EP1589142B1 - Support de ressort pour un ressort à oeillet à une pièce, un cadre ou similaire - Google Patents

Support de ressort pour un ressort à oeillet à une pièce, un cadre ou similaire Download PDFInfo

- Publication number

- EP1589142B1 EP1589142B1 EP05007498A EP05007498A EP1589142B1 EP 1589142 B1 EP1589142 B1 EP 1589142B1 EP 05007498 A EP05007498 A EP 05007498A EP 05007498 A EP05007498 A EP 05007498A EP 1589142 B1 EP1589142 B1 EP 1589142B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- spring

- groove

- hook

- frame

- shaft

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F37/00—Details specific to washing machines covered by groups D06F21/00 - D06F25/00

- D06F37/20—Mountings, e.g. resilient mountings, for the rotary receptacle, motor, tub or casing; Preventing or damping vibrations

Definitions

- the invention relates to a spring bearing for a spring eye of a spring on a component, frame or the like.

- a spring bearing for a spring eye of a spring is known.

- a plastic molded part is arranged in a recess in a fold of a frame or housing part, in which a curved groove for receiving the hook formed as a spring eye is provided.

- the spring eyelet can not be inclined, so that is to be expected at a corresponding stress with increased wear.

- the invention thus raises the problem of further developing a spring bearing for an eyelet on a component or a frame in such a way that overcomes the described disadvantages and in particular prevents the signs of wear and / or the acoustic phenomena in the bearing point.

- the spring bearing as such is formed according to the invention of a plastic molding in which on the one hand a curved groove for receiving the hook formed as spring eye is provided, and wherein the plastic molded part on the other hand has a molded shaft support, which preferably cooperates with a crank-like shaft, in turn is pivotally mounted to the component.

- the plastic molding according to the invention thus prevents contact of spring eye to the component or to the frame on which the spring is mounted. The forced pivoting movement when the spring is subjected to an inclination against the component or the frame via the crank-like shaft, so that the friction phenomena are kept to a minimum.

- Such a spring bearing has the sufficient degrees of freedom for a spring, which are used in particular in household appliances such as washing machines. That is, the spring can be pivoted transversely to the groove. A twisting of the spring in the longitudinal direction of the groove is not possible. In this direction, a relative movement is suppressed by the special shape of the plastic molded part. Should such a movement be forced by the spring, the relative movement takes place between the shaft and the component.

- a hook spring eyelet to prevent rotation of the plastic molded part in the form of a hook spring eyelet includes on one side to the groove a contact surface, which is aligned in accordance with the straight portion of the spring eye in the inserted state. To the other side of the groove is followed by a contact surface, which is formed according to the extension of the free hooks.

- the plastic molding is quasi edged by the hook-shaped spring eyelet and it is held in a predicament.

- a curved projection adjoins the contact surface for the hook, which protrudes into the plane of the contact surface for the straight section of the spring eye.

- the groove has a V-shaped profiling, wherein on the groove walls each ear segments are formed.

- the bearing surfaces for the hook ends of the spring eye are formed on the curved approach.

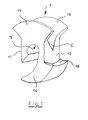

- FIG. 1 shows in perspective a plastic molding 1, which is a spring bearing 2 for a spring eye 3 on a component or on a frame 4, such as in the FIG. 2 represented, a washing machine forms.

- the plastic molded part 1 comprises on the one hand a curved groove 5 for receiving the hook 6 formed as a spring eye 3, and on the other hand, a molded shaft support 7, preferably with a crank-like shaft 8, as shown in particular FIGS. 3 and 4 is shown, cooperates.

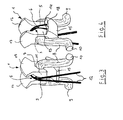

- the crank-like shaft 8 is with their lugs 9 and 10 on the frame 4 in the FIG. 2 pictured washing machine pivotally mounted.

- the groove 5 has a V-shaped profiling, wherein on the groove walls each ear segments 16 and 17 are integrally formed.

- a support surface 18 is formed for the hook ends of the spring lug 3 on the curved projection 15.

- FIG. 2 It can be seen that in particular on the frame 4, the spring eyes 3 are fixed, the spring eyes 3 are now equipped with the plastic molded part 1, which in turn with the crank-like shaft 8 in Active compound stand.

- the lugs 9 and 10 are pivotally mounted on the frame 4. If the drum 19 is now moved into an inclined position, as shown, the plastic moldings 1 according to the invention prevent wear and especially acoustic phenomena.

- the shaft support 7 shown in section has a narrowing of the diameter, so that a Klipsfunktion is to be realized.

- the plastic molded part 1 is mounted, in which the shaft 8 is guided through the recess, and the plastic molded part 1 is clipped onto the shaft 8 and thus held.

- the mounting aperture is configured to taper inwardly for ease of assembly.

- the mounting hole is not straight made for the reason.

- the straight legs of the crankshaft 8 thus encounter regardless of their position always in front of the front or back of the plastic molded part 1.

- the cross section the groove 5, in which the spring eye 3 is inserted must be designed so that a pivoting movement of the spring is allowed.

- a minimum radius of the cross section of the groove 5 corresponding to the wire thickness of the spring is required. Of course, this radius must grow to the sides.

- the ears 16 and 17 of the plastic molding on the one hand facilitate the assembly of the spring and prevent springing off of the spring in the event of shock, when no spring forces act more.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Springs (AREA)

Claims (6)

- Support de ressort pour le montage d'un oeillet de ressort d'un ressort sur un élément structurel, un bâti ou analogue, avec une pièce moulée (1) en matière plastique dans laquelle est prévue d'un côté une rainure cintrée (5) destinée à recevoir l'oeillet de ressort (3) réalisé sous forme de crochets (6),

caractérisé en ce que la pièce moulée (1) en matière plastique présente d'un autre côté un appui d'arbre (7) formé dans ladite pièce qui coopère avec un arbre (8) du genre bielle, sachant que cet arbre (8) du genre bielle est lui-même monté à pivotement sur l'élément structurel ou le bâti (4). - Support de ressort selon la revendication 1, caractérisé en ce qu'une surface d'application (11), qui est orientée conformément à la partie rectiligne (12) de l'oeillet de ressort (3), fait suite d'un côté à la rainure (5) pour le blocage en rotation de la pièce moulée (1) en matière plastique dans l'oeillet de ressort (3) réalisé sous forme de crochets (6).

- Support de ressort selon la revendication 2, caractérisé en ce qu'une autre surface d'application (13), qui est orientée conformément aux extrémités libres (14) des crochets (6), fait suite à l'autre côté de la rainure (5).

- Support de ressort selon la revendication 3, caractérisé en ce qu'une saillie cintrée (15), qui s'étend jusque dans le plan de la surface d'application (11) pour la partie rectiligne (12) de l'oeillet de ressort (3), fait suite à la surface d'application (13) pour les crochets (6).

- Support de ressort selon l'une des revendications 1 à 4, caractérisé en ce que la rainure (5) présente un profilage en forme de V, sachant que des segments d'oreilles respectifs (16 et 17) sont formés sur les parois de la rainure.

- Support de ressort selon l'une des revendications 1 à 5, caractérisé en ce qu'une surface d'appui (18) pour les extrémités des crochets de l'oeillet de ressort (3) est formée sur la saillie cintrée (15).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102004019902 | 2004-04-21 | ||

| DE102004019902A DE102004019902B3 (de) | 2004-04-21 | 2004-04-21 | Federlager für eine Federöse einer Feder an einem Bauteil oder Rahmen |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1589142A2 EP1589142A2 (fr) | 2005-10-26 |

| EP1589142A3 EP1589142A3 (fr) | 2006-08-16 |

| EP1589142B1 true EP1589142B1 (fr) | 2008-10-01 |

Family

ID=34934794

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05007498A Expired - Lifetime EP1589142B1 (fr) | 2004-04-21 | 2005-04-06 | Support de ressort pour un ressort à oeillet à une pièce, un cadre ou similaire |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1589142B1 (fr) |

| AT (1) | ATE409773T1 (fr) |

| DE (2) | DE102004019902B3 (fr) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4834735A (en) * | 1986-07-18 | 1989-05-30 | The Proctor & Gamble Company | High density absorbent members having lower density and lower basis weight acquisition zones |

| US9297104B2 (en) * | 2012-01-25 | 2016-03-29 | Illinois Tool Works Inc. | Washing machine suspension ball support |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE6752636U (de) * | 1968-06-06 | 1969-03-27 | Siemens Electrogeraete | Federlager fuer die das trommelaggregat einer waschmaschine haltenden zugfedern. |

| JPS5488668A (en) * | 1977-12-24 | 1979-07-13 | Matsushita Electric Ind Co Ltd | Single-tank washer |

| JPS58261A (ja) * | 1981-06-23 | 1983-01-05 | Matsushita Electric Ind Co Ltd | 洗濯機の脱水受筒支持装置 |

| JPH04189397A (ja) * | 1990-11-22 | 1992-07-07 | Matsushita Electric Ind Co Ltd | 電気洗濯機の防振装置 |

| DE9405703U1 (de) * | 1994-04-06 | 1994-05-26 | Texmato GmbH & Co, 49090 Osnabrück | Vorrichtung zur Befestigung von Wellenfedern an Rahmenstreben |

-

2004

- 2004-04-21 DE DE102004019902A patent/DE102004019902B3/de not_active Expired - Fee Related

-

2005

- 2005-04-06 EP EP05007498A patent/EP1589142B1/fr not_active Expired - Lifetime

- 2005-04-06 AT AT05007498T patent/ATE409773T1/de not_active IP Right Cessation

- 2005-04-06 DE DE502005005500T patent/DE502005005500D1/de not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP1589142A2 (fr) | 2005-10-26 |

| DE102004019902B3 (de) | 2005-12-01 |

| DE502005005500D1 (de) | 2008-11-13 |

| ATE409773T1 (de) | 2008-10-15 |

| EP1589142A3 (fr) | 2006-08-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2250944B1 (fr) | Elément de ressort pour l'installation dans un matelas, par exemple un matelas à ressort alvéolé | |

| AT510436B1 (de) | Karabinerhaken | |

| DE4421878A1 (de) | Schwingungsdämpfende Befestigung einer Scheibenwischerantriebseinrichtung | |

| EP3033538B1 (fr) | Ressort de retenue d'une garniture de frein et élément de retenue de garniture de frein pour frein à disque d'un véhicule automobile | |

| WO2013091792A1 (fr) | Entraînement à broche pour un élément mobile d'un véhicule automobile | |

| DE102005026471B4 (de) | Halter für eine Leitung in einem Automobil | |

| DE102008007107A1 (de) | Axialkugelgelenk mit Anschlagdämpfung | |

| DE102013101781A1 (de) | Bremsbelaghalterung für eine Scheibenbremse eines Kraftfahrzeugs | |

| DE2830096A1 (de) | Elastische halteklammer fuer rundstaebe mit variablen durchmessern | |

| DE2451084B2 (de) | Kugelgelenk | |

| DE102012208084B3 (de) | Anlenk-Vorrichtung zum Anlenken eines Reibungs-Dämpfers an eine Waschmaschine | |

| EP1589142B1 (fr) | Support de ressort pour un ressort à oeillet à une pièce, un cadre ou similaire | |

| EP1431641B1 (fr) | Collier pour tuyau | |

| EP2045405B1 (fr) | Plaque d'actionnement pour un dispositif d'actionnement d'un dispositif de rinçage | |

| EP2088228A1 (fr) | Aiguille à clapet | |

| DE20309732U1 (de) | Lüftungsdüse für ein Kraftfahrzeug | |

| EP3010735A1 (fr) | Élément élastique de torsion | |

| EP2167354B1 (fr) | Dispositif de fixation | |

| DE102011000339A9 (de) | Handhabe eines Kraftfahrzeugs | |

| EP1752577B1 (fr) | Machine à laver avec des fixations pour la suspension d'un groupe oscillant | |

| DE102012209058A1 (de) | Scheibenwischvorrichtung | |

| EP1741820A1 (fr) | Machine à laver avec un dispositif de fixation pour le transport | |

| DE102009000461A1 (de) | Zylinderkopfabdeckhaube | |

| EP1799897B1 (fr) | Palier-support pour metier mecanique et metier mecanique dote d'un palier-support | |

| EP4139586B1 (fr) | Dispositif de guidage de lignes, en particulier chaîne porte-câbles, et maillon de chaîne pourvu d'éléments d'amortissement |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20070111 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20070503 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502005005500 Country of ref document: DE Date of ref document: 20081113 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 746 Effective date: 20081104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081001 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090101 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081001 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090201 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081001 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090302 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081001 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081001 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081001 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081001 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081001 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090101 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081001 |

|

| 26N | No opposition filed |

Effective date: 20090702 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081001 |

|

| BERE | Be: lapsed |

Owner name: MIELE & CIE. K.G. Effective date: 20090430 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090406 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090406 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090402 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081001 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20150423 Year of fee payment: 11 Ref country code: DE Payment date: 20150430 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20150422 Year of fee payment: 11 Ref country code: IT Payment date: 20150427 Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502005005500 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20160406 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20161230 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161101 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160502 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160406 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160406 |