EP2016008B1 - Method and device for the production of hinge-lid boxes for cigarettes - Google Patents

Method and device for the production of hinge-lid boxes for cigarettes Download PDFInfo

- Publication number

- EP2016008B1 EP2016008B1 EP07724645A EP07724645A EP2016008B1 EP 2016008 B1 EP2016008 B1 EP 2016008B1 EP 07724645 A EP07724645 A EP 07724645A EP 07724645 A EP07724645 A EP 07724645A EP 2016008 B1 EP2016008 B1 EP 2016008B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- collar

- blank

- folding

- lid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 235000019504 cigarettes Nutrition 0.000 title claims abstract description 31

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 13

- 238000000034 method Methods 0.000 title claims description 13

- 210000002105 tongue Anatomy 0.000 claims description 21

- 239000003292 glue Substances 0.000 claims description 20

- 238000004026 adhesive bonding Methods 0.000 claims description 5

- 230000007246 mechanism Effects 0.000 claims 4

- 238000003780 insertion Methods 0.000 abstract description 7

- 230000037431 insertion Effects 0.000 abstract description 7

- 230000000149 penetrating effect Effects 0.000 abstract 1

- 238000004080 punching Methods 0.000 description 6

- 238000004806 packaging method and process Methods 0.000 description 5

- 238000005520 cutting process Methods 0.000 description 3

- 238000004049 embossing Methods 0.000 description 3

- 238000012856 packing Methods 0.000 description 3

- 238000013461 design Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 210000000056 organ Anatomy 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000008141 laxative Substances 0.000 description 1

- 230000002475 laxative effect Effects 0.000 description 1

- 210000004072 lung Anatomy 0.000 description 1

- 239000005022 packaging material Substances 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/64—Lids

- B65D5/66—Hinged lids

- B65D5/6602—Hinged lids formed by folding one or more extensions hinged to the upper edge of a tubular container body

- B65D5/6608—Hinged lids formed by folding one or more extensions hinged to the upper edge of a tubular container body the lid being held in closed position by self-locking integral flaps

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B19/00—Packaging rod-shaped or tubular articles susceptible to damage by abrasion or pressure, e.g. cigarettes, cigars, macaroni, spaghetti, drinking straws or welding electrodes

- B65B19/02—Packaging cigarettes

- B65B19/22—Wrapping the cigarettes; Packaging the cigarettes in containers formed by folding wrapping material around formers

- B65B19/228—Preparing and feeding blanks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/07—Containers, packaging elements or packages, specially adapted for particular articles or materials for compressible or flexible articles

- B65D85/08—Containers, packaging elements or packages, specially adapted for particular articles or materials for compressible or flexible articles rod-shaped or tubular

- B65D85/10—Containers, packaging elements or packages, specially adapted for particular articles or materials for compressible or flexible articles rod-shaped or tubular for cigarettes

- B65D85/1036—Containers formed by erecting a rigid or semi-rigid blank

- B65D85/1045—Containers formed by erecting a rigid or semi-rigid blank having a cap-like lid hinged to an edge

- B65D85/1056—Containers formed by erecting a rigid or semi-rigid blank having a cap-like lid hinged to an edge characterized by the lid

Definitions

- the invention relates to a method for producing folding boxes according to the preamble of claim 1. Furthermore, the invention relates to a device for carrying out the method.

- Folding cartons for a cigarette block as package contents usually consist of a one-piece blank to form a box part and a lid. An arranged within the box part, this partially outstanding collar consists of a separate blank.

- the blank for box part and lid is inserted into a pocket of a folding turret and partially folded.

- the cigarette block is introduced, together with the collar, which is positioned on the cigarette block.

- the package may include support stops in the region of side walls on which lower edges of the collar are supported for alignment ( DE 199 38 167 A1 . DE 199 45 514 A1 ).

- the package In the production of folding cartons for cigarettes in a particular design, namely with a total of rounded, approximately semicircular side walls, the package consists of two blanks which are folded together lying around a cross-sectional shape of the pack folding mandrel in a winding process.

- An inner blank which extends over the full height of the pack, is provided in the region of a front wall with a recess corresponding to a collar ( WO 03/070576 A1 ).

- the invention relates to the production of hinged boxes having a conventional collar or collar with front wall and side walls, which is anchored to a portion in the box part of the pack, but without support on a bottom wall.

- the invention has for its object to improve the production of such folding cartons for cigarettes in terms of a correct, reliable positioning of the collar within the pack.

- the positionally accurate by gluing with the blank for box part and lid connected to a unit collar is introduced as a unit with partial folding in the pocket of a revolver.

- the cigarette block is delivered without collar.

- the device is formed with the features of claim 6. It is about the supply of separate packaging parts, namely blank and collar, and the merger before handover to the folding turret.

- the main purpose of the invention is the production of cigarette packs of the folding box type in the "Side-Lid-Pack" version.

- the package consists of a (lower) box part 10, a lid 11 and a collar 12.

- Box part 10 and lid 11 are made of a unitary blank 13 of thin cardboard or the like Packaging material formed.

- the collar 12 consists of a separate blank ( Fig. 2 ).

- the elongate blank 13 is divided into panels by stamping lines and preferably embossed fold lines to form a box front wall 14, a bottom wall 15, a box back wall 16.

- Box side flaps 17, 18 are laterally attached to the box front panel 14. These are associated with corresponding, inner box side tabs 19, 20 in the region of the box rear wall 16.

- a blank area adjoining the box rear wall 16 is formed for the lid 11, namely with the lid rear wall 21, the end wall 22 and the lid front wall 23.

- Lateral tabs are also arranged in the area of the blank areas assigned to the lid 11.

- the blank 13 is therefore designed to use the Lticiansfalttamas.

- the box side flaps 17 and 19, and 18 and 20 are fully overlapped to form a box side wall 28.

- the box side flaps 18 and 20 are folded to cover and bonded together by glue an opposite box side wall. From the lid side tabs 24..27 lid side walls 30 and 31 are formed.

- a special feature is that the lid 11 in the region of a side wall via a hinge, namely via a line joint 32, hinged to the box part 10 is connected.

- the inner side flaps namely box side flaps 20 of the box rear wall 16 and lid side flaps 25 are connected together at the lid rear wall 21 and delimited from each other by a line joint 32 formed by embossing or otherwise.

- lid 11 and box part 10 are delimited from each other by closing edges, which - starting from the ends of the line joint 32 - to the opposite side, namely the box side wall 28 are inclined downwards.

- the closing edges consist of free, obliquely directed end edges 33, 34 of the blank 13.

- box rear wall 16 and lid rear wall 21 are separably connected to one another, by a slanted punching line 35 and Residual connections 36. These ensure a uniform blank 10 for the production of the package.

- the remaining connections 36 are severed, so that the punching line 35 forms a continuous separation between the box part 10 and lid 11.

- a continuous separating cut 37 is provided in the area of box side wall 28 and lid side wall 30 or in the area of box side tabs 19 and lid side tabs 24, so that in the region of the corresponding side walls 28, 30 box part 10 and lid 11 are separated from one another are.

- the collar 12 is designed such that the package contents, in the present case a cigarette block 37, that is to say a group of cigarettes surrounded by an inner blanket, are surrounded by the collar 12 all around.

- the collar 12 consists for this purpose of collar front wall 38, subsequent collar side wall 39, collar rear wall 40 and a peripheral collar side wall 41.

- collar front wall 38 Approximately in the middle of the collar side wall 39, within the collar 12 between the front wall 38 and Rear wall 40 is positioned, there is a recess 42 which in the finished package ( Fig. 5 ) in the region of the lid side wall 30 and in adjacent partial areas of the lid front wall 23 and the lid rear wall 21 extends.

- the folded collar 12 surrounds the cuboid cigarette block 37 such that the collar front wall 38 rests against the inside of the box front wall 14.

- the collar sidewall 39 faces the carton side wall 28 and the collar rear wall 40 of the carton rear wall 16.

- the attached as an end flap collar side wall 41 abuts against the box side wall 29.

- a closing aid for the cover 11 in the region of the lid side wall 30 is arranged.

- This consists of a tab or tongue 43 at the lower closing edge of the lid 11 and the lid side wall 30.

- a cooperating with this tongue 43 counter-member is formed on the collar 12 in matching relative position to the tongue 43. It is a recess in the collar side wall 39, in which the tongue 43 enters with the lid 11 in an upwardly directed position.

- the recess is formed in this case by a U- or C-shaped punch 44 to form an upwardly directed tab 45.

- This is pivotable about a transverse, lower line 46.

- the tab 45 is deformed slightly inwardly in the manufacture of the package, so that a U-shaped slot for the entry of the tongue 43 is formed.

- a special feature is the production of the package from two separate blanks. These are in the unfolded state or after folding only the tongue 43 against the inside of the lid side flap 26 merged into a unit by the collar 12 is placed in the pack relative position on the blank 10 (inside).

- the collar 12 is aligned with the collar back wall 40 aligned with the carton rear wall 16.

- the adjacent collar side wall 41 lies against the inner box side flap 20 and the opposite collar side wall 39 against the other box side flap 19 on.

- the collar front wall 38 projects laterally beyond the blank 10.

- the relative position is chosen such that an upper part of the collar 12 lies in the region of the cover 11 and thus protrudes out of the box part 10 in the finished package ( Fig. 5 ).

- For the closing aid namely for the tab 45 of the lid side tabs 24 is provided with a recess 47 which ensures the access of the arranged on the outer lid side tabs 26 tongue 43 to the counterpart of the entanglement on the collar 12.

- stops 81, 82 are formed, in the box side flap 20 on the one hand and in the box side flap 19 on the other. These are material deformations that are formed by punching and embossing, so that a stop edge is formed by the stops 81, 82 against which a (lower) edge of the collar 12 abuts, namely a lower edge of the collar side wall 41 on the one hand and the collar side wall 39, on the other hand.

- the stops 81, 82 are mounted by basically known punching and embossing tools.

- the collar 12 is fixed in the pack according to the positioning on the blank 13 by gluing, in the present case by a transverse row of glue dots 48, which extend over the full width of the blank 10 with at least one glue point 48 in the region of the box side tabs 19, 20. Further glue points 49 serve to fix the cigarette block 37 in the package.

- Unfolded blank unit 10, 12 is processed in a packaging machine to form a folding box.

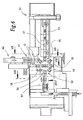

- the present example largely corresponds to a packaging machine known for the production of packages of the Hinge-Lid type with a folding turret 50, which is dish-shaped and can be rotated by means of an upright shaft 51 about a vertical axis.

- a plurality of pockets 52 are arranged, each for receiving a blank or a cutting unit including package contents.

- the folding turret 50 or outside the area of the same folding bodies are arranged, which fold the blank 10, 12 during the rotational movement to form the package.

- cigarettes for forming groups of cigarettes 53 are taken from a cigarette magazine 54 and fed to the folding turret 50 along a cigarette path in the radial direction.

- the cigarette group 53 is wrapped in an inner blank made of paper or Stanniol to form the cigarette block 37. This is inserted in a plug-in station 55 in there held bag 52 (with blank 13, 12).

- a Ausschubstation 56 On the opposite side of the folding turret 50 is a Ausschubstation 56 for transferring the largely finished packs to a radially laxative packing web 57.

- the blanks 13 are transported so that the side with the tongue 43 is directed forward. During transport, the tongue 43 is folded against the inside of the lid side flap 26, ie upwards.

- a special feature is the feeding of the individual blanks and transfer of the cutting unit to a pocket 52 in the region of an insertion station 58. This is offset by 90 ° to the stations 55, 56, that is arranged transversely to the conveying direction of the cigarette groups and packs.

- the blanks 13 are conveyed along a blank path 59 guided above the revolver 50 to the introduction station 58 along a blank path 59 guided diametrically to the folding turret 50.

- the blanks 13 are removed individually from a blank magazine 60 and then transported in a manner known per se along the blank web 59 to a defined position above the pocket 52.

- the collars 12 are fed on a separate web, namely collar web 61, to the introduction station 58 or to the associated blank 13, specifically in a conveying direction opposite to the blank web 59. Furthermore, the collar web 61 is offset from the blank web 59 so that the collars 12 arrive at a position adjacent to the blank 13 being held ready.

- the blank web 59 is disposed above the folding turret 50 substantially in a downwardly inclined plane.

- the collar web 61 runs in a plane inclined upward in the conveying direction, namely slightly upwardly offset in height from the blank web 59.

- the collar web 61 adjoins a collar aggregate 62 outside or next to the packaging machine.

- the individual collars 12 are separated from a material web and introduced into the collar web 61. This consists in the region of the collar unit 62 of conveyor rollers, in the packaging machine essentially from (two pairs of) superimposed conveyor belts 63, 64. Between the conveyor troughs, the collar 12 are initially transported in sealing position, finally with distances from each other.

- a special collar unit is formed. This consists of an end plate 65 which extends in the transverse direction into the region of the conveyor belts 63, 64.

- the end plate 65 forms the adjusting stop for the collar 12, and here as a cross-sectionally U-shaped, transverse guide profile 66th

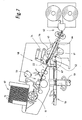

- the blank 13 is held in the insertion station 58 above a folding shaft 67 defined by molded bodies. This is located in the end region of the blank web 69.

- the blank 13 is aligned in a corresponding relative folding subsequent operation in lateral guides 68 in precise alignment with the pocket 52 located below the folding shaft 67.

- the collar 12 is moved at the end of the collar web 61 on the end plate 65 in the transverse direction.

- This is a special slide 69.

- This is provided with a holding member for detecting the collar 12, namely with a suction cup 70 which is connected via a suction line 71 to a vacuum source.

- the slider 69 detects the collar 12 with the sucker 70 at the top.

- a transverse stop 72 determines the position of the collar 12.

- the slider 69 returns after dropping the collar 12 in a slightly increased trajectory in the starting position to take over the next collar 12 back.

- a closed trajectory 73 of the slider 69 is shown by a dashed line.

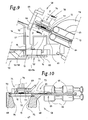

- Blank 13 and collar 12 are now in pack-oriented position over the folding shaft 67, initially spaced from each other ( Fig. 10 ).

- a folding member namely a folding plate 74 is first detected by downward movement of the collar 12 and then the blank 13 and taken in a downward folding movement.

- Parts of the blank 13 and of the collar 12 slide along fold guides 75 and 76 and are erected on the way to the pocket 52 located below the folding shaft 67.

- fold guides 75 are in particular the box side tabs 19 and 20 and the subsequent lid side tabs 24, 25 erected.

- the supply of the collar 12 in a folding position offset to the collar web 61 takes into account the present in the insertion station 58 folding organs, in particular the up and down movable folding plate 74.

- This is designed so that the slider 69, the collar 12 each in the folding position above the folding shaft 67th can transport.

- the folding plate 74 has for this purpose a lateral recess 77, in which the slider 69 in the end position above the folding shaft 67 occurs ( Fig. 10 ).

- the recess 77 is closed by a bell-shaped cover 78 upwards.

- the slider 69 can be solved in the end position of the collar 12, which fixed by the regions of the folding plate 74 outside of the recess 77 in the position above the blank 13 becomes. There is sufficient space for the slider 69 to return to the home position in a raised position before the folding plate 74 is moved downwardly.

- the folding plate 74 After retraction of the slider 69 in the starting position, the folding plate 74 is moved downward, by a stationary pivot lever 79. The folding plate 74 pushes the blank 13 with collar 12 until it rests on a pocket bottom 80 of the pocket 52 (FIGS. Fig. 13 ).

- the Faltrevolver 50 promotes the pocket 52 without substantial change of the folding tabs in the insertion station 55.

- the cigarette block 37 is inserted in the radial direction in the pocket 52, the blanks in cross-section from Fig. 13 assume an obvious position.

- the pocket 52 is provided with retaining members for the (partially folded) blank 13 including collar 12. These are holding tongues 83, 84, which are arranged at the upper edge of the U-shaped pocket 52 and abut folded tabs of the blank 13 and the collar 12 folded upwards.

- the retaining tongue 84 bears against the free edges of the box side flap 20 and the collar side wall 41.

- the retaining tongue 83 is located in the region of the erected collar front wall 38.

- the collar 12 is designed such that the retaining tongue 83 bears against edges of the blank 13 and of the collar 12.

- a punching line 85 which is formed in the region of a folding line between the collar front wall 38 and the collar side wall 39 serves as the edge free incision. Due to corresponding deformation, the sharpened retaining tongue 83 reaches the contact position for fixing the unit.

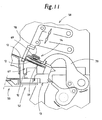

- the largely completed pack is pushed out of the folding turret 50 in the area of the ejection station 56 and transferred to the packing web 57.

- a glue station 86 for applying glue to the underside of the laterally directed folding flaps, namely the box side flaps 17, 18 and the lid side flaps 26, 27. These are then up to the plant to the already folded inner Lateral tabs 19, 20, 24, 25 folded over.

- the glue station 86 is provided with a lower glue roller 87, which dips into a glue pot and transmits glue as a result of rotational movement to the underside of the folding flaps.

- the glue roller 87 cooperates with a pressure roller 88 arranged above the movement path of the folding tabs.

- This roller is provided with a recess 89 on its circumference.

- the recess 89 is located in the region of the folded into the detent position tongue 43, namely on the underside of the provided with glue lid side flap 26.

- the tongue 43 is already in the area of the blank web 59 in the operative position according to Fig. 3 folded.

- the collar 12 is attached to the blank 13 in the pack according to the relative position and connected to the blank 13 by gluing, preferably by glue, so that a fixed relative to the relative position unit can be inserted into the folding turret. Furthermore, a combination of blank 13 and collar 12 is carried out in advance, so that they are fed as a unit to the folding turret.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Wrapping Of Specific Fragile Articles (AREA)

Abstract

Description

Die Erfindung betrifft ein Verfahren zum Herstellen von Klappschachteln gemäß Oberbegriff des Anspruchs 1. Weiterhin betrifft die Erfindung eine Vorrichtung zur Durchführung des Verfahrens.The invention relates to a method for producing folding boxes according to the preamble of

Klappschachteln für einen Zigarettenblock als Packungsinhalt bestehen üblicherweise aus einem einstückigen Zuschnitt zur Bildung eines Schachtelteils und eines Deckels. Ein innerhalb des Schachtelteils angeordneter, aus diesem teilweise herausragender Kragen besteht aus einem gesonderten Zuschnitt.Folding cartons for a cigarette block as package contents usually consist of a one-piece blank to form a box part and a lid. An arranged within the box part, this partially outstanding collar consists of a separate blank.

Bei der üblichen Herstellung derartiger Klappschachteln wird der Zuschnitt für Schachtelteil und Deckel in eine Tasche eines Faltrevolvers eingeführt und dabei teilweise gefaltet. In den so vorbereiteten Zuschnitt in der Tasche des Faltrevolvers wird der Zigarettenblock eingeführt, und zwar zusammen mit dem Kragen, der auf dem Zigarettenblock positioniert ist. Die Packung kann Stützanschläge im Bereich von Seitenwänden enthalten, auf denen sich untere Kanten des Kragens zur Ausrichtung abstützen (

Bei der Herstellung von Klappschachteln für Zigaretten in einer besonderen Gestaltung, nämlich mit insgesamt gerundeten, annähernd halbkreisförmigen Seitenwänden besteht die Packung aus zwei Zuschnitten, die aneinander liegend gemeinsam um einen die Querschnittsform der Packung aufweisenden Faltdorn in einem Wickelverfahren gefaltet werden. Ein Innenzuschnitt, der sich über die volle Höhe der Packung erstreckt, ist im Bereich einer Vorderwand mit einer einem Kragen entsprechenden Ausnehmung versehen (

Ein weiteres Faltverfahren ist aus

Die Erfindung befasst sich mit der Herstellung von Klappschachteln, die einen üblichen Kragen bzw. einen Kragen mit Vorderwand und Seitenwänden aufweisen, der mit einem Teilbereich im Schachtelteil der Packung verankert ist, jedoch ohne Abstützung auf einer Bodenwand.The invention relates to the production of hinged boxes having a conventional collar or collar with front wall and side walls, which is anchored to a portion in the box part of the pack, but without support on a bottom wall.

Der Erfindung liegt die Aufgabe zugrunde, die Herstellung derartiger Klappschachteln für Zigaretten hinsichtlich einer korrekten, zuverlässigen Positionierung des Kragens innerhalb der Packung zu verbessern.The invention has for its object to improve the production of such folding cartons for cigarettes in terms of a correct, reliable positioning of the collar within the pack.

Zur Lösung dieser Aufgabe dient ein Verfahren mit den Merkmalen des Kennzeichens des Anspruchs 1.To solve this problem is a method with the features of the characterizing part of

Erfindungsgemäß wird demnach der positionsgenau durch Klebung mit dem Zuschnitt für Schachtelteil und Deckel zu einer Einheit verbundene Kragen als Einheit unter Teilfaltung in die Tasche eines Revolvers eingeführt. Der Zigarettenblock wird ohne Kragen geliefert.According to the invention therefore the positionally accurate by gluing with the blank for box part and lid connected to a unit collar is introduced as a unit with partial folding in the pocket of a revolver. The cigarette block is delivered without collar.

Die Vorrichtung ist mit den Merkmalen des Anspruchs 6 ausgebildet. Es geht um die Zuführung der separaten Packungsteile, nämlich Zuschnitt und Kragen, und die Zusammenführung vor Übergabe an den Faltrevolver.The device is formed with the features of claim 6. It is about the supply of separate packaging parts, namely blank and collar, and the merger before handover to the folding turret.

Weitere Merkmale der Erfindung sind Gegenstand der Unteransprüche 2 bis 5 für das Verfahren sowie der Ansprüche 7 bis 13 für die Vorrichtung.Further features of the invention are the subject of the dependent claims 2 to 5 for the method and the claims 7 to 13 for the device.

Weitere Besonderheiten der Erfindung werden nachfolgend anhand der Zeichnung näher erläutert. Es zeigt:

- Fig. 1

- einen ausgebreiteten Zuschnitt, nämlich Packungs-Zuschnitt,

- Fig. 2

- einen ausgebreiteten Kragen-Zuschnitt,

- Fig. 3

- die in packungsgemäßer Relativstellung aneinander liegenden Zuschnitte gemäß

Fig. 1 und Fig. 2 , - Fig. 4

- eine mit dem erfindungsgemäßen Verfahren herstellbare Klappschachtel des Typs Side-Lid in perspektivischer Darstellung, bei geschlossenem Deckel,

- Fig. 5

- die Packung gemäß

Fig. 4 bei offenem Deckel, ebenfalls in Perspektive, - Fig. 6

- die Vorrichtung zum Herstellen von Packungen gemäß

Fig. 4, Fig. 5 in ver- einfachter Draufsicht, - Fig. 7

- eine Einzelheit der Vorrichtung gemäß

Fig. 6 in einem Quer- bzw. Radial- schnitt entsprechend Schnittebene VII-VII derFig. 6 , bei vergrößertem Maßstab, - Fig. 8

- einen gegenüber der Darstellung gemäß der

Fig. 7 versetzten Querschnitt in der Schnittebene VIII-VIII derFig. 6 , bei nochmals vergrößertem Maß- stab, - Fig. 9

- eine Einzelheit im Bereich einer Beschickungsstation eines Faltrevolvers in Queransicht bzw. im Querschnitt,

- Fig. 10

- Detail der

Fig. 9 in quer gerichteter Schnittebene X-X derFig. 9 bei vergrö- ßertem Maßstab, - Fig. 11

- eine Einzelheit XI der

Fig. 8 in vergrößertem Maßstab, bei veränderter Stel- lung von Organen, - Fig. 12

- den Faltrevolver der Vorrichtung gemäß

Fig. 6 in Draufsicht, bei vergrößer- tem Maßstab, - Fig. 13

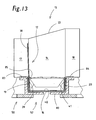

- eine Tasche des Faltrevolvers gemäß

Fig. 12 im Querschnitt in der Schnitt- ebene XIII-XIII derFig. 12 bei vergrößertem Maßstab, - Fig. 14

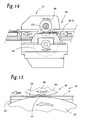

- eine Einzelheit der

Fig. 6 , nämlich eine Seitenansicht bzw. ein Längsschnitt in der Ebene XIV-XIV derFig. 6 , bei vergrößertem Maßstab, - Fig. 15

- eine Einzelheit XV der

Fig. 14 bei nochmals vergrößertem Maßstab.

- Fig. 1

- an unfolded blank, namely package blank,

- Fig. 2

- a spread collar blank,

- Fig. 3

- in accordance with the pack relative position blanks according to

Fig. 1 and Fig. 2 . - Fig. 4

- a folding box of the type side-lid, which can be produced by the method according to the invention, in perspective view, with the lid closed,

- Fig. 5

- the pack according to

Fig. 4 with the lid open, also in perspective, - Fig. 6

- the apparatus for producing packages according to

Fig. 4, Fig. 5 in simplified plan view, - Fig. 7

- a detail of the device according to

Fig. 6 in a transverse or radial section corresponding to sectional plane VII-VII ofFig. 6 on an enlarged scale, - Fig. 8

- one opposite to the representation according to the

Fig. 7 offset cross-section in the sectional plane VIII-VIII ofFig. 6 at a further enlarged scale, - Fig. 9

- a detail in the area of a loading station of a folding turret in transverse view or in cross section,

- Fig. 10

- Detail of

Fig. 9 in a cross-sectional plane XX of theFig. 9 on an enlarged scale, - Fig. 11

- a detail XI the

Fig. 8 on an enlarged scale, with altered position of organs, - Fig. 12

- the folding turret of the device according to

Fig. 6 in plan view, on an enlarged scale, - Fig. 13

- a pocket of the folding turret according to

Fig. 12 in cross-section in the sectional plane XIII-XIII ofFig. 12 on an enlarged scale, - Fig. 14

- a detail of

Fig. 6 , namely a side view and a longitudinal section in the plane XIV-XIV ofFig. 6 on an enlarged scale, - Fig. 15

- a detail XV of the

Fig. 14 at a further enlarged scale.

Es geht bei der Erfindung vor allem um die Fertigung von Zigarettenpackungen des Typs Klappschachtel in der Ausführung "Side-Lid-Pack". Die Packung besteht aus einem (unteren) Schachtelteil 1 0, einem Deckel 11 und einem Kragen 12. Schachtelteil 10 und Deckel 11 sind aus einem einheitlichen bzw. einstückigen Zuschnitt 13 aus dünnem Karton oder ähnlichem Verpackungsmaterial gebildet. Der Kragen 12 besteht aus einem eigenständigen Zuschnitt (

Der langgestreckte Zuschnitt 13 ist durch Stanzlinien und vorzugsweise geprägte Faltlinien in Felder aufgeteilt zur Bildung einer Schachtel-Vorderwand 14, einer Bodenwand 15, einer Schachtel-Rückwand 16. An der Schachtel-Vorderwand 14 sind Schachtel-Seitenlappen 17, 18 seitlich angebracht. Diese sind entsprechenden, innen liegenden Schachtel-Seitenlappen 19, 20 im Bereich der Schachtel-Rückwand 16 zugeordnet.The elongate blank 13 is divided into panels by stamping lines and preferably embossed fold lines to form a

In entsprechender Weise ist ein an die Schachtel-Rückwand 16 anschließender Zuschnittbereich für den Deckel 11 ausgebildet, nämlich mit Deckel-Rückwand 21, Stirnwand 22 und Deckel-Vorderwand 23. Auch im Bereich dieser dem Deckel 11 zugeordneten Zuschnittbereiche sind Seitenlappen angeordnet, nämlich Deckel-Seitenlappen 24, 25 im Bereich der Deckel-Rückwand 21 sowie Deckel-Seitenlappen 26, 27 an den Seiten der Deckel-Vorderwand 23. Der Zuschnitt 13 ist demnach zur Anwendung des Längsfaltprinzips ausgebildet.In a corresponding manner, a blank area adjoining the box

Bei der fertigen Packung bzw. Klappschachteln liegen die Schachtel-Seitenlappen 17 und 19 sowie 18 und 20 unter vollständiger Überdeckung aneinander unter Bildung einer Schachtel-Seitenwand 28. Entsprechend sind die Schachtel-Seitenlappen 18 und 20 zur Überdeckung gefaltet und miteinander durch Leim verbunden zur Bildung einer gegenüberliegenden Schachtel-Seitenwand. Aus den Deckel-Seitenlappen 24..27 werden Deckel-Seitenwände 30 und 31 gebildet.In the finished package, the box side flaps 17 and 19, and 18 and 20 are fully overlapped to form a

Eine Besonderheit besteht darin, dass der Deckel 11 im Bereich einer Seitenwand über ein Gelenk, nämlich über ein Liniengelenk 32, klappbar mit dem Schachtelteil 10 verbunden ist. Zu diesem Zweck sind die innen liegenden Seitenlappen, nämlich Schachtel-Seitenlappen 20 der Schachtel-Rückwand 16 und Deckel-Seitenlappen 25 an der Deckel-Rückwand 21 miteinander verbunden und durch ein durch Prägung oder auf andere Weise gebildetes Liniengelenk 32 voneinander abgegrenzt. Außerhalb dieses Liniengelenks 32 sind Deckel 11 und Schachtelteil 10 durch Schließkanten voneinander abgegrenzt, die - ausgehend von den Enden des Liniengelenks 32 - zur gegenüberliegenden Seite, nämlich zur Schachtel-Seitenwand 28 hin abwärts geneigt sind. Im Bereich der Schachtel-Vorderwand 14 und Deckel-Vorderwand 23 bestehen die Schließkanten aus freien, schräg gerichteten Endkanten 33, 34 des Zuschnitts 13. Gegenüberliegend, nämlich im Bereich der Rückseite, sind Schachtel-Rückwand 16 und Deckel-Rückwand 21 trennbar miteinander verbunden, und zwar durch eine schräg gerichtete Stanzlinie 35 und Restverbindungen 36. Diese gewährleisten einen einheitlichen Zuschnitt 10 für die Fertigung der Packung. Beim erstmaligen Öffnen durch Anheben des Deckels 11 werden die Restverbindungen 36 durchtrennt, so dass die Stanzlinie 35 eine durchgehende Trennung zwischen Schachtelteil 10 und Deckel 11 bildet. Im Bereich von Schachtel-Seitenwand 28 und Deckel-Seitenwand 30 bzw. im Bereich von Schachtel-Seitenlappen 19 und Deckel-Seitenlappen 24 ist ein durchgehender Trennschnitt 37 angebracht, so dass im Bereich der entsprechenden Seitenwände 28, 30 Schachtelteil 10 und Deckel 11 voneinander getrennt sind.A special feature is that the

Der Kragen 12 ist so ausgebildet, dass der Packungsinhalt, im vorliegenden Falle ein Zigarettenblock 37, also eine von einem Innenzuschnitt umgebene Zigarettengruppe, ringsherum von dem Kragen 12 umgeben ist. Der Kragen 12 besteht zu diesem Zweck aus Kragen-Vorderwand 38, anschließender Kragen-Seitenwand 39, Kragen-Rückwand 40 und einer randseitigen Kragen-Seitenwand 41. Etwa in der Mitte der Kragen-Seitenwand 39, die innerhalb des Kragens 12 zwischen Vorderwand 38 und Rückwand 40 positioniert ist, befindet sich eine Ausnehmung 42, die sich bei der fertigen Packung (

Als Besonderheit der Packung ist eine Schließhilfe für den Deckel 11 im Bereich der Deckel-Seitenwand 30 angeordnet. Diese besteht aus einer Lasche bzw. Zunge 43 an der unteren Schließkante des Deckels 11 bzw. der Deckel-Seitenwand 30. Ein mit dieser Zunge 43 zusammenwirkendes Gegenorgan ist am Kragen 12 in passender Relativstellung zur Zunge 43 gebildet. Es handelt sich dabei um eine Ausnehmung in der Kragen-Seitenwand 39, in die die Zunge 43 bei geschlossenem Deckel 11 in aufwärts gerichteter Position eintritt. Die Ausnehmung ist in diesem Falle durch eine U- bzw. C-förmige Stanzung 44 gebildet unter Bildung einer nach oben gerichteten Lasche 45. Diese ist um eine quergerichtete, untere Linie 46 schwenkbar. Die Lasche 45 wird bei der Fertigung der Packung leicht nach innen verformt, so dass ein U-förmiger Schlitz für den Eintritt der Zunge 43 entsteht.As a special feature of the pack, a closing aid for the

Eine Besonderheit ist die Fertigung der Packung aus zwei gesonderten Zuschnitten. Diese werden in ungefaltetem Zustand bzw. nach Umfalten lediglich der Zunge 43 gegen die Innenseite des Deckel-Seitenlappens 26 zu einer Einheit zusammengeführt, indem der Kragen 12 in packungsgemäßer Relativstellung auf den Zuschnitt 10 (Innenseite) aufgelegt wird. Bei dem konkreten Ausführungsbeispiel liegt der Kragen 12 mit der Kragen-Rückwand 40 ausgerichtet auf der Schachtel-Rückwand 16. Die benachbarte Kragen-Seitenwand 41 liegt am (inneren) Schachtel-Seitenlappen 20 und die gegenüberliegende Kragen-Seitenwand 39 an dem anderen Schachtel-Seitenlappen 19 an. Die Kragen-Vorderwand 38 ragt seitlich über den Zuschnitt 10 hinaus. Die Relativstellung ist so gewählt, dass ein oberer Teil des Kragens 12 im Bereich des Deckels 11 liegt und so bei der fertigen Packung aus dem Schachtelteil 10 hinausragt (

Die exakte Position des Kragens 12 auf bzw. an dem Zuschnitt 13 ist durch Anschläge 81, 82 gewährleistet. In einem seitlichen Bereich des Zuschnitts 13 sind zwei Anschläge 81, 82 gebildet, und zwar im Schachtel-Seitenlappen 20 einerseits und im Schachtel-Seitenlappen 19 andererseits. Es handelt sich dabei um Materialverformungen, die durch Stanzen und Prägen gebildet sind, sodass eine Anschlagkante durch die Anschläge 81, 82 gebildet ist, an der eine (untere) Kante des Kragens 12 anliegt, und zwar ein unterer Rand der Kragen-Seitenwand 41 einerseits und der Kragen-Seitenwand 39 andererseits. Die Anschläge 81, 82 werden durch grundsätzlich bekannte Stanz- und Prägewerkzeuge angebracht.The exact position of the

Der Kragen 12 ist in der packungsgemäßen Positionierung am Zuschnitt 13 durch Klebung fixiert, im vorliegenden Falle durch eine quergerichtete Reihe von Leimpunkten 48, die sich über die volle Breite des Zuschnitts 10 erstrecken mit mindestens jeweils einem Leimpunkt 48 im Bereich der Schachtel-Seitenlappen 19, 20. Weitere Leimpunkte 49 dienen zur Fixierung des Zigarettenblocks 37 in der Packung.The

Die in

In bekannter Weise werden Zigaretten zur Bildung von Zigarettengruppen 53 einem Zigarettenmagazin 54 entnommen und entlang einer Zigarettenbahn in Radialrichtung dem Faltrevolver 50 zugeführt. Im Bereich der Zigarettenbahn wird die Zigarettengruppe 53 in einen Innenzuschnitt aus Papier oder Stanniol eingehüllt unter Bildung des Zigarettenblocks 37. Dieser wird in einer Einschubstation 55 in die dort bereitgehaltene Tasche 52 (mit Zuschnitt 13, 12) eingeführt. Auf der gegenüberliegenden Seite des Faltrevolvers 50 befindet sich eine Ausschubstation 56 zur Übergabe der weitgehend fertig gestellten Packungen an eine radial abführende Packungsbahn 57. Die Zuschnitte 13 werden so transportiert, dass die Seite mit der Zunge 43 nach vorn gerichtet ist. Während des Transports wird die Zunge 43 gegen die Innenseite des Deckel-Seitenlappens 26, also nach oben, umgefaltet.In a known manner, cigarettes for forming groups of

Eine Besonderheit ist die Zuführung der Einzelzuschnitte und Übergabe der Zuschnitteinheit an eine Tasche 52 im Bereich einer Einführungsstation 58. Diese ist um 90° versetzt zu den Stationen 55, 56, also quer zur Förderrichtung der Zigarettengruppen und Packungen angeordnet. Die Zuschnitte 13 werden entlang einer diametral zum Faltrevolver 50 geführten Zuschnittbahn 59 oberhalb des Revolvers 50 zur Einführungsstation 58 gefördert. Die Zuschnitte 13 werden zu diesem Zweck einem Zuschnittmagazin 60 einzeln entnommen und dann in an sich bekannter Weiser entlang der Zuschnittbahn 59 bis in eine definierte Position oberhalb der Tasche 52 transportiert.A special feature is the feeding of the individual blanks and transfer of the cutting unit to a

Die Kragen 12 werden auf einer gesonderten Bahn, nämlich Kragenbahn 61, der Einführungsstation 58 bzw. dem zugeordneten Zuschnitt 13 zugeführt, und zwar in einer zur Zuschnittbahn 59 entgegengesetzten Förderrichtung. Des Weiteren ist die Kragenbahn 61 versetzt zur Zuschnittbahn 59 angeordnet, so dass die Kragen 12 in einer Position neben dem bereitgehaltenen Zuschnitt 13 ankommen.The

Die Zuschnittbahn 59 ist oberhalb des Faltrevolvers 50 im Wesentlichen in einer abwärts geneigten Ebene angeordnet. Die Kragenbahn 61 verläuft in einer in Förderrichtung aufwärts geneigten Ebene, und zwar der Höhe nach geringfügig nach oben versetzt zur Zuschnittbahn 59. Die Kragenbahn 61 schließt an ein Kragenaggregat 62 außerhalb bzw. neben der Verpackungsmaschine an. Im Bereich des Kragenaggregats 62 werden von einer Materialbahn die einzelnen Kragen 12 abgetrennt und in die Kragenbahn 61 eingeführt. Diese besteht im Bereich des Kragenaggregats 62 aus Förderrollen, im Bereich der Verpackungsmaschine im Wesentlichen aus (zwei Paaren von) übereinander liegenden Fördergurten 63, 64. Zwischen deren Fördertrumen werden die Kragen 12 zunächst in Dichtlage, schließlich mit Abständen voneinander transportiert.The

Am Ende der Kragenbahn 61 läuft der Kragen 12 gegen einen Anschlag, der eine exakte Querausrichtung auf den daneben und in einer nach unten versetzten Ebene bereitgehaltenen Zuschnitt 13 bewirkt. Im Bereich der Einführungsstation 58 ist eine besondere Krageneinheit gebildet. Diese besteht aus einer Endplatte 65, die sich in Querrichtung bis in den Bereich der Fördergurte 63, 64 erstreckt. Die Endplatte 65 bildet den justierenden Anschlag für den Kragen 12, und zwar hier als im Querschnitt U-förmiges, quer verlaufendes Führungsprofil 66.At the end of the

Der Zuschnitt 13 wird in der Einführungsstation 58 oberhalb eines durch Formkörper definierten Faltschachts 67 bereitgehalten. Dieser befindet sich im Endbereich der Zuschnittbahn 69. Der Zuschnitt 13 wird in einer dem nachfolgenden Faltvorgang entsprechenden Relativstellung in seitlichen Führungen 68 in genauer Ausrichtung auf die sich unterhalb des Faltschachts 67 befindende Tasche 52 ausgerichtet.The blank 13 is held in the

Der Kragen 12 wird am Ende der Kragenbahn 61 auf der Endplatte 65 in Querrichtung verschoben. Hierzu dient ein besonderer Schieber 69. Dieser ist mit einem Halteorgan zum Erfassen des Kragens 12 versehen, nämlich mit einem Sauger 70, der über eine Saugleitung 71 an eine Unterdruckquelle angeschlossen ist. Der Schieber 69 erfasst den Kragen 12 mit dem Sauger 70 an der Oberseite. Durch eine Querbewegung wird der Kragen 12 in eine ausgerichtete Position oberhalb des Zuschnitts 13 bewegt. Ein Queranschlag 72 bestimmt die Stellung des Kragens 12. Der Schieber 69 kehrt nach dem Ablegen des Kragens 12 in einer leicht erhöhten Bewegungsbahn in die Ausgangsstellung zur Übernahme des nächsten Kragens 12 zurück. Eine geschlossene Bewegungsbahn 73 des Schiebers 69 ist durch strichpunktierte Linie gezeigt.The

Zuschnitt 13 und Kragen 12 befinden sich nun in packungsgerechter Stellung über dem Faltschacht 67, zunächst mit Abstand voneinander (

Die Zuführung der Kragen 12 in einer zur Faltstellung versetzten Kragenbahn 61 berücksichtigt die in der Einführungsstation 58 vorhandenen Faltorgane, insbesondere die auf- und abbewegbare Faltplatte 74. Diese ist so ausgebildet, dass der Schieber 69 den Kragen 12 jeweils in die Faltposition oberhalb des Faltschachts 67 transportieren kann. Die Faltplatte 74 weist zu diesem Zweck eine seitliche Ausnehmung 77 auf, in die der Schieber 69 in der Endposition oberhalb des Faltschachts 67 eintritt (

Durch die Ausbildung der Faltplatte 74 mit Ausnehmung 77 und glockenartiger, jedenfalls erhöhter Abdeckung 78, kann der Schieber 69 in der Endstellung vom Kragen 12 gelöst werden, wobei dieser durch die Bereiche der Faltplatte 74 außerhalb der Ausnehmung 77 in der Position oberhalb des Zuschnitts 13 fixiert wird. Für den Schieber 69 besteht ein ausreichender Raum, um in einer abgehobenen Position in die Ausgangsstellung zurückzukehren, bevor die Faltplatte 74 abwärts bewegt wird.Due to the design of the

Nach Zurückziehen des Schiebers 69 in die Ausgangsstellung wird die Faltplatte 74 abwärts bewegt, und zwar durch einen ortsfesten Schwenkhebel 79. Die Faltplatte 74 drückt den Zuschnitt 13 mit Kragen 12 bis zur Auflage auf einem Taschenboden 80 der Tasche 52 (

Der Faltrevolver 50 fördert die Tasche 52 ohne wesentliche Veränderung der Faltlappen in die Einschubstation 55. Der Zigarettenblock 37 wird in Radialrichtung in die Tasche 52 eingeschoben, wobei die Zuschnitte im Querschnitt die aus

Die Tasche 52 ist mit Halteorganen für den (teilweise gefalteten) Zuschnitt 13 einschließlich Kragen 12 versehen. Es handelt sich dabei um Haltezungen 83, 84, die am oberen Rand der U-förmigen Tasche 52 angeordnet sind und an nach oben gerichteten Kanten gefalteter Lappen des Zuschnitts 13 sowie des Kragens 12 anliegen. Die Haltezunge 84 liegt an den freien Kanten des Schachtel-Seitenlappens 20 und der Kragen-Seitenwand 41 an. Die Haltezunge 83 befindet sich im Bereich der aufgerichteten Kragen-Vorderwand 38. Der Kragen 12 ist so ausgebildet, dass die Haltezunge 83 an Kanten des Zuschnitts 13 und des Kragens 12 anliegt. Hierzu dient eine Stanzlinie 85, die im Bereich einer Faltlinie zwischen Kragen-Vorderwand 38 und Kragen-Seitenwand 39 gebildet ist als zum Rand freier Einschnitt. Aufgrund entsprechender Verformung gelangt die angeschärfte Haltezunge 83 in die Anlagestellung zur Fixierung der Einheit.The

Im Anschluss an die Einschubstation 55 werden bei fortgesetzter Drehbewegung des Faltrevolvers 50 weitere Faltlappen gefaltet. Der aufgerichtete Teil des Kragens 12, nämlich die Kragen-Vorderwand 38, befindet sich in Bewegungsrichtung des Faltrevolvers 50 an der Vorderseite der Tasche 52. Durch ein ortsfestes Faltorgan (nicht gezeigt) wird durch die Drehbewegung des Faltrevolvers 50 die aufgerichtete Kragen-Vorderwand 38 gegen die Oberseite des Zigarettenblocks 37 gefaltet. Danach werden die aufgerichteten Bereiche des Zuschnitts 13, insbesondere die Schachtel-Vorderwand 14, ebenfalls gegen die Oberseite des Zigarettenblocks 37 bzw. gegen die Kragen-Vorderwand 38 gefaltet.Subsequent to the

Die weitgehend fertiggestellte Packung wird im Bereich der Ausschubstation 56 aus dem Faltrevolver 50 ausgeschoben und an die Packungsbahn 57 übergeben. Im Bereich dieser Packungsbahn 57 befindet sich eine Leimstation 86 zum Aufbringen von Leim auf die Unterseite der seitwärts gerichteten Faltlappen, nämlich der Schachtel-Seitenlappen 17, 18 sowie der Deckel-Seitenlappen 26, 27. Diese werden danach bis zur Anlage an den bereits gefalteten inneren Seitenlappen 19, 20, 24, 25 umgefaltet.The largely completed pack is pushed out of the

Die Leimstation 86 ist mit einer unteren Leimwalze 87 versehen, die in einen Leimtopf eintaucht und infolge Drehbewegung Leim auf die Unterseite der Faltlappen überträgt. Die Leimwalze 87 wirkt zusammen mit einer oberhalb der Bewegungsbahn der Faltlappen angeordneten Andrückwalze 88. Diese ist mit einer Ausnehmung 89 an ihrem Umfang versehen. Die Ausnehmung 89 befindet sich im Bereich der in die Raststellung umgefalteten Zunge 43, nämlich an der Unterseite des mit Leim zu versehenen Deckel-Seitenlappens 26. Die Zunge 43 ist bereits im Bereich der Zuschnittbahn 59 in die Wirkstellung gemäß

Erfindungsgemäß werden die zu vereinigenden Zuschnitte, nämlich Zuschnitte 13 und Kragen 12, vor der Einführung in den Faltrevolver zu einer Einheit zusammengeführt. Bei dieser Methode wird der Kragen 12 an dem Zuschnitt 13 in der packungsgemäßen Relativstellung angebracht und mit dem Zuschnitt 13 durch Klebung, vorzugsweise durch Leim verbunden, sodass eine hinsichtlich der Relativstellung fixierte Einheit in den Faltrevolver eingeführt werden kann. Des Weiteren erfolgt eine Zusammenführung von Zuschnitt 13 und Kragen 12 vorab, sodass diese als Einheit dem Faltrevolver zugeführt werden.According to the blanks to be united, namely

- 1010

- Schachtelteilbox part

- 1111

- Deckelcover

- 1212

- Kragencollar

- 1313

- Zuschnittcut

- 1414

- Schachtel-VorderwandBox front wall

- 1515

- Bodenwandbottom wall

- 1616

- Schachtel-RückwandBox rear wall

- 1717

- Schachtel-SeitenlappenBox side tabs

- 1818

- Schachtel-SeitenlappenBox side tabs

- 1919

- Schachtel-SeitenlappenBox side tabs

- 2020

- Schachtel-SeitenlappenBox side tabs

- 2121

- Deckel-RückwandLid rear wall

- 2222

- Stirnwandbulkhead

- 2323

- Deckel-VorderwandLid front wall

- 2424

- Deckel-SeitenlappenLid side tabs

- 2525

- Deckel-SeitenlappenLid side tabs

- 2626

- Deckel-SeitenlappenLid side tabs

- 2727

- Deckel-SeitenlappenLid side tabs

- 2828

- Schachtel-SeitenwandBox side wall

- 2929

- Schachtel-SeitenwandBox side wall

- 3030

- Deckel-SeitenwandLid sidewall

- 3131

- Deckel-SeitenwandLid sidewall

- 3232

- Liniengelenkline joint

- 3333

- Endkanteend edge

- 3434

- Endkanteend edge

- 3535

- Stanzliniecut line

- 3636

- Restverbindungresidual connection

- 3737

- Zigarettenblockcigarette block

- 3838

- Kragen-VorderwandCollar front wall

- 3939

- Kragen-SeitenwandCollar side wall

- 4040

- Kragen-RückwandCollar rear wall

- 4141

- Kragen-SeitenwandCollar side wall

- 4242

- Ausnehmungrecess

- 4343

- Zungetongue

- 4444

- Stanzungpunching

- 4545

- Lascheflap

- 4646

- Linieline

- 4747

- Ausnehmungrecess

- 4848

- Leimpunktspot of glue

- 4949

- Leimpunktspot of glue

- 5050

- Faltrevolverfolding turret

- 5151

- Wellewave

- 5252

- Taschebag

- 5353

- Zigarettengruppecigarette group

- 5454

- Zigarettenmagazincigarette magazine

- 5555

- Einschubstationinsertion station

- 5656

- Ausschubstationout station

- 5757

- Packungsbahnpacking sheet

- 5858

- Einführungsstationintroduction station

- 5959

- Zuschnittbahnblank path

- 6060

- Zuschnittmagazinblank magazine

- 6161

- Kragenbahncollar Bahn

- 6262

- Kragenaggregatcollar subassembly

- 6363

- Fördergurtconveyor belt

- 6464

- Fördergurtconveyor belt

- 6565

- Endplatteendplate

- 6666

- Führungsprofilguide profile

- 6767

- Faltschachtfolding shaft

- 6868

- Führungguide

- 6969

- Schieberpusher

- 7070

- Saugersucker

- 7171

- Saugleitungsuction

- 7272

- Queranschlagcross stop

- 7373

- Bewegungsbahntrajectory

- 7474

- Faltplattefaltplatte

- 7575

- Faltführungfolding guide

- 7676

- Faltführungfolding guide

- 7777

- Ausnehmungrecess

- 7878

- Abdeckungcover

- 7979

- Schwenkhebelpivoting lever

- 8080

- Taschenbodenpocket base

- 8181

- Anschlagattack

- 8282

- Anschlagattack

- 8383

- Haltezungeholding tongue

- 8484

- Haltezungeholding tongue

- 8585

- Stanzliniecut line

- 8686

- Leimstationgluing station

- 8787

- Leimwalzeglue roller

- 8888

- Andrückwalzepressure roller

- 8989

- Ausnehmungrecess

Claims (13)

- Method for producing hinge-lid boxes with a box part (10), lid (11) and collar (12) for a cigarette block (37), wherein the box part (10) and lid (11) form a joint, single-piece blank (13) and the collar (12) comprises a separate blank, wherein:a) the collar (12) is positioned in a pack-appropriate position relative to the non-folded blank (13) and is connected to the blank (13) by adhesive bonding to form a unit, andb) the unit comprising the blank (13) with collar (12) is fed to an introduction station (58) of a folding turret (50),characterized by the following feature:c) the unit made up of the blank (13) and collar (12) is then introduced jointly into a pocket (52) of the folding turret (50), with the blank (13) and the collar (10) being partially folded at the same time.

- Method according to Claim 1, characterized in that the collar (12) is connected to the blank (13) by a transversely directed row of spots of glue (48), with at least in each case one spot of glue (48) in the region of side box flaps (19, 20) of the blank (13).

- Method according to Claim 1, characterized by the following features:a) the blanks (13), on the one hand, and collars (12), on the other hand, are fed to the introduction station (58) on separate paths, namely a blank path (59), on the one hand, and a collar path (61), on the other hand,b) in the region of the introduction station (58), the blank (13) and collar (12) are guided into abutment against one another in a pack-appropriate position relative to one another,c) the blank (13) and collar (12) are then introduced jointly, as an adhesively bonded unit, into a pocket (52) of the folding turret (50).

- Method according to Claim 3, characterized by the following features:a) the blank path (59) and collar path (61) are spaced apart from one another or offset in the conveying direction,b) in the region of the introduction station (58), the collar (12) is conveyed by transverse movement into the pack-appropriate position relative to the blank (13), in particular in a plane at a small distance above the blank (13).

- Method according to Claim 1 or 3, characterized in that the collar is positioned in an offset manner on the inside of the blank (13) such that a front collar wall projects laterally beyond the blank (13), wherein the blank (13) and collar (12) are positioned in the pocket (52) of the folding turret (50) such that the front collar wall (38), which is upright following introduction into the pocket (52), is arranged on the front side of the pocket (52), as seen in the direction of rotation.

- Apparatus for producing hinge-lid boxes for, in particular, a cigarette block (37), comprising a box part (10), lid (11) and collar (12), characterized by the following features:a) blanks (13), on the one hand, and collars (12), on the other hand, can be fed along separate conveying paths, namely a blank path (59) and collar path (61), to a joint introduction station (58) above a folding turret (50), preferably in opposite conveying directions,b) the blank path (59) extends right up to the introduction station (58), the blank (13) being aligned above the pocket (52) of the folding turret (50),c) the collar path (61) extends in an offset manner in relation to the blank path (59), preferably in a slightly higher conveying plane,d) in the region of the introduction station (58), the collar (12) can be conveyed by transverse movement into a pack-appropriate position at a small distance above the blank (13),e) the collar (12) and blank (13) can be introduced into the associated pocket (52) by a joint folding mechanism, in particular by a downwardly moveable folding plate (74).

- Apparatus according to Claim 6, characterized in that the collars (12), which have been separated off from a web, can be transported by conveying belts (63, 64) at least in a sub-region of the collar path (61), and in that the collar (12) can be conveyed along the collar path (61) up to an end stop and then can be displaced by transverse movement along the end stop into the pack-appropriate position above the blank (13), preferably on an end plate (65) of the transversely directed guide profile (66) as the end stop.

- Apparatus according to Claim 6 or 7, characterized in that the collar (12) can be moved transversely by a pusher (69) out of the region of the collar path (61) into the position above the blank (13), preferably by way of a sucker (70) which is arranged on the pusher (69) and is intended for gripping the collar (12) on the top side.

- Apparatus according to Claim 8, characterized in that the pusher (69) can be moved into the region of the folding mechanism, namely of the folding plate (74), wherein the folding plate (74) has a recess (77) into which the pusher (69) can enter temporarily during transverse transportation of the collar (12).

- Apparatus according to Claim 6 or one of the further apparatus claims, characterized in that a folding well (67) made of essentially upright folding guides (75, 76) is formed in the region of the introduction station (58), above the pocket (52) of the folding turret (50), wherein the folding well (67) or lateral folding guides (75) has or have guides (68) for the blank (13) and, slightly above, for the collar (12).

- Apparatus according to Claim 6 or one of the further apparatus claims, characterized in that the pocket (52) of the folding turret (50) has retaining mechanisms for the partially folded blank (13) including collar (12), that is to say retaining tongues (83, 84) which are arranged on an upper periphery of the cross-sectionally U-shaped pocket (52) and butt against upwardly directed edges of folded flaps of the blank (13) and of the collar (12).

- Apparatus according to Claim 6 or one of the further apparatus claims, characterized in that, after the blank (13) with collar (12) has been introduced into the pocket (52) and once the cigarette block (37) has been pushed in, an upright leg of the collar (12), namely the front collar wall (38), can be folded against the upper side of the cigarette block (37) by a fixed-location folding mechanism, by way of rotary movement of the folding turret (50).

- Apparatus according to Claim 6 or one of the further apparatus claims, characterized in that the largely completed pack can be pushed out of the folding turret (50) and into a following pack path (57), wherein a glue subassembly with a glue roller (87) at the bottom and a pressure-exerting roller (88) at the top is arranged in the region of the pack path (57), the pressure-exerting roller (88) having a recess (89) in the region of the folded tongue (43).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102006021991A DE102006021991A1 (en) | 2006-05-10 | 2006-05-10 | Folding box for cigarettes and method and apparatus for producing the same |

| PCT/EP2007/003715 WO2007128435A2 (en) | 2006-05-10 | 2007-04-27 | Folding box for cigarettes, and method and device for the production thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2016008A2 EP2016008A2 (en) | 2009-01-21 |

| EP2016008B1 true EP2016008B1 (en) | 2010-11-03 |

Family

ID=38137362

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07724645A Ceased EP2016008B1 (en) | 2006-05-10 | 2007-04-27 | Method and device for the production of hinge-lid boxes for cigarettes |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP2016008B1 (en) |

| DE (2) | DE102006021991A1 (en) |

| WO (1) | WO2007128435A2 (en) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102008005407A1 (en) | 2008-01-21 | 2009-07-23 | Focke & Co.(Gmbh & Co. Kg) | Method and device for producing packages for cigarettes |

| US7845490B2 (en) | 2008-01-28 | 2010-12-07 | Philip Morris Usa Inc. | Side opening pack blank design |

| DE102008010433A1 (en) * | 2008-02-21 | 2009-08-27 | Focke & Co.(Gmbh & Co. Kg) | Method and device for producing packages for folding box type cigarettes |

| ITMO20080104A1 (en) * | 2008-04-14 | 2009-10-15 | Marco Vecchi | MEANS OF CONNECTION FOR ARTICLES |

| DE102008026450A1 (en) | 2008-06-03 | 2009-12-10 | Focke & Co.(Gmbh & Co. Kg) | Method and device for producing blanks for cigarette packets |

| DE102008027258A1 (en) | 2008-06-06 | 2009-12-10 | Focke & Co.(Gmbh & Co. Kg) | Method and device for producing cigarette packets |

| GB2488595A (en) | 2011-03-04 | 2012-09-05 | British American Tobacco Co | Cigarette Pack with Recess and Locking Element |

| GB2498733A (en) | 2012-01-25 | 2013-07-31 | British American Tobacco Co | A Smoking Article Pack for Removing Articles Sideways |

| DE102013114642A1 (en) * | 2013-12-20 | 2015-06-25 | Focke & Co. (Gmbh & Co. Kg) | Method and device for producing a packaging for products of the cigarette industry |

| DE102014222994A1 (en) * | 2014-09-16 | 2016-03-17 | Focke & Co. (Gmbh & Co. Kg) | Pack for cigarettes |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4034538A (en) | 1973-09-05 | 1977-07-12 | Alfred Schmermund | Method and apparatus for producing a container |

| DE2440006C2 (en) * | 1974-08-21 | 1984-06-28 | Focke & Co, 2810 Verden | Method and device for the production of (cuboid) hinged boxes |

| DE2551427C2 (en) * | 1975-11-15 | 1987-02-19 | Focke & Co (GmbH & Co), 2810 Verden | Box with hinged lid |

| LU81675A1 (en) * | 1978-09-22 | 1979-12-07 | Reemtsma H F & Ph | FOLDED CAP BOX |

| DE3150447A1 (en) * | 1981-12-19 | 1983-06-30 | Focke & Co, 2810 Verden | DEVICE FOR IMPORTING CIGARETTE GROUPS IN CIGARETTE PACKS |

| CA2023664C (en) * | 1989-08-22 | 1997-03-18 | Klaus Peter Lamm | Flip-top cartons |

| DE3941844A1 (en) * | 1989-12-19 | 1991-06-20 | Focke & Co | METHOD AND DEVICE FOR PRODUCING (CIGARETTE) PACKS |

| GB9008398D0 (en) * | 1990-04-12 | 1990-06-13 | Tabac Fab Reunies Sa | Novel cigarette pack |

| DE4122900A1 (en) * | 1991-07-11 | 1993-01-14 | Focke & Co | Hinged lid cigarette packet - has internal protrusions on walls forming positioning stops for internal collar |

| DE4141678A1 (en) * | 1991-12-17 | 1993-07-01 | Focke & Co | CARDBOARD PACKING AND METHOD AND DEVICE FOR PRODUCING THE SAME |

| GB9412819D0 (en) * | 1994-06-25 | 1994-08-17 | Imp Tobacco Co Ltd | Packs for smoking articles |

| DE19637259A1 (en) * | 1996-09-13 | 1998-03-19 | Focke & Co | Cuboid packaging for cigarettes and blank for packaging |

| IT1309034B1 (en) * | 1999-03-09 | 2002-01-15 | Gd Spa | METHOD AND DEVICE FOR THE FORMATION OF A PACK OF CIGARETTES |

| DE19938167A1 (en) * | 1999-08-16 | 2001-02-22 | Focke & Co | Hinged box for cigarettes |

| DE19945514A1 (en) * | 1999-09-23 | 2001-03-29 | Focke & Co | Hinged box for cigarettes |

| DE10208189A1 (en) * | 2002-02-20 | 2003-09-04 | Schmermund Verpackungstechnik | Process for packaging cigarettes and pack of cigarettes |

| ATE335674T1 (en) * | 2002-08-01 | 2006-09-15 | Europoligrafico S P A | CARDBOARD BOX WITH A HINGED LID |

| ITBO20040532A1 (en) * | 2004-08-26 | 2004-11-26 | Aticarta S P A | RIGID WRAPPING FOR SMOKING ITEMS WITH HINGED COVER CONNECTED BY GLUING |

| KR100698156B1 (en) * | 2005-07-04 | 2007-03-22 | 엘지전자 주식회사 | The display device having the function of blocking recorded files partially and method for controlling the same |

-

2006

- 2006-05-10 DE DE102006021991A patent/DE102006021991A1/en not_active Withdrawn

-

2007

- 2007-04-27 WO PCT/EP2007/003715 patent/WO2007128435A2/en active Application Filing

- 2007-04-27 DE DE502007005561T patent/DE502007005561D1/en active Active

- 2007-04-27 EP EP07724645A patent/EP2016008B1/en not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| WO2007128435A3 (en) | 2008-01-03 |

| DE102006021991A1 (en) | 2007-11-15 |

| WO2007128435A2 (en) | 2007-11-15 |

| DE502007005561D1 (en) | 2010-12-16 |

| EP2016008A2 (en) | 2009-01-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2016008B1 (en) | Method and device for the production of hinge-lid boxes for cigarettes | |

| EP2125573B1 (en) | Method for producing packs of cigarettes | |

| EP2234891B1 (en) | Method for the production of packages for cigarettes | |

| EP3169592A1 (en) | Method and device for producing packages, in particular cigarette packages | |

| EP2311632B1 (en) | Cigarette packaging and method and device for producing same | |

| DE2440006A1 (en) | PROCESS AND DEVICE FOR MANUFACTURING AND FILLING FOLDABLE BOXES FROM FOLDABLE MATERIAL, PREFERABLY FOR CIGARETTES | |

| EP1829783B1 (en) | Device and method for producing double packages | |

| EP2562092A1 (en) | Method and device for manufacturing packaging for cigarettes | |

| EP3366595A1 (en) | Method and device for producing (cigarette) packages | |

| EP2130773B1 (en) | Device and method for manufacturing cigarette packages | |

| EP0550406A1 (en) | Method and device for making (cigarette) packages | |

| EP2560883B1 (en) | Apparatus and method for producing cigarette packets | |

| DE102006047812A1 (en) | Method and device for producing (cigarette) packages | |

| EP2746166B1 (en) | Method and device for manufacturing a package for cigarettes | |

| EP1023991B1 (en) | Method and machine for making packages for cigarettes | |

| EP2030896B1 (en) | Method and device for manufacturing hinged lid cigarette packages | |

| DE102015010493A1 (en) | Method and device for producing (cigarette) packs of the cap box type | |

| EP3248903B1 (en) | Package for cigarettes and method and device for producing same | |

| DE102016004930A1 (en) | Pack of cigarettes and method and apparatus for making same | |

| EP2690033B1 (en) | Hinged lid box | |

| EP3999431A1 (en) | Method and device for handling a blank made of a dimensionally stable material | |

| DE202015005169U1 (en) | Folding box for cigarettes | |

| DE4308659A1 (en) | Method and device for producing cigarette sticks | |

| DE2463378C2 (en) | Device for producing packs, in particular hinged boxes |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20081024 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| TPAC | Observations by third parties |

Free format text: ORIGINAL CODE: EPIDOSNTIPA |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RBV | Designated contracting states (corrected) |

Designated state(s): DE GB IT |

|

| 17Q | First examination report despatched |

Effective date: 20090831 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RTI1 | Title (correction) |

Free format text: METHOD AND DEVICE FOR THE PRODUCTION OF HINGE-LID BOXES FOR CIGARETTES |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE GB IT |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REF | Corresponds to: |

Ref document number: 502007005561 Country of ref document: DE Date of ref document: 20101216 Kind code of ref document: P |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20110804 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502007005561 Country of ref document: DE Effective date: 20110804 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20160427 Year of fee payment: 10 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20170427 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170427 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180426 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20180420 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502007005561 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190427 |