EP2445659B1 - Method and device for processing a slab - Google Patents

Method and device for processing a slab Download PDFInfo

- Publication number

- EP2445659B1 EP2445659B1 EP09777913.6A EP09777913A EP2445659B1 EP 2445659 B1 EP2445659 B1 EP 2445659B1 EP 09777913 A EP09777913 A EP 09777913A EP 2445659 B1 EP2445659 B1 EP 2445659B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- slab

- location

- lateral force

- exertion

- furnace

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B39/00—Arrangements for moving, supporting, or positioning work, or controlling its movement, combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills

- B21B39/14—Guiding, positioning or aligning work

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B1/00—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations

- B21B1/46—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations for rolling metal immediately subsequent to continuous casting

- B21B1/466—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations for rolling metal immediately subsequent to continuous casting in a non-continuous process, i.e. the cast being cut before rolling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B13/00—Metal-rolling stands, i.e. an assembly composed of a stand frame, rolls, and accessories

- B21B13/06—Metal-rolling stands, i.e. an assembly composed of a stand frame, rolls, and accessories with axes of rolls arranged vertically, e.g. edgers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B15/00—Arrangements for performing additional metal-working operations specially combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills

- B21B15/0007—Cutting or shearing the product

- B21B2015/0014—Cutting or shearing the product transversely to the rolling direction

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B45/00—Devices for surface or other treatment of work, specially combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills

- B21B45/004—Heating the product

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B45/00—Devices for surface or other treatment of work, specially combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills

- B21B45/04—Devices for surface or other treatment of work, specially combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills for de-scaling, e.g. by brushing

- B21B45/06—Devices for surface or other treatment of work, specially combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills for de-scaling, e.g. by brushing of strip material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B45/00—Devices for surface or other treatment of work, specially combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills

- B21B45/04—Devices for surface or other treatment of work, specially combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills for de-scaling, e.g. by brushing

- B21B45/08—Devices for surface or other treatment of work, specially combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills for de-scaling, e.g. by brushing hydraulically

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/45—Scale remover or preventor

- Y10T29/4517—Rolling deformation or deflection

Definitions

- the invention relates to a method for processing a slab in a device having at least one furnace, at least one downstream of the furnace in the conveying direction of the slab processing device and one of the at least one processing device in the conveying direction of the slab rolling train, wherein means are provided with which a force can be exerted on the sides of the slab to move the axis of the slab in accordance with a predetermined position transverse to the conveying direction of the slab, in particular in accordance with the axis of the rolling train. Furthermore, the invention relates to a device for processing a slab.

- the DE 43 10 547 C2 also discloses a solution for centering a slab, but also here several and long rulers are used, which in this case come before the finishing train for the above reason out of the question. A similar solution goes out of the JP 63101004 A out.

- the present invention has for its object to provide a method of the type mentioned above and a corresponding device, with which it is possible with simple means just before the rolling mill, especially in front of the finishing line to center the slab exactly and to lead and in particular to allow a secure upsetting over the entire slab length. Furthermore, a problem-free rolling at the top and at the end of the slab should be ensured.

- the rolling process should thus be optimized by accurately introducing the slab into the rolling train. In particular, it is provided to realize the centering and guiding the slab just before the finishing mill so that no appreciable extension of the distance between the furnace and the finishing train is created.

- the solution of this object by the invention is procedurally characterized in that first means for exerting a lateral force on the slab at a first location act on the slab and that second means for exerting a lateral force on the slab at a second location on the slab act, wherein the second location in the conveying direction of the slab is spaced from the first location, wherein the first location is behind the furnace and wherein the second location in front of, inside or behind the at least one processing device.

- a more specific embodiment of the invention provides that the first location is behind the furnace and before the first of the at least one processing device, and that the second location lies within or behind the first of the at least one processing device.

- Rolling in the rolling train may be finish rolling the slab into a belt.

- a reliable mode of operation can be ensured if the position of the head of the slab in the region of at least one of the means is detected and the exertion of a lateral force on the slab by the delivery of a Contact element of the agent is started only when the head of the slab has passed the means.

- the slab can be subjected to a compression in the direction transverse to the conveying direction.

- the exertion of a lateral force on the slab by the means before the location of the compression and spaced therefrom takes place.

- the exertion of a lateral force on the slab by the means preferably takes place in front of the rolling train.

- the means for exerting a lateral force on the slab are preferably operated so that the tip of the slab runs centrally into the place of compression and / or into the rolling train.

- At least two means for exerting a lateral force on the slab may be disposed behind the furnace, the first location between the furnace and the first processing device and the second location between the at least two processing devices or within the second processing device. In this case, it has proven useful if the slab is subjected to a shearing process in the first processing device. In the second processing apparatus, the slab is preferably subjected to a descaling process.

- a further development provides that the position and / or the shape of the slab are determined transversely to the conveying direction of the slab along its movement in the conveying direction before the first location.

- the exertion of a lateral force on the slab from the means can be carried out in a controlled or regulated manner such that the axis of the slab in the conveying direction behind the second location assumes a desired position.

- the adjustment of the means for exerting a lateral force on the slab may be determined using a mathematical model depending on the geometry of the device and / or the shape of the slab and / or the eccentricity of the slab and / or the width of the slab.

- the device for processing a slab which has at least one furnace, at least one downstream of the furnace in the conveying direction of the slab processing device and one of the at least one processing device in the conveying direction of the slab downstream rolling train, in particular a finishing train, as well as means with which on the sides of the Slab can be exerted a force to move the axis of the slab in accordance with a predetermined position transverse to the conveying direction of the slab, in particular in accordance with the axis of the rolling mill, according to the invention provides that first means for exerting a lateral force on the Slabs are arranged at a first location and that second means for exerting a lateral force on the slab at a second location, the second location in the conveying direction of the slab being spaced from the first location, wherein the first location is behind the oven and wherein the second place before, pauses is located halfway or behind the at least one processing device.

- the first location is behind the oven and before the at least one processing device and that the second location is within or behind the first of the at least one processing device.

- the area within the furnace is preferably free of means for exerting a lateral force on the slab.

- a stuffer can be arranged for upsetting the slab in the direction transverse to the conveying direction.

- Side guide rulers for centering and guiding the slab may be arranged between the upshot and the first rolling stand of the rolling train. Furthermore, adjusting elements of the side guide rulers can be arranged below and / or above the side guide rulers.

- the means for exerting a lateral force on the slab may be spaced from the upset. They can also be arranged in front of the rolling train.

- a refinement provides that at least two means for exerting a lateral force are arranged on the slab behind the furnace, the first location being between the furnace and the first processing device and the second location lying between the at least two processing devices or within the second processing device.

- the first processing device is preferably a pair of scissors.

- the second processing device is preferably a descaling device.

- the means for exerting a lateral force on the slab may comprise at least one roller which is arranged on a pivot arm, wherein the swivel arm is mounted fixed at a bearing point and can be pivoted by an actuator which acts outside of the bearing point on the swivel arm.

- the means for exerting a lateral force on the slab can also comprise at least one roller, which is arranged on a linear actuator whose direction of movement is oriented transversely to the conveying direction of the slab.

- a training provides that the actuator or the linear actuator is designed as a hydraulic piston-cylinder system.

- the first means for exerting a lateral force on the slab can also be designed as guide rulers.

- the proposed device is preferably part of a thin slab casting rolling mill. It may also be part of a hot strip mill having a roughing and finishing line; In this case, the device is preferably arranged in front of the finishing train.

- the invention is based on the fact that a centering and guiding the slab just before the finishing train with roller side guides done so that a total of short distance between the furnace and finishing mill.

- the roller side guides are housed between the individual units (processing devices) at a suitable distance.

- an upshot and a mechanical or hydraulic side guide are preferably arranged in front of the first rolling stand of the finishing train.

- the proposed solution is preferably used in the so-called CSP technology. This is understood to mean the manufacture of a steel strip in a thin-slab caster rolling mill, which enables efficient production of hot strip.

- the proposed measures can increase the output and reduce the number of Kokillenver einen.

- a direct width control in front of the finishing train is made possible.

- the tape is improved.

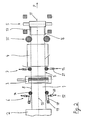

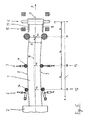

- FIGS. 1 and 2 is a device to see with a slab 1 can be processed in their promotion in the conveying direction F. Specifically, an end portion of a furnace 2 is shown and the first rolling stand of a rolling line 5, between which the slab 1 is conveyed. Between the furnace 2 and the rolling train 5, a first processing device 3 in the form of a pair of scissors and a second processing device 4 in the form of a descaling device are arranged.

- roller side guides which are equipped with contact elements in the form of rollers 14 which are against the sides of the 8th and 9 of the slab 1 can be pressed to center the slab so that the axis 10 of the slab 1 coincides with the axis 11 of the rolling train 5.

- the first means 6 for exerting a lateral force on the slab 1 at a first location 12 act on the slab 1 and that the second means 7 for exerting a lateral force on the slab 1 at a second location 13 on the slab 1 act.

- the second location 13 in the conveying direction F of the slab 1 is spaced from the first location 12;

- the first location 12 is behind the furnace 2 and before the first processing device 3, wherein the second location 13 is located inside or behind the first processing device 3 - in the embodiment between the two processing devices 3 and 4.

- the two means 6 and 7 thus provide for a centering of the slab, so that it enters centrally into a stuffer 15, which is arranged immediately in front of the first rolling stand of the finishing train 5. Between edger 15 and the first rolling stand of the finishing train 5 side guide rulers 16 and 17 are further arranged, which further center the slab 1.

- the means 6, 7 may have a pivot arm 18 which is mounted in a fixed bearing point 19 and carries at its end remote from the bearing point 19 end of the roller 14.

- An actuator 20 engages the pivot arm 18 and provides for the corresponding adjustment of the roller 14 against the side 8, 9 of the slab.

- the means 6, 7 may also comprise a linear actuator 21 which delivers the roller 14 directly linearly against the belt edge.

- the threading into the stuffer 15 is by driving rollers 22 (s. Fig. 1 ), which are integrated into the descaling device 4, at least until the stuffer 15 or the first stand of the finishing train 5 have taken supported.

- the second roller side guide pair 7, ie the second means for exerting a lateral force on the slab, can be arranged before the descaling device as shown, integrated within the Entzundingsvoriques or disposed behind the descaling device.

- a drive of the rollers 14 of the means 6 and 7 are provided.

- the second roller side guide 7 can be set in a straight guide in the width direction (see embodiment at the second location 13 in FIG Fig. 2 ) or via a swivel arm (as at the first location 12 in FIG Fig. 2 ).

- roller side guide roller instead of a larger roller side guide roller is in an alternative embodiment (not shown), the arrangement of two smaller close together arranged double roles in a leadership unit possible, but always so that is still given the short design. With the two roller side guides 6 and 7, which are spaced apart, the effect of a long continuous side guide is achieved. The roller side guides 6, 7 thereby form a control unit.

- the optimal positioning of the roller side guides 6, 7 is somewhat more complicated. It is then made a detection of the slab shape and the position over the slab length. For this purpose, laser distance measurements or other position detection signals are provided, for example, in front of the last oven part (behind the ferry), as shown in FIG Fig. 4 is illustrated for the detection and determination of the slab shape and position over the length. Also entered here is the eccentricity ⁇ y of the slab from the axis of the system.

- the width, position or generally the shape of the slab determines the length.

- the form and eccentricity ⁇ y i determined here are later used for optimum positioning of the roller side guides 6, 7 and / or the rollers of the stuffer 15.

- slab width and slab position detection behind the oven is also possible from the sides by means of the sensors 24 or from above or below.

- the positions of the rollers 14 and the rollers of the upshot 15 (X1, Y1, X2, Y2, X3, Y3 relative to the slab center) can be approached become.

- the positions are adapted when passing through the slab tip from the furnace 2 to the first stand of the finishing train 5 to the respective slab shape and partially moved so that the goal is achieved to guide the slab tip in the center of the edger 15.

- the rollers of the stuffer 15 can be asymmetrical, ie off-center, to support the roller side guides 6, 7.

- the goal is to center or center the roller side guides 6, 7 and the upshot 15 over the length of the slab, so that the slab 1 and in particular the slab end is as straight as possible is and thus enters the mill 5.

- the rollers of the upset 15 are fed in symmetrically (short stroke control) in order to avoid or reduce the excess width at the end of the slab. The same goes for the slab head.

- the width or position detection can take place via the displacement transmitters of the roller side guides and / or compression rollers. Furthermore, the detected width signal as well as the calculated spread or width change in the finishing train in the width model are used to determine the amount of compression and thus to control the stuffer.

- Niedefialte- or clamping rollers are provided, which are located exactly between the two compression rollers and press from the top and bottom in the middle of the slab 1 on the slab surface to prevent bulging.

- the compression rollers are lubricated. This increases the material crossflow, reduces the compression and buckling forces and also has a positive effect on the slab and compression roll roughness and thus on the life of the edging rolls.

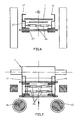

- a special mechanical side guide between the stuffer 15 and the first stand of the rolling train 5 is additionally provided (s. Fig. 1 and 2 ). Details on this go from the FIGS. 6 and 7 out.

- the aim is to arrange the stuffer 15 close to the first stand of the rolling train 5 and to position the mechanical side guide as close as possible to the first nip of the first stand.

- an adjustment of the mechanical side guides, d. h of the side guide rulers 16 and 17 can be performed without additional space and without weakening the stand posts of the rolling stand (with recesses therein), an adjustment below (or optionally also above) the side guide ruler 16, 17 is provided as advantageous 6 and 7 results.

- the adjustment of the side guide rulers 16, 17 is carried out together with the upsetting 15 employment. In this case, upseters and guide rulers would be firmly connected.

- the adjustment of the side guide rulers 16, 17 on a guide 27 is performed by two adjusting elements 26 (cylinders) per side.

- the adjusting elements 26 are provided at the top with a heat protection element 25 (cooled transfer table, insulation board).

- the position of the mechanical lateral guide during operation corresponds to the width position of the upshot 15 plus a defined amount (in millimeters).

- the described method and the apparatus shown are not limited to a CSP plant, but are also used in similar production plants behind a furnace part.

- the proposal according to the invention can also be used for example in conventional hot strip mills.

- the Vorbandform is detected behind a roughing stand during transport direction finishing mill and there met with suitable employment of roles before the finishing road the above objectives.

- the first centering effect in front of the shears can alternatively be carried out by guide rulers as an alternative to the use of the roller side guide unit 6.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Metal Rolling (AREA)

- Heat Treatments In General, Especially Conveying And Cooling (AREA)

Description

Die Erfindung betrifft ein Verfahren zum Bearbeiten einer Bramme in einer Vorrichtung, die zumindest einen Ofen, mindestens eine dem Ofen in Förderrichtung der Bramme nachgeordnete Bearbeitungsvorrichtung und eine der mindestens einen Bearbeitungsvorrichtung in Förderrichtung der Bramme nachgeordnete Walzstraße aufweist, wobei Mittel vorhanden sind, mit denen auf die Seiten der Bramme eine Kraft ausgeübt werden kann, um die Achse der Bramme in Übereinstimmung mit einer vorgegebenen Lage quer zur Förderrichtung der Bramme, insbesondere in Übereinstimmung mit der Achse der Walzstraße, zu bewegen. Des Weiteren betrifft die Erfindung eine Vorrichtung zum Bearbeigen einer Bramme.The invention relates to a method for processing a slab in a device having at least one furnace, at least one downstream of the furnace in the conveying direction of the slab processing device and one of the at least one processing device in the conveying direction of the slab rolling train, wherein means are provided with which a force can be exerted on the sides of the slab to move the axis of the slab in accordance with a predetermined position transverse to the conveying direction of the slab, in particular in accordance with the axis of the rolling train. Furthermore, the invention relates to a device for processing a slab.

Bei der Herstellung eines Bandes aus einer Bramme, beispielsweise einer Dünnbramme, wird diese in eine Förderrichtung durch die Bearbeitungsanlage transportiert. Während des Transports der Dünnbramme durch einen Tunnelofen (Rollenherdofen) kann die Bramme seitlich verlaufen. Das anschließende Einfädeln in die Fertigstraße wird durch diesen Versatz schwieriger. Vor der Fertigwalzstraße ist häufig ein Staucher vorgesehen. Ferner sind Seitenführungen in der Regel dafür angeordnet, die Bramme zur Achse der Walzstraße zu leiten. Der Staucher bzw. die mechanischen Führungen müssen deshalb am Kopf weit offen stehen und werden zumeist erst nach dem sicheren Einfädeln in das erste Horizontalgerüst der Fertigstraße auf eine engere Führungsstellung eingestellt. Wegen der ungünstigen Bedingungen bzw. wegen des Risikos, dass Brammen am Staucher stecken bleiben, wird der Staucher am Kopf der Bramme nicht genutzt. Ein spätes Zufahren des Stauchers und ein später Beginn des Stauchprozesses würden zu unterschiedlichen Breiten über der Bandlänge führen.When producing a strip from a slab, for example a thin slab, it is transported in a conveying direction through the processing system. During transport of the thin slab through a tunnel furnace (roller hearth furnace), the slab can run laterally. Subsequent threading into the finishing train becomes more difficult due to this offset. Before the finishing train a stuffer is often provided. Furthermore, side guides are typically arranged to direct the slab to the axis of the rolling train. The stuffer or the mechanical guides must therefore be wide open at the head and are usually adjusted to a narrower guide position only after the safe threading in the first horizontal stand of the finishing train. Because of the unfavorable conditions or because of the risk that slabs get stuck on the stuffer, the stuffer at the top of the slab is not used. A late approach of the stuffer and a late start of the upsetting process would lead to different widths over the strip length.

Um die Mittigkeit der Bramme beim Verlassen des Ofens zu verbessern, offenbart die

Günstig hinsichtlich der Zentrierung der Bramme wäre es, vor der Fertigstraße ein langes Führungslineal anzuordnen, wie es bei Vorgerüsten bekannt ist. Eine solche Lösung ist aus der

Die

Der vorliegenden Erfindung liegt die Aufgabe zugrunde, ein Verfahren der eingangs genannten Art und eine entsprechende Vorrichtung vorzuschlagen, mit dem bzw. mit der es möglich wird, mit einfachen Mitteln kurz vor der Walzstraße, insbesondere vor der Fertigstraße, die Bramme genau zu zentrieren und zu führen und insbesondere ein sicheres Stauchen über die gesamte Brammenlänge zu ermöglichen. Ferner soll ein problemfreies Walzen am Kopf und am Ende der Bramme sichergestellt werden. Der Walzvorgang soll somit durch genaues Einführen der Bramme in die Walzstraße optimiert werden. Insbesondere ist vorgesehen, die Zentrierung und die Führung der Bramme kurz vor der Fertigstraße so zu realisieren, dass keine nennenswerte Verlängerung des Abstandes zwischen Ofen und Fertigstraße entsteht.The present invention has for its object to provide a method of the type mentioned above and a corresponding device, with which it is possible with simple means just before the rolling mill, especially in front of the finishing line to center the slab exactly and to lead and in particular to allow a secure upsetting over the entire slab length. Furthermore, a problem-free rolling at the top and at the end of the slab should be ensured. The rolling process should thus be optimized by accurately introducing the slab into the rolling train. In particular, it is provided to realize the centering and guiding the slab just before the finishing mill so that no appreciable extension of the distance between the furnace and the finishing train is created.

Die Lösung dieser Aufgabe durch die Erfindung ist verfahrenstechnisch dadurch gekennzeichnet, dass erste Mittel zur Ausübung einer seitlichen Kraft auf die Bramme an einem ersten Ort auf die Bramme wirken und dass zweite Mittel zur Ausübung einer seitlichen Kraft auf die Bramme an einem zweiten Ort auf die Bramme wirken, wobei der zweite Ort in Förderrichtung der Bramme beabstandet vom ersten Ort liegt, wobei der erste Ort hinter dem Ofen liegt und wobei der zweite Ort vor, innerhalb oder hinter der mindestens einen Bearbeitungsvorrichtung liegt.The solution of this object by the invention is procedurally characterized in that first means for exerting a lateral force on the slab at a first location act on the slab and that second means for exerting a lateral force on the slab at a second location on the slab act, wherein the second location in the conveying direction of the slab is spaced from the first location, wherein the first location is behind the furnace and wherein the second location in front of, inside or behind the at least one processing device.

Eine speziellere Ausführungsform der Erfindung sieht vor, dass der erste Ort hinter dem Ofen und vor der ersten der mindestens einen Bearbeitungsvorrichtung liegt und dass der zweite Ort innerhalb oder hinter der ersten der mindestens einen Bearbeitungsvorrichtung liegt.A more specific embodiment of the invention provides that the first location is behind the furnace and before the first of the at least one processing device, and that the second location lies within or behind the first of the at least one processing device.

Das Walzen in der Walzstraße kann ein Fertigwalzen der Bramme zu einem Band sein.Rolling in the rolling train may be finish rolling the slab into a belt.

Eine zuverlässige Betriebsweise kann sichergestellt werden, wenn die Position des Kopfs der Bramme im Bereich mindestens eines der Mittel detektiert wird und die Ausübung einer seitlichen Kraft auf die Bramme durch Zustellung eines Kontaktelements des Mittels erst gestartet wird, wenn der Kopf der Bramme das Mittel passiert hat.A reliable mode of operation can be ensured if the position of the head of the slab in the region of at least one of the means is detected and the exertion of a lateral force on the slab by the delivery of a Contact element of the agent is started only when the head of the slab has passed the means.

Unmittelbar vor der Walzstraße kann die Bramme einer Stauchung in Richtung quer zur Förderrichtung unterzogen werden. In diesem Fall ist bevorzugt vorgesehen, dass die Ausübung einer seitlichen Kraft auf die Bramme durch die Mittel vor dem Ort der Stauchung und von diesem beabstandet erfolgt.Immediately before the rolling mill, the slab can be subjected to a compression in the direction transverse to the conveying direction. In this case, it is preferably provided that the exertion of a lateral force on the slab by the means before the location of the compression and spaced therefrom takes place.

Es kann also gesagt werden, dass bevorzugt vorgesehen ist, dass das erste Mittel zur Ausübung einer seitlichen Kraft auf die Bramme hinter dem Ofen und das zweite Mittel zur Ausübung einer seitlichen Kraft auf die Bramme beabstandet hierzu vor dem Staucher angeordnet ist.It can therefore be said that it is preferably provided that the first means for exerting a lateral force on the slab behind the furnace and the second means for exerting a lateral force on the slab spaced therefrom before the stuffer is arranged.

Die Ausübung einer seitlichen Kraft auf die Bramme durch die Mittel erfolgt bevorzugt vor der Walzstraße.The exertion of a lateral force on the slab by the means preferably takes place in front of the rolling train.

Die Mittel zur Ausübung einer seitlichen Kraft auf die Bramme werden bevorzugt so betrieben, dass die Spitze der Bramme zentrisch in den Ort der Stauchung und/oder in die Walzstraße einläuft.The means for exerting a lateral force on the slab are preferably operated so that the tip of the slab runs centrally into the place of compression and / or into the rolling train.

Mindestens zwei Mittel zur Ausübung einer seitlichen Kraft auf die Bramme können hinter dem Ofen angeordnet sein, wobei der erste Ort zwischen Ofen und erster Bearbeitungsvorrichtung und der zweite Ort zwischen den mindestens zwei Bearbeitungsvorrichtungen oder innerhalb der zweiten Bearbeitungsvorrichtung liegt. In diesem Falle hat es sich bewährt, wenn in der ersten Bearbeitungsvorrichtung die Bramme einem Schervorgang unterzogen wird. In der zweiten Bearbeitungsvorrichtung wird die Bramme bevorzugt einem Entzunderungsvorgang unterzogen.At least two means for exerting a lateral force on the slab may be disposed behind the furnace, the first location between the furnace and the first processing device and the second location between the at least two processing devices or within the second processing device. In this case, it has proven useful if the slab is subjected to a shearing process in the first processing device. In the second processing apparatus, the slab is preferably subjected to a descaling process.

Eine Weiterbildung sieht vor, dass die Lage und/oder die Form der Bramme quer zur Förderrichtung der Bramme entlang ihrer Bewegung in Förderrichtung vor dem ersten Ort ermittelt werden.A further development provides that the position and / or the shape of the slab are determined transversely to the conveying direction of the slab along its movement in the conveying direction before the first location.

Die Ausübung einer seitlichen Kraft auf die Bramme von den Mitteln kann dabei so in gesteuerter oder geregelter Weise erfolgen, dass die Achse der Bramme in Förderrichtung hinter dem zweiten Ort eine gewünschte Position einnimmt.The exertion of a lateral force on the slab from the means can be carried out in a controlled or regulated manner such that the axis of the slab in the conveying direction behind the second location assumes a desired position.

Die Einstellung der Mittel zur Ausübung einer seitlichen Kraft auf die Bramme kann in Abhängigkeit der Geometrie der Vorrichtung und/oder der ermittelten Form der Bramme und/oder der Außermittigkeit der Bramme und/oder der Breite der Bramme unter Nutzung eines Rechenmodells ermittelt werden.The adjustment of the means for exerting a lateral force on the slab may be determined using a mathematical model depending on the geometry of the device and / or the shape of the slab and / or the eccentricity of the slab and / or the width of the slab.

Die Vorrichtung zum Bearbeiten einer Bramme, die zumindest einen Ofen, mindestens eine dem Ofen in Förderrichtung der Bramme nachgeordnete Bearbeitungsvorrichtung und eine der mindestens einen Bearbeitungsvorrichtung in Förderrichtung der Bramme nachgeordnete Walzstraße, insbesondere eine Fertigwalzstraße, aufweist, sowie Mittel, mit denen auf die Seiten der Bramme eine Kraft ausgeübt werden kann, um die Achse der Bramme in Übereinstimmung mit einer vorgegebenen Lage quer zur Förderrichtung der Bramme, insbesondere in Übereinstimmung mit der Achse der Walzstraße, zu bewegen, sieht erfindungsgemäß vor, dass erste Mittel zur Ausübung einer seitlichen Kraft auf die Bramme an einem ersten Ort angeordnet sind und dass zweite Mittel zur Ausübung einer seitlichen Kraft auf die Bramme an einem zweiten Ort angeordnet sind, wobei der zweite Ort in Förderrichtung der Bramme beabstandet vom ersten Ort liegt, wobei der erste Ort hinter dem Ofen liegt und wobei der zweite Ort vor, innerhalb oder hinter der mindestens einen Bearbeitungsvorrichtung liegt.The device for processing a slab, which has at least one furnace, at least one downstream of the furnace in the conveying direction of the slab processing device and one of the at least one processing device in the conveying direction of the slab downstream rolling train, in particular a finishing train, as well as means with which on the sides of the Slab can be exerted a force to move the axis of the slab in accordance with a predetermined position transverse to the conveying direction of the slab, in particular in accordance with the axis of the rolling mill, according to the invention provides that first means for exerting a lateral force on the Slabs are arranged at a first location and that second means for exerting a lateral force on the slab at a second location, the second location in the conveying direction of the slab being spaced from the first location, wherein the first location is behind the oven and wherein the second place before, pauses is located halfway or behind the at least one processing device.

Bevorzugt ist dabei vorgesehen, dass der erste Ort hinter dem Ofen und vor der mindestens einen Bearbeitungsvorrichtung liegt und dass der zweite Ort innerhalb oder hinter der ersten der mindestens einen Bearbeitungsvorrichtung liegt.It is preferably provided that the first location is behind the oven and before the at least one processing device and that the second location is within or behind the first of the at least one processing device.

Der Bereich innerhalb des Ofens ist dabei bevorzugt frei von Mitteln zur Ausübung einer seitlichen Kraft auf die Bramme.The area within the furnace is preferably free of means for exerting a lateral force on the slab.

Unmittelbar vor der Walzstraße kann ein Staucher zum Stauchen der Bramme in Richtung quer zur Förderrichtung angeordnet sein.Immediately before the rolling train, a stuffer can be arranged for upsetting the slab in the direction transverse to the conveying direction.

Zwischen dem Staucher und dem ersten Walzgerüst der Walzstraße können Seitenführungslineale zum Zentrieren und Führen der Bramme angeordnet sein. Weiterhin können Verstellelemente der Seitenführungslineale unterhalb und/oder oberhalb der Seitenführungslineale angeordnet sein.Side guide rulers for centering and guiding the slab may be arranged between the upshot and the first rolling stand of the rolling train. Furthermore, adjusting elements of the side guide rulers can be arranged below and / or above the side guide rulers.

Die Mittel zur Ausübung einer seitlichen Kraft auf die Bramme können von dem Staucher beabstandet angeordnet sein. Sie können auch vor der Walzstraße angeordnet sein.The means for exerting a lateral force on the slab may be spaced from the upset. They can also be arranged in front of the rolling train.

Eine Fortbildung sieht vor, dass mindestens zwei Mittel zur Ausübung einer seitlichen Kraft auf die Bramme hinter dem Ofen angeordnet sind, wobei der erste Ort zwischen Ofen und erster Bearbeitungsvorrichtung und der zweite Ort zwischen den mindestens zwei Bearbeitungsvorrichtungen oder innerhalb der zweiten Bearbeitungsvorrichtung liegt. Die erste Bearbeitungsvorrichtung ist dabei bevorzugt eine Schere. Die zweite Bearbeitungsvorrichtung ist vorzugsweise eine Entzunderungsvorrichtung.A refinement provides that at least two means for exerting a lateral force are arranged on the slab behind the furnace, the first location being between the furnace and the first processing device and the second location lying between the at least two processing devices or within the second processing device. The first processing device is preferably a pair of scissors. The second processing device is preferably a descaling device.

Die Mittel zur Ausübung einer seitlichen Kraft auf die Bramme können mindestens eine Rolle umfassen, die an einem Schwenkarm angeordnet ist, wobei der Schwenkarm an einem Lagerpunkt ortsfest gelagert ist und von einem Aktuator geschwenkt werden kann, der außerhalb des Lagerpunkts am Schwenkarm angreift.The means for exerting a lateral force on the slab may comprise at least one roller which is arranged on a pivot arm, wherein the swivel arm is mounted fixed at a bearing point and can be pivoted by an actuator which acts outside of the bearing point on the swivel arm.

Die Mittel zur Ausübung einer seitlichen Kraft auf die Bramme können auch mindestens eine Rolle umfassen, die an einem Linearaktuator angeordnet ist, dessen Bewegungsrichtung quer zur Förderrichtung der Bramme ausgerichtet ist.The means for exerting a lateral force on the slab can also comprise at least one roller, which is arranged on a linear actuator whose direction of movement is oriented transversely to the conveying direction of the slab.

In beiden Fällen sieht eine Fortbildung vor, dass der Aktuator bzw. der Linearaktuator als hydraulisches Kolben-Zylinder-System ausgebildet ist.In both cases, a training provides that the actuator or the linear actuator is designed as a hydraulic piston-cylinder system.

Die ersten Mittel zur Ausübung einer seitlichen Kraft auf die Bramme können auch als Führungslineale ausgeführt sein.The first means for exerting a lateral force on the slab can also be designed as guide rulers.

Die vorgeschlagene Vorrichtung ist bevorzugt Bestandteil einer Dünnbrammen-Gießwalzanlage. Sie kann auch Bestandteil einer Warmbandstraße sein, die eine Vor- und eine Fertigstraße aufweist; in diesem Falle ist die Vorrichtung bevorzugt vor der Fertigstraße angeordnet.The proposed device is preferably part of a thin slab casting rolling mill. It may also be part of a hot strip mill having a roughing and finishing line; In this case, the device is preferably arranged in front of the finishing train.

Die Erfindung stellt also darauf ab, dass eine Zentrierung und Führung der Bramme kurz vor der Fertigstraße mit Rollenseitenführungen so erfolgt, dass eine insgesamt kurze Wegstrecke zwischen Ofen und Fertigstraße liegt. Die Rollenseitenführungen sind zwischen den einzelnen Aggregaten (Bearbeitungsvorrichtungen) in einem geeigneten Abstand untergebracht. Zusätzlich sind bevorzugt ein Staucher und eine mechanische oder hydraulische Seitenführung vor dem ersten Walzgerüst der Fertigstraße angeordnet.Thus, the invention is based on the fact that a centering and guiding the slab just before the finishing train with roller side guides done so that a total of short distance between the furnace and finishing mill. The roller side guides are housed between the individual units (processing devices) at a suitable distance. In addition, an upshot and a mechanical or hydraulic side guide are preferably arranged in front of the first rolling stand of the finishing train.

Die vorgeschlagene Lösung kommt bevorzugt bei der sogenannten CSP-Technologie zum Einsatz. Darunter ist das Fertigen eines Stahlbandes in einer Dünnbrammen-Gießwalzanlage zu verstehen, die eine effiziente Produktion von Warmband ermöglicht.The proposed solution is preferably used in the so-called CSP technology. This is understood to mean the manufacture of a steel strip in a thin-slab caster rolling mill, which enables efficient production of hot strip.

Durch die vorgeschlagenen Maßnahmen können unter anderem die Ausbringung gesteigert und die Anzahl der Kokillenverstellungen reduziert werden. Eine direkte Breitenbeeinflussung vor der Fertigstraße wird ermöglicht. Weiterhin wird der Bandlauf verbessert.Among other things, the proposed measures can increase the output and reduce the number of Kokillenverstellungen. A direct width control in front of the finishing train is made possible. Furthermore, the tape is improved.

In der Zeichnung sind Ausführungsbeispiele der Erfindung dargestellt. Es zeigen:

- Fig. 1

- schematisch die Seitenansicht einer Vorrichtung zum Bearbeiten und Führen einer Bramme zwischen einem nur teilweise dargestellten Ofen und dem ersten Walzgerüst einer Fertigwalzstraße,

- Fig. 2

- schematisch die zu

Fig. 1 zugehörige Draufsicht, - Fig. 3

- schematisch eine Darstellung der zum Einsatz kommenden Brammenführungselemente analog zur Darstellung gemäß

Fig. 2 in der Draufsicht auf die Vorrichtung, - Fig. 4

- eine zu

Fig. 3 ähnliche Darstellung, wobei hier ein größerer Abschnitt des Ofens dargestellt ist, - Fig. 5

- nochmals schematisch eine Darstellung der zum Einsatz kommenden Brammenführungselemente analog zur Darstellung gemäß

Fig. 2 und3 in der Draufsicht auf die Vorrichtung bei stärker gekrümmter Bramme, - Fig. 6

- die Vorderansicht - gesehen in Förderrichtung der Bramme - und

- Fig. 7

- die Draufsicht auf den in

Fig. 6 dargestellten Bereich der Vorrichtung unmittelbar vor dem ersten Walzgerüst der Fertigstraße.

- Fig. 1

- 1 is a schematic side view of an apparatus for processing and guiding a slab between an only partially shown furnace and the first rolling stand of a finishing train;

- Fig. 2

- schematic to the

Fig. 1 associated plan view, - Fig. 3

- schematically a representation of the used slab guide elements analogous to the representation according to

Fig. 2 in the plan view of the device, - Fig. 4

- one too

Fig. 3 similar representation, wherein here a larger portion of the furnace is shown, - Fig. 5

- again schematically a representation of the used slab guide elements analogous to the representation according to

Fig. 2 and3 in the plan view of the device with a more curved slab, - Fig. 6

- the front view - seen in the conveying direction of the slab - and

- Fig. 7

- the top view of the in

Fig. 6 shown area of the device immediately before the first rolling stand of the finishing train.

In den

Wesentlich ist, dass die ersten Mittel 6 zur Ausübung einer seitlichen Kraft auf die Bramme 1 an einem ersten Ort 12 auf die Bramme 1 wirken und dass die zweiten Mittel 7 zur Ausübung einer seitlichen Kraft auf die Bramme 1 an einem zweiten Ort 13 auf die Bramme 1 wirken. Dabei liegt der zweite Ort 13 in Förderrichtung F der Bramme 1 beabstandet vom ersten Ort 12; ferner liegt der erste Ort 12 hinter dem Ofen 2 und vor der ersten Bearbeitungsvorrichtung 3, wobei der zweite Ort 13 innerhalb oder hinter der ersten Bearbeitungsvorrichtung 3 liegt - im Ausführungsbeispiel zwischen den beiden Bearbeitungsvorrichtungen 3 und 4.It is essential that the

Die beiden Mittel 6 und 7 sorgen also für eine Zentrierung der Bramme, so dass diese zentrisch in einen Staucher 15 einläuft, der unmittelbar vor dem ersten Walzgerüst der Fertigstraße 5 angeordnet ist. Zwischen Staucher 15 und erstem Walzgerüst der Fertigstraße 5 sind weiterhin Seitenführungslineale 16 und 17 angeordnet, die die Bramme 1 weiter zentrieren.The two means 6 and 7 thus provide for a centering of the slab, so that it enters centrally into a

Wie in

Zum Verfahrensablauf sei folgendes erläutert:

- Beim

Transport der Bramme 1aus dem Ofen 2 inRichtung Fertigstraße 5 steht zunächst die ersteRollenseitenführung 6, also das erste Mittel zur Ausübung einer seitlichen Kraft auf die Bramme, auf Überbreite. Nachdem die Brammenspitze dieRollen 14 passiert hat (erfasst durch Heißmetalldetektoren oder durch eine Wegverfolgung), werden dieRollen 14 langsam gegen dieSeiten Zentrierung der Bramme 1 und dieMitnahme der Rollen 14. Dieser Zentriervorgang wird langsam und bei kontinuierlich vorwärts transportierter Bramme durchgeführt. Bei bewegter Bramme ist eine leichte Querverschiebung der Bramme 1 bei niedrigen Verschiebekräften ausführbar. Der Zentriervorgang sollte vor Erreichen des zweiten Rollenseitenführungspaars 7, d. h. der zweiten Mittel zur Ausübung einer seitlichen Kraft auf die Bramme, abgeschlossen sein. Passiert die Brammenspitze die zweite Rollenseitenführung, so findet dort der gleiche Zentriervorgang statt.Stehen beide Rollen 14 zentrisch, so ist mit hoher Wahrscheinlichkeit ein mittiges Einlaufen der Bramme inden Staucher 15 und indie Fertigstraße 5 gegeben.

- When transporting the

slab 1 out of thefurnace 2 in the direction of the finishingtrain 5, the firstroller side guide 6, that is to say the first means for exercising, is initially present a lateral force on the slab, on excess width. After the slab tip has passed the rollers 14 (detected by hot metal detectors or by tracking), therollers 14 are slowly driven against thesides slab 1 and the entrainment of therollers 14. This centering is carried out slowly and continuously transported forward slab. When the slab is moving, a slight transverse displacement of theslab 1 is possible at low displacement forces. The centering should be completed before reaching thesecond Rollenseitenführungspaars 7, ie the second means for exerting a lateral force on the slab. If the slab tip passes the second roller side guide, then the same centering procedure takes place there. If bothrollers 14 are centered, it is highly probable that the slab enters thestuffer 15 and the finishingtrain 5 centrally.

Das Einfädeln in den Staucher 15 wird durch Treibrollen 22 (s.

Das zweite Rollenseitenführungspaar 7, d. h. die zweiten Mittel zur Ausübung einer seitlichen Kraft auf die Bramme, kann - wie dargestellt - vor der Entzunderungsvorrichtung angeordnet, innerhalb der Entzundeningsvorrichtung integriert oder hinter der Entzunderungsvorrichtung angeordnet sein. Optional kann auch ein Antrieb der Rollen 14 der Mittel 6 und 7 vorgesehen werden. Die zweite Rollenseitenführung 7 kann in einer geraden Führung in Breitenrichtung angestellt werden (s. Ausgestaltung am zweiten Ort 13 in

Statt einer größeren Rollenseitenführungsrolle ist auch in einer alternativen Ausführungsform (nicht dargestellt) die Anordnung von zwei kleineren dicht nebeneinander angeordneten Doppelrollen in einer Führungseinheit möglich, aber stets so, dass immer noch die kurze Bauart gegeben ist. Mit den beiden Rollenseitenführungen 6 und 7, die voneinander beabstandet sind, wird der Effekt einer langen durchgehenden Seitenführung erreicht. Die Rollenseitenführungen 6, 7 bilden dabei steuerungstechnisch eine Einheit.Instead of a larger roller side guide roller is in an alternative embodiment (not shown), the arrangement of two smaller close together arranged double roles in a leadership unit possible, but always so that is still given the short design. With the two roller side guides 6 and 7, which are spaced apart, the effect of a long continuous side guide is achieved. The roller side guides 6, 7 thereby form a control unit.

Bei großer Brammenaußermittigkeit oder bei hohen auftretenden Verschiebekräften (dickere Dünnbrammen, lange Brammen, zu schwache Aktuatoren, limitierte Verschiebekräfte) kann optional von der oben beschriebenen Vorgehensweise der mittigen Einstellung beider Rollenseitenführungen 6, 7 abgewichen werden. Hierzu wird auf

Ist damit zu rechnen, dass die Bramme 1 eine beliebige gekrümmte Form (Säbel, S-förmig, Hakenform) annehmen kann und dabei noch außermittig liegt, dann ist die optimale Positionierung der Rollenseitenführungen 6, 7 etwas aufwändiger. Es wird dann eine Erfassung der Brammenform und der Position über der Brammenlänge vorgenommen. Hierzu sind Laserabstandsmessungen oder andere Positionserfassungssignale beispielsweise vor dem letzten Ofenteil (hinter der Fähre) vorgesehen, wie es in

Mit der Erfassung der Transportgeschwindigkeit der Bramme 1 und der Zuordnung der gemessenen Kantenabstandssignale durch Sensoren 23 zum Erkennen der Bandkante auf den beiden Seiten der Bramme lässt sich die Breite, Position oder allgemein die Form der Bramme (s. Punkte xbi, ybi) über der Länge ermitteln. Die hier ermittelte Form und Außermittigkeit Δyi wird später zur optimalen Positionierung der Rollenseitenführungen 6, 7 und/oder der Rollen des Stauchers 15 verwendet. Optional ist auch zusätzlich eine Brammenbreiten- und Brammenpositionserfassung hinter dem Ofen von den Seiten mittels der Sensoren 24 oder von oben bzw. unten möglich.With the detection of the transport speed of the

Details zur Einstellung der Rollenseitenführungen 6, 7 und der Rollen des Stauchers 15 sind aus

Mit Kenntnis der Brammenform (Punkte xbi, ybi und der Breite B der Bramme 1) können die Positionen der Rollen 14 und der Rollen des Stauchers 15 (X1, Y1; X2, Y2; X3, Y3 - bezogen auf die Brammenmitte) angefahren werden. Die Positionen werden beim Durchfahren der Brammenspitze vom Ofen 2 zum ersten Gerüst der Fertigstraße 5 an die jeweilige Brammenform angepasst und zum Teil noch verfahren, so dass das Ziel erreicht wird, die Brammenspitze mittig in den Staucher 15 zu führen. Dabei ist auch vorgesehen, dass die Rollen des Stauchers 15 asymmetrisch, d. h. außermittig stehen können, um die Rollenseitenführungen 6, 7 zu unterstützten.With knowledge of the slab shape (points xb i , yb i and the width B of the slab 1), the positions of the

Es kann auch optional oder zusätzlich nach dem gleichen erläuterten Prinzip das Ziel des zentrischen Einlaufs der Brammenspitze in das folgende Gerüst erreicht werden.It can also be achieved optionally or additionally according to the same explained principle, the goal of the central inlet of the slab tip in the following framework.

Nach dem Einfädeln der Bramme 1 in die Walzstraße 5 gilt das Ziel, die Rollenseitenführungen 6, 7 sowie den Staucher 15 über der Brammenlänge mittig zu positionieren bzw. zu zentrieren, so dass die Bramme 1 und insbesondere das Brammenende möglichst gerade liegt, zum Teil gerichtet wird und so auch in die Walzstraße 5 einläuft.After the

Am Brammenende werden die Rollen des Stauchers 15 symmetrisch zugefahren (short stroke control), um die Überbreite am Brammenende zu vermeiden oder zu vermindern. Ähnlich geht man auch am Brammenkopf vor.At the end of the slab, the rollers of the upset 15 are fed in symmetrically (short stroke control) in order to avoid or reduce the excess width at the end of the slab. The same goes for the slab head.

Alternativ oder zusätzlich zur optischen Breitenmessung kann die Breiten- bzw. Positionserfassung über die Weggeber der Rollenseitenführungen und/oder Stauchrollen erfolgen. Weiterhin werden das erfasste Breitensignal sowie die errechnete Breitung bzw. Breitenänderung in der Fertigstraße in dem Breitenmodell verwendet, um den Stauchbetrag zu ermitteln und somit den Staucher anzusteuern.As an alternative or in addition to the optical width measurement, the width or position detection can take place via the displacement transmitters of the roller side guides and / or compression rollers. Furthermore, the detected width signal as well as the calculated spread or width change in the finishing train in the width model are used to determine the amount of compression and thus to control the stuffer.

Um die Breitenreduktion am Staucher 15 zu erhöhen, sind Niedefialte- oder Klemmrollen vorgesehen, die genau zwischen den beiden Stauchrollen angeordnet sind und von oben und unten in der Mitte der Bramme 1 auf die Brammenoberfläche drücken, um ein Ausbeulen zu vermeiden.To increase the width reduction on the

Weiterhin kann vorgesehen werden, das Stauchen der Bramme dadurch zu vereinfachen, dass die Stauchwalzen geschmiert werden. Dies vergrößert den Materialquerfluss, reduziert die Stauch- und Beulkräfte und wirkt sich auch positiv auf die Brammen- und Stauchwalzenrauheit und somit auf die Standzeit der Stauchwalzen aus.Furthermore, it can be provided to simplify the upsetting of the slab in that the compression rollers are lubricated. This increases the material crossflow, reduces the compression and buckling forces and also has a positive effect on the slab and compression roll roughness and thus on the life of the edging rolls.

Um die Bedingungen am Brammenende ebenfalls zu verbessern und die Bramme möglichst lange zu führen, ist zusätzlich eine spezielle mechanische Seitenführung zwischen dem Staucher 15 und dem ersten Gerüst der Walzstraße 5 vorgesehen (s.

Die Verstellung der Seitenführungslineale 16, 17 auf einer Führung 27 wird von zwei Verstellelementen 26 (Zylindern) pro Seite durchgeführt. Die Verstellelemente 26 sind nach oben mit einem Wärmeschutzelement 25 versehen (gekühlter Überleittisch, Dämmplatte). Die Position der mechanischen Seitenführung während des Betriebs entspricht der Breitenposition des Stauchers 15 zuzüglich eines definierten Betrages (in Millimetern).The adjustment of the

Das erläuterte Verfahren bzw. die gezeigte Vorrichtung sind nicht auf eine CSP-Anlage beschränkt, sondern finden in ähnlichen Produktionsanlagen hinter einem Ofenteil ebenso Anwendung. Der erfindungsgemäße Vorschlag kann auch beispielsweise in konventionellen Warmbandstraßen verwendet werden. Hier wird die Vorbandform hinter einem Vorgerüst beim Transport Richtung Fertigstraße erfasst und dort mit geeigneter Anstellung von Rollen vor der Fertigstraβe die oben erläuterten Ziele erfüllt.The described method and the apparatus shown are not limited to a CSP plant, but are also used in similar production plants behind a furnace part. The proposal according to the invention can also be used for example in conventional hot strip mills. Here the Vorbandform is detected behind a roughing stand during transport direction finishing mill and there met with suitable employment of roles before the finishing road the above objectives.

In einer konventionellen Warmbandstraße kann der erste Zentriereffekt vor der Schere alternativ zum Einsatz der Rollenseitenführungseinheit 6 auch durch Führungslineale ausgeführt werden.In a conventional hot strip mill, the first centering effect in front of the shears can alternatively be carried out by guide rulers as an alternative to the use of the roller

- 11

- Bramme (Vorband)Slab

- 22

- Ofenoven

- 33

- erste Bearbeitungsvorrichtung (Schere)first processing device (scissors)

- 44

- zweite Bearbeitungsvorrichtung (Entzunderungsvorrichtung)second processing device (descaling device)

- 55

- Walzstraßerolling train

- 66

- erstes Mittel zur Ausübung einer seitlichen Kraft auf die Bramme (Rollenseitenführung)first means for exerting a lateral force on the slab (roller side guide)

- 77

- zweites Mittel zur Ausübung einer seitlichen Kraft auf die Bramme (Rollenseitenführung)second means for exerting a lateral force on the slab (roller side guide)

- 88th

- Seite der BrammeSide of the slab

- 99

- Seite der BrammeSide of the slab

- 1010

- Achse der BrammeAxis of the slab

- 1111

- Achse der WalzstraßeAxis of the rolling train

- 1212

- erster Ortfirst place

- 1313

- zweiter Ortsecond place

- 1414

- Kontaktelement (Rolle)Contact element (roller)

- 1515

- Staucheredger

- 1616

- SeitenführungslinealPage guide rule

- 1717

- SeitenführungslinealPage guide rule

- 1818

- Schwenkarmswivel arm

- 1919

- Lagerpunktbearing point

- 2020

- Aktuatoractuator

- 2121

- Linearaktuatorlinear actuator

- 2222

- Treibrollecapstan roller

- 2323

- Sensor zum Erkennen der BrammenkanteSensor for detecting the slab edge

- 2424

- Sensor zum Erkennen der BrammenkanteSensor for detecting the slab edge

- 2525

- WärmeschutzelementHeat protection element

- 2626

- Verstellelement des SeitenführungslinealsAdjustment element of the side guide ruler

- 2727

- Führungguide

- FF

- Förderrichtungconveying direction

- ΔyDy

- Außermittigkeiteccentricity

- BB

- Breite der BrammeWidth of the slab

- xB x B

- Längenkoordinate der BrammeLength coordinate of the slab

- yB y B

- Koordinate, die die Brammenform beschreibtCoordinate describing the slab form

Claims (16)

- Method of processing a slab (1), particularly for final rolling of the slab (1) to form a strip, in a device, which comprises at least one furnace (2), at least one processing device (3, 4) arranged downstream of the furnace (2) in conveying direction (F) of the slab (1) and a rolling train (5) arranged downstream of the at least one processing device (3, 4) in conveying direction (F) of the slab (1), wherein means (6, 7) are present by which force can be exerted on the sides (8, 9) of the slab (1) in order to move the axis (10) of the slab (1) in correspondence with a predetermined position transversely to the conveying direction (F) of the slab (1), particularly in correspondence with the axis (11) of the rolling train (5), characterised in that first means (6) for exerting a lateral force on the slab (1) act on the slab (1) at a first location (12) and that second means (7) for exerting a lateral force on the slab (1) act on the slab (1) at a second location (13), wherein the second location (13) is spaced from the first location (12) in conveying direction (F) of the slab (1), wherein the first location (12) lies behind the furnace (2) and wherein the second location (13) lies in front of, within or behind the at least one processing device (3, 4), wherein preferably the first location (12) lies behind the furnace (2) and in front of the first of the at least one processing device (3, 4) and the second location (13) lies within or behind the first of the at least one processing device (3, 4).

- Method according to claim 1, characterised in that the position of the head of the slab (1) is detected in the region of at least one means (6, 7) and the exertion of a lateral force on the slab (1) is commenced by adjustment of a contact element (14) of the means (6, 7) only when the head of the slab (1) has passed the means (6, 7).

- Method according to claim 1 or 2, characterised in that directly in front of the rolling train (5) the slab (1) is subjected to upsetting in a direction transverse to the conveying direction (F), wherein preferably the exertion of a lateral force on the slab (1) is carried out by the means (6, 7) in front of the location of the upsetting and at a spacing therefrom.

- Method according to any one of claims 1 to 3, characterised in that the exertion of a lateral force on the slab (1) is carried out by the means (6, 7) in front of the rolling train (5).

- Method according to one of claims 3 and 4, characterised in that the means (6, 7) for exertion of a lateral force on the slab (1) are so operated that the tip of the slab (1) runs centrally into the location of the upsetting and/or into the rolling train (5).

- Method according to any one of claims 1 to 5, characterised in that at least two means (6, 7) for exertion of a lateral force on the slab (1) are arranged behind the furnace (2), wherein the first location (12) lies between the furnace (2) and first processing device (3) and the second location (13) lies between the at least two processing devices (3, 4) or within the second processing device (4), wherein preferably the slab (1) is subjected to a cutting process in the first processing device (3) and/or the slab (1) is subjected to a descaling process in the second processing device (4).

- Method according to any one of claims 1 to 6, characterised in that the position and/or the shape (xB, yB, Δy) of the slab (1) transversely to the conveying direction (F) of the slab (1) is or are detected along the movement thereof in the conveying direction (F) in front of the first location (12), wherein preferably the setting of the means (6, 7) for exertion of a lateral force on the slab (1) is determined in dependence on the geometry (a1, a2, a3) of the device and/or the detected shape (xB, yB) of the slab (1) and/or the eccentricity (Δy) of the slab (1) and/or the width (B) of the slab (1) with use of a computation model.

- Method according to any one of claims 1 to 7, characterised in that the exertion of a lateral force on the slab (1) by the means (6, 7) is so carried out in controlled or regulated manner that the axis (10) of the slab (1) in the conveying direction (F) behind the second location (13) adopts a desired position, wherein preferably the setting of the means (6, 7) for exertion of a lateral force on the slab (1) is determined in dependence on the geometry (a1, a2, a3) of the device and/or the detected shape (xB, yB) of the slab (1) and/or of the eccentricity (Δy) of the slab (1) and/or the width (B) of the slab (1) with use of a computation model.

- Device for processing a slab (1), which comprises at least one furnace (2), at least one processing device (3, 4) arranged downstream of the furnace (2) in conveying direction (F) of the slab (1) and a rolling train (5), particularly a finishing rolling train, arranged downstream of the at least one processing device (3, 4) in the conveying direction (F) of the slab (1), as well as means (6, 7) by which a force can be exerted on the sides (8, 9) of the slab in order to move the axis (10) of the slab (1) in correspondence with a predetermined position transversely to the conveying direction (F) of the slab (1), particularly in correspondence with the axis (11) of the rolling train (5), particularly for performance of the method according to any one of claims 1 to 8, characterised in that first means (6) for exertion of a lateral force on the slab (1) are arranged at a first location (12) and that second means (7) for exertion of a lateral force on the slab (1) are arranged at a second location (13), wherein the second location (15) lies at a spacing from the first location (12) in the conveying direction (F) of the slab (1), wherein the first location (12) lies behind the furnace (2) and wherein the second location (13) lies in front of, within or behind the at least one processing device (3, 4), wherein preferably the first location (12) lies behind the furnace (2) and in front of the at least one processing device (3, 4) and the second location (13) lies within or behind the first of the at least one processing device (3, 4) and particularly preferably the region within the furnace (2) is free of means (6, 7) for exertion of a lateral force on the slab (1).

- Device according to claim 9, characterised in that upsetting means (15) for upsetting the slab (1) in a direction transverse to the conveying direction (F) is arranged directly in front of the rolling train (5), wherein lateral guide strips (16, 17) for centring and guiding the slab (1) are preferably arranged between the upsetting means (15) and the first roll stand of the rolling train (5), particularly preferably adjusting elements (26) of the lateral guide strips (16, 17) are arranged below and/or above the lateral guide strips (16, 17), and/or the means (6, 7) for exertion of a lateral force on the slab (1) are arranged at a spacing from the upsetting means (15).

- Device according to one of claims 9 and 10, characterised in that the means (6, 7) for exertion of a lateral force on the slab (1) are arranged in front of the rolling train (5).

- Device according to any one of claims 9 to 11, characterised in that at least two means (6, 7) for exertion of a lateral force on the slab (1) are arranged behind the furnace (2), wherein the first location (12) lies between the furnace (2) and the first processing device (3), preferably a shears, and the second location (13) lies between the at least two processing devices (3, 4) or within the second processing device (4), preferably a descaling device.

- Device according to any one of claims 9 to 12, characterised in that the means (6, 7) for exertion of a lateral force on the slab (1) comprise at least one roller (14), which is arranged at a pivot arm (18), wherein the pivot arm (18) is mounted at a bearing point (19) at a fixed location and can be pivoted by an actuator (20) engaging the pivot arm (18) outside the bearing point (19), or that the means (6, 7) for exertion of a lateral force on the slab (1) comprise at least one roller (14), which is arranged at a linear actuator (21), the direction of movement of which is oriented transversely to the conveying direction (F) of the slab (1), wherein preferably the actuator (20) or the linear actuator (21) is constructed as a hydraulic piston/cylinder system.

- Device according to any one of claims 9 to 13, characterised in that the first means (6) for exertion of a lateral force on the slab (1) are constructed as guide strips.

- Device according to any one of claims 9 to 14, characterised in that it is a component of a thin-slab casting/rolling plant.

- Device according to any one of claims 9 to 15, characterised in that it is a component of a hot-strip rolling train, which comprises a roughing train and a finishing train, particularly that it is preferably arranged in front of the finishing train.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102009029887 | 2009-06-23 | ||

| PCT/EP2009/005942 WO2010149192A1 (en) | 2009-06-23 | 2009-08-17 | Method and device for processing a slab |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2445659A1 EP2445659A1 (en) | 2012-05-02 |

| EP2445659B1 true EP2445659B1 (en) | 2014-04-09 |

Family

ID=41277477

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09777913.6A Not-in-force EP2445659B1 (en) | 2009-06-23 | 2009-08-17 | Method and device for processing a slab |

Country Status (13)

| Country | Link |

|---|---|

| US (1) | US20120096914A1 (en) |

| EP (1) | EP2445659B1 (en) |

| JP (1) | JP2012512746A (en) |

| KR (1) | KR101320930B1 (en) |

| CN (1) | CN102245322B (en) |

| AU (1) | AU2009348758B2 (en) |

| BR (1) | BRPI0925061B1 (en) |

| CA (1) | CA2765269C (en) |

| MX (1) | MX2011013099A (en) |

| RU (1) | RU2479367C2 (en) |

| UA (1) | UA100935C2 (en) |

| WO (1) | WO2010149192A1 (en) |

| ZA (1) | ZA201103236B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102021203170A1 (en) | 2021-03-30 | 2022-10-06 | Sms Group Gmbh | Process for guiding and centering a rolled metal stock in a rolling train |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2666558A1 (en) * | 2012-05-21 | 2013-11-27 | Siemens Aktiengesellschaft | Lateral guide for a mill train |

| EP2689863A1 (en) | 2012-07-27 | 2014-01-29 | Siemens Aktiengesellschaft | Method of influencing the geometry of a milled good in a targeted manner |

| DE102012224505A1 (en) | 2012-12-28 | 2014-07-03 | Sms Siemag Aktiengesellschaft | Apparatus and method for laterally guiding a rolled or cast product on a transport line |

| CN103567233A (en) * | 2013-10-26 | 2014-02-12 | 芜湖新兴铸管有限责任公司 | Rear steel moving push plate of cogging mill |

| SE538558C2 (en) * | 2014-12-18 | 2016-09-20 | Morgårdshammar Ab | A roller guide and a method for guiding stock |

| BR112018015432A2 (en) | 2016-02-02 | 2018-12-18 | Nippon Steel & Sumitomo Metal Corporation | A cast piece curvature detecting device and a curvature detecting method of a cast piece |

| JP6103158B1 (en) * | 2016-05-13 | 2017-03-29 | 新日鐵住金株式会社 | Width reduction method and width reduction device |

| CN108016918A (en) * | 2017-09-04 | 2018-05-11 | 海宁市睿创机械科技有限公司 | The centering device of semi-finished product material |

| CN107838202B (en) * | 2017-12-27 | 2019-07-26 | 安徽楚江特钢有限公司 | A kind of strip finishing mill import guide device |

| EP3714999B1 (en) * | 2019-03-28 | 2022-09-28 | Primetals Technologies Germany GmbH | Determination of the adjustment of a roll stand |

| DE102020206297A1 (en) * | 2019-09-19 | 2021-03-25 | Sms Group Gmbh | Interstand guidance on a vertical roll stand of a rolling train as well as a method for guiding the rolling stock using the interstand guidance |

| CN113695391B (en) * | 2021-09-15 | 2023-01-17 | 鞍钢股份有限公司 | Production method for steel width exceeding limit for hot rolling container |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS4915709B1 (en) * | 1969-07-05 | 1974-04-17 | ||

| JPS5522464A (en) * | 1978-08-07 | 1980-02-18 | Hitachi Ltd | Continuous rolling method of slab |

| JPS63101004A (en) * | 1986-10-15 | 1988-05-06 | Ishikawajima Harima Heavy Ind Co Ltd | Rolling equipment |

| US5218848A (en) * | 1990-02-13 | 1993-06-15 | Hitachi, Ltd. | Method and apparatus for correcting a widthwise bend in an end portion of a hot-rolled sheet-shaped product |

| JP2757553B2 (en) * | 1990-10-19 | 1998-05-25 | 石川島播磨重工業株式会社 | Stand side guide device and control method |

| US5634360A (en) * | 1992-09-21 | 1997-06-03 | Ishikawajima-Harima Heavy Industries Co., Ltd. | Guiding apparatus for roughing mill |

| KR0148512B1 (en) * | 1993-01-28 | 1998-11-02 | 미노루 다나까 | Continuous hot rolling method and rolled material joining apparatus |

| DE19540978A1 (en) * | 1995-11-03 | 1997-05-07 | Schloemann Siemag Ag | Production plant for the continuous or discontinuous rolling out of hot strip |

| US5927118A (en) * | 1996-05-28 | 1999-07-27 | Nkk Corporation | Method for making hot-rolled steel sheet and apparatus therefor |

| DE19713604A1 (en) * | 1997-04-02 | 1998-10-08 | Schloemann Siemag Ag | A position-controlled compression frame arranged upstream of a finishing train for continuously cast strip material |

| NL1007730C2 (en) * | 1997-12-08 | 1999-06-09 | Hoogovens Staal Bv | Apparatus and method for manufacturing a steel strip. |

| JP2000246309A (en) * | 1999-03-01 | 2000-09-12 | Kobe Steel Ltd | Rolling mill row for high-strength steel sheet |

| JP3914674B2 (en) * | 2000-01-18 | 2007-05-16 | 新日本製鐵株式会社 | Rolled material transport method in hot roughing mill |

| IT1314793B1 (en) * | 2000-02-15 | 2003-01-16 | Danieli Off Mecc | PROCEDURE FOR CHECKING THE AXIALITY FOR SLABS EXITING FROM THE CONTINUOUS COLATEUR AND RELATIVE DEVICE. |

| JP3596484B2 (en) * | 2000-05-10 | 2004-12-02 | 住友金属工業株式会社 | Hot rolling equipment and hot rolling method |

| DE10109055A1 (en) * | 2001-02-24 | 2002-09-05 | Sms Demag Ag | Continuous caster with downstream furnaces, roughing stands and a finishing train |

| AT410549B (en) * | 2001-09-13 | 2003-05-26 | Voest Alpine Schienen Gmbh & C | DEVICE FOR TURNING ROLLED GOODS WITH LONG LENGTH |

| JP4778832B2 (en) * | 2006-05-17 | 2011-09-21 | 三菱日立製鉄機械株式会社 | Width and width adjustment method and apparatus for first and second metal plates and continuous rolling equipment |

-

2009

- 2009-08-17 JP JP2011541118A patent/JP2012512746A/en active Pending

- 2009-08-17 WO PCT/EP2009/005942 patent/WO2010149192A1/en active Application Filing

- 2009-08-17 AU AU2009348758A patent/AU2009348758B2/en not_active Ceased

- 2009-08-17 BR BRPI0925061-1A patent/BRPI0925061B1/en not_active IP Right Cessation

- 2009-08-17 EP EP09777913.6A patent/EP2445659B1/en not_active Not-in-force

- 2009-08-17 UA UAA201109118A patent/UA100935C2/en unknown

- 2009-08-17 KR KR1020117011892A patent/KR101320930B1/en active IP Right Grant

- 2009-08-17 CN CN200980151587.3A patent/CN102245322B/en not_active Expired - Fee Related

- 2009-08-17 RU RU2011129323/02A patent/RU2479367C2/en active

- 2009-08-17 US US13/379,404 patent/US20120096914A1/en not_active Abandoned

- 2009-08-17 CA CA2765269A patent/CA2765269C/en not_active Expired - Fee Related

- 2009-08-17 MX MX2011013099A patent/MX2011013099A/en active IP Right Grant

-

2011

- 2011-05-05 ZA ZA2011/03236A patent/ZA201103236B/en unknown

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102021203170A1 (en) | 2021-03-30 | 2022-10-06 | Sms Group Gmbh | Process for guiding and centering a rolled metal stock in a rolling train |

| WO2022207151A1 (en) | 2021-03-30 | 2022-10-06 | Sms Group Gmbh | Method and device for guiding and centering a metal rolling stock in a rolling mill |

Also Published As

| Publication number | Publication date |

|---|---|

| KR101320930B1 (en) | 2013-10-23 |

| CN102245322B (en) | 2014-10-22 |

| US20120096914A1 (en) | 2012-04-26 |

| WO2010149192A9 (en) | 2011-04-21 |

| CA2765269A1 (en) | 2010-12-29 |

| EP2445659A1 (en) | 2012-05-02 |

| RU2479367C2 (en) | 2013-04-20 |

| KR20110079750A (en) | 2011-07-07 |

| BRPI0925061B1 (en) | 2020-03-03 |

| JP2012512746A (en) | 2012-06-07 |

| AU2009348758B2 (en) | 2013-08-29 |

| RU2011129323A (en) | 2013-01-20 |

| AU2009348758A1 (en) | 2012-01-19 |

| CA2765269C (en) | 2014-01-14 |

| CN102245322A (en) | 2011-11-16 |

| ZA201103236B (en) | 2012-03-28 |

| UA100935C2 (en) | 2013-02-11 |

| BRPI0925061A2 (en) | 2015-07-28 |

| WO2010149192A1 (en) | 2010-12-29 |

| MX2011013099A (en) | 2012-01-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2445659B1 (en) | Method and device for processing a slab | |

| EP2938445B1 (en) | Device and method for laterally guiding a rolled or cast product on a transport track | |

| EP3246102B1 (en) | Method and device for cooling a plate in a cooling section | |

| AT513299B1 (en) | Method and device for a cast-rolled composite plant | |

| AT509831B1 (en) | METHOD AND DEVICE FOR MINIMIZING THE STRAP TRAIN OF A ROLL | |

| EP2217394B1 (en) | Method and device for producing a metal strip | |

| DE60113657T2 (en) | ROLLING OF BELT MATERIAL | |

| EP1446242B1 (en) | Method and device for the continuous production of a rolled metal strip from a molten metal | |

| EP3177412B1 (en) | Adjustment of a targeted temperature profile on the strip head and strip foot before transversally cutting a metal strip | |

| EP3544751B1 (en) | Strip position control with force-limited placement of lateral guiding devices on the metal strip | |

| DE112007000641B4 (en) | Continuous cold rolling mill | |

| EP2741870B1 (en) | Rolling system and rolling method | |

| DE2723720A1 (en) | DEVICE FOR MAINTAINING A CERTAIN TENSION EXERCISED ON A METAL STRAP DURING A DIRECTIONAL PROCESS | |

| EP1132161A1 (en) | Process for continuous casting slabs, especially thin slabs | |

| EP3826781B1 (en) | Method and device for determining the lateral contour of a running metal strip | |

| EP3535071B1 (en) | Method and system for producing a metal strip | |

| DE19900779B4 (en) | Method for rolling metal strip and plant for carrying out the method | |

| EP4100177B1 (en) | Method for calibrating vertical rolls of a vertical roll stand, and rolling mill with calibrating assembly for carrying out the method | |

| DE102021203170A1 (en) | Process for guiding and centering a rolled metal stock in a rolling train | |

| EP3873685B1 (en) | Roll line | |

| AT526531B1 (en) | Deburring of rolled stock using a swing arm | |

| DE102010063093B4 (en) | Device and method for horizontal casting of metal strips | |

| DE102021209261A1 (en) | Method for controlling a rolling stock guide in a rolling train and intermediate stand guide |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |