EP2421997B1 - Production of spheroidal metal particles - Google Patents

Production of spheroidal metal particles Download PDFInfo

- Publication number

- EP2421997B1 EP2421997B1 EP10745842.4A EP10745842A EP2421997B1 EP 2421997 B1 EP2421997 B1 EP 2421997B1 EP 10745842 A EP10745842 A EP 10745842A EP 2421997 B1 EP2421997 B1 EP 2421997B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- molten mass

- particles

- granulation

- melt

- molten

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C23/00—Alloys based on magnesium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F1/00—Metallic powder; Treatment of metallic powder, e.g. to facilitate working or to improve properties

- B22F1/06—Metallic powder characterised by the shape of the particles

- B22F1/065—Spherical particles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F9/00—Making metallic powder or suspensions thereof

- B22F9/02—Making metallic powder or suspensions thereof using physical processes

- B22F9/06—Making metallic powder or suspensions thereof using physical processes starting from liquid material

- B22F9/08—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F9/00—Making metallic powder or suspensions thereof

- B22F9/02—Making metallic powder or suspensions thereof using physical processes

- B22F9/06—Making metallic powder or suspensions thereof using physical processes starting from liquid material

- B22F9/08—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying

- B22F9/082—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying atomising using a fluid

- B22F2009/0896—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying atomising using a fluid particle transport, separation: process and apparatus

Definitions

- the invention relates to a device for producing roundish metal particles of high size and shape uniformity; Process for producing roundish metal particles of high size and shape uniformity and the use of the method.

- the granulate particles produced in this way are particularly suitable, for example, for applications in which a particular flowability of the granulate is desired as far as possible without the formation of abrasion or particles of smaller particle size, as in thixomolding.

- a mechanical granulating apparatus or cutting apparatus can produce particles of fine structure, but it lacks the roundness, which causes a low internal friction of the granules in the dumping, conveying and pressing. Such particles often have poor uniformity of grain size and grain shape, and of course are not spheroidal. Furthermore, it is complicated, if not impossible, to produce granules with as large a grain as possible by mechanical granulation. Finally, the process itself is expensive, since the mechanical machining of billets and the like. Is expensive and much remains unzerspantes residual material that must be returned to the casting process. Also, metal granules produced by the cutting process generally suffer from uneven composition in general since irregularities such as inclusions are transferred from the billet to the powder.

- the spheres produced by melting form a substantially finer grain structure compared to the particles produced from pulverized cast masses, which has proven to be advantageous in particular in metal injection molding ( Czerwinski F .; Materials Science and Engineering A 367, 2004, pp. 261-271 ).

- Conventional turntable devices for making metal spheres include means for melting the metal and casting the metal on a rotating base which tosses the molten metal to form spheroidal particles. S. for example. JP 51-64456 . JP 07-179912 . JP 63-33508 JP 07054019 and JP 07-173510 , Such typical rotary disc devices produce spheroidal powders of relatively poor sphericity, limited micro dimensions, and improved uniformity of composition and shape.

- molten metal is conveyed from a melting furnace in a granulating tube (5) to melt outlet openings (16) in a granulation chamber (20). Furthermore, the device has a granulating turntable (1) below the granulating tube (5), which has at least one outlet for a molten metal jet on the turntable (1), wherein the rotating turntable (1) from the at least one outlet of the granulating tube (5 dripping molten metal in the form of roundish droplets. The melt drops solidify on the cold surface of the turntable to granules particles (12).

- An inert gas supply means (15) supplies specially selected gas to the molten metal discharged from the melt outlets (16) into a granulation chamber (20) in a manner preventing contact of the molten metal jet with air and oxidation of the metal.

- the gas supply can be done in countercurrent, perpendicular to the melt jet and obliquely to parallel to the melt jet. Possibly. a pulsating upward and downward movement of the granulating tube (5) for separating the melt jet into drops can be provided.

- the granulating turntable (1) is cooled.

- the granulation tube (5) has a blind flange in one embodiment.

- a high pressure can easily be built up and the melt is applied as quickly as possible.

- the granulating tube (5) is returned to the melting furnace (3), whereby a regular mixing of the melt and high reproducibility of the particle composition is ensured.

- a feed pump in / on the melting furnace (3) for conveying the molten metal to / in the granulation (5) is provided.

- Typical metals which are processed by the granulation method according to the invention for high reactivity in the melt are selected from the group consisting of Al, Mg, Ca, Zn and their alloys - but the method can also be used for other metals.

- the cooling of the dispersed droplets by gas is advantageously accomplished by means of a predetermined cooling gas of one or more inert gases in an open or closed granulation chamber 20 which provides the controlled atmosphere.

- spherical particles of fine grain structure of high shape and size uniformity from the melt is possible.

- Such particles having a fine grain structure are particularly suitable for applications such as thixomolding, sintering, metal injection molding and similar powder metallurgy processes.

- the inventive method is particularly suitable for the production of granules of magnesium or magnesium alloys.

- metal also refers to their respective alloys as well as the metal with minor impurities.

- spheroid any round shape, such as, for example, balls, lens shapes, elliptical shapes, etc., which has no sharp or angular edges.

- the access of reacting with the melt gases such as water vapor, oxygen, nitrogen is avoided as possible.

- the melting takes place under a protective cover or protective atmosphere and the transport of the melt through a closed pipe system to the outlet openings or nozzles.

- a wide variety of gases either inert or reactive gas, such as mixtures of dry air, nitrogen or carbon dioxide with sulfur dioxide, sulfur hexafluoride or R134a, above the melt, resulting in the formation of a protective layer on the melt surface.

- gases either inert or reactive gas, such as mixtures of dry air, nitrogen or carbon dioxide with sulfur dioxide, sulfur hexafluoride or R134a, above the melt, resulting in the formation of a protective layer on the melt surface.

- the transport tube the molten metal from the melting furnace for Promotes sputtering station, is heated to prevent deposition of magnesium or its compounds by convection in the heat transfer tube, while ensuring the most uniform possible heat distribution in the longitudinal direction of the tube. Corresponding measures are familiar to the person skilled in the art.

- the melt can be circulated, whereby a constant return does not take place on the turntable ejected melt in the furnace and thus a permanent mixing of the melt volume is achieved while maintaining a high homogeneity of the product and a homogeneous temperature distribution.

- the high flow velocity in the pipe is advantageous, so that impurities (eg oxides) are permanently transported, are not deposited in the pipe and clog it from the inside.

- the pipe itself can be heated over the whole area or only over part of the area, for example only in the lower area, in order to increase the convection there and to avoid settling of reaction products of the melt.

- the shape and size of the particles are influenced inter alia by density, viscosity, surface tension and diameter of the jet emerging from the discharge opening (nozzle diameter, nozzle material).

- the particle size variation in the method according to the invention is low, which can only be achieved in the case of machining processes by means of expensive further sieving / sifting operations.

- Adjusting the relationships between devices and methods according to the invention enables the production of relatively round, spheroidal, ellipsoidal or lenticular particles of various sizes and various applicability, such as in sintering, thixomolding (metal injection molding), pressing, etc.

- the invention provides methods, devices and systems for producing granular particles of uniform spheroidal shape and high sphericity consisting of metal and its alloys by use of an improved rotating disc apparatus.

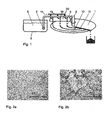

- Fig. 1 is schematically illustrated the system of the invention.

- melt 6 is fed into the granulating tube 5 with nozzles 16 by means of a feed pump 2.

- the melt exits the nozzles 16 into the inert gas-filled granulation chamber 20 and forms drops 8.

- the drops fall on the turntable 1, solidify to particles 12 and are passed through a scraper 13 in a container 2.

- Inert gas 14 is passed through lines 15 to the emerging from the nozzle 16 melt, which prevents the formation of oxides, nitrides and the like to the nozzle 16 of the granulation tube 5 and the granules, and promotes the disintegration of the melt jet to 8 drops.

- FIG. 3 schematically shows various embodiments of the course of the granulation tube 5.

- a granulator with return 7 is shown.

- a pump P is arranged, which ensures regular promotion of the melt.

- the return of non-discharged melt through the return pipe 7 in the furnace is apparent.

- a non-return embodiment in which the granulation tube 5 terminates in a blind flange is shown.

- a pump P which pressure in the granulating tube 5 can build up for faster deployment of the melt and also pressure surges, for example.

- Fig. 4 shows various granules from a plant according to the invention. Clearly here is a roundish lens shape of the present invention produced from the melt Mg granules visible.

- FIG. 2a shows a light micrograph of the microstructure of a step by a melt produced according to the invention particles of magnesium alloy AZ91 and Fig. 2b the microstructure of a particle made from Gußmasseln particles of the same alloy. It is clearly evident that the particles produced from the melt solidify rapidly and thus have a remarkably fine grain according to the invention, whereby their mechanical properties are favorably influenced.

- the invention provides methods, devices and systems for producing metal granules wherein the particles have a uniform spheroidal shape - such as Fig. 4 seen.

- At least one jet of molten metal which has been broken down into droplets, is directed onto a rotating dish.

- the molten steel is supplied with inert gas, here predominantly helium.

- a bell made of baffles below the Granulierrohres prevented as a granulation chamber outflow of the protective gas and maintains an atmosphere that prevents oxidation of the exiting the nozzle melt, upright.

- the droplets hit the cold, preferably cooled turntable.

- the turntable removes heat from the melt droplet so quickly that a rapid solidification of the melt results in a granular particle with a fine-grained microstructure.

- the rotational movement of the plate prevents the melting droplets from meeting / coalescing, thus ensuring solidification of the droplets into discrete particles.

- the particles are pushed here by the trained here as a strip scraper over the edge of the plate in a container. Also conceivable are other means for removing the solidified particles such as brushes, blowers, etc.

- the pressure in the granulation tube 5 is generated in this embodiment by a centrifugal pump.

- a centrifugal pump In general, all known pumping methods and systems for building up the melt pressure or the melt flow in the pouring tube suitable, such as piston pumps, induction pumps, pneumatic pumping systems, but also for pressurizing the furnace chamber and pump-free delivery systems, which work, for example, on the principle of communicating tubes can be used.

- the shape and size of the granulate particles can be influenced by various system parameters. These include, inter alia, the distance of the pouring tube to the turntable so the drop height of emerging from the nozzle melt; the nozzle diameter, the melt pressure, the melt temperature and the design of the granulation tube (with or without return). In addition, determine temperature, flow velocity, composition and angle of attack of the protective gas and the temperature of the turntable, the shape and size of the granular particles. Depending on the combination of parameters, the particle shape is different spheroid z. B. platelet, lens, spherical or cylindrical. For example, increasing the rotational speed of the plate causes a more elongate shape of the formed particle.

- the metallic starting materials Prior to granulation, the metallic starting materials, for example magnesium die-cast scrap, are selected under a protective gas atmosphere from the group consisting of noble gases such as argon, neon and helium or nitrogen, carbon dioxide or dry air with additions of sulfur dioxide, sulfur hexafluoride or r-134a or Mixtures thereof melted in the melting furnace 3.

- a protective gas atmosphere from the group consisting of noble gases such as argon, neon and helium or nitrogen, carbon dioxide or dry air with additions of sulfur dioxide, sulfur hexafluoride or r-134a or Mixtures thereof melted in the melting furnace 3.

- noble gases such as argon, neon and helium or nitrogen

- carbon dioxide or dry air with additions of sulfur dioxide, sulfur hexafluoride or r-134a or Mixtures thereof melted in the melting furnace 3.

- salts which leads to the formation of a protective layer of liquid salt on the melt surface and thus prevents a reaction of the melt with the air.

- Metal powders made by the machining process also generally suffer from uneven composition in general.

- the external gas pressure on the circumference of the dispersed droplets is preferably atmospheric pressure.

- Magnesium die casting scrap of the alloy AZ91 is melted in an electrically heated melting furnace under nitrogen with 0.20% r-134 a at 680 ° C.

- the melting furnace is a centrifugal pump, which at 5500 revolutions per minute, the magnesium melt in a from the melt furnace promotes leading, blind ending, closed, heated granulation tube with 16 dispensing nozzles.

- Under the dispensing nozzles runs a water-cooled turntable.

- a melt jet forms, which decays to droplets at a drop height of 120 mm.

- Helium is conducted as a protective gas against the melt jet.

- Guiding plates around the granulation tube form a bell, which prevent the escape of helium upwards and forms a granulation chamber 20 and a helium atmosphere for protecting the melt from oxidation between the granulation tube and turntable.

- the rotation of the plate is carried out according to the requirements of the particle shape at a speed of 4-10 revolutions per minute.

- the result is lenticular particles high form uniformity.

- the particles are guided with a scraper from the turntable into a container. By subsequent sieving large, sometimes not dimensionally stable particles can be separated.

- Fig. 4 shows 3 sieve fractions of so produced granules of the magnesium alloy AZ91.

- FIG Fig. 2a A light microscopic picture of a cross section of the particles thus produced is shown in FIG Fig. 2a shown in comparison with a cross-section of particles from the conventional machining process. It is noticeable that the section through the particles produced by machining shows considerably larger grains and transition zones than the fine-crystalline structure of the casting particles produced by the granulation method from the melt.

- the Mg particles produced according to the invention are superior to the particles produced by machining processes both in terms of their microstructure and their external shape.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Nanotechnology (AREA)

- Manufacture Of Metal Powder And Suspensions Thereof (AREA)

- Manufacture And Refinement Of Metals (AREA)

Description

Die Erfindung betrifft eine Vorrichtung zur Herstellung von rundlichen Metallpartikeln hoher Größen- und Form- Uniformität; Verfahren zur Herstellung von rundlichen Metallpartikeln hoher Größen- und Form Uniformität sowie die Verwendung des Verfahrens.The invention relates to a device for producing roundish metal particles of high size and shape uniformity; Process for producing roundish metal particles of high size and shape uniformity and the use of the method.

Die so hergestellten Granulatpartikel eignen sich insbesondere bspw. für Anwendungen, bei denen eine besondere Fließfähigkeit des Granulats möglichst ohne Ausbildung von Abrieb oder Teilchen kleinerer Korngröße erwünscht ist, wie beim Thixomolding.The granulate particles produced in this way are particularly suitable, for example, for applications in which a particular flowability of the granulate is desired as far as possible without the formation of abrasion or particles of smaller particle size, as in thixomolding.

Schmelzen von Metallen mit Verunreinigungen, wie Metalloxiden, Metallnitriden, Metallsiliciden, Mischverbindungen derselben oder Fremdmetallanteilen sowie üblichen Zusätzen sind übliche Roh-Ausgangsmaterialien zum Herstellen von Metallgranulaten. Dabei bilden sich insbesondere bei Magnesium und ähnlich unedlen Metallen durch Reaktionen mit der Atmosphäre im Schmelzeofen sowie dem Schmelztiegelmaterial, falls dieses durch die Schmelze angelöst wird oder Material desselben abplatzt, Oxide, Nitride, welche unter anderem die Auslässe für die Schmelze verstopfen. Ferner sind manche Verunreinigungen, bei Magnesium beispielsweise dessen Oxide, schwerer als das flüssige Metall, so dass diese in der Schmelze absinken und sich am Boden und an Flussrestriktionen, wie einem Auslaß, oder an kühleren Bereichen einer Anlage ablagern. Durch Reaktionen mit dem Tiegelmaterial des Schmelzofens kann es außerdem zur Bildung von intermetallischen Phasen kommen, die sich ebenfalls in diesem Sumpf ansammeln. Alle diese verstopfen Austrittsöffnungen, setzen Leitungen zu und führen zu einer ungleichmäßigen Zusammensetzung des Granulats.Melting of metals with impurities such as metal oxides, metal nitrides, metal silicides, mixed compounds thereof or foreign metal moieties as well as common additives are common raw starting materials for producing metal granules. In particular, magnesium and similar base metals form reactions with the atmosphere in the melting furnace and the crucible material, if this is dissolved by the melt or material thereof flakes off, oxides, nitrides, which inter alia clog the outlets for the melt. Further, some impurities, magnesium, for example, its oxides, are heavier than the liquid metal, so that they sink in the melt and settle to the bottom and to flow restrictions, such as an outlet, or to cooler areas of a plant. Reactions with the crucible material of the melting furnace can also lead to the formation of intermetallic phases, which also accumulate in this sump. All of these plug outlets, expose ducts and result in an uneven composition of the granules.

Grundlegend bestehen zur Herstellung von Metallpulvern zwei Möglichkeiten:

- a) mechanische Verfahren, bei denen durch Zerspanung oder Granulierung von Gussteilen Partikel hergestellt werden, und

- b) Schmelzverfahren, bei denen Tröpfchen der Schmelze erstarren und dann die Partikel bilden.

- a) mechanical processes in which particles are produced by machining or granulating castings, and

- b) Melting processes in which droplets of the melt solidify and then form the particles.

Eine mechanische Granulierungs-Vorrichtung oder Zerspanungsvorrichtung kann Partikel feiner Struktur herstellen, wobei es aber an der Rundlichkeit, die eine geringe innere Reibung des Granulats beim Schütten, Fördern und Pressen bewirkt, mangelt. Derartige Partikel weisen häufig eine schlechte Uniformität der Korngröße und Korn-Form auf, und sind selbstverständlich nicht sphäroid. Ferner ist es aufwendig, wenn nicht unmöglich, durch mechanische Granulierung Granulate mit möglichst runden Körnern herzustellen. Schließlich ist das Verfahren selbst teuer, da die mechanische Zerspanung von Barren und dgl. aufwendig ist und viel unzerspantes Restmaterial verbleibt, das wieder in das Gießverfahren zurückgeschleust werden muss. Metallgranulate, die über das Zerspanungsverfahren hergestellt werden, leiden ferner allgemein häufig an ungleichmäßiger Zusammensetzung, da Unregelmäßigkeiten, wie Einschlüsse aus dem Barren in das Pulver transferiert werden.A mechanical granulating apparatus or cutting apparatus can produce particles of fine structure, but it lacks the roundness, which causes a low internal friction of the granules in the dumping, conveying and pressing. Such particles often have poor uniformity of grain size and grain shape, and of course are not spheroidal. Furthermore, it is complicated, if not impossible, to produce granules with as large a grain as possible by mechanical granulation. Finally, the process itself is expensive, since the mechanical machining of billets and the like. Is expensive and much remains unzerspantes residual material that must be returned to the casting process. Also, metal granules produced by the cutting process generally suffer from uneven composition in general since irregularities such as inclusions are transferred from the billet to the powder.

Insbesondere entsteht ein hoher Feinanteil (< 0,8 mm). Diese kleinen Teilchen können sich in der Spritzgießmaschine zwischen die Stege der Extruder-Schnecke und den Zylinder klemmen. Die Folge ist ungleichmäßiges Drehen der Schnecke aufgrund von Drehmomentschwankungen. Es kommt zum ungleichmäßigen Aufdosieren. Dadurch kann es zu Beeinträchtigungen bei der Prozessstabilität kommen. Außerdem besteht aufgrund des Feinanteils erhöhte Explosionsgefahr. Beim Transport des Granulats kann es zur Entmischung des Granulats kommen, so dass sich Feinanteil anreichert. Weiterer Feinanteil kann durch Reibung der eckig geformten Granulatkörner entstehen, was das oben genannte Problem verstärkt. Es entstehen auch große Körner, die größer sein können als die Gangtiefe der Schnecke im Einzugsbereich. Auch dies kann zum Verklemmen der Schnecke führen.In particular, a high fines content (<0.8 mm) is produced. These small particles may jam in the injection molding machine between the flights of the extruder screw and the cylinder. The result is uneven turning of the worm due to torque fluctuations. It comes to uneven metering. This can lead to impairments in process stability. In addition, there is an increased risk of explosion due to the fines. When transporting the granules, it can lead to segregation of the granules, so that fines enriched. Further fines may be generated by friction of the angularly shaped granules, which aggravates the above problem. It also large grains, which may be greater than the depth of the snail in the catchment area. This too can lead to jamming of the screw.

Konventionelle Vorrichtungen und Verfahren zur Herstellung von Granulat bzw. Pulver aus der Schmelze wenden entweder Verdüsen an, wobei geschmolzenes Metall - häufig in Mischung mit Gas - mit hoher Geschwindigkeit explosionsartig aus einer Düse zerstäubt wird, was zu eher spratzigen Teilen führt, oder liefern rundliche Körner durch das sog. Rotating-Disc Verfahren, wobei Metallschmelze aus einem Schmelzebehälter oder -ofen auf eine rotierende Scheibe tropft und dort unter Abkühlen weggeschleudert wird - bevorzugt gegen einen aufsteigenden Gasstrom, welcher die Fallgeschwindigkeit der Tröpfchen abbremst und so ihre längliche Tropfenform im Fall abflacht. Durch das Verfahren werden relativ rundliche Partikel erhalten. Es wurde auch festgestellt, dass die durch Schmelzen hergestellten Kügelchen gegenüber den aus pulverisierten Gußmasseln hergestellten Teilchen eine wesentlich feinere Kornstruktur ausbilden, die sich als vorteilhaft insbesondere beim Metallspritzguss erwiesen hat (

Metalle, die in der Schmelze sehr reaktiv sind, wie Magnesium und seine Legierungen, die als leichte Materialien immer erwünschter werden und die häufig aus Magnesiumdruckgussschrott gewonnen werden, sind insofern problematisch, als sie in Schmelze hochreaktiv sind. Bspw. ist problematisch, dass die Auslässe für flüssiges Magnesium aus Schmelzenbehältern - sei es eine Düse oder aber ein einfaches Auslassrohr - leicht durch die aus der Schmelze gebildeten Oxide verstopfen und dann zu einer Unterbrechung der Produktion führen.Metals that are very reactive in the melt, such as magnesium and its alloys, which are becoming increasingly desirable as lightweight materials, and which are often derived from magnesium die casting scrap, are problematic in that they are highly reactive in melt. For example. It is problematic that the outlets for liquid magnesium from melt tanks - be it a nozzle or a simple outlet pipe - easily clogged by the oxides formed from the melt and then lead to an interruption of production.

Konventionelle Drehteller-Vorrichtungen zur Herstellung von Metallkügelchen umfassen Mittel zum Schmelzen des Metalls und Gießen des Metalls auf eine rotierende Basis, welche das geschmolzene Metall unter Ausbildung von sphäroiden Partikeln wegschleudert. S. bspw.

Es ist daher Aufgabe der Erfindung, die Herstellung von sphäroiden Metallgranulaten, wie von Leichtmetall und insbesondere Erdalkalimetall, zu verbessern.It is therefore an object of the invention to improve the production of spheroidal metal granules, such as light metal and in particular alkaline earth metal.

Die Aufgabe wird erfindungsgemäß durch eine Vorrichtung mit den Merkmalen des Patentanspruches 1 und ein Verfahren nach Patentanspruch 8 sowie die Verwendung nach Anspruch 13 gelöst.

Vorteilhafte Weiterbildungen ergeben sich aus den abhängigen Ansprüchen.The object is achieved by a device with the features of

Advantageous developments emerge from the dependent claims.

Erfindungsgemäß wird Metallschmelze aus einem Schmelzofen in einem Granulierrohr (5) zu Schmelzeaustrittsöffnungen (16) in eine Granulationskammer (20) gefördert. Ferner hat die Vorrichtung einen Granulier-Drehteller (1) unterhalb des Granulierrohrs (5), das mindestens einen Auslaß für einen Metallschmelzestrahl auf den Drehteller (1) aufweist, wobei der rotierende Drehteller (1) das aus dem mindestens einen Auslaß des Granulierrohrs (5) tropfende geschmolzene Metall in Form von rundlichen Tropfen auffängt. Die Schmelzetropfen erstarren auf der kalten Oberfläche des Drehtellers zu Granulatpartikeln (12). Eine Schutzgaszuführeinrichtung (15) führt speziell ausgewähltes Gas zu dem aus den Schmelzeaustrittöffnungen (16) austretenden Metallschmelzestahl in eine Granulationskammer (20) in einer Weise, die einen Kontakt des Metallschmelzestrahles mit Luft und eine Oxidation des Metalls verhindert. Die Gaszuführung kann dazu im Gegenstrom, senkrecht zum Schmelzestrahl sowie schräg bis parallel zum Schmelzestrahl erfolgen. Ggf. kann eine pulsierende Auf- und Abwärtsbewegung des Granulierrohres (5) zur Vereinzelung des Schmelzestrahles zu Tropfen vorgesehen werden.According to the invention, molten metal is conveyed from a melting furnace in a granulating tube (5) to melt outlet openings (16) in a granulation chamber (20). Furthermore, the device has a granulating turntable (1) below the granulating tube (5), which has at least one outlet for a molten metal jet on the turntable (1), wherein the rotating turntable (1) from the at least one outlet of the granulating tube (5 dripping molten metal in the form of roundish droplets. The melt drops solidify on the cold surface of the turntable to granules particles (12). An inert gas supply means (15) supplies specially selected gas to the molten metal discharged from the melt outlets (16) into a granulation chamber (20) in a manner preventing contact of the molten metal jet with air and oxidation of the metal. The gas supply can be done in countercurrent, perpendicular to the melt jet and obliquely to parallel to the melt jet. Possibly. a pulsating upward and downward movement of the granulating tube (5) for separating the melt jet into drops can be provided.

Vorteilhafterweise ist der Granulier- Drehteller (1) gekühlt. Zur Vermeidung von Niederschlägen im Granulierrohr (5) etc. kann es sinnvoll sein, dass das Granulierrohr (5) geheizt ist. Das Granulierrohr (5) weist bei einer Ausführungsform einen Blindflansch auf. Dadurch kann leicht ein hoher Druck aufgebaut werden und so schnell die Schmelze ausgebracht werden. Bei einer anderen Ausführungsform wird das Granulierrohr (5) in den Schmelzeofen (3) rückgeführt, wodurch eine regelmäßige Durchmischung der Schmelze und hohe Reproduzierbarkeit der Teilchenzusammensetzung gewährleistet wird. Häufig ist es sinnvoll, dass eine Förderpumpe im/am Schmelzeofen (3) zum Fördern der Metallschmelze zum/im Granulierrohr (5) vorgesehen ist.Advantageously, the granulating turntable (1) is cooled. To avoid precipitation in the granulation tube (5), etc., it may be useful for the granulation tube (5) to be heated. The granulation tube (5) has a blind flange in one embodiment. As a result, a high pressure can easily be built up and the melt is applied as quickly as possible. In another embodiment, the granulating tube (5) is returned to the melting furnace (3), whereby a regular mixing of the melt and high reproducibility of the particle composition is ensured. Often it makes sense that a feed pump in / on the melting furnace (3) for conveying the molten metal to / in the granulation (5) is provided.

Ein erfindungsgemäßes Verfahren zur Herstellung von rundlichen Metallpartikeln hoher Größen -und Sphärizität Uniformität weist folgende Schritte auf:

- Schmelzen des metallischen Ausgangsmaterials;

- Transportieren der Metallschmelze in ein Granulierrohr mit mindestens einem Schmelzeauslaß für einen Schmelzestrom;

- Dispergieren der Metallschmelze zu kleinen sphäroiden Tröpfchen durch Leiten mindestens eines Schmelzestroms aus dem Granulierrohr unter Schutzatmosphäre auf einen Drehteller;

- Abkühlen und Unterstützen der Vereinzelung des Metallstahles zu Metalltröpfchen durch Leiten eines kühlenden Inert-Gases in den Schmelzestrom gegebenenfalls unter pulsierender Auf- und Abwärtsbewegung des Granulierrohres (5), und

- Abkühlen und dispergieren der Metalltropfchen durch den rotierenden Drehteller unter Erstarren derselben zu diskreten Granulatpartikeln;

- Melting the metallic starting material;

- Transporting the molten metal into a granulation tube having at least one melt outlet for a melt stream;

- Dispersing the molten metal into small spheroidal droplets by passing at least one melt stream from the pelletizing tube under protective atmosphere onto a turntable;

- Cooling and assisting the separation of the metal steel into metal droplets by passing a cooling inert gas into the melt stream, optionally with pulsating up and down movement of the granulation pipe (5), and

- Cooling and dispersing the metal droplets through the rotating turntable, solidifying them to form discrete granule particles;

Typische Metalle, die nach dem erfindungsgemäßen Granulierverfahren wegen hoher Reaktivität in der Schmelze verarbeitet werden, sind ausgewählt aus der Gruppe bestehend aus Al, Mg, Ca, Zn sowie deren Legierungen - das Verfahren kann aber auch für andere Metalle eingesetzt werden.Typical metals which are processed by the granulation method according to the invention for high reactivity in the melt, are selected from the group consisting of Al, Mg, Ca, Zn and their alloys - but the method can also be used for other metals.

Aufgrund der hohen Reaktivität der Metallschmelze ist es sinnvoll, dass das Schmelzen des Metalls und die Handhabung der Schmelze unter einer kontrollierten Gasatmosphäre stattfindet. Auch das Abkühlen der dispergierten Tröpfchen durch Gas erfolgt vorteilhafterweise mittels eines vorherbestimmten Abkühl-Gases aus einem oder mehreren inerten Gasen in einer offenen oder geschlossenen Granulationskammer 20, welche die kontrollierte Atmosphäre bietet.Due to the high reactivity of the molten metal, it makes sense that the melting of the metal and the handling of the melt takes place under a controlled gas atmosphere. Also, the cooling of the dispersed droplets by gas is advantageously accomplished by means of a predetermined cooling gas of one or more inert gases in an open or

Durch das erfindungsgemäße Verfahren ist die Herstellung von sphäroiden Partikeln feiner Kornstruktur hoher Form- und Größen-Uniformität aus der Schmelze möglich. Derartige Partikel mit feiner Kornstruktur eigenen sich besonders für Anwendungen wie Thixomolding, Sintern, Metal injection molding und ähnliche pulvermetallurgische Verfahren.By the method according to the invention, the production of spherical particles of fine grain structure of high shape and size uniformity from the melt is possible. Such particles having a fine grain structure are particularly suitable for applications such as thixomolding, sintering, metal injection molding and similar powder metallurgy processes.

Das erfindungsgemäße Verfahren eignet sich in besonders vorteilhafter Weise für die Herstellung von Granulat aus Magnesium oder Magnesiumlegierungen.The inventive method is particularly suitable for the production of granules of magnesium or magnesium alloys.

Unter Metall werden nachfolgend auch dessen jeweilige Legierungen sowie das Metall mit geringfügigen Verunreinigungen verstanden.The term "metal" below also refers to their respective alloys as well as the metal with minor impurities.

Unter sphäroid wird jegliche runde Form verstanden, wie bspw. Kugeln, Linsenformen, elliptische Formen etc., die keine scharfen oder eckigen Kanten aufweist.By spheroid is meant any round shape, such as, for example, balls, lens shapes, elliptical shapes, etc., which has no sharp or angular edges.

Dadurch, dass nun die Herstellung von Granulat direkt aus der Schmelze durch Abtropfen der Schmelze aus Öffnungen auf einen Drehteller erfolgt, kann die zusätzliche Zerspanung eingespart und dadurch Aufwand vermieden werden. Ferner kann eine sehr enge Kornverteilung bei einer runden bis linsenförmigen Kornform erreicht werden, wozu bisher aufwendige Trennverfahren notwendig Waren und auch viel Ausschuss produziert wurde. Somit kann erfindungsgemäß Abfall vermieden und Verfahrensschritte eingespart werden.The fact that now the production of granules takes place directly from the melt by draining the melt from openings on a turntable, the additional cutting can be saved and thereby effort is avoided. Furthermore, a very narrow particle size distribution can be achieved in the case of a round to lenticular grain shape, for which previously expensive separation processes were necessary goods and also a lot of rejects were produced. Thus, according to the invention, waste can be avoided and process steps can be saved.

Im Falle von sehr unedlen Erdalkalimetallen, wie Magnesium oder Calcium, bzw. deren Legierungen Können bekannte rotating disc Verfahren nicht einfach auf diese Metalle übertragen werden, sondern es müssen auch besondere Maßnahmen zum Schutz der hochreaktiven Metallschmelze, besonders bei Schmelztiegeln mit großer Oberfläche, getroffen werden.In the case of very base alkaline earth metals, such as magnesium or calcium, or their alloys known rotating disc methods can not be easily transferred to these metals, but it must also special measures to protect the highly reactive molten metal, especially for crucibles with a large surface, are made ,

Erfindungsgemäß wird der Zutritt von mit der Schmelze reagierenden Gasen, wie Wasserdampf, Sauerstoff, Stickstoff möglichst vermieden. Dazu erfolgt das Schmelzen unter einer Schutzdecke oder Schutzatmosphäre und der Transport der Schmelze über ein geschlossenes Rohrsystem zu den Austrittsöffnungen oder Düsen.According to the invention the access of reacting with the melt gases, such as water vapor, oxygen, nitrogen is avoided as possible. For this purpose, the melting takes place under a protective cover or protective atmosphere and the transport of the melt through a closed pipe system to the outlet openings or nozzles.

Nachfolgend wird die Erfindung anhand von Magnesiumlegierungen näher erläutert, sie eignet sich aber auch für andere in der Schmelze hochreaktive Metalle.The invention will be explained in more detail below with reference to magnesium alloys, but it is also suitable for other highly reactive metals in the melt.

Als Gas im Schmelzeofen selbst eignen sich verschiedenste Gase, entweder Inertgas oder aber auch Reaktivgas, wie Mischungen aus trockener Luft, Stickstoff oder Kohlendioxid mit Schwefeldioxid, Schwefelhexafluorid oder R134a, über der Schmelze, was zum Entstehen einer Schutzschicht auf der Schmelzbadoberfläche führt. Das Transportrohr, das flüssiges Metall aus dem Schmelzeofen zur Zerstäubungsstation fördert, ist geheizt, um Ablagerung von Magnesium bzw. von dessen Verbindungen durch Wärmekonvektion im Transportrohr zu verhindern, wobei auf eine möglichst gleichmäßige Wärmeverteilung in Längsrichtung des Rohrs zu achten ist. Entsprechende Maßnahmen sind dem Fachmann geläufig. Dabei kann die Schmelze im Kreis geführt werden, wodurch ein ständiger Rücklauf nicht auf den Drehteller ausgebrachter Schmelze in den Schmelzofen erfolgt und somit eine permanente Durchmischung des Schmelzevolumens unter Erhalt einer hohen Homogenität des Produkts und einer homogenen Temperaturverteilung erzielt wird. Vorteilhaft ist die hohe Strömungsgeschwindigkeit im Rohr, so dass Verunreinigungen (z.B. Oxide) permanent transportiert werden, nicht im Rohr abgelagert werden und dieses von innen verstopfen.As a gas in the furnace itself, a wide variety of gases, either inert or reactive gas, such as mixtures of dry air, nitrogen or carbon dioxide with sulfur dioxide, sulfur hexafluoride or R134a, above the melt, resulting in the formation of a protective layer on the melt surface. The transport tube, the molten metal from the melting furnace for Promotes sputtering station, is heated to prevent deposition of magnesium or its compounds by convection in the heat transfer tube, while ensuring the most uniform possible heat distribution in the longitudinal direction of the tube. Corresponding measures are familiar to the person skilled in the art. In this case, the melt can be circulated, whereby a constant return does not take place on the turntable ejected melt in the furnace and thus a permanent mixing of the melt volume is achieved while maintaining a high homogeneity of the product and a homogeneous temperature distribution. The high flow velocity in the pipe is advantageous, so that impurities (eg oxides) are permanently transported, are not deposited in the pipe and clog it from the inside.

Es ist aber auch möglich, mit einem Granulationsrohr ohne Rücklauf zu arbeiten, was zum Aufbau höherer Drücke im Rohr mit schnellerem Durchsatz führt.But it is also possible to work with a Granulationsrohr without return, resulting in the construction of higher pressures in the pipe with faster throughput.

Ebenfalls möglich sind Mischformen, bei denen der Rücklauf der Schmelze in den Schmelzofen durch ein Ventil abgebremst und so der Druck im Granulierohr an den Ausbringöffnungen bzw. Düsen geregelt werden kann. Der Druck an den Ausbringöffnungen kann so auch dynamisch während des Granuliervorganges verändert werden, wodurch ein Verstopfen der Austrittöffnungen verhindert bzw. ein bereits gebildeter Niederschlag wieder gelöst werden kann. Beim Einsatz einer Metallpumpe kann eine derartige Druckregelung nicht nur über ein Ventil am Rücklauf sondern auch durch eine Regelung der Förderleitung der Pumpe realisiert werden.Also possible are mixed forms in which the return of the melt in the melting furnace is decelerated by a valve and so the pressure in the granulation tube at the discharge openings or nozzles can be regulated. The pressure at the discharge openings can also be changed dynamically during the granulation process, whereby clogging of the outlet openings is prevented or an already formed precipitate can be released again. When using a metal pump, such a pressure control can be realized not only via a valve on the return but also by regulating the delivery line of the pump.

Das Rohr selbst kann vollflächig oder aber nur teilflächig geheizt werden, bspw. nur im unteren Bereich, um gerade dort die Konvektion zu erhöhen und das Absetzen von Reaktionsprodukten der Schmelze zu vermeiden.The pipe itself can be heated over the whole area or only over part of the area, for example only in the lower area, in order to increase the convection there and to avoid settling of reaction products of the melt.

Zum Formen der entstehenden Partikel ist eine Betrachtung der Geschwindigkeitsunterschiede zwischen dem Tropfen und dem ihm umgebenden Gas unerlässlich. Ferner wird Form und Größe der Partikel unter anderem durch Dichte, Viskosität, Oberflächenspannung und Durchmesser des aus der Ausbringöffnung austretenden Strahls (Düsendurchmesser, Düsenmaterial) beeinflusst.To shape the resulting particles, it is essential to consider the differences in velocity between the droplet and the surrounding gas. Furthermore, the shape and size of the particles are influenced inter alia by density, viscosity, surface tension and diameter of the jet emerging from the discharge opening (nozzle diameter, nozzle material).

Mit steigender Geschwindigkeit treten auf: Abtropfen, Rayleigh Zerfall, Wellenzerfall, Zerstäuben (diese Begriffe sind in

Problematisch ist, dass auch beobachtet wurde, dass sich die Austrittsdüsen von außen verstopfen, sich also beim Austritt der Metallschmelze aus der Düse Ablagerungen bilden. Daher muss die Ausbildung von Oxiden, Nitriden etc. vermieden werden. Dies kann dadurch erzielt werden, dass unter Schutzgas gearbeitet wird. Bei einer vollständig gekapselten Anlage ist jegliches Schutzgas möglich, bei (teilweise) offenen Anlagen ist es sinnvoll, dass das Schutzgas leichter als Luft ist und so gegen die fallenden Tropfen geleitet wird, so dass Zutritt von unerwünschten Gasen wie Sauerstoff/Stickstoff zu den Düsen, was zur Ausbildung der unerwünschten Ablagerungen führt, verhindert wird. Dies kann bei offenen Kammern, in denen das Metall in das leichte Schutzgas tropft, bspw. durch Leitbleche am Granulationsrohr erreicht werden.The problem is that it has also been observed that the outlet nozzles clog from the outside, ie form deposits on exit of the molten metal from the nozzle. Therefore, the formation of oxides, nitrides, etc. must be avoided. This can be achieved by working under inert gas. In a fully enclosed plant any inert gas is possible, in (partially) open plants it makes sense that the shielding gas is lighter than air and thus directed against the falling drops, so that access of undesirable gases such as oxygen / nitrogen to the nozzles, which leads to the formation of unwanted deposits is prevented. This can be achieved with open chambers in which the metal drips into the light protective gas, for example. By baffles on the granulation tube.

Es ist aber auch wichtig, die Bildung von unerwünschten Verbindungen bereits im Schmelzeofen zu vermeiden - entweder durch Auswahl eines geeigneten Tiegelmaterials, wie es dem Fachmann bekannt ist, das sich nicht durch die Schmelze anlösen lässt oder aber auch durch Filtermaßnahmen vor der Schmelzenförderpumpe, welche grobe Teilchen zurückhalten.But it is also important to avoid the formation of undesirable compounds already in the furnace - either by selecting a suitable crucible material, as is known in the art, which can not dissolve through the melt or by filter measures before the melt feed pump, which coarse Withhold particles.

Es ist insbesondere überraschend, dass die Korngrößenvariation beim erfindungsgemäßen Verfahren gering ist, was bei Zerspanungsverfahren nur über aufwendige weitere Sieben/Sichten Betriebsschritte erzielt werden kann.It is particularly surprising that the particle size variation in the method according to the invention is low, which can only be achieved in the case of machining processes by means of expensive further sieving / sifting operations.

Bei der erfindungsgemäßen Herstellung sphäroider Partikel wurde beobachtet, dass das Verfahren bei geringerem Herstellungsaufwand Partikel gleicher und besserer Eigenschaften beim Thixomolding wie herkömmlich durch Zerspanen und Kornfraktionierung hergestellte Granulate lieferten.In the production of spherical particles according to the invention, it was observed that the process yielded particles of the same and better properties during thixomolding than granules conventionally produced by machining and grain fractionation with a lower production outlay.

Durch das erfindungsgemäße Verfahren werden unter anderem die nachfolgenden Vorteile erzielt:

- 1) niedrigere Herstellungskosten durch Einsparen des Zerspanens

- 2) weniger Rückstand gegenüber Zerspanen (die Barren können nicht vollständig zerspant werden)

- 3) Einsparung von Fraktionierungsstufen

- 4) Reduktion von das Förderverhalten und Reaktionsverhalten der Partikel änderndem Abrieb, der bei Transport des durch Zerspanen hergestellten scharfkantigen Granulats entsteht, durch runde Form

- 5) feinere Mikrostruktur der Granulatpartikel mit entsprechend besseren Eigenschaften von mit dem Granulat herstellten Bauteilen.

- 1) lower manufacturing costs by saving the cutting

- 2) less residue compared to machining (the ingots can not be machined completely)

- 3) Savings of fractionation levels

- 4) reduction of the conveying behavior and reaction behavior of the particle-changing abrasion, which results from transport of the sharp-edged granules produced by machining, by round shape

- 5) finer microstructure of the granule particles with correspondingly better properties of produced with the granules components.

Einstellen der Zusammenhänge zwischen Vorrichtungen und Verfahren gemäß der Erfindung ermöglicht die Herstellung relativ runder, sphäroider, elliptischer oder linsenförmiger Partikel verschiedener Größe und vielfältiger Anwendbarkeit, wie beim Sintern, Thixomolding (Metallspritzgießen), Pressen etc.Adjusting the relationships between devices and methods according to the invention enables the production of relatively round, spheroidal, ellipsoidal or lenticular particles of various sizes and various applicability, such as in sintering, thixomolding (metal injection molding), pressing, etc.

Die Erfindung schafft Verfahren, Vorrichtungen und Systeme zur Herstellung von Granulatpartikeln gleichmäßiger sphäroider Form und hoher Sphärizität, bestehend aus Metall und dessen Legierungen durch Einsatz einer verbesserten Rotating-Disc Anlage.The invention provides methods, devices and systems for producing granular particles of uniform spheroidal shape and high sphericity consisting of metal and its alloys by use of an improved rotating disc apparatus.

Nachfolgend wird die Erfindung im Einzelnen anhand von Ausführungsbeispielen, die lediglich der Erläuterung dienen und keinesfalls einschränkend sind, näher erläutert. Darin zeigt:

-

FIG. 1 eine Ausführungsform der erfindungsgemäßen Anlage mit der Granulationsvorrichtung; -

Fig. 2A und 2B Gefüge eines mechanischen Granulates und eines schmelzmetallurgisch hergestellten Granulates (AZ 91). -

FIGS. 3A und 3B schematisch verschiedene Ausführungsformen des Transportrohrs -

Fig. 4 erfindungsgemäß hergestelltes Granulat der Magnesiumlegierung AZ 91.

-

FIG. 1 an embodiment of the system according to the invention with the granulation device; -

FIGS. 2A and 2B Structure of a mechanical granulate and a melt-metallurgically produced granulate (AZ 91). -

FIGS. 3A and 3B schematically different embodiments of the transport tube -

Fig. 4 granules of the magnesium alloy AZ 91 produced according to the invention.

In

Die Erfindung schafft Verfahren, Vorrichtungen und Systeme zur Herstellung von Metall-Granulat wobei die Partikel gleichmäßig sphäroide Form haben - wie aus

Dazu wird mindestens ein zu Tröpfchen zerfallener Strahl des geschmolzen Metalls auf einen rotierenden Teller gerichtet. Der Schmelzestahl wird mit Schutzgas, hier überwiegend Helium, angeströmt. Eine Glocke aus Leitblechen unterhalb des Granulierrohres verhindert als Granulationskammer ein Abströmen des Schutzgases und hält eine Atmosphäre, die eine Oxidation der aus den Düsen austretenden Schmelze verhindert, aufrecht. Die Tröpfchen treffen auf den kalten, bevorzugt gekühlten Drehteller. Der Drehteller entzieht dem Schmelztröpfchen so schnell Wärme, dass es zu einer raschen Erstarrung der Schmelze zu einem Granulatpartikel mit feinkörniger Mikrostruktur kommt. Die Drehbewegung des Tellers verhindert ein Aufeinandertreffen/Koaleszenz der Schmelzetröpfchen und stellt so eine Erstarrung der Tropfen zu diskreten Partikeln sicher. Die Partikel werden hier durch den hier als eine Leiste ausgebildten Abstreifer über den Tellerrand in einen Behälter geschoben. Denkbar sind auch andere Einrichtungen zur Entfernung der erstarrten Partikel wie Bürsten, Gebläse, usw.For this purpose, at least one jet of molten metal, which has been broken down into droplets, is directed onto a rotating dish. The molten steel is supplied with inert gas, here predominantly helium. A bell made of baffles below the Granulierrohres prevented as a granulation chamber outflow of the protective gas and maintains an atmosphere that prevents oxidation of the exiting the nozzle melt, upright. The droplets hit the cold, preferably cooled turntable. The turntable removes heat from the melt droplet so quickly that a rapid solidification of the melt results in a granular particle with a fine-grained microstructure. The rotational movement of the plate prevents the melting droplets from meeting / coalescing, thus ensuring solidification of the droplets into discrete particles. The particles are pushed here by the trained here as a strip scraper over the edge of the plate in a container. Also conceivable are other means for removing the solidified particles such as brushes, blowers, etc.

Der Druck im Granulierrohr 5 wird bei dieser Ausführungsform durch eine Kreiselpumpe erzeugt. Generell sind alle bekannten Pumpverfahren und -Systeme zum Aufbau des Schmelzdruckes bzw. der Schmelzeströmung im Gießrohr geeignet, wie beispielsweise Kolbenpumpen, Induktionspumpen, pneumatische Pumpsysteme, aber auch zur Druckbeaufschlagung des Ofenraumes sowie pumpenfreie Fördersysteme, welche zum Beispiel nach dem Prinzip der kommunizierenden Röhren funktionieren, können eingesetzt werden.The pressure in the

Form und Größe der Granulatpartikel sind durch verschiedene Anlagenparameter beeinflussbar. Dazu gehören unter anderem der Abstand des Gießrohres zum Drehteller also die Fallhöhe der aus den Düsen austretenden Schmelze; der Düsendurchmesser, der Schmelzedruck, die Schmelzetemperatur sowie die Ausführung des Granulierohres (mit bzw. ohne Rücklauf). Darüber hinaus bestimmen Temperatur, Strömungsgeschwindigkeit, Zusammensetzung und Anströmwinkel des Schutzgases sowie die Temperatur des Drehtellers die Form und Größe der Granulatpartikel. Je nach Parameterkombination ist die Partikelform unterschiedlich sphäroid z. B. plättchen-, linsen-, kugel- bzw. zylinderförmig. Z. B. bewirkt Erhöhung der Drehgeschwindigkeit des Tellers eine länglichere Form des gebildeten Partikel.The shape and size of the granulate particles can be influenced by various system parameters. These include, inter alia, the distance of the pouring tube to the turntable so the drop height of emerging from the nozzle melt; the nozzle diameter, the melt pressure, the melt temperature and the design of the granulation tube (with or without return). In addition, determine temperature, flow velocity, composition and angle of attack of the protective gas and the temperature of the turntable, the shape and size of the granular particles. Depending on the combination of parameters, the particle shape is different spheroid z. B. platelet, lens, spherical or cylindrical. For example, increasing the rotational speed of the plate causes a more elongate shape of the formed particle.

Vor dem Granulieren werden die metallischen Ausgangsmaterialien, bspw. Magnesium-Druckgußschrott, unter einer schützenden Gasatmosphäre ausgewählt aus der Gruppe bestehend aus Edelgasen wie Argon, Neon und Helium oder Stickstoff, Kohlendioxid bzw. trockener Luft mit Zusätzen von Schwefeldixod, Schwefelhexafluorid oder r-134a oder Mischungen derselben im Schmelzeofen 3 geschmolzen. Es ist aber auch möglich, das Schmelzen unter Zugabe von Salzen durchzuführen, was zur Ausbildung einer Schutzschicht aus flüssigem Salz auf der Schmelzbadoberfläche führt und so eine Reaktion der Schmelze mit der Luft verhindert. Für diesen Prozessschritt sind alle bekannten Schutzmaßnahmen für Schmelzen aus dem jeweiligen Metall bei diesem Beispiel von Magnesium bzw. Magnesiumlegierungen geeignet.Prior to granulation, the metallic starting materials, for example magnesium die-cast scrap, are selected under a protective gas atmosphere from the group consisting of noble gases such as argon, neon and helium or nitrogen, carbon dioxide or dry air with additions of sulfur dioxide, sulfur hexafluoride or r-134a or Mixtures thereof melted in the

Ein Verfahren der Erfindung zur Herstellung kleiner sphäroider Partikel mit feinkristalliner Zusammensetzung und hoch-uniformer Größe und Form, umfaßt die nachfolgenden Schritte:

- ▪ Schmelzen des metallischen Ausgangsmaterials;

- ▪ Leiten des geschmolzenen Metalls in einem beheizten Granulierrohr über einen Drehteller.

- ▪ Austritt des geschmolzenen Metalls aus Düsen im Granulierohr auf den Drehteller.

- ▪ Erstarren des Metalls auf einem Drehteller zu sphäroiden Partikeln.

- ▪ melting of the metallic starting material;

- ▪ passing the molten metal in a heated granulating tube through a turntable.

- ▪ Outflow of molten metal from nozzles in the granulating tube to the turntable.

- ▪ Solidification of the metal on a turntable to spherical particles.

Ausführungsformen können bspw. umfassen:

- 1) Vereinzeln des als Strahl aus den Düsen im Granulierrohr austretenden geschmolzenen Metalls durch Strahlzerfall in Tröpfchen.

- 2) Austreten des geschmolzenen Metalls aus den Düsen unter Schutzgasanströmung.

- 3) Rückführung des Schmelzestromes im Granulierrohr in den Ofen

- 4) Kühlung des Drehtellers von unten z. B. mit Wasser

- 1) Separation of the molten metal emerging as a jet from the nozzles in the granulation tube by jet disintegration into droplets.

- 2) leakage of the molten metal from the nozzles under inert gas flow.

- 3) Return of the melt stream in Granulierrohr in the oven

- 4) cooling of the turntable from below z. B. with water

Metallpulver, die über das Zerspanungsverfahren hergestellt werden, leiden ferner allgemein häufig an ungleichmäßiger Zusammensetzung.

Beim Dispergieren des geschmolzen Metalls ist der äußere Gasdruck auf den Umfang der verteilten Tröpfchen bevorzugt atmosphärischer Druck.Metal powders made by the machining process also generally suffer from uneven composition in general.

When dispersing the molten metal, the external gas pressure on the circumference of the dispersed droplets is preferably atmospheric pressure.

Dadurch werden kleine sphäroide Partikel feinkristalliner Kornstruktur und hoch uniformer Größe und hoher Sphärizität erhalten, deren Größe und Form durch die Geschwindigkeit des Austritts der Metallschmelze aus den Austrittsöffnungen, die Schmelzetemperatur am Austritt, die Rotationsgeschwindigkeit des Drehtellers und die Form des Drehtellers gesteuert werden kann.As a result, small spherical particles of fine crystalline grain structure and highly uniform size and high sphericity are obtained, the size and shape of which can be controlled by the exit velocity of the molten metal, the melt temperature at the outlet, the rotation speed of the turntable, and the shape of the turntable.

Magnesiumdruckgussschrott der Legierung AZ91 wird in einem elektrisch beheizten Schmelzeofen unter Stickstoff mit 0,20 % r-134 a bei 680 °C geschmolzen. Im Schmelzeofen befindet sich eine Kreiselpumpe, welche mit 5500 Umdrehungen pro Minute die Magnesiumschmelze in ein aus dem Schmelzeofen führendes, blind endendes, geschlossenes, geheiztes Granulierrohr mit 16 Ausbringdüsen fördert. Unter den Ausbringdüsen läuft ein wassergekühlter Drehteller. Beim Austreten der Schmelze aus den Düsen bildet sich ein Schmelzestrahl, der in einer Fallhöhe von 120 mm zu Tropfen zerfällt. Helium wird als Schutzgas gegen den Schmelzestrahl geführt. Leitbleche um das Granulierrohr bilden eine Glocke, die ein Entweichen des Heliums nach oben verhindern und zwischen Granulierrohr und Drehteller eine Granulierkammer 20 und eine Heliumatmosphäre zum Schutz der Schmelze vor Oxidation bildet. Beim Auftreffen der Schmelztropfen auf den Teller erstarren diese zu Partikeln, bevor sie durch die Drehbewegung des Tellers die durch die Leitbleche gebildete offene Granulationskammer 20 verlassen. Die Drehung des Tellers erfolgt entsprechend den Anforderungen an die Partikelform mit einer Geschwindigkeit von 4-10 Umdrehungen pro Minute. Es entstehen linsenförmige Partikel hoher Formuniformität. Die Partikel werden mit einem Abstreifer von dem Drehteller in einen Behälter geleitet. Durch nachfolgende Siebungen können große, zum Teil nicht maßhaltige Partikel getrennt werden.

Ein lichtmikroskopisches Bild eines Querschnitts der so hergestellten Partikel ist in

Somit sind die erfindungsgemäß hergestellten Mg-Partikel sowohl hinsichtlich ihrer Mikrostruktur, als auch in ihrer äußeren Gestalt den durch Zerspanungsverfahren hergestellten Partikeln überlegen.Thus, the Mg particles produced according to the invention are superior to the particles produced by machining processes both in terms of their microstructure and their external shape.

Während die Erfindung anhand eines Ausführungsbeispiels näher erläutert wurde, ist dem Fachmann offensichtlich, dass verschiedenste Abwandlungen dieser Lehre im Rahmen des Schutzumfangs der Erfindung offensichtlich sind. Der Schutzumfang ist daher nur durch die beiliegenden Ansprüche begrenzt.While the invention has been explained in more detail with reference to an embodiment, it is obvious to the person skilled in the art that various modifications of this teaching are obvious within the scope of the invention. The scope of protection is therefore limited only by the appended claims.

- 11

- Drehtellerturntable

- 22

- Schmelzepumpemelt pump

- 33

- Schmelzeofenmelting furnace

- 55

- GranulierrohrGranulierrohr

- 66

- Schmelzemelt

- 77

- RücklaufrohrReturn pipe

- 88th

- Tröpfchendroplet

- 1212

- weggeschleuderte Partikelthrown particles

- 1414

- Inertgasstrominert gas

- 1616

- Austrittsöffnung im GranulierrohrOutlet opening in the granulation tube

- 2020

- Granulationskammergranulation

Claims (13)

- Device for manufacturing rounded metal particles having a high uniformity in size and shape from a molten mass, comprising:- a granulation chamber (20) which is substantially filled with inert gas and which has a closed granulation tube (5) with at least one molten mass exit opening (16), with the granulation tube (5) guiding the molten mass to the exit openings;- a rotary disc (1) which is located at a distance below the molten mass exit opening (16) of the granulation tube (5) and which can be operated with a selected speed, so that the molten metal that is dripping from the molten mass exit opening (16) solidifies in discrete particles on the surface of the disc, and- a gas introducing device for creating a controlled incident flow of protective gas within the counter flow that is impinging on the molten mass which exits from the exit opening and for creating a protective atmosphere in the granulation chamber (20).

- Device according to claim 1, characterized in that the granulating rotary disc (1) is cooled.

- Device according to claim 1 or 2, characterized in that the granulation tube (5) is heated.

- Device according to one of the preceding claims, characterized in that the granulation tube (5) comprises a blank flange.

- Device according to one of the claims 1 - 3, characterized in that the granulation tube (5) is guided back into the melting furnace (3).

- Device according to claim 5, characterized in that a valve device for controlling the throughflow is provided inside the granulation tube.

- Device according to one of the preceding claims, characterized in that a feed pump is provided in/at the melting furnace (3) for the purpose of feeding the molten metal mass to/into the granulation tube (5).

- Device for manufacturing rounded metal particles from a highly reactive molten metal mass that have a high uniformity with regard to their size and shape, comprising the following steps:- melting the metallic source material under the exclusion of air;- transporting the molten metal mass in a closed granulation tube from the melting furnace to at least one molten mass exit- exit of the molten mass from the molten mass exit above a rotary disc in the form of discrete droplets as a molten mass jet, which breaks up into droplets by the time it impinges on the rotary disc- guiding a stream of protective gas against the molten mass which is exiting from the molten mass exit,- collecting the molten mass in the form of discrete molten mass drops on the rotary disc,- solidifying of the molten mass drops into granulate particles through their contact with the colder surface of the rotary disc, and- guiding of the granulate particles from the rotary disc for packaging/further processing.

- Device according to claim 8, characterized in that the source material of the method is chosen from the group that consists of Al, Mg, Ca, Zn as well as their alloys.

- Device according to claim 8 or 9, characterized in that melting of the metal is carried out under a controlled gas atmosphere.

- Device according to the claims 8 - 10, characterized in that the stream of protective gas for the molten mass which is exiting from the molten mass exit includes helium.

- Device according to claims 8 - 11, characterized in that the breaking up of the melt jet which is exiting from the molten mass exit opening is supported by a pulsating up-and-down movement of the granulation tube.

- Use of the method according to claim 8 - 12 for the purpose of manufacturing spheric particles having a fine micro structure as well as a high uniformity with regard to their shape and size from the molten mass.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102009010600A DE102009010600A1 (en) | 2009-02-25 | 2009-02-25 | Production of roundish metal particles |

| PCT/DE2010/000324 WO2010097079A2 (en) | 2009-02-25 | 2010-02-25 | Production of spheroidal metal particles |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2421997A2 EP2421997A2 (en) | 2012-02-29 |

| EP2421997B1 true EP2421997B1 (en) | 2015-04-08 |

Family

ID=42665979

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10745842.4A Not-in-force EP2421997B1 (en) | 2009-02-25 | 2010-02-25 | Production of spheroidal metal particles |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20120195786A1 (en) |

| EP (1) | EP2421997B1 (en) |

| BR (1) | BRPI1008736A2 (en) |

| CA (1) | CA2753577A1 (en) |

| DE (2) | DE102009010600A1 (en) |

| MX (1) | MX2011008947A (en) |

| WO (1) | WO2010097079A2 (en) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102013000248B4 (en) | 2013-01-08 | 2019-10-17 | Volkswagen Aktiengesellschaft | Apparatus for producing metal granules from the liquid phase |

| DE102013000249A1 (en) | 2013-01-08 | 2014-07-10 | Volkswagen Aktiengesellschaft | Device for production of metal granules e.g. magnesium granules used for metal injection molding, has collecting device with which semi-solid granule bits are collected and are solidified into granule grains |

| US10661346B2 (en) | 2016-08-24 | 2020-05-26 | 5N Plus Inc. | Low melting point metal or alloy powders atomization manufacturing processes |

| JP6926844B2 (en) * | 2017-08-31 | 2021-08-25 | セイコーエプソン株式会社 | Raw material for thixomolding, manufacturing method of raw material for thixomolding and molded product |

| KR102546750B1 (en) | 2018-02-15 | 2023-06-22 | 5엔 플러스 아이엔씨. | Method for producing atomization of high melting point metal or alloy powder |

| CN112497563B (en) * | 2020-11-12 | 2022-05-20 | 建德市春盛塑业有限公司 | Plastic particle and preparation process thereof |

| EP4382228A1 (en) * | 2022-12-07 | 2024-06-12 | Fehrmann GmbH | Atomization apparatus for producing metal powder, use thereof and method for operating an atomization apparatus |

| CN117921013B (en) * | 2024-02-01 | 2024-09-13 | 安徽中体新材料科技有限公司 | Titanium alloy powder preparation facilities |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB746301A (en) * | 1953-03-18 | 1956-03-14 | Dow Chemical Co | Atomizing magnesium |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE739743C (en) * | 1936-02-08 | 1943-10-16 | Hermann Plauson | Process for the production of the finest metal powder from liquid metal |

| DE1081741B (en) * | 1953-03-18 | 1960-05-12 | Dow Chemical Co | Process for producing magnesium alloys in spherical form |

| GB754180A (en) * | 1953-09-18 | 1956-08-01 | Dow Chemical Co | Atomizing aluminium or aluminium alloys |

| JPS5164456A (en) | 1974-12-02 | 1976-06-03 | Nisshin Steel Co Ltd | KYUJOKINZOKU FUNMATSUNO SEIZOHO OYOBI SOCHI |

| DE2936691C2 (en) * | 1979-09-11 | 1984-08-02 | Itoh Metal Abrasive Co., Ltd., Nagoya, Aichi | Device for producing spherical particles or fibers |

| US4687510A (en) * | 1983-01-24 | 1987-08-18 | Gte Products Corporation | Method for making ultrafine metal powder |

| JPS6333508A (en) | 1986-07-25 | 1988-02-13 | Natl Res Inst For Metals | Production of metallic powder of alloy powder |

| JPH07173510A (en) | 1992-05-15 | 1995-07-11 | Shin Etsu Chem Co Ltd | Production of globular metal fine particle |

| JPH0754019A (en) * | 1993-08-17 | 1995-02-28 | Nippon Sozai Kk | Production of powder by multistage fissure and quenching |

| JPH07179912A (en) | 1993-12-22 | 1995-07-18 | Minerva Kiki Kk | Production of globular metallic grain |

| US5951738A (en) * | 1995-10-27 | 1999-09-14 | Alcan International Limited | Production of granules of reactive metals, for example magnesium and magnesium alloy |

-

2009

- 2009-02-25 DE DE102009010600A patent/DE102009010600A1/en not_active Withdrawn

-

2010

- 2010-02-25 MX MX2011008947A patent/MX2011008947A/en not_active Application Discontinuation

- 2010-02-25 DE DE202010018019U patent/DE202010018019U1/en not_active Expired - Lifetime

- 2010-02-25 US US13/203,145 patent/US20120195786A1/en not_active Abandoned

- 2010-02-25 WO PCT/DE2010/000324 patent/WO2010097079A2/en active Application Filing

- 2010-02-25 BR BRPI1008736A patent/BRPI1008736A2/en not_active Application Discontinuation

- 2010-02-25 EP EP10745842.4A patent/EP2421997B1/en not_active Not-in-force

- 2010-02-25 CA CA2753577A patent/CA2753577A1/en not_active Abandoned

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB746301A (en) * | 1953-03-18 | 1956-03-14 | Dow Chemical Co | Atomizing magnesium |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2421997A2 (en) | 2012-02-29 |

| WO2010097079A2 (en) | 2010-09-02 |

| DE102009010600A1 (en) | 2010-11-11 |

| BRPI1008736A2 (en) | 2016-03-08 |

| MX2011008947A (en) | 2012-02-08 |

| DE202010018019U1 (en) | 2013-08-09 |

| WO2010097079A3 (en) | 2011-12-29 |

| US20120195786A1 (en) | 2012-08-02 |

| WO2010097079A4 (en) | 2012-03-01 |

| CA2753577A1 (en) | 2010-09-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2421997B1 (en) | Production of spheroidal metal particles | |

| DE68905448T2 (en) | Silicon powder and process for its manufacture. | |

| DE68917132T2 (en) | METHOD AND DEVICE FOR SPRAYING A METAL MELT. | |

| DE69508581T2 (en) | METHOD AND DEVICE FOR INJECTION MOLDING METALS IN SEMI-SOLID CONDITION | |

| DE3505659A1 (en) | MELT SPRAYING WITH REDUCED GAS FLOW AND DEVICE FOR SPRAYING | |

| AT522377B1 (en) | Production of a metal powder of an aluminum alloy for use as a material in additive manufacturing | |

| DE2252139A1 (en) | METHOD AND APPARATUS FOR THE PRODUCTION OF PRECISION MOLDS FROM MOLTEN METALS | |

| DE3505660A1 (en) | DEVICE AND METHOD FOR SPRAYING UNSTABLE MELTING FLOWS | |

| EP1474224B1 (en) | Method for producing particle-shaped material | |

| DE3341184A1 (en) | Process for the production of ultrafine solid metal particles | |

| DE3505662A1 (en) | METHOD FOR THE PRODUCTION OF FINE POWDER FROM MOLTEN METAL AND A DEVICE FOR SPRAYING | |

| DE69504346T2 (en) | METHOD FOR SPRAYING A DISPERSABLE LIQUID | |

| EP0007536B1 (en) | Method and device for granulating a metal melt so as to produce powder | |

| DE2553131A1 (en) | SHOULDING GOODS FROM SECTIONS OF METAL FOR THE PRODUCTION OF METAL POWDER FOR POWDER METALLURGICAL PURPOSES AND METHODS FOR MANUFACTURING THE SHOEING GOODS | |

| DE69224505T2 (en) | METHOD AND DEVICE FOR PRODUCING METAL POWDER | |

| AT524161B1 (en) | PREPARATION OF A METAL POWDER | |

| DE69418938T2 (en) | ADDITIVES FOR THE PRODUCTION OF ALLOYS | |

| DE19800433C2 (en) | Continuous casting process for casting an aluminum plain bearing alloy | |

| WO2001077403A1 (en) | Metal or metal alloy based sputter target and method for the production thereof | |

| DE2049458C3 (en) | Device for the production of metal granulate and process for their operation | |

| DE2558908B2 (en) | Method and device for the production of solid slag material | |

| DE2263268A1 (en) | METHOD OF MANUFACTURING LEAD ALUMINUM ALLOYS | |

| WO2008067868A1 (en) | Process for production of particles of free-flowing material and spraying unit therefor | |

| DE60210126T2 (en) | PREPARATION OF MATERIAL FOR FORMING IN HALF-RESISTANT CONDITION | |

| DE19918231C2 (en) | Method of manufacturing blanks for cylinder liners |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA RS |

|

| 17P | Request for examination filed |

Effective date: 20120628 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20130320 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20141110 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 720650 Country of ref document: AT Kind code of ref document: T Effective date: 20150515 Ref country code: CH Ref legal event code: NV Representative=s name: TROESCH SCHEIDEGGER WERNER AG, CH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502010009307 Country of ref document: DE Effective date: 20150521 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20150408 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150810 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150808 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150709 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 |

|