 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 238000012937 correction Methods 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000007812 deficiency Effects 0.000 description 1

- 210000000940 dendritic epidermal T lymphocyte Anatomy 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- LMBWSYZSUOEYSN-UHFFFAOYSA-N diethyldithiocarbamic acid Chemical compound CCN(CC)C(S)=S LMBWSYZSUOEYSN-UHFFFAOYSA-N 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000009472 formulation Methods 0.000 description 1

- 208000015181 infectious disease Diseases 0.000 description 1

- 210000000629 knee joint Anatomy 0.000 description 1

- 210000003041 ligament Anatomy 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 230000000399 orthopedic effect Effects 0.000 description 1

- 230000003362 replicative effect Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 210000001519 tissue Anatomy 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/50—Prostheses not implantable in the body

- A61F2/76—Means for assembling, fitting or testing prostheses, e.g. for measuring or balancing, e.g. alignment means

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/46—Special tools or methods for implanting or extracting artificial joints, accessories, bone grafts or substitutes, or particular adaptations therefor

- A61F2/468—Testing instruments for artificial joints

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/50—Prostheses not implantable in the body

- A61F2/68—Operating or control means

- A61F2/70—Operating or control means electrical

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J17/00—Joints

- B25J17/02—Wrist joints

- B25J17/0258—Two-dimensional joints

- B25J17/0266—Two-dimensional joints comprising more than two actuating or connecting rods

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09B—EDUCATIONAL OR DEMONSTRATION APPLIANCES; APPLIANCES FOR TEACHING, OR COMMUNICATING WITH, THE BLIND, DEAF OR MUTE; MODELS; PLANETARIA; GLOBES; MAPS; DIAGRAMS

- G09B23/00—Models for scientific, medical, or mathematical purposes, e.g. full-sized devices for demonstration purposes

- G09B23/28—Models for scientific, medical, or mathematical purposes, e.g. full-sized devices for demonstration purposes for medicine

- G09B23/30—Anatomical models

- G09B23/32—Anatomical models with moving parts

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/02—Prostheses implantable into the body

- A61F2/30—Joints

- A61F2/38—Joints for elbows or knees

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/50—Prostheses not implantable in the body

- A61F2/68—Operating or control means

- A61F2/74—Operating or control means fluid, i.e. hydraulic or pneumatic

- A61F2/741—Operating or control means fluid, i.e. hydraulic or pneumatic using powered actuators, e.g. stepper motors or solenoids

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/50—Prostheses not implantable in the body

- A61F2/68—Operating or control means

- A61F2/70—Operating or control means electrical

- A61F2002/701—Operating or control means electrical operated by electrically controlled means, e.g. solenoids or torque motors

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/50—Prostheses not implantable in the body

- A61F2/68—Operating or control means

- A61F2/70—Operating or control means electrical

- A61F2002/704—Operating or control means electrical computer-controlled, e.g. robotic control

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T74/00—Machine element or mechanism

- Y10T74/20—Control lever and linkage systems

- Y10T74/20207—Multiple controlling elements for single controlled element

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T74/00—Machine element or mechanism

- Y10T74/20—Control lever and linkage systems

- Y10T74/20207—Multiple controlling elements for single controlled element

- Y10T74/20341—Power elements as controlling elements

- Y10T74/20348—Planar surface with orthogonal movement and rotation

Definitions

- Prosthetic implant failure mechanisms are numerous. Among the most prevalent causes of failure are polyethylene wear, loosening, infection, and mal-alignment. Polyethylene wear comprises the largest single identifiable cause of implant failure today. Moreover, polyethylene wear can predispose implants to loosening as a result of increased loading of the reformed tissues. As implant technology evolves, new and more complex modes of wear, damage, and failure are being identified. As a consequence of these facts, there is a great need for rigorous implant life cycle testing in simulator machines that are capable of replicating the subtleties of human motion.

- Simulator machines address the implant longevity problem by providing a non-human environment in which new and existing prosthetic devices are evaluated using accelerated life testing. These machines allow researchers to isolate and study design deficiencies, identify and correct materials problems, and ultimately provide physicians and patients with longer life prosthetic systems. Simulator machines approximate human joint motion. Clearly, the closer the approximations of human joint motion, the more reliable are the results.

- US2007/0051180A1 describes a virtual soft tissue control system that provides enhanced motion control to a prosthetic simulator machine.

- the present invention relates to a joint simulators and methods of driving a prosthetic device to simulate a joint motion as set forth in the claims.

- the present invention provides enhanced motion control to a prosthetic simulator.

- the present invention provides a non-human environment in which to evaluate new and existing prosthetic devices, particularly implantable prosthetic devices, through accelerated life testing.

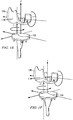

- FIG. 1A illustrates a simulation system 100.

- one element of the joint is mounted into an upper mount 102 and the other element of the joint is mounted to a lower mount (platform) 104.

- the lower mount 104 also referred to herein as the specimen stage or mechanical stage, is controllable with X-Y-Z- ⁇ degrees of freedom.

- FIG. 1B illustrates a prosthetic knee joint, though the system can carry prosthetic elements of any joint.

- the joint elements 106, 108 butt against each other between the two mounts and are separately driven through a programmed motion.

- a prior simulation system is described in the U.S. Patent No. 7,823,460 to Bruce F. White.

- the upper mount was moveable by actuators in the lateral Y direction 35 and was also rotatable 31 about a front to rear axis X with the angle ⁇ .

- the lower platform was moveable in the Z axis 37 and was also rotatable 33 about the vertical Z axis through an angle ⁇ .

- uncontrolled degrees of freedom include translation 39 and rotation 41 of the lower platform.

- the prior simulator includes a multi-axis force/torque transducer 19 mounted beneath a tibial tray 23 of the simulator stage so that the three components of femoral-tibial contact force (and moment) can be monitored.

- Transducer 19 can be a six-channel strain gauge transducer.

- the prior simulator can include one or more position sensors or transducers to measure the relative translational and rotational positions of the femoral 22 and tibial 23 components of the simulator. As shown in FIG. 1B , the position sensor can monitor the flexion/extension angle 31, internal/external (IE) rotation angle 33, anterior/posterior (AP) translation 35, and vertical (compression/distraction) position 37 of the prosthesis.

- the medio-lateral (ML) knee translation 39 and varus valgus rotation 41 can also be monitored.

- the combined motions of the prior simulation system allow for complex relative movement between the two joint elements for wear testing, they are not able to completely simulate the normal biological movement.

- the prior system does not control relative movement along the X axis.

- the rotational axes are fixed; whereas, in the body, the axis of rotation may be displaced from the center and may even move through action of the joint.

- One or more aspects allow for control in each of the X, Y and Z axes as well as rotational movement in the angle ⁇ about a center of rotation that itself can move along the X and Y axes.

- one or more aspects could be similarly applied to that mount to allow for movement of the center of rotation of the angle ⁇ .

- a goal of a joint simulator is to achieve and/or control the right, e.g., anatomically correct, contact kinematics among rigid bodies, e.g., the prosthetic joint elements.

- one or more aspects provide independent programmatic control of the center of rotation in two orthogonal axes without relative translation of the contacting rigid bodies.

- center of rotation and axis of rotation is used interchangeably.

- the term instantaneous center of rotation can apply to a velocity (instant) center of rotation and to an acceleration center of rotation.

- a velocity center of rotation is typically defined relative to a fixed or global reference frame. Take for example a wheel rolling on a planar surface, the surface being fixed relative to the global reference frame. The wheel's motion can be described as a translation in a direction parallel to the planar surface and a contemporaneous rotation about the center of the wheel.

- the acceleration center of rotation is at the center of the wheel while the velocity (instant) center of rotation is at the point of contact with the surface.

- a shaft rotates about a fixed axis, e.g., the center axis of the shaft.

- the velocity center of rotation is the same as the acceleration center of rotation at any given point in time.

- the instantaneous center of rotation of the exemplary shaft is both the velocity (instant) and acceleration center of rotation.

- FIGS. 1C-F illustrate potential motion of joint elements 106, 108 of a prosthetic knee.

- FIGS. 1C and 1D illustrate rotation of the lower tibial element 108 about the normal fixed Z axis of the system.

- FIGS. IE and IF illustrate translation of the center of rotation of the lower tibial element 108, such that the tibial element rotates about an axis Z' other than the normal Z axis of the system.

- the Z' axis is an instant center of rotation.

- the described prior art only allows for the motion of FIGS. 1C-1D , not the motion of FIGS. 1E-1F .

- FIG. 2 illustrates the system of FIG. 1A with the lower cabinet and a hydraulic fluid collection system removed.

- a Z axis actuator 206 which results in vertical movement of the lower platform 104.

- the three X-Y- ⁇ actuators drive the sleeve of the Z axis actuator in the X and Y directions, and also rotate the sleeve through the angle ⁇ about a center of rotation that may be displaced in the X and Y directions.

- FIG. 3 is a view of the three X-Y- ⁇ actuators 208, 210 and 302 as viewed from below.

- each actuator includes a drive piston pinned to the vertical actuator sleeve.

- Each of the actuators 208, 210 and 302 is mounted to the bottom of table top 212.

- actuator 208 is mounted through a support post 304 to the bottom of the table

- actuator 302 is mounted through a support post 306 to the bottom of the table

- actuator 210 is mounted through a support post 308 to the bottom of the table.

- the actuators 208, 210 and 302 are coupled to the support posts via pins 305, 307, and 309, respectively.

- each actuator includes a pinned end 319 and a free end 320.

- the actuators can be connected to hydraulic valve manifold 316 via suitable hydraulic conduits (not shown).

- a controller can drive each actuator by sending a drive signal to the valves of valve manifold 316.

- actuators 208, 210 and 302 are described herein as being hydraulically driven, it will be understood that other types of controllable actuators can be used as the X-Y- ⁇ actuators. In general, three or more independently and interdependently linear or rotary actuators may be used to produce X-Y translation and angular rotation in ⁇ .

- FIG. 4 illustrates further detail of the lower platform actuator assembly.

- Motion diagram 402 shows translation in the x, y, z direction and rotation ⁇ about a center of rotation of lower mount 104.

- the outer sleeve of the vertical actuator 206 is mounted to a hydrostatic bearing plate 408 which butts up against the bottom of the table top 212 and is supported by a plate 318 suspended below the table top.

- bearing plate 408 In each of its upper and lower surfaces, bearing plate 408 includes three oval ports 410, 412 and 414 through which hydraulic fluid is expressed to form the hydrostatic bearing. In this way, the expressed hydraulic fluid can create a hydrostatic film on the upper 409 and lower (not shown) surfaces of bearing plate 408. Hydrostatic fluid is provided to ports 410, 412 and 414 through feed tubes 420.

- the joint element support platform or specimen plate 416 is coupled to the Z axis actuator through an opening (612 in FIG. 6C ) in the table top 212 as will be discussed below.

- Table top 212 can include

- FIG. 5 is a partial cut-away view of the lower platform actuator assembly.

- FIGS. 6A-C are perspective, top, and cross-sectional views, respectively, of the lower platform actuator assembly with actuators 208, 210 and 310 removed for clarity.

- the vertical actuator 206 includes an outer sleeve 502 in which two hydraulically driven pistons 504 and 506 are positioned. Each of the pistons 504, 506 is directly coupled to the specimen platform 416 through a load sensor 508.

- the load sensor 508 senses forces in three orthogonal linear directions and three orthogonal moments about those axes.

- the load sensor 508 can be a six-channel strain gauge transducer, such as transducer 19 described with reference to FIG. 1B .

- the piston 504 is coupled to the transducer plate 512 directly through a pin 510.

- the lower piston 506 is coupled to the same plate 512 through upper guide plate 513 and through three rods 310, 312 and 314 that extend through the sleeve 502 from a ring (lower guide plate) 514 fixed to the lower piston 506.

- a plug 516 is fixed to the sleeve 502 between the pistons 504 and 506. Hydraulic fluid is introduced to the space between the plug 516 and piston 504 through a port 518 at pressure P1. Separately, hydraulic fluid at pressure P2 is introduced to the space between the plug 516 and piston 506 through a port 520. It can be seen then that the hydraulic fluid at pressure P1 presses upwardly against the piston 504 to drive the specimen platform 416 upwardly; whereas, the pressure P2 drives the piston 506 downwardly to move the specimen platform downwardly through the rods 310, 312 and 314. The differential between pressures P1 and P2 determines whether the specimen platform moves upward, downward or not at all, with the pistons moving together through their common connection, the plate 512. Lower piston 506 includes magnets 522 and 524 that magnetically couple to a Hall effect sensor for vertical displacement sensing of the piston assembly and specimen mount.

- vertical actuator 206 is coupled to specimen platform 416 through load sensor 508, the coupling extending through opening 612 in table top 212.

- the positions of actuators 208, 210 and 302 relative to vertical actuator 206 are shown in FIGS. 4 and 5 and, in phantom at 604, 606 and 608 in FIG. 6C .

- the actuators 208, 210 and 302 are displaced vertically along sleeve 502 of vertical actuator 206.

- actuator 302 is coupled to sleeve 502 of vertical actuator 206 through a bracket and a pin 610 that extends along the Z axis.

- actuators 208 and 210 are each coupled to sleeve 502 though a bracket and a pin (see FIGS. 4 and 5 ) at a level corresponding to the location of phantoms 606 and 604, respectively.

- isolation tube 602 attached to table top 212 and surrounding load sensor 508.

- the isolation tube provides a shield against contamination of the lower actuator assembly with fluids and lubricants that can arise from cadaveric testing and wear testing.

- PC board 603 attached to the bottom of sleeve 502 can include control circuitry for Z axis actuator 206, such as for vertical displacement sensing.

- FIG. 7 illustrates detail of one of the three X-Y- ⁇ actuators, it being understood that the three actuators are identical but displaced angularly by 120 degrees and displaced vertically along the sleeve 502 to prevent interference with each other.

- the actuator 210 includes a single piston 704 within an outer cylinder 702.

- the cylinder 702 is pinned at one end to support post 308 through a pin 309 that extends along the Z axis.

- the other end of cylinder 702 is free.

- the cylinder 702 is cut away along a length adjacent to the vertical actuator 206 to expose the piston and enable it to be coupled to the sleeve 502 of the vertical actuator through a bracket 708 and a pin 710 that extends along the Z axis.

- the piston itself is cut away (706) at the bracket 708 to allow for a more compact assembly.

- Hydraulic fluid is applied at distinct pressures through oil ports (fittings) 711 and 713 to oil volumes 712 and 714 at opposite ends of the piston within the cylinder 702.

- the differential pressure volumes cause the piston to move along its axis and apply a force through the pin 710 to the sleeve or cylinder 502 of the Z axis actuator.

- Magnets 716 and 718 are embedded at opposite ends of the piston 704 and are sensed by Hall effect sensors mounted to a bracket 720 on the cylinder 702 for sensing displacement of the piston 704 within cylinder 702.

- length of the actuator e.g., the distance between pin 309 and pin 710, can be sensed.

- a controller can then drive the actuators based on the sensed length or change in length.

- the combined linear movement of the three pistons in linear actuators 208, 210 and 302 results in movement in any X-Y direction and rotation through the angle ⁇ about any center of rotation within an allowable range of the system.

- the sleeve 502 would rotate about a center axis in a counterclockwise direction as viewed in FIG. 7 .

- rotation can be about a different axis and X-Y movement can be imposed.

- the pistons in each of actuators 208 and 302 are driven toward the actuator 210, as no force is applied to piston 210, the Z actuator sleeve 502 and thus the specimen would move in the direction toward the pin 708 of actuator 210.

- control system used in this simulator may be an extension of that disclosed in U.S. Patent application number 12/942,886, by Bruce F. White, filed November 9, 2010 .

- a specific implementation is presented below. With the controller, the center of rotation is controllable and infinitely variable within a range independent of X-Y translations of the mount.

- Inputs to the system of actuators include translations, rotation and constraints. These inputs are:

- Constraint of the axis of rotation is necessary mathematically in order to unambiguously differentiate between rotation and translation.

- a translation may be considered a rotation about an axis at infinity.

- An x translation would be a rotation about an axis at y infinity, where a y translation would be a rotation about an axis at x infinity.

- the usual formulation of a rotational transformation is about the origin (i.e., 0,0).

- the axis of rotation can be chosen to be anywhere within a range of x and y positions - so then it is chosen to be somewhere (constrained) in order to compute the desired extensions (displacement lengths) of each of the actuators.

- the control problem can be considered as two mathematical processes: 1) composition of the actuator drive signals from the input set point signals, and 2) decomposition of the measured position and orientation into components which may be compared to the set point signals, or to the actuator drive signals, to determine the current tracking error.

- the inputs to the system which include the set point x and y positions, the set point angular rotation and the chosen x, y coordinates of the center of rotation, are referred to as the input set point signals.

- the actuator drive signals include the individual signals provided as inputs to each of the control loops that can be used to provide, for example, a valve drive signal for hydraulically driven actuators.

- the valve drive signal differs from the actuator drive signal in that it has been determined from one or more measures of error (e.g., x-y position error) and has been acted on by the control process.

- rotations are taken about the origin.

- rigid body mechanics when the coordinates of a reference frame embedded in the rigid body (at the desired center of rotation) relative to a global coordinate system are known, a rotation can be applied to the rigid body. The body can be translated to the origin using those known coordinates, then rotated, then translated back to the original position (of the center of rotation).

- a single angle and two linear coordinates are sufficient to solve the problem. Since the coordinates of each of the actuator attachment points relative to the embedded coordinate system are known, and given that their initial positions were known relative to a global system, the transformed coordinates of each attachment point may be determined. From these coordinates unique extension lengths of each of the individual actuators may be determined.

- actuator extensions lengths

- these measurements may be used directly for feedback control of the simulator. Otherwise, a global measurement system that determines three parameters for the rigid body may be used. Angle and x, y coordinates of the center of rotation can provide a natural means of providing feedback. These measurements can be treated in much the same manner as the set point signals to determine a set of unique actuator extensions, which can then be used as feedback signals to the control channels.

- the center of rotation can be established from calculated forces and torques, e.g. based on ligaments and joint surfaces.

- the center of rotation may also be based on sensed forces and torques, e.g. forces and torques sensed by a multi-axis sensing element such as load sensor 508 ( FIG. 5 ).

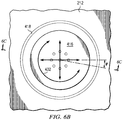

- a joint motion simulator includes a platform, mount or stage 104 designed to permit three degrees of freedom, namely x and y translations and rotation about an arbitrary axis.

- the stage itself can be rigid body constrained to move in a plane by a hydrostatic support system.

- Motion can be imparted to the stage by three actuators, each coupled to the stage at one end of the actuator and coupled to the machine body at the other end, although coupling need not occur at the actuator ends (see e.g., FIG. 3 ).

- the actuators may be coupled to the machine body or the stage with a revolute joint having an axis normal to the plane of motion.

- the actuator 800 is comprised of three linear actuators 801, 802, 803 with lengths d 1 , d 2 and d 3 oriented at corresponding angles ⁇ 1 , ⁇ 2 and ⁇ 3 with respect to the x axis of a global reference frame.

- a global reference frame 804 is defined with origin at O G and a movable reference frame 806, attached to the movable stage or mount 808 is defined with origin at O M .

- the position of O M relative to O G is specified by the position vector r m while the angle of rotation of O M relative to O G is defined as ⁇ .

- the actuators 801, 802, 803 are attached to the machine frame by revolute joints at each of A 1 , A 2 , and A 3 , while similarly attached to a movable stage 808 by revolute joints at points C 1 , C 2 , and C 3 .

- Position vectors r a i and r c i denote the positions of the points A i and C i relative to O G respectively.

- a particular pose or configuration 810 of the stage 808 relative to O G is specified by a pose position vector r p , the orientation angle ⁇ , and a position vector r° defining the axes of rotation relative to O M with the stage in the reference position.

- FIG. 9 illustrates two successive poses 902 and 904 of the stage 808 at times t 0 and t 1 .

- the orientation of the stage at successive time intervals is shown as the angle ⁇ (t 1 ).

- FIG. 10 illustrates the vector r o which can be used to specify the center or axis of rotation relative to the origin of the stage O m .

- the figure illustrates two poses 1002, 1004 of stage 808.

- Pose 1004 represents a rotation about the new center of rotation which has been specified to be repositioned from the origin of the stage O m by an amount r o resulting in a new center of rotation at 'O m .

- 'O m is the translated center of rotation as specified by r o .

- FIG. 10 illustrates that the center of rotation may be programmatically modified by the vector r o .

- the inverse kinematics described below can be used to drive the simulator stage.

- the position or pose of the simulator stage is specified, e.g. the x-y translation, angle of rotation, and position of the center of rotation

- the inverse kinematics can calculate the lengths of the linear actuators to achieve that position or pose.

- the forward kinematics described below can be used to determine the position and/or orientation of the stage, e.g., relative to a global reference frame, given the lengths of the linear actuators.

- the lengths of the actuators may be sensed using displacement sensors.

- a controller can then drive the actuators using feedback control based on the sensed length, based on the position of the stage as determined using forward kinematics, or both.

- the inverse kinematics solution determines the requisite lengths (d 1 , d 2 , d 3 ) of the three actuator elements to achieve a specified actuator pose, where the pose is specified by r p , r o and ⁇ .

- r i c are the positions of each of the revolute joints labeled C 1 , C 2 and C 3 required to produce the desired pose relative to O G

- r o is the position of the rotational axis relative to O M

- r i a are the positions of the revolute joints (the points labeled A 1 , A 2 , and A 3 ) attaching the actuators to the global frame O G

- the position vector r m is the position of O M relative to O G in the reference position and r p is the desired displacement of O M to achieve the desired configuration or pose.

- R cos ⁇ ⁇ ⁇ sin ⁇ ⁇ sin ⁇ ⁇ cos ⁇ ⁇

- the center of rotation position vector r° is subtracted from the position vector r i c for each of the revolute joints before applying the rotational transformation using R.

- the position vectors of the revolute joints are first translated to the origin O M of the stage. Note that it is the addition of the r o term in equation (5) that permits the programmatic control of the axis of rotation of this system. This is a key feature of the control scheme and is not found expressed in any of the cited references.

- Equations (5) and (6) are the inverse kinematic relationships necessary to control the actuator in position control.

- Independent variables (inputs) are the pose as specified by r p , r o and ⁇ .

- the dependent variables (outputs) are d i .

- Constants of machine design are r i a and r i c .

- the solution of the forward kinematics problem determines the current position, r p , and orientation ⁇ of the stage from the lengths, d i , of the three actuators.

- the forward kinematics problem is developed from the vector equations expressed in (5) and the length equations expressed in (6). Expansion of (5) and (6) results in three nonlinear equations which must be solved simultaneously.

- Three points A i are specified relative to the fixed frame O G

- the points C i are specified relative to the moving frame O M

- X and y are the components of the translation of the moving stage and ⁇ is the rotation of the stage.

- L i are the lengths of the extended actuators (d i earlier). The stage is assumed to rotate about O M .

- F i can be considered a dummy variable which is determined by the three equations expressed in equation (8).

- J X ⁇ F 1 ⁇ x ⁇ F 1 ⁇ y ⁇ F 1 ⁇ ⁇ F 2 ⁇ x ⁇ F 2 ⁇ y ⁇ F 2 ⁇ ⁇ F 3 ⁇ x ⁇ F 3 ⁇ y ⁇ F 3 ⁇

- Equations (7), (8), (9) and (10) are used to formulate an iterative solution to the forward kinematics problem using the Newton-Raphson technique.

- the control system 1100 schematically shown in FIG. 11 illustrates one control approach.

- Three time series data inputs or reference waveforms 1101 representing two orthogonal forces Fx and Fy and the perpendicular moment Mz, which characterize the active forces of the musculature acting through one cycle of physiologic motion, are recorded by an instrumented orthopedic implant or determined by analytical means. These signals are input to the system at 1102 and represent the desired control action of the control system and actuator.

- the inputs are summed with one of three feedback signals 1113 at summing junctions 1103.

- the feedback signals 1113 represent forces and moments measured by the multiaxis load cell 1117, which measures the contact forces of the prosthetic device under test.

- summing junctions 1103 are also presented at summing junctions 1103. Both feedback sources 1106 and 1113 are inverted before summing at the summing junction 1103 and therefore the output of the summing junction is an error signal representing the difference between the constraint force and the reference force presented at the system input 1102.

- the error signals are presented to PID control algorithms 1104, which can be tuned to provide the desired control proportional, integral and derivative gain. Typically only proportional gain will be used at 1104.

- the output of the PID blocks 1104 are input to one of three summing junctions 1123 where the signals are summed with the time derivative signals calculated at 1111 from one of three feedback sources 1114.

- Summing junctions 1123 calculate a velocity error signal 1124. If the forces and torques are balanced then the outputs of summing junctions 1103 will be zero and the output of the PID control blocks 1104 will likewise be zero and the inputs to summing junctions 1123 will likewise be zero. This will drive the velocity control loop to zero causing movement to cease when the desired force level has been reached. If force equilibrium has not been reached then there will be some net signal applied to summing junctions 1123, which will cause the system to maintain some velocity and hence continue to seek force equilibrium.

- the velocity error signals 1124 are presented to PI blocks 1107, which serve to integrate the velocity error to produce a displacement (position, orientation) error.

- the requisite displacements X, Y and ⁇ are input to the inverse kinematic solution block 1108, which in turn determines the requisite lengths of each of the three actuators and outputs them to one of three summing junctions 1109. Feedback of the actual length 1115 measured by length sensors in each of the three actuators is inverted and presented to the summing junctions 1109.

- the length error signal determined at the summing junctions 1109 is input into PID control blocks 1110 where proportional, integral and derivative calculations are performed. The signals from these control blocks are converted to analog drive signals and are used to drive the linear actuators of the actuator system stage 1112.

- Each actuator length is measured by a linear displacement transducer 1116 and the three outputs are fed to the forward kinematic solution block 1118.

- the forward kinematic solution block 1118 determines the current position and orientation and outputs the three signals X, Y and ⁇ 1119.

- the three output signals 1119 are routed to the derivative calculation blocks 1111 and to the inputs of the soft tissue constraint model 1122.

- the soft tissue constraint model 1122 utilizes six inputs, three inputs 1120 originating from this control loop and three inputs 1121 originating from measurement of the displacements of the flexion actuator (e.g., flexion 31 in FIG. 1B ) and the vertical position actuator and from measurement of varus valgus rotation (e.g., rotation 41 in FIG. 1B ).

- the soft tissue constraint model 1122 determines the constraint forces that would be supplied by the soft tissue structure and outputs these constraint forces 1106, which are in turn summed with the input drive forces at summing junctions 1103.

- the location of the center of rotation of the actuator is provided at input 1105.

- the center of rotation values are input into the Inverse Kinematics Solution control block 1108.

- FIGS. 12A-H illustrate some of the possible motions of the test machine's actuator stage, e.g. lower mount 104 of FIG. 1A .

- the motions are illustrated by a sequence of poses of the stage that include an initial pose 1202, a final pose 1204a, 1204b, 1204c, 1204d, 1204e, 1204f, 1204g, 1204h, respectively, and three intermediate poses.

- FIGS. 12A and 12B illustrate x and y translations, respectively, while FIG. 12C illustrates combined x-y translation.

- FIG. 12D illustrates combined x-y translation coupled with a rotation about the center of the stage.

- FIG. 12E illustrates pure rotation about the center of the stage (0,0), the center of the stage being an instant center of rotation

- FIGS. 12F-H illustrate respective rotations about each of the vertices of the stage.

- the upper left vertex of the stage (pose 1202) is an instant center of rotation.

- the upper right vertex is an instant center of rotation, while in FIG. 12H , it is the lower vertex. Note that the center of rotation is freely programmable and is not limited to the several examples given in the figures.

- the actuators need not be hydraulic or linear and need not drive the sleeve of a Z actuator.

- the actuators could be pneumatic, electric, or powered by any other means.

Landscapes

- Health & Medical Sciences (AREA)

- Engineering & Computer Science (AREA)

- General Health & Medical Sciences (AREA)

- Transplantation (AREA)

- Life Sciences & Earth Sciences (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Vascular Medicine (AREA)

- Oral & Maxillofacial Surgery (AREA)

- Animal Behavior & Ethology (AREA)

- Cardiology (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Orthopedic Medicine & Surgery (AREA)

- General Physics & Mathematics (AREA)

- Physics & Mathematics (AREA)

- Medical Informatics (AREA)

- Pure & Applied Mathematics (AREA)

- Chemical & Material Sciences (AREA)

- Algebra (AREA)

- Computational Mathematics (AREA)

- Physical Education & Sports Medicine (AREA)

- Mathematical Analysis (AREA)

- Mathematical Optimization (AREA)

- Mathematical Physics (AREA)

- Medicinal Chemistry (AREA)

- Business, Economics & Management (AREA)

- Educational Administration (AREA)

- Educational Technology (AREA)

- Theoretical Computer Science (AREA)

- Robotics (AREA)

- Mechanical Engineering (AREA)

- Prostheses (AREA)

- Instructional Devices (AREA)

- Manipulator (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US41387310P | 2010-11-15 | 2010-11-15 | |

| PCT/US2011/060599 WO2012068015A2 (en) | 2010-11-15 | 2011-11-14 | Method and apparatus for joint motion simulation |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2638537A2 EP2638537A2 (en) | 2013-09-18 |

| EP2638537B1 true EP2638537B1 (en) | 2020-01-15 |

Family

ID=44993963

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP11784916.6A Active EP2638537B1 (en) | 2010-11-15 | 2011-11-14 | Method and apparatus for joint motion simulation |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US9351857B2 (ja) |

| EP (1) | EP2638537B1 (ja) |

| JP (1) | JP5981931B2 (ja) |

| CN (1) | CN103503050B (ja) |

| BR (1) | BR112013011963B1 (ja) |

| WO (1) | WO2012068015A2 (ja) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11136234B2 (en) | 2007-08-15 | 2021-10-05 | Bright Cloud International Corporation | Rehabilitation systems and methods |

| US20090131225A1 (en) * | 2007-08-15 | 2009-05-21 | Burdea Grigore C | Rehabilitation systems and methods |

| CN103503050B (zh) | 2010-11-15 | 2017-03-15 | 先进机械技术公司 | 用于关节运动模拟的方法和设备 |

| US9642725B2 (en) * | 2011-11-14 | 2017-05-09 | Advanced Mechanical Technology, Inc. | System and method for joint testing |

| ITUD20120011A1 (it) * | 2012-01-30 | 2013-07-31 | Diego Minen | Apparato per la simulazione della conduzione di un veicolo terrestre |

| US9865180B2 (en) | 2013-06-21 | 2018-01-09 | Val-Chum, Limited Partnership | Heart phantom assembly |

| US10531968B2 (en) * | 2014-05-23 | 2020-01-14 | Joseph Coggins | Prosthetic limb test apparatus and method |

| CN104146777B (zh) * | 2014-08-20 | 2016-08-24 | 范存义 | 一种简易肘关节生物力学实验装置 |

| CN104721016B (zh) * | 2015-03-25 | 2017-03-01 | 北京航空航天大学 | 一种用于下肢康复机器人的3ups并联变胞机构 |

| CN104706453B (zh) * | 2015-03-25 | 2016-09-21 | 北京航空航天大学 | 一种可在3urs和2rrs/urs两种构型之间转换的下肢康复机器人机构 |

| WO2016195363A1 (ko) * | 2015-06-01 | 2016-12-08 | 고려대학교 산학협력단 | 의료영상장비 내에서 구동 가능한 관절 시뮬레이터 |

| CN105699224B (zh) * | 2016-04-08 | 2018-07-06 | 浙江大学城市学院 | 腰椎疲劳试验机 |

| CN106625572A (zh) * | 2016-09-30 | 2017-05-10 | 华南理工大学 | 基于摆动气缸驱动的并联三自由度机构装置和控制方法 |

| CN107036897B (zh) * | 2016-10-12 | 2019-10-11 | 上海大学 | 一种用于髌骨关节生物力学性能测试的实验装置 |

| US11525941B2 (en) * | 2018-03-28 | 2022-12-13 | Halliburton Energy Services, Inc. | In-situ calibration of borehole gravimeters |

| CN113397531B (zh) * | 2021-06-25 | 2022-10-21 | 北京航空航天大学 | 基于机器人结构的人工膝关节耐久性测试装置及方法 |

| CN114112337B (zh) * | 2021-10-22 | 2024-07-02 | 武汉奥绿新生物科技股份有限公司 | 一种模拟膝关节伸直时生物力学的装置及加载方法 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20070051180A1 (en) * | 2005-08-12 | 2007-03-08 | White Bruce F | Prosthetic simulator with soft tissue modeling |

Family Cites Families (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4235025A (en) * | 1979-07-26 | 1980-11-25 | General Motors Corporation | Knee joint for anthropomorphic dummy |

| US5014719A (en) | 1984-02-02 | 1991-05-14 | Mcleod Paul C | Knee loading and testing apparatus and method |

| AT393954B (de) | 1990-02-28 | 1992-01-10 | Bock Orthopaed Ind | Verfahren und vorrichtung zur bestimmung von gebrauchseigenschaften eines prothesenschaftes |

| DE4232602C2 (de) * | 1992-09-29 | 1995-01-12 | Bock Orthopaed Ind | Gelenk in orthopädischen Prothesen und Orthesen |

| US6223604B1 (en) * | 1998-01-23 | 2001-05-01 | Wisconsin Alumni Research Foundation | Mobile truss testing apparatus |

| US6673117B1 (en) * | 2000-11-30 | 2004-01-06 | Adam Soss | Single axis knee joint assembly |

| DE10130485C2 (de) * | 2001-06-25 | 2003-06-26 | Robert Riener | Programmierbarer Gelenksimulator |

| WO2003004223A2 (en) * | 2001-07-05 | 2003-01-16 | Microdexterity Systems, Inc. | Parallel manipulator |

| GB0300703D0 (en) * | 2003-01-13 | 2003-02-12 | Browne Wilkinson Oliver | Orthopaedic skeletal demonstration aid |

| US6865954B2 (en) * | 2003-03-10 | 2005-03-15 | Spinecore, Inc. | Joint simulator testing machine |

| ES2331007T3 (es) * | 2004-09-08 | 2009-12-18 | Synthes Gmbh | Protesis de disco intervertebral de aplicacion universal. |

| US7361192B2 (en) * | 2005-04-22 | 2008-04-22 | Doty Keith L | Spinal disc prosthesis and methods of use |

| US8156824B2 (en) * | 2006-01-13 | 2012-04-17 | Mts Systems Corporation | Mechanism arrangement for orthopedic simulator |

| JP4992076B2 (ja) | 2006-03-31 | 2012-08-08 | 国立大学法人佐賀大学 | 股関節運動シミュレータ |

| US7597017B2 (en) * | 2006-07-21 | 2009-10-06 | Victhom Human Bionics, Inc. | Human locomotion simulator |

| US8020503B2 (en) * | 2006-07-31 | 2011-09-20 | Edwards Lifesciences Corporation | Automated surgical implant sewing system and method |

| US20080257057A1 (en) * | 2006-09-29 | 2008-10-23 | Habeger Jason A | Device for fatigue testing an implantable medical device |

| CZ2008238A3 (cs) * | 2008-04-17 | 2009-07-22 | Vysoké ucení technické v Brne | Zarízení pro mechanické zkoušení funkcních segmentu lidského tela |

| EP2306436B1 (en) * | 2008-05-06 | 2016-11-09 | Simbionix Ltd. | Articulated knee for arthroscopy simulation |

| US8480752B2 (en) * | 2008-06-30 | 2013-07-09 | DePuy Synthes Products, LLC | Tibial bearing having increased axial-rotation |

| US8187335B2 (en) * | 2008-06-30 | 2012-05-29 | Depuy Products, Inc. | Posterior stabilized orthopaedic knee prosthesis having controlled condylar curvature |

| AU2010314879B2 (en) | 2009-11-09 | 2014-07-17 | Advanced Mechanical Technology, Inc. | System and method for joint motion simulation |

| CN103503050B (zh) | 2010-11-15 | 2017-03-15 | 先进机械技术公司 | 用于关节运动模拟的方法和设备 |

| FR2977649B1 (fr) * | 2011-07-08 | 2013-08-02 | Thales Sa | Actionneur lineaire |

-

2011

- 2011-11-14 CN CN201180065019.9A patent/CN103503050B/zh active Active

- 2011-11-14 JP JP2013538973A patent/JP5981931B2/ja active Active

- 2011-11-14 WO PCT/US2011/060599 patent/WO2012068015A2/en active Application Filing

- 2011-11-14 US US13/295,610 patent/US9351857B2/en active Active

- 2011-11-14 EP EP11784916.6A patent/EP2638537B1/en active Active

- 2011-11-14 BR BR112013011963-2A patent/BR112013011963B1/pt active IP Right Grant

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20070051180A1 (en) * | 2005-08-12 | 2007-03-08 | White Bruce F | Prosthetic simulator with soft tissue modeling |

Non-Patent Citations (1)

| Title |

|---|

| ATUL RAVINDRA JOSHI: "DESIGN AND CONTROL OF A THREE DEGREE-OF-FREEDOM PLANAR PARALLEL ROBOT", 31 August 2003 (2003-08-31), XP055277012, Retrieved from the Internet <URL:https://etd.ohiolink.edu/rws_etd/document/get/ohiou1175180058/inline> [retrieved on 20160601] * |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2014506333A (ja) | 2014-03-13 |

| CN103503050B (zh) | 2017-03-15 |

| BR112013011963B1 (pt) | 2021-05-18 |

| US20120123592A1 (en) | 2012-05-17 |

| CN103503050A (zh) | 2014-01-08 |

| BR112013011963A2 (pt) | 2020-08-04 |

| WO2012068015A3 (en) | 2012-07-26 |

| EP2638537A2 (en) | 2013-09-18 |

| WO2012068015A2 (en) | 2012-05-24 |

| JP5981931B2 (ja) | 2016-08-31 |

| US9351857B2 (en) | 2016-05-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2638537B1 (en) | Method and apparatus for joint motion simulation | |

| EP3714448B1 (en) | Impactor mechanism for virtual reality surgery simulation system and telesurgery | |

| Fujie et al. | Forces and moments in six-DOF at the human knee joint: mathematical description for control | |

| Stokes et al. | Measurement of a spinal motion segment stiffness matrix | |

| Fujie et al. | The use of a universal force-moment sensor to determine in-situ forces in ligaments: a new methodology | |

| US7895899B2 (en) | Multi-axis, programmable spine testing system | |

| Chen et al. | The three-dimensional kinematics and flexibility characteristics of the human ankle and subtalar joint—Part II: flexibility characteristics | |

| AU2010314879B2 (en) | System and method for joint motion simulation | |

| Sposito et al. | Exoskeleton kinematic design robustness: An assessment method to account for human variability | |

| JP2002286608A (ja) | 人工関節摩擦摩耗試験機 | |

| Essomba et al. | Kinematic analysis and design of a six-degrees of freedom 3-RRPS mechanism for bone reduction surgery | |

| Zheng et al. | Dynamic modeling and experimental study of hybrid compliant mechanism stretching trapezoidal membrane | |

| Green et al. | A reconfigurable multiplanar in vitro simulator for real-time absolute motion with external and Musculotendon forces | |

| Funabashi et al. | Quantification of loading in biomechanical testing: the influence of dissection sequence | |

| Hosseinabadi et al. | Multi-axis force sensing in laparoscopic surgery | |

| Nayak et al. | Development and multisite assessment of a novel shoulder motion joint simulator | |

| De Coninck et al. | Computational modeling of a dynamic knee simulator | |

| Forlani | A new test rig for in-vitro evaluation of the knee joint behaviour | |

| BOTTINI | Ground reaction forces estimation using IMU-based kinematics and OpenSim Moco | |

| Herrmann | Dynamic testing of total hip and knee replacements under physiological conditions | |

| Fontanieri | Bandwidth-optimized force platform for a multiaxial shaker | |

| Singh et al. | Model-Based Force Control of a Fluidic-Muscle Driven Parallel Platform | |

| Lanovaz et al. | Experimental validation of a 3D dynamic finite-element model of a total knee replacement | |

| Moissenet et al. | Validation of a Redundant Robotic Manipulator for Shoulder in Vitro Biomechanical Testing. | |

| Rosvold | An Instrumented Spatial Linkage to Measure In-Vivo Kinematics and Motion Reproduction with a Robotic Test System |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20130611 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20160609 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 602011064649 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: G09B0023320000 Ipc: A61F0002760000 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: A61F 2/76 20060101AFI20190905BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20191004 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| GRAR | Information related to intention to grant a patent recorded |

Free format text: ORIGINAL CODE: EPIDOSNIGR71 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| INTC | Intention to grant announced (deleted) | ||

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| INTG | Intention to grant announced |

Effective date: 20191210 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602011064649 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1224507 Country of ref document: AT Kind code of ref document: T Effective date: 20200215 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200607 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200515 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200416 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602011064649 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 1224507 Country of ref document: AT Kind code of ref document: T Effective date: 20200115 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20201016 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201114 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20201130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20230919 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20240926 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240923 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20240926 Year of fee payment: 14 |