EP1574447B1 - Sac en film multicouche muni de poignées - Google Patents

Sac en film multicouche muni de poignées Download PDFInfo

- Publication number

- EP1574447B1 EP1574447B1 EP04005425A EP04005425A EP1574447B1 EP 1574447 B1 EP1574447 B1 EP 1574447B1 EP 04005425 A EP04005425 A EP 04005425A EP 04005425 A EP04005425 A EP 04005425A EP 1574447 B1 EP1574447 B1 EP 1574447B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- film

- composite

- bag

- functional regions

- zones

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000002131 composite material Substances 0.000 title claims description 48

- 239000011888 foil Substances 0.000 title abstract description 15

- 239000002985 plastic film Substances 0.000 claims description 20

- 229920006255 plastic film Polymers 0.000 claims description 20

- -1 polyethylene Polymers 0.000 claims description 12

- 239000004698 Polyethylene Substances 0.000 claims description 9

- 229920000573 polyethylene Polymers 0.000 claims description 9

- 238000004381 surface treatment Methods 0.000 claims description 9

- 229920000139 polyethylene terephthalate Polymers 0.000 claims description 7

- 239000005020 polyethylene terephthalate Substances 0.000 claims description 7

- 210000003850 cellular structure Anatomy 0.000 claims description 3

- 239000005026 oriented polypropylene Substances 0.000 claims description 2

- 238000003475 lamination Methods 0.000 claims 1

- 150000001875 compounds Chemical class 0.000 abstract description 2

- 239000010410 layer Substances 0.000 description 11

- 238000010030 laminating Methods 0.000 description 10

- 238000004080 punching Methods 0.000 description 8

- 230000003287 optical effect Effects 0.000 description 3

- 239000012790 adhesive layer Substances 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 229920006267 polyester film Polymers 0.000 description 2

- 208000032544 Cicatrix Diseases 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 238000004040 coloring Methods 0.000 description 1

- 238000010835 comparative analysis Methods 0.000 description 1

- 230000032798 delamination Effects 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 239000012939 laminating adhesive Substances 0.000 description 1

- 230000001590 oxidative effect Effects 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 231100000241 scar Toxicity 0.000 description 1

- 230000037387 scars Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000011282 treatment Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D33/00—Details of, or accessories for, sacks or bags

- B65D33/06—Handles

- B65D33/08—Hand holes

Definitions

- the invention relates to a film bag made of a two- or multi-layer composite film with a Griffausstanzung, which is formed as a straight or arcuate cut line, the composite film consists of at least two connected by laminating films and the bag inside film of Kaschierverbundes is a sealable plastic film with good elongation properties, wherein the film surface of the composite film has functional areas in which the bond strength between the bag-inside sealable plastic film and the adjoining film of Kaschierverbundes is smaller than in the area surrounding the functional areas, and wherein the Griffausstanzung is arranged at least partially in these functional areas.

- the term "foil bag” is intended to include both open pockets and circumferentially closed product packages. Last can be provided with tear-open and re-closures.

- EP 1 129 960 A1 A foil bag with the features described above is made EP 1 129 960 A1 known.

- the film layers of the composite film in the handle punching are not glued together. Under load, the inside of the film on the inside of the pouch can expand unhindered locally in the area of the handle punching, which has a favorable effect on the tear strength of the composite foil in the grip area. Both from an optical point of view and with regard to handling, however, it is unsatisfactory that even before the first use of the film bag, the film layers of the composite film in the grip area do not lie firmly against one another or are connected to one another.

- the invention has for its object to provide a provided with a Griffausstanzung foil bag made of a two- or multi-layer composite film, the film layers are connected in the area of Griffausstanzung area and which is characterized at the same time by a high tensile strength in the range of Griffausstanzung.

- the object is achieved in that the sealable plastic film of Kaschierverbundes outside the functional areas has a surface modified by surface treatment to which the adjacent layer of Kaschierverbundes firmly adheres, and that on the surface portions which the Functional areas form, no surface treatment was performed or this was performed there weaker and / or this was limited to small patches that form a pattern within the functional areas.

- Surface treatments which affect the adhesion properties of the film surface include, for example, treatment of the surface with a gas flame in excess of oxygen or an oxidizing surface treatment by corona discharges.

- the film is guided through an arc area where numerous small discharges cause tiny scars on the plastic surface and thereby changing the physical and chemical properties of the surface.

- the invention is based on the observation that the tear strength of the composite film is smaller than the tensile strength of the sealable plastic film used in the laminating composite.

- a film firmly laminated to the sealable plastic film impedes the stretching of the sealable film and prevents a uniform force in this film under a tensile load.

- zones are provided within the composite foil by functional regions in which the bond strength between the layers is reduced at least to such an extent that the foils separate under tensile stress in a locally limited area and the elongation of the sealable foil in this region is not thereby or only slightly hampered.

- a local delamination of the film layers under tensile load, which is restricted to the functional areas, is accepted in order to ensure the introduction of force into the sealable plastic film under load.

- the handle punching is arranged completely within the described functional areas. It may happen that the layers of the composite film in the handling of the film bag on the periphery of the Griffausstanzung from each other. Although this does not affect the function, but can be perceived as disturbing from an optical point of view.

- the functional areas described are assigned to sections of the handle punching on which the composite foil preferably tears when the filled foil bag is carried. These are sections in which the introduction of force preferably takes place when the foil bag is worn and the greatest tensile stresses occur. The sections depend on the shape of the handle punching and can be determined by calculation or by means of less orienting tests.

- the handle punching formed as a straight or arcuate section line, wherein the ends of the cutting line are each arranged within an associated functional area and wherein a central portion of the cutting line is introduced into a functional area surrounding film surface of the composite film whose bond strength is greater than in the functional areas.

- the bag-sealable plastic film is also connected in the functional areas with the adjacent film, with the proviso that the bond strength is lower here than in the area surrounding the functional area.

- the laminating composite in the functional areas has a contact surface with a pattern of well-adhering and poorly adhering zones. Due to the proportion of areas of poorly adhering zones, the bond strength is changeable.

- the area fraction of the poorly adhering film, based on the area of the functional area is preferably more than 20%.

- the described pattern may consist of parallel or intersecting lines or be formed by a pattern with a cellular structure. In the context of the invention, it is also the case that the sealable plastic film with the adjoining film in the functional areas is connected to one another in a point-like manner, ie the well-adhering zones of the pattern consist of punctiform surfaces.

- composite films are used which consist of at least two films adhesively bonded to one another in two dimensions, the film on the inside of the film being a sealable plastic film having good elongation properties is.

- the sealable plastic film may be a monofilm or a coextruded film.

- films of polyethylene or polymers with comparable elongation and sealing properties are particularly advantageous in the case of the use of composite films comprising a laminating composite made of a polyethylene film as a sealable plastic film on the inside of the bag and a rigid and brittle film in comparison, in particular of polyethylene terephthalate (PET) or an oriented polypropylene.

- PET polyethylene terephthalate

- the outer bag-side film of the laminating composite can be printed, for example, with a counterpressure on the inner surface.

- the in Fig. 1 shown foil bag consists of a two- or multi-layer composite foil 1 and has a Griffausstanzung 2 on.

- the composite film 1 consists of at least two connected by laminating films 3, 4, wherein the bag inside film 3 of Kaschierverbundes a sealable plastic film with good elongation properties, eg. B. a polyethylene film is.

- the film surface of the composite film has functional areas 5, in which the bond strength between the bag-side sealable plastic film 3 and the adjoining film 4 of the laminated composite is smaller as in the area surrounding the functional areas 5 6.

- the functional areas 5 are optically not visible on the outside of the film and in Fig. 1 indicated for clarity only by a dashed line.

- the Fig. 1 makes it clear that the Griffausstanzung 2 is at least partially disposed in these functional areas 5.

- the functional regions 5, which have a reduced bond strength between the bag-inside sealable plastic film 3 and the adjacent film 4 of the laminating composite, are assigned to sections of the handle punch 2 on which the composite film 1 preferably tears when carrying the filled film bag.

- the Griffausstanzung 2 is formed as an arcuate section line, wherein the ends of the cutting line are each arranged within an associated functional area 5.

- the middle section a of the section line is introduced into a film surface 6 of the composite film surrounding the functional regions, whose bond strength is greater than in the functional regions 5.

- Composite film 1 shown consists of a laminating composite of a polyethylene film as a bag inside sealable plastic film 3 and a stiff and brittle in comparison to polyester film (PET) 4, which forms the outside of the composite film.

- the two films are glued surface with a laminating adhesive, which is shown as an adhesive layer 7, glued.

- the bag outer side film 4 is on the inner surface with a counter pressure, which in Fig. 2 is represented by a color layer 8, printed.

- the composite side surface 9 of the polyethylene film has been surface treated to improve the adhesion of the adjacent adhesive layer 7. Outside the functional areas, the surface treatment was carried out flat, so that the laminating composite has a high bond strength between the bag-inside polyethylene film 3 and the outer polyester film 4.

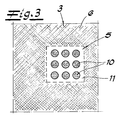

- the surface treatment limited to small patches 10, which within the functional areas a in Fig. 3 form a pattern.

- the patches 10 form well-adhering zones and consist in the embodiment of Fig. 3 from point-shaped surfaces, which can be made visible by coloring the film surface.

- the laminating compound in the functional regions 5 has a contact surface with a pattern of well-adhering zones 10 and poorly adhering zones 11, wherein the poorly adhering zones 11 should have an area fraction of more than 20% relative to the area of the functional area.

- Diverse patterns are conceivable.

- pattern of parallel and intersecting lines and patterns with a cellular structure are possible.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Bag Frames (AREA)

- Laminated Bodies (AREA)

- Wrappers (AREA)

Claims (7)

- Sac en feuille constitué d'une feuille bi- ou multicouche (1) avec une découpe de poignée (2), réalisée sous forme de ligne de coupe rectiligne ou en arc,

la feuille multicouche (1) étant constituée d'au moins deux feuilles (3, 4) assemblées par contre-collage et la feuille du côté intérieur du sac du compound contre-collé étant une feuille de matière plastique (3) apte au scellement avec de bonnes propriétés d'allongement,

la surface de la feuille multicouche comportant des zones fonctionnelles (5), dans lesquelles la résistance du compound entre la feuille de matière plastique (3) apte au scellement du côté intérieur du sac et la feuille (4) limitrophe du compound contre-collé est plus faible que dans la surface entourant les zones fonctionnelles (5), et

la découpe de poignée (2) étant disposée au moins en partie dans ces zones fonctionnelles (5),

caractérisé en ce que la feuille de matière plastique (3), apte au scellement, du compound contre-collé présente à l'extérieur des zones fonctionnelles une surface modifiée par traitement superficiel, sur laquelle adhère fixement la couche limitrophe (7) du compound contre-collé, et que, sur les sections superficielles formant les zones fonctionnelles (5), aucun traitement superficiel n'a été effectué ou ce dernier n'y a été réalisé que plus faiblement et/ou ce traitement a été limité à de petites pièces superficielles (10), qui forment un modèle à l'intérieur des zones fonctionnelles (5). - Sac en feuille suivant la revendication 1, caractérisé en ce que les extrémités de la ligne de coupe, formant la découpe de poignée, sont respectivement disposées à l'intérieur d'une zone fonctionnelle associée (5), qui présente une résistance de compound réduite entre la feuille de matière plastique (3) apte au scellement, du côté intérieur du sac, et la feuille limitrophe (4) du compound contre-collé, et qu'une section centrale (a) de la ligne de coupe est pratiquée dans une surface (6) de la feuille multicouche, entourant ces zones fonctionnelles, dont la résistance de compound est plus élevée que dans les zones fonctionnelles (5).

- Sac en feuille suivant l'une des revendications 1 et 2, caractérisé en ce que le compound contre-collé présente dans les zones fonctionnelles (5) une surface de contact avec un modèle de zones (10) de bonne adhérence et de zones (11) de mauvaise adhérence.

- Sac en feuille suivant la revendication 3, caractérisé en ce que les zones de mauvaise adhérence (11) présentent un pourcentage surfacique de plus de 20% rapporté à la surface de la zone fonctionnelle (5).

- Sac en feuille suivant l'une des revendications 3 et 4, caractérisé en ce que le modèle constitué de zones de bonne adhérence et de zones de mauvaise adhérence (10, 11) forme un modèle de lignes parallèles ou en croix ou un modèle avec une structure cellulaire.

- Sac en feuille suivant l'une des revendications 3 et 4, caractérisé en ce que les zones de bonne adhérence (10) sont constituées de surfaces ponctuelles.

- Sac en feuille suivant l'une des revendications 1 à 6, caractérisé en ce que la feuille multicouche (1) présente un compound contre-collé constitué d'une feuille de polyéthylène, en tant que feuille de matière plastique (3) apte au scellement du côté intérieur du sac, et d'une feuille rigide et fragile par rapport à cette dernière, en particulier en polyéthylènetéraphtalate (PET) ou en un polypropylène orienté.

Priority Applications (10)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL04005425T PL1574447T3 (pl) | 2004-03-08 | 2004-03-08 | Worek foliowy z dwu- lub wielowarstwowym kompozytem foliowym ze stanowiącym uchwyt wycięciem |

| AT05003837T ATE432226T1 (de) | 2004-03-08 | 2004-03-08 | Folienbeutel aus einer zwei- oder mehrlagigen verbundfolie mit einer griffausstanzung |

| EP04005425A EP1574447B1 (fr) | 2004-03-08 | 2004-03-08 | Sac en film multicouche muni de poignées |

| ES04005425T ES2302991T3 (es) | 2004-03-08 | 2004-03-08 | Bolsa de laminas formada por una lamina compuesta de dos o mas capas con una estampacion de agarre. |

| DK04005425T DK1574447T3 (da) | 2004-03-08 | 2004-03-08 | Foliepose af en to eller flerlags lamineret folie med en udstansning til greb |

| AT04005425T ATE396119T1 (de) | 2004-03-08 | 2004-03-08 | Folienbeutel aus einer zwei- oder mehrlagigen verbundfolie mit einer griffausstanzung |

| DE502004009525T DE502004009525D1 (de) | 2004-03-08 | 2004-03-08 | Folienbeutel aus einer zwei- oder mehrlagigen Verbundfolie mit einer Griffausstanzung |

| EP05003837A EP1588953B1 (fr) | 2004-03-08 | 2004-03-08 | Sac en film multicouche muni de poignées |

| DE502004007219T DE502004007219D1 (de) | 2004-03-08 | 2004-03-08 | Folienbeutel aus einer zwei- oder mehrlagigen Verbundfolie mit einer Griffausstanzung |

| PCT/EP2005/002382 WO2005085080A2 (fr) | 2004-03-08 | 2005-03-07 | Sachet en film constitue d'un film composite a au moins deux couches avec une region de saisie decoupee |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP04005425A EP1574447B1 (fr) | 2004-03-08 | 2004-03-08 | Sac en film multicouche muni de poignées |

Related Child Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05003837A Division EP1588953B1 (fr) | 2004-03-08 | 2004-03-08 | Sac en film multicouche muni de poignées |

| EP05003837.1 Division-Into | 2005-02-23 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1574447A1 EP1574447A1 (fr) | 2005-09-14 |

| EP1574447B1 true EP1574447B1 (fr) | 2008-05-21 |

Family

ID=34814255

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04005425A Expired - Lifetime EP1574447B1 (fr) | 2004-03-08 | 2004-03-08 | Sac en film multicouche muni de poignées |

| EP05003837A Expired - Lifetime EP1588953B1 (fr) | 2004-03-08 | 2004-03-08 | Sac en film multicouche muni de poignées |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05003837A Expired - Lifetime EP1588953B1 (fr) | 2004-03-08 | 2004-03-08 | Sac en film multicouche muni de poignées |

Country Status (7)

| Country | Link |

|---|---|

| EP (2) | EP1574447B1 (fr) |

| AT (2) | ATE396119T1 (fr) |

| DE (2) | DE502004007219D1 (fr) |

| DK (1) | DK1574447T3 (fr) |

| ES (1) | ES2302991T3 (fr) |

| PL (1) | PL1574447T3 (fr) |

| WO (1) | WO2005085080A2 (fr) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2472739T3 (es) | 2008-03-11 | 2014-07-02 | Amcor Flexibles Kreuzlingen Ltd. | Estratificado con un área que tiene una resistencia al desgarro mejorada |

| DE202010005231U1 (de) * | 2010-04-16 | 2010-09-30 | Kobusch-Sengewald Gmbh & Co. Kg | Laminat aus Schichtmaterial unterschiedlicher Reissfestigkeit |

| DE102011002315A1 (de) * | 2011-04-28 | 2012-10-31 | Nordenia Technologies Gmbh | Folienverpackung, insbesondere für Feuchttücher |

| WO2023026722A1 (fr) * | 2021-08-24 | 2023-03-02 | 株式会社フジシール | Contenant en forme de poche |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2633793A1 (de) * | 1976-07-28 | 1978-02-02 | Bosch Gmbh Robert | Beutelpackung mit grifflasche |

| DE3232321A1 (de) * | 1982-08-31 | 1984-03-01 | Bischof Und Klein Gmbh & Co, 4540 Lengerich | Trageverpackung aus flexiblem werkstoff in sack- oder beutelform |

| EP0266670B1 (fr) * | 1986-11-05 | 1992-03-04 | Stiegler Gmbh Maschinenfabrik | Sac de transport en feuille de matière thermoplastique |

| ITMI20000289A1 (it) * | 2000-02-18 | 2001-08-18 | Goglio Spa Luigi Milano | Contenitore in materiale flessibile con maniglia rinforzata per evitare lacerazioni |

-

2004

- 2004-03-08 PL PL04005425T patent/PL1574447T3/pl unknown

- 2004-03-08 ES ES04005425T patent/ES2302991T3/es not_active Expired - Lifetime

- 2004-03-08 EP EP04005425A patent/EP1574447B1/fr not_active Expired - Lifetime

- 2004-03-08 DE DE502004007219T patent/DE502004007219D1/de not_active Expired - Lifetime

- 2004-03-08 AT AT04005425T patent/ATE396119T1/de active

- 2004-03-08 DK DK04005425T patent/DK1574447T3/da active

- 2004-03-08 DE DE502004009525T patent/DE502004009525D1/de not_active Expired - Lifetime

- 2004-03-08 AT AT05003837T patent/ATE432226T1/de active

- 2004-03-08 EP EP05003837A patent/EP1588953B1/fr not_active Expired - Lifetime

-

2005

- 2005-03-07 WO PCT/EP2005/002382 patent/WO2005085080A2/fr not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| DE502004007219D1 (de) | 2008-07-03 |

| DE502004009525D1 (de) | 2009-07-09 |

| PL1574447T3 (pl) | 2008-10-31 |

| EP1574447A1 (fr) | 2005-09-14 |

| DK1574447T3 (da) | 2008-09-15 |

| ATE396119T1 (de) | 2008-06-15 |

| ES2302991T3 (es) | 2008-08-01 |

| ATE432226T1 (de) | 2009-06-15 |

| WO2005085080A2 (fr) | 2005-09-15 |

| WO2005085080A3 (fr) | 2005-12-22 |

| EP1588953B1 (fr) | 2009-05-27 |

| EP1588953A1 (fr) | 2005-10-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2522595B1 (fr) | Feuille multicouche pour emballages déchirables | |

| EP3720707B1 (fr) | Film complexe de plastique, emballage plastique et procédé de fabrication d'un film complexe de plastique | |

| EP1306209B1 (fr) | Film multicouche produit par co-extrusion | |

| EP1918094A1 (fr) | Feuille d'emballage | |

| DE102004026980A1 (de) | Standbeutel mit optimiertem Aufreißverhalten und Verfahren zu seiner Herstellung | |

| AT519866A4 (de) | Recyclingfreundliches, einfach reißbares Verpackungslaminat mit guter Barrierewirkung und Verfahren zu dessen Herstellung | |

| DE10201480B4 (de) | Stretchfolie | |

| EP2374604B1 (fr) | Couvercle à feuille destiné à la fermeture d'un récipient et son procédé de fabrication | |

| EP2364848A1 (fr) | Film, notamment pour emballages déchirables et procédé de fabrication d'un emballage de sac en utilisation ce film | |

| EP1777167B1 (fr) | Sachet d'emballage en film | |

| EP1574447B1 (fr) | Sac en film multicouche muni de poignées | |

| EP1849579A1 (fr) | Procédé pour la fabrication d'un film pour emballages déchirables | |

| EP1055612B1 (fr) | Méthode de fabrication d'un sachet déchirable | |

| EP0686478B1 (fr) | Pièce métallique doublée et procédé pour sa fabrication | |

| DE102009043360A1 (de) | Aufreißverpackung | |

| WO2006058621A1 (fr) | Film de revetement en papillote et son utilisation comme film d'emballage | |

| EP1475223B1 (fr) | Feuille composite pour emballages déchirables et procédé d'obtention | |

| DE10307250A1 (de) | Folienelement | |

| DE102013214076A1 (de) | Mehrschichtige Kunststoff-Wirkstofffolie | |

| DE102009021082A1 (de) | Mehrschichtiges Laminat, Verfahren zur Herstellung, dessen Verwendung und daraus hergestellter Verpackungsbehälter, insbesondere für zumindest partiell dehydratisierte Lebensmittel | |

| DE29716238U1 (de) | Verpackungsfolie | |

| DE102017123135A1 (de) | Laminat mit einem Folienverbund, Verfahren zur Herstellung des Laminats, aus dem Laminat hergestellte Verpackung, Verwendung des Folienverbunds zur Herstellung des Laminats und Verwendung des Laminats zur Herstellung einer Verpackung | |

| EP1439056A1 (fr) | Structure stratifiée comprenant deux matériaux en feuille ayant une résistance au déchirement différente, en particulier en polyester et en polyéthylène | |

| DE102009026309B4 (de) | Verfahren zum Herstellen und Verpacken von Hygieneartikeln | |

| EP3113948A1 (fr) | Matériau de film pour la fabrication d'un emballage |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20050726 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20070323 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: BLOCK, JOACHIM |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: KELLER & PARTNER PATENTANWAELTE AG Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 502004007219 Country of ref document: DE Date of ref document: 20080703 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2302991 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E003832 Country of ref document: HU |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081021 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080821 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20090224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080821 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080822 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20120326 Year of fee payment: 9 Ref country code: IE Payment date: 20120322 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20120322 Year of fee payment: 9 Ref country code: BE Payment date: 20120329 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20120327 Year of fee payment: 9 |

|

| BERE | Be: lapsed |

Owner name: NORDENIA DEUTSCHLAND HALLE G.M.B.H. Effective date: 20130331 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20131001 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130331 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130308 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130331 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130331 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20140312 Year of fee payment: 11 Ref country code: ES Payment date: 20140320 Year of fee payment: 11 Ref country code: IT Payment date: 20140327 Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 396119 Country of ref document: AT Kind code of ref document: T Effective date: 20150308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150308 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20160928 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150309 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20210323 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20210226 Year of fee payment: 18 Ref country code: DE Payment date: 20210305 Year of fee payment: 18 Ref country code: GB Payment date: 20210324 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: HU Payment date: 20210420 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004007219 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20220308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220309 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220308 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220331 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220308 |