EP2458213A1 - Hermetic compressor - Google Patents

Hermetic compressor Download PDFInfo

- Publication number

- EP2458213A1 EP2458213A1 EP10752711A EP10752711A EP2458213A1 EP 2458213 A1 EP2458213 A1 EP 2458213A1 EP 10752711 A EP10752711 A EP 10752711A EP 10752711 A EP10752711 A EP 10752711A EP 2458213 A1 EP2458213 A1 EP 2458213A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pump

- free end

- compressor

- shaft

- oil

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000005086 pumping Methods 0.000 description 12

- 238000005057 refrigeration Methods 0.000 description 5

- 238000005119 centrifugation Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 230000003028 elevating effect Effects 0.000 description 2

- 230000037361 pathway Effects 0.000 description 2

- 230000001737 promoting effect Effects 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 239000011230 binding agent Substances 0.000 description 1

- 230000002860 competitive effect Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000005265 energy consumption Methods 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 230000004907 flux Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 230000001050 lubricating effect Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 238000009877 rendering Methods 0.000 description 1

- 238000004513 sizing Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B39/00—Component parts, details, or accessories, of pumps or pumping systems specially adapted for elastic fluids, not otherwise provided for in, or of interest apart from, groups F04B25/00 - F04B37/00

- F04B39/02—Lubrication

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B39/00—Component parts, details, or accessories, of pumps or pumping systems specially adapted for elastic fluids, not otherwise provided for in, or of interest apart from, groups F04B25/00 - F04B37/00

- F04B39/02—Lubrication

- F04B39/0223—Lubrication characterised by the compressor type

- F04B39/023—Hermetic compressors

- F04B39/0238—Hermetic compressors with oil distribution channels

- F04B39/0246—Hermetic compressors with oil distribution channels in the rotating shaft

- F04B39/0253—Hermetic compressors with oil distribution channels in the rotating shaft using centrifugal force for transporting the oil

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B53/00—Component parts, details or accessories not provided for in, or of interest apart from, groups F04B1/00 - F04B23/00 or F04B39/00 - F04B47/00

- F04B53/18—Lubricating

Definitions

- the present invention refers to a hermetic compressor and, more specifically, to a hermetic compressor comprising a centrifugal pump to provide oil for the moving parts of said compressor.

- a compressor has the function of elevating the pressure of a certain volume of fluid to a pressure that is required to carry out a determined work.

- the Refrigeration Industry commonly utilizes hermetic compressors comprising, in general, a sealed shell which defines, in its interior, an oil reservoir and an oil pump device that is responsible for leading the oil of the reservoir to the moving parts of the compressor.

- a difficulty that results from the reduction of operational rotation is the pumping of the oil. Pumps normally used in those compressors are based on the centrifugal effect to lead the oil towards the parts to be lubricated. Those pumps are widely used due to its low cost and high reliability. Other alternatives with different principles can make the pumping in low rotation speeds possible, but the cost and the reliability are not competitive.

- the prior art oil pumps comprise an oil intake tube having an oil input.

- the intake stage depends on the centrifugal effect, wherein the pump rotation speed forces the oil that goes into the orifice against the walls of the tube, promoting the increase in pressure, and, consequently, its elevation.

- the pumping energy that is necessary for lubricating, is obtained from the rotation and from the diameter of the pump.

- a lower rotation is defined for the compressor to achieve a better performance of the same, which is applied to the refrigeration system, such rotation tends to be as low as possible, wherein the oil pump is the main limiting factor to decrease the rotation.

- the diameter of the oil input orifice the upsetting height (i.e. height between the suction point of the pump and the highest elevation point of the oil) and the radius or diameter of the pump.

- the diameter of the input orifice of the pump creates a pressure equalization region, rendering such region inactive.

- the increase in pressure, which is resulted from the centrifugation, only occurs in regions having a higher diameter than the one of the input orifice.

- an input orifice having a very big diameter will prejudice the performance of the pump in low rotation speeds.

- the radius or diameter of the pump in the oil output region i.e., in the region of the input orifice of the first bearing of the compressor

- the radius or diameter of the pump in the oil output region is fundamental to the efficiency of the pump. This is due to the fact that the path followed by the oil through the shaft interior up to such output orifice shall consider the parabolic form acquired by the oil from its centrifugation, wherein no protuberance can intercept such parabola (if an interception occurs, the flux of oil will be simply interrupted).

- the design of the pump has an important role in the performance of the compressor, further considering the need of a pump that is suitable for a compressor operating at a reduced rotation.

- one of the objectives of the invention is the provision of an efficient oil pump for being utilized with a hermetic compressor having a variable speed driver.

- Another objective of the present invention is the provision of an oil pump designed to efficiently actuate in a compressor operating at a reduced rotation.

- a hermetic compressor comprising a shell which involves the component parts of a compressor, an oil reservoir in the inferior part of the shell, a cylinder block that incorporates a bearing to support a vertical shaft on which a rotor is assembled, and a centrifugal pump that leads the oil to the moving parts of the compressor, wherein said vertical shaft extends axially from the rotor to form a free end in its inferior portion, the free end being sized to be received in a corresponding end of the centrifugal pump, and at least one portion of the inner sidewall of the end of the pump and at least one portion of the outer sidewall portion of the shaft assuming a juxtaposed condition after the reception.

- the free end of the vertical shaft extends axially, and only enough, to enable the attachment of the end of the pump, wherein, in a preferred embodiment, the free end of such vertical shaft extends up to a maximum of 6 mm.

- the free end presents a machined portion having a reduced external diameter in order to facilitate the assembly of the end of the pump.

- the assembly between the free end of the shaft and the corresponding end of the pump is preferably effectuated by interference fit, but alternative means, such as binding, would be equally used.

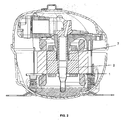

- FIGS 1 and 2 illustrate compressors comprising pumping solutions that are already in the prior art.

- the oil pump (1) is inserted in the rotor of the engine (2).

- the pump (1) has an end (3) plunged in the oil (4) disposed in a reservoir of the shell (5) and another end (6) inserted in the rotor (2).

- This configuration creates a free pathway for the oil, but restricts the region that is available for attaching the shaft (7) and the pump.

- the shaft (7) is continuous up to the superior end (6) of the pump.

- the pump (1) is inserted in the shaft (7), wherein said shaft (7) extends up to the end of the rotor (2).

- This configuration improves the region that is available for attaching the shaft (7), but the diameter of the oil passage is affected to enable the insertion of the pump in the shaft.

- the present invention discloses a pumping solution capable of guaranteeing a suitable diameter for passing the oil, an optimization of the upsetting height, and a simplified assembly means for the oil pump.

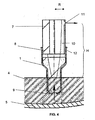

- the shaft (7) extends slightly from the rotor (2), leaving a free end (8) to enable the assembly of the centrifugal pump (1).

- the free end (8) has only a necessary extension for enabling the assembly of the pump (1). This is due to the need of non-extending too far the shaft (8), what would result in an unnecessary use of the material, elevating, therefore, the final cost of the compressor. Thus, in a preferred embodiment of the present invention, the extension of the free end is limited to 6 mm.

- one end of the pump (1) is plunged in the oil (4), wherein such end further comprises an input orifice (9) in its more extreme portion.

- the other end (12) of the pump (1) is sized to be connected with the free end (8) of the shaft (7), wherein the outer side wall of the shaft and the inner side wall of the pump are arranged in a juxtaposed condition after fitting.

- one part of the free end of the shaft (7) is machined to reduce its external diameter, wherein such machined part is reserved for receiving the end of the pump to be assembled.

- the assembly of the pump (1) on the free end (8) of the shaft (7) is carried out by interference fit, not being necessary the use of binders or adhesives.

- the assembly of the pump (1) on the free end (8) of the shaft (7) is carried out by means of binding.

- the centrifugal power causes the elevation of oil in the inner side wall of both pump and shaft in a parabolic configuration, as shown by number (10) in figure 4 .

- the pumping energy shall be sufficient so as the upsetting height reaches the output orifice where the first bearing is disposed, as shown by number (11) in such figure.

- the correct sizing of the parabolic column up to a height H depends on guaranteeing a sufficient radius R.

- the assembly of the pump (1) in an external position in relation to both shaft and rotor guarantees a suitable upsetting height, wherein the input orifice is naturally disposed closer to the shaft.

- the configuration for assembling the pump of the present invention achieves, by means of a simple and economic construction, a pumping solution that is efficient at providing a compressor operating at low rotation.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Compressor (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| BRPI0902430-1A BRPI0902430A2 (pt) | 2009-07-24 | 2009-07-24 | compressor hermético |

| PCT/BR2010/000257 WO2011009186A1 (pt) | 2009-07-24 | 2010-07-26 | Compressor hermético |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP2458213A1 true EP2458213A1 (en) | 2012-05-30 |

Family

ID=43063437

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10752711A Withdrawn EP2458213A1 (en) | 2009-07-24 | 2010-07-26 | Hermetic compressor |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US20120189437A1 (enExample) |

| EP (1) | EP2458213A1 (enExample) |

| JP (1) | JP2013500415A (enExample) |

| KR (1) | KR20120034759A (enExample) |

| CN (1) | CN102483052A (enExample) |

| BR (1) | BRPI0902430A2 (enExample) |

| IN (1) | IN2012DN00706A (enExample) |

| MX (1) | MX2012001053A (enExample) |

| SG (1) | SG177748A1 (enExample) |

| WO (1) | WO2011009186A1 (enExample) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT15828U1 (de) * | 2016-12-27 | 2018-07-15 | Secop Gmbh | Schmiermittelaufnahme für einen kältemittelkompressor und kältemittelkompressor |

| AT15924U1 (de) * | 2017-04-28 | 2018-09-15 | Secop Gmbh | Kältemittelverdichter |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3285504A (en) * | 1964-12-10 | 1966-11-15 | Gen Motors Corp | Refrigerant apparatus |

| US4488855A (en) * | 1982-12-27 | 1984-12-18 | The Trane Company | Main bearing lubrication system for scroll machine |

| IT1159578B (it) * | 1983-05-03 | 1987-03-04 | Aspera Spa | Albero a gomito per compressori ermetici di frigoriferi e simili |

| US4518323A (en) * | 1983-07-25 | 1985-05-21 | Copeland Corporation | Hermetic refrigeration compressor |

| JPS60166784A (ja) * | 1984-02-10 | 1985-08-30 | Mitsubishi Electric Corp | スクロ−ル圧縮機 |

| JPS61155666A (ja) * | 1984-12-27 | 1986-07-15 | Matsushita Refrig Co | 冷媒圧縮機 |

| KR870002381A (ko) * | 1985-08-23 | 1987-03-31 | 미다 가쓰시게 | 스크로울 압축기 |

| JPH0647991B2 (ja) * | 1986-05-15 | 1994-06-22 | 三菱電機株式会社 | スクロ−ル圧縮機 |

| JPH0735790B2 (ja) * | 1986-06-23 | 1995-04-19 | 株式会社日立製作所 | スクロ−ル圧縮機 |

| US5219281A (en) * | 1986-08-22 | 1993-06-15 | Copeland Corporation | Fluid compressor with liquid separating baffle overlying the inlet port |

| GB2202905B (en) * | 1987-03-12 | 1991-07-24 | Matsushita Electric Industrial Co Ltd | Scroll compressor |

| JPS63223374A (ja) * | 1987-03-12 | 1988-09-16 | Matsushita Electric Ind Co Ltd | 電動圧縮機 |

| JPH04140491A (ja) * | 1990-09-28 | 1992-05-14 | Sanyo Electric Co Ltd | 密閉型電動圧縮機 |

| CN1063831C (zh) * | 1994-04-04 | 2001-03-28 | 巴西船用压缩机有限公司 | 用于变速密封压缩机的油泵 |

| DE10106234C2 (de) * | 2001-02-10 | 2002-12-12 | Danfoss Compressors Gmbh | Kolbenverdichter |

| JP2005140066A (ja) * | 2003-11-10 | 2005-06-02 | Hitachi Ltd | 流体圧縮機 |

| SI1957796T1 (sl) * | 2005-11-28 | 2010-09-30 | Arcelik As | Kompresor |

-

2009

- 2009-07-24 BR BRPI0902430-1A patent/BRPI0902430A2/pt not_active IP Right Cessation

-

2010

- 2010-07-26 CN CN2010800375873A patent/CN102483052A/zh active Pending

- 2010-07-26 SG SG2012005237A patent/SG177748A1/en unknown

- 2010-07-26 KR KR1020127002084A patent/KR20120034759A/ko not_active Withdrawn

- 2010-07-26 MX MX2012001053A patent/MX2012001053A/es not_active Application Discontinuation

- 2010-07-26 IN IN706DEN2012 patent/IN2012DN00706A/en unknown

- 2010-07-26 US US13/386,829 patent/US20120189437A1/en not_active Abandoned

- 2010-07-26 JP JP2012520867A patent/JP2013500415A/ja active Pending

- 2010-07-26 WO PCT/BR2010/000257 patent/WO2011009186A1/pt not_active Ceased

- 2010-07-26 EP EP10752711A patent/EP2458213A1/en not_active Withdrawn

Non-Patent Citations (1)

| Title |

|---|

| See references of WO2011009186A1 * |

Also Published As

| Publication number | Publication date |

|---|---|

| SG177748A1 (en) | 2012-03-29 |

| BRPI0902430A2 (pt) | 2011-04-05 |

| JP2013500415A (ja) | 2013-01-07 |

| US20120189437A1 (en) | 2012-07-26 |

| CN102483052A (zh) | 2012-05-30 |

| IN2012DN00706A (enExample) | 2015-06-19 |

| WO2011009186A1 (pt) | 2011-01-27 |

| MX2012001053A (es) | 2012-03-14 |

| KR20120034759A (ko) | 2012-04-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1325796C (zh) | 密闭型电动压缩机 | |

| EP1985860A2 (en) | Rotary compressor | |

| CN202370792U (zh) | 一种应用于制冷压缩机的曲轴 | |

| EP3214312A1 (en) | Two-cylinder hermetic compressor | |

| US8978826B2 (en) | Compressor | |

| EP3214263A1 (en) | Two-cylinder hermetic compressor | |

| EP3409949A1 (en) | Rotary compressor having two cylinders | |

| CN104074764A (zh) | 旋转压缩机 | |

| EP2458213A1 (en) | Hermetic compressor | |

| CN104819155B (zh) | 用于旋转式压缩机的曲轴、旋转式压缩机及制冷循环装置 | |

| US9841024B2 (en) | Compressor and method for producing compressor | |

| EP3922854A1 (en) | Rotary compressor, method for manufacturing rotary compressor, and refrigeration cycle device | |

| CN204627989U (zh) | 用于旋转式压缩机的曲轴、旋转式压缩机及制冷循环装置 | |

| CN208816288U (zh) | 曲轴及变频压缩机 | |

| EP2918773B1 (en) | Rotary compressor | |

| US10859076B2 (en) | Compressor | |

| US20040234386A1 (en) | Discharge muffler having an internal pressure relief valve | |

| CN102439313A (zh) | 压缩机,特别是将二氧化碳作为冷却剂的径向活塞压缩机 | |

| CN205977618U (zh) | 一种压缩机机架及使用该机架的压缩机 | |

| US20200158100A1 (en) | Refrigerant compressor | |

| CN109185154B (zh) | 泵体组件及压缩机 | |

| KR101646044B1 (ko) | 밀폐형 압축기 및 이것을 이용한 냉장고 | |

| CN107387419B (zh) | 控油组件、泵和旋转式压缩机 | |

| CN219101593U (zh) | 曲轴导油组件以及压缩机 | |

| US20240418158A1 (en) | Reciprocating compressor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20120124 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20141211 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20150422 |