EP1637726B1 - Arrangement of an air filter housing for an internal combustion engine in the motor compartment of a motor vehicle - Google Patents

Arrangement of an air filter housing for an internal combustion engine in the motor compartment of a motor vehicle Download PDFInfo

- Publication number

- EP1637726B1 EP1637726B1 EP20050017571 EP05017571A EP1637726B1 EP 1637726 B1 EP1637726 B1 EP 1637726B1 EP 20050017571 EP20050017571 EP 20050017571 EP 05017571 A EP05017571 A EP 05017571A EP 1637726 B1 EP1637726 B1 EP 1637726B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- air

- internal combustion

- shell

- combustion engine

- filter housing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M35/00—Combustion-air cleaners, air intakes, intake silencers, or induction systems specially adapted for, or arranged on, internal-combustion engines

- F02M35/10—Air intakes; Induction systems

- F02M35/10006—Air intakes; Induction systems characterised by the position of elements of the air intake system in direction of the air intake flow, i.e. between ambient air inlet and supply to the combustion chamber

- F02M35/10013—Means upstream of the air filter; Connection to the ambient air

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M35/00—Combustion-air cleaners, air intakes, intake silencers, or induction systems specially adapted for, or arranged on, internal-combustion engines

- F02M35/02—Air cleaners

- F02M35/0201—Housings; Casings; Frame constructions; Lids; Manufacturing or assembling thereof

- F02M35/021—Arrangements of air flow meters in or on air cleaner housings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M35/00—Combustion-air cleaners, air intakes, intake silencers, or induction systems specially adapted for, or arranged on, internal-combustion engines

- F02M35/10—Air intakes; Induction systems

- F02M35/10373—Sensors for intake systems

- F02M35/10386—Sensors for intake systems for flow rate

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M35/00—Combustion-air cleaners, air intakes, intake silencers, or induction systems specially adapted for, or arranged on, internal-combustion engines

- F02M35/16—Combustion-air cleaners, air intakes, intake silencers, or induction systems specially adapted for, or arranged on, internal-combustion engines characterised by use in vehicles

- F02M35/161—Arrangement of the air intake system in the engine compartment, e.g. with respect to the bonnet or the vehicle front face

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M35/00—Combustion-air cleaners, air intakes, intake silencers, or induction systems specially adapted for, or arranged on, internal-combustion engines

- F02M35/02—Air cleaners

- F02M35/04—Air cleaners specially arranged with respect to engine, to intake system or specially adapted to vehicle; Mounting thereon ; Combinations with other devices

- F02M35/06—Air cleaners specially arranged with respect to engine, to intake system or specially adapted to vehicle; Mounting thereon ; Combinations with other devices combined or associated with engine's cooling blower or fan, or with flywheel

Definitions

- a filter for cleaning the unfiltered air is arranged, which flows as clean air further in the direction of the internal combustion engine.

- the clean air tray is designed as a lid for the Rohluftschale to have access to the filter.

- the filter is arranged in the clean air tray and according to the Rohluftschale is designed as a lid for the clean air bowl.

- a disadvantage of the described embodiment is a relatively large space requirement for the entire arrangement.

- Object of the present invention is to integrate a generic air filter housing particularly space-saving in the engine compartment of a motor vehicle and at the same time to dampen unwanted noise.

- the air is sucked through the intake, generally called intake snorkel, above the coolant heat exchanger.

- intake snorkel By formed by the body at least one air guide at the entrance to the air filter housing, the unfiltered air is deflected into the deep part of the air filter housing, where water and coarse particles are excreted and drained so that the filter is less polluted, or moistened.

- Moist intake air cools an air mass meter faster than dry, so that when the intake air is too moist, too large an intake air mass is determined and thus an incorrect amount of fuel is supplied to the internal combustion engine.

- the pre-cleaned unfiltered air is fed to the air filter via an inflow opening with a catch collar. The cleaned after the air filter air then flows to an air flow measuring element, which is also integrated in the air filter module.

- a further embodiment variant may be arranged according to claim 2 in the main flow before the air flow measuring element another flow element, whereby the air is rectified before the air flow measurement and a more accurate and precise measurement is possible.

- the pressure loss is reduced by the flow guide to the air flow measuring element and the flow conditions of the air flow measuring element improves, whereby the characteristic of the air flow measuring element is improved, that is linearized.

- the air quantity measuring element is a particularly robust hot film air mass sensor.

- the Roh Kunststoffschale according to claim 4 has an opening through which the previously deposited pre-separated moisture and coarse dirt particles are excreted. This measure minimizes the danger of water hammer and extends the service life of the air filter.

- the arrangement according to claim 5 allows a vibration control decoupling between air filter housing and internal combustion engine.

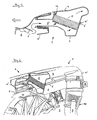

- Fig. 1 shows a section through an inventive air filter housing 1.

- the reference numerals Fig. 1 apply to the same components also for Fig. 2 ,

- the air filter housing 1 consists of a Rohluftschale 3 and a clean air bowl 4, between which a filter element 5, a commercially available air filter, is arranged.

- the Roh Kunststoffschale 3 and the clean air tray 4 are detachably connected to each other at the peripheral edges 3 ', 4'. Between the peripheral edges 3 ', 4', a seal 12 is arranged.

- the raw air shell 3 has a suction region 3 ", which is arranged on the body of the vehicle front 6.

- the body forms in the present case, two air guide elements 6 'in the air intake.

- the forward direction of travel of the motor vehicle is indicated by a double arrow.

- Fig. 2 shows a mounting situation for a cut, perspective illustrated air filter housing 1 in the engine compartment of a motor vehicle.

- the intake area 3 is arranged above a coolant heat exchanger 7 of the internal combustion engine.”

- the coolant heat exchanger 7 is largely covered by a cooling fan 11.

- Geodetically above the coolant heat exchanger 7 is the intake area 3 "of the air filter housing 1.

- the air duct 4 is also the air duct 4 "recognizable, through which the clean air leaves the clean air tray 4.

- an air quantity measuring element 8 in the present case a hot-film air mass meter, is integrated into the air duct 4 ", downstream of the air duct 4", the intake air is conducted further in a pipe 10 in the direction of the internal combustion engine.

- This is at least partially formed in a preferred embodiment as a corrugated pipe.

- the air filter housing 1 arranged according to the invention has a resonator 9, which in the exemplary embodiment is arranged, for example, on the tube 10.

- such resonators with which unwanted suction noise can be damped, can also be arranged on the untreated air shell 3 or on the clean air shell 4.

- hot-wire air mass meters can also be used instead of the hot-film air mass meter.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Analytical Chemistry (AREA)

- Manufacturing & Machinery (AREA)

- Filtering Of Dispersed Particles In Gases (AREA)

- Measuring Volume Flow (AREA)

Description

Aus den

Nachteilig an der beschriebenen Ausgestaltung ist ein relativ großer Bauraumbedarf für die gesamte Anordnung.A disadvantage of the described embodiment is a relatively large space requirement for the entire arrangement.

Aufgabe der vorliegenden Erfindung ist es, ein gattungsgemäßes Luftfiltergehäuse besonders Platz sparend in den Motorraum eines Kraftfahrzeuges zu integrieren und gleichzeitig ungewünschte Geräusche zu dämpfen.Object of the present invention is to integrate a generic air filter housing particularly space-saving in the engine compartment of a motor vehicle and at the same time to dampen unwanted noise.

Diese Aufgabe wird durch die Merkmale im kennzeichnenden Teil des Patentanspruchs 1 gelöst.This object is solved by the features in the characterizing part of

Durch die erfindungsgemäße Ausgestaltung wird die Luft durch den Ansaugbereich, allgemein Ansaugschnorchel genannt, oberhalb des Kühlmittelwärmetauschers angesaugt. Durch das von der Karosserie gebildete zumindest eine Luftleitelement am Eintritt in das Luftfiltergehäuse, wird die Rohluft in den tiefen Teil des Luftfiltergehäuses umgelenkt, wo Wasser und Grobpartikel ausgeschieden und drainiert werden sodass der Filter weniger verschmutzt, bzw. angefeuchtet wird. Dies ist insbesondere für selbstzündende Brennkraftmaschinen wichtig, da über die der Brennkraftmaschine zugeführte Luftmasse die aktuell notwendige Brennstoffmenge ermittelt wird. Feuchte Ansaugluft kühlt jedoch einen Luftmassenmesser schneller ab als Trockene, wodurch bei feuchter Ansaugluft eine zu große Ansaugluftmasse ermittelt wird und somit eine falsche Brennstoffmenge der Brennkraftmaschine zugeführt wird. Weiter wird über eine Einströmöffnung mit einem Fangkragen die vorgereinigte Rohluft dem Luftfilter zugeführt. Die nach dem Luftfilter gereinigte Luft strömt anschließend zu einem Luftmengenmesselement, das ebenfalls im Luftfiltermodul integriert ist.Due to the inventive design, the air is sucked through the intake, generally called intake snorkel, above the coolant heat exchanger. By formed by the body at least one air guide at the entrance to the air filter housing, the unfiltered air is deflected into the deep part of the air filter housing, where water and coarse particles are excreted and drained so that the filter is less polluted, or moistened. This is particularly important for self-igniting internal combustion engines, since the currently required amount of fuel is determined via the air mass supplied to the internal combustion engine. Moist intake air, however, cools an air mass meter faster than dry, so that when the intake air is too moist, too large an intake air mass is determined and thus an incorrect amount of fuel is supplied to the internal combustion engine. Furthermore, the pre-cleaned unfiltered air is fed to the air filter via an inflow opening with a catch collar. The cleaned after the air filter air then flows to an air flow measuring element, which is also integrated in the air filter module.

In einer weiteren Ausgestaltungsvariante kann gemäß Patentanspruch 2 in Hauptströmrichtung vor dem Luftmengenmesselement ein weiteres Strömungselement angeordnet sein, wodurch die Luft vor der Luftmengenmessung gleichgerichtet wird und eine genauere und präzisere Messung möglich ist. Zusätzlich wird der Druckverlust durch das Strömungsleitelement zum Luftmengenmesselement verringert und die Anströmverhältnisse des Luftmengenmesselementes verbessert, wodurch die Kennlinie des Luftmengenmesselementes verbessert, d. h. linearisiert wird.In a further embodiment variant may be arranged according to claim 2 in the main flow before the air flow measuring element another flow element, whereby the air is rectified before the air flow measurement and a more accurate and precise measurement is possible. In addition, the pressure loss is reduced by the flow guide to the air flow measuring element and the flow conditions of the air flow measuring element improves, whereby the characteristic of the air flow measuring element is improved, that is linearized.

Gemäß Patentanspruch 3 ist das Luftmengenmesselement ein besonders robuster Heißfilmluftmassensensor.According to

Ferner verfügt die Rohluftschale gemäß Patentanspruch 4 über eine Öffnung, durch die die zuvor beschriebene vorab abgeschiedene Feuchtigkeit sowie grobe Schmutzpartikel ausgeschieden werden. Durch diese Maßnahme ist die Wasserschlaggefahr minimiert und die Lebensdauer des Luftfilters verlängert.Furthermore, the Rohluftschale according to

Die Anordnung gemäß Patentanspruch 5 erlaubt eine schwingungstechnische Entkopplung zwischen Luftfiltergehäuse und Brennkraftmaschine.The arrangement according to claim 5 allows a vibration control decoupling between air filter housing and internal combustion engine.

Im Folgenden ist das erfindungsgemäße Luftfiltergehäuse anhand eines bevorzugten Ausführungsbeispieles in zwei Figuren näher erläutert.

- Fig. 1

- zeigt einen Schnitt durch eine erfindungsgemäße Luftfiltergehäuseanordnung,

- Fig. 2

- zeigt die Einbausituation eines geschnittenen Luftfiltergehäuses in dem Motorraum eines Kraftfahrzeuges.

- Fig. 1

- shows a section through an inventive air filter housing assembly,

- Fig. 2

- shows the installation situation of a cut air filter housing in the engine compartment of a motor vehicle.

Beim Betrieb der Brennkraftmaschine saugt diese aus der Kfz-Front 6 an den Luftleitelementen 6' vorbei die Ansaugluft, vor dem Filterelement 5 auch Rohluft genannt, an. Der Weg der Ansaugluft ist durch einen Pfeil dargestellt. Nach den Luftleitelementen 6, 6' tritt die Rohluft in den Ansaugbereich 3" ein und anschließend in die Rohluftschale 3. An den Luftleitelementen 6', sowie in der Rohluftschale 3 werden die gröbsten Staubpartikel sowie Feuchtigkeit oder Wassertropfen ausgefällt. Anschließend wird die Ansaugluft durch das Filterelement 5 gesaugt, wo es endgereinigt wird und als so genannte Reinluft in die Reinluftschale 4 eintritt. Weiter wird die Ansaugluft durch einen, in

In den Luftführungskanal 4" ist wie oben beschrieben ein Luftmengenmesselement 8, im vorliegenden Fall ein Heißfilmluftmassenmesser, integriert. Nach dem Luftführungskanal 4" wird die Ansaugluft weiter in einem Rohr 10 in Richtung Brennkraftmaschine geleitet. Dieses ist zumindest abschnittsweise in einer bevorzugten Ausführungsform als Wellrohr ausgebildet. Des weiteren weist das erfindungsgemäß angeordnete Luftfiltergehäuse 1 einen Resonator 9 auf, der im Ausführungsbeispiel beispielsweise an das Rohr 10 angeordnet ist.As described above, an air

In weiteren Ausführungsbeispielen können derartige Resonatoren, mit der ungewünschte Ansauggeräusche gedämpft werden, auch an der Rohluftschale 3 oder an der Reinluftschale 4 angeordnet sein. Ferner können anstelle der Heißfilmluftmassenmesser auch Hitzdrahtluftmassenmesser eingesetzt werden.In further embodiments, such resonators, with which unwanted suction noise can be damped, can also be arranged on the

Claims (5)

- A motor vehicle with an internal combustion engine arranged in an engine compartment (2) and with an arrangement of an air filter housing (1) in the engine compartment (2), wherein- the air filter housing (1) has an unfiltered air shell (3), the peripheral edge (3') of which is sealed against a second edge (4') of a clean air shell (4), wherein- the unfiltered air shell (3) has an inlet region (3") in the direction of a motor vehicle front (6) and- the inlet region (3") is geodetically arranged above a coolant heat exchanger (7) of the internal combustion engine and wherein- the clean air shell (4) has an air guidance channel (4") in the direction of the internal combustion engine,characterised in that- a filter element (5) is arranged between the unpurified air shell (3) and the clean air shell (4) and- an air guiding element (6') is formed by the engine compartment (6) upstream of the inlet region (3") and- an air quantity measuring element (8) is arranged in the air guidance channel (4"), wherein- a resonator (9) is arranged on the unpurified air shell (3) and/or on the clean air shell (4).

- An arrangement according to claim 1, characterised in that a flow guiding element is arranged in the air guidance channel (4") in the main flow direction upstream of the air quantity measuring element (8).

- An arrangement according to claim 1 or 2, characterised in that the air quantity measuring element (8) is a hot film or a heat wire air mass sensor.

- An arrangement according to any one of the previously mentioned claims, characterised in that the unpurified air shell (3) has an opening to remove a liquid and/or particles which have collected in the unpurified air shell (3).

- An arrangement according to any one of the previously mentioned claims, characterised in that the air guidance channel (4") is connected to the internal combustion engine by at least one flexible, gas-guiding tube (10).

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE200410045270 DE102004045270A1 (en) | 2004-09-17 | 2004-09-17 | Arrangement of an air filter housing for an internal combustion engine in the engine compartment of a motor vehicle |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1637726A1 EP1637726A1 (en) | 2006-03-22 |

| EP1637726B1 true EP1637726B1 (en) | 2010-12-01 |

Family

ID=35376972

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20050017571 Expired - Lifetime EP1637726B1 (en) | 2004-09-17 | 2005-08-12 | Arrangement of an air filter housing for an internal combustion engine in the motor compartment of a motor vehicle |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1637726B1 (en) |

| DE (2) | DE102004045270A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105804897A (en) * | 2015-01-19 | 2016-07-27 | 铃木株式会社 | Air inlet device of engine |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102008058431B4 (en) | 2007-11-26 | 2019-10-02 | Denso Corporation | Air cleaner unit for vehicle and fan cover with this |

| JP4730411B2 (en) * | 2008-08-07 | 2011-07-20 | マツダ株式会社 | Engine intake passage structure at the front of the vehicle body |

| JP4712096B2 (en) | 2009-01-07 | 2011-06-29 | 本田技研工業株式会社 | Air intake structure for automobiles |

| US8807113B2 (en) | 2009-05-04 | 2014-08-19 | Ford Global Technologies, Llc | Device and method for integrating an air cleaner into a radiator fan shroud |

| DE102013007157A1 (en) * | 2013-04-24 | 2014-10-30 | GM Global Technology Operations, LLC (n.d. Ges. d. Staates Delaware) | Air guiding device |

| WO2016135972A1 (en) * | 2015-02-27 | 2016-09-01 | 本田技研工業株式会社 | Intake structure for vehicle |

| DE102017009492A1 (en) | 2017-10-12 | 2019-04-18 | Daimler Ag | Method for adjusting an engine acoustics of an internal combustion engine |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5072698A (en) * | 1989-05-30 | 1991-12-17 | Mazda Motor Corporation | Intake apparatus for engine |

| US5059221A (en) * | 1989-08-15 | 1991-10-22 | Siemens-Bendix Automotive Electronics Limited | Integrated air cleaner assembly |

| US5120334A (en) * | 1991-05-23 | 1992-06-09 | Ford Motor Company | Air cleaner for internal combustion engine |

| DE9202785U1 (en) * | 1992-03-03 | 1992-04-23 | Adam Opel AG, 6090 Rüsselsheim | Structure for the engine air intake of internal combustion engines |

| DE4302659C1 (en) * | 1993-01-30 | 1994-04-21 | Daimler Benz Ag | Induction air guide for vehicle combustion engine - has exchangeable, insertable throttle as diffusor forming annular space with guidance channel and held in place by burls |

| DE19632205A1 (en) | 1996-08-09 | 1998-04-02 | Bayerische Motoren Werke Ag | Arrangement of an air filter housing in the engine compartment of a motor vehicle |

| JP3713865B2 (en) * | 1997-01-23 | 2005-11-09 | 株式会社デンソー | Intake device for internal combustion engine |

| US5899196A (en) * | 1997-12-19 | 1999-05-04 | Jeffrey S. Melcher | Method and apparatus for supplying warm air to an air intake of an engine |

| MXPA01003866A (en) * | 1998-10-22 | 2002-05-06 | Mccord Winn Textron Inc | Fan shroud and air intake arrangement. |

| US6736871B1 (en) * | 2002-12-09 | 2004-05-18 | Visteon Global Technologies, Inc. | Integrated filter screen and hydrocarbon adsorber |

-

2004

- 2004-09-17 DE DE200410045270 patent/DE102004045270A1/en not_active Withdrawn

-

2005

- 2005-08-12 EP EP20050017571 patent/EP1637726B1/en not_active Expired - Lifetime

- 2005-08-12 DE DE200550010606 patent/DE502005010606D1/en not_active Expired - Lifetime

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105804897A (en) * | 2015-01-19 | 2016-07-27 | 铃木株式会社 | Air inlet device of engine |

| CN105804897B (en) * | 2015-01-19 | 2019-01-11 | 铃木株式会社 | The inlet duct of engine |

Also Published As

| Publication number | Publication date |

|---|---|

| DE102004045270A1 (en) | 2006-03-23 |

| EP1637726A1 (en) | 2006-03-22 |

| DE502005010606D1 (en) | 2011-01-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3044451B1 (en) | Airfilter | |

| DE10200673B4 (en) | Automotive air filter | |

| EP2221097B1 (en) | Filter device for hydrocarbon adsorption | |

| EP1637726B1 (en) | Arrangement of an air filter housing for an internal combustion engine in the motor compartment of a motor vehicle | |

| DE102014226508A1 (en) | air conditioning | |

| DE10053145A1 (en) | Air inlet system for engine with protection against snow and water ingress, closes valve in main inlet when pressure differential across filter becomes excessive | |

| DE202006019335U1 (en) | Fine dust extraction device in a vehicle | |

| EP1340056A1 (en) | Device for measuring air flow, comprising a device for separating foreign particles | |

| EP1210565B1 (en) | Use of a flow rectifier as a condensation trap for a liquid in a gas flow | |

| DE102009048684B4 (en) | Kit with an air filter cartridge and a restrictor element | |

| DE102015216290B4 (en) | CHAMBER FOR REDUCING NOISE OPERATION OF A MAGNETIC EXHAUST CONTROL VALVE FOR AN EVAPORATIVE EMISSION CONTROL SYSTEM | |

| EP2169209B1 (en) | Assembly of an air mass flow measuring device in an intake system of a combustion engine | |

| EP1520977B1 (en) | Intake device for a pre-cleaning device in connection with a fan cover | |

| DE202007003292U1 (en) | Oil separator with at least one cyclone | |

| DE10209132A1 (en) | Suction device used as air intake, especially for motor vehicle, has tapered slat extending into air duct from top wall of duct | |

| EP3737919B1 (en) | Measuring arrangement for determining a parameter of a fluid medium flowing through a fluid flow channel and fluid flow channel with such a measuring arrangement | |

| DE102007034518A1 (en) | Air filter for an air suction system of a multi-cylinder internal combustion engine | |

| EP1591653B1 (en) | Air filter element for an intake system of an IC engine | |

| DE10316652B4 (en) | Air filter for an internal combustion engine | |

| EP1827955B1 (en) | Splash water collecting device for vehicles, more particularly motorcycles | |

| DE102018129957B4 (en) | Motor vehicle | |

| DE102016223955A1 (en) | separating | |

| DE19835104A1 (en) | Air intake system for a diesel engine in a truck | |

| DE102015109684B3 (en) | Nozzle device with dust collector and method for measuring an air mass flow | |

| EP3855024B1 (en) | Suction arrangement for a centrifugal air filter |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK YU |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: WIMMER, RUDOLF Inventor name: SCHOBER, MARTIN |

|

| 17P | Request for examination filed |

Effective date: 20060729 |

|

| 17Q | First examination report despatched |

Effective date: 20060824 |

|

| AKX | Designation fees paid |

Designated state(s): DE FR GB IT |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REF | Corresponds to: |

Ref document number: 502005010606 Country of ref document: DE Date of ref document: 20110113 Kind code of ref document: P |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20110902 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502005010606 Country of ref document: DE Effective date: 20110902 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230502 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240801 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20240822 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240821 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20240830 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 502005010606 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20250811 |