EP2069166B1 - Kraftfahrzeug mit einem boden mit langschwelle und verfahren zur herstellung des entsprechenden bodens - Google Patents

Kraftfahrzeug mit einem boden mit langschwelle und verfahren zur herstellung des entsprechenden bodens Download PDFInfo

- Publication number

- EP2069166B1 EP2069166B1 EP07858529A EP07858529A EP2069166B1 EP 2069166 B1 EP2069166 B1 EP 2069166B1 EP 07858529 A EP07858529 A EP 07858529A EP 07858529 A EP07858529 A EP 07858529A EP 2069166 B1 EP2069166 B1 EP 2069166B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- floor

- longitudinal member

- rib

- length

- spar

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B62—LAND VEHICLES FOR TRAVELLING OTHERWISE THAN ON RAILS

- B62D—MOTOR VEHICLES; TRAILERS

- B62D25/00—Superstructure or monocoque structure sub-units; Parts or details thereof not otherwise provided for

- B62D25/20—Floors or bottom sub-units

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B62—LAND VEHICLES FOR TRAVELLING OTHERWISE THAN ON RAILS

- B62D—MOTOR VEHICLES; TRAILERS

- B62D25/00—Superstructure or monocoque structure sub-units; Parts or details thereof not otherwise provided for

- B62D25/20—Floors or bottom sub-units

- B62D25/2009—Floors or bottom sub-units in connection with other superstructure subunits

- B62D25/2036—Floors or bottom sub-units in connection with other superstructure subunits the subunits being side panels, sills or pillars

Definitions

- the invention also relates to a method of manufacturing a corresponding floor.

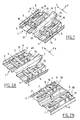

- Motor vehicles comprise a floor, part of which is known in the art. figure 1 .

- the known floor 1 has an upper face 11, a lower face 12 and a series of ribs 2.

- the upper face 11 designates the face facing the side of the passenger compartment of the vehicle

- the lower face 12 designates the face facing the support on which the vehicle rolls.

- each rib 2 is a part of the floor 1 projecting from an average plane of the floor 1.

- each rib 2 is a fold formed in the thin sheet metal plate of the floor 1. The fold can be formed towards the upper face 11 or the lower face 12 of the floor 1.

- Each rib 2 extends in a rectilinear direction 15 over at least one length.

- Each rib 2 also has a constant cross section on at least a portion L of said length.

- the vehicle also comprises at least one spar fixed on the lower face 12 of the floor, each spar being generally associated with another spar forming overlong 4.

- a longitudinal axis of the spar and a longitudinal axis of the sill 4 extend substantially parallel to an axis X. of the figure 1 .

- the X axis represents the "front-rear" direction of the vehicle.

- the sill 4 is fixed on the upper face 11 of the floor, at the spar 3, although being fixed on an opposite face of the floor.

- the vehicle also comprises crosspieces 5 whose main axis of extension is perpendicular to the longitudinal axis of the spar and / or to the longitudinal axis of the sill.

- the main axis of the crosspieces 5 extends substantially parallel to a Y axis of the figure 1 .

- Each crosspiece 5 is fixed on the one hand to a longitudinal beam 6, the latter extending parallel to the X axis in the lateral part of the floor 1, and on the other hand to a tunnel 7, the latter extending longitudinally parallel also to the X axis in the central part of floor 1.

- the floor 1 is rigid and allows comfort and safety for passengers of the vehicle.

- the beams 6 form low flap reinforcements.

- the tunnel 7 also strengthens the floor 1 while allowing the passage of the vehicle exhaust line.

- the sleepers 5 transversely reinforce the floor 1 and allow energy absorption during side impacts on the vehicle.

- the sleepers 5 also allow the attachment of seats for passengers of the vehicle.

- the longerons and the sill also have a role of energy absorption during a possible impact on the vehicle.

- the ribs 2 impart increased rigidity to the floor 1 in the rectilinear direction in which they extend. They thus ensure the distribution of forces and resistance to bending during an impact on the vehicle. They also provide good acoustic floor properties, avoiding vibrations corresponding in particular to floor panel modes.

- the ribs 2 In order for the ribs 2 to properly perform their mechanical and acoustic function, they must be recessed at their ends with at least one rigid part fixed to the floor 1.

- each rib 2 comes into abutment at its ends on reinforcing parts 13 parallel to the X axis and / or reinforcement pieces 14 parallel to the Y axis and / or the cross members 5, or even the longitudinal members and / or overlong.

- the position of the longitudinal members and the sill is also defined in particular by the position of the engine block of the vehicle.

- the position of the longerons and overhangs along the X and Y axes is thus defined for a given vehicle model floor.

- the invention proposes to overcome these disadvantages.

- the invention also relates to a method of manufacturing a floor according to the invention.

- the invention has many advantages.

- the invention makes it possible to provide a common floor for several different vehicle models.

- the position of the beams and / or the sill is finalized for each model only when they are fastened to the floor, thanks to the sliding of the spar and / or overlongeron with respect to certain ribs of the floor.

- the solution according to the invention makes it possible to obtain a good embedding of the ribs, the latter thus conferring a good stiffening and good acoustic properties to the floor.

- the Figures 2A and 2B schematically represent a part of a possible embodiment of a floor 1 of a motor vehicle according to the invention.

- the Figure 2A represents a perspective view of an upper face 11 of the floor 1.

- the Figure 2B schematically represents a perspective view of a lower face 12 of the floor 1.

- the vehicle comprises substantially similar elements to those described with reference to the figure 1 . Such similar elements are not repeated here for the sake of clarity and brevity.

- the floor 1 having at least one rib 2 extending in a rectilinear direction 15 over at least one length.

- the rib 2 has a constant cross section on at least a portion L of said length.

- the floor also comprises at least one spar 3 fixed on the lower face 12 of the floor 1.

- the spar 3 is fixed on the floor 1 at said portion L of said length of the rib 2.

- the spar 3 is also suitable, before being fixed on the floor 1, to slide on the rib 2 on said portion L of said length.

- the rib 2 has a constant section in the direction 15 on at least the portion L, the portion L having a length required for a common design of the floor for several different models of vehicles, allowing a sliding on the length of the part L.

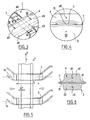

- the spar 3 has a cross section, along a longitudinal axis 35 and a transverse axis 36, complementary to the cross section of the rib 2 along axes parallel respectively to the longitudinal axis 35 and to the transverse axis 36.

- the Figures 2A, 2B and 5 show that the rectilinear direction 15 on which the rib 2 extends in a constant cross section is perpendicular to a longitudinal axis 35 of the spar. In other words, the direction 15 is parallel to the Y direction.

- the spar 3 comprises a main portion 32 and rebates 31 forming a flange on either side of the main portion 32 and integrally on the main portion 32.

- the cross section of the spar 3, along the axes 35 and 36 to be complementary to the cross section of the rib 2 along respective parallel axes, for example forming a sinking in each rabbet 31 of the spar 3 at the rib 2.

- each spar 3 is associated with another spar 4.

- the spar 3 forms a first spar fixed on the lower face 12 of the floor 1, and a second longeron spar 4 is fixed on the upper face 11 of the floor 1 at the first spar 3.

- the sill 4 has the same characteristics as the spar 3.

- the sill 4 is fixed on the floor 1 at the portion L of the rectilinear length of the rib 2.

- the sill 4 is also suitable, before being fixed on the floor 1, to slide on the rib 2 on said portion L of said length.

- the sill 4 has a cross section, along a longitudinal axis 45 and a transverse axis 46, complementary to the cross section of the rib 2 according to axes parallel to the longitudinal axis 45 and to the transverse axis 46, respectively.

- the sill 4 comprise a main portion 42 and rabbets 41 forming a flange on either side of the main portion 42 and integral with the main portion 42.

- the cross section of the sill 4 along the axes 45 and 46 to be complementary to the cross section of the rib 2 according to respective parallel axes, for example forming a trimming in each rabbet 41 of the overlongeron 4 at the rib 2.

- the attachment of the spar 3 and the sill 4 on the floor 1 is made by welding, for example in a few points.

- the main spar is attached to the underside of the floor.

- the vehicle comprises a spar according to the invention on the upper face of the floor, this spar then being very preferably associated with another spar according to the invention on the lower face of the floor.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Transportation (AREA)

- Mechanical Engineering (AREA)

- Body Structure For Vehicles (AREA)

- Passenger Equipment (AREA)

- Soil Working Implements (AREA)

- Fertilizing (AREA)

- Manufacture Of Motors, Generators (AREA)

Claims (10)

- Kraftfahrzeug, umfassend:- einen Fußboden (1), der eine Oberseite (11), eine Unterseite (12) und mindestens eine Rippe (2) aufweist, die sich in einer geradlinigen Richtung (15) über mindestens eine Länge erstreckt und über mindestens einen Teil der Länge einen konstanten Querschnitt aufweist,- mindestens einen Längsträger (3, 4), der an der Unterseite (12) oder Oberseite (11) des Fußbodens (1) befestigt ist,dadurch gekennzeichnet, dass- der Längsträger (3, 4) an dem Teil der Länge der Rippe (2) am Fußboden befestigt ist,- der Längsträger (3, 4) des Weiteren vor seiner Befestigung an dem Fußboden auf der Rippe auf dem Teil der Länge gleiten kann.

- Fahrzeug nach Anspruch 1, wobei der Längsträger (3, 4) einen Querschnitt entlang einer Längsachse (35, 45) und einer Querachse (36, 46) aufweist, der zu dem Querschnitt der Rippe (2) entlang Achsen, die parallel zu der Längsachse bzw. Querachse verlaufen, komplementär ist.

- Fahrzeug nach Anspruch 1 oder 2, wobei der Längsträger (3, 4) mit dem Fußboden (1) verschweißt ist.

- Fahrzeug nach einem der Ansprüche 1 bis 3, wobei die geradlinige Richtung (15), entlang der sich die Rippe (2) erstreckt, an dem Teil der Länge senkrecht zu einer Längsachse (35, 45) des Längsträgers (3, 4) verläuft.

- Fahrzeug nach einem der Ansprüche 1 bis 4, das mindestens zwei Längsträger aufweist,- einen ersten Längsträger (3), der an der Unterseite des Fußbodens (1) befestigt ist,- einen einen Überlängsträger (4) bildenden zweiten Längsträger, welcher an der Oberseite des Fußbodens (1) in Höhe des ersten Längsträgers (3) befestigt ist.

- Fahrzeug nach Anspruch 5, wobei der erste Längsträger (3) und der zweite Längsträger (4) auf der Rippe gleiten können.

- Verfahren zur Herstellung eines Fußbodens (1) eines Kraftfahrzeugs, das einen Schritt des:- Bereitstellens eines Fußbodens (1) umfasst, der eine Oberseite (11), eine Unterseite (12) und mindestens eine Rippe (2) aufweist, die sich in einer geradlinigen Richtung (15) über mindestens eine Länge erstreckt und über mindestens einen Teil der Länge einen konstanten Querschnitt aufweist,dadurch gekennzeichnet, dass es folgende Schritte umfasst:- Schieben mindestens eines Längsträgers (3, 4) auf der Rippe über den Teil der Länge,- Befestigen des Längsträgers (3, 4) auf der Unterseite (12) oder Oberseite (11) des Fußbodens (1),wobei der Längsträger (3, 4) an dem Teil der Länge der Rippe (2) an dem Fußboden befestigt ist.

- Verfahren nach Anspruch 7, wobei das Befestigen durch Schweißen erfolgt.

- Verfahren nach Anspruch 7 oder 8, das einen Schritt des Befestigens zweier Längsträger umfasst, nämlich:- eines ersten Längsträgers (3) auf der Unterseite des Fußbodens (1),- eines einen Überlängsträger bildenden zweiten Längsträgers (4) auf der Oberseite des Fußbodens (1) in Höhe des ersten Längsträgers (3).

- Verfahren nach Anspruch 9, das einen Schritt des Schiebens des ersten Längsträgers (3) und des zweiten Längsträgers (4) auf der Rippe umfasst.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0608791A FR2906783B1 (fr) | 2006-10-06 | 2006-10-06 | Vehicule automobile comportant un plancher avec un longeron, procede de fabrication du plancher associe |

| PCT/FR2007/052098 WO2008040920A1 (fr) | 2006-10-06 | 2007-10-08 | Vehicule automobile comportant un plancher avec un longeron, procede de fabrication du plancher associe |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2069166A1 EP2069166A1 (de) | 2009-06-17 |

| EP2069166B1 true EP2069166B1 (de) | 2010-02-24 |

Family

ID=37875769

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07858529A Not-in-force EP2069166B1 (de) | 2006-10-06 | 2007-10-08 | Kraftfahrzeug mit einem boden mit langschwelle und verfahren zur herstellung des entsprechenden bodens |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP2069166B1 (de) |

| AT (1) | ATE458646T1 (de) |

| DE (1) | DE602007005010D1 (de) |

| FR (1) | FR2906783B1 (de) |

| WO (1) | WO2008040920A1 (de) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6522982B2 (ja) * | 2015-02-18 | 2019-05-29 | 本田技研工業株式会社 | 車体構造 |

| FR3075746B1 (fr) * | 2017-12-22 | 2020-08-14 | Plastic Omnium Cie | Structure de plancher mono-piece en matiere composite |

| FR3096333B1 (fr) * | 2019-05-22 | 2022-07-15 | Psa Automobiles Sa | Plancher avant, traverse de fixation pour siège avant et véhicule comprenant de tels éléments |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7416234B2 (en) * | 2002-02-08 | 2008-08-26 | Bequette Lawrence M | Vehicle sliding floor extension |

-

2006

- 2006-10-06 FR FR0608791A patent/FR2906783B1/fr not_active Expired - Fee Related

-

2007

- 2007-10-08 DE DE602007005010T patent/DE602007005010D1/de active Active

- 2007-10-08 EP EP07858529A patent/EP2069166B1/de not_active Not-in-force

- 2007-10-08 AT AT07858529T patent/ATE458646T1/de not_active IP Right Cessation

- 2007-10-08 WO PCT/FR2007/052098 patent/WO2008040920A1/fr not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| WO2008040920A1 (fr) | 2008-04-10 |

| WO2008040920A9 (fr) | 2008-06-05 |

| ATE458646T1 (de) | 2010-03-15 |

| FR2906783B1 (fr) | 2008-12-26 |

| EP2069166A1 (de) | 2009-06-17 |

| DE602007005010D1 (de) | 2010-04-08 |

| FR2906783A1 (fr) | 2008-04-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2008132366A1 (fr) | Soubassement de vehicule automobile | |

| EP1434710B1 (de) | Kraftfahrzeugfahrgestell | |

| EP2069166B1 (de) | Kraftfahrzeug mit einem boden mit langschwelle und verfahren zur herstellung des entsprechenden bodens | |

| EP1868871B1 (de) | Verstärkungsstruktur für ein kraftfahrzeug zur begrenzung von vibrationen des armaturenbretts und entsprechendes kraftfahrzeug | |

| WO2016055703A1 (fr) | Planche a talon avec insert structurant | |

| FR3022520A1 (fr) | Plancher de vehicule automobile avec podium de renfort composite | |

| EP3787957B1 (de) | Spriegel mit heckversteifung | |

| FR2653087A1 (fr) | Structure interne d'un poste de conduite. | |

| EP1819543B1 (de) | Türplattenversteifer | |

| FR3037011A1 (fr) | Dispositif d’anti sous marinage pour vehicule automobile | |

| EP3386845B1 (de) | Kraftfahrzeugkarosserieelement und zugehöriges verfahren zur herstellung | |

| FR2983816A1 (fr) | Caisse de vehicule munie d'un renfort de doublure d'aile en y. | |

| FR2911303A1 (fr) | Amenagement d'un compartiment moteur | |

| FR3111615A1 (fr) | Renfort de liaison entre un pied avant de véhicule automobile et une ligne de brancard dudit véhicule automobile | |

| EP3505425B1 (de) | Lokale behandlung auf einschichtboden der eingänge und verteilung der belastung bei seitlichem aufprall | |

| EP3781461B1 (de) | Kraftfahrzeugkarosseriestruktur mit rücksitzgestellquerträgerverstärkung | |

| EP1759962B1 (de) | Aufbau einer Rohbaukarosserie für ein Kraftfahrzeug und hinterer Bodenplatte | |

| FR3013304A1 (fr) | Structure d'un vehicule automobile | |

| WO2024200940A1 (fr) | Structure de renfort pour véhicule automobile | |

| FR3139783A1 (fr) | extension de longeronnet arrière pour véhicule automobile | |

| EP3823881B1 (de) | Seitenschienenwände zur biegebelastung bei einem seitenaufprall | |

| WO2025215306A1 (fr) | Arrangement de plancher pour véhicule automobile | |

| FR3160378A1 (fr) | ensemble de plancher pour véhicule automobile | |

| WO2015082793A1 (fr) | Véhicule automobile comprenant un châssis délimité par des flancs latéraux horizontaux et verticaux et un bavolet associé | |

| FR2910427A1 (fr) | Chassis de vehicule automobile integrant une coupelle d'amortisseur |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20090401 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REF | Corresponds to: |

Ref document number: 602007005010 Country of ref document: DE Date of ref document: 20100408 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20100224 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20100224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100625 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100624 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100604 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100525 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100524 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 |

|

| 26N | No opposition filed |

Effective date: 20101125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 |

|

| BERE | Be: lapsed |

Owner name: RENAULT SAS Effective date: 20101031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111031 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100825 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101008 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100224 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20211020 Year of fee payment: 15 Ref country code: GB Payment date: 20211022 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20211021 Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602007005010 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20221008 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221031 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230503 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221008 |