EP2340397B1 - Burner insert for a gas turbine combustion chamber and gas turbine - Google Patents

Burner insert for a gas turbine combustion chamber and gas turbine Download PDFInfo

- Publication number

- EP2340397B1 EP2340397B1 EP09823099.8A EP09823099A EP2340397B1 EP 2340397 B1 EP2340397 B1 EP 2340397B1 EP 09823099 A EP09823099 A EP 09823099A EP 2340397 B1 EP2340397 B1 EP 2340397B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- combustion chamber

- burner

- gas turbine

- wall

- burner insert

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000002485 combustion reaction Methods 0.000 title claims description 92

- 239000012809 cooling fluid Substances 0.000 claims description 6

- 239000007789 gas Substances 0.000 description 40

- 238000001816 cooling Methods 0.000 description 33

- 239000000567 combustion gas Substances 0.000 description 4

- 239000003344 environmental pollutant Substances 0.000 description 3

- 231100000719 pollutant Toxicity 0.000 description 3

- 239000000446 fuel Substances 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 238000005524 ceramic coating Methods 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 230000010355 oscillation Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 238000009827 uniform distribution Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R3/00—Continuous combustion chambers using liquid or gaseous fuel

- F23R3/002—Wall structures

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R3/00—Continuous combustion chambers using liquid or gaseous fuel

- F23R3/02—Continuous combustion chambers using liquid or gaseous fuel characterised by the air-flow or gas-flow configuration

- F23R3/04—Air inlet arrangements

- F23R3/10—Air inlet arrangements for primary air

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R2900/00—Special features of, or arrangements for continuous combustion chambers; Combustion processes therefor

- F23R2900/03042—Film cooled combustion chamber walls or domes

Definitions

- the present invention relates to a combustor liner for a gas turbine combustor having a burner port for inserting a combustor.

- the invention relates to a gas turbine.

- Gas turbine combustors have a burner-side end and a turbine-side end.

- the turbine-side end is open and allows outflow of combustion gases in the hot combustion gases to the turbine.

- a burner insert is present, which has a heat-resistant hot side and a cooled cold side. The burner is inserted into an opening of the burner insert.

- cooling air which usually comes from the compressor, flows along the cold side from the burner opening of the burner insert to its outer edge, from where the cooling air flows into the combustion chamber.

- An example of a burner insert in a tube combustion chamber is in US 2005/0016178 A1 described. Another similar example is in US 5,396,759 A disclosed.

- annular combustion chambers that is to say of combustion chambers which extend annularly around the turbine rotor

- a multiplicity of combustion inserts in the circumferential direction of the annular combustion chamber are usually arranged next to one another.

- the cooling air flowing past the cold side of the burner side then flows into the combustion chamber between the radially outer wall and the radially inner wall of the combustion chamber.

- cooling air can also be introduced into the combustion chamber by gaps between circumferentially adjacent combustion inserts.

- Such an annular combustion chamber is, for example, in EP 1 557 607 A1 described.

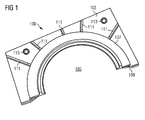

- FIG. 1 A burner insert for an annular combustion chamber is shown schematically in FIG. 1 shown.

- the figure shows a burner insert for an annular combustion chamber in a cut perspective view on its cold side 103.

- an opening 105 In the center of the cold side 103 of the burner insert 100 is an opening 105 into which the burner can be used.

- the burner insert is fastened by means of an annular ridge 107 in a cold side projecting portion 109 of the burner insert 100 to a support structure in the gas turbine housing.

- the cold side 103 of the burner insert 100 is provided with ribs 111.

- support screws 113 are present, which in FIG. 1 are indicated only schematically.

- the screws 113 and the ribs 111 represent support sections, with which the cold side comes to rest on the support structure in the gas turbine housing.

- it may lead to the formation of a non-uniform gap along the peripheral edge of the burner insert, which can lead to an oversupply of cooling air in places with increased gap.

- this is due to the fact that in addition to the ribs 111 and the support bolts 113 are present, a static overdetermination, since the burner insert 100 is to rest on the screws except at the same time on the ribs 11.

- the first object is achieved by a burner insert according to claim 1, the second object by a gas turbine combustor according to claim 5 or a gas turbine according to claim 9.

- the dependent claims contain advantageous embodiments of the invention.

- An inventive burner insert for a gas turbine combustor has a burner insert wall with a cold side and a hot side.

- a burner opening for inserting a burner is formed in the burner insert wall.

- the burner insert has an outer edge delimiting the burner insert wall with an at least partially encircling edge web projecting over the cold side.

- the edge may in this case be substantially circular, for example in the case of a tube combustion chamber, or, for example in the case of an annular combustion chamber, have the shape of the edge of a circular ring cutout. Other contours are basically possible depending on the shape of the combustion chamber.

- the edge web of the burner insert according to the invention leads to an increase in the natural frequencies in comparison to a burner insert according to the prior art, as with reference to FIG. 1 has been described.

- the vibration load of the burner insert during operation of the combustion chamber is therefore reduced in comparison to the burner insert from the prior art.

- the edge web can rest completely on the support structure in the gas turbine housing, so that a uniform gap, preferably a zero gap, is present along the entire edge.

- the edge web is provided with openings for the passage of cooling fluid. To realize the openings, the edge web has pinnacles, between which the openings are formed

- the edge web runs around the entire edge of the burner insert.

- the rigidity of the edge of the burner insert is then particularly high.

- the burner opening is surrounded by an annular, over the cold side projecting and provided with an annular web wall portion. Otherwise, the burner insert wall is formed flat, d. H.

- the existing in the art ribs there are no other structures, such as the existing in the art ribs. In the case of the burner insert according to the invention such ribs are superfluous, since it has been shown that a uniform distribution of the cooling air takes place even without such ribs. Also, a stiffening function of the ribs is not needed in the burner insert according to the invention.

- the burner insert according to the invention makes it possible to save cooling air, since no uneven gap dimensions occur, which can lead to an oversupply in the cooling air supply.

- the reduced supply of cooling air into the combustion chamber results in a reduced pollutant emissions of the gas turbine and higher turbine inlet temperatures, which in turn allows an increase in efficiency of the gas turbine.

- the design of the burner insert according to the invention also enables a cost reduction, since the stiffening screws are eliminated and therefore fewer components are required in comparison to the burner insert described in the introduction.

- a gas turbine combustor according to the invention has at least one burner, at least one combustion chamber wall surrounding a combustion chamber interior, and at least one burner end wall on the burner side. It comprises a burner insert according to the invention whose burner insert wall forms the combustion chamber end wall, the hot side of the burner insert wall facing the combustion chamber interior.

- the combustion chamber wall may be cylindrical in the case of a tube combustion chamber. In the case of an annular combustion chamber, however, two combustion chamber walls are present, namely a radially outer and a radially inner combustion chamber wall.

- a gap may be present between the combustion chamber closure wall formed by the at least one burner insert and the at least one combustion chamber wall, which allows the outflow of cooling air from the cold side of the combustion insert into the combustion chamber.

- the burner-side combustion chamber end wall can be formed in particular by a number in the circumferential direction of the combustion chamber juxtaposed burner inserts. There may be gaps between adjacent burner inserts which allow the flow of cooling air between the burner inserts into the annular combustion chamber.

- a gas turbine according to the invention is equipped with at least one gas turbine combustion chamber, which is designed as a gas turbine combustion chamber according to the invention.

- the gas turbine according to the invention comprises a cooling fluid reservoir, for example a combustion chamber plenum communicating with the output of a compressor, wherein the cold side of the burner insert wall is fluidically connected to the cooling fluid reservoir.

- FIG. 2 shows a gas turbine 1 in a longitudinal section.

- This comprises a compressor section 3, a combustion chamber section 5 and a turbine section 7.

- a shaft 9 extends through all sections of the gas turbine 1.

- the shaft 9 is provided with rings of compressor blades 11 and in the turbine section 7 with rings of turbine blades 13.

- Wreaths of compressor guide vanes 15 are located between the rotor blade rings in the compressor section 3 and rings of turbine guide vanes 17 in the turbine section 17.

- the guide vanes extend from the housing 19 of the gas turbine installation 1 essentially in the radial direction to the shaft 9.

- air 23 is sucked in through an air inlet 21 of the compressor section 3 and compressed by the compressor rotor blades 11.

- the compressed air is supplied to a combustion chamber 25 arranged in the combustion chamber 25, which is configured in the present embodiment as an annular combustion chamber, into which a gaseous or liquid fuel via at least one burner 27 is injected.

- the resulting air-fuel mixture is ignited and burned in the combustion chamber 25.

- the hot combustion exhaust gases flow from the combustor 25 into the turbine section 7, where they expand and cool, imparting momentum to the turbine blades 13.

- the turbine guide vanes 17 serve as nozzles for optimizing the momentum transfer to the rotor blades 13.

- the rotation of the shaft 9 brought about by the momentum transfer is used to drive a load, for example an electric generator.

- the expanded and cooled combustion gases are finally discharged from the gas turbine 1 through an outlet 31.

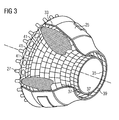

- the annular combustion chamber 25 of in FIG. 2 shown gas turbine is in FIG. 3 shown in a perspective, partially cutaway view.

- Both the outer combustion chamber wall 33 and the inner combustion chamber wall 35 are provided with a hot gas-resistant lining, which is formed from heat shield elements 37.

- heat shield elements in the present embodiment ceramic heat shield elements are used.

- the turbine section 7 facing the end of the combustion chamber has a hot gas outlet opening 39, through which the resulting inside the combustion chamber 25 hot combustion gases can flow to the turbine.

- At the hot gas outlet 39 opposite end of the annular combustion chamber 25 is formed from burner inserts 41 Brennschschschschillerwand available. In each burner insert 41, a burner 27 is received.

- the burner inserts 41 are in this case not directly connected to the outer combustion chamber wall 33 and the inner combustion chamber wall 35, but arranged on a support structure (not shown), which in turn is attached to the housing of the gas turbine. Between the individual burner inserts 41 on the one hand and the outer wall 33 and the inner wall 35 on the other hand remains a gap which allows the inflow of cooling air along the respective wall into the interior of the combustion chamber.

- the burner inserts 41 are arranged so that between them, ie between circumferentially adjacent edges of the burner inserts 41, remain gaps that allow the entry of cooling air into the combustion chamber interior.

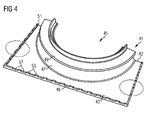

- a burner insert is in FIG. 4 shown in a partially cut perspective view. It comprises a burner insert wall 42 with a cold side 43 and a hot side 44, which is to be turned to the combustion chamber interior (the hot side is in FIG. 4 not recognizable).

- the cold side 43 communicates with the outlet of the compressor in fluid communication, so that compressor air can be bypassed for cooling purposes on the cold side 43 to the temperature of the hot side on a for the material of the burner insert 41 acceptable level.

- the hot side is also provided with a heat-insulating coating, for example in the form of a ceramic coating, in order to reduce the need for cooling air.

- the burner insert 41 has an opening 45 into which the outlet of a burner 27 can be inserted.

- the opening 45 is delimited by a section 47 of the burner insert wall 42 projecting beyond the cold side 43. From this projecting portion 47 extending in the radial direction of the opening 45 extending annular ridge, with which the burner insert 41 can be attached to a support structure.

- the entire outer edge 46 of the burner insert 41 is provided with an over the cold side 43 projecting edge web 51, which gives the edge 46 increased rigidity and ensures that the natural frequency of the burner insert wall 42 is increased.

- Detail views of the edge 46 with the edge web 51 are in the FIGS. 5 and 6 shown.

- the edge web 51 has battlements 53, which are formed by portions of the edge web 51, which project further beyond the cold side 43 than the remaining portions 54 of the edge web 51. If the burner insert is attached to a support structure and forms part of a combustion chamber end wall, lie Pinnacles 53 with the most distant from the cold side 43 end faces 55 on a contact surface of the support structure with a zero gap. Between the pinnacles 53 windows 57 are then formed, can flow through the cooling air, which is usually supplied in the region of the projecting wall portion 47 from the compressor into the combustion chamber. The cooling air can then flow along the cold side 43, which is completely flat except for the edge web 51 and the protruding wall region 47, for cooling.

- the windows 57 between the pinnacles 53 represent openings for the flowing cooling air with a defined passage cross-section, since the end faces 55 of the pinnacles 53 abut with zero gap on the investment structure.

- edge bar 51 in the FIGS. 4 to 6 In the embodiment shown, with crenellations 53 provided to define window openings 57 for the cooling air, in one example, which does not fall under the scope of the invention, it is also possible to project the edge web 51 uniformly over the cold side 43. Cooling air passages can then be realized by means of through-holes 59, for example in the form of bores. A corresponding embodiment of a burner insert is in FIG. 7 shown.

- the edge web extends along the entire outer edge 46 of the burner insert 41

- embodiments are conceivable in which areas of the outer edge 46 of the burner insert 41 have no edge web 51.

- embodiments for cylindrical combustion chambers are possible.

- the outer edge of the burner insert would be substantially circular and the edge web would be present at least along a part of the circumference, preferably around the entire circumference.

- the invention makes it possible to increase the natural frequency of the burner insert and at the same time the targeted adjustment of the outflow of cooling air into the combustion chamber, so that the cooling air can flow only through the predefined column. Associated with this, there are further advantages of the invention such as a longer service life of the burner insert and - by the cooling air saved at the burner insert - a reduction of pollutants at the same power of the burner inserts provided with the gas turbine, when the saved cooling air is supplied to the burner. Alternatively, higher outputs can be achieved with the same emissions.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Gas Burners (AREA)

- Pre-Mixing And Non-Premixing Gas Burner (AREA)

Description

Die vorliegende Erfindung betrifft einen Brennereinsatz für eine Gasturbinenbrennkammer, der eine Brenneröffnung zum Einsetzen eines Brenners aufweist. Daneben betrifft die Erfindung eine Gasturbine.The present invention relates to a combustor liner for a gas turbine combustor having a burner port for inserting a combustor. In addition, the invention relates to a gas turbine.

Gasturbinenbrennkammern weisen ein brennerseitiges Ende und ein turbinenseitiges Ende auf. Das turbinenseitige Ende ist offen und ermöglicht ein Ausströmen der in der Brennkammer entstehenden heißen Verbrennungsgase zur Turbine. Am brennerseitigen Ende ist häufig ein Brennereinsatz vorhanden, der eine hitzeresistente Heißseite und eine gekühlte Kaltseite aufweist. Der Brenner ist in eine Öffnung des Brenneinsatzes eingesetzt. Im Betrieb der Gasturbine strömt Kühlluft, die in der Regel vom Verdichter kommt, entlang der Kaltseite von der Brenneröffnung des Brennereinsatzes zu seinem äußeren Rand, von wo aus die Kühlluft in die Brennkammer strömt. Ein Beispiel für einen Brennereinsatz in einer Rohrbrennkammer ist in

Im Falle von Ringbrennkammern, also von Brennkammern, die sich ringförmig um den Turbinenläufer herum erstrecken, sind in der Regel eine Vielzahl von Brenneinsätzen in Umfangsrichtung der Ringbrennkammer nebeneinander angeordnet. Die an der Kaltseite des Brennerseite vorbeiströmende Kühlluft strömt dann zwischen der radial äußeren Wand und der radial inneren Wand der Brennkammer in die Brennkammer ein. Zudem kann Kühlluft auch durch Spalte zwischen in Umfangsrichtung benachbarten Brenneinsätzen in die Brennkammer eingeführt werden. Eine derartige Ringbrennkammer ist beispielsweise in

Ein Brennereinsatz für eine Ringbrennkammer ist schematisch in

Während des Betriebs der Gasturbinenbrennkammer kann es in dieser zu Druckschwankungen kommen, welche den Brennereinsatz zu hochfrequenten Schwingungen anregen können. Diese belasten den Brennereinsatz und verkürzen seine Lebensdauer. Um den Brennereinsatz zu versteifen und um die Kühlluft zu leiten, ist die Kaltseite 103 des Brennereinsatzes 100 mit Rippen 111 versehen. Außerdem sind Stützschrauben 113 vorhanden, die in

Gegenüber diesem Stand der Technik ist es Aufgabe der vorliegenden Erfindung, einen vorteilhaften Brennereinsatz für eine Gasturbinenbrennkammer zur Verfügung zu stellen. Eine weitere Aufgabe ist es, eine vorteilhafte Gasturbinenbrennkammer sowie eine vorteilhafte Gasturbine zur Verfügung zu stellen.Compared to this prior art, it is an object of the present invention to provide an advantageous burner insert for a gas turbine combustor available. Another The object is to provide an advantageous gas turbine combustion chamber and an advantageous gas turbine available.

Die erste Aufgabe wird durch einen Brennereinsatz nach Anspruch 1 gelöst, die zweite Aufgabe durch eine Gasturbinenbrennkammer nach Anspruch 5 beziehungsweise eine Gasturbine nach Anspruch 9. Die abhängigen Ansprüche enthalten vorteilhafte Ausgestaltungen der Erfindung.The first object is achieved by a burner insert according to claim 1, the second object by a gas turbine combustor according to

Ein erfindungsgemäßer Brennereinsatz für eine Gasturbinenbrennkammer weist eine Brennereinsatzwand mit einer Kaltseite und einer Heißseite auf. In der Brennereinsatzwand ist eine Brenneröffnung zum Einsetzen eines Brenners ausgebildet. Der Brennereinsatz weist einen die Brennereinsatzwand begrenzenden äußeren Rand mit einem wenigstens teilweise umlaufenden und über die Kaltseite vorstehenden Randsteg auf. Der Rand kann hierbei weitgehend kreisförmig ausgebildet sein, etwa im Fall einer Rohrbrennkammer, oder, beispielsweise im Falle einer Ringbrennkammer, die Form des Randes eines Kreisringausschnittes aufweisen. Auch andere Konturen sind je nach Form der Brennkammer grundsätzlich möglich.An inventive burner insert for a gas turbine combustor has a burner insert wall with a cold side and a hot side. In the burner insert wall, a burner opening for inserting a burner is formed. The burner insert has an outer edge delimiting the burner insert wall with an at least partially encircling edge web projecting over the cold side. The edge may in this case be substantially circular, for example in the case of a tube combustion chamber, or, for example in the case of an annular combustion chamber, have the shape of the edge of a circular ring cutout. Other contours are basically possible depending on the shape of the combustion chamber.

Der Randsteg des erfindungsgemäßen Brennereinsatzes führt zu einer Erhöhung der Eigenfrequenzen im Vergleich zu einem Brennereinsatz nach Stand der Technik, wie er mit Bezug auf

. Dadurch, dass mittels der Zinnen definierte Öffnungen im Randsteg hergestellt werden können, ist eine exakte Einstellung der durch den Randsteg hindurch tretenden Kühlluftmenge durch geeignete Wahl der Zinnengröße möglich. Im Falle von Zinnen können diese etwa durch Unterbrechen des Randsteges erzeugt werden. Vorteilhaft ist es jedoch, wenn der Randsteg nicht unterbrochen wird und statt dessen der Randsteg in den Zinnenbereichen weiter über die Kaltseite vorsteht, als in den übrigen Bereichen des Randstegs., The fact that defined by means of the pinnacles openings can be made in the edge web, an exact adjustment of passing through the edge web passing through cooling air amount is possible by a suitable choice of the pinnacle size. In the case of battlements, these can be generated, for example, by interrupting the edge web. It is advantageous, however, if the edge web is not interrupted and, instead, the edge web projects further in the crenellated areas over the cold side than in the remaining regions of the edge web.

Vorzugsweise läuft der Randsteg um den gesamten Rand des Brennereinsatzes um. Die Steifigkeit des Randes des Brennereinsatzes ist dann besonders hoch.Preferably, the edge web runs around the entire edge of the burner insert. The rigidity of the edge of the burner insert is then particularly high.

In einer besonderen Ausgestaltung des erfindungsgemäßen Brennereinsatzes ist die Brenneröffnung von einem ringförmigen, über die Kaltseite vorstehenden und mit einem ringförmigen Steg versehenen Wandbereich umgeben. Ansonsten ist die Brenneinsatzwand flach ausgebildet, d. h. es existieren keine weiteren Strukturen, wie etwa die im Stand der Technik vorhandenen Rippen. Im Falle des erfindungsgemäßen Brennereinsatzes sind derartige Rippen überflüssig, da sich gezeigt hat, dass ein gleichmäßige Verteilung der Kühlluft auch ohne solche Rippen erfolgt. Auch eine versteifende Funktion der Rippen wird im erfindungsgemäßen Brennereinsatz nicht benötigt.In a particular embodiment of the burner insert according to the invention the burner opening is surrounded by an annular, over the cold side projecting and provided with an annular web wall portion. Otherwise, the burner insert wall is formed flat, d. H. There are no other structures, such as the existing in the art ribs. In the case of the burner insert according to the invention such ribs are superfluous, since it has been shown that a uniform distribution of the cooling air takes place even without such ribs. Also, a stiffening function of the ribs is not needed in the burner insert according to the invention.

Insgesamt ermöglicht der erfindungsgemäße Brennereinsatz eine Einsparung an Kühlluft, da keine ungleichmäßigen Spaltmaße auftreten, die bei der Kühlluftversorgung zu einer Überversorgung führen können. Die verringerte Kühllufteinspeisung in die Brennkammer führt in Folge zu einem verringerten Schadstoffausstoß der Gasturbine und zu höheren Turbineneintrittstemperaturen, was wiederum eine Effizienzsteigerung der Gasturbine ermöglicht.Overall, the burner insert according to the invention makes it possible to save cooling air, since no uneven gap dimensions occur, which can lead to an oversupply in the cooling air supply. The reduced supply of cooling air into the combustion chamber results in a reduced pollutant emissions of the gas turbine and higher turbine inlet temperatures, which in turn allows an increase in efficiency of the gas turbine.

Außerdem ist die Einstellung eines Nullspaltes zwischen der Stirnfläche des Randsteges bzw. der Zinnen und der Tragstruktur bzw. der Brennkammerwand möglich. Schließlich ermöglicht die Ausgestaltung des erfindungsgemäßen Brennereinsatzes auch eine Kostenreduzierung, da die Versteifungsschrauben entfallen und daher im Vergleich zu dem in der Einleitung beschriebenen Brennereinsatz weniger Bauteile nötig sind.In addition, the setting of a zero gap between the end face of the edge web or the pinnacles and the support structure or the combustion chamber wall is possible. Finally, the design of the burner insert according to the invention also enables a cost reduction, since the stiffening screws are eliminated and therefore fewer components are required in comparison to the burner insert described in the introduction.

Eine erfindungsgemäße Gasturbinenbrennkammer weist wenigstens einen Brenner, wenigstens eine einen Brennkammerinnenraum umgebende Brennkammerwand und wenigstens eine brennerseitige Brennkammerabschlusswand auf. Sie umfasst einen erfindungsgemäßen Brennereinsatz, dessen Brennereinsatzwand die Brennkammerabschlusswand bildet, wobei die Heißseite der Brennereinsatzwand dem Brennkammerinneren zugewandt ist. In der erfindungsgemäßen Brennkammer kann die Brennkammerwand im Falle einer Rohrbrennkammer zylinderförmig ausgebildet sein. Im Falle einer Ringbrennkammer sind dagegen zwei Brennkammerwände vorhanden, nämlich eine radial äußere und eine radial innere Brennkammerwand.A gas turbine combustor according to the invention has at least one burner, at least one combustion chamber wall surrounding a combustion chamber interior, and at least one burner end wall on the burner side. It comprises a burner insert according to the invention whose burner insert wall forms the combustion chamber end wall, the hot side of the burner insert wall facing the combustion chamber interior. In the combustion chamber according to the invention, the combustion chamber wall may be cylindrical in the case of a tube combustion chamber. In the case of an annular combustion chamber, however, two combustion chamber walls are present, namely a radially outer and a radially inner combustion chamber wall.

Die mit dem erfindungsgemäßen Brennereinsatz erreichbaren Vorteile lassen sich damit in der erfindungsgemäßen Gasturbinenbrennkammer realisieren.The achievable with the burner insert advantages of the invention can thus be realized in the gas turbine combustor according to the invention.

In der erfindungsgemäßen Gasturbinebrennkammer kann zwischen der von dem wenigstens einen Brennereinsatz gebildeten Brennkammerabschlusswand und der wenigstens einen Brennkammerwand ein Spalt vorhanden sein, der das Abströmen von Kühlluft von der Kaltseite des Brenneinsatzes in die Brennkammer ermöglicht.In the gas turbine combustor according to the invention, a gap may be present between the combustion chamber closure wall formed by the at least one burner insert and the at least one combustion chamber wall, which allows the outflow of cooling air from the cold side of the combustion insert into the combustion chamber.

Im Falle einer als Ringbrennkammer ausgebildeten Gasturbinenbrennkammer mit einem zwischen einer inneren Brennkammerwand und einer äußeren Brennkammerwand gebildeten ringförmigen Brennkammerinnenraum kann die brennerseitige Brennkammerabschlusswand insbesondere durch eine Anzahl in Umfangsrichtung der Brennkammer nebeneinander angeordnete Brennereinsätze gebildet sein. Zwischen benachbarten Brennereinsätzen können Spalte vorhanden sein, die das Einströmen von Kühlluft zwischen den Brennereinsätzen in die Ringbrennkammer ermöglichen.In the case of a gas turbine combustor designed as an annular combustion chamber with an annular combustion chamber formed between an inner combustion chamber wall and an outer combustion chamber wall Combustor interior, the burner-side combustion chamber end wall can be formed in particular by a number in the circumferential direction of the combustion chamber juxtaposed burner inserts. There may be gaps between adjacent burner inserts which allow the flow of cooling air between the burner inserts into the annular combustion chamber.

Eine erfindungsgemäße Gasturbine ist mit wenigstens einer Gasturbinenbrennkammer ausgestattet, die als erfindungsgemäße Gasturbinenbrennkammer ausgestaltet ist. Außerdem umfasst die erfindungsgemäße Gasturbine ein Kühlfluidreservoir, beispielsweise ein mit dem Ausgang eines Verdichters in Verbindung stehendes Brennkammerplenum, wobei die Kaltseite der Brennereinsatzwand strömungstechnisch mit dem Kühlfluidreservoir in Verbindung steht. Eine derartige Gasturbine ermöglicht es, die Vorteile einer Brennkammer mit erfindungsgemäßem Brennereinsatz zu realisieren.A gas turbine according to the invention is equipped with at least one gas turbine combustion chamber, which is designed as a gas turbine combustion chamber according to the invention. In addition, the gas turbine according to the invention comprises a cooling fluid reservoir, for example a combustion chamber plenum communicating with the output of a compressor, wherein the cold side of the burner insert wall is fluidically connected to the cooling fluid reservoir. Such a gas turbine makes it possible to realize the advantages of a combustion chamber with burner insert according to the invention.

Weitere Merkmale, Eigenschaften und Vorteile der vorliegenden Erfindung ergeben sich aus der nachfolgenden Beschreibung eines Ausführungsbeispiels unter Bezugnahme auf die beiliegenden Figuren.

-

Figur 1 zeigt einen Brennereinsatz nach Stand der Technik. -

Figur 2 zeigt eine Gasturbine in einem Längsteilschnitt. -

Figur 3 -

Figur 4 zeigt einen erfindungsgemäßen Brennereinsatz. -

Figur 5Figur 4 . -

Figur 6 zeigt den Rand des Brennereinsatzes in einer Detailansicht. -

Figur 7

-

FIG. 1 shows a burner insert according to the prior art. -

FIG. 2 shows a gas turbine in a longitudinal section. -

FIG. 3 shows an annular combustion chamber in a partially sectioned perspective view. -

FIG. 4 shows a burner insert according to the invention. -

FIG. 5 shows the edge of the burner insertFIG. 4 , -

FIG. 6 shows the edge of the burner insert in a detailed view. -

FIG. 7 shows the edge of a burner insert in a detail view, which does not fill the scope of the invention.

Im Betrieb der Gasturbine 1 wird Luft 23 durch einen Lufteinlass 21 des Verdichterabschnittes 3 eingesaugt und von den Verdichterlaufschaufeln 11 komprimiert. Die komprimierte Luft wird einer im Brennkammerabschnitt 5 angeordneten Brennkammer 25, die im vorliegenden Ausführungsbeispiel als Ringbrennkammer ausgestaltet ist, zugeleitet, in die auch ein gasförmiger oder flüssiger Brennstoff über wenigstens einen Brenner 27 eingedüst wird. Das dadurch entstehende Luft-BrennstoffGemisch wird gezündet und in der Brennkammer 25 verbrannt. Entlang des Strömungspfades 29 strömen die heißen Verbrennungsabgase von der Brennkammer 25 in den Turbinenabschnitt 7, wo sie expandieren und abkühlen und dabei Impuls auf die Turbinenlaufschaufeln 13 übertragen. Die Turbinenleitschaufeln 17 dienen dabei als Düsen zum Optimieren des Impulsübertrages auf die Laufschaufeln 13. Die durch den Impulsübertrag herbeigeführte Rotation der Welle 9 wird dazu genutzt, einen Verbraucher, beispielsweise einen elektrischen Generator, anzutreiben. Die entspannten und abgekühlten Verbrennungsgase werden schließlich durch einen Auslass 31 aus der Gasturbine 1 abgeleitet.During operation of the gas turbine 1,

Die Ringbrennkammer 25 der in

Ein Brennereinsatz ist in

In seinem Zentrum weist der Brennereinsatz 41 eine Öffnung 45 auf, in die der Ausgang eines Brenners 27 eingesetzt werden kann. Die Öffnung 45 ist von einem über die Kaltseite 43 vorstehenden Abschnitt 47 der Brennereinsatzwand 42 begrenzt. Von diesem vorstehenden Abschnitt 47 aus erstreckt sich ein in Radialrichtung der Öffnung 45 verlaufender ringförmiger Steg, mit dem der Brennereinsatz 41 an einer Haltestruktur befestigt werden kann.At its center, the

Im vorliegenden Ausführungsbeispiel ist der gesamte äußere Rand 46 des Brennereinsatzes 41 mit einem über die Kaltseite 43 überstehenden Randsteg 51 versehen, der dem Rand 46 eine erhöhte Steifigkeit verleiht und dafür sorgt, dass die Eigenfrequenz der Brennereinsatzwand 42 erhöht wird. Detailansichten des Randes 46 mit dem Randsteg 51 sind in den

Der Randsteg 51 weist Zinnen 53 auf, die durch Abschnitte des Randstegs 51 gebildet sind, die weiter über die Kaltseite 43 vorstehen als die übrigen Abschnitte 54 des Randstegs 51. Wenn der Brennereinsatz an einer Tragstruktur befestigt ist und einen Teil einer Brennkammerabschlusswand bildet, liegen die Zinnen 53 mit den von der Kaltseite 43 entferntesten Stirnflächen 55 an einer Anlagefläche der Haltestruktur mit einem Nullspalt an. Zwischen den Zinnen 53 sind dann Fenster 57 gebildet, durch die Kühlluft, die in der Regel im Bereich des vorspringenden Wandabschnittes 47 vom Verdichter zugeführt wird, in die Brennkammer abströmen kann. Die Kühlluft kann dann an der Kaltseite 43, die bis auf den Randsteg 51 und den vorstehenden Wandbereich 47 völlig flach ausgebildet ist, zur Kühlung entlang strömen. Die Fenster 57 zwischen den Zinnen 53 stellen für die strömende Kühlluft Öffnungen mit definierten Durchtrittsquerschnitt dar, da die Stirnflächen 55 der Zinnen 53 mit Nullspalt an der Anlagestruktur anliegen. Durch geeignete Wahl der Breite und Höhe der Randstegabschnitte 54 zwischen den Zinnen 53 im Verhältnis zur Höhe und Breite der Zinnen 53 kann die in die Brennkammer einströmende Kühlluftmenge gezielt eingestellt werden. Aufgrund der erhöhten Steifigkeit, die der Randsteg 51 dem Rand 46 vermittelt, entstehen auch keine wesentlichen Abweichungen des Spaltes zwischen den Zinnenflächen 55 und der Auflagefläche, so dass der für die Kühlluft vorhandene und durch die Fenster definierte Strömungsquerschnitt auch im Betrieb der Gasturbine weitgehend erhalten bleibt. Überangebote an Kühlluft durch sich vergrößernde Spaltmaße können dadurch im Vergleich zum Stand der Technik erheblich reduziert werden, was wiederum zu einer Senkung des Kühllufteintrags in die Brennkammer und so letztendlich zu einer Senkung der Schadstoffe sowie zu höheren Turbineneintrittstemperaturen führt.The

Obwohl der Randsteg 51 im in den

Obwohl sich in den vorliegenden Ausführungsbeispielen der Randsteg entlang des gesamten äußeren Randes 46 des Brennereinsatzes 41 erstreckt, sind Ausführungsvarianten denkbar, in denen Bereiche des äußeren Randes 46 des Brennereinsatzes 41 keinen Randsteg 51 aufweisen. Außerdem sind Ausführungsvarianten für zylinderförmige Brennkammern möglich. In einer solchen Ausführungsvariante wäre der äußere Rand des Brennereinsatzes im Wesentlichen kreisförmig und der Randsteg wäre zumindest entlang eines Teils des Kreisumfangs, vorzugsweise um den gesamten Kreisumfang herum, vorhanden.Although in the present embodiments, the edge web extends along the entire

Die Erfindung ermöglicht die Erhöhung der Eigenfrequenz des Brennereinsatzes und gleichzeitig das gezielte Einstellen der Abströmung von Kühlluft in die Brennkammer, so dass die Kühlluft nur durch die vordefinierten Spalte abströmen kann. Damit verbunden, ergeben sich weitere Vorteile der Erfindung wie beispielsweise eine längere Lebensdauer des Brennereinsatzes und - durch die eingesparte Kühlluft am Brennereinsatz - eine Senkung der Schadstoffe bei gleicher Leistung der mit erfindungsgemäßen Brennereinsätzen versehenen Gasturbine, wenn die gesparte Kühlluft dem Brenner zugeführt wird. Alternativ lässt sich bei gleichen Emissionen eine höhere Leistung erzielen.The invention makes it possible to increase the natural frequency of the burner insert and at the same time the targeted adjustment of the outflow of cooling air into the combustion chamber, so that the cooling air can flow only through the predefined column. Associated with this, there are further advantages of the invention such as a longer service life of the burner insert and - by the cooling air saved at the burner insert - a reduction of pollutants at the same power of the burner inserts provided with the gas turbine, when the saved cooling air is supplied to the burner. Alternatively, higher outputs can be achieved with the same emissions.

Claims (9)

- Burner insert (41) for a gas turbine combustion chamber (25), which comprises a burner insert wall (42) having a cold side (43) and a hot side (44), wherein a burner opening (45) for inserting a burner (27) is formed in the burner insert wall (42), and which has an edge (46) delimiting the burner insert wall (42), which has an at least partially circumferential edge bar (51) projecting beyond the cold side (43) and has openings (57) for the passage of cooling fluid.

characterised in that

the edge bar (51) has merlons (53) and the openings (57) are formed between the merlons (53). - Burner insert (41) according to claim 1,

characterised in that

the merlons (53) are formed by edge bar sections which project further beyond the cold side (43) than the remaining edge bar sections (54). - Burner insert (41) according to one of the preceding claims,

characterised in that

the edge bar (51) runs around the entire edge (46). - Burner insert (41) according to one of the preceding claims,

characterised in that

the burner opening (45) is surrounded by an annular wall region (47) projecting beyond the cold side (43) and provided with an annular bar (49) and the burner insert wall (42) is otherwise flat in form. - Gas turbine combustion chamber (25) having at least one burner (27), at least one combustion chamber wall (33, 35) surrounding a combustion chamber interior and one burner-side combustion chamber end wall,

characterised in that

at least one burner insert (41) according to one of the preceding claims is present, the burner insert wall (42) of which at least in part forms the combustion chamber end wall, whereby the hot side (44) of the burner insert wall (42) faces the combustion chamber interior. - Gas turbine combustion chamber (25) according to claim 5,

characterised in that

a gap is present between the combustion chamber end wall formed by the at least one burner insert (41) and the at least one combustion chamber wall (33, 35). - Gas turbine combustion chamber (25) according to claim 5 or claim 6,

characterised in that

it is embodied as an annular combustion chamber having an annular combustion chamber interior formed between an inner combustion chamber wall (35) and an outer combustion chamber wall (33) and the burner-side combustion chamber end wall is formed by a number of burner inserts (41) arranged side by side in the circumferential direction of the annular combustion chamber (25). - Gas turbine combustion chamber (25) according to claim 7,

characterised in that

gaps are present between adjacent burner inserts (41). - Gas turbine (1) having at least one gas turbine combustion chamber (25)

characterised in that- the at least one gas turbine combustion chamber (25) is a gas turbine combustion chamber according to one of claims 5 to 8,- a cooling fluid reservoir is present and- the cold side (43) of the burner insert wall (42) has a flow connection with the cooling fluid reservoir.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09823099.8A EP2340397B1 (en) | 2008-10-29 | 2009-09-14 | Burner insert for a gas turbine combustion chamber and gas turbine |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP08018907A EP2182285A1 (en) | 2008-10-29 | 2008-10-29 | Burner insert for a gas turbine combustion chamber and gas turbine |

| EP09823099.8A EP2340397B1 (en) | 2008-10-29 | 2009-09-14 | Burner insert for a gas turbine combustion chamber and gas turbine |

| PCT/EP2009/061854 WO2010049206A1 (en) | 2008-10-29 | 2009-09-14 | Burner inserts for a gas turbine combustion chamber and gas turbine |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2340397A1 EP2340397A1 (en) | 2011-07-06 |

| EP2340397B1 true EP2340397B1 (en) | 2013-07-31 |

Family

ID=40672584

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08018907A Withdrawn EP2182285A1 (en) | 2008-10-29 | 2008-10-29 | Burner insert for a gas turbine combustion chamber and gas turbine |

| EP09823099.8A Active EP2340397B1 (en) | 2008-10-29 | 2009-09-14 | Burner insert for a gas turbine combustion chamber and gas turbine |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08018907A Withdrawn EP2182285A1 (en) | 2008-10-29 | 2008-10-29 | Burner insert for a gas turbine combustion chamber and gas turbine |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US9074771B2 (en) |

| EP (2) | EP2182285A1 (en) |

| JP (1) | JP5349605B2 (en) |

| CN (1) | CN102203509B (en) |

| ES (1) | ES2426395T3 (en) |

| RU (1) | RU2530684C2 (en) |

| WO (1) | WO2010049206A1 (en) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102012204103A1 (en) * | 2012-03-15 | 2013-09-19 | Siemens Aktiengesellschaft | Heat shield element for a compressor air bypass around the combustion chamber |

| US9322560B2 (en) * | 2012-09-28 | 2016-04-26 | United Technologies Corporation | Combustor bulkhead assembly |

| US20150033746A1 (en) * | 2013-08-02 | 2015-02-05 | Solar Turbines Incorporated | Heat shield with standoffs |

| US9534786B2 (en) * | 2014-08-08 | 2017-01-03 | Pratt & Whitney Canada Corp. | Combustor heat shield |

| US10267521B2 (en) | 2015-04-13 | 2019-04-23 | Pratt & Whitney Canada Corp. | Combustor heat shield |

| DE102016206188A1 (en) * | 2016-04-13 | 2017-10-19 | Rolls-Royce Deutschland Ltd & Co Kg | Combustor shingle of a gas turbine |

| DE102016224632A1 (en) * | 2016-12-09 | 2018-06-14 | Rolls-Royce Deutschland Ltd & Co Kg | Plate-shaped component of a gas turbine and method for its production |

| US10830435B2 (en) | 2018-02-06 | 2020-11-10 | Raytheon Technologies Corporation | Diffusing hole for rail effusion |

| US11248791B2 (en) | 2018-02-06 | 2022-02-15 | Raytheon Technologies Corporation | Pull-plane effusion combustor panel |

| US11009230B2 (en) | 2018-02-06 | 2021-05-18 | Raytheon Technologies Corporation | Undercut combustor panel rail |

| US11022307B2 (en) * | 2018-02-22 | 2021-06-01 | Raytheon Technology Corporation | Gas turbine combustor heat shield panel having multi-direction hole for rail effusion cooling |

| US20190285276A1 (en) * | 2018-03-14 | 2019-09-19 | United Technologies Corporation | Castellated combustor panels |

| DE102018212394B4 (en) | 2018-07-25 | 2024-03-28 | Rolls-Royce Deutschland Ltd & Co Kg | Combustion chamber assembly with a wall element having a flow guide device |

| US11015807B2 (en) * | 2019-01-30 | 2021-05-25 | Pratt & Whitney Canada Corp. | Combustor heat shield cooling |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2107448B (en) * | 1980-10-21 | 1984-06-06 | Rolls Royce | Gas turbine engine combustion chambers |

| US4914918A (en) * | 1988-09-26 | 1990-04-10 | United Technologies Corporation | Combustor segmented deflector |

| GB9018014D0 (en) * | 1990-08-16 | 1990-10-03 | Rolls Royce Plc | Gas turbine engine combustor |

| GB2287310B (en) * | 1994-03-01 | 1997-12-03 | Rolls Royce Plc | Gas turbine engine combustor heatshield |

| US5419115A (en) * | 1994-04-29 | 1995-05-30 | United Technologies Corporation | Bulkhead and fuel nozzle guide assembly for an annular combustion chamber |

| DE4427222A1 (en) * | 1994-08-01 | 1996-02-08 | Bmw Rolls Royce Gmbh | Heat shield for a gas turbine combustor |

| US6032457A (en) * | 1996-06-27 | 2000-03-07 | United Technologies Corporation | Fuel nozzle guide |

| US5974805A (en) * | 1997-10-28 | 1999-11-02 | Rolls-Royce Plc | Heat shielding for a turbine combustor |

| US6164074A (en) * | 1997-12-12 | 2000-12-26 | United Technologies Corporation | Combustor bulkhead with improved cooling and air recirculation zone |

| US6751961B2 (en) * | 2002-05-14 | 2004-06-22 | United Technologies Corporation | Bulkhead panel for use in a combustion chamber of a gas turbine engine |

| US6792757B2 (en) * | 2002-11-05 | 2004-09-21 | Honeywell International Inc. | Gas turbine combustor heat shield impingement cooling baffle |

| RU31818U1 (en) * | 2002-11-21 | 2003-08-27 | ОАО Самарский научно-технический комплекс им. Н.Д. Кузнецова | NK-37 gas turbine engine, compressor, combustion chamber, turbine |

| US7080515B2 (en) | 2002-12-23 | 2006-07-25 | Siemens Westinghouse Power Corporation | Gas turbine can annular combustor |

| ATE483138T1 (en) | 2004-01-21 | 2010-10-15 | Siemens Ag | BURNER WITH COOLED COMPONENT, GAS TURBINE AND METHOD FOR COOLING THE COMPONENT |

| RU52982U1 (en) * | 2005-08-03 | 2006-04-27 | ЭКОЛ спол. с.р.о. | BURNER FOR LOW EMISSIONS OF HARMFUL SUBSTANCES AND BURNER SYSTEM |

| EP1767855A1 (en) | 2005-09-27 | 2007-03-28 | Siemens Aktiengesellschaft | Combustion Chamber and Gas Turbine Plant |

| RU52992U1 (en) | 2005-10-24 | 2006-04-27 | Ираклий Отарович Чиквиладзе | RADIATOR OF THE INTERNAL COMBUSTION ENGINE OF THE RACING CAR |

| US7665306B2 (en) * | 2007-06-22 | 2010-02-23 | Honeywell International Inc. | Heat shields for use in combustors |

-

2008

- 2008-10-29 EP EP08018907A patent/EP2182285A1/en not_active Withdrawn

-

2009

- 2009-09-14 ES ES09823099T patent/ES2426395T3/en active Active

- 2009-09-14 US US13/126,239 patent/US9074771B2/en not_active Expired - Fee Related

- 2009-09-14 CN CN200980142861.0A patent/CN102203509B/en active Active

- 2009-09-14 JP JP2011533647A patent/JP5349605B2/en not_active Expired - Fee Related

- 2009-09-14 RU RU2011121647/06A patent/RU2530684C2/en active

- 2009-09-14 EP EP09823099.8A patent/EP2340397B1/en active Active

- 2009-09-14 WO PCT/EP2009/061854 patent/WO2010049206A1/en active Application Filing

Also Published As

| Publication number | Publication date |

|---|---|

| EP2182285A1 (en) | 2010-05-05 |

| CN102203509B (en) | 2014-07-09 |

| US20110197590A1 (en) | 2011-08-18 |

| ES2426395T3 (en) | 2013-10-23 |

| JP5349605B2 (en) | 2013-11-20 |

| US9074771B2 (en) | 2015-07-07 |

| WO2010049206A1 (en) | 2010-05-06 |

| EP2340397A1 (en) | 2011-07-06 |

| JP2012506991A (en) | 2012-03-22 |

| CN102203509A (en) | 2011-09-28 |

| RU2530684C2 (en) | 2014-10-10 |

| RU2011121647A (en) | 2012-12-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2340397B1 (en) | Burner insert for a gas turbine combustion chamber and gas turbine | |

| DE60105531T2 (en) | Gas turbine combustor, gas turbine and jet engine | |

| DE102005025823B4 (en) | Method and device for cooling a combustion chamber lining and a transition part of a gas turbine | |

| EP0244693B1 (en) | Hot gas overheating protection device for gas turbine power plants | |

| DE102008022669A1 (en) | Fuel nozzle and method for its production | |

| DE102015112767A1 (en) | Fuel injector assemblies in combustion turbines | |

| DE102014103005B4 (en) | Method and device for improving heat transfer in turbine sections of gas turbines | |

| EP2179143B1 (en) | Gap cooling between combustion chamber wall and turbine wall of a gas turbine installation | |

| EP1904717B1 (en) | Hot gas-conducting housing element, protective shaft jacket, and gas turbine system | |

| CH701454B1 (en) | Burner with a flow conditioner. | |

| EP3132202B1 (en) | Bypass heat shield element | |

| DE102011055109A1 (en) | A system for directing the flow of air in a fuel nozzle assembly | |

| EP1724526A1 (en) | Shell for a Combustion Chamber, Gas Turbine and Method for Powering up and down a Gas Turbine. | |

| DE102015113146A1 (en) | Systems and devices related to gas turbine combustors | |

| EP2507557B1 (en) | Burner assembly | |

| DE102019104814B4 (en) | Turbine blade equipped with an insert carrier | |

| EP3245451B1 (en) | Gas turbine combustion chamber having a wall contour | |

| EP2187125A1 (en) | Method and device for damping combustion oscillation | |

| EP2236932A1 (en) | Burner and method for operating a burner, in particular for a gas turbine | |

| EP2409086B1 (en) | Burner assembly for a gas turbine | |

| EP2725203B1 (en) | Cool air guide in a housing structure of a fluid flow engine | |

| DE102022210198A1 (en) | Transition piece, combustor and gas turbine engine | |

| EP1284391A1 (en) | Combustion chamber for gas turbines | |

| EP3004741B1 (en) | Tubular combustion chamber with a flame tube end area and gas turbine | |

| DE102019219700B4 (en) | GAS TURBINE COMBUSTION CHAMBER, MANUFACTURING PROCESS FOR GAS TURBINE AND GAS TURBINE COMBUSTION CHAMBER |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20110323 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA RS |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SIEMENS AKTIENGESELLSCHAFT |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 624881 Country of ref document: AT Kind code of ref document: T Effective date: 20130815 Ref country code: CH Ref legal event code: NV Representative=s name: SIEMENS SCHWEIZ AG, CH |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502009007699 Country of ref document: DE Effective date: 20130926 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2426395 Country of ref document: ES Kind code of ref document: T3 Effective date: 20131023 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20130731 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130724 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131031 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131202 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131101 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 |

|

| BERE | Be: lapsed |

Owner name: SIEMENS A.G. Effective date: 20130930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20140530 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| 26N | No opposition filed |

Effective date: 20140502 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130914 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130930 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502009007699 Country of ref document: DE Effective date: 20140502 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130731 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130914 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20090914 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 624881 Country of ref document: AT Kind code of ref document: T Effective date: 20140914 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140914 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20161202 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCOW Free format text: NEW ADDRESS: WERNER-VON-SIEMENS-STRASSE 1, 80333 MUENCHEN (DE) |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20181217 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502009007699 Country of ref document: DE Owner name: SIEMENS ENERGY GLOBAL GMBH & CO. KG, DE Free format text: FORMER OWNER: SIEMENS AKTIENGESELLSCHAFT, 80333 MUENCHEN, DE |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20210128 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190915 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20220818 AND 20220824 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20230920 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240926 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20240924 Year of fee payment: 16 |