EP2028126B1 - Carrier with handle - Google Patents

Carrier with handle Download PDFInfo

- Publication number

- EP2028126B1 EP2028126B1 EP20080013311 EP08013311A EP2028126B1 EP 2028126 B1 EP2028126 B1 EP 2028126B1 EP 20080013311 EP20080013311 EP 20080013311 EP 08013311 A EP08013311 A EP 08013311A EP 2028126 B1 EP2028126 B1 EP 2028126B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- handle

- carrying handle

- containers

- carrying

- elements

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 238000004806 packaging method and process Methods 0.000 claims description 17

- 239000011049 pearl Substances 0.000 claims description 2

- 230000002787 reinforcement Effects 0.000 claims 3

- 210000003739 neck Anatomy 0.000 description 25

- 239000000463 material Substances 0.000 description 12

- 230000003014 reinforcing effect Effects 0.000 description 10

- 210000003811 finger Anatomy 0.000 description 8

- 239000004033 plastic Substances 0.000 description 7

- 229920003023 plastic Polymers 0.000 description 7

- 235000013361 beverage Nutrition 0.000 description 6

- 238000005452 bending Methods 0.000 description 4

- 210000003813 thumb Anatomy 0.000 description 4

- 229920001903 high density polyethylene Polymers 0.000 description 3

- 239000004700 high-density polyethylene Substances 0.000 description 3

- 230000006978 adaptation Effects 0.000 description 2

- 239000000969 carrier Substances 0.000 description 2

- 239000013013 elastic material Substances 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- WYTGDNHDOZPMIW-RCBQFDQVSA-N alstonine Natural products C1=CC2=C3C=CC=CC3=NC2=C2N1C[C@H]1[C@H](C)OC=C(C(=O)OC)[C@H]1C2 WYTGDNHDOZPMIW-RCBQFDQVSA-N 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 239000011324 bead Substances 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 210000000078 claw Anatomy 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 210000005224 forefinger Anatomy 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 230000013011 mating Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 239000002985 plastic film Substances 0.000 description 1

- 239000012858 resilient material Substances 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 229920006300 shrink film Polymers 0.000 description 1

- 239000003381 stabilizer Substances 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D71/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material

- B65D71/50—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material comprising a plurality of articles held together only partially by packaging elements formed otherwise than by folding a blank

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2203/00—Decoration means, markings, information elements, contents indicators

- B65D2203/06—Arrangements on packages concerning bar-codes

Definitions

- the invention relates to a carrying handle for a plurality of containers with a handle member and receiving elements for receiving the container, wherein the handle member extends between the receiving elements and is arranged parallel to the plane of the carrying handle telescopically liftable over at least two places on the carrying handle, and a packaging unit of a Carrying handle and at least two containers.

- a container package for holding and carrying a plurality of containers, bottles, and the like, and a method for assembling the same, and a package for a group of containers each having a neck portion.

- the juxtaposed containers each have a body portion and a neck portion projecting upwardly and inwardly therefrom, which is smaller than the body portion, the containers being arranged side by side in parallel with each other in a grape-shaped group.

- an elastic support is slid with a plurality of for accommodating the neck portion of a respective container serving constricting recesses whose mutual center distances are smaller as the center distances between corresponding abutting containers, whereby the foot portions of the containers are applied to the outside with respect to the container group.

- an elastic endless belt is guided around, through which the foot portion of the Container resiliently acted upon in a laterally abutting position. The carrier and the endless belt are under a sufficiently high tension to hold the containers in the package.

- a bottle carrier for collectively detecting at least two bottles, which are in particular beverage bottles known.

- the bottleneck are provided below its bead partially embracing approaches.

- the bottle carrier is made of a resilient material, such as plastic.

- the DE 25 31 325 A1 discloses a container package having a plurality of containers disposed substantially adjacent to one another and divided into a plurality of groups, each comprising at least two containers.

- An upper support member includes and secures first end portions of each container, whereas a second sheet or foil support portion has interconnected portions.

- the container package includes and holds each container group.

- the interconnected parts of the second sheet or foil support member include band portions comprising two containers without extending between the two containers.

- the upper support member has two openings for engagement with the thumb and a finger to allow the container packaging to be carried.

- the carrier itself comprises a structural frame carrying a plurality of collars, each of which can receive the neck of a container and engage with the projection located on the periphery of the container. Further, each collar has a resilient edge depending therefrom which cooperates with a portion of the outer surface of the respective container to prevent relative movement between the container and the carrier.

- the collars have a plurality of spaced apart resilient tabs or tabs which engage the projections of the containers. For wear, the wearer has two openings in which can be grasped with thumb and a finger to carry the container packaging or the carrier.

- an elongated support body which has a support bracket above the support body and on its underside at least two hanging rail-like receptacles for receiving a plurality of bottles in a row.

- individual receptacles arranged at a distance in the longitudinal direction can also be provided for accommodating only one bottle at a time.

- the recordings are closed at one end or provided with a stop stop and at the other end for the bottle supply educated.

- a holding member for securing the respective bottle necks is also provided in the receptacle.

- a container carrier which has a flexible platform.

- This includes a container engaging portion having an opening through the platform for receiving the neck of a container, a handle portion having a base extending transversely to a longitudinal axis of the platform, a pair of handle legs, the proximal ends of the handle legs integrally formed with the ends of the base member are.

- the distal ends of the handle leg are integral with the container engaging portion at opposite points on the container engaging portion and having a flange integral with the base member and extending inwardly from the base member over substantially the length of the base member.

- the inner periphery of the The container engaging portion and the handle portion provide an opening to allow the fingers of a user to engage.

- the flange has transverse fold lines formed in the surface of the platform. In this way, a bending of the handle portion to its gripping is possible.

- the DE 20 2005 005 970 U1 discloses a bottle feeder for PET returnable bottles, which consists of the same material as the returnable bottles themselves and has six punched holes for receiving the bottle necks or bottle heads.

- Thestationnbündler is U-shaped from a strong plastic sheet.

- the DE 20 2005 014 112 U1 discloses a carrying handle having a substantially plate-shaped support member, at the lateral peripheral edge of which a plurality of snap-in devices for snapping and holding objects are provided spaced therefrom. These snap-in devices are designed like a claw. Furthermore, the carrying handle has a rigid, upwardly projecting handle, which is formed integrally with the carrier element. As a common stabilizing agent, a band is provided in the lower region of the recorded objects.

- the US 2004/0256250 A1 further discloses a bottle carrier in which annular receiving elements are provided for receiving bottle necks. The bottle necks are held therein over resilient tab-like elements. A U-shaped handle is also attached at two locations on webs between the individual receiving elements for the bottle necks via a hinged hinge.

- a similar structure only for receiving a container discloses the US 6,394,517 B1 , This is the handle, however attached laterally to the receiving element for receiving the Falschenhalses and spent by bending in a vertical carrying position.

- the EP 1 710 171 A1 discloses a corresponding carrier for a plurality of bottles, in which, in contrast to the two abovementioned but still protruding tabs are arranged end to the carrier, which are to serve for facilitating the application and removal of rings on and from bottle necks.

- protruding elements are also in the US 5,306,060 disclosed, wherein in these straps another handle is provided for engaging. For carrying is attacked only at a bridge between two receiving elements for receiving bottlenecks.

- a modification to the structure mentioned in this document is in the US 5,735,562 disclosed. Here, three or four receiving elements are connected by webs crosswise.

- US 6,715,810 B2 is disclosed a corresponding structure with again outer side tabs according to the above prior art.

- a carrier for carrying two tube-like containers is in the US 2006/0254934 A1 disclosed.

- retaining lugs are externally formed on receiving rings, which hold on the lid of the container.

- the US 6,129,397 discloses a six-fold carrier having six receiving elements with inwardly projecting retaining tabs for receiving the bottle necks and between the individual receiving elements connecting webs. For carrying is attacked at the connecting webs or in particular at the central connecting web by engaging in two correspondingly provided openings.

- An alternative variant to this is in the US 2007/0039836 A1 disclosed.

- two handle tabs are arranged in the inner openings of the carrier, which can be grasped by the thumb and a finger of one hand. The two grip tabs are bent out of the plane of the carrier when grasped.

- the US 3,084,792 A discloses a container carrier which is punched out of a flat elastic material.

- two opposing rows are formed with holes for receiving bottlenecks or upper ends of the container.

- An elastic band for holding the containers is formed integrally with the carrier.

- the connection to the rest of the carrier is formed via predetermined breaking points, wherein after the attachment of the carrier on the upper sides of the container or bottle necks, the tape is pushed down to hold the container in the lower area together.

- two openings are formed, which can be engaged with the fingers.

- a central tear strip may be formed between the container receptacles, which is provided with a bow-shaped handle for supporting the carrier.

- the WO 02/40357 A2 discloses a handle assembly for holding together a large-sized fluid container pair.

- the two containers are surrounded by a flexible band, which is tightened tightly.

- a retaining wire is attached to the respective container handles.

- the wire serves as a handle and is shaped in a special way to hold on to the container handles.

- an additional handle member is disclosed, which formed in accordance with Loops of the wire is hung. A carrying the container is then possible on this handle element.

- the present invention is therefore based on the object to further develop a carrying handle according to the preamble of claim 1 that a very good stackability of several handles above each other is possible and at the same time a comfortable grip on the handle for carrying a plurality of containers, especially bottles, being straight at Carrying several bottles a compact well-to-carry packaging unit should be created.

- the object is achieved in a carrying handle according to the preamble of claim 1 with the characterizing features.

- a carrying handle for one or more containers is provided with at least one gripping element and at least one receiving element for receiving the at least one container, wherein the gripping element is in the unused state of the carrying handle in the plane thereof and only for the use of the carrying handle, so the Attaching to the container, the handle element is pulled out of the plane of the carrying handle, wherein it is in contrast to the prior art

- the handle element thereby does not form U-shaped over the plane of the handle, but by telescoping or "Entwringen” a central portion of the handle element remains substantially straight and thus can be better attacked by the person wearing a U-shaped handle forming element which usually cuts into the forefinger and small finger of the hand of the wearer and thereby leads to a poor wearing comfort.

- the gripping element can be telescoped out of the plane of the carrying handle so far that the distance between the gripping element and the uppermost extent of at least one container received in the carrying handle permits the insertion of a hand of a carrying person.

- the carrying person can conveniently reach over the uppermost extent of the container received in the carrying handle under the gripping element and carry the packaging unit.

- the lying in the plane of the handle for the handle element proves to be very beneficial, especially with respect to the handles of the prior art, in which the gripping elements project rigidly over the plane of the carrying handle.

- the space required for such a grip element of the prior art is therefore much larger than in the invention, which does not lead to a larger footprint for the carrying handle. This proves to be extremely advantageous not only in pick and place machines, but of course also in warehousing.

- the grip element advantageously has at least one slightly curved section for centering when stacking a plurality of carrying handles on each other.

- Another stacking aid for facilitating centering of the carrying handles on each other can be provided that the receiving elements for receiving the container, that is, of the head portions, not completely flat, but have a slight inclination.

- the at least one receiving element for receiving the at least one container is advantageously formed like a collar with inwardly projecting retaining tabs or retaining lugs.

- both the inwardly projecting retaining tabs or retaining lugs may have a slight inclination and the circumferential collar of the receiving elements, whereby a self-centering can be achieved in this area of stacked carrying handles.

- multipacks can be produced, for example, four or six grouped containers, especially bottles or cans.

- the respective torsion points on the handle elements serve as Aufricht Anlagen.

- At least one ring element for surrounding the outside of the container is detachably attached to the carrying handle.

- This ring element surrounds the receiving elements and arranged between them stiffening or connecting webs, that is arranged on the outside of this.

- the ring element is provided, so to speak, as an outer boundary of the carrying handle and can be separated from this.

- it is advantageously releasably connected by web elements with the at least one receiving element and / or the stiffening webs.

- a predetermined breaking point between the ring element and web elements is provided or between the web elements and the at least one receiving element and / or the stiffening webs.

- the ring element By breaking the predetermined breaking points, the ring element can be separated from the rest of the carrying handle and pushed down along the containers on the outside so far that they experience a good external grip against breaking out of the container structure to the outside.

- the ring member is thus provided instead of bands or shrink film for holding the containers together. Since it is molded with the molding of the handle on this, no additional material for the ring member is required. Rather, in a simple manner by means of a device for applying the carrying handles to containers, in particular a placement machine, via a device for engaging the ring member of the carrying handle a downshift of this carried along the containers.

- the carrying handle is thus placed on a group of containers, which are advantageously already positioned accordingly to fit with their container heads or necks into the receiving elements, so that the container heads protrude through the receiving elements.

- attaching the carrying handle to the container engages the means for engaging the ring member this and tearing it from further down the rest of the handle from, breaking the predetermined breaking points.

- breaking the predetermined breaking points As it moves onward, it pushes the ring element down so far along the containers that either a predefinable contact point is reached on the containers or a predefined position is assumed by the ring element.

- the ring member such a material that a stretching or spreading of the ring member when pushed down along the container walls after reaching the end position for the ring element, ie immediately eliminates the expansion force when the elastic force disappears, the ring element sets directly to the outer surfaces of this surrounded container.

- at least one closure device for fastening to the containers is advantageously provided on the ring element.

- the closure device can be detected by a device for closing the device for applying the carrying handles and can be closed after the ring element has been pushed down along the containers. This closing may be accomplished by a juxtaposed movement of parts of the means for closing the closure means.

- the means for closing the closure means may comprise sliding elements which engage two ends of the closure means and close them by movement towards each other. Instead of sliding elements, other means can be provided which allow a closure of the respective closure device.

- the closure device may comprise at least one barbed element and at least one mating element cooperating therewith.

- the barbed element is pressed against the counter-element cooperating therewith, so that both elements interlock with one another and lead to closure of the closure device and thus closure of the ring element.

- the closure device may advantageously comprise a latching device, in particular a housing part provided with shoulders and a closure part which can be inserted therein and is provided with at least one outside projection.

- the closure part provided with the at least one outer-side projection is used to close the ring element in the Housing part inserted and locked behind the heels of the housing part.

- Another possibility, which can also be combined with the other variants, is to provide a closure device in the manner of a string of pearls with elements lined up in a row, in particular conical elements.

- conical elements for example, attack each other so that they hooked like barbs together and thereby allow a closure.

- the ring element for generating a support surface for engaging when pushed down along the container walls on an upper support surface is V-shaped.

- a support surface on the ring member in the region in which the means for pushing down attacks, for this a better application of force to the ring member for separating the remaining handle is possible.

- the ring element can for example also be formed in cross-section T-shaped, in turn, an upper Support surface can be created with as little additional material consumption.

- the outside stiffening webs may be formed in particular as secants between the individual receiving elements. As a result, further material savings is possible. Further, for the device acting on the ring element of the device for applying the carrying handles to the container, it becomes more easily possible to grip between the ring element and corresponding openings in the carrying handle in the region of the stiffening webs, when these are arranged approximately parallel to one another.

- the carrying handle is advantageously designed as an injection molded part.

- it consists of a recyclable plastic, including HDPE, ie a high density polyethylene produced under low pressure.

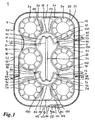

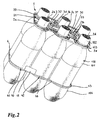

- FIG. 1 shows a plan view of a first embodiment of a handle 1 for six bottles 100, which in FIG. 2 are shown.

- the carrying handle 1 has six receiving elements 2a to 2f for receiving the bottle heads 102. Furthermore, the carrying handle has a gripping element 3, which extends between the receiving elements 2a to 2f. On the outside, the receiving elements are surrounded by a ring element 4. Between the individual receiving elements 2a to 2f 4 stiffening webs 5, 6, 7, 8, 9, 10 are provided with an edge approximately parallel to the ring member.

- the stiffening webs 5 to 9 have an approximately parallel to the ring member extending edge and extending with flat curved portions 50, 51, 60, 61, 70, 71, 80, 81, 90, 91 between the respective adjacent receiving elements.

- the stiffening web 10 is formed bent between the two receiving elements 2a and 2f.

- an identification flag 11 as an embodiment of an identification element for characterizing the later packaging unit of carrying handle and bottles is disposed on the ring member 4 and also extends into the space between the two receiving members 2a and 2f.

- an identification band or another form of identification element can be provided which is or is connected in a suitable manner to the carrying handle, in particular ring element.

- the identification flag 11 is arranged on a portion 40 of the ring element, which is connected via two torsion points 41, 42 to the rest of the ring element 4. About the two torsion points, it is possible to bend out the portion 40 with the identification flag 11 from the plane of the handle. As a result, a slight hiring of Ken Vietnamesesfähnchens in the later position of the ring member is possible, which is separated from the rest of the handle and along the bottles with respect to this pushed down to keep the bottles together also in the lower area. The final position of the flag 11 may be better FIG. 2 be removed.

- the identification flag 11 is here at an angle of about 65 ° relative to the horizontal. In such a position, an easy detection of the contents of the identification flag, eg the data of the packaging unit, including price data, eg by a scanner cash register, is possible.

- the grip element 3 surrounding, further connecting webs 12, 13, 14, 15, 16, 17 are provided. All connecting webs have a curved shape, wherein the connecting webs 12 to 16 are supported by further planar stiffening sections 120, 121, 130, 131, 140, 141, 150, 151, 160, 161 relative to the receiving elements 2a to 2f. Only the connecting web 17, which is arranged in the region of the identification flag 11, has no further stiffening sections. In principle, however, this could also have further stiffening sections, which are omitted for reasons of space here.

- the grip element 3 has a straight in the plan view middle holding portion 30 which is secured via four torsion bars 31, 32, 33, 34 to the connecting webs 13, 14, 16, 17.

- the attachment takes place via respective torsion points 35, 36, 37, 38.

- the middle holding portion 30 of the handle member 3 has a slightly curved shape in the side view, which better the FIG. 2 can be removed. By this slightly curved shape of the middle holding portion centering when stacking several carrying handles on each other for storage in a simple manner possible.

- the individual receiving elements can be designed accordingly to facilitate stacking.

- the receiving elements 2a to 2f each have retaining tabs 20 which engage on the underside of a protruding portion on the bottle head, which in FIG. 2 you can see.

- the retaining tabs 20 protrude inward from a circumferential retaining ring 21 and are, as well FIG. 2 can be better taken out of the plane of the handle out slightly inclined.

- retaining tabs 20 also other holding devices may be provided, such as retaining lugs or webs.

- retaining lugs or webs instead of the respective nine retaining tabs, a different number of retaining tabs can be provided, in particular when providing a different shape for this.

- the shape can also be chosen here arbitrarily, in particular, an adaptation to the respective bottle neck shape or bottle head shape is possible here.

- the surrounding the carrying handle ring member 4 is what the top view in FIG. 1 can not be removed, formed in cross-section approximately V-shaped to have a sufficient support surface 43 when pushing down the ring member along the bottles.

- the ring element is not rectangular in cross-section or square, so that can be saved by the V-shape over such a square or rectangular cross-sectional shape material.

- the ring member 4 is further secured via web members 44, 45, 46 to the remainder of the carrying handle, namely the stiffening webs 6, 7, 9.

- a respective predetermined breaking point 47, 48, 49 is provided between the web elements 44 to 46 and the stiffening webs 6, 7, 9.

- the closure member 113 is inserted into the housing 112 and locked in the desired paragraph 111 with its front projection 114. Due to the latching an unintentional release is no longer possible here, so that the closure device ensures that the container or bottles 100 of the ring element 4 tightly enclosed.

- This may also be the perspective view in FIG. 3 be removed. Here, the latched position of the closure device is shown. According to the embodiment in FIG. 3 can the case on its top open, so that the proper locking within the housing is visible from the outside. Likewise, the housing 112 may be formed closed.

- corresponding devices may be provided in automatic placement machines or the device for applying the carrying handles to the containers, via slide elements or corresponding other devices in the region of the housing 112 and in the region of the closure part 113 attacks and move them against each other until a close concern of the ring member 4 is done around the bottles around.

- FIG. 4 shows a non-inventive carrying handle 200, which is designed to accommodate six cans.

- six receiving elements 2a to 2f are formed, but provide shorter retaining tabs 245, since usually the upper edge is less pronounced in doses as a circumferential projection in beverage bottles.

- each stiffening webs 205 to 210 are also provided. In contrast to the stiffening webs 5 to 10, these are all formed uniformly, since a flag ID 211 is disposed within the receiving element 2d.

- the stiffening webs 205 to 210 are each formed as narrow, slightly curved webs between the individual receiving elements 2a to 2f.

- each further connecting webs 218, 219, 220, 221 are provided between the respective stiffening webs and connecting webs on the outside and inside of the carrying handle. They are wider than the stiffening and connecting webs, so that over this a stiffening of the entire handle is possible.

- the two receiving elements 2c and 2f are also connected via a further connecting web 222 connected together to stiffen the middle portion of the handle.

- the identification flag 211 is arranged via telescopic webs 240 to 243 within the receiving element 2d. Also, the telescopic webs 240 are serpentine curved back and forth, so that pushing out of the identification flag 11 from the plane of

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Details Of Rigid Or Semi-Rigid Containers (AREA)

Description

Die Erfindung betrifft einen Tragegriff für mehrere Behälter mit einem Griffelement und Aufnahmeelementen zur Aufnahme der Behälter, bei dem das Griffelement sich zwischen den Aufnahmeelementen erstreckt und parallel zu der Ebene des Tragegriffs teleskopartig anhebbar über zumindest zwei Stellen am Tragegriff angeordnet ist, sowie eine Verpackungseinheit aus einem Tragegriff und zumindest zwei Behältern.The invention relates to a carrying handle for a plurality of containers with a handle member and receiving elements for receiving the container, wherein the handle member extends between the receiving elements and is arranged parallel to the plane of the carrying handle telescopically liftable over at least two places on the carrying handle, and a packaging unit of a Carrying handle and at least two containers.

In der

Weitere Tragegriffe sind im Stand der Technik zahlreich bekannt. Beispielsweise geht aus der

Aus der

Aus der

Die

Die

Aus der

Die

Auch der in der

Auch der aus der

Aus der

Aus der

Die

Die

Die

Ein Träger zum Tragen von zwei tubenartigen Behältern ist in der

Eine weitere Möglichkeit eines Trägers für Flaschen ist in der

Ein weiterer Träger zum Tragen mehrerer Flaschen ist in der

Die

Die

Die

All diejenigen Träger des Standes der Technik, die ein Eingreifen durch Daumen und einen Finger der Hand des Tragenden vorsehen, erweisen sich bei der Verwendung gerade für mehrere Flaschen aufgrund der einschneidenden Wirkung der Tragelaschen oder Öffnungen des Trägers in die Hand des Tragenden als nachteilig. Umgekehrt erweist sich das Vorsehen von starren Griffelementen oder Handgriffen beim Stapeln mehrerer Träger als nachteilig, da diese verhältnismäßig viel Platz einnehmen.All those prior art carriers that provide for intervention by the thumb and finger of the wearer's hand prove disadvantageous in use for just a few bottles due to the incising effect of the wearer's latches or openings in the wearer's hand. Conversely, the provision of rigid handle elements or handles when stacking multiple carriers proves to be disadvantageous because they occupy a relatively large amount of space.

Der vorliegenden Erfindung liegt daher die Aufgabe zugrunde, einen Tragegriff nach dem Oberbegriff des Anspruchs 1 dahingehend fortzubilden, dass eine sehr gute Stapelbarkeit mehrerer Tragegriffe übereinander möglich ist und zugleich ein komfortables Angreifen an dem Tragegriff zum Tragen auch mehrerer Behälter, insbesondere Flaschen, wobei gerade beim Tragen mehrerer Flaschen eine kompakte gut zu tragende Verpackungseinheit geschaffen sein soll.The present invention is therefore based on the object to further develop a carrying handle according to the preamble of

Die Aufgabe wird bei einem Tragegriff nach dem Oberbegriff des Anspruchs 1 gelöst mit den kennzeichneden Merkmalen.The object is achieved in a carrying handle according to the preamble of

Weiterbildungen der Erfindung sind in den abhängigen Ansprüchen definiert.Further developments of the invention are defined in the dependent claims.

Dadurch wird ein Tragegriff für einen oder mehrere Behälter mit zumindest einem Griffelement und zumindest einem Aufnahmeelement zur Aufnahme des zumindest einen Behälters geschaffen, bei dem das Griffelement im unbenutzten Zustand des Tragegriffs in der Ebene von diesem liegt und erst für die Benutzung des Tragegriffs, also das Auffügen auf Behälter, das Griffelement aus der Ebene des Tragegriffs herausgezogen wird, wobei es im Unterschied zum Stand der Technik über zumindest zwei Torsionsstellen am Tragegriff herausteleskopiert wird. Der Vorteil besteht darin, dass das Griffelement dadurch sich nicht u-förmig über der Ebene des Tragegriffs ausformt, sondern durch das Teleskopieren oder "Entwringen" ein mittlerer Abschnitt des Griffelements weiterhin im Wesentlichen gerade bleibt und damit durch die tragende Person besser angegriffen werden kann als ein sich u-förmig ausbildendes Griffelement, das üblicherweise in Zeigefinger und kleinen Finger der Hand des Trägers einschneidet und dadurch zu einem schlechten Tragekomfort führt. Vorteilhaft kann das Griffelement so weit aus der Ebene des Tragegriffs heraus teleskopiert werden, dass der Abstand zwischen dem Griffelement und der obersten Erstreckung von zumindest einem in dem Tragegriff aufgenommenen Behälter das Einfügen einer Hand einer tragenden Person zulässt. Somit kann die tragende Person bequem über der obersten Erstreckung der in dem Tragegriff aufgenommenen Behälter unter das Griffelement greifen und die Verpackungseinheit tragen. Es wird also ein solcher Abstand zwischen Griffelement und Ebene des Tragegriffs vorgesehen, dass eine Hand eines Trägers bzw. einer tragenden Person bequem nach der Aufnahme von Behältern in dem Tragegriff das Griffelement untergreifen kann. Im Stand der Technik ist ein solch ausreichender Platz für das Angreifen an den dortigen Griffelementen nicht gegeben. Vielmehr liegen dort die in die Grifflaschen eingekrallten Finger der Hand einer tragenden Person bzw. eines Trägers stets unbequem zwischen Flaschenhälsen oder Behälterköpfen.As a result, a carrying handle for one or more containers is provided with at least one gripping element and at least one receiving element for receiving the at least one container, wherein the gripping element is in the unused state of the carrying handle in the plane thereof and only for the use of the carrying handle, so the Attaching to the container, the handle element is pulled out of the plane of the carrying handle, wherein it is in contrast to the prior art heraustelkoped at least two torsion points on the carrying handle. The advantage is that the handle element thereby does not form U-shaped over the plane of the handle, but by telescoping or "Entwringen" a central portion of the handle element remains substantially straight and thus can be better attacked by the person wearing a U-shaped handle forming element which usually cuts into the forefinger and small finger of the hand of the wearer and thereby leads to a poor wearing comfort. Advantageously, the gripping element can be telescoped out of the plane of the carrying handle so far that the distance between the gripping element and the uppermost extent of at least one container received in the carrying handle permits the insertion of a hand of a carrying person. Thus, the carrying person can conveniently reach over the uppermost extent of the container received in the carrying handle under the gripping element and carry the packaging unit. It is therefore provided such a distance between the handle element and the plane of the carrying handle that a hand of a wearer or a person wearing can comfortably grip the grip element after receiving containers in the carrying handle. In the prior art, such a sufficient space for attacking the local handle elements is not given. On the contrary, the fingers of the hand of a carrying person or of a wearer who are clasped in the grip bottles are always uncomfortable between bottle necks or container heads.

Für die Stapelfähigkeit der Tragegriffe vor dem Auffügen auf Behälter erweist sich das Liegen in der Ebene des Tragegriffs für das Griffelement als sehr vorteilhaft, insbesondere gegenüber den Tragegriffen des Standes der Technik, bei denen die Griffelemente starr über der Ebene des Tragegriffs vorstehen. Der Platzbedarf für ein solches Griffelement des Standes der Technik ist daher sehr viel größer als bei dem erfindungsgemäßen, das zu keinem größeren Platzbedarf für den Tragegriff führt. Dies erweist sich nicht nur in Bestückungsautomaten, sondern natürlich auch bei der Lagerhaltung als äußerst vorteilhaft.For the stackability of the handles before mounting on containers, the lying in the plane of the handle for the handle element proves to be very beneficial, especially with respect to the handles of the prior art, in which the gripping elements project rigidly over the plane of the carrying handle. The space required for such a grip element of the prior art is therefore much larger than in the invention, which does not lead to a larger footprint for the carrying handle. This proves to be extremely advantageous not only in pick and place machines, but of course also in warehousing.

Das Griffelement weist vorteilhaft zumindest einen leicht gekrümmten Abschnitt zum Zentrieren beim Stapeln von mehreren Tragegriffen aufeinander auf. Eine weitere Stapelhilfe zum Erleichtern eines Zentrierens der Tragegriffe aufeinander kann dadurch vorgesehen werden, dass die Aufnahmeelemente zur Aufnahme der Behälter, das heißt von deren Kopfabschnitten, nicht vollständig eben ausgebildet sind, sondern eine leichte Neigung aufweisen. Das zumindest eine Aufnahmeelement zur Aufnahme des zumindest einen Behälters ist vorteilhaft kragenförmig mit nach innen ragenden Haltelaschen oder Haltenasen ausgebildet. Somit können sowohl die nach innen ragenden Haltelaschen oder Haltenasen eine leichte Neigung aufweisen als auch der umlaufende Kragen der Aufnahmeelemente, wodurch eine Selbstzentrierung in diesem Bereich von aufeinander gestapelten Tragegriffen erreicht werden kann.The grip element advantageously has at least one slightly curved section for centering when stacking a plurality of carrying handles on each other. Another stacking aid for facilitating centering of the carrying handles on each other can be provided that the receiving elements for receiving the container, that is, of the head portions, not completely flat, but have a slight inclination. The at least one receiving element for receiving the at least one container is advantageously formed like a collar with inwardly projecting retaining tabs or retaining lugs. Thus, both the inwardly projecting retaining tabs or retaining lugs may have a slight inclination and the circumferential collar of the receiving elements, whereby a self-centering can be achieved in this area of stacked carrying handles.

Als weiter vorteilhaft erweist es sich, bei Vorsehen mehrerer Aufnahmeelemente diese durch bezüglich des Tragegriffs außenseitig angeordnete Versteifungsstege untereinander zu verbinden. Hierdurch wird eine besondere Stabilität des gesamten Tragegriffs erzielt, was ein seitliches Ausbrechen der in den Tragegriff eingefügten Behälter zumindest einschränken kann. Auch ein ungewolltes Verwinden des Tragegriffs kann hierdurch vermieden werden. Insbesondere sind nicht nur die bezüglich des Tragegriffs außenseitig angeordneten Versteifungsstege zwischen den einzelnen Aufnahmeelementen zur Aufnahme der Behälterhälse beziehungsweise -köpfe vorgesehen, sondern auch noch weitere Verbindungsstege zwischen den einzelnen Aufnahmeelementen im inneren Bereich des Tragegriffs. Das Griffelement kann daher an dem zumindest einen Aufnahmeelement und/oder den Verbindungsstegen und/oder den Versteifungsstegen befestigt sein. Die Befestigung erfolgt in jedem Falle über die bereits erwähnten Torsionsstellen, um das teleskopartige Anheben des Griffelements etwa parallel zur Ebene des Tragegriffs zu ermöglichen und ein Ausbeulen des Griffelements zu verhindern.It proves to be further advantageous, when several receiving elements are provided, to connect them to one another by means of stiffening webs arranged on the outside with respect to the carrying handle. As a result, a particular stability of the entire carrying handle is achieved, which can at least limit a lateral breaking out of the container inserted into the carrying handle. An unintentional twisting of the carrying handle can be avoided thereby. In particular, not only with respect to the carrying handle on the outside arranged stiffening webs between the individual receiving elements for receiving the container necks or heads are provided, but also further connecting webs between the individual receiving elements in the inner region of the carrying handle. The gripping element can therefore be attached to the at least one receiving element and / or the connecting webs and / or the stiffening webs. The attachment takes place in any case on the already mentioned torsion points to the telescopic lifting of the To allow grip element approximately parallel to the plane of the handle and to prevent buckling of the handle member.

Mit den Tragegriffen können sogenannte Multipacks erzeugt werden von beispielsweise vier oder sechs gruppierten Behältern, insbesondere Flaschen oder Dosen.With the carrying handles so-called multipacks can be produced, for example, four or six grouped containers, especially bottles or cans.

Die jeweiligen Torsionspunkte an den Griffelementen dienen als Aufrichthilfe.The respective torsion points on the handle elements serve as Aufrichthilfe.

Als weiter vorteilhaft erweist es sich, wenn zumindest ein Ringelement zum außenseitigen Umgeben der Behälter lösbar an dem Tragegriff befestigt ist. Dieses Ringelement umgibt die Aufnahmeelemente und die zwischen diesen angeordneten Versteifungs- bzw. Verbindungsstege, ist also außenseitig von diesen angeordnet. Das Ringelement ist sozusagen als äußere Umgrenzung des Tragegriffs vorgesehen und kann von diesem abgetrennt werden. Hierzu ist es vorteilhaft durch Stegelemente mit dem zumindest einen Aufnahmeelement und/oder den Versteifungsstegen lösbar verbunden. Zum Erzeugen der Lösbarkeit ist vorzugsweise eine Sollbruchstelle zwischen Ringelement und Stegelementen vorgesehen bzw. zwischen den Stegelementen und dem zumindest einen Aufnahmeelement und/oder den Versteifungsstegen. Durch Durchbrechen der Sollbruchstellen kann das Ringelement von dem Rest des Tragegriffs abgetrennt und entlang den Behältern auf deren Außenseite so weit herunter geschoben werden, dass diese einen guten äußeren Halt gegen ein Ausbrechen aus dem Behälterverband nach außen erfahren. Das Ringelement wird somit anstelle von Banderolen oder Schrumpffolie zum Halten der Behälter aneinander vorgesehen. Da es beim Formen des Tragegriffs an diesem mit angeformt wird, ist kein zusätzliches Material für das Ringelement erforderlich. Vielmehr kann auf einfache Art und Weise mittels einer Vorrichtung zum Aufbringen der Tragegriffe auf Behälter, insbesondere einen Bestückungsautomaten, über eine Einrichtung zum Angreifen an dem Ringelement des Tragegriffs ein Herabschieben von diesem entlang den Behältern erfolgen. Der Tragegriff wird somit auf eine Gruppe von Behältern, die vorteilhafterweise bereits entsprechend positioniert sind, um mit ihren Behälterköpfen bzw. -hälsen in die Aufnahmeelemente zu passen, aufgefügt, so dass die Behälterköpfe durch die Aufnahmeelemente ragen. Beim Auffügen des Tragegriffs auf die Behälter ergreift die Einrichtung zum Angreifen an dem Ringelement dieses und reißt es beim weiteren Herabfahren von dem Rest des Tragegriffs ab, wobei die Sollbruchstellen zerbrechen. Beim Weiterbewegen schiebt sie das Ringelement so weit an den entlang Behältern herab, dass entweder eine vorgebbare Auflagestelle an den Behältern erreicht wird oder eine vordefinierte Position von dem Ringelement eingenommen wird.As it proves to be further advantageous if at least one ring element for surrounding the outside of the container is detachably attached to the carrying handle. This ring element surrounds the receiving elements and arranged between them stiffening or connecting webs, that is arranged on the outside of this. The ring element is provided, so to speak, as an outer boundary of the carrying handle and can be separated from this. For this purpose, it is advantageously releasably connected by web elements with the at least one receiving element and / or the stiffening webs. To generate the solubility preferably a predetermined breaking point between the ring element and web elements is provided or between the web elements and the at least one receiving element and / or the stiffening webs. By breaking the predetermined breaking points, the ring element can be separated from the rest of the carrying handle and pushed down along the containers on the outside so far that they experience a good external grip against breaking out of the container structure to the outside. The ring member is thus provided instead of bands or shrink film for holding the containers together. Since it is molded with the molding of the handle on this, no additional material for the ring member is required. Rather, in a simple manner by means of a device for applying the carrying handles to containers, in particular a placement machine, via a device for engaging the ring member of the carrying handle a downshift of this carried along the containers. The carrying handle is thus placed on a group of containers, which are advantageously already positioned accordingly to fit with their container heads or necks into the receiving elements, so that the container heads protrude through the receiving elements. When attaching the carrying handle to the container engages the means for engaging the ring member this and tearing it from further down the rest of the handle from, breaking the predetermined breaking points. As it moves onward, it pushes the ring element down so far along the containers that either a predefinable contact point is reached on the containers or a predefined position is assumed by the ring element.

Ist für den Tragegriff und insbesondere das Ringelement ein solches Material gewählt, dass ein Dehnen oder Spreizen des Ringelements beim Herabschieben entlang den Behälterwänden nach dem Erreichen der Endposition für das Ringelement, also bei Wegfall der Dehnkraft sofort wieder zu einem Zusammenziehen führt, legt sich das Ringelement direkt an die äußeren Oberflächen von diesem umgebenen Behälter an. Weist das Material des Ringelements eine solche Eigenschaft jedoch nicht auf, wird am Ringelement vorteilhaft zumindest eine Verschlusseinrichtung zum Befestigen an den Behältern vorgesehen. Die Verschlusseinrichtung kann von einer Einrichtung zum Verschließen der Vorrichtung zum Aufbringen der Tragegriffe erfasst und nach dem Herabschieben des Ringelements entlang den Behältern verschlossen werden. Dieses Verschließen kann durch eine aufeinander zugerichtete Bewegung von Teilen der Einrichtung zum Verschließen der Verschlusseinrichtung durchgeführt werden. Zu diesem Zweck kann die Einrichtung zum Verschließen der Verschlusseinrichtung Schiebelemente umfassen, die an zwei Enden der Verschlusseinrichtung angreifen und diese durch aufeinander zu gerichtete Bewegung verschließen. Anstelle von Schiebeelementen können auch andere Einrichtungen vorgesehen werden, die ein Verschließen der jeweiligen Verschlusseinrichtung ermöglichen.Is selected for the carrying handle and in particular the ring member such a material that a stretching or spreading of the ring member when pushed down along the container walls after reaching the end position for the ring element, ie immediately eliminates the expansion force when the elastic force disappears, the ring element sets directly to the outer surfaces of this surrounded container. However, if the material of the ring element does not have such a property, at least one closure device for fastening to the containers is advantageously provided on the ring element. The closure device can be detected by a device for closing the device for applying the carrying handles and can be closed after the ring element has been pushed down along the containers. This closing may be accomplished by a juxtaposed movement of parts of the means for closing the closure means. For this purpose, the means for closing the closure means may comprise sliding elements which engage two ends of the closure means and close them by movement towards each other. Instead of sliding elements, other means can be provided which allow a closure of the respective closure device.

In einer Ausführungsform kann die Verschlusseinrichtung zumindest ein mit Widerhaken versehenes Element und zumindest ein damit zusammenwirkendes Gegenelement umfassen. Das mit Widerhaken versehene Element wird gegen das damit zusammenwirkende Gegenelement gedrückt, so dass sich beide Elemente ineinander verhaken und zum Verschließen der Verschlusseinrichtung und somit Schließen des Ringelements führen. Alternativ oder zusätzlich kann die Verschlusseinrichtung vorteilhaft eine Verrastungseinrichtung enthalten, insbesondere ein mit Absätzen versehenes Gehäuseteil und ein darin einschiebbares mit zumindest einer außenseitigen Auskragung versehenes Verschlussteil aufweist. Das mit der zumindest einen außenseitigen Auskragung versehene Verschlussteil wird zum Verschließen des Ringelements in das Gehäuseteil eingeschoben und verrastet darin hinter den Absätzen des Gehäuseteils. Hierdurch ist beispielsweise auch eine Anpassung an unterschiedliche Umfänge, die von dem Ringelement umschlossen werden sollen, möglich, da das mit der zumindest einen außenseitigen Auskragung versehene Verschlussteil hinter verschiedenen Absätzen des Gehäuseteils verrastet werden kann.In one embodiment, the closure device may comprise at least one barbed element and at least one mating element cooperating therewith. The barbed element is pressed against the counter-element cooperating therewith, so that both elements interlock with one another and lead to closure of the closure device and thus closure of the ring element. Alternatively or additionally, the closure device may advantageously comprise a latching device, in particular a housing part provided with shoulders and a closure part which can be inserted therein and is provided with at least one outside projection. The closure part provided with the at least one outer-side projection is used to close the ring element in the Housing part inserted and locked behind the heels of the housing part. As a result, for example, an adaptation to different circumferences that are to be enclosed by the ring element, possible because the provided with the at least one outer side projection locking part can be locked behind different paragraphs of the housing part.

Eine weitere Möglichkeit eines Verschließens des Ringelements um die Behälter herum besteht darin, das Ringelement mit einem Abschnitt mit ineinander hakbaren Widerhaken zu versehen. Das Ringelement ist hierbei geschlossen ausgebildet und weist den Abschnitt als beispielsweise v-förmig geknickten Abschnitt auf. Die Widerhaken können beim weiteren Zusammendrücken des v-förmigen Abschnitts ineinander verhakt werden, so dass hierdurch eine Reduzierung der Länge des Ringelements und entsprechend ein gewünschtes festes Umgreifen der Behälter durch das Ringelement ermöglicht wird.Another way of closing the ring element around the containers is to provide the ring element with a section of barbs hooked into one another. The ring element is in this case formed closed and has the portion as an example V-shaped bent portion. The barbs can be hooked into each other upon further compression of the V-shaped portion, so that thereby a reduction in the length of the ring member and, correspondingly, a desired firm embrace of the container is made possible by the ring member.

Eine weitere auch mit den anderen Varianten kombinierbare Möglichkeit besteht darin, eine Verschlusseinrichtung nach Art einer Perlenschnur mit aneinander gereihten Elementen, insbesondere konischen Elementen vorzusehen. Derartige konische Elemente können beispielsweise so aneinander angreifen, dass sie sich wie Widerhaken aneinander verhaken und hierdurch ein Verschließen ermöglichen.Another possibility, which can also be combined with the other variants, is to provide a closure device in the manner of a string of pearls with elements lined up in a row, in particular conical elements. Such conical elements, for example, attack each other so that they hooked like barbs together and thereby allow a closure.

Vorteilhaft weist das Ringelement zum Erzeugen einer Abstützungsfläche zum Angreifen beim Herabschieben entlang den Behälterwänden eine obere Abstützfläche auf, insbesondere ist das Ringelement im Querschnitt v-förmig. Durch das Vorsehen einer solchen Abstützungsfläche an dem Ringelement in dem Bereich, in dem die Einrichtung zum Herabschieben angreift, ist für diese eine bessere Kraftausübung auf das Ringelement zum Trennen von dem restlichen Tragegriff möglich. Durch das Ausbilden des Ringelements als im Querschnitt etwa v-förmiges Element wird einerseits eine solche Abstützungsfläche geschaffen, andererseits jedoch so wenig wie möglich an Material hierfür verbraucht. Alternativ kann das Ringelement beispielsweise auch im Querschnitt T-förmig ausgebildet werden, wobei wiederum eine obere Abstützungsfläche bei möglichst wenig zusätzlichem Materialverbrauch geschaffen werden kann. Bei einem T-förmigen Querschnitt könnte es jedoch bei ungleichmäßiger Kraftausübung auf diesen zu einem einseitigen Einknicken der Abstützungsfläche kommen, was bei einem v-förmigen Querschnitt im Allgemeinen aufgrund seiner höheren Stabilität nicht auftreten wird. Aus diesem Grunde wird trotz des etwas höheren Materialverbrauchs ein v-förmiger Querschnitt gegenüber einem T-förmigen Querschnitt bevorzugt.Advantageously, the ring element for generating a support surface for engaging when pushed down along the container walls on an upper support surface, in particular, the ring element in cross-section is V-shaped. By providing such a support surface on the ring member in the region in which the means for pushing down attacks, for this a better application of force to the ring member for separating the remaining handle is possible. By forming the ring element as a cross-sectionally approximately v-shaped element, on the one hand, such a support surface is created, on the other hand, however, consumed as little as possible of material for this purpose. Alternatively, the ring element can for example also be formed in cross-section T-shaped, in turn, an upper Support surface can be created with as little additional material consumption. However, with a T-shaped cross-section, uneven application of force to the support surface could result in a one-sided buckling of the support surface, which in general will not occur with a V-shaped cross section due to its higher stability. For this reason, in spite of the somewhat higher material consumption, a V-shaped cross section is preferred over a T-shaped cross section.

Die außenseitigen Versteifungsstege können insbesondere als Sekanten zwischen den einzelnen Aufnahmeelementen ausgebildet sein. Hierdurch ist eine weitere Materialeinsparung möglich. Ferner wird es für die an dem Ringelement angreifende Einrichtung der Vorrichtung zum Aufbringen der Tragegriffe auf die Behälter leichter möglich, zwischen das Ringelement und entsprechende Öffnungen in dem Tragegriff im Bereich der Versteifungsstege zu greifen, wenn diese etwa parallel zueinander angeordnet sind.The outside stiffening webs may be formed in particular as secants between the individual receiving elements. As a result, further material savings is possible. Further, for the device acting on the ring element of the device for applying the carrying handles to the container, it becomes more easily possible to grip between the ring element and corresponding openings in the carrying handle in the region of the stiffening webs, when these are arranged approximately parallel to one another.

Ein Ringelement ist nicht bei allen Arten von Behältern erforderlich, sondern insbesondere bei größerformatigen Behältern, die anderenfalls dazu neigen, in dem nicht in dem Tragegriff aufgenommenen Abschnitt sich voneinander weg zu bewegen. Dies ist insbesondere bei größeren Getränkeflaschen der Fall, weswegen es sich hier besonders eignet, einen Tragegriff mit einem solchen Ringelement zu verwenden, wobei das Ringelement das Auseinandergleiten der größerformatigen Getränkeflaschen verhindert. Ein Stapeln derartiger Verpackungseinheiten aus beispielsweise sechs Getränkeflaschen ist problemlos möglich, da das Ringelement so angeordnet ist, dass kein zusätzlicher Platzbedarf erforderlich ist, sondern vielmehr in gewohnter Art und Weise ein Bestücken einer Palette möglich ist.A ring member is not required in all types of containers, but especially in larger-sized containers, which otherwise tend to move away from each other in the portion not received in the carrying handle. This is particularly the case with larger bottles of beverage, which is why it is particularly suitable here to use a carrying handle with such a ring element, wherein the ring element prevents the larger-sized beverage bottles sliding apart. A stacking of such packaging units, for example, six bottles of beverage is easily possible because the ring element is arranged so that no additional space is required, but rather in the usual way, a populating a pallet is possible.

Der Tragegriff ist vorteilhaft als Spritzgussteil ausgebildet. Vorteilhaft besteht er aus einem recyclingfähigen Kunststoff, unter anderem aus HDPE, also einem unter niedrigem Druck hergestellten Polyethylen hoher Dichte.The carrying handle is advantageously designed as an injection molded part. Advantageously, it consists of a recyclable plastic, including HDPE, ie a high density polyethylene produced under low pressure.

Zur näheren Erläuterung werden im Folgenden Ausführungsbeispiele näher anhand der Zeichnungen beschrieben. Diese zeigen in:

Figur 1- eine Draufsicht auf eine Ausführungsform eines erfindungsgemäßen Tragegriffs für sechs Flaschen,

Figur 2- eine perspektivische Ansicht einer erfindungsgemäßen Verpackungseinheit mit einem Tragegriff gemäß

Figur 1 , Figur 3- eine perspektivische Ansicht der Verpackungseinheit gemäß

Figur 2 , in einem um 90 Grad gedrehten Blickwinkel, und Figur 4- eine Draufsicht auf einen nicht erfindungsgemäßen Tragegriff für die Verwendung für sechs Dosen.

- FIG. 1

- a top view of an embodiment of a handle according to the invention for six bottles,

- FIG. 2

- a perspective view of a packaging unit according to the invention with a carrying handle according to

FIG. 1 . - FIG. 3

- a perspective view of the packaging unit according to

FIG. 2 in a 90 degree rotated angle, and - FIG. 4

- a plan view of a non-inventive handle for use for six cans.

Das Kennungsfähnchen 11 ist an einem Abschnitt 40 des Ringelements angeordnet, der über zwei Torsionsstellen 41, 42 an dem restlichen Ringelement 4 angebunden ist. Über die beiden Torsionsstellen ist es möglich, den Abschnitt 40 mit dem Kennungsfähnchen 11 aus der Ebene des Tragegriffs herauszubiegen. Hierdurch ist ein leichtes Anstellen des Kennungsfähnchens in der späteren Position des Ringelements möglich, das von dem Rest des Tragegriffs getrennt und entlang den Flaschen in Bezug auf diese nach unten geschoben wird, um die Flaschen aneinander auch im unteren Bereich zu halten. Die letztendliche Position des Kennungsfähnchens 11 kann besser der

Zwischen den einzelnen Aufnahmeelementen 2a bis 2f sind bezüglich des Tragegriffs im Inneren, das Griffelement 3 umgebend, weitere Verbindungsstege 12, 13, 14, 15, 16, 17 vorgesehen. Alle Verbindungsstege weisen eine gebogene Form auf, wobei die Verbindungsstege 12 bis 16 sich über weitere flächige Versteifungsabschnitte 120, 121, 130, 131, 140, 141, 150, 151, 160, 161 gegenüber den Aufnahmeelementen 2a bis 2f abstützen. Lediglich der Verbindungssteg 17, der im Bereich des Kennungsfähnchens 11 angeordnet ist, weist keine weiteren Versteifungsabschnitte auf. Grundsätzlich könnte jedoch auch dieser weitere Versteifungsabschnitte aufweisen, die jedoch aus Platzgründen hier weggelassen sind.Between the

Das Griffelement 3 weist einen in der Draufsicht geraden mittleren Halteabschnitt 30 auf, der über vier Torsionsstege 31, 32, 33, 34 an den Verbindungsstegen 13, 14, 16, 17 befestigt ist. Die Befestigung erfolgt über jeweilige Torsionsstellen 35, 36, 37, 38. Hiermit ist es möglich, das Griffelement, das heißt den mittleren Halteabschnitt 30 zu ergreifen und aus der Ebene des Tragegriffs heraus zu teleskopieren, da sich die Torsionsstege hierbei tordieren, also aus der Ebene des Tragegriffs herausdrehen, so dass ein paralleles Anheben des Halteabschnitts in Bezug auf die Ebene des Tragegriffs möglich ist. Auch in der ausgestellten Trageposition des Griffelements tritt dadurch nicht das Problem auf, dass sich dieses o-förmig verbiegt, was im Stand der Technik zu einer sehr unkomfortablen Trageposition führt.The

Der mittlere Halteabschnitt 30 des Griffelements 3 weist in der Seitenansicht eine leicht gebogene Form auf, was besser der

Anstelle der Haltelaschen 20 können auch anderweitige Halteeinrichtungen vorgesehen werden, wie beispielsweise Haltenasen oder Stege. Anstelle der jeweils neun Haltelaschen kann auch eine andere Anzahl von Haltelaschen vorgesehen werden, insbesondere bei Vorsehen einer anderen Formgebung für diese. Die Formgebung kann hier ebenfalls beliebig gewählt werden, wobei insbesondere auch eine Anpassung an die jeweilige Flaschenhalsform beziehungsweise Flaschenkopfform hier möglich ist.Instead of the retaining

Das den Tragegriff außenseitig umgebende Ringelement 4 ist, was der Draufsicht in

Das Ringelement 4 ist ferner über Stegelemente 44, 45, 46 an den Rest des Tragegriffs, nämlich den Versteifungsstegen, 6, 7, 9 befestigt. Wie in

Das Ringelement kann aus einem solchen elastischen Material besteht, dass nach dem Herabschieben, somit Dehnen des Ringelements im Bereich der Ausbauchungen 101 der Flaschen 100, dieses wieder in seine ursprüngliche nicht gedehnte Form zurückspringt. Weist das Ringelement eine solche Elastizität nicht auf, wird eine Verschlusseinrichtung 110 zum Verschließen, also Zusammenzurren des Ringelements um die Flaschen herum, vorgesehen. Eine solche Verschlusseinrichtung 110 ist in einer Ausführungsform in

Zum Verschließen der Verschlusseinrichtung bzw. Verrasten des Verschlussteils 113 innerhalb des Gehäuses 112 können entsprechende Einrichtungen in Bestückungsautomaten bzw. der Vorrichtung zum Aufbringen der Tragegriffe auf den Behältern vorgesehen sein, die über Schieberelemente oder entsprechende andere Einrichtungen im Bereich des Gehäuses 112 und im Bereich des Verschlussteils 113 angreift und diese gegeneinander so weit verschieben, bis ein enges Anliegen des Ringelements 4 um die Flaschen herum erfolgt ist.For closing the locking device or latching of the

Zur Verwendung bei Dosen weist der Tragegriff zwei Griffelemente 230, 231 auf. Beide sind innerhalb eines jeweiligen Aufnahmeelementes, nämlich innerhalb der Aufnahmeelemente 2c und 2f, angeordnet. Beide Griffelemente sind spiegelsymmetrisch zueinander ausgebildet und weisen jeweils einen mittleren Steg 232, 233 sowie sich von diesem v-förmig zueinander erstreckende Torsionsstege 234, 235, 236, 237 auf. Diese sind über jeweilige Torsionsstellen 238 an den Aufnahmeelementen 2c und 2f befestigt. Durch die V-Förmigkeit der Torsionsstege und der weiteren Biegung gegenüber den jeweiligen mittleren Stegen der Griffelemente 230, 231 können diese wiederum beim Herausziehen aus der Ebene des Tragegriffs teleskopiert werden, wobei sich beim Herausziehen aus der Ebene des Tragegriffs ferner über die Torsionsstellen wiederum ein Tordieren der Torsionsstege und hierdurch ein etwa paralleles Herausziehen der mittleren Stege 232, 233 aus der Ebene des Tragegriffs ergibt. Die beiden Griffelemente 230, 231 werden in Richtung zu dem Verbindungssteg 222 zwischen den beiden Aufnahmeelementen 2c und 2f zusammengeführt und können dann von einer Hand einer tragenden Person ergriffen und die Verpackungseinheit aus Tragegriff und sechs Dosen komfortabel getragen werden.For use with cans, the carrying handle has two

Um eine Kennzeichnung der Verpackungseinheit zu ermöglichen, beispielsweise mit einem EAN-Code oder anderen Produktinformationen, ist das Kennungsfähnchen 211 bzw. bei dem Tragegriff gemäß

In

Tragegriffs problemlos möglich ist. Dieses erfolgt, wenn ein Dosenkopf in das Aufnahmeelement 2d eingefügt wird, automatisch. Zu diesem Zweck erweist es sich weiter als vorteilhaft, die vier Teleskopstege 240 bis 243 über entsprechende Torsionsstellen 244 an dem Aufnahmeelement 2d beziehungsweise dessen Haltelaschen 245 anzubinden.Carrying handle is easily possible. This is done automatically when a can head is inserted into the receiving

In den

Anstelle der Griffelemente gemäß

Alle Tragegriffe können aus HDPE bestehen oder aus einem anderen geeigneten Material, insbesondere Kunststoffmaterial.All handles can be made of HDPE or of any other suitable material, in particular plastic material.

Neben der im Vorstehenden beschriebenen und in den Figuren dargestellten Ausführungsform von Tragegriffen können noch zahlreiche weitere entworfen werden, bei denen jeweils das Griffelement aus der Ebene des Tragegriffs heraus teleskopiert wird, über zumindest zwei Torsionsstellen am Tragegriff bzw. zumindest ein Ringelement zum außenseitigen Umgeben der Behälter, die von dem Tragegriff aufgenommen werden, lösbar an dem Tragegriff befestigt ist bzw. bei dem zumindest ein Kennungselement, wie ein Kennungsfähnchen, Kennungsband, etc., an dem Tragegriff bzw. einer Verpackungseinheit aus mehreren Behältern angeordnet ist. Insbesondere können entsprechende Tragegriffe für andere Verpackungseinheitsgrößen gebildet werden, bei denen jeweils ebenfalls ein Ringelement bzw. Kennungselement bzw. ein entsprechendes über Torsionsstellen an dem Tragegriff befestigtes Griffelement vorgesehen sind. Alle im Vorstehenden genannten und in den Figuren gezeigten Merkmale können beliebig untereinander kombiniert werden.In addition to the embodiment of carrying handles described in the foregoing and shown in the figures, numerous other can be designed in which each of the handle element is telescoped out of the plane of the handle, at least two torsion points on the handle or at least one ring element for surrounding the container on the outside , which are detachably attached to the carrying handle, or in which at least one identification element, such as a identification flag, identification band, etc., is arranged on the carrying handle or a packaging unit of a plurality of containers. In particular, corresponding carrying handles for other packaging unit sizes can be formed, in which in each case likewise a ring element or identification element or a corresponding grip element fastened to the carrying handle via torsion points are provided. All mentioned in the foregoing and shown in the figures features can be combined with each other.

Claims (8)

- Carrying handle (1) for a plurality of containers (100) with a handle element (3) and receiving elements (2a, 2b, 2c, 2d, 2e, 2f) for receiving the containers (100), in which the handle element (3) has a straight central holding portion (30) in plan view, extends between the receiving elements and is arranged parallel to the plane of the carrying handle (1) to be telescopically liftable by means of at least two points (35, 36, 37, 38) on the carrying handle (1), characterised in that the handle element (3) in the unused state lies in the plane of the carrying handle, in that the at least two points are configured as torsion points (35, 36, 37, 38) on the carrying handle (1) and the holding portion (30) is fastened by torsion webs (31, 32, 33, 34) on connecting webs (13, 14, 16, 17) between individual receiving elements (2a, 2b, 2c, 2d, 2e, 2f) by means of the torsion points (35, 36, 37, 38), wherein the torsion webs (31, 32, 33, 34) during the telescopic lifting of the handle element (3) out of the plane of the carrying handle (1) rotate out of this plane for the parallel lifting of the holding portion in relation to the plane of the carrying handle (1).

- Carrying handle (1) according to claim 1, characterised in that the receiving elements (2a, 2b, 2c, 2d, 2e, 2f), in particular, two four or six receiving elements, are connected to one another by reinforcement webs (5, 6, 7, 8, 9, 10) arranged on the outside with respect to the carrying handle (1).

- Carrying handle (1) according to any one of the preceding claims, characterised in that the handle element (3) has at least one slightly curved portion for centring when stacking carrying handles on one another.

- Carrying handle (1) according to any one of the preceding claims, characterised in that at least one ring element (4) is releasably fastened to the carrying handle (1) to surround the container (100) on the outside.

- Carrying handle (1) according to claim 4, characterised in that the ring element (4) is provided with at least one closure device (110) for fastening to the containers (100), in particular has a portion with barbed hooks that can be hooked into one another, or the closure device (110) comprises at least one element provided with barbed hooks and at least one counter-element cooperating therewith and/or contains a latching device, in particular has a housing part (112) provided with recesses (111, 116) and a closure part (113), which can be inserted therein and is provided with at least one external projection (114, 115), and/or there is provided a closure device in the manner of a string of pearls with elements arranged next to one another in a row, in particular conical elements.

- Carrying handle (1) according to claim 4 or 5, characterised in that the ring element (4) has an upper support face (43) to produce a bearing face for engagement when pushing down on the container walls, and is, in particular, v-shaped in cross section.

- Carrying handle (1) according to any one of claims 4 to 6, characterised in that the ring element (4) is releasably connected by web elements (44, 45, 46) to the at least one receiving element (2a, 2b, 2c, 2d, 2e, 2f) and/or the reinforcement webs (5, 6, 7, 8, 9, 10), in particular a desired breaking point (47, 48, 49) is provided between the ring element (4) and web elements (44, 45, 46) and/or a desired breaking point is provided between the web elements (44, 45, 46) and the at least one receiving element (2a, 2b, 2c, 2d, 2e, 2f) and/or the reinforcement webs (5, 6, 7, 8, 9, 10).

- Packaging unit consisting of a carrying handle (1) according to any one of claims 1 to 7 and at least two containers (100), characterised in that the containers (100) are surrounded by an ring element (4), the ring element (4) being provided with at least one closure device (110) for fastening to the containers (100).

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE200710034870 DE102007034870A1 (en) | 2007-07-24 | 2007-07-24 | handle |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2028126A1 EP2028126A1 (en) | 2009-02-25 |

| EP2028126B1 true EP2028126B1 (en) | 2013-05-01 |

Family

ID=39760929

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20080013311 Not-in-force EP2028126B1 (en) | 2007-07-24 | 2008-07-24 | Carrier with handle |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP2028126B1 (en) |

| DE (1) | DE102007034870A1 (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB0920396D0 (en) | 2009-11-23 | 2010-01-06 | Dijofi Ltd | A plastics container carrier |

| DE102011102683A1 (en) * | 2011-05-20 | 2012-11-22 | Khs Gmbh | Container, method for producing containers and device for handling, conveying, packaging and / or palletizing articles |

| WO2013004339A1 (en) * | 2011-07-05 | 2013-01-10 | Khs Gmbh | Pack and method for producing such a pack |

| GB2511622B (en) | 2013-01-22 | 2016-07-13 | Loadhog Ltd | Load capping arrangement |

| GB201317547D0 (en) * | 2013-10-03 | 2013-11-20 | P4Ck Ltd | Drinks Carrier |

| EP4417536A3 (en) * | 2016-05-02 | 2025-04-16 | WestRock Packaging Systems, LLC | Blank for forming an article carrier |

| US11001428B2 (en) * | 2017-07-14 | 2021-05-11 | Oregon Precision Industries, Inc. | Container carrier with flexible raised handle |

Family Cites Families (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3084792A (en) * | 1960-09-23 | 1963-04-09 | Illinois Tool Works | Container carrier |

| DE1138194B (en) | 1960-10-19 | 1962-10-18 | Snap Pac Corp | Carrying and holding device for containers |

| CA933889A (en) | 1970-04-30 | 1973-09-18 | Owens-Illinois | Container package |

| US3727754A (en) * | 1971-06-16 | 1973-04-17 | Illinois Tool Works | Container carrier |

| DE2144334A1 (en) | 1971-09-03 | 1973-03-08 | Walter Heubl | BOTTLE CARRIER |

| US3946862A (en) | 1974-07-16 | 1976-03-30 | Illinois Tool Works Inc. | Container package |

| US4545480A (en) * | 1983-10-17 | 1985-10-08 | Illinois Tool Works Inc. | Bottle multi-package and multi-packaging device |

| DE8915740U1 (en) | 1989-06-02 | 1991-04-04 | Grafenwald Kunststoff GmbH & Co Verarbeitungs und Vertriebs KG, 5508 Hermeskeil | Containers consisting of containers and support frames |

| US5306060A (en) | 1992-07-06 | 1994-04-26 | Oregon Precision Industries, Inc. | Carrier strap for bottles or jugs |

| GB9307372D0 (en) | 1993-04-08 | 1993-06-02 | Mouldamatic Limited | Carrier for bottles and like containers |

| US5735562A (en) | 1997-02-18 | 1998-04-07 | Oregon Precision Industries, Inc. | Multi-container carrier |

| IT243928Y1 (en) | 1998-04-10 | 2002-03-06 | Affaba & Ferrari S N C | DEVICE FOR THE TRANSPORT OF BOTTLES OR SIMILAR CONTAINERS |

| US6129397A (en) | 1998-07-15 | 2000-10-10 | Oregon Precision Industries | Six pack carrier |

| US6145656A (en) * | 1998-12-24 | 2000-11-14 | Illinois Tool Works Inc. | Film multipackage |

| US6536820B1 (en) * | 2000-11-14 | 2003-03-25 | Flexible Products Co. | Handle assembly for bulk fluid containers |

| US6394517B1 (en) | 2001-04-11 | 2002-05-28 | Oregon Precision Industries | Single bottle carrier |

| US6715810B2 (en) | 2002-09-09 | 2004-04-06 | Oregon Precision Industries, Inc. | Three bottle carrier |

| EP1597165A2 (en) | 2003-02-26 | 2005-11-23 | Schoeller Wavin Systems Services GmbH | Carrier for containers, especially bottles |

| US20040256250A1 (en) | 2003-06-23 | 2004-12-23 | Borg Zakary J. | Balanced multiple container carrier |

| US7108128B2 (en) | 2003-06-23 | 2006-09-19 | Oregon Precision Industries, Inc. | Balanced multiple container carrier |

| DE20311628U1 (en) | 2003-07-29 | 2003-09-25 | Guzik, Werner, 92224 Amberg | Bottle holder especially for plastics bottles has several holding elements on strip or ring shaped carrier |

| US6789828B1 (en) | 2003-08-04 | 2004-09-14 | Oregon Precision Industries, Inc. | Stabilizing two-bottle carrier |

| DE102004019437A1 (en) | 2004-04-19 | 2005-11-03 | Markus E.Kfm. Wulf | Bottle carrier comprises a plate made from first plastic which has apertures, through which necks of bottles pass, flexible edgings on apertures which are made from a second plastic, supporting collars on bottle necks |

| DE112004002843T5 (en) | 2004-05-13 | 2007-05-10 | Roberts Polypro Inc. | container carrier |

| DE202005005970U1 (en) | 2005-04-14 | 2005-07-21 | Seifert, Gregor | Device for bundling empty returnable plastic bottles is made of a foil consisting of the same material as the bottles, has a U-shaped configuration, and is provided with six holes produced by a punching process |

| US7387200B2 (en) | 2005-05-16 | 2008-06-17 | Oregon Precision Industries, Inc. | Tandem harness for tub-like containers |

| DE202005014112U1 (en) | 2005-08-01 | 2005-12-29 | Terramark Markencreation Gmbh | Grip for carrying objects comprises a plate whose edge is provided with cutouts capable of securely holding such objects |

| US7147100B1 (en) | 2005-08-09 | 2006-12-12 | Oregon Precision Industries, Inc. | Multiple-bottle securement and carrying device |