EP1990204B1 - Process and device for coating a surface - Google Patents

Process and device for coating a surface Download PDFInfo

- Publication number

- EP1990204B1 EP1990204B1 EP07009417.2A EP07009417A EP1990204B1 EP 1990204 B1 EP1990204 B1 EP 1990204B1 EP 07009417 A EP07009417 A EP 07009417A EP 1990204 B1 EP1990204 B1 EP 1990204B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- coated

- coating

- gloss value

- coating material

- gloss

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J3/00—Typewriters or selective printing or marking mechanisms characterised by the purpose for which they are constructed

- B41J3/28—Typewriters or selective printing or marking mechanisms characterised by the purpose for which they are constructed for printing downwardly on flat surfaces, e.g. of books, drawings, boxes, envelopes, e.g. flat-bed ink-jet printers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J11/00—Devices or arrangements of selective printing mechanisms, e.g. ink-jet printers or thermal printers, for supporting or handling copy material in sheet or web form

- B41J11/0015—Devices or arrangements of selective printing mechanisms, e.g. ink-jet printers or thermal printers, for supporting or handling copy material in sheet or web form for treating before, during or after printing or for uniform coating or laminating the copy material before or after printing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J3/00—Typewriters or selective printing or marking mechanisms characterised by the purpose for which they are constructed

- B41J3/407—Typewriters or selective printing or marking mechanisms characterised by the purpose for which they are constructed for marking on special material

Definitions

- the invention relates to a method for coating a surface of an object, in particular a workpiece, according to the preamble of claim 1.

- the EP 1 726 443 A1 a method and a device for coating and simultaneously patterning the narrow surfaces of plate-shaped workpieces by means of an ink-jet print head. This allows any pattern to be generated on the surface of the workpiece.

- the applied patterning depending on the subject for example, a wood or natural stone grain

- the EP 1260 368 A1 also discloses a method of printing a material to produce a particular gloss.

- the invention is based on the finding that the overall appearance of a coated surface depends not only on the color / pattern of the coated surface, but also to a considerable extent on the light reflectivity or the gloss of the coated surface.

- the invention provides that in a generic method before producing a coating, a desired gloss value of the coated surface from a gloss scale, preferably measured as Reflektometerwert according to ISO 2813 is selected, and that the coating material as claimed from the outlet openings to the coating surface is ejected, that results in the selected gloss value of the coated surface.

- the most varied variables or parameters are varied within the scope of the method according to the invention.

- the inventors have found that some key parameters are particularly suitable for reliably and reproducibly varying the gloss level in a simple and effective manner.

- the degree of gloss can be tailored to the respective motif of the coated surface in order to achieve an optimal, high-quality appearance in harmony of gloss and motif.

- the targeted application of the coating material not only the appearance but also the feel of the coated surface can be optimized by the surface structure can be matched to the particular motif of the coated surface. For example, by means of the applied coating, a leather feel or the feel of a wood grain can be simulated, while at the same time the gloss value of the material, which may be variable along the coated surface, can also be reproduced or adjusted as desired.

- the method according to the invention can be carried out with comparatively simple means, for example because no additional components such as embossing rollers or the like are required to achieve the selected gloss value.

- the inventive method allows a very flexible production, as by means of the method in a simple way each individual workpiece can be manufactured individually (number of pieces-1-production), without modification work is required.

- At least two objects are coated with a predetermined coating material, in particular a predetermined type of ink, such that the gloss value of the coated surface of at least one object deviates from that of at least one other article.

- a predetermined coating material in particular a predetermined type of ink

- the machine does not have to be reconfigured for every change in the gloss value of different workpieces (eg other coating material, other embossing roll, etc.), but the production can continuously go through with a single machine configuration. This drastically reduces non-productive time and sources of error.

- the coating of the article in the context of the invention does not have to affect a possibly existing motif on the object

- the article is provided by the coating process with a patterning and / or a surface structuring. In this way, the number of process steps can be reduced in the case of patterned or structured workpieces, since the coating process according to the invention can be used not only to achieve the selected Glanzwerst, but at the same time to achieve a desired patterning and / or surface texturing or feel.

- the coating material is at least semi-transparent, preferably transparent.

- the coating material may primarily have a function for selectively adjusting the selected gloss value, while a motif located under the applied coating remains still partially or completely visible.

- the gloss value of the surface to be coated is read or determined, and that the application of the coating material takes into account the gloss value the surface to be coated is performed to obtain the selected gloss value of the coated surface.

- the gloss value of the coated surface is, as already mentioned, preferably measured according to ISO 2813 as a reflectometer value, with a 20 ° reflectometer value having proven to be meaningful for many applications.

- the method according to the invention can be carried out in a particularly simple, rapid and efficient manner using the following apparatus.

- the device has a control device which is set up to control the coating head in such a way that the coating material is ejected from the outlet openings onto the surface to be coated such that the selected gloss value of the coated surface results.

- expensive additional components such as several embossing rollers, different reservoirs for coating materials, etc. can be dispensed with.

- the inventively desired variability of the gloss value results from a few, matched components, namely primarily the print head and the control device set up to achieve the gloss value.

- the device also has an input device for inputting a selected gloss value of the coated surface.

- the device when the device is to process a semitransparent or transparent coating material, it is provided that the device further comprises a measuring device for measuring a gloss value, in particular reflectometer value according to ISO 2813, of a surface of the object to be coated and / or coated. In this way it can be ensured that the desired gloss value results in the interaction of the gloss value of the surface to be coated and the parameters of the coating to be applied.

- a gloss value in particular reflectometer value according to ISO 2813

- FIG Fig. 1 An apparatus 1 for coating a surface of an article 2 is shown in FIG Fig. 1 shown schematically.

- the objects to be coated 2 may be, for example, plate-shaped or strip-shaped workpieces, as are frequently used in the furniture industry and which are preferably at least partially made of wood, wood-based materials, plastic or the like. It should be noted, however, that the present invention is applicable to other types of workpieces.

- the device 1 initially has a conveyor 20, which may be configured for example in the form of a conveyor belt, a conveyor table, a conveyor chain or the like.

- a conveyor 20 Above the conveyor 20 two portals 4 are arranged in the present embodiment, which may for example be designed as a boom or the like.

- At the portals 4 at least one coating head 10 is arranged in each case, which is movable via a carriage 6 along the portal 4.

- the coating heads 10 can also be on the portals 4 more Be arranged units, for example, processing units for performing cutting or other processing, Kantenanleimtechniken, pre- or post-treatment units, etc.

- the workpiece 2 can also be arranged in each case stationary, and that instead the portals 4 can be designed movable, so that it is a stationary machine, as in the field of CNC technology often for Use comes. Combinations of continuous and stationary machines are also possible.

- the coating head has a plurality of outlet openings 12 for the coating material, which may be, for example, ink, paint or other curable materials.

- the coating head 10 has distance sensors 16 in order to allow a more accurate relative positioning between the coating head 10 and the workpiece 2.

- the coating head 10 has a measuring device 14 for measuring a gloss value, in particular a reflectometer value according to ISO 2813, of a surface of the object 2 to be coated and / or coated.

- the measuring device 14 can be arranged such that it measures the gloss value of the surface either before or after Performing the coating process recorded.

- the measuring device may be, for example, a type 406 Novo Gloss device from Elcometer (www.elcometer.com).

- the apparatus 1 further comprises a control device configured to control the coating head 10 in such a manner that the coating material is ejected on the discharge openings 12 onto the surface of the workpiece 2 to be coated such that a selected gloss value of the coated surface results, for example, selected by means of an input device not shown in detail gloss value.

- the gloss value can be reproduced in the context of the present invention by a very wide variety of parameters, with a 20 ° reflectometer value according to ISO 2813 in particular having proven to be a suitable size for the gloss value.

- the present invention is not limited thereto, the generation or variation of a predetermined gloss value when a surface is coated is ultimately based on the surface being given a surface structure which influences the reflectivity of the surface upon incidence of light.

- at least the drop spacing of the coating material applied by means of the coating head is varied.

- FIG. 12 shows a case where a relatively fast-drying coating material 12 'was used so that the material 12' has little time to run on the surface of the workpiece 2 and thus has a comparatively small width B and a relatively high height H the single drop of coating material 12 'on the surface results. This generally leads to a relatively low gloss value, ie a matt surface.

- Fig. 3 an example in which the workpiece 2 is already provided with a decoration or pattern 2 'on the surface before application of the coating material 12'.

- the already mentioned above measuring device 14 may be used to first determine the gloss value of the pattern 2 'and then to perform the subsequent coating process such that the overall result is the desired gloss value, resulting from the properties of the existing sampling 2 'and the coating material 12' composed.

- the coating material 12 'can also be used to give the surface a certain feel, for example a leather or wood feel.

- the inventive method is further characterized by the fact that no conversion of the device 1 is required to achieve the desired, variable gloss values. Rather, in the method according to the invention and the device according to the invention, it is readily possible to provide workpieces with a coating continuously while using a (single) Coating material - within certain limits - always to achieve the desired gloss value of the surface. In other words, in the present invention, no varying coating materials, embossing rolls or the like are required to achieve a variety of gloss levels of the coated surface in a variety of workpieces.

Landscapes

- Application Of Or Painting With Fluid Materials (AREA)

Description

Die Erfindung betrifft ein Verfahren zum Beschichten einer Oberfläche eines Gegenstands, insbesondere eines Werkstücks, nach dem Oberbegriff von Anspruch 1.The invention relates to a method for coating a surface of an object, in particular a workpiece, according to the preamble of

Zum Beschichten und ggf. Bemustern von Gegenständen, wie beispielsweise plattenförmigen Werkstücken im Bereich der Möbelindustrie, sind vielfältige Verfahren und Vorrichtungen bekannt.For coating and possibly patterning of objects, such as plate-shaped workpieces in the furniture industry, a variety of methods and devices are known.

So offenbart beispielsweise die

Ferner offenbart die

Es ist Aufgabe der vorliegenden Erfindung, ein Verfahren der eingangs genannten Art bereitzustellen, die ein verbessertes Gesamterscheinungsbild einer beschichteten Oberfläche ermöglichen.It is an object of the present invention to provide a method of the type mentioned, which allow an improved overall appearance of a coated surface.

Diese Aufgabe wird erfindungsgemäß durch ein Verfahren nach Anspruch 1 gelöst. Besonders bevorzugte Weiterbildungen der Erfindung sind in den abhängigen Ansprüchen angegeben.This object is achieved by a method according to

Der Erfindung liegt die Erkenntnis zugrunde, dass das Gesamterscheinungsbild einer beschichteten Oberfläche nicht nur von der Farbe/dem Muster der beschichteten Oberfläche, sondern in erheblichem Umfang auch von dem Lichtreflektionsvermögen bzw. dem Glanz der beschichteten Oberfläche anhängt. Insbesondere findet bei herkömmlichen, gattungsgemäßen Beschichtungsverfahren keine gezielte Abstimmung zwischen der Farbe/dem Muster der beschichteten Oberfläche einerseits und dem Glanz der beschichteten Oberfläche andererseits statt. Vor diesem Hintergrund ist erfindungsgemäß vorgesehen, das bei einem gattungsgemäßen Verfahren vor dem Erzeugen einer Beschichtung ein gewünschter Glanzwert der beschichteten Oberfläche aus einer Glanzskala, bevorzugt gemessen als Reflektometerwert nach ISO 2813, ausgewählt wird, und dass das Beschichtungsmaterial wie beansprucht aus den Austrittsöffnungen auf die zu beschichtende Oberfläche ausgestoßen wird, dass sich der ausgewählte Glanzwert der beschichteten Oberfläche ergibt.The invention is based on the finding that the overall appearance of a coated surface depends not only on the color / pattern of the coated surface, but also to a considerable extent on the light reflectivity or the gloss of the coated surface. In particular, in conventional, generic coating method no specific coordination between the color / the pattern of the coated surface on the one hand and the gloss of the coated surface on the other hand instead. Against this background, the invention provides that in a generic method before producing a coating, a desired gloss value of the coated surface from a gloss scale, preferably measured as Reflektometerwert according to ISO 2813 is selected, and that the coating material as claimed from the outlet openings to the coating surface is ejected, that results in the selected gloss value of the coated surface.

Zur Erzielung des ausgewählten Glanzwertes werden im Rahmen des erfindungsgemäßen Verfahrens unterschiedlichste Einflussgrößen bzw. Parameter variiert. Die Erfinder haben jedoch festgestellt, dass einige Hauptparameter besonders geeignet sind, um auf einfache und wirksame Weise den Glanzgrad zuverlässig und reproduzierbar zu variieren. Vor diesem Hintergrund ist gemäß der Erfindung vorgesehen, dass zur Erzielung des ausgewählten Glanzwerts zumindest der Tropfenabstand variiert wird.In order to achieve the selected gloss value, the most varied variables or parameters are varied within the scope of the method according to the invention. However, the inventors have found that some key parameters are particularly suitable for reliably and reproducibly varying the gloss level in a simple and effective manner. Against this background, it is provided according to the invention that, in order to achieve the selected gloss value, at least the drop spacing is varied.

Auf diese Weise eröffnen sich völlig neue Möglichkeiten bei der Gestaltung des Erscheinungsbildes beschichteter Oberflächen von Gegenständen. So kann der Glanzgrad gezielt auf das jeweilige Motiv der beschichteten Oberfläche abgestimmt werden, um im Zusammenklang von Glanz und Motiv ein optimales, hochwertiges Erscheinungsbild zu erreichen. Darüber hinaus kann durch das gezielte Aufbringen des Beschichtungsmaterial nicht nur die Optik, sondern auch die Haptik der beschichteten Oberfläche optimiert werden, indem die Oberflächenstruktur auf das jeweilige Motiv der beschichteten Oberfläche abgestimmt werden kann. Beispielsweise kann mittels der aufgebrachten Beschichtung eine Lederhaptik oder die Haptik einer Holzmaserung nachgebildet werden, während gleichzeitig auch der ggf. entlang der beschichteten Oberfläche veränderliche Glanzwert des Materials nachgebildet oder wie gewünscht eingestellt werden kann.In this way, completely new possibilities open up in the design of the appearance of coated surfaces of objects. Thus, the degree of gloss can be tailored to the respective motif of the coated surface in order to achieve an optimal, high-quality appearance in harmony of gloss and motif. In addition, the targeted application of the coating material not only the appearance but also the feel of the coated surface can be optimized by the surface structure can be matched to the particular motif of the coated surface. For example, by means of the applied coating, a leather feel or the feel of a wood grain can be simulated, while at the same time the gloss value of the material, which may be variable along the coated surface, can also be reproduced or adjusted as desired.

Weiterhin kann das erfindungsgemäße Verfahren mit vergleichsweise einfachen Mitteln durchgeführt werden, beispielsweise da zur Erzielung des ausgewählten Glanzwertes keine Zusatzbauteile wie Prägewalzen oder dergleichen erforderlich sind.Furthermore, the method according to the invention can be carried out with comparatively simple means, for example because no additional components such as embossing rollers or the like are required to achieve the selected gloss value.

Nicht zuletzt ermöglicht das erfindungsgemäße Verfahren eine sehr flexible Produktion, da mittels des Verfahrens auf einfache Weise jedes einzelne Werkstück individuell gefertigt werden kann (Stückzahl-1-Fertigung), ohne dass Umbauarbeiten erforderlich sind.Not least, the inventive method allows a very flexible production, as by means of the method in a simple way each individual workpiece can be manufactured individually (number of pieces-1-production), without modification work is required.

Hieran anknüpfend ist gemäß einer Weiterbildung der Erfindung vorgesehen, dass mindestens zwei Gegenstände mit einem vorbestimmten Beschichtungsmaterial, insbesondere einer vorbestimmten Tintenart, derart beschichtet werden, dass der Glanzwert der beschichteten Oberfläche mindestens eines Gegenstands von demjenigen mindestens eines anderen Gegenstands abweicht. Bei diesem Verfahren muss nicht für jede Änderung des Glanzwerts unterschiedlicher Werkstücke die Maschine umkonfiguriert werden (z.B. anderes Beschichtungsmaterial, andere Prägewalze, etc.), sondern die Produktion kann kontinuierlich mit einer einzigen Maschinenkonfiguration durchlaufen. Hierdurch werden Nebenzeiten und Fehlerquellen drastisch reduziert.Following this, according to a development of the invention, it is provided that at least two objects are coated with a predetermined coating material, in particular a predetermined type of ink, such that the gloss value of the coated surface of at least one object deviates from that of at least one other article. With this method, the machine does not have to be reconfigured for every change in the gloss value of different workpieces (eg other coating material, other embossing roll, etc.), but the production can continuously go through with a single machine configuration. This drastically reduces non-productive time and sources of error.

Obgleich die Beschichtung des Gegenstands im Rahmen der Erfindung sich nicht auf ein möglicherweise bereits vorhandenes Motiv auf dem Gegenstand auswirken muss, ist gemäß einer Weiterbildung der Erfindung vorgesehen, dass der Gegenstand durch den Beschichtungsvorgang mit einer Bemusterung und/oder einer Oberflächenstrukturierung versehen wird. Auf diese Weise lässt sich bei bemusterten oder strukturierten Werkstücken die Anzahl der Verfahrensschritte vermindern, da der erfindungsgemäße Beschichtungsvorgang nicht nur zum Erzielen des ausgewählten Glanzwerst, sondern gleichzeitig auch zum Erzielen einer gewünschten Bemusterung und/oder Oberflächenstrukturierung bzw. Haptik genutzt werden kann.Although the coating of the article in the context of the invention does not have to affect a possibly existing motif on the object, according to a development of the invention, the article is provided by the coating process with a patterning and / or a surface structuring. In this way, the number of process steps can be reduced in the case of patterned or structured workpieces, since the coating process according to the invention can be used not only to achieve the selected Glanzwerst, but at the same time to achieve a desired patterning and / or surface texturing or feel.

Gemäß einer Weiterbildung der Erfindung ist ferner vorgesehen, dass das Beschichtungsmaterial zumindest semi-transparent, bevorzugt transparent ist. In diesem Falle kann das Beschichtungsmaterial primär eine Funktion zum gezielten Einstellen des ausgewählten Glanzwerts besitzen, während ein sich unter der aufgebrachten Beschichtung befindliches Motiv weiterhin ganz oder teilweise sichtbar bleibt.According to one embodiment of the invention, it is further provided that the coating material is at least semi-transparent, preferably transparent. In this case, the coating material may primarily have a function for selectively adjusting the selected gloss value, while a motif located under the applied coating remains still partially or completely visible.

Um insbesondere bei einem derartigen, visuellen Zusammenspiel von Beschichtungsmaterial und darunter befindlicher Oberfläche ein optimales Erscheindungsbild zu erzielen, ist gemäß einer Weiterbildung der Erfindung vorgesehen, dass der Glanzwert der zu beschichtenden Oberfläche eingelesen oder bestimmt wird, und dass das Aufbringen des Beschichtungsmaterials unter Berücksichtigung des Glanzwerts der zu beschichtenden Oberfläche durchgeführt wird, um den ausgewählten Glanzwert der beschichteten Oberfläche zu erzielen. Hierdurch lassen sich gezielt reproduzierbare Ergebnisse erzielen, bei denen durch einen Zusammenklang von beschichteter Oberfläche und aufgebrachtem Beschichtungsmaterial eine Oberfläche mit gewünschtem Motiv, gewünschtem Glanzgrad und gegebenenfalls gewünschter Haptik entsteht.In order to achieve an optimal appearance image especially in the case of such a visual interaction of the coating material and the surface underneath, it is provided according to a development of the invention that the gloss value of the surface to be coated is read or determined, and that the application of the coating material takes into account the gloss value the surface to be coated is performed to obtain the selected gloss value of the coated surface. As a result, reproducibly reproducible results can be achieved in which a surface with a desired motif, desired degree of gloss and, if desired, desired feel is created by a harmony of the coated surface and the applied coating material.

Der Glanzwert der beschichteten Oberfläche wird, wie bereits eingangs erwähnt, bevorzugt nach ISO 2813 als Reflektometerwert gemessen, wobei sich für viele Anwendungen ein 20°-Reflektometerwert als aussagekräftige Größe erwiesen hat.The gloss value of the coated surface is, as already mentioned, preferably measured according to ISO 2813 as a reflectometer value, with a 20 ° reflectometer value having proven to be meaningful for many applications.

Das erfindungsgemäße Verfahren lässt sich besonders einfach, zügig und effizient unter Einsatz folgender Vorrichtung durchführen. Diese zeichnet sich dadurch aus, dass die Vorrichtung eine Steuereinrichtung aufweist, die eingerichtet ist, den Beschichtungskopf auf solche Weise zu steuern, dass das Beschichtungsmaterial derart aus den Austrittsöffnungen auf die zu beschichtende Oberfläche ausgestoßen wird, dass sich der ausgewählte Glanzwert der beschichteten Oberfläche ergibt. Hierdurch kann, wie bereits oben erwähnt, auf aufwändige Zusatzbauteile wie mehrere Prägewalzen, unterschiedliche Vorratsbehälter für Beschichtungsmaterialien, etc. verzichtet werden. Vielmehr ergibt sich die erfindungsgemäß angestrebte Variabilität des Glanzwerts durch wenige, aufeinander abgestimmte Bauteile, nämlich primär den Druckkopf und die auf die Erzielung des Glanzwerts eingerichtete Steuereinrichtung.The method according to the invention can be carried out in a particularly simple, rapid and efficient manner using the following apparatus. This is characterized in that the device has a control device which is set up to control the coating head in such a way that the coating material is ejected from the outlet openings onto the surface to be coated such that the selected gloss value of the coated surface results. As a result, as already mentioned above, expensive additional components such as several embossing rollers, different reservoirs for coating materials, etc. can be dispensed with. Rather, the inventively desired variability of the gloss value results from a few, matched components, namely primarily the print head and the control device set up to achieve the gloss value.

Um den gewünschten Glanzwert präzise und flexibel festlegen zu können, ist vorgesehen, dass die Vorrichtung ferner eine Eingabeeinrichtung zur Eingabe eines ausgewählten Glanzwerts der beschichteten Oberfläche aufweist.In order to be able to determine the desired gloss value precisely and flexibly, it is provided that the device also has an input device for inputting a selected gloss value of the coated surface.

Insbesondere wenn die Vorrichtung ein semitransparentes oder transparentes Beschichtungsmaterial verarbeiten soll, ist vorgesehen, dass die Vorrichtung ferner eine Messeinrichtung zum Messen eines Glanzwertes, insbesondere Reflektometerwerts nach ISO 2813, einer zu beschichtenden und/oder beschichteten Oberfläche des Gegenstands aufweist. Auf diese Weise kann sichergestellt werden, dass sich im Zusammenspiel des Glanzwerts der zu beschichtenden Oberfläche und den Parametern der aufzubringenden Beschichtung insgesamt der gewünschte Glanzwert ergibt.In particular, when the device is to process a semitransparent or transparent coating material, it is provided that the device further comprises a measuring device for measuring a gloss value, in particular reflectometer value according to ISO 2813, of a surface of the object to be coated and / or coated. In this way it can be ensured that the desired gloss value results in the interaction of the gloss value of the surface to be coated and the parameters of the coating to be applied.

Kurze Beschreibung der ZeichnungenBrief description of the drawings

- Fig. 1Fig. 1

- zeigt schematisch eine Perspektivansicht einer Ausführungsform einer Vorrichtung;schematically shows a perspective view of an embodiment of a device;

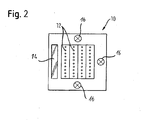

- Fig. 2Fig. 2

- zeigt schematisch eine Draufsicht eines im Rahmen der vorliegenden Erfindung einsetzbaren Druckkopfes;schematically shows a plan view of a usable in the present invention printhead;

- Fig. 3Fig. 3

- zeigt schematisch Detailansichten von Werkstücken, die gemäß der Erfindung beschichtet wurden.shows schematically detailed views of workpieces that have been coated according to the invention.

Bevorzugte Ausführungsformen der vorliegenden Erfindung werden nachfolgend ausführlich unter Bezugnahme auf die begleitenden Zeichnungen beschrieben.Preferred embodiments of the present invention will be described below in detail with reference to the accompanying drawings.

Eine Vorrichtung 1 zum Beschichten einer Oberfläche eines Gegenstands 2 ist in

Die Vorrichtung 1 besitzt zunächst eine Fördereinrichtung 20, die beispielsweise in Form eines Förderbandes, eines Fördertisches, einer Förderkette oder dergleichen ausgestaltet sein kann. Oberhalb der Fördereinrichtung 20 sind in der vorliegenden Ausführungsform zwei Portale 4 angeordnet, die beispielsweise auch als Ausleger oder dergleichen ausgestaltet sein können. An den Portalen 4 ist jeweils mindestens ein Beschichtungskopf 10 angeordnet, der über einen Schlitten 6 entlang des Portals 4 verfahrbar ist. Neben den Beschichtungsköpfen 10 können an den Portalen 4 auch weitere Einheiten angeordnet sein, beispielsweise Bearbeitungseinheiten zur Durchführung spanender oder sonstiger Bearbeitungen, Kantenanleimeinheiten, Vor- oder Nachbehandlungseinheiten etc.The

Ferner ist zu beachten, dass bei der Vorrichtung 1 das Werkstück 2 auch jeweils stationär angeordnet sein kann, und dass stattdessen die Portale 4 verfahrbar ausgestaltet sein können, dass es sich also um eine Stationärmaschine handelt, wie sie im Bereich der CNC-Technik häufig zum Einsatz kommt. Auch Kombinationen von Durchlauf- und Stationärmaschinen sind möglich.It should also be noted that in the

Ein Beispiel für die Ausgestaltung des Beschichtungskopfes ist in

Obgleich in den Figuren nicht gezeigt, umfasst die Vorrichtung 1 ferner eine Steuereinrichtung, die eingerichtet ist, den Beschichtungskopf 10 auf solche Weise zu steuern, dass das Beschichtungsmaterial derart auf den Austrittsöffnungen 12 auf die zu beschichtende Oberfläche des Werkstücks 2 ausgestoßen wird, dass sich ein ausgewählter Glanzwert der beschichteten Oberfläche ergibt, beispielsweise ein mittels einer nicht näher gezeigten Eingabeeinrichtung ausgewählter Glanzwert.Although not shown in the figures, the

Der Glanzwert kann im Rahmen der vorliegenden Erfindung durch unterschiedlichste Parameter wiedergegeben werden, wobei sich insbesondere ein 20°-Reflektometerwert nach ISO 2813 als geeignete Größe für den Glanzwert erwiesen hat. Obgleich die vorliegende Erfindung nicht hierauf beschränkt ist, beruht die Erzeugung bzw. Variation eines vorbestimmten Glanzwerts bei Beschichtung einer Oberfläche letztlich darauf, dass die beschichtete Oberfläche eine Oberflächenstrukturierung erhält, die das Reflektionsvermögen der Oberfläche bei Lichteinfall beeinflusst. Zur Erzielung eines ausgewählten Glanzwertes variiert man zumindest dem Tropfenabstand des mittels des Beschichtungskopfes aufgebrachten Beschichtungsmaterials.The gloss value can be reproduced in the context of the present invention by a very wide variety of parameters, with a 20 ° reflectometer value according to ISO 2813 in particular having proven to be a suitable size for the gloss value. Although the present invention is not limited thereto, the generation or variation of a predetermined gloss value when a surface is coated is ultimately based on the surface being given a surface structure which influences the reflectivity of the surface upon incidence of light. To achieve a selected gloss value, at least the drop spacing of the coating material applied by means of the coating head is varied.

Rein beispielhaft lässt sich der Einfluss der Trocknungsdauer des Beschichtungsmaterials auf die Oberflächenstrukturierung und somit den Glanzwert der beschichteten Oberfläche anhand von

Bei der unteren Zeichnung in

Ähnliche Zusammenhänge gelten für die übrigen Parameter. Beispielsweise führen ein geringerer Tropfenabstand und eine größere Tropfengröße tendentiell zu einer weniger ausgeprägten Strukturierung und somit einem höheren Glanzwert.Similar relationships apply to the other parameters. For example, a smaller drop spacing and a larger drop size tend to result in a less pronounced structuring and thus a higher gloss value.

Ferner zeigt

Alternativ oder zusätzlich ist es ebenso möglich, durch das Beschichtungsmaterial ebenfalls eine Bemusterung vorzusehen, sodass gegebenenfalls auf die in

Das erfindungsgemäße Verfahren zeichnet sich ferner dadurch aus, dass für die Erzielung der gewünschten, veränderlichen Glanzwerte kein Umbau der Vorrichtung 1 erforderlich ist. Vielmehr ist es bei dem erfindungsgemäßen Verfahren und der erfindungsgemäßen Vorrichtung ohne Weiteres möglich, kontinuierlich Werkstücke mit einer Beschichtung zu versehen und dabei unter Verwendung eines (einzigen) Beschichtungsmaterials - in gewissen Grenzen - stets den gewünschten Glanzwert der Oberfläche zu erzielen. Mit anderen Worten sind bei der vorliegenden Erfindung keine variierenden Beschichtungsmaterialien, Prägewalzen oder dergleichen erforderlich, um bei einer Vielzahl von Werkstücken unterschiedlichste Glanzgrade der beschichteten Oberfläche zu erzielen.The inventive method is further characterized by the fact that no conversion of the

Claims (6)

- Method for coating a surface of an object (2), having the steps of:providing an object (2), in particular a workpiece, which is to be coated on one surface,producing a coating on the surface of the object (2) to be coated by means of a coating head (10), in particular ink jet head, which has a plurality of outlet openings (12) for the coating material,the coating material is expelled from the outlet openings (12) onto the surface to be coated in such a way that the result is a selected gloss value of the coated surface, whereinthe gloss value of the surface to be coated is read or determined, and application of the coating material is carried out in consideration of the gloss value of the surface to be coated in order to obtain a selected gloss value of the coated surface, characterised in that before producing a coating the desired gloss value of the coated surface is selected from a gloss scale, preferably measured as a reflectometer value according to ISO 2813, and at least the interval between drops is varied to obtain the selected gloss value.

- Method according to claim 1, characterised in that at least two objects are coated with a predetermined coating material, in particular a predetermined type of ink, in such a way that the gloss value of the coated surface of at least one object differs from that of at least one other object.

- Method according to claim 1 or 2, characterised in that the object is provided by the coating operation with a pattern and/or surface structure.

- Method according to any of the preceding claims, characterised in that the coating material is at least semi-transparent, preferably transparent.

- Method according to any of the preceding claims, characterised in that, when the coating material is applied, the surface structure is coordinated with the motif of the coated surface, in particular when the surface structure simulates a leather feel or wood grain feel.

- Method according to any of the preceding claims, characterised in that the coated surface in at least one section has a gloss value measured as a 20° reflectometer value according to ISO 2813.

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07009417.2A EP1990204B1 (en) | 2007-05-10 | 2007-05-10 | Process and device for coating a surface |

| PL07009417T PL1990204T3 (en) | 2007-05-10 | 2007-05-10 | Process and device for coating a surface |

| ES07009417.2T ES2564242T3 (en) | 2007-05-10 | 2007-05-10 | Procedure and device for coating a surface |

| CNA2008101003571A CN101301821A (en) | 2007-05-10 | 2008-05-05 | Method and device for coating a surface |

| US12/118,389 US20080280028A1 (en) | 2007-05-10 | 2008-05-09 | Method and device for coating a surface |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07009417.2A EP1990204B1 (en) | 2007-05-10 | 2007-05-10 | Process and device for coating a surface |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1990204A1 EP1990204A1 (en) | 2008-11-12 |

| EP1990204B1 true EP1990204B1 (en) | 2015-12-02 |

Family

ID=38234904

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07009417.2A Active EP1990204B1 (en) | 2007-05-10 | 2007-05-10 | Process and device for coating a surface |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20080280028A1 (en) |

| EP (1) | EP1990204B1 (en) |

| CN (1) | CN101301821A (en) |

| ES (1) | ES2564242T3 (en) |

| PL (1) | PL1990204T3 (en) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102011114522A1 (en) * | 2011-09-29 | 2013-04-04 | Focke & Co. (Gmbh & Co. Kg) | Method and apparatus for producing a package for a group of smokable articles |

| CN103660639B (en) * | 2013-12-08 | 2015-12-30 | 志邦厨柜股份有限公司 | A kind of kitchen cabinet plate code spraying method |

| DE102014206697A1 (en) * | 2014-04-07 | 2015-10-08 | Homag Holzbearbeitungssysteme Gmbh | Device and method for creating solids |

| DE102014224176A1 (en) * | 2014-11-26 | 2016-06-02 | Weeke Bohrsysteme Gmbh | Device for the formation of solids |

| MX2017012482A (en) * | 2015-06-18 | 2018-07-06 | Projecta Eng S R L | Digital decorating machine for ceramic products. |

| DE102016002484A1 (en) * | 2016-03-03 | 2017-09-07 | Sca Schucker Gmbh & Co. Kg | simulation methods |

| DE102017207993A1 (en) * | 2017-05-11 | 2018-11-15 | Homag Gmbh | System for processing valuables |

| ES2802801T3 (en) | 2017-06-13 | 2021-01-21 | Hymmen Gmbh Maschinen & Anlagenbau | Procedure and device for the production of a structured surface |

| DE102017212987B4 (en) * | 2017-07-27 | 2020-09-03 | Koenig & Bauer Ag | Sheet-fed printing press |

| CN108583023A (en) * | 2018-03-16 | 2018-09-28 | 浙江慕容时尚家居有限公司 | A kind of sofa production printing machine |

| DE102019206431A1 (en) | 2019-05-03 | 2020-11-05 | Hymmen GmbH Maschinen- und Anlagenbau | Method for producing a structure on a surface |

| DE102020125679A1 (en) | 2020-10-01 | 2022-04-07 | Homag Gmbh | Device and method for processing, in particular for finishing, surfaces |

| DE102020125687A1 (en) | 2020-10-01 | 2022-04-07 | Homag Gmbh | Device and method for coating a surface |

| DE102021103564A1 (en) | 2021-02-16 | 2022-08-18 | Homag Gmbh | Method and device for coating a surface |

| US20230109593A1 (en) * | 2021-10-06 | 2023-04-06 | Norikazu YANASE | Liquid discharge apparatus |

| DE102022114231A1 (en) | 2022-06-07 | 2023-12-07 | Homag Gmbh | Method for sampling a workpiece |

| CN115487960B (en) * | 2022-09-09 | 2024-07-30 | 松井新材料研究院(广东)有限公司 | Ink jet coating device |

Family Cites Families (85)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3811915A (en) * | 1971-04-27 | 1974-05-21 | Inmont Corp | Printing method for forming three dimensional simulated wood grain,and product formed thereby |

| US3975740A (en) * | 1973-10-02 | 1976-08-17 | Siemens Aktiengesellschaft | Liquid jet recorder |

| DE2433719A1 (en) * | 1974-07-13 | 1976-01-29 | Agfa Gevaert Ag | INK WRITING DEVICE FOR THE INKJET PROCESS |

| SE421055B (en) * | 1978-04-19 | 1981-11-23 | Klaus Mielke | DEVICE FOR LABELING OF PACKAGES OR OTHER FORMS |

| EP0036297A3 (en) * | 1980-03-14 | 1981-10-07 | Willett International Limited | Ink jet printing apparatus and process |

| US4514742A (en) * | 1980-06-16 | 1985-04-30 | Nippon Electric Co., Ltd. | Printer head for an ink-on-demand type ink-jet printer |

| JPS60264285A (en) * | 1984-06-13 | 1985-12-27 | Pilot Ink Co Ltd | Reversible thermal recording composition |

| US5113757A (en) * | 1986-01-10 | 1992-05-19 | Alliance Rubber Company, Inc. | Method and apparatus for making printed elastic bands |

| US4814795A (en) * | 1987-05-01 | 1989-03-21 | Marsh Company | Ink jet head holder |

| JPH03205A (en) * | 1989-05-26 | 1991-01-07 | Norin Suisansyo Shinrin Sogo Kenkyusho | High speed bonding method of wood by heating surface |

| US5935331A (en) * | 1994-09-09 | 1999-08-10 | Matsushita Electric Industrial Co., Ltd. | Apparatus and method for forming films |

| JPH08119239A (en) * | 1994-10-31 | 1996-05-14 | Sony Corp | Apparatus and method for treating carton |

| US5581284A (en) * | 1994-11-25 | 1996-12-03 | Xerox Corporation | Method of extending the life of a printbar of a color ink jet printer |

| US6053231A (en) * | 1995-03-23 | 2000-04-25 | Osaka Sealing Printing Co., Ltd. | Bonding apparatus for cutting label continuum having labels formed thereon and bonding label to object |

| JPH09123435A (en) * | 1995-11-06 | 1997-05-13 | Hitachi Ltd | Print head for ink jet recorder |

| DE69733496D1 (en) * | 1996-01-11 | 2005-07-14 | Gregory Edye Ross | PERIMETER COATING PROCESS |

| JP3658714B2 (en) * | 1996-02-09 | 2005-06-08 | アイン興産株式会社 | Pattern formation method for woody synthetic board |

| GB9609379D0 (en) * | 1996-05-03 | 1996-07-10 | Willett Int Ltd | Mechanism and method |

| CA2208153C (en) * | 1996-06-20 | 2002-07-16 | Canon Kabushiki Kaisha | Method and apparatus for discharging liquid by a gas bubble controlled by a moveable member to communicate with the atmosphere |

| US6072509A (en) * | 1997-06-03 | 2000-06-06 | Eastman Kodak Company | Microfluidic printing with ink volume control |

| CA2299428A1 (en) * | 1997-08-01 | 1999-02-11 | George Henry Dick | Self-priming ink system for ink jet printers |

| US5986680A (en) * | 1997-08-29 | 1999-11-16 | Eastman Kodak Company | Microfluidic printing using hot melt ink |

| EP0931649A3 (en) * | 1998-01-27 | 2000-04-26 | Eastman Kodak Company | Apparatus and method for making a contoured surface having complex topology |

| US6578276B2 (en) * | 1998-01-27 | 2003-06-17 | Eastman Kodak Company | Apparatus and method for marking multiple colors on a contoured surface having a complex topography |

| ES2196897T3 (en) * | 1998-12-03 | 2003-12-16 | Akzo Nobel Nv | PROCEDURE FOR THE PREPARATION OF A DECORATED SUBSTRATE. |

| DE19907043B4 (en) * | 1999-02-19 | 2005-03-24 | Karl Otto Braun Kg | Thermoplastic bandage material and method for its production |

| US6193361B1 (en) * | 1999-06-03 | 2001-02-27 | Eastman Kodak Company | Apparatus for forming textured layers over images |

| US6694872B1 (en) * | 1999-06-18 | 2004-02-24 | Holographic Label Converting, Inc. | In-line microembossing, laminating, printing, and diecutting |

| US6286920B1 (en) * | 1999-07-29 | 2001-09-11 | Paul Anthony Ridgway | Venetian blind printing system |

| JP2001053943A (en) * | 1999-08-11 | 2001-02-23 | Mitsubishi Paper Mills Ltd | Image forming system |

| SE516696C2 (en) * | 1999-12-23 | 2002-02-12 | Perstorp Flooring Ab | Process for producing surface elements comprising an upper decorative layer as well as surface elements produced according to the method |

| IT1317205B1 (en) * | 2000-04-11 | 2003-05-27 | Comital S P A | METHOD FOR THE PRODUCTION OF POLYCHROME DECORATIONS WITH METAL SUMANUFACTURE PRINT AND RELATED EQUIPMENT |

| DE10031030B4 (en) * | 2000-06-26 | 2005-08-04 | Bauer, Jörg R. | Method and device for producing flat components with a predetermined surface appearance and planar component, in particular front panel of a kitchen element |

| JP2002037224A (en) * | 2000-07-21 | 2002-02-06 | Fuji Photo Film Co Ltd | Package manufacturing method, package, and printing apparatus |

| US6755518B2 (en) * | 2001-08-30 | 2004-06-29 | L&P Property Management Company | Method and apparatus for ink jet printing on rigid panels |

| EP1190864A1 (en) * | 2000-09-21 | 2002-03-27 | GRETAG IMAGING Trading AG | Method and device for printing digital image information |

| US6930696B2 (en) * | 2000-09-27 | 2005-08-16 | Seiko Epson Corporation | Printing up to edges of printing paper without platen soiling |

| AU2002239731A1 (en) * | 2000-11-13 | 2002-06-03 | Imaging Alternatives, Inc. | Wood surface inkjet receptor medium and method of making and using same |

| AU2002306803A1 (en) * | 2001-03-21 | 2002-10-08 | Macdermid Colorspan, Inc. | Co-operating mechanical subassemblies for a scanning carriage, digital wide-format color inkjet print engine |

| US20020189754A1 (en) * | 2001-04-30 | 2002-12-19 | Hill David A. | System and method for forming wood products |

| NL1018114C2 (en) * | 2001-05-21 | 2002-11-25 | Oce Tech Bv | Inkjet printer and a method for printing on a receiving material. |

| US20030020767A1 (en) * | 2001-07-24 | 2003-01-30 | Saksa Thomas A. | Grain forming ink jet printer for printing a grain on a workpiece and method of assembling the printer |

| DE10139633C1 (en) * | 2001-08-11 | 2003-04-24 | Amtec Kistler Gmbh | Device for applying a coating agent |

| US20030048343A1 (en) * | 2001-08-30 | 2003-03-13 | Anderson Brian L. | Process for preparing a laminated ink jet print |

| US20050274272A1 (en) * | 2001-10-09 | 2005-12-15 | Ralph Machesky | Multipurpose label apparatus |

| US7556708B2 (en) * | 2003-06-13 | 2009-07-07 | Advanced Label Systems, Inc. | Apparatus and method for applying labels |

| GB0130485D0 (en) * | 2001-12-21 | 2002-02-06 | Plastic Logic Ltd | Self-aligned printing |

| US20030217807A1 (en) * | 2002-01-25 | 2003-11-27 | Leif Lesmann | Method and apparatus for gluing |

| GB2384931B (en) * | 2002-01-30 | 2005-06-29 | Hewlett Packard Co | Printer device and method |

| KR20100013351A (en) * | 2002-04-03 | 2010-02-09 | 메이소나이트 코오포레이션 | Method and apparatus for creating an image on an article, and printed article |

| WO2003096257A2 (en) * | 2002-05-08 | 2003-11-20 | Erich Utsch Ag | Motor vehicle number plate |

| US20030211251A1 (en) * | 2002-05-13 | 2003-11-13 | Daniels Evan R. | Method and process for powder coating molding |

| US6634729B1 (en) * | 2002-06-12 | 2003-10-21 | J.M. Huber Corporation | Apparatus for applying ink indicia to boards |

| US6964722B2 (en) * | 2002-08-07 | 2005-11-15 | Trio Industries Holdings, L.L.C. | Method for producing a wood substrate having an image on at least one surface |

| DE10239630B3 (en) * | 2002-08-23 | 2004-04-08 | Espera-Werke Gmbh | Device and method for labeling objects |

| US6819886B2 (en) * | 2002-10-23 | 2004-11-16 | Nex Press Solutions Llc | Gloss/density measurement device with feedback to control gloss and density of images produced by an electrographic reproduction apparatus |

| US6790335B2 (en) * | 2002-11-15 | 2004-09-14 | Hon Hai Precision Ind. Co., Ltd | Method of manufacturing decorative plate |

| JP4225076B2 (en) * | 2003-02-19 | 2009-02-18 | セイコーエプソン株式会社 | Droplet discharge device |

| JP2004335492A (en) * | 2003-03-07 | 2004-11-25 | Junji Kido | Coater of organic electronic material and process for producing organic electronic element using it |

| JP2004284144A (en) * | 2003-03-20 | 2004-10-14 | Konica Minolta Holdings Inc | Image forming method and inkjet recording device, as well as active light curing ink |

| JP2004299054A (en) * | 2003-03-28 | 2004-10-28 | Konica Minolta Holdings Inc | Image recording method, image recording apparatus, and ultraviolet curing type ink |

| JP2005059215A (en) * | 2003-08-08 | 2005-03-10 | Sharp Corp | Electrostatic attraction fluid discharging apparatus |

| JP4387727B2 (en) * | 2003-08-14 | 2009-12-24 | 富士通株式会社 | Component mounting assembly cell |

| US20050156964A1 (en) * | 2004-01-19 | 2005-07-21 | Konica Minolta Medical & Graphic, Inc. | Ink-jet recording apparatus |

| US7354845B2 (en) * | 2004-08-24 | 2008-04-08 | Otb Group B.V. | In-line process for making thin film electronic devices |

| US20050279450A1 (en) * | 2004-06-16 | 2005-12-22 | Kevin King | Method and apparatus for producing laminated products of infinite length |

| EP1772215A4 (en) * | 2004-06-25 | 2009-07-29 | Mitsubishi Materials Corp | Metal colloid particles, metal colloid and use of the colloid |

| JP4508762B2 (en) * | 2004-07-29 | 2010-07-21 | 大日本スクリーン製造株式会社 | Printing inspection apparatus, printing apparatus including the same, and printing inspection method |

| US20060021535A1 (en) * | 2004-07-30 | 2006-02-02 | Heidelberger Druckmaschinen Ag | Method for printing and aftertreating a print |

| DE102005031779B4 (en) * | 2004-07-30 | 2016-03-24 | Heidelberger Druckmaschinen Ag | Method for printing and after-treatment of an imprint |

| US20060075917A1 (en) * | 2004-10-08 | 2006-04-13 | Edwards Paul A | Smooth finish UV ink system and method |

| CN1311913C (en) * | 2004-10-28 | 2007-04-25 | 博奥生物有限公司 | Trace amount liquid jet system |

| DE102005005638B3 (en) * | 2005-02-05 | 2006-02-09 | Cryosnow Gmbh | Method for cleaning, activating or treating workpieces using carbon dioxide snow streams comprises adding a carbon dioxide mixture via a nozzle opening of a mixing chamber into which a central gas stream and further processing |

| PL1853671T3 (en) * | 2005-03-04 | 2014-01-31 | Inktec Co Ltd | Conductive inks and manufacturing method thereof |

| JP4584003B2 (en) * | 2005-04-07 | 2010-11-17 | セイコーエプソン株式会社 | Label production method and label production apparatus |

| DE502005000877D1 (en) | 2005-04-28 | 2007-07-26 | Homag Holzbearbeitungssysteme | Apparatus and method for patterning the narrow sides of plate-shaped workpieces |

| US20060275590A1 (en) * | 2005-06-03 | 2006-12-07 | Lorenz Daniel W | Method of printing a durable UV cured ink design on a substrate |

| FR2886880B1 (en) * | 2005-06-14 | 2008-10-03 | Mgi France Sa | DIGITAL JET MACHINE FOR REMOVING A COATING ON A SUBSTRATE |

| US20100098887A1 (en) * | 2005-08-03 | 2010-04-22 | Mitsubishi Kagaku Media Co., Ltd. | Optical recording medium and ink composition |

| US20070044324A1 (en) * | 2005-08-30 | 2007-03-01 | Arthur Harris | Power Tool Attachments |

| KR100708469B1 (en) * | 2005-10-24 | 2007-04-18 | 삼성전자주식회사 | Apparatus for automatically adjusting using nozzles, image forming apparatus having the same, and method for automatically adjusting using nozzles thereof |

| US7669947B2 (en) * | 2006-05-10 | 2010-03-02 | Rsi Systems, Llc | Industrial ink jet print head system |

| EP1935657B1 (en) * | 2006-12-20 | 2013-02-13 | Homag Holzbearbeitungssysteme AG | Method and device for coating workpieces |

| US7762647B2 (en) * | 2007-09-25 | 2010-07-27 | Eastman Kodak Company | MEMS printhead based compressed fluid printing system |

| US20090252933A1 (en) * | 2008-04-04 | 2009-10-08 | 3M Innovative Properties Company | Method for digitally printing electroluminescent lamps |

-

2007

- 2007-05-10 ES ES07009417.2T patent/ES2564242T3/en active Active

- 2007-05-10 PL PL07009417T patent/PL1990204T3/en unknown

- 2007-05-10 EP EP07009417.2A patent/EP1990204B1/en active Active

-

2008

- 2008-05-05 CN CNA2008101003571A patent/CN101301821A/en active Pending

- 2008-05-09 US US12/118,389 patent/US20080280028A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| EP1990204A1 (en) | 2008-11-12 |

| PL1990204T3 (en) | 2016-04-29 |

| CN101301821A (en) | 2008-11-12 |

| US20080280028A1 (en) | 2008-11-13 |

| ES2564242T3 (en) | 2016-03-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1990204B1 (en) | Process and device for coating a surface | |

| EP3415319B1 (en) | Method and device for producing a decorative surface | |

| EP2292437B1 (en) | Method and device for the production of a component with a pre-determined surface appearance | |

| DE102010010784C5 (en) | Method and device for producing a plate-shaped product with a surface having a decoration | |

| EP2313281B2 (en) | Method for producing a printed surface on a flat workpiece | |

| EP1862304B1 (en) | Method for creating surface decoration on a panel and printing press for performing the process | |

| WO2011064075A2 (en) | Method and device for generating a three dimensional surface structure on a work piece | |

| EP4093612B1 (en) | Method for printing on a workpiece and printing device | |

| WO2008067933A1 (en) | Method and device for producing indivdualised surfaces by printing at least one individual pattern derived from a prototype thereon | |

| EP3415318A1 (en) | Workpiece and method and device for forming a decorative workpiece | |

| EP3415317B1 (en) | Method and device for producing a decorative surface | |

| DE102019103267A1 (en) | Method and device for coating a narrow side of a plate-shaped workpiece | |

| DE202004000662U1 (en) | Machine for printing the narrow sides of plate-shaped workpieces | |

| EP2065149B1 (en) | Method and device for marking a stack of board-shaped elements, marked stacks and board-shaped element | |

| EP2301762B9 (en) | Method and a device for applying a structure to a composite wood board | |

| DE102017113036B4 (en) | Method and device for producing a decorative workpiece and workpiece | |

| DE102017113035B4 (en) | Method and device for producing a decorative surface | |

| EP4069482B1 (en) | Device and method to cover the surface of a workpiece | |

| EP3656566B1 (en) | Method for printing longitudinal profile strips and profile strips | |

| DE102022114231A1 (en) | Method for sampling a workpiece | |

| DE102021103564A1 (en) | Method and device for coating a surface | |

| DE102021133045A1 (en) | Method for creating a printed decoration, method for printing a workpiece and system | |

| DE10003412A1 (en) | Method for surface finishing and refining three-dimensional wooden curtain rings, involves initially printing on one side of the ring and then on the other side in a two-step process |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| 17P | Request for examination filed |

Effective date: 20090211 |

|

| AKX | Designation fees paid |

Designated state(s): DE ES FR IT PL |

|

| 17Q | First examination report despatched |

Effective date: 20090714 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20150701 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR IT PL |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502007014428 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2564242 Country of ref document: ES Kind code of ref document: T3 Effective date: 20160321 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502007014428 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20160905 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20200520 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20200506 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210510 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230529 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20230523 Year of fee payment: 17 Ref country code: ES Payment date: 20230602 Year of fee payment: 17 Ref country code: DE Payment date: 20220615 Year of fee payment: 17 |