EP2005873A2 - Maschine und Waschverfahren für Geschirr und andere Waren - Google Patents

Maschine und Waschverfahren für Geschirr und andere Waren Download PDFInfo

- Publication number

- EP2005873A2 EP2005873A2 EP08158296A EP08158296A EP2005873A2 EP 2005873 A2 EP2005873 A2 EP 2005873A2 EP 08158296 A EP08158296 A EP 08158296A EP 08158296 A EP08158296 A EP 08158296A EP 2005873 A2 EP2005873 A2 EP 2005873A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- dishes

- washing

- ware

- washing machine

- centrifugal pumps

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L15/00—Washing or rinsing machines for crockery or tableware

- A47L15/24—Washing or rinsing machines for crockery or tableware with movement of the crockery baskets by conveyors

- A47L15/241—Washing or rinsing machines for crockery or tableware with movement of the crockery baskets by conveyors the dishes moving in a horizontal plane

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L15/00—Washing or rinsing machines for crockery or tableware

- A47L15/42—Details

- A47L15/4214—Water supply, recirculation or discharge arrangements; Devices therefor

- A47L15/4225—Arrangements or adaption of recirculation or discharge pumps

Definitions

- the present invention relates to a washing machine for dishes and other ware and to the washing process using said machine.

- dishwashers which comprise a washing area, equipped with fixed or moveable nozzles for the supply of a liquid substance, generally water mixed with detergents/cleansing agents, and a pump connected to the above nozzles for the pressurized feeding of the same liquid substance.

- a first category relates to washing machines which assemble a medium/low-power pump, for example about 500-3000 Watt, which are used exclusively for the washing of dishes.

- the second category relates to washing machines which assemble a medium/high-power pumping group, for example about 3000-6000 Watt, which are used for the washing of saucepans, containers, cooking utensils, etc. which normally have a much greater degree of dirt than dishes.

- washing machines are commonly called “warewashers” indicating the fact that they are capable of cleaning the above elements which will be called herein with the term “other items”, which differ in the greater degree of dirt with respect to that present on dishes.

- the machines comprise a single operating station suitable for both washing and rinsing

- the second category comprises so-called “tunnel machines” in which the washing and rinsing stations are distinct and separate areas.

- the latter tunnel machines generally consist of three main functioning areas situated in series, pre-washing, washing and rinsing respectively, through which, during the functioning of the machine, the dishes or "other ware” pass, depending on the power of the pump installed, situated on specific moving means, such as conveyor belts or baskets.

- washing machines As already specified above, whether they be single-station washing machines or tunnel washing machines, at present there are no washing machines suitable for washing both dishes and other ware without having to resort to incorrect washings or with high energy consumption.

- An objective of the present invention is to provide a device capable of solving the above drawbacks of the known art in an extremely simple, economical and particular functional way.

- Another objective of the invention is to provide a machine and washing process for dishes and other ware capable of correctly cleaning both the dishes and other ware using the necessary power each time without energy waste.

- this shows a single-station washing machine 10 for dishes and other ware according to the present invention

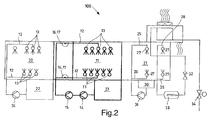

- figure 2 shows a tunnel washing machine 100 for dishes and other ware according to the present invention.

- the washing machine 10, 100 for dishes and/or other ware comprises at least one washing area 11 equipped with supply means 12, 13 of a liquid substance, generally water or water mixed with detergents, suitable for being distributed under pressure on the dishes and/or other ware to be washed.

- a liquid substance generally water or water mixed with detergents

- the washing machine 10 is a single-station washing machine 10

- the washing machine 100 is a tunnel washing machine.

- the washing machine 10, 100 for dishes and/or other ware for distributing the above liquid substance, according to a pressure established each time, on the dishes and/or other ware to be washed also comprises at least two centrifugal feeding pumps 14, 15 connected to the supply means 12, 13, said pumps being situated in series one after another and can be independently activated.

- the powers of the above at least two centrifugal pumps 14, 15 can be the same or different and, as already mentioned, can be independently activated for producing various configurations of use, or different supply pressures of the liquid substance, according to the requirements.

- the washing machine 10, 100 in accordance with the present invention allows both dishes and other dirtier ware to be washed, always obtaining an optimum cleaning degree without wasting energy by feeding the supply means 12, 13 each time with an optimal pressure for the desired washing.

- Any possible energy waste is in fact minimized by activating, according to the requirements, one or more pumps of the at least two pumps 14, 15 present, in relation to the ware to be washed.

- the activation, depending on the requirements, of the above at least two pumps 14, 15 is therefore of particular importance and, according to the present invention, said activation can be manual or, alternatively, automatic.

- the washing machine 10, 100 also comprises automatic activation means 16, 17 of the at least two centrifugal pumps 14, 15.

- Said automatic activation means 16, 17 of the at least two centrifugal pumps 14, 15 can, for example, be at least one optical sensor 16 electronically connected to the at least two centrifugal pumps 14, 15, or alternatively they can be at least one captive sensor 17, also electronically connected to the at least two centrifugal pumps 14, 15.

- said at least one optical sensor 16 or said at least one captive sensor 17 are preferably positioned at the entrance of the washing area 11 to analyze the degree of dirt of the ware entering the washing area 11 itself.

- the machine 100 is a tunnel washing machine 100 and, in addition to the washing area 11, comprises a pre-washing area 20 and at least one rinsing area 21.

- the dishes and/or other ware to be washed possibly positioned on specific transporting means, such as conveyor belts or baskets, pass through these areas, according to the succession shown in figure 2 .

- the stations of the pre-washing area 20 and washing area 11 have a pre-washing tank 22, a washing tank 23 respectively, to which they are connected by at least one pump 24, and by the above at least two pumps 14, 15, respectively.

- the supply means 12, 13 connected to the at least two pumps 14, 15 are spray nozzles 13 situated on specific collector arms 12.

- the rinsing station 21 is equipped with a rinsing tank 30 connected by a pump 31 to an upper transversal collector arm 25 and a lower transversal collector arm 26, each equipped with a plurality of spray nozzles 27.

- the rinsing station 21 advantageously also has at least one additional supply arm 28, 29 which can be activated or deactivated in relation to the advance rate of the dishes.

- Said supply arm 28, 29 is activated when the machine functions with a high feeding rate of the dishes and is deactivated at a low speed.

- the rinsing station 21 also comprises at least one regulation valve 32 suitable for activating or deactivating the supply arm 28, 29 in relation to the advance rate of the dishes.

- a boiler 33 for heating the water to be supplied during the rinsing, at least one electrovalve 34 for closing or opening the connection with the water supply which feeds the rinsing water.

- both the pre-washing and the rinsing are effected in the same washing area 11 with the difference that the pressurized liquid substance supplied is different each time and suitable for the treatment required and taken from a relative tank 40.

- the washing process for dishes and other ware by means of a washing machine 10, 100 as described above and object of the present invention comprises the following phases:

- washing machine 10, 100 object of the present invention, it is possible to wash both normal dishes and also other ware by selectively activating at least one of the at least two centrifugal pumps 14, 15 depending on the degree of dirt present on the dishes and/or other ware.

- the energy power consumed for pressurizing the washing/rinsing liquid is therefore correctly dimensioned each time to the required washing level.

- the phase of introducing the dishes and/or other ware into the washing area 11 can be effected manually, as in the presence of the single-station washing machine 10 shown in figure 1 , or automatically, as in the presence of the tunnel washing machine 100 shown in figure 2 .

- phase of analyzing the degree of dirt present on the dishes and/or other ware can also advantageously be effected automatically, for example by means of at least one optical sensor 16 electronically connected to the at least two centrifugal pumps 14, 15, or by means of at least one captive sensor 17 also electronically connected to the at least two centrifugal pumps 14, 15.

- the activation phase of at least one of the two centrifugal pumps 14, 15 for obtaining said required pressure without energy waste can be effected manually or automatically through the above automatic activation means 16, 17.

Landscapes

- Engineering & Computer Science (AREA)

- Water Supply & Treatment (AREA)

- Washing And Drying Of Tableware (AREA)

- Food-Manufacturing Devices (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ITMI20071247 ITMI20071247A1 (it) | 2007-06-21 | 2007-06-21 | Macchina e procedimento di lavaggio per stoviglie ed altri oggetti |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2005873A2 true EP2005873A2 (de) | 2008-12-24 |

| EP2005873A3 EP2005873A3 (de) | 2010-02-17 |

Family

ID=39717613

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08158296A Withdrawn EP2005873A3 (de) | 2007-06-21 | 2008-06-16 | Maschine und Waschverfahren für Geschirr und andere Waren |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP2005873A3 (de) |

| IT (1) | ITMI20071247A1 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8394204B2 (en) | 2007-05-26 | 2013-03-12 | Premark Feg L.L.C. | Commercial dishwasher with centrifugal pumps arranged in series |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10339130A1 (de) * | 2002-08-23 | 2004-03-25 | Aweco Appliance Systems Gmbh & Co. Kg | Haushaltsmaschine |

| DE102005023429B4 (de) * | 2005-05-20 | 2007-03-29 | Premark Feg L.L.C. (N.D.Ges.D. Staates Delaware), Wilmington | Gewerbliche Geschirrspülmaschine, insbesondere Gläserspülmaschine |

| DE202007018745U1 (de) * | 2007-05-26 | 2009-03-12 | Premark Feg L.L.C., Wilmington | Gewerbliche Geschirrspülmaschine |

-

2007

- 2007-06-21 IT ITMI20071247 patent/ITMI20071247A1/it unknown

-

2008

- 2008-06-16 EP EP08158296A patent/EP2005873A3/de not_active Withdrawn

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8394204B2 (en) | 2007-05-26 | 2013-03-12 | Premark Feg L.L.C. | Commercial dishwasher with centrifugal pumps arranged in series |

Also Published As

| Publication number | Publication date |

|---|---|

| ITMI20071247A1 (it) | 2008-12-22 |

| EP2005873A3 (de) | 2010-02-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA1270311A (en) | Low energy, low water consumption warewasher and method | |

| EP3319499B1 (de) | Flaschenwaschvorrichtung zur verwendung auf dem geschirrkorb | |

| EP2346619B1 (de) | System zum waschen von spülgut und verfahren zum betreiben eines derartigen systems | |

| EP2273907B1 (de) | Geschirrspüler und verfahren zum reinigen von spülgut | |

| US8394204B2 (en) | Commercial dishwasher with centrifugal pumps arranged in series | |

| CN108272413A (zh) | 被设计为批量洗碗机的商用用具清洗机或洗碗机的形式的洗碗机 | |

| EP2320785B1 (de) | Geschirrspülmaschine in form eines programmautomaten und verfahren zu deren betrieb | |

| US20100139699A1 (en) | Steam activation or deactivation of chemistry in an appliance | |

| US9351627B2 (en) | Dishwashing machine and method for the operation thereof | |

| WO2017015254A1 (en) | Dishwasher in the form of a commercial utensil washer or dishwasher which is designed as a batch dishwasher | |

| US7938913B2 (en) | Conveyor dishwasher and operating method for same | |

| EP0547011B1 (de) | Waschprozess für einen industriellen Geschirrspüler | |

| EP2254453B1 (de) | Geschirrspüler und verfahren zur geschirrreinigung damit | |

| EP3373792B1 (de) | Geschirrspüler | |

| KR20180103383A (ko) | 식기세척기 및 그 제어방법 | |

| EP1800589A2 (de) | Geschirrspülmaschine und Verfahren zur Wasserversorgung für Geschirrspülmaschine | |

| CA1295212C (en) | Low energy, low water consumption warewasher | |

| EP2005873A2 (de) | Maschine und Waschverfahren für Geschirr und andere Waren | |

| KR20110112990A (ko) | 식기 세척 구조 | |

| US11980332B2 (en) | Dishwasher | |

| CN209932634U (zh) | 一种独立分区洗碗机 | |

| WO2009023466A1 (en) | Dishwasher and method for cleaning items to be washed with such a diswasher | |

| WO2014102319A1 (en) | A dishwasher comprising a storage tank | |

| JPH09122060A (ja) | 自動食器洗浄装置 | |

| JP2002065571A (ja) | 食器洗い乾燥機 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| AKY | No designation fees paid | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20100818 |