EP1663756B1 - Rail-mounted car having an articulated joint for permanently connecting two underbodies of the rail-mounted car - Google Patents

Rail-mounted car having an articulated joint for permanently connecting two underbodies of the rail-mounted car Download PDFInfo

- Publication number

- EP1663756B1 EP1663756B1 EP04775362A EP04775362A EP1663756B1 EP 1663756 B1 EP1663756 B1 EP 1663756B1 EP 04775362 A EP04775362 A EP 04775362A EP 04775362 A EP04775362 A EP 04775362A EP 1663756 B1 EP1663756 B1 EP 1663756B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- link

- chassis

- rail

- car

- hinge

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000926 separation method Methods 0.000 claims abstract description 6

- 230000008878 coupling Effects 0.000 abstract description 24

- 238000010168 coupling process Methods 0.000 abstract description 24

- 238000005859 coupling reaction Methods 0.000 abstract description 24

- 230000033001 locomotion Effects 0.000 description 3

- 238000012423 maintenance Methods 0.000 description 3

- 230000008439 repair process Effects 0.000 description 3

- 238000010276 construction Methods 0.000 description 2

- 229920001971 elastomer Polymers 0.000 description 2

- 239000000806 elastomer Substances 0.000 description 2

- 238000013519 translation Methods 0.000 description 2

- 230000014616 translation Effects 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- 229910001018 Cast iron Inorganic materials 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 238000013016 damping Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000003534 oscillatory effect Effects 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 238000012876 topography Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B61—RAILWAYS

- B61F—RAIL VEHICLE SUSPENSIONS, e.g. UNDERFRAMES, BOGIES OR ARRANGEMENTS OF WHEEL AXLES; RAIL VEHICLES FOR USE ON TRACKS OF DIFFERENT WIDTH; PREVENTING DERAILING OF RAIL VEHICLES; WHEEL GUARDS, OBSTRUCTION REMOVERS OR THE LIKE FOR RAIL VEHICLES

- B61F3/00—Types of bogies

- B61F3/12—Types of bogies specially modified for carrying adjacent vehicle bodies of articulated trains

- B61F3/125—Types of bogies specially modified for carrying adjacent vehicle bodies of articulated trains with more than one axle or wheel set

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B61—RAILWAYS

- B61G—COUPLINGS; DRAUGHT AND BUFFING APPLIANCES

- B61G5/00—Couplings for special purposes not otherwise provided for

- B61G5/02—Couplings for special purposes not otherwise provided for for coupling articulated trains, locomotives and tenders or the bogies of a vehicle; Coupling by means of a single coupling bar; Couplings preventing or limiting relative lateral movement of vehicles

Definitions

- This invention relates to a rail-mounted car that comprises two chassis, which are permanently connected via a link device, which comprises two link members connected to a chassis each, which members are turnably connected to each other via a hinge.

- the invention relates to a link device as such intended for permanently connecting two car chassis.

- Link devices or link couplings for permanently connecting two chassis or car bodies included in a rail-mounted car or railroad car are richly described in the patent literature. See, for instance, US-A-2 051 958 , US-A-3 667 820 , DE-A-1 094 289 , DE-AS-1 605 188 , DE-19638763A1 , DE-4121080A1 , DE-10153460A1 , FR-A-2 398 651 , EP-A-0279245 , EP-A-0343482 , EP0771710A1 and EP1312527B1 .

- the hinge that connects the two link members in couplings of the kind in question has the purpose of, between the link members, transferring intermittent tensile, compressive and torsion stresses of the type that arise under all the conditions that occur in driving train units at low as well as high speeds, i.e., allowing all types of translations and rotations irrespective of these acting in the longitudinal, lateral or vertical direction, e.g., upon cornering and in driving in hilly topography, respectively.

- the hinge has to be made with a vertical pin in order to enable horizontal turning laterally, as well as a more sophisticated, spherical bearing in which an elastic impact- and vibration-absorbing body (elastomer body) is included, and which can absorb the translations and rotations of the link members.

- Such link couplings are permanent in the sense that they essentially have the purpose of permanently holding together two or more wheel-carried chassis or car bodies that together form an individual car, which in turn may be connected to and disconnected from other cars.

- the chassis in one and the same car are permanently connected to each other.

- EP 1 312 527 discloses a link device for a rail car comprising two chassis which are permanently connected via the link device.

- a first link member connected to a first car chassis is hinged to a second link member connected to a second car chassis.

- the hinge For disconnection of the car chassis, either the hinge must be opened, or any of the link members must be dismounted from its associated car chassis. Either of these operations involves the problems discussed above.

- US 4,962,861 disclose an articulated connector for joining together two rail car platforms which are supported on a common truck bolster.

- a hinged drawbar connection between connector portions requires dismounting.

- the connector portions are rigidly secured to the rail car chassis such as by welding.

- EP 1 151 905 discloses an articulated connection between links secured by bolts to the chassis of two interconnected rail cars which requires, in order for separation of the rail cars, that either the articulated connection be opened and dismounted, or the links be dismounted from the rail car chassis.

- EP 1 312 527 discloses a link device for a rail car comprising two chassis which are permanently connected via the link device.

- a first link member connected to a first car chassis is hinged to a second link member connected to a second car chassis.

- the hinge For disconnection of the car chassis, either the hinge must be opened, or any of the link members must be dismounted from its associated car chassis. Either of these operations involves the problems discussed above.

- US 4,962,861 disclose an articulated connector for joining together two rail car platforms which are supported on a common truck bolster.

- a hinged drawbar connection between connector portions requires dismounting.

- the connector portions are rigidly secured to the rail car chassis such as by welding.

- EP 1 151 905 discloses an articulated connection between links secured by bolts to the chassis of two interconnected rail cars which requires, in order for separation of the rail cars, that either the articulated connection be opened and dismounted, or the links be dismounted from the rail car chassis.

- a primary object of the invention is to provide a link coupling that enables disconnection and connection, respectively, of two chassis included in a car without having to dismount and remount, respectively, the hinge between the two link members of the coupling, or dismounting and remounting, respectively, anyone of the fixings of the link members against a chassis; all with the purpose of enabling a quick and simple disconnection and connection, respectively, of two car chassis, e.g., in connection with intermittently occurring repair and maintenance work.

- the invention is based on the idea to make one of the two link members of the link coupling partable by constructing the same from two parts releasably connected to each other, namely a first part, which may be permanently connected to the hinge, and a second part, which is fastenable on one of the chassis, wherein the second link member can be allowed to be permanently fastened on the other chassis. Separation of the chassis may then be carried out by removing dismountable connecting elements, e.g., screws, which normally hold together the two parts of the partable link member.

- one part of the partable link member may be of a male-like character and insertable in a female-like seating in the second part.

- the two chassis of the car may be brought together without major demand on precision in connection with reconnection.

- the invention in connection with such cars that include two independently wheel-carried chassis or car bodies, i.e., chassis that individually are carried by two pairs of wheel or wheel bogies, the same is particularly suitable for use in cars of the type that includes a so-called Jakobs bogie, i.e., a bogie that simultaneously carries ends of chassis facing each other, which chassis have own wheels or wheel bogies only at the opposite ends thereof.

- numerals 1, 2 designate parts of two chassis or car bodies, which together form a rail-mounted car for railway traffic.

- the two chassis are carried by a common Jakobs bogie generally designated 3, while the same chassis at the non-visible ends thereof are carried by own wheels or wheel bogies.

- the schematically shown Jakobs bogie 3 includes a framework 4 and at least two pairs of wheels 5 and shock absorption means in the form of four elastic cushions 6 arranged in pairs and applied under assembling plates 7, which can be fixed underneath the individual chassis.

- the joint between the assembling plates 7 and the individual car chassis is outlined by means of male elements or pins 8 on the top sides of the plates and downward open seatings or holes 9 on the bottom sides of the chassis.

- This link coupling is generally designated 10 and includes two link members, which are interconnected via a hinge in its entirety designated 11, which in the previously described way includes a vertical pin 12, which enables turning of the link members in relation to each other in the horizontal direction, as well as a partly spherical bearing box 13 (so-called elastomer bearing), which enables rotary motions and oscillatory motions in the vertical direction between the link members.

- the vertical, geometrical axis of the pivot pin 12 is designated C.

- a first link member 14, which is connected to the chassis 2, is situated to the right of the hinge 11 in fig.

- link members 14, 15 are permanently fixed at the respective chassis in so far that they after initial mounting on the chassis should not need to be removed even in connection with repairs and maintenance.

- the link members are not welded to the chassis, but rather connected to the same via releasable connecting elements, which enable exchange of the link members, e.g., after emergence of serious damage on the same or the chassis.

- one of the two link members 14, 15, namely. the first link member 14, is partable by being composed of two parts releasably connected to each other, namely a first part 16, which is permanently connected to the second link member 15 via the hinge 11 (see figs. 2 and 5 ), and a second part 17 (see figs. 3 and 6 ), which is permanently connected to the chassis 2.

- the part 16 is denominated "bearing bracket", while the part 17 popularly is denominated "shelf". More concrete, the first link part 16 is of a male-like character and insertable in a female-like seating in the second link part 17.

- the link part 17 is composed of a bottom plate 18, an upright transverse end plate 19, and two vertical side pieces or side plates 20, which are stiffly united to the end plate 19 as well as the bottom plate 18, preferably by being welded against the same.

- an upward as well as forward open seating or space is defined in which the bearing bracket 16 can be received.

- two fastening plates 21 extend to which two longitudinal, vertical guide plates 22 are stiffly united. Said last-mentioned plates may be inserted between two blocks 23 protruding downward from the bottom side of the chassis and being of a type that is standard on car chassis of the kind in question.

- the blocks 23 are located in the area between the two support surfaces 24, which rest against the assembling plates 7 of the Jakobs bogie. Together, the plates 18-22 (see fig. 3 ) form a shelf-like frame that is form-stiff and capable of sustaining weight.

- holes 25 are recessed for dismountable fastening or locking elements 26, e.g., screws, by means of which the fastening plates may be fixed against the bottom sides of the blocks 23.

- holes 27 are formed in the end wall 19 for horizontal screws or fastening elements 28, which may be tightened in holes in the front surfaces of the blocks 23.

- the first centring device 33 is in the form of a protruding male element having a rotationally symmetrical basic shape, while the device 34 consists of a downwardly opening, analogously shaped seating in which the male element 33 engages.

- the seating 33 is formed in the bottom side of the bottom plate 18 the link part 17, the pivot pin 12 not having contact with the centring devices.

- the link part 16 is stiffly united to the link part 17 (by means of the screws 31), the construction being so formed that the pivot pin 12 and the male element 33 automatically are centred in relation to the geometrical centre axis C when the link part 16 assumes correct position in relation to the link part 17.

- the second link member 15 includes a front link head 35 and a rear carrier generally fixedly connectable to an appurtenant chassis and designated 36.

- said carrier includes one or two bottom plates 37 and a vertical plate 38 in the form of a front plate from which two vertical side pieces 39 extend, which are stiffly united to the front plate as well as the bottom plate.

- the side pieces are oriented perpendicularly to the front plate and mutually spaced-apart, at the same time as they separately are located at a certain distance inside the opposite side edges of the bottom plate 37.

- the frame 36 (as well as the frame 17) is made from a strong steel plate, e.g., having a thickness within the range of 25-50 mm.

- a back piece 40 included in the carrier is even stronger, which piece advantageously can be made in the form of a solid cast iron body, which is connected to the side pieces 39 of the frame 36 via one or more strong connecting elements 41, e.g., thick bolts or pins.

- the frame 36 may be connected to the appurtenant chassis by means of bolts that are tightened in the block 23 of the chassis via holes 25, 27.

- an axially oriented guide bar 48 is arranged, which engages a co-operating groove 43 in the cross piece 42 of the link head. Upon translational move of the link head in relation to the frame, accordingly the link head is guided by the bars 48.

- a collision protection is integrated in the link member 15, which in the example is in the form of three tubes or sleeves 49, 50, namely a central tube 49 of a first type, and two co-lateral tubes 50 of another type. All tubes are deformable and co-operate with through bores 51, 52 formed in the back piece 40, which bores have a smaller diameter than the appurtenant tube.

- the intermediate deformation tube 49 together with the appurtenant bore 51 has a larger diameter than the two co-lateral tubes 50 and the bores 52 thereof.

- the bores 50, 51 have different diameters, the same are formed in principally the same way. See in this respect fig.

- FIG. 10 which shows a thin deformation tube 50 together with the appurtenant bore 52.

- a funnel-like, conical mouth 53 is formed, which widens in the forward direction.

- the deformation tube 50 is of a cylindrical basic shape, but has at the rear end thereof a conical tapering portion 54, which is inserted into the conical mouth 53. In this position, the tube is kept in place by means of a holder in its entirety designated 55.

- the mouth 53 and the conical portion 54 of the tube has one and the same conicity or cone angle. Said cone angle should amount to at least 5° and at most 20°, and suitably be within the range of 10-16°. Tests that form the basis of the invention have been most successful when the cone angles have varied within the range of 11-15°.

- the deformation tube 50 is distanced from the cross piece 42 of the link head via a gap 57.

- the tube end 56 may advantageously consist of a planar, ring-shaped surface, which extends perpendicularly to the geometrical longitudinal axis of the tube.

- the axial extension of the gap 57 may be within the range of 10-20 mm.

- the corresponding gap of the intermediate deformation tube 49 may have another, for instance smaller, axial extension than the gap 57 of each thin deformation tube 50.

- the corresponding gap length of the tube 49 may be within the range of 5-15 mm.

- the cross piece 42 impinges on the deformation tubes 49, 50, which will be pressed into the appurtenant bore 51, 52 in the back piece up to a point where the cross piece is stopped against the back piece.

- the individual tube is pressed into the appurtenant bore, the same will be deformed successively by being compressed or pressed together in the radial direction, while the outer diameter of the tube is reduced to the same inner diameter as the smallest diameter of the cone mouth 53.

- the kinetic energy in the detached link head is converted into heat in the deformation tubes as well as the back piece. This means that a substantial part of the kinetic energy is extincted before it has time to be transferred from one of the car chassis to the other.

- the link part 17 is mounted on one of the chassis 2 and the link member 15, with the ensuing link part 16, on the other chassis 1. Fixation of the shelf and box-like frames 36, 17, respectively, is carried out in the above described way by means of screws or bolts 26, 28, which are tightened in threaded holes in the blocks 23 of the chassis.

- the end of the chassis 2 not equipped with wheels is lifted in above the Jakobs bogie 3 and is located in a position in which the male elements 8 can be brought to engagement with the seatings 9 at the same time as the centring devices 33, 34 engage each other.

- a fundamental advantage of the invention is that two chassis included in a car can be connected and disconnected without any need for manipulating the hinge between the link members of the link coupling. Neither the more or less theoretical possibility of removing a link member from the appurtenant chassis needs to be resorted to.

- the invention is not limited only to the embodiment described above and shown in the drawings.

- the invention is applicable also to such link devices or link couplings that lack collision protection. It is also feasible to apply the invention to such link couplings that do not co-operate with any Jakobs bogie.

- the link coupling can also be used for such cars the chassis of which are separately wheel-carried at the two ends thereof.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Body Structure For Vehicles (AREA)

- Handcart (AREA)

- Leg Units, Guards, And Driving Tracks Of Cranes (AREA)

- Railway Tracks (AREA)

- Machines For Laying And Maintaining Railways (AREA)

- Steering-Linkage Mechanisms And Four-Wheel Steering (AREA)

- Passenger Equipment (AREA)

- Current-Collector Devices For Electrically Propelled Vehicles (AREA)

Abstract

Description

- This invention relates to a rail-mounted car that comprises two chassis, which are permanently connected via a link device, which comprises two link members connected to a chassis each, which members are turnably connected to each other via a hinge.

- More precisely, the invention relates to a link device as such intended for permanently connecting two car chassis.

- Link devices or link couplings for permanently connecting two chassis or car bodies included in a rail-mounted car or railroad car are richly described in the patent literature. See, for instance,

US-A-2 051 958 ,US-A-3 667 820 ,DE-A-1 094 289 ,DE-AS-1 605 188 ,DE-19638763A1 ,DE-4121080A1 ,DE-10153460A1 ,FR-A-2 398 651 EP-A-0279245 ,EP-A-0343482 ,EP0771710A1 andEP1312527B1 . - The hinge that connects the two link members in couplings of the kind in question has the purpose of, between the link members, transferring intermittent tensile, compressive and torsion stresses of the type that arise under all the conditions that occur in driving train units at low as well as high speeds, i.e., allowing all types of translations and rotations irrespective of these acting in the longitudinal, lateral or vertical direction, e.g., upon cornering and in driving in hilly topography, respectively. For this reason, the hinge has to be made with a vertical pin in order to enable horizontal turning laterally, as well as a more sophisticated, spherical bearing in which an elastic impact- and vibration-absorbing body (elastomer body) is included, and which can absorb the translations and rotations of the link members.

- Such link couplings are permanent in the sense that they essentially have the purpose of permanently holding together two or more wheel-carried chassis or car bodies that together form an individual car, which in turn may be connected to and disconnected from other cars. Thus, during normal circumstances, the chassis in one and the same car are permanently connected to each other. However, every now and then, need arises for separating the chassis of the car from each other, e.g., in connection with repairs and maintenance and upon transportation to final customer.

- It is common for previously known link couplings that they in practice only enable separation and renewed connection, respectively, of the chassis by dismounting and remounting, respectively, of the hinge between the two link members. However, this is a delicate work and difficult to carry out because the hinge includes a plurality of components, which in particular upon renewed connection has to be brought together with high accuracy; something which is complicated, time-consuming and ergonomically trying because the proper link members as well as the different hinge components are extraordinary heavy. The work is made more difficult if the chassis of the car would not be set up on an ideally horizontal ground.

- Theoretically, it is feasible, per se, to dismount or release the fixing of one of the link members against the appurtenant chassis. However, in practice, this alternative is even more difficult to carry out and at times entirely impossible for reasons of construction and space.

-

EP 1 312 527 - Similar to

EP 1 312 527 ,US 4,962,861 disclose an articulated connector for joining together two rail car platforms which are supported on a common truck bolster. In order to separate the rail cars, a hinged drawbar connection between connector portions requires dismounting. The connector portions are rigidly secured to the rail car chassis such as by welding. - Likewise similar to

EP 1 312 527EP 1 151 905 discloses an articulated connection between links secured by bolts to the chassis of two interconnected rail cars which requires, in order for separation of the rail cars, that either the articulated connection be opened and dismounted, or the links be dismounted from the rail car chassis. -

EP 1 312 527 - Similar to

EP 1 312 527 ,US 4,962,861 disclose an articulated connector for joining together two rail car platforms which are supported on a common truck bolster. In order to separate the rail cars, a hinged drawbar connection between connector portions requires dismounting. The connector portions are rigidly secured to the rail car chassis such as by welding. - Likewise similar to

EP 1 312 527EP 1 151 905 discloses an articulated connection between links secured by bolts to the chassis of two interconnected rail cars which requires, in order for separation of the rail cars, that either the articulated connection be opened and dismounted, or the links be dismounted from the rail car chassis. - The present invention aims at obviating the above-mentioned drawbacks of previously known link couplings and at providing an improved link coupling or link device, as well as a rail-mounted car having improved possibilities of separating and again connecting two chassis included in the car. Thus, a primary object of the invention is to provide a link coupling that enables disconnection and connection, respectively, of two chassis included in a car without having to dismount and remount, respectively, the hinge between the two link members of the coupling, or dismounting and remounting, respectively, anyone of the fixings of the link members against a chassis; all with the purpose of enabling a quick and simple disconnection and connection, respectively, of two car chassis, e.g., in connection with intermittently occurring repair and maintenance work.

- According to the invention, the above-mentioned object is attained by the features defined in the characteristic parts of the

independent claim 1. Preferred embodiments of the link device according to the invention are furthermore defined in the dependent claims. - The invention is based on the idea to make one of the two link members of the link coupling partable by constructing the same from two parts releasably connected to each other, namely a first part, which may be permanently connected to the hinge, and a second part, which is fastenable on one of the chassis, wherein the second link member can be allowed to be permanently fastened on the other chassis. Separation of the chassis may then be carried out by removing dismountable connecting elements, e.g., screws, which normally hold together the two parts of the partable link member. Advantageously, one part of the partable link member may be of a male-like character and insertable in a female-like seating in the second part. In such a way, the two chassis of the car may be brought together without major demand on precision in connection with reconnection. Although it is feasible, per se, to apply the invention in connection with such cars that include two independently wheel-carried chassis or car bodies, i.e., chassis that individually are carried by two pairs of wheel or wheel bogies, the same is particularly suitable for use in cars of the type that includes a so-called Jakobs bogie, i.e., a bogie that simultaneously carries ends of chassis facing each other, which chassis have own wheels or wheel bogies only at the opposite ends thereof.

- In the drawings:

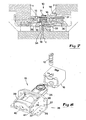

- Fig. 1

- is a simplified, perspective exploded view showing parts of two chassis or bodies included in a car, and a centrally placed Jakobs bogie carrying the same, as well as parts of a link coupling according to the invention, all objects being shown regarded obliquely from above,

- Fig. 2

- is an enlarged perspective view of a link arrangement belonging to the left chassis in

fig. 1 , - Fig. 3

- is corresponding perspective view of a link arrangement belonging to the right chassis in

fig. 1 , - Fig. 4

- is an exploded view corresponding to

fig. 1 and showing the chassis and the Jakobs bogie obliquely from below, - Fig. 5

- is an exploded view corresponding to

fig. 2 and showing said link arrangement obliquely from below, - Fig. 6

- is a perspective view corresponding to

fig. 3 and show- ing the same link arrangement obliquely from below, - Fig. 7

- is an enlarged, partial longitudinal section through the link coupling according to the invention in assem- bled state,

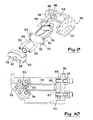

- Fig. 8

- is a perspective and additionally enlarged exploded view showing the arrangement according to

fig. 2 more in detail, - Fig. 9

- is a perspective exploded view illustrating a collision protection included in the arrangement according to

fig. 8 , and - Fig. 10

- is an enlarged longitudinal section showing a detail included in said collision protection.

- In

figs. 1 and4 ,numerals Jakobs bogie 3 includes aframework 4 and at least two pairs ofwheels 5 and shock absorption means in the form of fourelastic cushions 6 arranged in pairs and applied under assembling plates 7, which can be fixed underneath the individual chassis. The joint between the assembling plates 7 and the individual car chassis is outlined by means of male elements orpins 8 on the top sides of the plates and downward open seatings or holes 9 on the bottom sides of the chassis. - Reference is now made to

fig. 7 , which in longitudinal section illustrates an assembled link coupling according to the invention. This link coupling is generally designated 10 and includes two link members, which are interconnected via a hinge in its entirety designated 11, which in the previously described way includes avertical pin 12, which enables turning of the link members in relation to each other in the horizontal direction, as well as a partly spherical bearing box 13 (so-called elastomer bearing), which enables rotary motions and oscillatory motions in the vertical direction between the link members. The vertical, geometrical axis of thepivot pin 12 is designated C. Afirst link member 14, which is connected to thechassis 2, is situated to the right of thehinge 11 infig. 7 , while asecond link member 15, which is connected to thechassis 1, is situated to the left of thehinge 11. At the ends thereof turned away from each other, saidlink members - In accordance with the invention, one of the two

link members first link member 14, is partable by being composed of two parts releasably connected to each other, namely afirst part 16, which is permanently connected to thesecond link member 15 via the hinge 11 (seefigs. 2 and5 ), and a second part 17 (seefigs. 3 and6 ), which is permanently connected to thechassis 2. Among the applicant's designers, thepart 16 is denominated "bearing bracket", while thepart 17 popularly is denominated "shelf". More concrete, thefirst link part 16 is of a male-like character and insertable in a female-like seating in thesecond link part 17. - As is seen in

figs. 3 and6 , thelink part 17 is composed of abottom plate 18, an uprighttransverse end plate 19, and two vertical side pieces orside plates 20, which are stiffly united to theend plate 19 as well as thebottom plate 18, preferably by being welded against the same. Thus, between the side pieces, an upward as well as forward open seating or space is defined in which thebearing bracket 16 can be received. In the backward direction from the end plate, twofastening plates 21 extend to which two longitudinal,vertical guide plates 22 are stiffly united. Said last-mentioned plates may be inserted between twoblocks 23 protruding downward from the bottom side of the chassis and being of a type that is standard on car chassis of the kind in question. Theblocks 23 are located in the area between the two support surfaces 24, which rest against the assembling plates 7 of the Jakobs bogie. Together, the plates 18-22 (seefig. 3 ) form a shelf-like frame that is form-stiff and capable of sustaining weight. In the rearward protrudingfastening plates 21, holes 25 are recessed for dismountable fastening or lockingelements 26, e.g., screws, by means of which the fastening plates may be fixed against the bottom sides of theblocks 23. In an analogous way, holes 27 are formed in theend wall 19 for horizontal screws orfastening elements 28, which may be tightened in holes in the front surfaces of theblocks 23. In the part of theend plate 19 that extends between theside pieces 20,additional holes 29 are formed, which are through and co-operate withsleeves 30, which extend in the direction axially rearward from the end plate. By means of saidsleeves 30, comparatively long bolts or screws 31 may be guided inward towards theholes 29 and be inserted through the same in order to be tightened in threadedholes 32 in the end surface of the link part or of the bearing bracket 16 (seefig. 5 ). - In this connection, it should be pointed out that in the area axially behind the

blocks 23 together with the abutment surfaces 24, there is a fairly well sized space for the operator that has the task of mounting and dismounting, respectively, thescrews 31. Therefore, the work of, on one hand, connecting the twolink parts - In order to centre the Jakobs bogie and the

hinge 11 in relation to each other - in the case such a bogie is included in the car - two co-operating centring devices are arranged, namely afirst device 33 on theframework 4 of the bogie and a second device 34 (seefig. 6 ), which is included in thelink part 17. In the example, thefirst centring device 33 is in the form of a protruding male element having a rotationally symmetrical basic shape, while thedevice 34 consists of a downwardly opening, analogously shaped seating in which themale element 33 engages. As is seen infig. 7 , theseating 33 is formed in the bottom side of thebottom plate 18 thelink part 17, thepivot pin 12 not having contact with the centring devices. However, in the assembled state of the link coupling, thelink part 16 is stiffly united to the link part 17 (by means of the screws 31), the construction being so formed that thepivot pin 12 and themale element 33 automatically are centred in relation to the geometrical centre axis C when thelink part 16 assumes correct position in relation to thelink part 17. - In

fig. 8 , it is seen how thesecond link member 15 includes afront link head 35 and a rear carrier generally fixedly connectable to an appurtenant chassis and designated 36. Like the shelf-like link part 17, said carrier includes one or twobottom plates 37 and avertical plate 38 in the form of a front plate from which twovertical side pieces 39 extend, which are stiffly united to the front plate as well as the bottom plate. The side pieces are oriented perpendicularly to the front plate and mutually spaced-apart, at the same time as they separately are located at a certain distance inside the opposite side edges of thebottom plate 37. In practice, the frame 36 (as well as the frame 17) is made from a strong steel plate, e.g., having a thickness within the range of 25-50 mm. Aback piece 40 included in the carrier is even stronger, which piece advantageously can be made in the form of a solid cast iron body, which is connected to theside pieces 39 of theframe 36 via one or more strong connectingelements 41, e.g., thick bolts or pins. In analogy with thelink part 17, theframe 36 may be connected to the appurtenant chassis by means of bolts that are tightened in theblock 23 of the chassis viaholes - Reference is now made to

figs. 9 and 10 , which more in detail illustrate the nature of thelink member 15. Infig. 9 , it is seen that thelink head 35 at a rear end has across piece 42, which extends perpendicularly to the geometrical longitudinal axis of the link head. More precisely, thecross piece 42 is of a rectangular basic shape,grooves 43 being recessed in the opposite short side edges thereof. In the mounted state, thelink head 35 projects through acentral opening 44 in thefront plate 38 of theframe 36, the cross piece abutting against the back side of the front plate. In thecross piece 42, four threadedholes 45 are formed for receipt of equally many screws or bolts 46 (seefig. 10 ), which have the purpose of holding the link head in place. In the area between the male thread and head of the individual screw, the shank of the screw is somewhat weakened via awaist 47, the diameter of which decides the strength of the screw. By endowing the waist 47 a suitable diameter, it may be predetermined at which stress the screw should break. If the link coupling in its entirety would be exposed to extreme, axial impulsive forces of the type that may arise in connection with collisions, accordingly thelink head 35 may be detached from theframe 36 by the fact that thescrews 46 break, and then be set in an axial, translational motion in the backward direction. - On the inside of the

individual side piece 39, an axially orientedguide bar 48 is arranged, which engages aco-operating groove 43 in thecross piece 42 of the link head. Upon translational move of the link head in relation to the frame, accordingly the link head is guided by thebars 48. - In the shown, preferred embodiment of the link coupling, a collision protection is integrated in the

link member 15, which in the example is in the form of three tubes orsleeves central tube 49 of a first type, and twoco-lateral tubes 50 of another type. All tubes are deformable and co-operate with throughbores back piece 40, which bores have a smaller diameter than the appurtenant tube. As is clearly seen infig. 9 , theintermediate deformation tube 49 together with theappurtenant bore 51 has a larger diameter than the twoco-lateral tubes 50 and thebores 52 thereof. Although thebores fig. 10 , which shows athin deformation tube 50 together with theappurtenant bore 52. In this bore, a funnel-like,conical mouth 53 is formed, which widens in the forward direction. Thedeformation tube 50 is of a cylindrical basic shape, but has at the rear end thereof aconical tapering portion 54, which is inserted into theconical mouth 53. In this position, the tube is kept in place by means of a holder in its entirety designated 55. Themouth 53 and theconical portion 54 of the tube has one and the same conicity or cone angle. Said cone angle should amount to at least 5° and at most 20°, and suitably be within the range of 10-16°. Tests that form the basis of the invention have been most successful when the cone angles have varied within the range of 11-15°. - At the opposite,

front end 56 thereof, thedeformation tube 50 is distanced from thecross piece 42 of the link head via agap 57. Thetube end 56 may advantageously consist of a planar, ring-shaped surface, which extends perpendicularly to the geometrical longitudinal axis of the tube. The axial extension of thegap 57 may be within the range of 10-20 mm. In this connection, it should be pointed out that the corresponding gap of theintermediate deformation tube 49 may have another, for instance smaller, axial extension than thegap 57 of eachthin deformation tube 50. For instance, the corresponding gap length of thetube 49 may be within the range of 5-15 mm. By the fact that the gaps are of different sizes, the different deformation tubes will be impinged by thecross piece 42 at different points of time. - Here, it should be pointed out that the collision protection shown in

figs. 8-10 and briefly described is the subject of a simultaneously filed Swedish patent application having the denomination "COLLISION PROTECTION IN A COUPLER FOR RAIL-MOUNTED VEHICLES AND A COUPLER EQUIPPED THEREWITH FOR PERMANENTLY CONNECTING TWO RAIL-MOUNTED VEHICLE UNITS". In the same patent application, the collision protection is described more in detail. Briefly, it should, however, be mentioned that thescrews 46 upon a strong collision break, whereby thelink head 35 is detached and can move in the direction of theback piece 40. In doing so, thecross piece 42 impinges on thedeformation tubes appurtenant bore cone mouth 53. During this deformation work, the kinetic energy in the detached link head is converted into heat in the deformation tubes as well as the back piece. This means that a substantial part of the kinetic energy is extincted before it has time to be transferred from one of the car chassis to the other. - When the two chassis or

car bodies link part 17 is mounted on one of thechassis 2 and thelink member 15, with the ensuinglink part 16, on theother chassis 1. Fixation of the shelf and box-like frames bolts blocks 23 of the chassis. In the next step, the end of thechassis 2 not equipped with wheels is lifted in above theJakobs bogie 3 and is located in a position in which themale elements 8 can be brought to engagement with theseatings 9 at the same time as thecentring devices other chassis 1 not equipped with wheels is lifted in above the Jakobs bogie and is lowered down so that the male-like link part or bearingbracket 16 is located in the female-like seating that is delimited by the bottom plate, end plate and side pieces of thelink part 17. Vertical lowering of thelink part 16 into said seating is possible as a consequence of the seating being open upward. In a final step, thelink parts screws 31. - During normal circumstances, the described link coupling in co-operation with the Jakobs bogie guarantee a permanent keeping together of the two chassis. However, would a need arise for separating the chassis from each other, this can be carried out by means of the simple measure of dismounting the

screws 31 and remove the chassis from the Jakobs bogie in the opposite order. - A fundamental advantage of the invention is that two chassis included in a car can be connected and disconnected without any need for manipulating the hinge between the link members of the link coupling. Neither the more or less theoretical possibility of removing a link member from the appurtenant chassis needs to be resorted to.

- The invention is not limited only to the embodiment described above and shown in the drawings. Thus, the invention is applicable also to such link devices or link couplings that lack collision protection. It is also feasible to apply the invention to such link couplings that do not co-operate with any Jakobs bogie. Thus, the link coupling can also be used for such cars the chassis of which are separately wheel-carried at the two ends thereof.

-

- 1

- Chassis

- 2

- Chassis

- 3

- Jakobs bogie

- 4

- Framework

- 5

- Wheels

- 6

- Damping cushions

- 7

- Assembling plates

- 8

- Male element

- 9

- Seatings

- 10

- Link coupling

- 11

- Hinge

- 12

- Pivot pin

- 13

- Bearing box

- 14

- First link member

- 15

- Second link member

- 16

- First link part

- 17

- Second link part

- 18

- Bottom plate

- 19

- End plate

- 20

- Side pieces

- 21

- Fastening plates

- 22

- Guide plates

- 23

- Blocks

- 24

- Support surfaces

- 25

- Screw hole

- 26

- Screws

- 27

- Screw hole

- 28

- Screws

- 29

- Via hole

- 30

- Sleeves

- 31

- Screws

- 32

- Screw hole

- 33

- Lower centring device

- 34

- Upper centring device

- 35

- Link head

- 38

- Front plate

- 39

- Side pieces

- 40

- Back pieces

- 41

- Fixing screws

- 42

- Cross piece

- 43

- Guiding groove

- 44

- Opening

- 45

- Screw hole

- 46

- Screws

- 47

- Waist

- 48

- Guide bar

- 49

- Intermediate deformation tube

- 50

- Lateral deformation tube

- 51

- Bore

- 52

- Bore

- 53

- Coned mouth

- 54

- Cone tip

- 55

- Holder

- 56

- Tube end

- 57

- Gap

- 36

- Carrier

- 37

- Bottom plate

Claims (4)

- A link device for permanently connecting two chassis of a rail-mounted car, comprising two link members (14, 15) connectable to a chassis each, which members are pivotally connected to each other via a hinge (11), wherein a first link member (14) is divisible by being composed of two parts (16, 17) releasably connected to each other, namely a first part (16) connected to the hinge (11) and a second part (17) which is connectable to one of the chassis (2), and the second link member (15) being connectable to the other chassis (1), the releasable joint between said link parts (16, 17) having the purpose of enabling separation of the chassis from each other, and wherein the first part (16) of the divisible link member (14) is of a male-like character and inserted into a female-like seating in the second part (17) and fixed therein by means of dismountable connecting elements (31), characterized in that said second link part comprises a shelf-like frame (17) composed of a bottom plate (18), an upright end plate (19), and two vertical side pieces (20) which project in the forward direction from the end plate and are stiffly united to the same as well as to the bottom plate while defining said seating.

- The link device according to claim 1, characterized in that one or more fastening plates (21) extend rearward from the end plate (19) for connection to a chassis.

- The link device according to claim 1 or 2, characterized in that in the end plate (19) a number of through holes (29) are formed adjacent to which there are sleeves (30) extending rearward for said connecting elements (31).

- The link device according to claim 1 or 2, characterized in that the bottom plate (18) of the frame (17) includes a centring device (33) for co-operation with an analogous centring device (34) on a Jakobs bogie.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL04775362T PL1663756T3 (en) | 2003-09-10 | 2004-09-01 | Rail-mounted car having an articulated joint for permanently connecting two underbodies of the rail-mounted car |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SE0302410A SE526057C2 (en) | 2003-09-10 | 2003-09-10 | Rail-bound trolley and linkage device for permanent coupling of two chassis included in such trolley |

| PCT/SE2004/001256 WO2005023619A1 (en) | 2003-09-10 | 2004-09-01 | Rail-mounted car having an articulated joint for permanently connecting two underbodies of the rail-mounted car |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1663756A1 EP1663756A1 (en) | 2006-06-07 |

| EP1663756B1 true EP1663756B1 (en) | 2011-08-24 |

Family

ID=28787295

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04775362A Expired - Lifetime EP1663756B1 (en) | 2003-09-10 | 2004-09-01 | Rail-mounted car having an articulated joint for permanently connecting two underbodies of the rail-mounted car |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP1663756B1 (en) |

| AT (1) | ATE521516T1 (en) |

| DK (1) | DK1663756T3 (en) |

| ES (1) | ES2372178T3 (en) |

| PL (1) | PL1663756T3 (en) |

| SE (1) | SE526057C2 (en) |

| WO (1) | WO2005023619A1 (en) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE527014C2 (en) * | 2004-04-20 | 2005-12-06 | Dellner Couplers Ab | Train vehicles and clamping device for fixing a towing device for such vehicles |

| DE102005023946A1 (en) * | 2005-05-20 | 2006-11-23 | Siemens Ag | Railway car coupling has two halves linked by a two-part element secured without fixtures e.g. bolts |

| FR2945266A1 (en) | 2009-05-06 | 2010-11-12 | Alstom Transport Sa | COUPLING JOINT BETWEEN A FIRST CAR AND A SECOND CAR OF A VEHICLE, IN PARTICULAR RAILWAY VEHICLE |

| DE102010040840A1 (en) * | 2010-09-15 | 2012-03-15 | Siemens Aktiengesellschaft | Multi-part rail vehicle with at least two car bodies connected by a double joint |

| EP2554452B1 (en) | 2011-08-01 | 2014-10-15 | Ego International B.V. | Link device suitable for linking a first chassis and a second chassis of a rail - mounted vehicle |

| CN205034125U (en) | 2015-07-24 | 2016-02-17 | 虎伯拉铰接系统(上海)有限公司 | Track vehicle |

| EP3162652B1 (en) * | 2015-10-30 | 2022-12-28 | Dellner Couplers AB | Pivot anchor and car |

| DE102017114376A1 (en) | 2017-06-28 | 2019-01-03 | Axtone S.A. | A hinge assembly for a bogie comprising at least one deformation element and a method for energy conversion |

| DE102018113349A1 (en) * | 2018-06-05 | 2019-12-05 | Bombardier Transportation Gmbh | Swivel joint for a bogie of a rail vehicle |

| CN109501830A (en) * | 2018-11-06 | 2019-03-22 | 中车株洲电力机车有限公司 | Four module trolleybuses of one kind and its course changing control articulated system |

| FR3119148B1 (en) * | 2021-01-27 | 2025-03-07 | Speedinnov | Safety device for fixing two vehicle elements |

| DE102023104207A1 (en) * | 2022-02-21 | 2023-08-24 | Voith Patent Gmbh | Articulated arrangement for the articulated connection of two adjacent car bodies of a track-guided vehicle |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1151905A2 (en) * | 2000-05-05 | 2001-11-07 | SCHARFENBERGKUPPLUNG GmbH & Co. KG | Device for the articulated connection of the bodies of a multi-unit railway vehicle |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2051958A (en) | 1931-02-10 | 1936-08-25 | Jennie M Madison | Articulated car construction |

| DE1094289B (en) | 1956-12-31 | 1960-12-08 | Orenstein & Koppel Ag | Trunnions of a bogie for rail vehicles |

| DE1605188B2 (en) | 1967-05-30 | 1973-08-09 | Moskowskij Ordena Lenina I Ordena Trudowowo Krasnowo Snameni Institut Inschenerow Schelesnodoroschnowo Transporta, Moskau | COUPLING DEVICE FOR THE ENDS OF TWO CONNECTED VEHICLE UNITS OF A RAIL-MOUNTED ARTICULATED VEHICLE |

| US3667820A (en) | 1970-12-11 | 1972-06-06 | Lord Corp | Railway car having resilient center bearing |

| FR2398651A1 (en) | 1977-07-25 | 1979-02-23 | Venissieux Atel | Coupling arrangement for articulated vehicles - has pivot of spherical type with end play and friction surfaces in fork and tenon sections |

| DE3866127D1 (en) | 1987-01-30 | 1991-12-19 | Alsthom Gec | CONNECTING DEVICE BETWEEN TWO RAIL VEHICLES. |

| US4962861A (en) | 1988-04-04 | 1990-10-16 | A. Stucki Company | Articulated connector |

| FR2631917B1 (en) | 1988-05-24 | 1990-08-10 | Alsthom | COUPLING ARTICULATION OF TWO RAIL VEHICLES |

| DE4121080A1 (en) | 1991-06-26 | 1993-01-14 | Waggon Union Gmbh | COUPLING DEVICE FOR THE END OF TWO JOINTLY CONNECTED VEHICLE UNITS BASED ON A COMMON BOGIE |

| SE9503808L (en) | 1995-10-30 | 1996-10-28 | Skf Ab | Car coupler unit |

| DE19638763C2 (en) | 1996-09-21 | 2001-02-15 | Daimler Chrysler Ag | Bogie connection for Jacobs bogies |

| EP1312527B1 (en) | 2001-09-17 | 2003-06-04 | Voith Turbo Scharfenberg GmbH & Co. KG | Articulated coupling |

| DE10153460A1 (en) | 2001-10-30 | 2003-05-22 | Voith Turbo Scharfenberg Gmbh | Railcar or wagon coupling offers lengthways maneuvrability via destructive buffer to guard against overloading of cars and coupling forks and bolt lashing. |

-

2003

- 2003-09-10 SE SE0302410A patent/SE526057C2/en not_active IP Right Cessation

-

2004

- 2004-09-01 AT AT04775362T patent/ATE521516T1/en active

- 2004-09-01 PL PL04775362T patent/PL1663756T3/en unknown

- 2004-09-01 WO PCT/SE2004/001256 patent/WO2005023619A1/en not_active Ceased

- 2004-09-01 EP EP04775362A patent/EP1663756B1/en not_active Expired - Lifetime

- 2004-09-01 DK DK04775362.9T patent/DK1663756T3/en active

- 2004-09-01 ES ES04775362T patent/ES2372178T3/en not_active Expired - Lifetime

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1151905A2 (en) * | 2000-05-05 | 2001-11-07 | SCHARFENBERGKUPPLUNG GmbH & Co. KG | Device for the articulated connection of the bodies of a multi-unit railway vehicle |

Also Published As

| Publication number | Publication date |

|---|---|

| SE0302410L (en) | 2005-03-11 |

| ATE521516T1 (en) | 2011-09-15 |

| ES2372178T3 (en) | 2012-01-16 |

| SE0302410D0 (en) | 2003-09-10 |

| EP1663756A1 (en) | 2006-06-07 |

| WO2005023619A1 (en) | 2005-03-17 |

| SE526057C2 (en) | 2005-06-21 |

| PL1663756T3 (en) | 2012-01-31 |

| DK1663756T3 (en) | 2011-12-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1663756B1 (en) | Rail-mounted car having an articulated joint for permanently connecting two underbodies of the rail-mounted car | |

| CA1122482A (en) | End underframe for a railway car | |

| US7410069B2 (en) | Railway vehicle and a clamping arrangement for the fixation of a towing arrangement in such vehicles | |

| JP5725779B2 (en) | Shinkansen vehicle connection device and removal method | |

| CA2525500C (en) | Muff coupling for vehicle couplers | |

| CA2020697C (en) | Railway vehicle rotary drawbar arrangement | |

| CA2022580C (en) | Slackless rotary drawbar assembly | |

| CA2084932C (en) | Center sill with short yoke member | |

| MX172362B (en) | TRACTION BAR COUPLER FOR A RAILWAY TRUCK | |

| EP0456221A1 (en) | Articulated coupling apparatus for connecting a pair of railway cars together | |

| CA2355494C (en) | End sill assembly with center plate casting | |

| RU2374109C2 (en) | Two-component casing of cushioning unit with built-in yoke | |

| US6435102B1 (en) | Front section of a railway car | |

| CA2122541C (en) | Support housing for a rotary end of a slackless drawbar | |

| US4570807A (en) | Railway car underframe | |

| EP1127769B1 (en) | Coupling shock resistant (CSR) coupler | |

| US3888358A (en) | Coupling assembly | |

| EP0766631A1 (en) | Articulated spine car | |

| EP0483924A1 (en) | Universal trailer | |

| CA2425055C (en) | Articulated railway bogie connector | |

| US5167334A (en) | Apparatus to provide versatility in securing male and female connection members of an articulated coupler to a center sill member of a railway car | |

| US5092204A (en) | Apparatus for aligning spherical member during assembly of an articulated coupling system | |

| US6065622A (en) | Spool for lightweight drawbar assembly | |

| AU737444B2 (en) | Light weight draft sill | |

| EP0680864B1 (en) | A female connection member for a slackless drawbar assembly using a ball and race assembly |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20060328 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20081013 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602004034131 Country of ref document: DE Effective date: 20111020 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: BOVARD AG |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20110824 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2372178 Country of ref document: ES Kind code of ref document: T3 Effective date: 20120116 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110824 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111226 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110824 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110824 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111125 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110824 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110824 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110824 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110824 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110824 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110824 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110901 |

|

| 26N | No opposition filed |

Effective date: 20120525 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602004034131 Country of ref document: DE Effective date: 20120525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111124 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110824 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20220809 Year of fee payment: 19 Ref country code: SE Payment date: 20220916 Year of fee payment: 19 Ref country code: GB Payment date: 20220919 Year of fee payment: 19 Ref country code: DK Payment date: 20220915 Year of fee payment: 19 Ref country code: DE Payment date: 20220921 Year of fee payment: 19 Ref country code: AT Payment date: 20220921 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20220802 Year of fee payment: 19 Ref country code: FR Payment date: 20220915 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20220920 Year of fee payment: 19 Ref country code: ES Payment date: 20221006 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20220923 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602004034131 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20230930 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 521516 Country of ref document: AT Kind code of ref document: T Effective date: 20230901 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20230901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230901 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230930 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240403 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230930 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230930 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20241025 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230901 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230902 |