EP1952011B1 - Fuel injection apparatus for an internal combustion engine having direct fuel injection - Google Patents

Fuel injection apparatus for an internal combustion engine having direct fuel injection Download PDFInfo

- Publication number

- EP1952011B1 EP1952011B1 EP06807052.3A EP06807052A EP1952011B1 EP 1952011 B1 EP1952011 B1 EP 1952011B1 EP 06807052 A EP06807052 A EP 06807052A EP 1952011 B1 EP1952011 B1 EP 1952011B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pressure

- valve element

- fuel injection

- injection device

- chamber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 239000000446 fuel Substances 0.000 title claims description 63

- 238000002347 injection Methods 0.000 title claims description 32

- 239000007924 injection Substances 0.000 title claims description 32

- 238000002485 combustion reaction Methods 0.000 title claims description 5

- 230000008878 coupling Effects 0.000 claims description 15

- 238000010168 coupling process Methods 0.000 claims description 15

- 238000005859 coupling reaction Methods 0.000 claims description 15

- 239000012530 fluid Substances 0.000 claims 1

- 238000007789 sealing Methods 0.000 description 12

- 238000004519 manufacturing process Methods 0.000 description 6

- 238000000034 method Methods 0.000 description 4

- 238000013461 design Methods 0.000 description 3

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 230000018109 developmental process Effects 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 230000004323 axial length Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000002655 kraft paper Substances 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 238000013519 translation Methods 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M61/00—Fuel-injectors not provided for in groups F02M39/00 - F02M57/00 or F02M67/00

- F02M61/16—Details not provided for in, or of interest apart from, the apparatus of groups F02M61/02 - F02M61/14

- F02M61/20—Closing valves mechanically, e.g. arrangements of springs or weights or permanent magnets; Damping of valve lift

- F02M61/205—Means specially adapted for varying the spring tension or assisting the spring force to close the injection-valve, e.g. with damping of valve lift

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M47/00—Fuel-injection apparatus operated cyclically with fuel-injection valves actuated by fluid pressure

- F02M47/02—Fuel-injection apparatus operated cyclically with fuel-injection valves actuated by fluid pressure of accumulator-injector type, i.e. having fuel pressure of accumulator tending to open, and fuel pressure in other chamber tending to close, injection valves and having means for periodically releasing that closing pressure

- F02M47/027—Electrically actuated valves draining the chamber to release the closing pressure

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M61/00—Fuel-injectors not provided for in groups F02M39/00 - F02M57/00 or F02M67/00

- F02M61/04—Fuel-injectors not provided for in groups F02M39/00 - F02M57/00 or F02M67/00 having valves, e.g. having a plurality of valves in series

- F02M61/10—Other injectors with elongated valve bodies, i.e. of needle-valve type

- F02M61/12—Other injectors with elongated valve bodies, i.e. of needle-valve type characterised by the provision of guiding or centring means for valve bodies

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M2200/00—Details of fuel-injection apparatus, not otherwise provided for

- F02M2200/70—Linkage between actuator and actuated element, e.g. between piezoelectric actuator and needle valve or pump plunger

- F02M2200/703—Linkage between actuator and actuated element, e.g. between piezoelectric actuator and needle valve or pump plunger hydraulic

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M2547/00—Special features for fuel-injection valves actuated by fluid pressure

- F02M2547/001—Control chambers formed by movable sleeves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M2547/00—Special features for fuel-injection valves actuated by fluid pressure

- F02M2547/003—Valve inserts containing control chamber and valve piston

Definitions

- the invention relates to a fuel injection device for an internal combustion engine with direct fuel injection according to the preamble of claim 1.

- the DE 100 24 702 A1 and DE 100 24 703 A1 each show a fuel injection device with which the fuel can be injected directly into its associated combustion chamber of an internal combustion engine.

- a valve element is arranged in a housing, which in the region of a fuel outlet opening has a total acting in the opening direction of the valve element pressure surface.

- a control surface acting in the closing direction is present, which delimits a control chamber.

- a high fuel pressure is present at a region of the pressure surface acting in the opening direction and at the control surface acting in the closing direction, as is provided by a fuel rail.

- the excess force acting in the closing direction is achieved by the pressure surface acting in the opening direction at least when the valve element is closed is smaller than the control surface acting in the closing direction.

- the pressure applied to the control surface is lowered until the hydraulic force resultant in the opening direction on the pressure surface exceeds the forces acting in the closing direction. As a result, opening of the valve element is effected.

- valve element In both known fuel injectors, the valve element "floats" in high fuel pressure.

- measures are proposed with which the pressure in the control room after lowering can be raised again very quickly.

- Object of the present invention is to develop a fuel injection device of the type mentioned so that it closes very quickly. Another object is a simplified manufacture of the device.

- the closing of the valve element is assisted by the fact that when the valve element is open is lowered at the pressure acting in the opening direction of the pressure surface (or at least at a part thereof). This is possible, for example, by a corresponding throttling between the valve element and a housing-side valve seat region and / or by an additional valve spool section.

- the restriction can be adjusted so that at least slightly open valve element, the force acting in the opening direction is smaller than when the valve element is closed. As a result, the closing process is supported and accelerated. The valve element is "sucked" to close the quasi to the valve seat.

- the invention makes it possible in a special way to design the pressure surface acting in the opening direction and the control surface acting in the closing direction, each projecting onto a plane perpendicular to the direction of movement of the valve element, at least approximately the same size. This allows a low-cost production of the valve element.

- the fuel injection device according to the invention operates with a high efficiency, since the existing in earlier devices leakage between the valve element and the housing is no longer available. A return line can be made smaller in the sequence.

- valve element as a whole can be arranged in a high-pressure space connected to the high-pressure connection.

- a sealing sleeve can be provided. This can be radially free, ie without guidance, so that manufacturing tolerances can be easily compensated.

- the control of the control chamber can then be done by an existing example in the sleeve control channel.

- the valve element is multi-part and at least two parts of the valve element are coupled to each other via a hydraulic coupler.

- the hydraulic coupler may comprise an intermediate disc which geometrically separates a first coupling space from a second coupling space. This simplifies the production.

- the hydraulic coupler comprises a connecting channel which connects the two coupling spaces hydraulically with each other. This allows the optimization of the coupler, for example by designing the connecting channel as a flow restrictor.

- At least one of the parts of the valve element can be designed as an elastic pressure rod such that an opening movement of the control chamber limiting part of the valve element is time-delayed transmits to the cooperating with the valve seat part of the valve element.

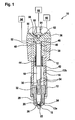

- a fuel injector carries in the figure as a whole the reference numeral 10. It comprises a housing 12, which in turn has a nozzle body 12a, a Injector body 12b, and a nozzle lock nut 12c includes.

- a stepped recess 14 is provided in its longitudinal direction, of which in FIG. 1 Lower end fuel outlet channels 16 go out, which pass through the wall of the nozzle body 12 a.

- a needle-like valve element 18 is arranged in the recess 14. This has an overall substantially constant diameter D.

- the valve element 18 has a conical tip formed by a first conical annular surface 20 and a second conical end surface 22.

- the annular surface 20 and the end surface 22 have a different conicity, so that a sealing edge 24 is formed between them. This is when the valve element 18 is closed at an opposite also conical valve seat surface 26 in FIG. 1 lower end portion of the recess 14 in the nozzle body 12a. In this way, the valve element 18 can separate the fuel discharge passages 16 from an annular high-pressure space 28 present upstream of the sealing edge 24 between the valve element 18 and the housing 12.

- the high pressure chamber 28 extends over the entire length of the recess 14 and the valve element 18. The latter is guided in the housing 12 above all over a only a small axial length having guide portion 30, which with a complementary guide portion 32 at in FIG. 1 cooperates with the upper end of the nozzle body 12a.

- the high-pressure chamber 28 is not interrupted by the two guide sections 30 and 32:

- the valve element 18 In the region of the guide section 30, the valve element 18 has four flattened portions 34 distributed over its circumference, through which the corresponding guide sections 30 and 32 pass Flow channels are formed, which are also part of the high-pressure chamber 28.

- the flats 34 are dimensioned such that a throttling of the flow, which flows through the flow channels formed, is substantially zero.

- the recess 14 is in FIG. 1 closed at the top by a valve piece 36.

- the valve piece 36 is attached to the injector body 12b in a manner not shown. Between the sleeve portion 38 and a slightly spaced from this annular collar 42 on the valve element 18, a spring 44 is clamped, by which the valve element 18 is acted upon very easily in the closing direction.

- a control surface 46 is present at the in FIG. 1 upper end of the valve element 18, a control surface 46 is present. It represents a part of a boundary of a control chamber 48 formed between the sleeve portion 38 and the valve element 18.

- the control chamber 48 Via an inlet throttle 50, the control chamber 48 is connected to the high pressure chamber 28, which in turn is connected via a channel 52 in the injector body 12 b with a high pressure port 54.

- This in turn is connected in the operation of the fuel injection device 10 with a fuel rail ("rail"), which in FIG. 1 but not shown.

- fuel rail fuel can be stored under very high pressure.

- a plurality of fuel injectors may be connected.

- An outlet throttle 56 connects the control chamber 48 further with a switching valve 58.

- the switching valve 58 in this example has a valve ball 62, which in turn is acted upon by a valve stem 64 which in turn either hydraulically or directly via a corresponding actuator 66 is actuated.

- fuel injector 10 is operated as follows: In an initial state, the switching valve 58 is closed.

- the high fuel pressure (up to 1800 bar) prevailing at the high-pressure connection 54 prevails in the high-pressure space 28 and is also transmitted through the inlet throttle 50 into the control chamber 48.

- the high pressure is also at the conical annular surface 20 in FIG. 1 lower end of the valve element 18 at.

- the hydraulic conical annular surface 20 acting in the opening direction is smaller overall than the control surface 46 acting in the closing direction. For this reason, a force resultant in the closing direction acts altogether on the valve element 18, which ensures that the sealing edge 24 of the valve element 18 abuts against the opposite valve seat surface 26 is pressed.

- the connection of the high-pressure chamber 28 is interrupted to the fuel outlet channels 16.

- the switching valve 58 is opened.

- the control chamber 48 is now connected via the outlet throttle 56 to the low pressure port 60. Since the inlet throttle 50 throttles more than the outlet throttle 56, the pressure in the control chamber 48 and consequently also the force acting on the control surface 46 and acting in the closing direction decreases Force. As soon as it falls below the hydraulic force acting on the conical annular surface 20 and acting in the opening direction (minus the force of the spring 44), the valve element 18 with the sealing edge 24 lifts away from the valve seat surface 26. Fuel now flows from the high-pressure chamber 28 to the fuel outlet channels 16.

- the switching valve 58 In order to stop the injection of fuel by the fuel injection device 10, the switching valve 58 is closed. The connection of the control chamber 48 to the low pressure port 60 is therefore interrupted. Fuel can now flow back through the inlet throttle 50 into the control chamber 48, so that there adjusts the pressure prevailing at the high pressure port 54 and the high pressure chamber 28.

- the fact that the valve element 18 now executes a closing movement, although the hydraulic cross-sectional area of the control surface 46 acting in the closing direction and the hydraulic cross-sectional area of the pressure surfaces 20 and 22 acting in the opening direction are the same, is related to the following: In the region of the sealing edge 24, the flow between the both annular surfaces 20 and 22 on the one hand and the opposite valve seat surface 26 on the other hand very slightly throttled.

- the geometry of the conical annular surface 20 and the conical end surface 22, in particular the conicity of these two surfaces 20 and 22, relative to the valve seat surface 26 is selected so that over a stroke H a course of the force acting in the opening direction F is achieved, as in FIG. 2 is shown.

- the force F 1 acting in the opening direction is smaller than the force F 0 acting in the opening direction due to throttling effects.

- a force F 2 Only at a further increased stroke H acts in the opening direction, a force F 2 , which is significantly greater than the force F 0 .

- valve element 18 is virtually "sucked” toward the end of the closing operation and accordingly closes quickly.

- a force course, as in FIG. 2 is shown, in addition or reinforced by the formation of a valve spool portion (in FIG. 1 not shown), which cooperates with a corresponding housing-side section.

- valve element 18 is in one piece as a whole.

- a certain elasticity which causes a certain compression with closed valve element 18, which can be used to even the smallest amounts of fuel in the range of 1 mm 3 targeted and precise inject.

- FIG. 3 A first embodiment of a fuel-one embodiment of a fuel injection device is in FIG. 3 shown.

- the sleeve portion 38 is formed as a separate part of the valve 36. It is pushed onto the end region 40 of the valve element 18 and is acted upon by the spring 44 against the valve piece 36.

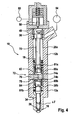

- a further modified second embodiment shows FIG. 4 ,

- the valve element 18 is divided into two, with a nozzle needle 68 and a control piston 70.

- the control piston 34 is comparatively long and dimensioned so that it, as will be explained in more detail below, has a significant elasticity.

- Nozzle needle 68 and control piston 70 are coupled to each other via a hydraulic coupler 72 comprising two hydraulic coupling chambers 74a and 74b.

- the two coupling spaces 74a and 74b are geometrically separated from each other by a housing-side washer 76, but hydraulically connected to each other via a connecting channel 78.

- the upper coupling space 74a is bounded radially by a sleeve 80a, the lower of a sleeve 80b.

- the sleeves are each pressed against the intermediate disc 76 in a spring 81a and 81b, which is supported on the housing side (spring 81a) or on the nozzle needle 68 (spring 81b).

- the control piston 70 defines with an end face 82 axially the upper coupling space 74a, the nozzle needle with an end face 84 the lower coupling space 74b.

- the control piston 70 moves in FIG. 4 up.

- the pressure in the upper coupling chamber 74a decreases, which transfers via the connecting channel 78 into the lower coupling space 74b and also leads there to a pressure reduction.

- the nozzle needle 68 is quasi wound up.

- FIG. 4 it can be seen that the control piston 70 and the nozzle needle 68 "float" in the high pressure of the above and below the washer 76 high-pressure chambers 28a and 28b.

- corresponding passages (without reference numerals) are present in the intermediate disk 76. As a result, the sealing problem is reduced.

- control piston 34 Due to the elasticity and length L, in particular of the control piston 34, it is possible that even very small amounts of fuel can be injected with the fuel injection device 18. This is due to the fact that the control piston initially, when the nozzle needle 68 rests against the housing-side valve seat, is elastically compressed by the high pressure in the control chamber 48. At a pressure reduction in the control chamber 48, the control piston 70 must first be lengthen to bring about the above-mentioned pressure reduction in the coupling chambers 74a and 74b.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Fuel-Injection Apparatus (AREA)

Description

Die Erfindung betrifft eine Kraftstoff-Einspritzvorrichtung für eine Brennkraftmaschine mit Kraftstoff-Direkteinspritzung nach dem Oberbegriff des Anspruchs 1.The invention relates to a fuel injection device for an internal combustion engine with direct fuel injection according to the preamble of claim 1.

Die

Bei geschlossener Kraftstoff-Einspritzvorrichtung liegt an einem Bereich der in Öffnungsrichtung wirkenden Druckfläche und an der in Schließrichtung wirkenden Steuerfläche ein hoher Kraftstoffdruck an, wie er beispielsweise von einer Kraftstoff-Sammelleitung ("Rail") bereitgestellt wird. Der in Schließrichtung wirkende Kraftüberschuss wird erreicht, indem die in Öffnungsrichtung wirkende Druckfläche zumindest bei geschlossenem Ventilelement kleiner ist als die in Schließrichtung wirkende Steuerfläche.When the fuel injection device is closed, a high fuel pressure is present at a region of the pressure surface acting in the opening direction and at the control surface acting in the closing direction, as is provided by a fuel rail. The excess force acting in the closing direction is achieved by the pressure surface acting in the opening direction at least when the valve element is closed is smaller than the control surface acting in the closing direction.

Zum Öffnen des Ventilelements wird der an der Steuerfläche anliegende Druck abgesenkt, bis die in Öffnungsrichtung wirkende hydraulische Kraftresultierende an der Druckfläche die in Schließrichtung wirkenden Kräfte übersteigt. Hierdurch wird ein Öffnen des Ventilelements bewirkt.To open the valve element, the pressure applied to the control surface is lowered until the hydraulic force resultant in the opening direction on the pressure surface exceeds the forces acting in the closing direction. As a result, opening of the valve element is effected.

Bei beiden bekannten Kraftstoff-Einspritzvorrichtungen "schwimmt" das Ventilelement im hohen Kraftstoffdruck. Bei dem in der

In der

Aufgabe der vorliegenden Erfindung ist es, eine Kraftstoff-Einspritzvorrichtung der eingangs genannten Art so weiterzubilden, dass sie sehr schnell schließt. Eine weitere Aufgabe ist eine vereinfachte Herstellung der Vorrichtung.Object of the present invention is to develop a fuel injection device of the type mentioned so that it closes very quickly. Another object is a simplified manufacture of the device.

Diese Aufgabe wird durch eine Kraftstoff-Einspritzvorrichtung mit den Merkmalen des Anspruchs 1 gelöst. Ferner wird die Aufgabe durch ein Verfahren mit den Merkmalen des nebengeordneten Verfahrensanspruches gelöst. Vorteilhafte Weiterbildungen sind in Unteransprüchen angegeben.This object is achieved by a fuel injection device having the features of claim 1. Furthermore, the object is achieved by a method having the features of the independent method claim. Advantageous developments are specified in subclaims.

Erfindungsgemäß wird das Schließen des Ventilelements dadurch unterstützt, dass bei geöffnetem Ventilelement der an der in Öffnungsrichtung wirkenden Druckfläche (oder zumindest an einem Teil hiervon) anliegende Druck abgesenkt wird. Dies ist beispielsweise durch eine entsprechende Drosselung zwischen dem Ventilelement und einem gehäuseseitigen Ventilsitzbereich und/oder durch einen zusätzlichen Ventilschieberabschnitt möglich.According to the invention, the closing of the valve element is assisted by the fact that when the valve element is open is lowered at the pressure acting in the opening direction of the pressure surface (or at least at a part thereof). This is possible, for example, by a corresponding throttling between the valve element and a housing-side valve seat region and / or by an additional valve spool section.

Mittels einer entsprechenden Ausformung einerseits des gehäuseseitigen Ventilsitzbereichs und andererseits eines entsprechenden Dichtbereichs am Ventilelement kann die Drosselung so eingestellt werden, dass mindestens bei etwas geöffnetem Ventilelement die in Öffnungsrichtung wirkende Kraft kleiner ist als bei geschlossenem Ventilelement. Hierdurch wird der Schließvorgang unterstützt und beschleunigt. Das Ventilelement wird zum Schließen quasi an den Ventilsitz "angesaugt".By means of a corresponding shaping on the one hand of the housing-side valve seat portion and on the other hand a corresponding sealing region on the valve element, the restriction can be adjusted so that at least slightly open valve element, the force acting in the opening direction is smaller than when the valve element is closed. As a result, the closing process is supported and accelerated. The valve element is "sucked" to close the quasi to the valve seat.

Die Erfindung ermöglicht es in besonderer Weise, die in Öffnungsrichtung wirkende Druckfläche und die in Schließrichtung wirkende Steuerfläche, jeweils auf eine Ebene senkrecht zur Bewegungsrichtung des Ventilelements projiziert, wenigstens in etwa gleich groß auszugestalten. Dies gestattet eine preiswerte Fertigung des Ventilelements.The invention makes it possible in a special way to design the pressure surface acting in the opening direction and the control surface acting in the closing direction, each projecting onto a plane perpendicular to the direction of movement of the valve element, at least approximately the same size. This allows a low-cost production of the valve element.

Vorgeschlagen wird auch, in allen zwischen Steuerraum und Druckraum liegenden Räumen, die das Ventilelement umgeben, im Betrieb wenigstens zeitweise und wenigstens in etwa der am Hochdruckanschluss herrschende hohe Kraftstoffdruck herrscht. Dies kann beispielsweise dadurch realisiert werden, dass die Ausnehmung, in der das Ventilelement insgesamt aufgenommen ist, mit dem Hochdruckanschluss verbunden ist. Ein Niederdruckbereich ist demzufolge nicht mehr vorhanden ("druckausgeglichenes" Ventil). Somit kann keine Leckage zwischen dem Hoch- und einem solchen Niederdruckbereich auftreten, so dass auch die entsprechende Abdichtung und eine hierfür erforderliche Leckageleitung entfallen können.It is also proposed, in all lying between the control chamber and pressure chamber spaces surrounding the valve element, during operation at least temporarily and at least approximately prevails at the high pressure connection prevailing high fuel pressure. This can be realized, for example, in that the recess in which the valve element is accommodated in its entirety is connected to the high-pressure connection. A low pressure area is therefore no longer available ("pressure balanced" valve). Thus, no leakage between the high and such Low pressure area occur, so that the corresponding seal and a leaking line required for this purpose can be omitted.

Dies gestattet einen einfacheren Aufbau der Kraftstoff-Einspritzvorrichtung mit insgesamt weniger Teilen, was zum einen die Montage erleichtert und zum anderen eine kleinere Bauweise ermöglicht. Darüber hinaus arbeitet die erfindungsgemäße Kraftstoff-Einspritzvorrichtung mit einem hohen Wirkungsgrad, da die bei früheren Vorrichtungen vorhandene Leckage zwischen Ventilelement und Gehäuse nicht mehr vorhanden ist. Eine Rücklaufleitung kann in der Folge kleiner ausgelegt werden.This allows a simpler structure of the fuel injection device with fewer parts, which on the one hand facilitates the assembly and on the other hand allows a smaller design. In addition, the fuel injection device according to the invention operates with a high efficiency, since the existing in earlier devices leakage between the valve element and the housing is no longer available. A return line can be made smaller in the sequence.

Dadurch, dass eine Abdichtung zwischen der in Öffnungsrichtung wirkenden Druckfläche und der in Schließrichtung wirkenden Steuerfläche nicht mehr im bisherigen Sinne erforderlich ist, kann das Ventilelement insgesamt in einem mit dem Hochdruckanschluss verbundenen Hochdruckraum angeordnet sein. Um eine Druckabsenkung im Steuerraum dennoch erreichen zu können, kann dann einfach eine Dichthülse vorgesehen sein. Diese kann radial frei, also ohne Führung, sein, so dass Fertigungstoleranzen einfach ausgeglichen werden können. Die Ansteuerung des Steuerraums kann dann durch einen beispielsweise in der Hülse vorhandenen Steuerkanal erfolgen.Due to the fact that sealing between the pressure surface acting in the opening direction and the control surface acting in the closing direction is no longer required in the previous sense, the valve element as a whole can be arranged in a high-pressure space connected to the high-pressure connection. In order to still be able to achieve a pressure reduction in the control room, then simply a sealing sleeve can be provided. This can be radially free, ie without guidance, so that manufacturing tolerances can be easily compensated. The control of the control chamber can then be done by an existing example in the sleeve control channel.

Um mit der erfindungsgemäßen Kraftstoff-Einspritzvorrichtung auch Kleinstmengen im Bereich,von 1 mm3 einspritzen zu können, wird eine "Stauchung" des Ventilelements durch eine entsprechende Längenbeziehungsweise Materialauswahl des Ventilelements eingestellt. Alle vorangegangenen Maßnahmen ermöglichen einen Betrieb der Kraftstoff-Einspritzvorrichtung auch bei sehr hohen Drücken von bis zu 1800 bar.In order to be able to inject very small amounts in the range of 1 mm 3 with the fuel injection device according to the invention, a "compression" of the valve element is adjusted by a corresponding Längenbeziehungsweise material selection of the valve element. All previous measures allow operation of the fuel injector even at very high pressures of up to 1800 bar.

Erfindungsgemäß ist das Ventilelement mehrteilig und mindestens zwei Teile des Ventilelements über einen hydraulischen Koppler miteinander gekoppelt sind. Hierdurch wird die Freiheit bei der Auslegung der Kraftstoff-Einspritzvorrichtung erheblich erhöht. Auch die Herstellung der Vorrichtung wird vereinfacht.According to the invention, the valve element is multi-part and at least two parts of the valve element are coupled to each other via a hydraulic coupler. As a result, the freedom in the design of the fuel injection device is considerably increased. The manufacture of the device is simplified.

In Weiterbildung hierzu wird vorgeschlagen, dass die beiden Teile des Ventilelements im hydraulischen Koppler dann, wenn das Ventilelement am Ventilsitz anliegt, voneinander beabstandet sind. Hierdurch wird eine direkte mechanische Kopplung der beiden Teile und somit ein mögliches Prellen verhindert.In a further development, it is proposed that the two parts of the valve element in the hydraulic coupler, when the valve element rests against the valve seat, are spaced from each other. As a result, a direct mechanical coupling of the two parts and thus a possible bouncing is prevented.

Dabei kann der hydraulische Koppler eine Zwischenscheibe umfassen, die einen ersten Koppelraum von einem zweiten Koppelraum geometrisch trennt. Dies vereinfacht die Herstellung.In this case, the hydraulic coupler may comprise an intermediate disc which geometrically separates a first coupling space from a second coupling space. This simplifies the production.

Möglich ist, dass der hydraulische Koppler einen die beiden Koppelräume hydraulisch miteinander verbindenden Verbindungskanal umfasst. Dies gestattet die Optimierung des Kopplers, beispielsweise durch Ausgestaltung des Verbindungskanals als Strömungsdrossel.It is possible that the hydraulic coupler comprises a connecting channel which connects the two coupling spaces hydraulically with each other. This allows the optimization of the coupler, for example by designing the connecting channel as a flow restrictor.

Mindestens eines der Teile des Ventilelements kann als elastische Druckstange derart ausgebildet sein, dass eine Öffnungsbewegung des den Steuerraum begrenzenden Teils des Ventilelements sich zeitverzögert auf den mit dem Ventilsitz zusammenarbeitenden Teil des Ventilelements überträgt. Auf diese Weise können trotz des Einsatzes eine preiswerten Magnetventils zur Steuerung des Drucks im Steuerraum auch sehr kurze Öffnungszeiten und damit die Fähigkeit, auch Kleinstmengen einspritzen zu können, realisiert werden.At least one of the parts of the valve element can be designed as an elastic pressure rod such that an opening movement of the control chamber limiting part of the valve element is time-delayed transmits to the cooperating with the valve seat part of the valve element. In this way, despite the use of a cheap solenoid valve to control the pressure in the control room and very short opening times and thus the Ability to inject even very small quantities can be realized.

Ausführungsbeispiele der vorliegenden Erfindung unter Bezugnahme auf die beiliegende Zeichnung näher erläutert. In der Zeichnung zeigen:

- Figur 1

- einen teilweisen Schnitt durch einen Bereich einer einer Kraftstoff-Einspritzvorrichtung, die nicht Teil der Erfindung ist;

- Figur 2

- ein Diagramm, in dem ein Verlauf einer in Öffnungsrichtung wirkenden Kraft über dem Hub eines Ventilelements der Kraftstoff-Einspritzvorrichtung von

Figur 1 aufgetragen ist; - Figur 3

- einen teilweisen Schnitt durch einen Bereich einer ersten Ausführungsform einer Kraftstoff-Einspritzvorrichtung; und

- Figur 4

- eine Darstellung ähnlich zu

Figur 1 einer zweiten Ausführungsform einer Kraftstoff-Einspritzvorrichtung.

- FIG. 1

- a partial section through a portion of a fuel injection device, which is not part of the invention;

- FIG. 2

- a diagram in which a curve of an opening force acting on the stroke of a valve element of the fuel injection device of

FIG. 1 is applied; - FIG. 3

- a partial section through a portion of a first embodiment of a fuel injection device; and

- FIG. 4

- a representation similar to

FIG. 1 a second embodiment of a fuel injection device.

Eine Kraftstoff-Einspritzvorrichtung trägt in Figur insgesamt das Bezugszeichen 10. Sie umfasst ein Gehäuse 12, welches wiederum einen Düsenkörper 12a, einen Injektorkörper 12b, und eine Düsenspannmutter 12c umfasst. In dem Gehäuse 12 ist in seiner Längsrichtung eine gestufte Ausnehmung 14 vorhanden, von deren in

In der Ausnehmung 14 ist ein nadelartiges Ventilelement 18 angeordnet. Dieses weist einen insgesamt im Wesentlichen konstanten Durchmesser D auf. An seinem in

Der Hochdruckraum 28 erstreckt sich über die gesamte Länge der Ausnehmung 14 bzw. des Ventilelements 18. Letzteres wird im Gehäuse 12 vor allem über einen eine nur geringe axiale Länge aufweisenden Führungsabschnitt 30 geführt, welcher mit einem komplementären Führungsabschnitt 32 am in

Die Ausnehmung 14 wird in

Am in

Eine Ablaufdrossel 56 verbindet den Steuerraum 48 ferner mit einem Schaltventil 58. Dieses verbindet den Steuerraum 48 in geöffnetem Zustand mit einem Niederdruckanschluss 60. Hierzu verfügt das Schaltventil 58 in diesem Bespiel über eine Ventilkugel 62, die wiederum von einem Ventilstößel 64 beaufschlagt wird, der wiederum entweder hydraulisch oder direkt über einen entsprechenden Aktor 66 betätigt wird.An

Die in

Damit Kraftstoff von der Kraftstoff-Einspritzvorrichtung 10 abgegeben werden kann, wird das Schaltventil 58 geöffnet. Der Steuerraum 48 ist nun über die Ablaufdrossel 56 mit dem Niederdruckanschluss 60 verbunden. Da die Zulaufdrossel 50 stärker drosselt als die Ablaufdrossel 56, sinkt der Druck im Steuerraum 48 und in der Folge auch die an der Steuerfläche 46 angreifende und in Schließrichtung wirkende Kraft. Sobald diese unter die an der konischen Ringfläche 20 angreifende und in Öffnungsrichtung wirkende hydraulische Kraft (abzüglich der Kraft der Feder 44) absinkt, hebt das Ventilelement 18 mit der Dichtkante 24 von der Ventilsitzfläche 26 ab. Kraftstoff strömt nun vom Hochdruckraum 28 zu den Kraftstoff-Austrittskanälen 16.In order for fuel to be delivered from the

Nun wirkt zusätzlich auch an der konischen Endfläche 22 ein hydraulischer Druck, der an dieser konischen Endfläche 22 eine zusätzliche in Öffnungsrichtung wirkende Kraft erzeugt (zum Verlauf der Kraft im Verhältnis zum Hub wird weiter unten im Zusammenhang mit

Um die Einspritzung von Kraftstoff durch die Kraftstoff-Einspritzvorrichtung 10 zu beenden, wird das Schaltventil 58 geschlossen. Die Verbindung des Steuerraums 48 zum Niederdruckanschluss 60 ist daher unterbrochen. Kraftstoff kann nun durch die Zulaufdrossel 50 wieder in den Steuerraum 48 nachströmen, so dass sich dort der am Hochdruckanschluss 54 und im Hochdruckraum 28 herrschende Druck einstellt. Dass das Ventilelement 18 nun eine Schließbewegung ausführt, obwohl die in Schließrichtung wirkende hydraulische Querschnittsfläche der Steuerfläche 46 und die in Öffnungsrichtung wirkende hydraulische Querschnittsfläche der Druckflächen 20 und 22 gleich groß sind, hängt mit Folgendem zusammen: Im Bereich der Dichtkante 24 wird die Strömung zwischen den beiden Ringflächen 20 und 22 einerseits und der gegenüberliegenden Ventilsitzfläche 26 andererseits ganz leicht gedrosselt.In order to stop the injection of fuel by the

Damit liegt zumindest an einem Bereich der konischen Endfläche 22 ein Druck an, der kleiner ist als der Druck im Hochdruckraum 28. Dies hängt auch mit dem Abströmen des Kraftstoffs durch die Kraftstoff-Austrittskanäle 16 zusammen.This is at least at a portion of the

Trotz eines insgesamt im Hochdruckraum 28 und im Steuerraum 48 gleichen Drucks und trotz gleicher in Schließrichtung und in Öffnungsrichtung wirkender hydraulisch wirksamer Querschnittsflächen ist also die in der Summe an der konischen Ringfläche 20 und der konischen Endfläche 22 in Öffnungsrichtung wirkende Kraft kleiner als die an der Steuerfläche 46 in Schließrichtung wirkende Kraft. Die am Ventilelement 18 insgesamt angreifende Kraftresultierende wirkt also in Schließrichtung, was zu einer Schließbewegung des Ventilelements 18 führt.Despite a total in the high-

Die Geometrie der konischen Ringfläche 20 und der konischen Endfläche 22, insbesondere die Konizität dieser beiden Flächen 20 und 22, relativ zur Ventilsitzfläche 26 ist so gewählt, dass über einen Hub H ein Verlauf der in Öffnungsrichtung wirkenden Kraft F erzielt wird, wie er in

Dies bedeutet im Umkehrschluss während des gerade beschriebenen Schließvorgangs, dass das Ventilelement 18 gegen Ende des Schließvorgangs quasi "angesaugt" wird und entsprechend schnell schließt. Ein Kraftverlauf, wie er in

Es versteht sich, dass für ein sicheres Öffnen der Druck im Steuerraum 48 so weit abgesenkt werden muss, dass die an der Steuerfläche 46 in Schließrichtung wirkende Kraft zuzüglich der Kraft der Feder 44 kleiner ist als die Kraft F1.It is understood that must be lowered so far for a safe opening of the pressure in the

Man erkennt aus

Eine erste Ausführungsform einer Kraftstoff-Eine Ausführungsform einer Kraftstoff-Einspritzvorrichtung ist in

In radialer Richtung ist der Hülsenabschnitt 38 nicht gehalten. Die Führung des Ventilelements 18 erfolgt somit ausschließlich durch den Führungsabschnitt 30 am Ventilelement 18 und den Führungsabschnitt 32 am Düsenkörper 12a. Hierdurch wird eine leichtgängige Bewegung des Ventilelements 18 trotz gewisser Fertigungstoleranzen gewährleistet. Auch die Abdichtung des Steuerraums 48 wird hierdurch verbessert.In the radial direction of the

Es versteht sich, dass unter dem Begriff der hydraulisch wirksamen Querschnittsfläche einerseits der Druckfläche 20, 22 und andererseits der Steuerfläche 46 die Fläche der konischen Ringfläche 20, der konischen Endfläche 22, und der Steuerfläche 46 gemeint ist, die auf eine senkrecht zur Bewegungsrichtung des Ventilelements 18 liegende Ebene projiziert ist. Da der Durchmesser des Ventilelements 18 konstant ist (Wert D), sind diese hydraulisch wirksamen Querschnittsflächen identisch.It is understood that by the term of the hydraulically effective cross-sectional area on the one hand the

Eine nochmals geänderte zweite Ausführungsform zeigt

Der obere Koppelraum 74a wird radial von einer Hülse 80a, der untere von einer Hülse 80b begrenzt. Die Hülsen werden jeweils in einer Feder 81a und 81b, die sich gehäuseseitig (Feder 81a) bzw. an der Düsennadel 68 (Feder 81b) abstützt, gegen die Zwischenscheibe 76 gedrückt. Der Steuerkolben 70 begrenzt mit einer Endfläche 82 axial den oberen Koppelraum 74a, die Düsennadel mit einer Endfläche 84 den unteren Koppelraum 74b.The

Wird der Druck im Steuerraum 60 durch eine Ansteuerung des Aktors 66 (hier ein Magnetaktor) gesenkt, bewegt sich der Steuerkolben 70 in

Aus

Durch die Elastizität und Länge L vor allem des Steuerkolbens 34 wird es ermöglicht, dass mit der Kraftstoff-Einspritzvorrichtung 18 auch sehr kleine Kraftstoffmengen eingespritzt werden können. Dies dadurch, dass der Steuerkolben zunächst, wenn die Düsennadel 68 am gehäuseseitigen Ventilsitz anliegt, durch den hohen Druck im Steuerraum 48 elastisch zusammengedrückt wird. Bei einer Druckabsenkung im Steuerraum 48 muss sich der Steuerkolben 70 erst längen, um die oben genannte Druckabsenkung in den Koppelräumen 74a und 74b herbeizuführen.Due to the elasticity and length L, in particular of the

Bei der Ausführungsform nach

Claims (9)

- Fuel injection device (10) for an internal combustion engine with direct fuel injection, having a housing (12), having a valve element (18) which is arranged in the housing (12) and which has a hydraulic pressure surface (20, 22) which acts in an opening direction, which hydraulic pressure surface delimits a high-pressure chamber (28a, 28b) which is connected to a high-pressure port (54), and having a hydraulic control surface (46) which acts in a closing direction and which delimits a control chamber (48) in which a variable control pressure prevails during operation, wherein the closed valve element (18) bears, by way of a conical tip, against a valve seat surface (26) and thus separates fuel outlet ducts (16) from the high-pressure chamber (28a, 28b), and wherein the valve element (18), in an open position (H1) or an open position range, interacts in a throttling manner with a housing region (26) such that a pressure which is lower than the pressure in the high-pressure chamber (28a, 28b) acts at least on one part of the pressure surface (20, 22), characterized in that the valve element (18) is of multi-part form (68, 70) and at least two parts (68, 70) of the valve element (18) are coupled to one another via a hydraulic coupler (72).

- Fuel injection device (10) according to Claim 1, characterized in that, when the valve element (18) is open, the hydraulically acting pressure surface (20, 22) and the hydraulically acting control surface (46) are, when projected in each case onto a plane perpendicular to the direction of movement of the valve element (18), of at least approximately the same size.

- Fuel injection device (10) according to one of the preceding claims, characterized in that, during operation, at least approximately the high fuel pressure prevailing at the high-pressure port (54) at least intermittently prevails in spaces (28a, 28b) which are situated between the control chamber (48) and high-pressure chamber (28a, 28b) and which surround the valve element (18).

- Fuel injection device (10) according to one of the preceding claims, characterized in that the valve element (18) has a valve slide portion which, at least intermittently, in particular during closing, interacts in a throttling manner with a housing-side region (12) in such a way that the pressure acting at least on one part of the pressure surface (20, 22) falls below the pressure in the high-pressure chamber (28a, 28b).

- Fuel injection device (10) according to one of the preceding claims, characterized in that the control chamber (48) is fluidically separated from the high-pressure chamber (28a, 28b) by a sleeve portion (38) which is not guided radially by the housing (12).

- Fuel injection device (10) according to one of the preceding claims, characterized in that the valve element (18) has a guide portion (30) on which it is guided (32) in the housing (12) so as to permit a passage of fluid.

- Fuel injection device (10) according to Claim 1, characterized in that the two parts (68, 70) of the valve element (18) in the hydraulic coupler (72) are spaced apart from one another when the valve element (18) bears against the valve seat (26).

- Fuel injection device (10) according to Claim 7, characterized in that the hydraulic coupler (72) comprises an intermediate disc (76) which geometrically separates a first coupling chamber (74a) from a second coupling chamber (74b).

- Fuel injection device (10) according to Claim 8, characterized in that the hydraulic coupler (72) comprises a connecting duct (78) which hydraulically connects the two coupling chambers (74a, 74b) to one another.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102005054385 | 2005-11-15 | ||

| DE102006012078A DE102006012078A1 (en) | 2005-11-15 | 2006-03-16 | Fuel injection device for an internal combustion engine with direct fuel injection |

| PCT/EP2006/067156 WO2007057252A1 (en) | 2005-11-15 | 2006-10-06 | Fuel injection apparatus for an internal combustion engine having direct fuel injection |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1952011A1 EP1952011A1 (en) | 2008-08-06 |

| EP1952011B1 true EP1952011B1 (en) | 2013-07-24 |

Family

ID=37606965

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP06807052.3A Ceased EP1952011B1 (en) | 2005-11-15 | 2006-10-06 | Fuel injection apparatus for an internal combustion engine having direct fuel injection |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1952011B1 (en) |

| DE (1) | DE102006012078A1 (en) |

| WO (1) | WO2007057252A1 (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102007043540A1 (en) * | 2007-09-12 | 2009-05-07 | Robert Bosch Gmbh | Leak-free fuel injector with long nozzle needle |

| DE102008001425A1 (en) | 2008-04-28 | 2009-10-29 | Robert Bosch Gmbh | Fuel injector |

| DE102008001601A1 (en) | 2008-05-06 | 2009-11-12 | Robert Bosch Gmbh | Fuel injector and manufacturing process |

| DE102008001907A1 (en) * | 2008-05-21 | 2009-11-26 | Robert Bosch Gmbh | Fuel injector |

| DE102008042154A1 (en) | 2008-09-17 | 2010-03-18 | Robert Bosch Gmbh | Fuel injector |

| DE102009028993A1 (en) | 2009-08-28 | 2011-03-03 | Robert Bosch Gmbh | fuel injector |

| DE102015211672A1 (en) | 2015-06-24 | 2016-12-29 | Robert Bosch Gmbh | Fuel injector |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10229418A1 (en) * | 2002-06-29 | 2004-01-29 | Robert Bosch Gmbh | Device for damping the needle stroke on fuel injectors |

| DE10348925A1 (en) * | 2003-10-18 | 2005-05-12 | Bosch Gmbh Robert | Fuel injector with multipart, directly controlled injection valve member |

| DE10352736A1 (en) * | 2003-11-12 | 2005-07-07 | Robert Bosch Gmbh | Fuel injector with direct needle injection |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3704957B2 (en) * | 1998-07-06 | 2005-10-12 | いすゞ自動車株式会社 | Injector |

| DE10024703A1 (en) | 2000-05-18 | 2001-11-22 | Bosch Gmbh Robert | Injection arrangement for fuel storage injection system has valve unit blocking auxiliary channel and outlet path in alternation |

| DE10024702A1 (en) | 2000-05-18 | 2001-11-22 | Bosch Gmbh Robert | Fuel injector for storage injection system includes bypass channel injecting into outlet path at valve chamber |

| DE10100392C1 (en) * | 2001-01-05 | 2002-06-13 | Bosch Gmbh Robert | Fluid control valve for IC engine fuel injection has setting piston and operating piston received in adjacent bores in valve body |

| EP1555427B1 (en) * | 2004-01-13 | 2007-10-10 | Delphi Technologies, Inc. | Fuel injector |

| DE102004002309A1 (en) * | 2004-01-16 | 2005-08-04 | Robert Bosch Gmbh | Fuel injector with direct needle spreader |

-

2006

- 2006-03-16 DE DE102006012078A patent/DE102006012078A1/en not_active Withdrawn

- 2006-10-06 WO PCT/EP2006/067156 patent/WO2007057252A1/en active Application Filing

- 2006-10-06 EP EP06807052.3A patent/EP1952011B1/en not_active Ceased

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10229418A1 (en) * | 2002-06-29 | 2004-01-29 | Robert Bosch Gmbh | Device for damping the needle stroke on fuel injectors |

| DE10348925A1 (en) * | 2003-10-18 | 2005-05-12 | Bosch Gmbh Robert | Fuel injector with multipart, directly controlled injection valve member |

| DE10352736A1 (en) * | 2003-11-12 | 2005-07-07 | Robert Bosch Gmbh | Fuel injector with direct needle injection |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2007057252A1 (en) | 2007-05-24 |

| DE102006012078A1 (en) | 2007-05-16 |

| EP1952011A1 (en) | 2008-08-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0898650B1 (en) | Fuel injection device for internal combustion engines | |

| EP1654456B1 (en) | Fuel injection device for an internal combustion engine | |

| WO2005052354A1 (en) | Fuel injection device, especially for a direct injection internal combustion engine, and method for the production thereof | |

| EP1552135B1 (en) | Fuel injection device for an internal combustion engine | |

| EP1952011B1 (en) | Fuel injection apparatus for an internal combustion engine having direct fuel injection | |

| EP1379775A1 (en) | Valve for controlling liquids | |

| EP1910663B1 (en) | Fuel injection device for an internal combustion engine using direct fuel injection | |

| WO2007000371A1 (en) | Injector with a pressure intensifier that can be switched on | |

| EP2294309B1 (en) | Fuel injector | |

| EP2011995B1 (en) | Injector with a valve element which opens to the outside | |

| EP1925812B1 (en) | Fuel injector valve for combustion engines | |

| EP1541859B1 (en) | Injection valve | |

| WO2005038235A2 (en) | Fuel injection device, especially for a direct injection internal combustion engine | |

| DE102006050033A1 (en) | Injector, in particular common rail injector | |

| DE102007034319A1 (en) | injector | |

| EP2957760B1 (en) | Nozzle assembly for a fuel injector and fuel injector | |

| DE10160490B4 (en) | Fuel injection device, fuel system and internal combustion engine | |

| DE102007005573A1 (en) | Common Rail injector for internal-combustion engine of motor vehicle, has stopper limiting stroke movement of coupler, which is adjustable during opening movement of valve element together with control bar and needle in axial direction | |

| WO2005017342A1 (en) | Fuel injection device, particularly for a direct injection internal combustion engine | |

| DE10152253B4 (en) | Valve for controlling fluids | |

| WO2004063553A1 (en) | Fuel injection device | |

| WO2005014998A1 (en) | Fuel injection valve, especially for an internal combustion engine with direct fuel injection | |

| EP1636481A1 (en) | Injector for internal combustion engines | |

| DE102007018042A1 (en) | Fuel injector i.e. common-rail-injector, for internal combustion engine, has valve element including control rod and needle, which are hydraulically coupled with each other, where coupler area is temporarily connected with low-pressure area | |

| WO2005014996A1 (en) | Fuel injection device for a combustion engine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20080616 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE ES FR GB IT |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): DE ES FR GB IT |

|

| 17Q | First examination report despatched |

Effective date: 20090423 |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20130423 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB IT |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502006013059 Country of ref document: DE Effective date: 20130919 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130724 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20131024 |

|

| 26N | No opposition filed |

Effective date: 20140425 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131024 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502006013059 Country of ref document: DE Effective date: 20140425 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20201020 Year of fee payment: 15 Ref country code: IT Payment date: 20201030 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20201214 Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502006013059 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220503 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211006 |