EP2162251B1 - A thin cast strip product with microalloy additions, and method for making the same - Google Patents

A thin cast strip product with microalloy additions, and method for making the same Download PDFInfo

- Publication number

- EP2162251B1 EP2162251B1 EP08747717.0A EP08747717A EP2162251B1 EP 2162251 B1 EP2162251 B1 EP 2162251B1 EP 08747717 A EP08747717 A EP 08747717A EP 2162251 B1 EP2162251 B1 EP 2162251B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- steel strip

- niobium

- steel

- strip

- strength

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims description 18

- 238000007792 addition Methods 0.000 title description 29

- 229910000831 Steel Inorganic materials 0.000 claims description 171

- 239000010959 steel Substances 0.000 claims description 171

- 239000010955 niobium Substances 0.000 claims description 138

- 229910052758 niobium Inorganic materials 0.000 claims description 128

- GUCVJGMIXFAOAE-UHFFFAOYSA-N niobium atom Chemical compound [Nb] GUCVJGMIXFAOAE-UHFFFAOYSA-N 0.000 claims description 111

- 238000003483 aging Methods 0.000 claims description 48

- 239000002245 particle Substances 0.000 claims description 41

- 229910052720 vanadium Inorganic materials 0.000 claims description 41

- 238000005266 casting Methods 0.000 claims description 40

- 238000005098 hot rolling Methods 0.000 claims description 39

- LEONUFNNVUYDNQ-UHFFFAOYSA-N vanadium atom Chemical compound [V] LEONUFNNVUYDNQ-UHFFFAOYSA-N 0.000 claims description 37

- 229910000859 α-Fe Inorganic materials 0.000 claims description 35

- 239000006104 solid solution Substances 0.000 claims description 28

- 230000009467 reduction Effects 0.000 claims description 26

- 229910001566 austenite Inorganic materials 0.000 claims description 22

- 229910001563 bainite Inorganic materials 0.000 claims description 22

- 229910001208 Crucible steel Inorganic materials 0.000 claims description 19

- 229910052799 carbon Inorganic materials 0.000 claims description 19

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 16

- 238000001816 cooling Methods 0.000 claims description 14

- 229910052750 molybdenum Inorganic materials 0.000 claims description 13

- 238000001953 recrystallisation Methods 0.000 claims description 12

- XEEYBQQBJWHFJM-UHFFFAOYSA-N iron Substances [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims description 10

- 229910052751 metal Inorganic materials 0.000 claims description 10

- 239000002184 metal Substances 0.000 claims description 10

- 229910052710 silicon Inorganic materials 0.000 claims description 10

- 239000010703 silicon Substances 0.000 claims description 10

- 239000000203 mixture Substances 0.000 claims description 9

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 claims description 8

- 239000011733 molybdenum Substances 0.000 claims description 8

- WPBNNNQJVZRUHP-UHFFFAOYSA-L manganese(2+);methyl n-[[2-(methoxycarbonylcarbamothioylamino)phenyl]carbamothioyl]carbamate;n-[2-(sulfidocarbothioylamino)ethyl]carbamodithioate Chemical compound [Mn+2].[S-]C(=S)NCCNC([S-])=S.COC(=O)NC(=S)NC1=CC=CC=C1NC(=S)NC(=O)OC WPBNNNQJVZRUHP-UHFFFAOYSA-L 0.000 claims description 6

- 229910052782 aluminium Inorganic materials 0.000 claims description 5

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 5

- 229910052742 iron Inorganic materials 0.000 claims description 4

- 239000012535 impurity Substances 0.000 claims 2

- 239000000047 product Substances 0.000 description 47

- 238000000137 annealing Methods 0.000 description 33

- 230000000694 effects Effects 0.000 description 30

- 238000005728 strengthening Methods 0.000 description 22

- 230000015572 biosynthetic process Effects 0.000 description 20

- 238000010438 heat treatment Methods 0.000 description 20

- 239000002244 precipitate Substances 0.000 description 17

- 238000005246 galvanizing Methods 0.000 description 15

- 230000032683 aging Effects 0.000 description 11

- 230000001965 increasing effect Effects 0.000 description 11

- 238000001556 precipitation Methods 0.000 description 11

- 238000004627 transmission electron microscopy Methods 0.000 description 11

- 238000012545 processing Methods 0.000 description 9

- 239000000523 sample Substances 0.000 description 9

- 238000004519 manufacturing process Methods 0.000 description 8

- 230000008569 process Effects 0.000 description 8

- 230000000717 retained effect Effects 0.000 description 8

- 229910000760 Hardened steel Inorganic materials 0.000 description 7

- 230000002829 reductive effect Effects 0.000 description 7

- 229910052719 titanium Inorganic materials 0.000 description 7

- 239000010936 titanium Substances 0.000 description 7

- 238000005275 alloying Methods 0.000 description 6

- 238000005097 cold rolling Methods 0.000 description 6

- 239000011572 manganese Substances 0.000 description 6

- 229910000742 Microalloyed steel Inorganic materials 0.000 description 5

- 238000004458 analytical method Methods 0.000 description 5

- 238000011084 recovery Methods 0.000 description 5

- 239000000243 solution Substances 0.000 description 5

- 230000009466 transformation Effects 0.000 description 5

- 238000009826 distribution Methods 0.000 description 4

- 239000011888 foil Substances 0.000 description 4

- 230000014759 maintenance of location Effects 0.000 description 4

- 239000000463 material Substances 0.000 description 4

- 238000005096 rolling process Methods 0.000 description 4

- 239000007787 solid Substances 0.000 description 4

- 230000001629 suppression Effects 0.000 description 4

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 4

- QTBSBXVTEAMEQO-UHFFFAOYSA-N Acetic acid Chemical compound CC(O)=O QTBSBXVTEAMEQO-UHFFFAOYSA-N 0.000 description 3

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 3

- 238000013459 approach Methods 0.000 description 3

- 229910052796 boron Inorganic materials 0.000 description 3

- 229910052757 nitrogen Inorganic materials 0.000 description 3

- 238000003303 reheating Methods 0.000 description 3

- 238000007711 solidification Methods 0.000 description 3

- 230000008023 solidification Effects 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 239000006185 dispersion Substances 0.000 description 2

- 238000005530 etching Methods 0.000 description 2

- 239000010419 fine particle Substances 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 238000001000 micrograph Methods 0.000 description 2

- 230000006911 nucleation Effects 0.000 description 2

- 238000010899 nucleation Methods 0.000 description 2

- 238000000879 optical micrograph Methods 0.000 description 2

- VLTRZXGMWDSKGL-UHFFFAOYSA-N perchloric acid Chemical compound OCl(=O)(=O)=O VLTRZXGMWDSKGL-UHFFFAOYSA-N 0.000 description 2

- 238000007712 rapid solidification Methods 0.000 description 2

- 230000035882 stress Effects 0.000 description 2

- 230000000930 thermomechanical effect Effects 0.000 description 2

- 238000011282 treatment Methods 0.000 description 2

- 229910001209 Low-carbon steel Inorganic materials 0.000 description 1

- 229910018643 Mn—Si Inorganic materials 0.000 description 1

- GRYLNZFGIOXLOG-UHFFFAOYSA-N Nitric acid Chemical compound O[N+]([O-])=O GRYLNZFGIOXLOG-UHFFFAOYSA-N 0.000 description 1

- 238000001016 Ostwald ripening Methods 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 230000004913 activation Effects 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 230000001427 coherent effect Effects 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000009749 continuous casting Methods 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 239000003792 electrolyte Substances 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 230000001747 exhibiting effect Effects 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 230000012010 growth Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 230000001939 inductive effect Effects 0.000 description 1

- 230000002401 inhibitory effect Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000011068 loading method Methods 0.000 description 1

- 230000033001 locomotion Effects 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 230000005499 meniscus Effects 0.000 description 1

- 150000001247 metal acetylides Chemical class 0.000 description 1

- RJSRQTFBFAJJIL-UHFFFAOYSA-N niobium titanium Chemical compound [Ti].[Nb] RJSRQTFBFAJJIL-UHFFFAOYSA-N 0.000 description 1

- 229910017604 nitric acid Inorganic materials 0.000 description 1

- 150000004767 nitrides Chemical class 0.000 description 1

- 230000036961 partial effect Effects 0.000 description 1

- 229910001562 pearlite Inorganic materials 0.000 description 1

- 229910052698 phosphorus Inorganic materials 0.000 description 1

- 238000005554 pickling Methods 0.000 description 1

- 238000004881 precipitation hardening Methods 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 238000007670 refining Methods 0.000 description 1

- 230000010076 replication Effects 0.000 description 1

- 238000009751 slip forming Methods 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 229910052717 sulfur Inorganic materials 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- 230000001131 transforming effect Effects 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/06—Continuous casting of metals, i.e. casting in indefinite lengths into moulds with travelling walls, e.g. with rolls, plates, belts, caterpillars

- B22D11/0622—Continuous casting of metals, i.e. casting in indefinite lengths into moulds with travelling walls, e.g. with rolls, plates, belts, caterpillars formed by two casting wheels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/06—Continuous casting of metals, i.e. casting in indefinite lengths into moulds with travelling walls, e.g. with rolls, plates, belts, caterpillars

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/12—Accessories for subsequent treating or working cast stock in situ

- B22D11/124—Accessories for subsequent treating or working cast stock in situ for cooling

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/005—Heat treatment of ferrous alloys containing Mn

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/008—Heat treatment of ferrous alloys containing Si

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/02—Hardening by precipitation

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0221—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the working steps

- C21D8/0226—Hot rolling

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/12—Ferrous alloys, e.g. steel alloys containing tungsten, tantalum, molybdenum, vanadium, or niobium

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/005—Ferrite

Definitions

- This invention relates to making of high strength thin cast strip, and the method for making such cast strip by a twin roll caster.

- molten metal is introduced between a pair of counterrotated, internally cooled casting rolls so that metal shells solidify on the moving roll surfaces, and are brought together at the nip between them to produce a solidified strip product, delivered downwardly from the nip between the casting rolls.

- the term "nip" is used herein to refer to the general region at which the casting rolls are closest together.

- the molten metal is poured from a ladle through a metal delivery system comprised of a tundish and a core nozzle located above the nip to form a casting pool of molten metal, supported on the casting surfaces of the rolls above the nip and extending along the length of the nip.

- This casting pool is usually confined between refractory side plates or dams held in sliding engagement with the end surfaces of the rolls so as to dam the two ends of the casting pool against outflow.

- JP H05 171293 which is considered to represent the closest prior art, discloses a coiled steel product which includes P, S, Ti, B and N as deliberate alloying elements.

- JP H10 30149 JP 2001 172745 , WO 03/024644 and WO 02/26422 .

- the steel strip may have a tensile strength of at least 410 MPa.

- the steel product may have a yield strength of at least 485 MPa and a tensile strength of at least of at least 520 MPa.

- the total elongation may be at least 10%.

- the thin cast steel strip may have fine oxide particles of silicon and iron distributed through the steel microstructure having an average particle size less than 50 nanometers

- the thin cast steel strip may have a thickness of less than 2.5 mm.

- the thin cast steel strip may have a thickness of less than 2.0 mm.

- the thin cast steel strip may have a thickness in the range from about 0.5 mm to about 2 mm.

- the present invention further provides a method of preparing coiled thin cast steel strip according to claim 9.

- the method may provide in the steel strip as coiled fine oxide particles of silicon and iron distributed through the steel microstructure having an average particle size less than 50 nanometers.

- the step of coiling the hot rolled steel strip may be carried out at a temperature less than 650 °C.

- the method may further comprise the step of age hardening the steel strip to increase the tensile strength at a temperature of at least 550 °C.

- the age hardening may occur at a temperature between 625 °C and 800 °C.

- the age hardening may occur at a temperature between 650 °C and 750 °C.

- the method may provide the age hardened steel strip having niobium carbonitride particles with an average particle size of less than 10 nanometers.

- the age hardened steel strip has substantially no niobium carbonitride particles greater than 50 nanometers.

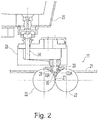

- FIG. 1 illustrates successive parts of strip caster for continuously casting steel strip.

- FIGS. 1 and 2 illustrate a twin roll caster 11 that continuously produces a cast steel strip 12, which passes in a transit path 10 across a guide table 13 to a pinch roll stand 14 having pinch rolls 14A.

- the strip passes into a hot rolling mill 16 having a pair of reduction rolls 16A and backing rolls 16B where the cast strip is hot rolled to reduce a desired thickness.

- the hot rolled strip passes onto a run-out table 17 where the strip may be cooled by convection and contact with water supplied via water jets 18 (or other suitable means) and by radiation.

- the rolled and cooled strip is then passes through a pinch roll stand 20 comprising a pair of pinch rolls 20A and then to a coiler 19. Final cooling of the cast strip takes place after coiling.

- twin roll caster 11 comprises a main machine frame 21, which supports a pair of laterally positioned casting rolls 22 having casting surfaces 22A.

- Molten metal is supplied during a casting operation from a ladle (not shown) to a tundish 23, through a refractory shroud 24 to a distributor or moveable tundish 25, and then from the distributor 25 through a metal delivery nozzle 26 between the casting rolls 22 above the nip 27.

- the molten metal delivered between the casting rolls 22 forms a casting pool 30 above the nip.

- the casting pool 30 is restrained at the ends of the casting rolls by a pair of side closure dams or plates 28, which are pushed against the ends of the casting rolls by a pair of thrusters (not shown) including hydraulic cylinder units (not shown) connected to the side plate holders.

- the upper surface of casting pool 30 (generally referred to as the "meniscus" level) usually rises above the lower end of the delivery nozzle so that the lower end of the delivery nozzle is immersed within the casting pool 30.

- Casting rolls 22 are internally water cooled so that shells solidify on the moving roller surfaces as they pass through the casting pool, and are brought together at the nip 27 between them to produce the cast strip 12, which is delivered downwardly from the nip between the casting rolls.

- the twin roll caster may be of the kind that is illustrated and described in some detail in U.S. Patent. Nos. 5,184,668 and 5,277,243 or U.S. Patent. No. 5,488,988 . Reference may be made to those patents for appropriate construction details of a twin roll caster appropriate for use in an embodiment of the present invention.

- a high strength thin cast strip product can be produced using the twin roll caster that overcomes the shortcomings of conventional light gauge steel products and produces a high strength, light gauge, steel strip product.

- the invention utilizes the elements including niobium (Nb), vanadium (V), or molybdenum (Mo), or a combination thereof.

- Microalloying elements in steel are commonly taken to refer to the elements titanium niobium, and vanadium. These elements were usually added in the past in levels below 0.1%, but in some cases levels as high as 0.2%. These elements are capable of exerting strong effects on the steel microstructure and properties via a combination of hardenability, grain refining and strengthening effects (in the past as carbonitride formers). Molybdenum has not normally been regarded as a microalloying element since on its own it is a relatively weak carbonitride former, but may be effective in the present circumstances and may form complex carbonitride particles along with niobium and vanadium. Carbonitride formation is inhibited in the hot rolled strip with these elements as explained below.

- the high strength thin cast strip product combines several attributes to achieve a high strength light gauge cast strip product by microalloying with these elements.

- Strip thicknesses is less than 3 mm, less than 2.5 mm, or less than 2.0 mm, and may be in a range of 0.5 mm to 2.0 mm.

- the cast strip is produced by hot rolling without the need for cold rolling to further reduce the strip to the desired thickness.

- the high strength thin cast strip product overlaps both the light gauge hot rolled thickness ranges and the cold rolled thickness ranges desired.

- the strip is cooled at a rate of 10 °C per second and above, and still form a microstructure that is a majority and typically predominantly bainite and acicular ferrite.

- the present high strength thin cast steel strip product comprising, by weight, less than 0.25% carbon, between 0.20 and 2.00% manganese, between 0.05 and 0.50% silicon, less than 0.01% aluminum, and at least one element selected from the group consisting of niobium between 0.01% and 0.20%, and vanadium between 0.01% and 0.20%, and optionally molybdenum between 0.05% and 0.50%, and having a majority of the microstructure comprised of bainite and acicular ferrite.

- the steel product may further comprising fine oxide particles of silicon and iron distributed through the steel microstructure having an average particle size less than 50 nanometers.

- the steel product may further comprise a more even distribution of microalloys through the microstructure than previously produced with conventional slab cast product.

- the high strength thin cast steel strip product may comprise, by weight, less than 0.25% carbon, between 0.20 and 2.0% manganese, between 0.05 and 0.50% silicon, less than 0.01% aluminum, and niobium between 0.01% and 0.20%, and having a majority of the microstructure comprising bainite and acicular ferrite and having more than 70% soluble niobium.

- a coiled steel product may comprise, by weight, less than 0.25% carbon, between 0.20 and 2.0% manganese, between 0.05 and 0.50% silicon, less than 0.01% aluminum, and at least one element selected from the group consisting of niobium between 0.01% and 0.20% and vanadium between 0.01% and 0.20%, and a combination thereof, and having more than 70% soluble niobium and vanadium, as selected, after coiling and cooling.

- the coiled high strength thin cast steel strip product has more than 70% soluble niobium and vanadium, as selected, particularly after hot rolling reduction and subsequent coiling and before age hardening.

- the microstructure is a mixture of bainite and acicular ferrite.

- the microstructure of the hot rolled and subsequently coiled and cooled steel may comprise bainite and acicular ferrite with more than 80% niobium and/or vanadium remaining in solid solution, and alternately may have more than 90% remaining in solid solution.

- the steel product has a total elongation of at least 6% or greater than 10%.

- the steel product has a yield strength of at least 340 MPa (about 49 ksi) and may have a tensile strength of at least 410 MPa, exhibiting satisfactory ductility.

- the relationship between yield strength and total elongation in the hot rolled product is shown in FIG. 8 .

- the hot rolled steel strip may be coiled at a temperature in the range from about 500-700 °C.

- the thin cast steel strip may also be further processed by age hardening the steel strip to increase the tensile strength at a temperature of at least 550 °C.

- the age hardening may occur at a temperature between 550 °C and 800 °C, or between 625 °C and 750 °C, or between 675 °C and 750 °C.

- Conventional furnaces of continuous galvanizing or annealing lines are thus capable of providing the age hardening temperatures needed to harden the microalloyed cast strip product.

- a steel composition was prepared by making a steel composition of a 0.026% niobium, 0.04% by weight carbon, 0.85% by weight manganese, 0.25% by weight silicon that has been cast by a thin cast strip process.

- the strip was cast at 1.7 mm thick and inline hot rolled to a range of strip thickness from 1.5 mm to 1.1 mm using a twin roll caster as illustrated in FIGS. 1 and 2 .

- the strip was coiled at coiling temperatures of 590-620 °C (1094-1148 °F).

- the yield and tensile strength levels achieved in the present cast strip are compared to the yield and tensile strength levels achievable in the base, non-microalloyed, cast strip steel composition over a range of coiling temperatures. It can be seen that the niobium steel strip achieved yield strengths in the range of 420-440 MPa (about 61-64 ksi) and tensile strengths of about 510 MPa (about 74 ksi).

- the present cast strip product is compared to C-Mn-Si base steel compositions processed with the same coiling temperature as the microalloyed steel, with the niobium steel producing substantially higher strength levels.

- the compared base steel strip had to be coiled at very low temperatures to approach comparable strength levels to the cast niobium steel product.

- the cast niobium steel product did not need to be coiled at low coiling temperatures to achieve its strengthening potential with the hot rolling.

- the yield and tensile strength levels for the cast niobium steel was not significantly affected by the degree of inline hot rolling with a reduction of at least 19% to 37% as shown in FIG. 7 .

- FIG. 9 The hardenability of the present steels is shown in FIG. 9 .

- a niobium level of as little as 0.007% was effective in increasing the strength of the final strip, and yield strength levels of over 380 MPa were achieved with niobium levels greater than about 0.01%.

- niobium levels less than about 0.005% may be considered residual. Thus even very small additions of microalloying elements can be effective in substantial strengthening.

- FIG. 4b shows that proeutectic ferrite formed along the prior austenite grain boundaries (allotriomorphic ferrite) in the base steel, but it was not present in the niobium steel shown in FIG. 4a .

- the hardenability effects of the niobium addition suppressed the ferrite transformation, hence enabling the stronger bainitic and acicular ferrite microstructure to be produced while using conventional cooling rates during cooling and higher coiling temperatures.

- the final microstructure of the present niobium steels comprises mostly a combination of bainite and acicular ferrite.

- the base steel shown in FIG. 4b was cooled to a relatively low coiling temperature, less than 500 °C, a cooling condition known to suppress ferrite formation at the austenite grain boundaries.

- the effect of hot reduction on yield strength is reduced in the present niobium steel.

- the coiling temperature was kept constant, and covering the range of hot rolling reductions up to at least 40% represented the strip thickness range of 1.0mm to 1.5mm.

- the strength levels of the niobium microalloyed steels of the present disclosure in the as-hot rolled cast strip product are relatively insensitive to the degree of hot rolled reduction for reductions up to at least 40%. Further, these high strength levels were achieved using conventional coiling temperatures in the range of 550 °C to 650 °C, as shown in FIG. 3 .

- the austenite grain size was measured at each thickness in the 0.026 Nb steel.

- the base steel tended to be fully recrystallized above about 25% hot reduction

- the 0.026 Nb steel showed only limited recrystallization even at 40% reduction.

- the niobium in solid solution reduced the effect of hot reduction on the strength properties by suppressing static recrystallization of the deformed austenite after hot rolling.

- FIG. 10 shows that the austenite grains have been elongated by the hot rolling reduction without recrystallising into finer grains. Finer grains increase the austenite grain boundary area, thereby reducing the steel hardenability.

- the thin cast strip niobium steel product had consistent yield and tensile strength levels over the range of hot rolling applied, and capable of providing a yield strength of at least 410 MPa with a reduction of between 20% and 40%.

- the prior austenite grain size was determined for each strip thickness. The austenite grain size measurements indicated that only very limited recrystallization had occurred at high hot rolling reductions, whereas in the comparable base steel strip, the microstructure almost fully recrystallized at hot rolling reductions over about 25%.

- the addition of niobium to the cast steel strip suppressed the recrystallization of the coarse as-cast austenite grain size during the hot rolling process, and resulted in the hardenability of the steel being retained after hot rolling and retention of niobium in solution.

- the higher strength of the present steel strip after hot rolling was mostly due to the microstructure formed.

- the microstructure of the cast niobium steel was comprised of a majority if not mostly bainite for all strip thicknesses.

- the comparable non-microalloyed steel achieved similar strength by coiling at a low coiling temperature and had a microstructure comprising mostly acicular ferrite with some grain boundary ferrite.

- the addition of niobium to the steel strip provided an increase in the hardenability of the steel and suppressed the formation of the grain boundary ferrite and promoted the bainitic microstructure, even at considerably higher coiling temperatures.

- the yield and tensile strength results from the trial steels, shown in Table 2 below, in the as-hot rolled condition are summarized in FIG. 11 .

- the strength level increases with increasing niobium content, with yield strength of at least 340 MPa, with levels up to about 500 MPa in the as-hot rolled condition.

- the tensile strength may be at least 410 MPa.

- the initial rapid increase in strength is attributed to the suppression of proeutectic ferrite formation and the promotion of bainite and acicular ferrite, while the subsequent strengthening can be attributed to continued microstructural refinement and possibly solid solution hardening from niobium retained in solid solution.

- TEM transmission electron microscopy

- the transmission electron microscopy (TEM) examination may be used to determine the size, identity and volume fraction of niobium carbonitride particles present in the steel.

- TEM transmission electron microscopy

- the absence of any niobium carbonitride particles upon TEM examination supported the view that the observed strength was largely attributable to the microstructure being largely bainite rather than ferrite.

- the subsequent observed strengthening increment arising from an age hardening heat treatment therefore leads to the conclusion that niobium had been substantially in solution in the hot rolled strip.

- the amount of microalloy element in solid solution can be concluded.

- Thin foils or carbon replicates may be evaluated by TEM in determining the amount of the present carbonitride particles.

- TEM transmission electron microscope

- a foil is prepared.

- the foil is cut and ground to a thickness of 0.1 mm.

- the sample is then thinned to electron transparency by electropolishing using a 5% perchloric acid, 95% acetic acid electrolyte in a Tenupole-2 electropolishing unit.

- the sample can then be directly transferred to the TEM.

- a desired sample may be prepared by etching a polished sample in Nital (a solution of alcohol and nitric acid) after etching, coating the samples with carbon, and then scoring the carbon coating into appropriate dimensions (for example 2 mm square) for TEM analysis. After scoring, carbon replicas may be liberated from the sample by dissolving the ferrite matrix in 3% Nital. The carbon replica samples are collected on 3mm diameter support grids, then repeatedly washed in ethanol/water solutions. The carbon extraction replica with the supporting grid can then be transferred to the TEM.

- Nital a solution of alcohol and nitric acid

- the extremely rapid initial solidification in forming the cast strip (in about 160 microseconds) is believed to inhibit pre-clustering and/or solid state precipitation of carbonitride particles, and in turn, slow and reduce the kinetics for precipitation of the microalloys in subsequent processing including rolling and coiling operations.

- the microalloys of Nb, V, and Mo are relatively more evenly distributed in the austenite and ferrite phases, than in thin steel strip previously made by conventional slab casting and processing.

- Atom probe analysis of niobium cast strip made by forming from a casting pool between casting rolls as above described has verified the more even distribution of microalloys (indicating reduced pre-clustering and/or solid state precipitation) in both the as cast and the hot rolled strip when coiled at about 650 °C or lower.

- This more even distribution of elements is believed to be inhibiting the formation of carbonitrides in the coiling operation under conditions where fine coherent precipitation of such elements occurred in previous conventionally made and processed microalloyed slab cast steel.

- the reduction or absence of pre-clustering and/or solid state formation of carbonitrides in the microalloyed cast strip made by twin roll casting also slows the kinetics of formation of carbonitrides during subsequent thermo-mechanical processing such as annealing. This then permits the opportunity for age hardening at temperatures higher than those where the particles in previously conventionally processed strip lost their strengthening capacity through coarsening (Ostwald ripening) mechanisms.

- the microstructure of the present age hardened steel product may have niobium carbonitride particles with an average particle size of 10 nanometers and less.

- the microstructure of the age hardened steel product may have substantially no niobium carbonitride particles greater than 50 nanometers.

- short time age hardening is carried out to simulate the ageing potential from processing the niobium microalloyed cast steel product through an annealing furnace attached to continuous galvanizing line or conventional continuous annealing line.

- the age hardened high strength strip product maybe subsequently galvanized, painted or utilized uncoated.

- the yield strengths achieved for steel C and steel F are shown in FIG. 12 , and the yield strength results for the 0.014% Nb heat, steel A, produced with a lower Mn content, are presented in FIG. 13 .

- the niobium additions increased the yield strength at all coiling temperatures relative to the base steel composition.

- the yield strength increased by about 70 to 100 MPa (10 to 15 ksi) for the 0.014% Nb and 0.026 Nb additions, and by about 140 to 175 MPa (20-25 ksi) for the 0.065 Nb addition.

- From FIG. 12 it can be seen that the 0.026% Nb steel achieved higher yield strengths than the 0.8 Mn base steel for similar coiling temperatures, and comparable yield strengths to when the 0.8 Mn base steel was coiled a low temperatures.

- the strengths achieved in the 0.8 Mn base steel at low coiling temperatures (about 500°C) can be achieved at higher coiling temperatures (about 600°C) with this Nb addition.

- the microstructure of the hot rolled and subsequently coiled and cooled steel comprises bainite and acicular ferrite with more than 70% niobium and/or vanadium remaining in solid solution.

- the microstructure of the hot rolled and subsequently coiled and cooled steel may comprise bainite and acicular ferrite with more than 80% niobium and/or vanadium remaining in solid solution, and alternately may have more than 90 % remaining in solid solution.

- the niobium cast strip results in light gauge, high strength, steel product.

- the niobium addition firstly is capable of suppressing the austenite recrystallization during hot rolling, which enhances the hardenability of the steel by retaining the relatively coarse as cast austenite size.

- the niobium being retained in solid solution in austenite after hot rolling directly increases the steel's hardenability, which assists in transforming the austenite to a final microstructure comprised mostly of bainite, even at relatively high coiling temperatures.

- the formation of a bainitic microstructure promoted the retention of the niobium addition in solid solution in the hot rolled strip.

- microalloying elements such as niobium and vanadium in solid solution by the prior processing conditions provided considerable hardenability for subsequent age hardening cycle.

- Such an age hardening cycle can be produced using a suitable continuous galvanizing line or continuous annealing facility.

- a microalloyed steel strip made using a thin strip casting process, combined with an age hardening heat treatment provided by a suitable galvanizing line or annealing line, is a unique manufacturing path providing a unique strengthening approach for this type of steel product.

- microalloying elements such as niobium and vanadium

- the microalloying elements in solid solution are available for age hardening during a subsequent heat treatment to increase strength.

- Laboratory age hardening studies established that substantial strengthening could be achieved even with relatively short heat treatment cycles, such as available with continuous annealing lines and galvanizing lines.

- the results from laboratory simulated continuous annealing cycles applied to trial Steel C (0.026% Nb), Steel F (0.065% Nb), and Steel G (0.084% Nb) are shown in FIGS. 15, through 18 .

- a 10 second hold cycle may be used between about 675 °C to 725 °C to prevent overaging.

- the temperature range is a function of the holding time. Increasing the hold time to 20 seconds lowered the temperature range slightly, while for the zero hold time, the temperature range was increased slightly, as shown in FIG. 17 .

- the age hardening temperature range may be between about 625 °C and 800 °C depending upon on the overall heat treatment cycle time, i.e. heating rates, the holding time, and cooling rates.

- FIG. 6 shows results of laboratory heat treatments carried out for 20 and 120 minutes. The results show that substantial hardening was achieved for a heat treatment of 120 minutes at 550 °C, but the 120 minute aging at temperatures over about 650 °C reduced the hardness of the steel.

- TEM Transmission electron microscopy

- the microstructure of the age hardened microalloyed steel product may have niobium carbonitride particles, with an average particle size of 10 nanometers and less.

- the microstructure of the age hardened steel product may have substantially no niobium carbonitride particles greater than 50 nanometers. Samples of the present niobium steel were inspected using TEM evaluation, and portions of the microstructure had no measurable amount of niobium carbonitride particles.

- the enhanced strength/elongation relationship in the present age hardened steel may be due to portions of the microstructure being substantially free of particles greater than 5 nanometers in size, or "precipitate free zones," and nano-clusters.

- precipitate free zones may influence the strength and tensile elongation relationship by providing reduced hardness regions adjacent to grain boundaries.

- the relaxation of stress concentrations in precipitate free zones has been reported to enhance strength and elongation.

- the beneficial effects of precipitate free zones on elongation and strength may appear in circumstances where the precipitate free zones are narrow and the size of grain boundary precipitates is small.

- the element additions may provide for increased elongation with increased strength after age hardening by producing smaller precipitate free zone width and smaller change in hardness than in conventionally produced niobium steels. Because of the more even dispersion of elements in rapidly solidified steels, the kinetics of age hardening can be retarded so as to effectively expand the time-temperature window over which the formation of nano-clusters can be stably controlled.

- the element nano-clusters may provide strengthening in the early stages of age hardening. Cluster strengthening may be due to the extra energy required for dislocations to cut the diffuse boundary of the cluster of solute species. The clusters may provide substantial strengthening without reducing ductility because their elastically soft boundaries do not severely inhibit dislocation movement or cause pile-ups in the way that normal second phase particles do.

- the microstructure of the hot rolled and subsequently coiled and cooled steel comprises bainite and acicular ferrite with more than 70% niobium and/or vanadium addition remaining in solid solution and substantially no niobium carbonitride particles greater than 50 nanometers.

- the microstructure of the hot rolled and subsequently coiled and cooled steel may comprise bainite and acicular ferrite with more than 80% niobium and/or vanadium addition remaining in solid solution, and alternately may have more than 90% remaining in solid solution.

- the elements remain trapped in solution in the hot rolled coil and do not precipitate if the coiling temperature is below about 650 °C. Formation is effectively retarded because the prior associations of atoms (such as in the form of particles) that normally occur in conventional slab casting and reheating for hot strip rolling are prevented in the present process. The observed increase in strength that occurs in the hot rolled coils may thus be largely attributable to hardenability and solid solution hardening effects.

- Formation of carbonitride particles can be activated during heat treatment. Additionally, during age hardening, pre-precipitation clusters and finer particles are stable over an extended range of time and temperature because of the significant amount of niobium and/or vanadium in solid solution prior to age hardening.

- the precipitate free zones that form near grain boundaries as a normal precipitation phenomenon are narrower and contain more evenly dispersed nano-clusters and finer precipitates than for conventionally produced steels. Thus the hardness changes in the precipitate free zones relative to the grain interior are relatively small for the present steels. We believe that narrower precipitate free zones and small hardness changes across precipitate free zones reduce stress concentrations in the precipitate free zones reducing microcracking from preferential deformation in the precipitate free zones.

- the cluster strengthening may be characterized by a strength increase without a deterioration in ductility since dislocation pile-up does not occur at clusters.

- the combination of narrow precipitate free zones and cluster strengthening mechanisms is believed to lead to precipitate free zones of the present steels. This results in improved elongation because cracks are more difficult to initiate and less constrained to the grain boundary precipitate free zone region.

- the nano-clusters may co-exist with distinct particles within the grain interior regions over a certain annealing temperature/time combinations.

- An annealing furnace may be used to perform the age hardening, which is not a current strengthening approach for processing such products.

- the annealing condition may be a continuous annealing cycle with a peak temperature of at least 650 °C and less than 800 °C and better 675 °C to 750 °C.

- strengthening may be achieved in a production environment using a very short age hardening cycle available with conventional annealing furnaces incorporated in continuous galvanizing lines.

- the final strength levels recorded in the full scale plant trials were similar to that produced with the laboratory heat treatments of the respective steels.

- niobium between about 0.01% and about 0.20%, molybdenum between about 0.05% and about 0.50%, and vanadium between about 0.01% and about 0.20%.

- the composition of the present steel utilizing vanadium is shown as steel H in Table 2.

- the yield strength of steel H is shown in FIG. 23 .

- the vanadium steel was produced with two different coiling temperatures, and was subsequently aged for 20 minutes at 650 °C and 700 °C to induce hardening by vanadium in solid solution. The results show that significant strengthening was achieved from these heat treatment conditions.

- the strengthening increment was slightly higher for the material produced with the higher coiling temperature, which may be due to the effects of opposing processes of precipitation hardening and microstructural softening.

- the strengthening increment realized with the material produced at the lower coiling temperature was of the same order of that achieved with the 0.026% Nb steel.

- FIGS. 23 and 24 indicate that the vanadium steel achieved higher strength levels than the plain carbon base steel, even though it was produced using higher coiling temperatures.

- the coiling temperature of steel H was 570 °C, and the base steel coiling temperature was less than 500 °C.

- a strength increase was realized in the vanadium steel from an age hardening using the annealing furnaces on a continuous galvanising line, but the strength increase was less than was realized from an equivalent niobium content.

- the yield strength of the sample in FIG. 24 on the galvanizing line was about 450 MPa in the galvanised condition, which is in the order achieved with the longer term laboratory heat treatments shown in FIG. 23 .

- the strength of the vanadium steel may be more sensitive to coiling temperature than the niobium steels.

- This thin cast strip enables production of new steel product types including:

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Crystallography & Structural Chemistry (AREA)

- Thermal Sciences (AREA)

- Physics & Mathematics (AREA)

- Heat Treatment Of Sheet Steel (AREA)

- Continuous Casting (AREA)

- Metal Rolling (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

- Shaping Of Tube Ends By Bending Or Straightening (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL08747717T PL2162251T3 (pl) | 2007-05-06 | 2008-05-06 | Wyrób w postaci cienkiej odlewanej taśmy z dodatkami mikrostopów i sposób jego wytwarzania |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/744,881 US20070212249A1 (en) | 2005-10-20 | 2007-05-06 | Thin cast strip product with microalloy additions, and method for making the same |

| US94378107P | 2007-06-13 | 2007-06-13 | |

| PCT/US2008/062781 WO2008137899A1 (en) | 2007-05-06 | 2008-05-06 | A thin cast strip product with microalloy additions, and method for making the same |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2162251A1 EP2162251A1 (en) | 2010-03-17 |

| EP2162251A4 EP2162251A4 (en) | 2014-08-27 |

| EP2162251B1 true EP2162251B1 (en) | 2021-07-28 |

Family

ID=39943999

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08747717.0A Active EP2162251B1 (en) | 2007-05-06 | 2008-05-06 | A thin cast strip product with microalloy additions, and method for making the same |

| EP08747719.6A Active EP2162252B1 (en) | 2007-05-06 | 2008-05-06 | An age hardened thin cast strip product with microalloy additions, and method for making the same |

| EP08747712.1A Active EP2152451B1 (en) | 2007-05-06 | 2008-05-06 | A thin cast strip product with microalloy additions, and method for making the same |

Family Applications After (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08747719.6A Active EP2162252B1 (en) | 2007-05-06 | 2008-05-06 | An age hardened thin cast strip product with microalloy additions, and method for making the same |

| EP08747712.1A Active EP2152451B1 (en) | 2007-05-06 | 2008-05-06 | A thin cast strip product with microalloy additions, and method for making the same |

Country Status (18)

| Country | Link |

|---|---|

| EP (3) | EP2162251B1 (zh) |

| JP (1) | JP5385899B2 (zh) |

| KR (2) | KR101576963B1 (zh) |

| CN (3) | CN101765469B (zh) |

| AU (3) | AU2008247366B2 (zh) |

| BR (1) | BRPI0811554B1 (zh) |

| CA (1) | CA2686495C (zh) |

| CO (1) | CO6241142A2 (zh) |

| CR (1) | CR11111A (zh) |

| EC (1) | ECSP099784A (zh) |

| ES (2) | ES2894332T3 (zh) |

| MA (1) | MA31401B1 (zh) |

| MX (1) | MX2009012021A (zh) |

| MY (3) | MY157870A (zh) |

| NZ (3) | NZ581424A (zh) |

| PL (3) | PL2152451T3 (zh) |

| RU (1) | RU2471589C2 (zh) |

| WO (3) | WO2008137899A1 (zh) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102022204069A1 (de) | 2022-04-27 | 2023-11-02 | Sms Group Gmbh | Gieß-Walz-Anlage und Verfahren zur Erzeugung eines Stahlbandes |

Families Citing this family (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20100215981A1 (en) * | 2009-02-20 | 2010-08-26 | Nucor Corporation | Hot rolled thin cast strip product and method for making the same |

| CN103305754B (zh) * | 2012-03-14 | 2015-09-23 | 宝山钢铁股份有限公司 | 一种时效硬化薄带连铸低碳微合金钢带制造方法 |

| CN103305759B (zh) * | 2012-03-14 | 2014-10-29 | 宝山钢铁股份有限公司 | 一种薄带连铸700MPa级高强耐候钢制造方法 |

| CN103302255B (zh) * | 2012-03-14 | 2015-10-28 | 宝山钢铁股份有限公司 | 一种薄带连铸700MPa级高强耐大气腐蚀钢制造方法 |

| CN103305746B (zh) * | 2012-03-14 | 2015-09-23 | 宝山钢铁股份有限公司 | 一种时效硬化薄带连铸低碳微合金高强钢带制造方法 |

| CN103305770B (zh) * | 2012-03-14 | 2015-12-09 | 宝山钢铁股份有限公司 | 一种薄带连铸550MPa级高强耐大气腐蚀钢带的制造方法 |

| CN103305755B (zh) * | 2012-03-14 | 2015-10-28 | 宝山钢铁股份有限公司 | 一种薄带连铸低碳微合金高强钢带制造方法 |

| CN102978512B (zh) * | 2012-12-21 | 2014-10-29 | 武汉钢铁(集团)公司 | 一种高强涂漆捆带及其制备方法 |

| ES2864636T3 (es) * | 2013-10-28 | 2021-10-14 | Nanosteel Co Inc | Producción de acero metálico por fundición de planchones |

| JP6527942B2 (ja) * | 2014-05-30 | 2019-06-12 | 宝山鋼鉄股▲分▼有限公司 | 溶鋼から直接に製造された酸洗不要の溶融めっき薄板帯製品の製造方法 |

| CN104630623B (zh) * | 2015-01-30 | 2017-03-01 | 首钢总公司 | 具有高扩孔性能的热轧酸洗带钢及其生产方法 |

| US10174398B2 (en) * | 2016-02-22 | 2019-01-08 | Nucor Corporation | Weathering steel |

| EP4033000A4 (en) | 2019-09-19 | 2023-03-15 | Baoshan Iron & Steel Co., Ltd. | MARTENSITIC STEEL STRIP AND METHOD OF MANUFACTURING THEREOF |

| CN112522576B (zh) | 2019-09-19 | 2022-11-18 | 宝山钢铁股份有限公司 | 一种薄规格高耐蚀钢及其生产方法 |

| CN111014602B (zh) * | 2019-12-30 | 2022-04-08 | 中国科学院合肥物质科学研究院 | 一种以前驱粉诱导形核通过薄带连铸工艺制备氧化物弥散强化钢的方法 |

Family Cites Families (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3726723A (en) * | 1970-05-11 | 1973-04-10 | American Metal Climax Inc | Hot-rolled low alloy steels |

| JPS579831A (en) | 1980-05-21 | 1982-01-19 | British Steel Corp | Steel production |

| CA1207639A (en) * | 1983-03-17 | 1986-07-15 | Rodney J. Jesseman | Low alloy steel plate and process for production therefor |

| EP0288054B1 (en) * | 1987-04-24 | 1993-08-11 | Nippon Steel Corporation | Method of producing steel plate with good low-temperature toughness |

| DE69126229T2 (de) | 1990-04-04 | 1997-12-18 | Bhp Steel (Jla) Pty. Ltd., Melbourne, Victoria | Verfahren und Vorrichtung zum kontinuierlichen Bandgiessen |

| JPH04325657A (ja) * | 1991-04-26 | 1992-11-16 | Kobe Steel Ltd | 伸びフランジ性の優れた高強度熱延鋼板及びその製造方法 |

| JPH0826411B2 (ja) * | 1991-12-25 | 1996-03-13 | 株式会社神戸製鋼所 | 深絞り性に優れた高強度冷延鋼板の製造方法 |

| CN1040343C (zh) * | 1993-04-26 | 1998-10-21 | 新日本制铁株式会社 | 具有优越的外卷边性能的薄钢板及其制造方法 |

| IN181634B (zh) | 1993-05-27 | 1998-08-01 | Bhp Steel Jla Pty Ltd Ishikawa | |

| JPH0841537A (ja) * | 1994-07-29 | 1996-02-13 | Kobe Steel Ltd | 高強度高靭性ボルト用鋼材の製法 |

| JP3276258B2 (ja) * | 1995-01-20 | 2002-04-22 | 株式会社神戸製鋼所 | 化成処理性及び加工性の良好な高強度熱延鋼板及びその製造方法 |

| JPH08260042A (ja) | 1995-03-22 | 1996-10-08 | Nippon Steel Corp | 高張力を有する構造用厚鋼板の製造方法 |

| JP3251506B2 (ja) * | 1996-07-15 | 2002-01-28 | 株式会社神戸製鋼所 | 圧壊特性に優れた高強度熱延鋼板及びその製造方法 |

| IT1291931B1 (it) * | 1997-06-19 | 1999-01-21 | Voest Alpine Ind Anlagen | Procedimento per la produzione di nastri grezzi di colaggio in acciaio a basso contenuto di carbonio e nastri cosi' ottenibili |

| KR100415718B1 (ko) * | 1999-09-16 | 2004-01-24 | 제이에프이 엔지니어링 가부시키가이샤 | 고강도 박강판 및 그 제조방법 |

| JP3601387B2 (ja) * | 1999-12-15 | 2004-12-15 | Jfeスチール株式会社 | 加工性と疲労特性に優れた高強度熱延鋼板およびその製造方法 |

| CN1286999C (zh) * | 2000-06-20 | 2006-11-29 | 杰富意钢铁株式会社 | 薄钢板及其制造方法 |

| AUPR047900A0 (en) * | 2000-09-29 | 2000-10-26 | Bhp Steel (Jla) Pty Limited | A method of producing steel |

| IT1316029B1 (it) * | 2000-12-18 | 2003-03-26 | Acciai Speciali Terni Spa | Processo per la produzione di acciaio magnetico a grano orientato. |

| US6488790B1 (en) * | 2001-01-22 | 2002-12-03 | International Steel Group Inc. | Method of making a high-strength low-alloy hot rolled steel |

| BRPI0212499B1 (pt) * | 2001-09-14 | 2015-12-08 | Nucor Corp | processo para produzir tira de aço por lingotamento contínuo e tira de aço fina produzida pelo mesmo |

| US7485196B2 (en) * | 2001-09-14 | 2009-02-03 | Nucor Corporation | Steel product with a high austenite grain coarsening temperature |

| JP2003147477A (ja) * | 2001-11-07 | 2003-05-21 | Kawasaki Steel Corp | 700MPa超級非調質低降伏比厚鋼板およびその製造方法 |

| GB2386906B (en) * | 2002-03-26 | 2004-09-22 | Japan Steel Works Ltd | Heat-resisting steel and method of manufacturing the same |

| TW200940723A (en) * | 2004-07-21 | 2009-10-01 | Nippon Steel Corp | A weldable structural steel excellent in low temperature toughness at heat affected zone |

| WO2006103991A1 (ja) * | 2005-03-28 | 2006-10-05 | Kabushiki Kaisha Kobe Seiko Sho | 穴拡げ加工性に優れた高強度熱延鋼板およびその製造方法 |

| JP4523893B2 (ja) * | 2005-08-22 | 2010-08-11 | 新日本製鐵株式会社 | 母材及び溶接熱影響部の靱性に優れた引張強度590N/mm2級の溶接構造用鋼およびその製造方法 |

-

2008

- 2008-05-06 MY MYPI20094705A patent/MY157870A/en unknown

- 2008-05-06 AU AU2008247366A patent/AU2008247366B2/en active Active

- 2008-05-06 MY MYPI20094704A patent/MY149968A/en unknown

- 2008-05-06 AU AU2008247367A patent/AU2008247367B2/en active Active

- 2008-05-06 WO PCT/US2008/062781 patent/WO2008137899A1/en active Application Filing

- 2008-05-06 KR KR1020097025584A patent/KR101576963B1/ko active IP Right Grant

- 2008-05-06 NZ NZ581424A patent/NZ581424A/en unknown

- 2008-05-06 CN CN200880023157.9A patent/CN101765469B/zh active Active

- 2008-05-06 MY MYPI20094706A patent/MY150225A/en unknown

- 2008-05-06 EP EP08747717.0A patent/EP2162251B1/en active Active

- 2008-05-06 JP JP2010507600A patent/JP5385899B2/ja active Active

- 2008-05-06 ES ES08747717T patent/ES2894332T3/es active Active

- 2008-05-06 RU RU2009145115/02A patent/RU2471589C2/ru active

- 2008-05-06 CN CN200880023167A patent/CN101765470A/zh active Pending

- 2008-05-06 WO PCT/US2008/062776 patent/WO2008137898A1/en active Application Filing

- 2008-05-06 AU AU2008247365A patent/AU2008247365B2/en active Active

- 2008-05-06 EP EP08747719.6A patent/EP2162252B1/en active Active

- 2008-05-06 ES ES08747719T patent/ES2884217T3/es active Active

- 2008-05-06 PL PL08747712T patent/PL2152451T3/pl unknown

- 2008-05-06 NZ NZ581423A patent/NZ581423A/en unknown

- 2008-05-06 NZ NZ581394A patent/NZ581394A/en unknown

- 2008-05-06 MX MX2009012021A patent/MX2009012021A/es active IP Right Grant

- 2008-05-06 KR KR1020097025585A patent/KR101527735B1/ko active IP Right Grant

- 2008-05-06 EP EP08747712.1A patent/EP2152451B1/en active Active

- 2008-05-06 WO PCT/US2008/062783 patent/WO2008137900A1/en active Application Filing

- 2008-05-06 CN CN200880023586A patent/CN101795792A/zh active Pending

- 2008-05-06 BR BRPI0811554A patent/BRPI0811554B1/pt active IP Right Grant

- 2008-05-06 PL PL08747717T patent/PL2162251T3/pl unknown

- 2008-05-06 CA CA2686495A patent/CA2686495C/en active Active

- 2008-05-06 PL PL08747719T patent/PL2162252T3/pl unknown

-

2009

- 2009-11-16 CR CR11111A patent/CR11111A/es unknown

- 2009-11-19 CO CO09131765A patent/CO6241142A2/es not_active Application Discontinuation

- 2009-11-30 MA MA32386A patent/MA31401B1/fr unknown

- 2009-12-04 EC EC2009009784A patent/ECSP099784A/es unknown

Non-Patent Citations (1)

| Title |

|---|

| None * |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102022204069A1 (de) | 2022-04-27 | 2023-11-02 | Sms Group Gmbh | Gieß-Walz-Anlage und Verfahren zur Erzeugung eines Stahlbandes |

| WO2023208679A1 (de) | 2022-04-27 | 2023-11-02 | Sms Group Gmbh | GIEß-WALZ-ANLAGE UND VERFAHREN ZUR ERZEUGUNG EINES STAHLBANDES |

Also Published As

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2162251B1 (en) | A thin cast strip product with microalloy additions, and method for making the same | |

| EP2398929B1 (en) | A high strength thin cast strip product and method for making the same | |

| US9149868B2 (en) | Thin cast strip product with microalloy additions, and method for making the same | |

| US20070212249A1 (en) | Thin cast strip product with microalloy additions, and method for making the same | |

| US20180257133A1 (en) | Thin Cast Strip Product with Microalloy Additions, and Method for Making the Same | |

| US20140014238A1 (en) | High strength thin cast strip product and method for making the same | |

| KR20150127739A (ko) | 미소합금 첨가물을 갖는 박판 주조 스트립 제품과 그 제조 방법 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20091124 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| DAX | Request for extension of the european patent (deleted) | ||

| A4 | Supplementary search report drawn up and despatched |

Effective date: 20140728 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: C22C 38/04 20060101ALI20140722BHEP Ipc: B22D 11/124 20060101ALI20140722BHEP Ipc: C22C 38/02 20060101ALI20140722BHEP Ipc: C21D 6/02 20060101ALI20140722BHEP Ipc: C21D 8/02 20060101ALI20140722BHEP Ipc: B22D 11/06 20060101AFI20140722BHEP Ipc: C22C 38/12 20060101ALI20140722BHEP Ipc: C21D 6/00 20060101ALI20140722BHEP |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20180508 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20201214 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| RAP3 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: NUCOR CORPORATION |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1414259 Country of ref document: AT Kind code of ref document: T Effective date: 20210815 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602008064120 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20210728 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20210402786 Country of ref document: GR Effective date: 20211111 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 1414259 Country of ref document: AT Kind code of ref document: T Effective date: 20210728 |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: T3 Ref document number: E 38543 Country of ref document: SK |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210728 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210728 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210728 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20211028 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20211129 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210728 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20211028 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210728 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210728 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2894332 Country of ref document: ES Kind code of ref document: T3 Effective date: 20220214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210728 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210728 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602008064120 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210728 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210728 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20220429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210728 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20220531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210728 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220506 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220531 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220506 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20080506 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210728 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20240521 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240521 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20240523 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20240626 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CZ Payment date: 20240429 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SK Payment date: 20240429 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240529 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20240426 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20240426 Year of fee payment: 17 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210728 |