EP2096397B1 - Ailette pour un échangeur thermique - Google Patents

Ailette pour un échangeur thermique Download PDFInfo

- Publication number

- EP2096397B1 EP2096397B1 EP08017257.0A EP08017257A EP2096397B1 EP 2096397 B1 EP2096397 B1 EP 2096397B1 EP 08017257 A EP08017257 A EP 08017257A EP 2096397 B1 EP2096397 B1 EP 2096397B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- edge

- fin

- approximately

- face

- heat exchanger

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 239000012530 fluid Substances 0.000 claims description 18

- 230000000694 effects Effects 0.000 claims description 3

- 239000002826 coolant Substances 0.000 claims description 2

- 230000007423 decrease Effects 0.000 claims description 2

- 238000004378 air conditioning Methods 0.000 claims 1

- 238000002386 leaching Methods 0.000 description 10

- 238000004519 manufacturing process Methods 0.000 description 8

- 229910052782 aluminium Inorganic materials 0.000 description 6

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 6

- 238000005096 rolling process Methods 0.000 description 5

- 238000013461 design Methods 0.000 description 4

- 238000012546 transfer Methods 0.000 description 4

- 239000000463 material Substances 0.000 description 3

- 229910052751 metal Inorganic materials 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 238000011160 research Methods 0.000 description 3

- 230000001154 acute effect Effects 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 230000018109 developmental process Effects 0.000 description 2

- 238000004049 embossing Methods 0.000 description 2

- 230000002349 favourable effect Effects 0.000 description 2

- 238000005457 optimization Methods 0.000 description 2

- 230000000630 rising effect Effects 0.000 description 2

- 229910000838 Al alloy Inorganic materials 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000005192 partition Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F3/00—Plate-like or laminated elements; Assemblies of plate-like or laminated elements

- F28F3/02—Elements or assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with recesses, with corrugations

- F28F3/025—Elements or assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with recesses, with corrugations the means being corrugated, plate-like elements

- F28F3/027—Elements or assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with recesses, with corrugations the means being corrugated, plate-like elements with openings, e.g. louvered corrugated fins; Assemblies of corrugated strips

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D53/00—Making other particular articles

- B21D53/02—Making other particular articles heat exchangers or parts thereof, e.g. radiators, condensers fins, headers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F1/00—Tubular elements; Assemblies of tubular elements

- F28F1/10—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses

- F28F1/12—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element

- F28F1/126—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element consisting of zig-zag shaped fins

- F28F1/128—Fins with openings, e.g. louvered fins

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D21/00—Heat-exchange apparatus not covered by any of the groups F28D1/00 - F28D20/00

- F28D2021/0019—Other heat exchangers for particular applications; Heat exchange systems not otherwise provided for

- F28D2021/008—Other heat exchangers for particular applications; Heat exchange systems not otherwise provided for for vehicles

- F28D2021/0082—Charged air coolers

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/4935—Heat exchanger or boiler making

Definitions

- ribs in fluid-flow channels are provided to improve the heat exchanger performance.

- Such ribs may be formed, for example, as smooth ribs, gill ribs or ribbed ribs.

- Bar ribs show a particularly significant improvement of the heat exchange performance given the size, but also mean an often undesirably large pressure drop across the flow channel.

- Web ribs are used inter alia in intercoolers of motor vehicles, and mainly on the side of the charge air.

- DD 0 152 187 describes a strip-shaped tube installation element for shell and tube heat exchangers in the field of the petrochemical industry, in which trapezoidal louvers are provided for generating turbulence.

- the louvers have a variable width in the direction of flow, the lugs being bent out of the strip by an angle of greater than 30 ° about a longer of two parallel edges of the trapezoid.

- the WO 2009/015805 A1 discloses a rib for a heat exchanger in which a tab is disclosed.

- the first edge, at least one end edge of the at least one side wall and a second straight edge of the wall surface form an opening oriented essentially perpendicular to the flow direction and permeable by the first fluid, which has a substantially triangular shape.

- the tab surface is connected via a third edge to the wall surface, wherein the tab surface is angled over the third edge to the wall surface and the angle is advantageously between about eight degrees and about sixteen degrees, in particular about twelve degrees.

- the length of the third edge is advantageously between about twice and about four times, in particular about three times the length of the first edge. Overall, this is a hood-like leaching provided with very low pressure drop with good heat transfer of the air flowing through, as has been shown by experiments.

- a rib according to the invention can also be made of steel or another material which is suitable depending on the requirements.

- the shape of the tab surface starting from the first edge has approximately the parameterization [0; 2,500], [0.805; 2,470], [1.610; 2,290], [2,420; 1,910], [3,220; 1.540], [4.030; 1,210], [4,840; 0.980], [5.640; 0.780], [6.440; 0.590], [7.240; 0.400], [8.050; 0.210], the first value indicating the distance from the first edge in the flow direction, and the second value respectively indicating the distance of the side wall from the third edge.

- Such a shape corresponds in plan view of the tab surface approximately one on its central axis halved "NACA air inlet" according to the aforementioned research report number RM A9L29.

- a width of the tab surface decreases with increasing distance from the first edge, so that a nozzle effect for flowing along the leaching air flows.

- the curvature of the at least one side wall in its course at least one inflection point with respect to the direction of curvature, whereby a particularly good modulation of the air flow to improve the heat transfer is achieved at the same time low pressure drop.

- the inclination of the tab surface relative to the wall surface is between about five degrees and about ten degrees, in particular about seven degrees.

- the rib in the flow direction on several successively arranged leaching resulting in particular in long ribs a meaningful arrangement for the purpose of multiple deflection of the air over the ribs. Otherwise, the Air flow only affects part of the rib on advantageous way through the leaching.

- At least one of the plurality of louvers is particularly preferably arranged in the reverse orientation, with an overall effect of the leaching on the fluid flow being largely independent of its direction.

- the rib can be installed without impact in both orientations.

- At least two latches are provided with different opening direction or Ausstellraum with respect to the wall surface.

- the angle W3 is not less than about 10 °, in particular between about 15 ° and about 20 °.

- the angle of inclination of the wall allows sufficiently large or deep structures in the wall surface to affect the flow of the fluid in a desired manner and, secondly, the wall surface is still sufficiently steep in terms of mechanical strength.

- the wall surface may form a tie rod between the walls of a high-pressure fluid flat tube, such as in the case of using the rib as an inner corrugated fin of an intercooler.

- the rib is produced as a quasi-endless molded part from a sheet-metal strip by means of longitudinal rolling in the flow direction A.

- the rib can be formed particularly cost-effective with high production speed.

- the folding of the wall surfaces of the rib as well as the structures in the wall surfaces can be produced.

- a quasi-endless rib can be easily cut to the length of particularly large heat exchangers. In this way it is avoided that a plurality of individual ribs have to be plugged into an exchanger tube in order to provide it with ribs over the entire length.

- the rib consists of a sheet having a thickness between about 0.05 mm and about 0.35 mm, in particular between about 0.1 mm and about 0.15 mm.

- the material is expediently an aluminum alloy, wherein due to the good formability of the aluminum in conjunction with the selected sheet thicknesses, a longitudinal rolling of the rib as a production method is particularly well possible.

- the structure may be formed as an embossing and / or incision and / or offset in the wall surface.

- dislocations in the flow are particularly effective on the flow of the first fluid Wall surface, so that the fluid can partially pass through the wall surface in an adjacent flow space.

- the rib next to the inclined by the angle W3 wall surface also has a substantially perpendicular to the plane wall surface.

- These wall surfaces can be present in particular alternately.

- the vertical wall surfaces cause a particularly good mechanical stiffness of the rib against tensile and compressive forces.

- no structure is preferably provided in the wall surface perpendicular to the plane.

- all wall surfaces can be inclined and in particular provided with structures.

- the rib is designed as an inner corrugated rib of a charge air cooler.

- the rib is designed as an inner corrugated rib of a charge air cooler.

- intercoolers of high power density structured wall surfaces are favorable in contrast to conventional smooth ribs.

- the invention also relates to a heat exchanger having at least one rib according to the invention as claimed in any one of claims 1 to 9.

- the heat exchanger is preferably a heat exchanger for a motor vehicle, in particular a heat exchanger from the group of coolant coolers, climatic heat exchangers or intercoolers. Especially in motor vehicles and especially passenger cars, there is an increasing lack of space, so that the related to the size transmission capacity of a heat exchanger is of great importance. Due to the inventive design of the ribs of the heat exchanger, the heat exchanger performance can be improved with the same size.

- the angle is not less than about 10 °, in particular between about 15 ° and about 20 °.

- the rib is produced as a quasi-endless molded part from a sheet-metal strip by means of longitudinal rolling in the flow direction.

- the rib consists of a sheet having a thickness between about 0.05 mm and about 0.35 mm, in particular between about 0.1 mm and about 0.15 mm.

- the structure is formed as an embossing and / or incision and / or offset in the wall surface.

- the rib has a wall surface which is substantially perpendicular to the plane.

- the rib is designed as an inner corrugated rib of a charge air cooler.

- This in Fig. 1 shown embodiment of the invention comprises a rib 1 made of a multi-bent aluminum sheet. Between two mutually inclined wall surfaces 1a, 1b, a flow channel 2 is formed through which a first fluid of the heat exchanger, in the present case air, flows in the direction of the arrow A.

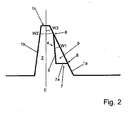

- the angle of inclination W3 of the wall surfaces 1a, 1b to each other is about 14 degrees, wherein the one wall surface 1a is inclined relative to a plane E of the heat exchanger by an angle W2 of about 12 degrees and the other wall surface accordingly by an angle W3-W2 of about 2 degrees (please refer Fig. 2 ).

- the heat exchanger is constructed such that a plurality of the ribs 1 are arranged side by side to form parallel adjacent flow channels 2. Above and below the ribs 1 are exchanger tubes or partitions (not shown), which delimit a second fluid, surface connected to the ribs 1, in particular soldered flat. For this purpose, the rib has a contact region 1c.

- At least one of the side walls 1a of the rib 1 a lashing 3 is arranged with a substantially smooth and against the side wall 1a with respect to the flow direction A inclined tab surface. 4

- the inclination angle in the flow direction is about 7 degrees.

- the geometric shape is identical.

- the lashing 3 is arranged only in each case different orientation in the wall surface 1a.

- the leaching is exposed to the same side with respect to the wall surface 1a, but the orientation with respect to the direction of the fluid flow A is inverted.

- the versions c and d the same applies, with the lashing being issued in relation to the wall surface 1a in the opposite orientation compared to the versions a and b respectively.

- the tab surface 4 has a first straight edge 5, it extends perpendicular to the flow direction A and at an angle of about 12 degrees to the wall surface 1 a.

- the tab surface 4 is connected via a curved extending side wall 7 with the wall surface 1a of the rib.

- the side wall 7 of the lashing 3 is approximately perpendicular to the wall surface 1a of the rib 1. According to the inclination of the tab surface 4 in the flow direction A, the height of the side wall 7 in the flow direction A increases.

- a front edge 7a of maximum height of the side wall 7 is formed, which lies together with the first edge 5 and the second edge 6 in a plane perpendicular to the wall surface 1a, wherein the three edges 5, 6 and 7a a triangular, perpendicular to the Form wall surface 1a standing opening or opening 9.

- the triangle 9 has two long sides, formed by the edges 5 and 6, which enclose an acute angle W1 of 12 degrees (see Fig. 2 ) and an acute angle opposite short side, which is formed by the front edge 7a of the side wall 7.

- the tab surface 7 merges into the wall surface 1a in a third edge 8 which is approximately parallel to the direction of flow, wherein the third edge forms a kink, via which the tab surface 4 is angled relative to the wall surface 1a.

- the curved side wall 7 has at its beginning, as viewed in the flow direction A according to Fig. 1a , First, a smallest distance from the third edge 8, in the present example, approximately a distance of zero, wherein the distance over the length L of the tab surface grows monotonically. Both at the beginning of their course as well as at the end of the sidewall is almost parallel to the third edge. 8

- the length L of the tab surface 4 is approximately eight times the maximum height of the side wall. 7

- the side wall 7 changes its direction of curvature on approximately half of its course, so that the curvature has exactly one turning point.

- a parameterization of the course of the side walls of the preferred embodiment is: [0; 2,500], [0.805; 2,470], [1.610; 2,290], [2,420; 1,910], [3,220; 1.540], [4.030; 1,210], [4,840; 0.980], [5.640; 0.780], [6.440; 0.590], [7.240; 0.400], [8.050; 0.210].

- the first digit of a coordinate pair [x; y] the distance in the direction of the third edge 8, starting from the first edge 5, ie opposite to the flow direction A.

- the second digit y describes at this point the vertical distance of the side wall 7 of the third edge 8.

- Side wall 7 has a maximum height of about 1.0 and the maximum width B of the tab surface 4, which runs along the first straight edge, corresponding to 2.5.

- any sequence of orientation of the louvers 3 in a rib according to the invention is possible.

- the production of the rib takes place in the present embodiment of a thin aluminum sheet, in which first the leaching by material deformation such as deep drawing are introduced and the following is bent to the rib shown.

- the rib is formed objectively as in the preceding embodiments and is produced by means of a longitudinal rolling process.

- a quasi-endless sheet-metal strip of aluminum of a thickness of about 0.1 mm to about 0.15 mm (depending on the requirements and thicker or thinner sheets can be used) fed in a feed direction and over several in the feed direction successively following stations reshaped the rib.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Geometry (AREA)

- Heat-Exchange Devices With Radiators And Conduit Assemblies (AREA)

Claims (11)

- Ailette pour un échangeur de chaleur, comprenant un corps d'ailette (1) s'étendant dans une direction d'écoulement (A) d'un premier fluide et ayant une surface de paroi (1a) baignée des deux côtés par le premier fluide,

où il est prévu, dans la surface de paroi (1a), au moins une languette saillante (3) à travers laquelle est formée une ouverture (9) de la surface de paroi (1a) pouvant être traversée par le premier fluide,

où une première arête (5) de la languette saillante (3) est disposée, pour la formation de l'ouverture (9), en étant à distance de la surface de paroi (1a),

où la languette saillante (3) présente une surface de languette (4) inclinée par rapport à la surface de paroi (1a), laquelle surface de languette se termine par la première arête (5),

caractérisée en ce que

la surface de languette (4) est reliée à la surface de paroi (1a) par au moins une paroi latérale (7) de la languette saillante (3), paroi latérale qui s'étend de façon incurvée et qui, en partant de la première arête (5), présente une hauteur diminuant de façon correspondant à l'inclinaison de la surface de languette (4), où la première arête (5), au moins une arête d'extrémité (7a) de la paroi latérale (7) au moins au nombre de un, et une deuxième arête (6) de la surface de paroi (1a), forment une ouverture (9) orientée en étant sensiblement perpendiculaire a la direction d'écoulement (A) et pouvant être traversée par le premier fluide, et ou l'ouverture (9) a une forme sensiblement triangulaire, où la surface de languette (4) est reliée à la surface de paroi (1a) par une troisième arête (8), la surface de languette (4) est coudée par la troisième arête (8), par rapport a la surface de paroi (1a), et une largeur de la surface de languette (4) se réduit avec une distance qui augmente par rapport à la première arête (5). - Ailette selon la revendication 1, caractérisée en ce que l'angle formé est compris entre huit degrés environ et seize degrés environ, étant en particulier de douze degrés environ.

- Ailette selon l'une des revendications 1 ou 2, caractérisée en ce que la longueur (L) de la troisième arête (8) est comprise entre à peu près le double et à peu près le quadruple, étant en particulier à peu près égale au triple d'une longueur de la première arête (5).

- Ailette selon l'une quelconque des revendications 1 à 3, caractérisée en ce que la forme de la surface de languette (4) présente, en partant de la première arête (5), sensiblement le paramétrage [0 ; 2,500], [0,805 ; 2,470], [1,610 ; 2,2901, [2,420 ; 1,910], [3,220 ; 1,540], [4,030 ; 1,210], [4,840 ; 0,980], [5,640 ; 0,780], [6,440 ; 0,590], [7,240 ; 0,400], [8,050 ; 0,210], où la première valeur indique a chaque fois la distance par rapport à la première arête (5) dans la direction d'écoulement (A), la seconde valeur indiquant à chaque fois la distance de la paroi Latérale (7) par rapport à la troisième arête (8).

- Ailette selon l'une quelconque des revendications précédentes, caractérisée en ce que la courbure de la paroi latérale (7) au moins au nombre de un présente, dans son profil, au moins un point d'inflexion par rapport à la direction de courbure.

- Ailette selon l'une quelconque des revendications précédentes, caractérisée en ce que l'inclinaison de la surface de languette par rapport à la surface de paroi (1a) est, dans la direction d'écoulement (A), comprise entre cinq degrés environ et dix degrés environ, étant en particulier de sept degrés environ.

- Ailette selon l'une quelconque des revendications précédentes, caractérisée en ce que l'ailette (1) présente, dans la direction d'écoulement, plusieurs languettes saillantes (3) qui se suivent.

- Ailette selon la revendication 7, caractérisée en ce qu'au moins l'une parmi la pluralité de languettes saillantes (3) est disposée suivant une orientation inversée, où en particulier un effet d'ensemble des languettes saillantes (3), sur le flux de fluide, est dans une large mesure indépendant de la direction dudit flux de fluide.

- Ailette selon au moins l'une quelconque des revendications précédentes, comprenant un corps d'ailette (1) s'étendant dans une direction d'écoulement (A) d'un premier fluide et ayant une surface de paroi (1a) baignée des deux côtés par le premier fluide,

ou il est prévu, dans la surface de paroi (1a), au moins une structure (3) par laquelle peut être influencé un écoulement du premier fluide,

où le corps d'ailette s'étend dans un plan, caractérisée en ce que La surface de paroi (1a) est inclinée par rapport a une perpendiculaire du plan, suivant un angle (W3) qui est compris entre 2° environ et 45° environ. - Echangeur de chaleur comprenant au moins une ailette selon l'une quelconque des revendications 1 à 9.

- Echangeur de chaleur selon la revendication 10, caractérisé en ce que l'échangeur de chaleur est un échangeur de chaleur pour un véhicule automobile, en particulier un échangeur de chaleur faisant partie du groupe comprenant un radiateur à liquide de refroidissement, un échangeur de chaleur de climatisation ou un refroidisseur d'air de suralimentation.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102007048307 | 2007-10-08 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2096397A2 EP2096397A2 (fr) | 2009-09-02 |

| EP2096397A3 EP2096397A3 (fr) | 2013-07-17 |

| EP2096397B1 true EP2096397B1 (fr) | 2015-01-21 |

Family

ID=40522281

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08017257.0A Ceased EP2096397B1 (fr) | 2007-10-08 | 2008-10-01 | Ailette pour un échangeur thermique |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US8267161B2 (fr) |

| EP (1) | EP2096397B1 (fr) |

| DE (1) | DE102008049851A1 (fr) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102007036308A1 (de) * | 2007-07-31 | 2009-02-05 | Behr Gmbh & Co. Kg | Rippe für einen Wärmetauscher |

| DE102009005038A1 (de) * | 2009-01-17 | 2010-07-22 | Mahle International Gmbh | Turbulenzblech |

| JP5884055B2 (ja) * | 2014-05-09 | 2016-03-15 | パナソニックIpマネジメント株式会社 | 熱交換器および熱交換器用オフセットフィン |

| DE102014222983A1 (de) | 2014-11-11 | 2016-05-12 | Mahle International Gmbh | Wellrippe für einen Wärmeübertrager |

| JP2015180852A (ja) * | 2015-07-24 | 2015-10-15 | 株式会社小松製作所 | コルゲートフィンおよびそれを備える熱交換器 |

| DE102017208324A1 (de) * | 2017-05-17 | 2018-11-22 | Mahle International Gmbh | Wärmeübertrager |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1116621A (en) * | 1963-12-27 | 1968-06-12 | Ass Eng Ltd | Improvements in or relating to heat exchangers |

| US3584682A (en) | 1968-07-29 | 1971-06-15 | Borg Warner | Tubular heat transfer device |

| DD152187A1 (de) | 1980-07-23 | 1981-11-18 | Ernst Roth | Streifenfoermiges rohreinbauelement |

| US4501321A (en) * | 1982-11-10 | 1985-02-26 | Blackstone Corporation | After cooler, charge air cooler and turbulator assemblies and methods of making the same |

| JPS62112997A (ja) * | 1985-11-08 | 1987-05-23 | Matsushita Refrig Co | 熱交換器 |

| DE19511665A1 (de) | 1995-03-30 | 1996-10-02 | Abb Management Ag | Verfahren und Vorrichtung zur Luftkühlung von Hubkolben-Verbrennungskraftmaschinen |

| US5669438A (en) * | 1996-08-30 | 1997-09-23 | General Motors Corporation | Corrugated cooling fin with louvers |

| US6170565B1 (en) * | 1996-12-04 | 2001-01-09 | Zexel Corporation | Heat exchanger |

| JP2002277180A (ja) * | 2001-03-16 | 2002-09-25 | Calsonic Kansei Corp | 一体型熱交換器のコア部構造 |

| JP2006078035A (ja) * | 2004-09-08 | 2006-03-23 | Denso Corp | 熱交換装置 |

| DE102007036308A1 (de) * | 2007-07-31 | 2009-02-05 | Behr Gmbh & Co. Kg | Rippe für einen Wärmetauscher |

-

2008

- 2008-10-01 EP EP08017257.0A patent/EP2096397B1/fr not_active Ceased

- 2008-10-01 DE DE102008049851A patent/DE102008049851A1/de not_active Withdrawn

- 2008-10-08 US US12/247,822 patent/US8267161B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| EP2096397A3 (fr) | 2013-07-17 |

| US8267161B2 (en) | 2012-09-18 |

| DE102008049851A1 (de) | 2009-07-02 |

| US20090090497A1 (en) | 2009-04-09 |

| EP2096397A2 (fr) | 2009-09-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE10127084B4 (de) | Wärmeübertrager, insbesondere für Kraftfahrzeuge | |

| EP3359902B1 (fr) | Procédé de fabrication d'une lamelle et un échangeur de chaleur à plaque avec une lamelle fabriquée à l'aide d'un tel procédé | |

| DE69911131T2 (de) | Wärmetauscher | |

| EP2096397B1 (fr) | Ailette pour un échangeur thermique | |

| EP1701125A2 (fr) | Echangeur de chaleur à tubes plats et tube plat pour échangeur de chaleur | |

| EP2242979A1 (fr) | Tube filé pour échangeur de chaleur | |

| EP1657512B1 (fr) | Echangeur de chaleur avec un profilé ouvert en tant que boîtier | |

| DE10054158A1 (de) | Mehrkammerrohr mit kreisförmigen Strömungskanälen | |

| DE10100241A1 (de) | Wärmetauscherrohr für flüssige oder gasförmige Medien | |

| EP1640684A1 (fr) | echangeur de chaleur à tubes plats et ailettes ondulées | |

| EP2185884B1 (fr) | Ailette pour un échangeur de chaleur | |

| EP2394126B1 (fr) | Corps chauffant pour véhicules automobiles | |

| EP1706698A1 (fr) | Echangeur de chaleur | |

| EP1711771B1 (fr) | Echangeur de chaleur | |

| EP2678629B1 (fr) | Échangeur de chaleur | |

| DE102008015064A1 (de) | Turbulenzeinsatz und Verfahren zu dessen Herstellung | |

| DE102008020230A1 (de) | Wärmetauscher sowie Wärmetauscherrohr | |

| EP1934545A1 (fr) | Corps chauffant, circuit de refrigerant, appareil de climatisation pour une installation de climatisation de vehicule automobile, et installation de climatisation pour un vehicule automobile | |

| EP2062002B1 (fr) | Noyau d' échangeur thermique, procédé de fabrication, ligne de profilage à galets | |

| EP1632742B1 (fr) | Echangeur de chaleur, en particulier pour installation de climatisation | |

| EP0268831B1 (fr) | Lamelle | |

| DE102012216146A1 (de) | Wärmeübertragungseinrichtung, Wärmeübertrager sowie Verfahren zur Übertragung von Wärme von einem ersten Fluid auf ein zweites Fluid | |

| EP1398592B1 (fr) | Echangeur de chaleur à tubes plats | |

| EP3184949A2 (fr) | Élément de tôle comprenant une structure nervurée présentant une grille d'un caloporteur et procédé de fabrication | |

| DE102010043309A1 (de) | Verfahren zum Anbringen von Winglets an einem Grundmaterial und Wingletrohr |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| RTI1 | Title (correction) |

Free format text: FIN FOR A HEAT EXCHANGER AND MANUFACTURING METHOD |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F28F 3/02 20060101ALI20130607BHEP Ipc: B21D 53/02 20060101ALI20130607BHEP Ipc: F28F 1/12 20060101AFI20130607BHEP |

|

| 17P | Request for examination filed |

Effective date: 20140117 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AKX | Designation fees paid |

Designated state(s): DE FR |

|

| 17Q | First examination report despatched |

Effective date: 20140307 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20140624 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20141113 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502008012628 Country of ref document: DE Effective date: 20150305 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: MAHLE BEHR GMBH & CO. KG |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502008012628 Country of ref document: DE Representative=s name: GRAUEL, ANDREAS, DIPL.-PHYS. DR. RER. NAT., DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502008012628 Country of ref document: DE Owner name: MAHLE BEHR GMBH & CO. KG, DE Free format text: FORMER OWNER: BEHR GMBH & CO. KG, 70469 STUTTGART, DE Effective date: 20150423 Ref country code: DE Ref legal event code: R082 Ref document number: 502008012628 Country of ref document: DE Representative=s name: GRAUEL, ANDREAS, DIPL.-PHYS. DR. RER. NAT., DE Effective date: 20150423 Ref country code: DE Ref legal event code: R081 Ref document number: 502008012628 Country of ref document: DE Owner name: MAHLE INTERNATIONAL GMBH, DE Free format text: FORMER OWNER: BEHR GMBH & CO. KG, 70469 STUTTGART, DE Effective date: 20150423 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502008012628 Country of ref document: DE Representative=s name: GRAUEL, ANDREAS, DIPL.-PHYS. DR. RER. NAT., DE Ref country code: DE Ref legal event code: R081 Ref document number: 502008012628 Country of ref document: DE Owner name: MAHLE INTERNATIONAL GMBH, DE Free format text: FORMER OWNER: MAHLE BEHR GMBH & CO. KG, 70469 STUTTGART, DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 Ref country code: DE Ref legal event code: R097 Ref document number: 502008012628 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20151022 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20181030 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20181026 Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502008012628 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191031 |