EP1978262A1 - Dispositif d'entraînement - Google Patents

Dispositif d'entraînement Download PDFInfo

- Publication number

- EP1978262A1 EP1978262A1 EP07006940A EP07006940A EP1978262A1 EP 1978262 A1 EP1978262 A1 EP 1978262A1 EP 07006940 A EP07006940 A EP 07006940A EP 07006940 A EP07006940 A EP 07006940A EP 1978262 A1 EP1978262 A1 EP 1978262A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- drive device

- module carrier

- receiving recess

- housing

- module

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B15/00—Fluid-actuated devices for displacing a member from one position to another; Gearing associated therewith

- F15B15/08—Characterised by the construction of the motor unit

- F15B15/14—Characterised by the construction of the motor unit of the straight-cylinder type

- F15B15/1423—Component parts; Constructional details

- F15B15/1428—Cylinders

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B15/00—Fluid-actuated devices for displacing a member from one position to another; Gearing associated therewith

- F15B15/08—Characterised by the construction of the motor unit

- F15B15/14—Characterised by the construction of the motor unit of the straight-cylinder type

- F15B15/149—Fluid interconnections, e.g. fluid connectors, passages

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B15/00—Fluid-actuated devices for displacing a member from one position to another; Gearing associated therewith

- F15B15/20—Other details, e.g. assembly with regulating devices

- F15B15/202—Externally-operated valves mounted in or on the actuator

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B15/00—Fluid-actuated devices for displacing a member from one position to another; Gearing associated therewith

- F15B15/20—Other details, e.g. assembly with regulating devices

- F15B15/28—Means for indicating the position, e.g. end of stroke

Definitions

- the invention relates to a drive device, comprising a device housing accommodating a movable drive means, in the housing wall of which at least one receiving recess is formed which is open to the outer surface of the housing wall, and having a plurality of independent functional modules fixed in each such receiving recess and cooperating with the drive means.

- the EP 0837248 B2 shows a fluid-operated linear drive, in which are housed in the interior of the device housing in the region of the end faces insert body which define fluid channels and which also have seats ofratisregulier immunityen.

- the adjustment screws for the speed regulation are here taken up separately from the insert body in holes of the end cover of the device housing.

- modules are combined with a module carrier carrying them jointly to form a functional unit, wherein the module carrier can be used or inserted into a receiving recess of the housing wall for fixing the functional unit fixed to the housing.

- the invention can be used in any type of drive device, but proves to be particularly advantageous in connection with fluid-operated drives and in this case especially with fluid-operated linear drives.

- a functional module designed as a fluid line connection device and a functional module designed as a speed regulating device, so that ultimately the fluid supply as well as the speed regulation can take place via one and the same functional unit.

- the two functional modules are independent modules, there is also a high degree of equipment flexibility in the production of the functional unit, for example by providing fluid line connection devices of different flow cross-sections, depending on the application can or speed regulators of different types, for example as a simple throttle device or as a combined throttle check device.

- a module carrier can also be equipped with more than two functional units.

- a functional module in the form of a sensor device.

- the function modules can be combined as desired within a functional unit, whereby other functional module types are also suitable, for example valve modules or electronic control modules.

- the space requirement compared to conventional designs is not or only slightly larger because the functional unit is housed at least partially sunk in the housing.

- the module carrier can at least for the most part dive into the housing wall.

- the module carrier is expediently in turn equipped with further receiving recesses, in each of which a functional module can be used.

- a functional module can be used for fixing here in particular a locking connection is recommended, although in principle other types of attachment are possible.

- One or more function modules may protrude beyond the module carrier. This applies in particular to adjusting members or other actuators. The latter can protrude outward over the housing wall, so that they are easy to grasp.

- the module carrier is in particular designed so that it can be inserted by plug-in mounting in the receiving recess.

- One possible embodiment provides for such a design that the plug-in direction coincides with the depth direction of the receiving recess.

- the assembly process can be exhausted in the insertion process.

- locking connection means are used, but also a fixation by separate securing means would be conceivable, for example by using screws or locking pins.

- the aforementioned anti-displacement device can be easily realized in that in the region of a sideways oriented mounting opening of the receiving recess as a stop acting fuse element is placed.

- This may be a separate element, but preferably a housing part of the device housing, if the latter is designed in several parts.

- the receiving recess may be formed in a cover plate, wherein it is laterally open to a subsequent pipe piece and wherein this pipe piece acts in the assembled state of the device housing as a fuse element.

- the module carrier may be provided with sealing means which cause a seal between it and the housing wall when the installation is completed in the receiving recess.

- one and the same drive device can simultaneously have a plurality of receiving recesses which can each be equipped with one functional unit.

- receiving recesses which can each be equipped with one functional unit.

- at least one such receiving recess is recommended in each case in each of the two front-side end covers.

- the drive devices represented by the two embodiments are linear drive devices which are actuated by fluid force. Their basic structure is identical, so that in the embodiment of FIGS. 6 to 10 could be dispensed with a picture of the rear end portion.

- the further description of the invention will take on the basis of these fluidic linear drive devices, although it should be noted that the inventive measures are also applicable to other types of drive devices, for example in rotary actuators and, for example, in electrical or combined electric-fluidic drive devices. The following statements apply mutatis mutandis to these types of drive devices.

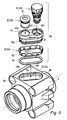

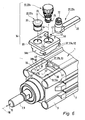

- FIGS. 1 to 5 illustrated first embodiment as well as for in FIGS. 6 to 10 Pictured second embodiment of a linear drive device.

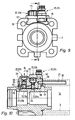

- the drive device has an elongated housing 1 multi-part structure and contains as a central housing part a pipe section 2, on the front side on this side a first and beyond a second end cover 3, 4 as further housing parts are attached. These three housing parts are clamped axially by way of example by tie rods, but could also be fastened to each other in other ways. One of the end covers could also be integrally connected to the pipe section 2.

- the pipe section 2 and the two end covers 3, 4 define a housing interior 5 in which movable drive means 7 are accommodated in the direction of the longitudinal axis 6 of the device housing 1.

- These drive means 7 comprise a drive piston 8, which bears in a sliding manner against the inner surface of the pipe section 2 and has a piston rod 9 connected thereto, which projects out of the device housing 1 through the first end cover 3.

- the outer end portion of the piston rod 9 defines a mounting portion 12 to which a non-illustrated, to be moved component can be fixed.

- the drive means 7 could also have other means for transmitting the driving force of the drive piston 8 to the outside.

- each of the two end covers 3, 4 passes through a fluid passage 13, via which the two axially separated from the drive piston 8 in the housing interior 5 working chambers 14, 15 are acted upon by fluidic pressure medium to the drive means 7 to a by a double arrow indicated linear drive movement 16 relative to the device housing 1 to drive.

- the fluid channel 13 terminates on the outside of the device housing 1 in a connection opening 17, to which a in FIG. 1 dash-dotted lines indicated fluid line 18 can be releasably connected, via which the fluid transport is handled to and away from the drive device.

- each have a plurality of functional modules 22 are fixed to the housing. They cooperate with the drive means 7 in different ways.

- each end cover 3, 4 has a first functional module embodied as a fluid line connection device 22a. It includes the already mentioned connection opening 17 and allows the detachable fixed connection of a fluid line 18. By way of example, it is designed as a plug-in connection device, but it could also be a threaded connection device. The cooperation with the drive means 7 is done here by passing the serving for acting on the drive means 7 drive medium.

- each end cover 3, 4 is equipped with a second function module designed as a speed regulating device 22b.

- the speed regulator 22b includes a throttle valve portion 23 and a check valve portion 24 which are fluidly interconnected such that inflowing fluid bypassing the throttle valve portion 23 can flow via the check valve portion 24 at a relatively high flow rate while the outflowing drive fluid is stopped by the check valve portion 24, so that it can only flow throttled, with reduced flow rate, via the throttle valve section 23.

- An adjusting member 25 formed, for example, by a rotary knob enables a variable specification of the throttling intensity. About the set Throttling intensity can affect the speed of the moving drive means 7.

- FIGS. 1 to 5 unavailable.

- the embodiment of FIGS. 6 to 10 on the other hand, per closure cover 3, 4 still has a sensor device 22c as the third functional module. It has an example bar-like sensitive portion 26, which protrudes axially, starting from the respective end cap 3, 4 in a channel-like, closed around recess 27 of the pipe section 2.

- the recess 27 is formed in the housing interior 5 enclosing the tube wall 28 of the pipe section 2, in particular in the form of an axially continuous channel.

- the cooperation with the drive means 7 consists here in a position detection of the drive piston 8, which activates the sensitive portion 26 when it passes in the vicinity of the drive movement 16 in the vicinity, in particular when it reaches the Hubendlage.

- the piston 8 preferably carries a special actuating element, in particular a permanent magnet.

- the sensor device 22c is also equipped with a connection head 32, on which connection contacts are present, to which an electrical cable can be connected, via which the values can be supplied to an external electronic control device.

- the functional modules 22 assigned to a respective end cap 3, 4 each in the first exemplary embodiment and in each case three in the second exemplary embodiment are designed as independent components together with a module carrier 33 supporting them as a functional unit 34 Assembly unit summarized.

- the module carrier 33 is in particular a one-piece body of metal or of plastic material. Conveniently, it consists of the same material as the associated end cover 3, 4. It may be formed in particular plate-shaped or disc-shaped or block-shaped.

- the functional unit 34 is attached as a whole to the associated end cap 3, 4.

- the attachment takes place exclusively on the module carrier 33, the function modules 22 are not involved.

- a receiving recess 36 which is open towards the outer surface of the housing wall and into which the module carrier 33 is inserted from the outside is formed in the housing wall 35 of the device housing 1 on the affected end cover 3, 4.

- Fastening means 37 of suitable type ensure a firm cohesion between the module carrier 33 and the housing wall 35.

- the receiving recess 36 On its side opposite the opening, has a bottom 39 formed by the housing wall 35.

- the module carrier 33 and the receiving recess 36 have coordinated mounting interfaces 38a, 38b, which is accomplished, for example, by an outer contour of the module carrier 33 matched to the inner contour of the receiving recess 36. These contours are formed substantially complementary to one another and thus allow an exact assembly.

- the cross section of the receiving recess 36 deviates from the circular shape and also the cross-section of the module carrier 33 adapted thereto is thereby ensured that the module carrier 33 can only be used with a very specific orientation and the functional modules 22 are placed in the correct orientation.

- an elongate cross section is selected, in particular with rounded end faces, while in the second embodiment, a rectangular and preferably square cross-section is present.

- the fluid channel 13 is subdivided by a housing-side channel section 13a extending in the housing wall 35 and a carrier-side channel section 13b extending in the module carrier 33, which open out on the inner surface of the receiving recess 36 and on the outer surface of the module carrier 33 so that they are in the module carrier 33 inserted communicate with each other.

- a comparable assignment exists when a plurality of fluid channels between the housing wall 35 and the module carrier 33 extend or if additional or alternatively electrical connections are to create.

- the transition region between the channel sections 13a, 13b or between any electrical connections is located in particular between the bottom 39 of the receiving recess 36 and the underside of the module carrier 33 facing it.

- FIGS. 4 and 10 can remove, connects the carrier-side channel section 13b, the first and second functional module 22a, 22b within the module carrier 33 to ensure the desired functionality. He ends in the region of the fluid line connection device 22a and communicates there with the connection opening 17.

- the functional modules 22 are mutually independent modules that are not in turn combined to form a structural unit, but that are arranged independently on the module carrier 33.

- the module carrier 33 which is preferably in the form of a one-piece body and has a plate-like design, has a further receiving recess 43a for each functional module 22, the longitudinal axis of which coincides in particular with the already mentioned depth direction 42 of the receiving recess 36 of the device housing 1.

- the further receiving recesses 43a are arranged next to one another and are capable of accommodating a functional module 22 in each case. It is particularly provided that the function modules 22 according to arrows 44 in the cross-sectionally matched further receiving recesses 43a are inserted and held securely in the inserted state by latching connection means 45.

- the further receiving recess 43b for the embodiment of the FIGS. 6 to 10 existing third functional module 22c is running outgoing corner. It is on the one hand as the just explained further receiving recesses 43a to the Bodden 39 of the receiving recess 36 opposite outer surface 46 of the module carrier 33 out open, but also laterally, to the pipe section 2 out.

- the sensor device 22c can thus be inserted from the side with its connection head 32 into the further receiving recess 43b, as shown by the arrow 47 transversely to the insertion direction 44.

- the sensor device 22c mounted in this way projects laterally away from the module carrier 33 with its sensitive section 26 and can dip into the recess 27 of the adjoining pipe section 2 in the manner already explained.

- the receiving recess 36 of the housing 35 is closed laterally all around.

- the assembly of the functional unit 34 here is a pure plug-in assembly, by the module carrier 33 is inserted according to arrow 48 in the depth direction 42 in the receiving recess 36.

- the fastening means 37 are designed here as a latching connection means 37a, to the latching except the already mentioned insertion process 48 no further action is taken.

- the latching connection means 37a comprise a latching band 52 fixedly mounted on the module carrier 33 and elastically bendable latching arms 53, which latch into one or more latching recesses 54 on the inside of the side wall of the receiving recess 36, in particular comparable to a barb function.

- the module carrier 33 In the locked state, the module carrier 33 is supported on the bottom 39 of the receiving recess 36, which expediently takes place with the interposition of an annular seal 55, which seals the fluid channel 13 and the other internal fluid connections in the joining region between module carrier 33 and housing wall 35. Through this seal 55, the module carrier 33 also experiences a constant action against the insertion direction 48, so that the latching arms 53 are firmly clamped to the latching depressions 54 and there is a play-free connection.

- a screw connection could be realized or a connection by means of pins or other separate securing means.

- the mounting interfaces 38a, 38b are coordinated so that the insertion of the module carrier 33 has to take place in the context of a plug-VerschiebeVorganges.

- the module carrier 33 is inserted into the receiving recess 36, comparable to the first exemplary embodiment according to arrow 48 in the depth direction 42, whereby it has not yet found its final place after this insertion process transverse to the depth direction 42. This is only the case when the module carrier 33 is subsequently displaced transversely to the depth direction 42 within the scope of a displacement process 56 indicated by a further arrow.

- the displacement direction 56 expediently coincides with the longitudinal axis 10 of the device housing 1.

- the receiving recess 36 in the second embodiment with a Pipe piece 2 facing side mounting opening 57 provided. It makes it possible to insert the module carrier in a position in the receiving recess 36, in which the module carrier projects laterally out of the receiving recess 36 with a lateral edge section 58 through the mounting opening 57. Only in the subsequent displacement process 56 of the module carrier 33 dives with its entire cross-section in the receiving recess 36, wherein at the same time a locking operation takes place, through which the module carrier 33 is locked in the axial direction of the depth direction 42 with respect to the housing wall 35 form-fitting manner. An accidental unlocking by pushing back of the module carrier 33 is prevented by the mounted after insertion of the module carrier 33 pipe piece 2, which projects at least partially in front of the mounting opening 57 and covers it so far that a module carrier 33 in position holding stop is formed.

- the mentioned locking is caused by the fastening means 37 designed as locking means 37b.

- locking projections 62 are formed, which engage in the sliding movement 56 in locking recesses 63 inside of the side wall of the receiving recess 36.

- the pairs of locking projections 62 and locking recesses 63 are assigned to the four corner regions of the rectangularly contoured module carrier 33.

- the mounting interfaces 38a, 38b could also be matched to one another in such a way that insertion of the module carrier 33 has to take place by means of a pure insertion process 56 transversely to the depth direction 42.

- the module carrier 33 is then inserted similar to a drawer in the laterally open receiving recess 36.

- the insertion-permitting lateral mounting opening 57 could also be oriented differently than in the axial direction of the longitudinal axis 10, for example transversely thereto.

- the inserted module carrier 33 is expediently received in the receiving recess 36 with at least the largest part of its overall height. Preferably, however, it has at its top a circumferentially protruding edge portion 65, which covers the parting line between it and the side wall of the receiving recess 36 and prevents ingress of impurities.

- the insertion of the module carrier 33 in the receiving recess 36 is advantageously carried out in the equipped with the functional modules 22 state.

- the functional unit 34 is installed as a unit.

- a receiving recess 36 that can be equipped with a functional unit 34 on each end cap 3, 4. However, one of these could be dispensed with if necessary. If the fluidic connection made in the interior of the device housing 1 is selected accordingly, then the embodiment of the one end cover could also be assigned Function modules 22 are also attached to the other end cover, be it in conjunction with an installed in an additional receiving recess 36 further functional unit 34 or as an integral part of the existing functional unit 34 by equipping them with a corresponding plurality of functional modules 22.

- FIG. 7 a significant advantage of the invention will become apparent.

- two differently equipped functional units 34 which are alternatively installed in one and the same receiving recess 36.

- the module carriers 33 of these two functional units 34 agree with respect to the design of their mounting interfaces 38a and can thus be combined with the mounting interface 38b of the receiving recess 36 without problems.

- differences arise in the module configuration in that in the case of the functional unit 34 shown on the right, three functional modules 22 are fixed on the module carrier 33 and only two functional modules 22 on the functional unit 34 shown on the left.

- the fluid line connection devices 22a present in both functional units 34 differ in their connection diameter, so that fluid lines of different cross sections can be connected.

- the drive device may be associated with a plurality of functional units 34 which are equipped with different types and / or numbers of functional modules 22 but which have identical mounting interfaces 38a, so that they can alternatively be installed in receiving recesses 36 having a mounting interface 38b adapted thereto.

- receiving recesses 36 with matching mounting interfaces 38b on the respective device housing 1, which then has to equip only with the desired functional unit 34.

- the mounting interfaces 38a, 38b are thus standardized, and it requires the part of the device housing 1 no cumbersome, specific processing operations.

- the module carrier 33 can at least for the most part be integrated into the housing wall 35, so that there is no disadvantageous increase in the external dimensions of the drive device compared to conventional designs.

- At least one receiving recess 36 for a functional unit 34 could also be additionally or alternatively formed on the pipe section 2.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Actuator (AREA)

- Valve Housings (AREA)

- Infusion, Injection, And Reservoir Apparatuses (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07006940.6A EP1978262B1 (fr) | 2007-04-03 | 2007-04-03 | Dispositif d'entraînement |

| CNA2008100905982A CN101280795A (zh) | 2007-04-03 | 2008-04-03 | 驱动装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07006940.6A EP1978262B1 (fr) | 2007-04-03 | 2007-04-03 | Dispositif d'entraînement |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1978262A1 true EP1978262A1 (fr) | 2008-10-08 |

| EP1978262B1 EP1978262B1 (fr) | 2016-05-25 |

Family

ID=38474113

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07006940.6A Not-in-force EP1978262B1 (fr) | 2007-04-03 | 2007-04-03 | Dispositif d'entraînement |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1978262B1 (fr) |

| CN (1) | CN101280795A (fr) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2010108589A1 (fr) * | 2009-03-25 | 2010-09-30 | Festo Ag & Co. Kg | Tube de carter et entraînement linéaire équipé de ce dernier |

| DE102016107393A1 (de) | 2016-04-21 | 2017-10-26 | Festo Ag & Co. Kg | Modulares Antriebssystem |

| DE102016107394A1 (de) | 2016-04-21 | 2017-10-26 | Festo Ag & Co. Kg | Verbindungsvorrichtung |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0520212A1 (fr) * | 1991-06-24 | 1992-12-30 | Smc Kabushiki Kaisha | Commande de vitesse |

| DE19952881A1 (de) | 1998-11-06 | 2000-05-11 | Smc Corp | Luftzylinder mit Dämpfungsmechanismus |

| EP1369633A1 (fr) * | 2002-06-07 | 2003-12-10 | FESTO AG & Co | Dispositif de connexion pour des conduits de fluide |

| EP0837248B2 (fr) * | 1996-10-15 | 2005-09-07 | Ab Rexroth Mecman | Verin à fluide sous pression. |

| EP1309803B1 (fr) * | 2000-08-19 | 2006-01-11 | Festo Ag & Co. | Entrainement lineaire |

-

2007

- 2007-04-03 EP EP07006940.6A patent/EP1978262B1/fr not_active Not-in-force

-

2008

- 2008-04-03 CN CNA2008100905982A patent/CN101280795A/zh active Pending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0520212A1 (fr) * | 1991-06-24 | 1992-12-30 | Smc Kabushiki Kaisha | Commande de vitesse |

| EP0837248B2 (fr) * | 1996-10-15 | 2005-09-07 | Ab Rexroth Mecman | Verin à fluide sous pression. |

| DE19952881A1 (de) | 1998-11-06 | 2000-05-11 | Smc Corp | Luftzylinder mit Dämpfungsmechanismus |

| EP1309803B1 (fr) * | 2000-08-19 | 2006-01-11 | Festo Ag & Co. | Entrainement lineaire |

| EP1369633A1 (fr) * | 2002-06-07 | 2003-12-10 | FESTO AG & Co | Dispositif de connexion pour des conduits de fluide |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2010108589A1 (fr) * | 2009-03-25 | 2010-09-30 | Festo Ag & Co. Kg | Tube de carter et entraînement linéaire équipé de ce dernier |

| DE102016107393A1 (de) | 2016-04-21 | 2017-10-26 | Festo Ag & Co. Kg | Modulares Antriebssystem |

| DE102016107394A1 (de) | 2016-04-21 | 2017-10-26 | Festo Ag & Co. Kg | Verbindungsvorrichtung |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1978262B1 (fr) | 2016-05-25 |

| CN101280795A (zh) | 2008-10-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2479465B1 (fr) | Dispositif de soupape doté d'un dispositif d'actionnement auxiliaire manuel | |

| DE4004834A1 (de) | Ventilbaugruppe | |

| EP3004702B1 (fr) | Combination d'un boîtier et d'une soupape | |

| EP0681128A1 (fr) | Electrovanne | |

| WO2010057560A1 (fr) | Vanne et procédé de montage | |

| EP1134428B1 (fr) | Agencement de distributeur | |

| DE102005003982A1 (de) | Pneumatisches Wegeventil mit einem Ventilschieber | |

| DE102009017861A1 (de) | Ventileinrichtung | |

| DE102006018084B4 (de) | Lagertragstruktur für Stellglied | |

| EP3390873B1 (fr) | Dispositif formant soupape électromagnétique et utilisation de celui-ci | |

| DE102014004213B3 (de) | Ventilanordnung | |

| EP1978262B1 (fr) | Dispositif d'entraînement | |

| EP1939461A2 (fr) | Vanne pneumatique modulaire à tiroir | |

| EP2153096A1 (fr) | Système de soupape comportant un dispositif d'actionnement auxiliaire manuel | |

| DE102011100327B3 (de) | Fluidtechnische Baugruppe | |

| EP2217812B1 (fr) | Ensemble de soupapes et systeme d'armoire de distribution equipe de cet ensemble | |

| EP1218656B1 (fr) | Ensemble vanne | |

| DE10014906B4 (de) | Mehrwegeventil (Deckelbefestigung) | |

| DE102006018085B4 (de) | Verschiebungsdifferenzabsorptionsmechanismus für Zylindervorrichtung | |

| EP2781811B1 (fr) | Dispositif d'aération | |

| DE8807543U1 (de) | Pneumatisches Stellelement | |

| EP1752693B1 (fr) | Soupape électromagnétique | |

| DE102006024762B4 (de) | Ventil | |

| DE10104878C2 (de) | Vereinzelungseinrichtung mit einer Druckmittelzylinderanordnung | |

| DE10334206B4 (de) | Ventileinheit |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20080116 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160107 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN Ref country code: AT Ref legal event code: REF Ref document number: 802574 Country of ref document: AT Kind code of ref document: T Effective date: 20160615 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502007014836 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160926 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160826 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502007014836 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20170228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20170315 Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20170403 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20171229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170502 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170430 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170403 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170403 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170403 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170430 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 802574 Country of ref document: AT Kind code of ref document: T Effective date: 20170403 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170403 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502007014836 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20070403 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160925 |