EP1574447B1 - Foil bag from two or multiple layer composite film with hand hole - Google Patents

Foil bag from two or multiple layer composite film with hand hole Download PDFInfo

- Publication number

- EP1574447B1 EP1574447B1 EP04005425A EP04005425A EP1574447B1 EP 1574447 B1 EP1574447 B1 EP 1574447B1 EP 04005425 A EP04005425 A EP 04005425A EP 04005425 A EP04005425 A EP 04005425A EP 1574447 B1 EP1574447 B1 EP 1574447B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- film

- composite

- bag

- functional regions

- zones

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000002131 composite material Substances 0.000 title claims description 48

- 239000011888 foil Substances 0.000 title abstract description 15

- 239000002985 plastic film Substances 0.000 claims description 20

- 229920006255 plastic film Polymers 0.000 claims description 20

- -1 polyethylene Polymers 0.000 claims description 12

- 239000004698 Polyethylene Substances 0.000 claims description 9

- 229920000573 polyethylene Polymers 0.000 claims description 9

- 238000004381 surface treatment Methods 0.000 claims description 9

- 229920000139 polyethylene terephthalate Polymers 0.000 claims description 7

- 239000005020 polyethylene terephthalate Substances 0.000 claims description 7

- 210000003850 cellular structure Anatomy 0.000 claims description 3

- 239000005026 oriented polypropylene Substances 0.000 claims description 2

- 238000003475 lamination Methods 0.000 claims 1

- 150000001875 compounds Chemical class 0.000 abstract description 2

- 239000010410 layer Substances 0.000 description 11

- 238000010030 laminating Methods 0.000 description 10

- 238000004080 punching Methods 0.000 description 8

- 230000003287 optical effect Effects 0.000 description 3

- 239000012790 adhesive layer Substances 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 229920006267 polyester film Polymers 0.000 description 2

- 208000032544 Cicatrix Diseases 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 238000004040 coloring Methods 0.000 description 1

- 238000010835 comparative analysis Methods 0.000 description 1

- 230000032798 delamination Effects 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 239000012939 laminating adhesive Substances 0.000 description 1

- 230000001590 oxidative effect Effects 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 231100000241 scar Toxicity 0.000 description 1

- 230000037387 scars Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000011282 treatment Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D33/00—Details of, or accessories for, sacks or bags

- B65D33/06—Handles

- B65D33/08—Hand holes

Definitions

- the invention relates to a film bag made of a two- or multi-layer composite film with a Griffausstanzung, which is formed as a straight or arcuate cut line, the composite film consists of at least two connected by laminating films and the bag inside film of Kaschierverbundes is a sealable plastic film with good elongation properties, wherein the film surface of the composite film has functional areas in which the bond strength between the bag-inside sealable plastic film and the adjoining film of Kaschierverbundes is smaller than in the area surrounding the functional areas, and wherein the Griffausstanzung is arranged at least partially in these functional areas.

- the term "foil bag” is intended to include both open pockets and circumferentially closed product packages. Last can be provided with tear-open and re-closures.

- EP 1 129 960 A1 A foil bag with the features described above is made EP 1 129 960 A1 known.

- the film layers of the composite film in the handle punching are not glued together. Under load, the inside of the film on the inside of the pouch can expand unhindered locally in the area of the handle punching, which has a favorable effect on the tear strength of the composite foil in the grip area. Both from an optical point of view and with regard to handling, however, it is unsatisfactory that even before the first use of the film bag, the film layers of the composite film in the grip area do not lie firmly against one another or are connected to one another.

- the invention has for its object to provide a provided with a Griffausstanzung foil bag made of a two- or multi-layer composite film, the film layers are connected in the area of Griffausstanzung area and which is characterized at the same time by a high tensile strength in the range of Griffausstanzung.

- the object is achieved in that the sealable plastic film of Kaschierverbundes outside the functional areas has a surface modified by surface treatment to which the adjacent layer of Kaschierverbundes firmly adheres, and that on the surface portions which the Functional areas form, no surface treatment was performed or this was performed there weaker and / or this was limited to small patches that form a pattern within the functional areas.

- Surface treatments which affect the adhesion properties of the film surface include, for example, treatment of the surface with a gas flame in excess of oxygen or an oxidizing surface treatment by corona discharges.

- the film is guided through an arc area where numerous small discharges cause tiny scars on the plastic surface and thereby changing the physical and chemical properties of the surface.

- the invention is based on the observation that the tear strength of the composite film is smaller than the tensile strength of the sealable plastic film used in the laminating composite.

- a film firmly laminated to the sealable plastic film impedes the stretching of the sealable film and prevents a uniform force in this film under a tensile load.

- zones are provided within the composite foil by functional regions in which the bond strength between the layers is reduced at least to such an extent that the foils separate under tensile stress in a locally limited area and the elongation of the sealable foil in this region is not thereby or only slightly hampered.

- a local delamination of the film layers under tensile load, which is restricted to the functional areas, is accepted in order to ensure the introduction of force into the sealable plastic film under load.

- the handle punching is arranged completely within the described functional areas. It may happen that the layers of the composite film in the handling of the film bag on the periphery of the Griffausstanzung from each other. Although this does not affect the function, but can be perceived as disturbing from an optical point of view.

- the functional areas described are assigned to sections of the handle punching on which the composite foil preferably tears when the filled foil bag is carried. These are sections in which the introduction of force preferably takes place when the foil bag is worn and the greatest tensile stresses occur. The sections depend on the shape of the handle punching and can be determined by calculation or by means of less orienting tests.

- the handle punching formed as a straight or arcuate section line, wherein the ends of the cutting line are each arranged within an associated functional area and wherein a central portion of the cutting line is introduced into a functional area surrounding film surface of the composite film whose bond strength is greater than in the functional areas.

- the bag-sealable plastic film is also connected in the functional areas with the adjacent film, with the proviso that the bond strength is lower here than in the area surrounding the functional area.

- the laminating composite in the functional areas has a contact surface with a pattern of well-adhering and poorly adhering zones. Due to the proportion of areas of poorly adhering zones, the bond strength is changeable.

- the area fraction of the poorly adhering film, based on the area of the functional area is preferably more than 20%.

- the described pattern may consist of parallel or intersecting lines or be formed by a pattern with a cellular structure. In the context of the invention, it is also the case that the sealable plastic film with the adjoining film in the functional areas is connected to one another in a point-like manner, ie the well-adhering zones of the pattern consist of punctiform surfaces.

- composite films are used which consist of at least two films adhesively bonded to one another in two dimensions, the film on the inside of the film being a sealable plastic film having good elongation properties is.

- the sealable plastic film may be a monofilm or a coextruded film.

- films of polyethylene or polymers with comparable elongation and sealing properties are particularly advantageous in the case of the use of composite films comprising a laminating composite made of a polyethylene film as a sealable plastic film on the inside of the bag and a rigid and brittle film in comparison, in particular of polyethylene terephthalate (PET) or an oriented polypropylene.

- PET polyethylene terephthalate

- the outer bag-side film of the laminating composite can be printed, for example, with a counterpressure on the inner surface.

- the in Fig. 1 shown foil bag consists of a two- or multi-layer composite foil 1 and has a Griffausstanzung 2 on.

- the composite film 1 consists of at least two connected by laminating films 3, 4, wherein the bag inside film 3 of Kaschierverbundes a sealable plastic film with good elongation properties, eg. B. a polyethylene film is.

- the film surface of the composite film has functional areas 5, in which the bond strength between the bag-side sealable plastic film 3 and the adjoining film 4 of the laminated composite is smaller as in the area surrounding the functional areas 5 6.

- the functional areas 5 are optically not visible on the outside of the film and in Fig. 1 indicated for clarity only by a dashed line.

- the Fig. 1 makes it clear that the Griffausstanzung 2 is at least partially disposed in these functional areas 5.

- the functional regions 5, which have a reduced bond strength between the bag-inside sealable plastic film 3 and the adjacent film 4 of the laminating composite, are assigned to sections of the handle punch 2 on which the composite film 1 preferably tears when carrying the filled film bag.

- the Griffausstanzung 2 is formed as an arcuate section line, wherein the ends of the cutting line are each arranged within an associated functional area 5.

- the middle section a of the section line is introduced into a film surface 6 of the composite film surrounding the functional regions, whose bond strength is greater than in the functional regions 5.

- Composite film 1 shown consists of a laminating composite of a polyethylene film as a bag inside sealable plastic film 3 and a stiff and brittle in comparison to polyester film (PET) 4, which forms the outside of the composite film.

- the two films are glued surface with a laminating adhesive, which is shown as an adhesive layer 7, glued.

- the bag outer side film 4 is on the inner surface with a counter pressure, which in Fig. 2 is represented by a color layer 8, printed.

- the composite side surface 9 of the polyethylene film has been surface treated to improve the adhesion of the adjacent adhesive layer 7. Outside the functional areas, the surface treatment was carried out flat, so that the laminating composite has a high bond strength between the bag-inside polyethylene film 3 and the outer polyester film 4.

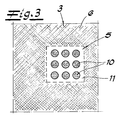

- the surface treatment limited to small patches 10, which within the functional areas a in Fig. 3 form a pattern.

- the patches 10 form well-adhering zones and consist in the embodiment of Fig. 3 from point-shaped surfaces, which can be made visible by coloring the film surface.

- the laminating compound in the functional regions 5 has a contact surface with a pattern of well-adhering zones 10 and poorly adhering zones 11, wherein the poorly adhering zones 11 should have an area fraction of more than 20% relative to the area of the functional area.

- Diverse patterns are conceivable.

- pattern of parallel and intersecting lines and patterns with a cellular structure are possible.

Abstract

Description

Die Erfindung betrifft einen Folienbeutel aus einer zwei- oder mehrlagigen Verbundfolie mit einer Griffausstanzung, die als gerade oder bogenförmige Schnittlinie ausgebildet ist, wobei die Verbundfolie aus mindestens zwei durch Kaschieren verbundenen Folien besteht und die beutelinnenseitige Folie des Kaschierverbundes eine siegelfähige Kunststofffolie mit guten Dehnungseigenschaften ist, wobei die Folienfläche der Verbundfolie Funktionsbereiche aufweist, in denen die Verbundfestigkeit zwischen der beutelinnenseitigen siegelfähigen Kunststofffolie und der daran angrenzenden Folie des Kaschierverbundes kleiner ist als in der die Funktionsbereiche umgebenden Fläche, und wobei die Griffausstanzung zumindest zum Teil in diesen Funktionsbereichen angeordnet ist. Unter dem Begriff "Folienbeutel" sollen sowohl offene Taschen als auch umfänglich geschlossene Produktverpackungen fallen. Letzte können mit Aufreißhilfen und Wiederverschlüssen versehen sein.The invention relates to a film bag made of a two- or multi-layer composite film with a Griffausstanzung, which is formed as a straight or arcuate cut line, the composite film consists of at least two connected by laminating films and the bag inside film of Kaschierverbundes is a sealable plastic film with good elongation properties, wherein the film surface of the composite film has functional areas in which the bond strength between the bag-inside sealable plastic film and the adjoining film of Kaschierverbundes is smaller than in the area surrounding the functional areas, and wherein the Griffausstanzung is arranged at least partially in these functional areas. The term "foil bag" is intended to include both open pockets and circumferentially closed product packages. Last can be provided with tear-open and re-closures.

Für Folienbeutel, insbesondere solche für Produktverpackungen, werden Verbundfolien eingesetzt, deren eine Seite siegelfähig ist und deren andere Seite sich durch gute optische Eigenschaften auszeichnet und bedruckbar ist. Häufig werden in der Praxis zweilagige Kaschierverbundfolien aus Polyethylen und Polyester, insbesondere Polyethylenterephthalat (PET), sowie dreilagige Kaschierverbundfolien mit einer beutelinnenseitigen Polyethylenfolie, einer außenseitigen Folie aus Polyester sowie einer anwendungsspezifisch festgelegten mittleren Folie verwendet. Die Grifffestigkeit der aus Verbundfolien gefertigten Folienbeutel genügt den Anforderungen in der Praxis häufig nicht, denn der Folienabschnitt oberhalb der Griffausstanzung reißt unter dem Gewicht des Pack- oder Füllgutes bisweilen aus.For film bags, especially those for product packaging, composite films are used, one side of which is sealable and whose other side is characterized by good optical properties and is printable. Frequently, in practice, two-ply Kaschierverbundfolien of polyethylene and polyester, especially polyethylene terephthalate (PET), and three-ply Kaschierverbundfolien with a bag-side polyethylene film, an outside film made of polyester and an application-specific set middle film used. The grip strength of the film bag made of composite films often does not meet the requirements in practice, because the film section above the handle punching breaks under the weight of the packing or filling sometimes.

Ein Folienbeutel mit den eingangs beschriebenen Merkmalen ist aus

Der Erfindung liegt die Aufgabe zugrunde, ein mit einer Griffausstanzung versehenen Folienbeutel aus einer zwei- oder mehrlagigen Verbundfolie anzugeben, deren Folienlagen im Bereich der Griffausstanzung flächig miteinander verbunden sind und die sich gleichzeitig durch eine hohe Reißfestigkeit im Bereich der Griffausstanzung auszeichnet.The invention has for its object to provide a provided with a Griffausstanzung foil bag made of a two- or multi-layer composite film, the film layers are connected in the area of Griffausstanzung area and which is characterized at the same time by a high tensile strength in the range of Griffausstanzung.

Ausgehend von einem Folienbeutel mit den eingangs beschriebenen Merkmalen wird die Aufgabe erfindungsgemäß dadurch gelöst, dass die siegelfähige Kunststofffolie des Kaschierverbundes außerhalb der Funktionsbereiche eine durch Oberflächenbehandlung modifizierte Oberfläche aufweist, an der die angrenzende Schicht des Kaschierverbundes fest haftet, und dass an den Flächenabschnitten, welche die Funktionsbereiche bilden, keine Oberflächenbehandlung erfolgte oder diese dort schwächer ausgeführt wurde und/oder diese auf kleine Flächenstücke, die innerhalb der Funktionsbereiche ein Muster bilden, beschränkt wurde. Oberflächenbehandlungen, welche die Hafteigenschaften der Folienoberfläche beeinflussen, umfassen beispielsweise eine Behandlung der Oberfläche mit einer Gasflamme unter Sauerstoffüberschuss oder eine oxidierend wirkende Oberflächenbehandlung durch Koronaentladungen. Hier wird die Folie durch eine Lichtbogenbereich geführt bei dem zahlreiche kleine Entladungen für winzige Narben auf der Kunststoffoberfläche sorgen und dabei die physikalischen und chemischen Eigenschaften der Oberfläche verändern.Starting from a film bag with the features described above, the object is achieved in that the sealable plastic film of Kaschierverbundes outside the functional areas has a surface modified by surface treatment to which the adjacent layer of Kaschierverbundes firmly adheres, and that on the surface portions which the Functional areas form, no surface treatment was performed or this was performed there weaker and / or this was limited to small patches that form a pattern within the functional areas. Surface treatments which affect the adhesion properties of the film surface include, for example, treatment of the surface with a gas flame in excess of oxygen or an oxidizing surface treatment by corona discharges. Here, the film is guided through an arc area where numerous small discharges cause tiny scars on the plastic surface and thereby changing the physical and chemical properties of the surface.

Der Erfindung liegt die Beobachtung zugrunde, dass die Reißfestigkeit der Verbundfolie kleiner ist als die Reißfestigkeit der im Kaschierverbund verwendeten siegelfähigen Kunststofffolie. Eine fest auf die siegelfähige Kunststofffolie aufkaschierte Folie behindert die Dehnung der siegelfähigen Folie und verhindert bei einer Zugbelastung eine gleichmäßige Krafteinleitung in diese Folie. Um Abhilfe zu schaffen, werden erfindungsgemäß durch Funktionsbereiche Zonen innerhalb der Verbundfolie bereitgehalten, in denen die Verbundfestigkeit zwischen den Schichten zumindest soweit herabgesetzt ist, dass die Folien sich unter Zugbeanspruchung in einem lokal begrenzten bereich trennen und die Dehnung der siegelfähigen Folie in diesem Bereich dadurch nicht oder nur wenig behindert wird. Es wird eine auf die Funktionsbereiche beschränktes lokales Delaminieren der Folienlagen unter Zuglast in Kauf genommen, um die Krafteinleitung in die siegelfähige Kunststofffolie unter Last sicher zu stellen.The invention is based on the observation that the tear strength of the composite film is smaller than the tensile strength of the sealable plastic film used in the laminating composite. A film firmly laminated to the sealable plastic film impedes the stretching of the sealable film and prevents a uniform force in this film under a tensile load. To remedy this, according to the invention zones are provided within the composite foil by functional regions in which the bond strength between the layers is reduced at least to such an extent that the foils separate under tensile stress in a locally limited area and the elongation of the sealable foil in this region is not thereby or only slightly hampered. A local delamination of the film layers under tensile load, which is restricted to the functional areas, is accepted in order to ensure the introduction of force into the sealable plastic film under load.

Im Rahmen der Erfindung liegt es, dass die Griffausstanzung vollständig innerhalb der beschriebenen Funktionsbereiche angeordnet ist. Hierbei kann es auftreten, dass sich die Lagen der Verbundfolie bei der Handhabung des Folienbeutels am Umfang der Griffausstanzung voneinander ablösen. Dies beeinträchtigt zwar nicht die Funktion, kann aber unter optischen Gesichtspunkten als störend empfunden werden. Gemäß einer bevorzugten Ausführung der Erfindung sind die beschriebenen Funktionsbereiche Abschnitten der Griffausstanzung zugeordnet, an der die Verbundfolie beim Tragen des gefüllten Folienbeutels bevorzugt einreißt. Es handelt sich um Abschnitte, in denen die Krafteinleitung beim Tragen des Folienbeutels bevorzugt erfolgt und die größten Zugspannungen auftreten. Die Abschnitte sind abhängig von der Form der Griffausstanzung und lassen sich rechnerisch oder anhand weniger orientierender Versuche ermitteln. Gemäß einer bevorzugten Ausführung der Erfindung ist die Griffausstanzung als gerade oder bogenförmige Schnittlinie ausgebildet, wobei die Enden der Schnittlinie jeweils innerhalb eines zugeordneten Funktionsbereiches angeordnet sind und wobei ein mittlerer Abschnitt der Schnittlinie in eine die Funktionsbereiche umgebende Folienfläche der Verbundfolie eingebracht ist, deren Verbundfestigkeit größer ist als in den Funktionsbereichen. Beim Tragen des Folienbeutels unter Last sind bei dieser bevorzugten Ausführung der Erfindung nur kleinflächige Ablösungen jeweils an den Enden der Griffausstanzung möglich, die optisch nicht und nur wenig in Erscheinung treten.In the context of the invention it is that the handle punching is arranged completely within the described functional areas. It may happen that the layers of the composite film in the handling of the film bag on the periphery of the Griffausstanzung from each other. Although this does not affect the function, but can be perceived as disturbing from an optical point of view. According to a preferred embodiment of the invention, the functional areas described are assigned to sections of the handle punching on which the composite foil preferably tears when the filled foil bag is carried. These are sections in which the introduction of force preferably takes place when the foil bag is worn and the greatest tensile stresses occur. The sections depend on the shape of the handle punching and can be determined by calculation or by means of less orienting tests. According to a preferred embodiment of the invention the handle punching formed as a straight or arcuate section line, wherein the ends of the cutting line are each arranged within an associated functional area and wherein a central portion of the cutting line is introduced into a functional area surrounding film surface of the composite film whose bond strength is greater than in the functional areas. When carrying the foil bag under load in this preferred embodiment of the invention only small-scale detachments are possible in each case at the ends of the Griffausstanzung that optically not and only slightly appear.

Erfindungsgemäß ist die beutelinnenseitige siegelfähige Kunststofffolie auch in den Funktionsbereichen mit der angrenzenden Folie verbunden, und zwar mit der Maßgabe, dass die Verbundfestigkeit hier geringer ist als in der den Funktionsbereich umgebenden Fläche. Dies kann durch verschiedene technische Maßnahmen erreicht werden. Gemäß einer bevorzugten Ausführung der Erfindung weist der Kaschierverbund in den Funktionsbereichen eine Kontaktfläche mit einem Muster aus gut haftenden und schlecht haftenden Zonen auf. Durch den Flächenanteil der schlecht haftenden Zonen ist die Verbundfestigkeit veränderbar. Der Flächenanteil der schlecht haftenden Folie, bezogen auf die Fläche des Funktionsbereiches, beträgt vorzugsweise mehr als 20 %. Das beschriebene Muster kann aus parallelen oder sich kreuzenden Linien bestehen oder von einem Muster mit einer zellenförmigen Struktur gebildet werden. Im Rahmen der Erfindung liegt es auch, dass die siegelfähige Kunststofffolie mit der angrenzenden Folie in den Funktionsbereichen punktförmig fest miteinander verbunden ist, also die gut haftenden Zonen des Musters aus punktförmigen Flächen bestehen.According to the invention, the bag-sealable plastic film is also connected in the functional areas with the adjacent film, with the proviso that the bond strength is lower here than in the area surrounding the functional area. This can be achieved by various technical measures. According to a preferred embodiment of the invention, the laminating composite in the functional areas has a contact surface with a pattern of well-adhering and poorly adhering zones. Due to the proportion of areas of poorly adhering zones, the bond strength is changeable. The area fraction of the poorly adhering film, based on the area of the functional area, is preferably more than 20%. The described pattern may consist of parallel or intersecting lines or be formed by a pattern with a cellular structure. In the context of the invention, it is also the case that the sealable plastic film with the adjoining film in the functional areas is connected to one another in a point-like manner, ie the well-adhering zones of the pattern consist of punctiform surfaces.

Im Rahmen der erfindungsgemäßen Lehre werden Verbundfolien verwendet, die aus mindestens zwei flächig miteinander verklebten Folien bestehen, wobei die beutelinnenseitige Folie eine siegelfähige Kunststofffolie mit guten Dehnungseigenschaften ist. Bei der siegelfähigen Kunststofffolie kann es sich um eine Monofolie oder einer coextrudierten Folie handeln. Bevorzugt sind Folien aus Polyethylen oder Polymeren mit vergleichbaren Dehnungs- und Siegeleigenschaften. Die erfindungsgemäße Lehre ist insbesondere vorteilhaft bei der Verwendung von Verbundfolien, die einen Kaschierverbund aus einer Polyethylenfolie als beutelinnenseitige siegelfähige Kunststofffolie und eine im Vergleich dazu steife und spröde Folie, insbesondere aus Polyethylenterephthalat (PET) oder einem orientierten Polypropylen, aufweist. Die beutelaußenseitige Folie des Kaschierverbundes kann beispielsweise mit einem Konterdruck an der Innenfläche bedruckt sein.Within the scope of the teaching according to the invention, composite films are used which consist of at least two films adhesively bonded to one another in two dimensions, the film on the inside of the film being a sealable plastic film having good elongation properties is. The sealable plastic film may be a monofilm or a coextruded film. Preferred are films of polyethylene or polymers with comparable elongation and sealing properties. The teaching according to the invention is particularly advantageous in the case of the use of composite films comprising a laminating composite made of a polyethylene film as a sealable plastic film on the inside of the bag and a rigid and brittle film in comparison, in particular of polyethylene terephthalate (PET) or an oriented polypropylene. The outer bag-side film of the laminating composite can be printed, for example, with a counterpressure on the inner surface.

Im Folgenden wird die Erfindung anhand einer lediglich ein Ausführungsbeispiel darstellenden Zeichnung erläutert. Es zeigen schematisch:

- Fig. 1

- einen aus einer Verbundfolie gefertigten Folienbeutel mit einer Griffausstanzung,

- Fig. 2

- einen Längsschnitt durch die Verbundfolie,

- Fig. 3

- den Schnitt A-A aus

Fig. 2 .

- Fig. 1

- a film bag made of a composite film with a handle punch,

- Fig. 2

- a longitudinal section through the composite film,

- Fig. 3

- the cut AA

Fig. 2 ,

Der in

Die Folienfläche der Verbundfolie weist Funktionsbereiche 5 auf, in denen die Verbundfestigkeit zwischen der beutelinnenseitigen siegelfähigen Kunststofffolie 3 und der daran angrenzenden Folie 4 des Kaschierverbundes kleiner ist als in der die Funktionsbereiche 5 umgebenden Fläche 6. Die Funktionsbereiche 5 sind an der Außenseite der Folie optisch nicht erkennbar und in

Die Funktionsbereiche 5, die eine reduzierte Verbundfestigkeit zwischen der beutelinnenseitigen siegelfähigen Kunststofffolie 3 und der angrenzenden Folie 4 des Kaschierverbundes aufweisen, sind Abschnitten der Griffausstanzung 2 zugeordnet, an der die Verbundfolie 1 beim Tragen des gefüllten Folienbeutels bevorzugt einreißt. Im Ausführungsbeispiel ist die Griffausstanzung 2 als bogenförmige Schnittlinie ausgebildet, wobei die Enden der Schnittlinie jeweils innerhalb eines zugeordneten Funktionsbereiches 5 angeordnet sind. Der mittlere Abschnitt a der Schnittlinie ist in eine die Funktionsbereiche umgebende Folienfläche 6 der Verbundfolie eingebracht, deren Verbundfestigkeit größer ist als in den Funktionsbereichen 5.The

Die in den

Aus einer vergleichenden Betrachtung der

Claims (7)

- Film bag composed of a double-layered or multilayered composite film (1) with a handle cutout (2) which is designed as a straight or curved cut line,

wherein the composite film (1) consists of at least two films (3, 4) joined by lamination, and the film of the laminated composite which forms the inner side of the bag is a sealable plastic film (3) with good stretch properties,

wherein the film surface of the composite film has functional regions (5) in which the bond strength between the sealable plastic film (3) which forms the inner side of the bag and the adjoining film (4) of the laminated composite is lower than in the area surrounding the functional regions (5), and

wherein the handle cutout (2) is arranged at least partially in these functional regions (5),

characterised in that the sealable plastic film (3) of the laminated composite has, outside the functional regions, a surface which has been modified by surface treatment and to which the adjoining layer (7) of the laminated composite securely adheres, and in that no surface treatment took place on the surface sections which form the functional regions (5), or said surface treatment was carried out to a lesser extent in these regions and/or was restricted to small surface parts (10) which form a pattern within the functional regions (5). - Film bag according to claim 1, characterised in that the ends of the cut line forming the handle cutout are in each case arranged within an associated functional region (5) which has a reduced bond strength between the sealable plastic film (3) which forms the inner side of the bag and the adjoining film (4) of the laminated composite, and in that a central section (a) of the cut line is formed in a film surface (6) of the composite film which surrounds these functional regions and in which the bond strength is greater than in the functional regions (5).

- Film bag according to claim 1 or 2, characterised in that the laminated composite has in the functional regions (5) a contact surface with a pattern consisting of zones (10) of good adhesion and zones (11) of poor adhesion.

- Film bag according to claim 3, characterised in that the zones (11) of poor adhesion comprise a surface area of more than 20% relative to the surface area of the functional region (5).

- Film bag according to claim 3 or 4, characterised in that the pattern consisting of zones (10, 11) of good adhesion and of poor adhesion forms a pattern of parallel or intersecting lines or a pattern with a cellular structure.

- Film bag according to claim 3 or 4, characterised in that the zones (10) of good adhesion consist of spot-shaped areas.

- Film bag according to one of claims 1 to 6, characterised in that the composite film (1) comprises a laminated composite consisting of a polyethylene film as the sealable plastic film (3) which forms the inner side of the bag and a film which is stiff and brittle by comparison, in particular made from polyethylene terephthalate (PET) or an oriented polypropylene.

Priority Applications (10)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP05003837A EP1588953B1 (en) | 2004-03-08 | 2004-03-08 | Foil bag from two or multiple layer composite film with hand hole |

| AT04005425T ATE396119T1 (en) | 2004-03-08 | 2004-03-08 | FILM BAG MADE OF A TWO-LAYER OR MULTI-LAYER COMPOSITE FILM WITH A CUT-OUT HANDLE |

| PL04005425T PL1574447T3 (en) | 2004-03-08 | 2004-03-08 | Foil bag from two or multiple layer composite film with hand hole |

| DE502004009525T DE502004009525D1 (en) | 2004-03-08 | 2004-03-08 | Foil bag made of a two- or multi-layer composite film with a handle punching |

| DE502004007219T DE502004007219D1 (en) | 2004-03-08 | 2004-03-08 | Foil bag made of a two- or multi-layer composite film with a handle punching |

| AT05003837T ATE432226T1 (en) | 2004-03-08 | 2004-03-08 | FILM BAG MADE OF A TWO-LAYER OR MULTI-LAYER COMPOSITE FILM WITH A CUT-OUT HANDLE |

| DK04005425T DK1574447T3 (en) | 2004-03-08 | 2004-03-08 | Foil bag of a two or multilayer laminated foil with a punch for grip |

| EP04005425A EP1574447B1 (en) | 2004-03-08 | 2004-03-08 | Foil bag from two or multiple layer composite film with hand hole |

| ES04005425T ES2302991T3 (en) | 2004-03-08 | 2004-03-08 | BAG OF SHEETS FORMED BY A SHEET COMPOSED OF TWO OR MORE LAYERS WITH A GRIP STAMP. |

| PCT/EP2005/002382 WO2005085080A2 (en) | 2004-03-08 | 2005-03-07 | Film bag consisting of a double-layered or multi-layered composite film comprising a punched-out grip region |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP04005425A EP1574447B1 (en) | 2004-03-08 | 2004-03-08 | Foil bag from two or multiple layer composite film with hand hole |

Related Child Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05003837A Division EP1588953B1 (en) | 2004-03-08 | 2004-03-08 | Foil bag from two or multiple layer composite film with hand hole |

| EP05003837.1 Division-Into | 2005-02-23 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1574447A1 EP1574447A1 (en) | 2005-09-14 |

| EP1574447B1 true EP1574447B1 (en) | 2008-05-21 |

Family

ID=34814255

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05003837A Expired - Lifetime EP1588953B1 (en) | 2004-03-08 | 2004-03-08 | Foil bag from two or multiple layer composite film with hand hole |

| EP04005425A Expired - Lifetime EP1574447B1 (en) | 2004-03-08 | 2004-03-08 | Foil bag from two or multiple layer composite film with hand hole |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05003837A Expired - Lifetime EP1588953B1 (en) | 2004-03-08 | 2004-03-08 | Foil bag from two or multiple layer composite film with hand hole |

Country Status (7)

| Country | Link |

|---|---|

| EP (2) | EP1588953B1 (en) |

| AT (2) | ATE396119T1 (en) |

| DE (2) | DE502004007219D1 (en) |

| DK (1) | DK1574447T3 (en) |

| ES (1) | ES2302991T3 (en) |

| PL (1) | PL1574447T3 (en) |

| WO (1) | WO2005085080A2 (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2100721B1 (en) | 2008-03-11 | 2014-05-14 | Amcor Flexibles Kreuzlingen Ltd. | Laminate with an area having improved tear resistance |

| DE202010005231U1 (en) * | 2010-04-16 | 2010-09-30 | Kobusch-Sengewald Gmbh & Co. Kg | Laminate of layer material of different tensile strength |

| DE102011002315A1 (en) * | 2011-04-28 | 2012-10-31 | Nordenia Technologies Gmbh | Foil packaging, especially for wet wipes |

| WO2023026722A1 (en) * | 2021-08-24 | 2023-03-02 | 株式会社フジシール | Pouch container |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2633793A1 (en) * | 1976-07-28 | 1978-02-02 | Bosch Gmbh Robert | POUCH PACK WITH BOTTLE HANDLE |

| DE3232321A1 (en) * | 1982-08-31 | 1984-03-01 | Bischof Und Klein Gmbh & Co, 4540 Lengerich | Portable package made of flexible material in the form of a sack or bag |

| DE3777078D1 (en) * | 1986-11-05 | 1992-04-09 | Stiegler Maschf Gmbh | CARRYING BAG IN THERMOPLASTIC PLASTIC FILM. |

| ITMI20000289A1 (en) * | 2000-02-18 | 2001-08-18 | Goglio Spa Luigi Milano | FLEXIBLE MATERIAL CONTAINER WITH REINFORCED HANDLE TO AVOID LACERATION |

-

2004

- 2004-03-08 AT AT04005425T patent/ATE396119T1/en active

- 2004-03-08 EP EP05003837A patent/EP1588953B1/en not_active Expired - Lifetime

- 2004-03-08 AT AT05003837T patent/ATE432226T1/en active

- 2004-03-08 ES ES04005425T patent/ES2302991T3/en not_active Expired - Lifetime

- 2004-03-08 PL PL04005425T patent/PL1574447T3/en unknown

- 2004-03-08 DE DE502004007219T patent/DE502004007219D1/en not_active Expired - Lifetime

- 2004-03-08 DE DE502004009525T patent/DE502004009525D1/en not_active Expired - Lifetime

- 2004-03-08 EP EP04005425A patent/EP1574447B1/en not_active Expired - Lifetime

- 2004-03-08 DK DK04005425T patent/DK1574447T3/en active

-

2005

- 2005-03-07 WO PCT/EP2005/002382 patent/WO2005085080A2/en active Application Filing

Also Published As

| Publication number | Publication date |

|---|---|

| DK1574447T3 (en) | 2008-09-15 |

| DE502004007219D1 (en) | 2008-07-03 |

| PL1574447T3 (en) | 2008-10-31 |

| ATE396119T1 (en) | 2008-06-15 |

| ATE432226T1 (en) | 2009-06-15 |

| WO2005085080A3 (en) | 2005-12-22 |

| ES2302991T3 (en) | 2008-08-01 |

| EP1588953A1 (en) | 2005-10-26 |

| DE502004009525D1 (en) | 2009-07-09 |

| EP1574447A1 (en) | 2005-09-14 |

| EP1588953B1 (en) | 2009-05-27 |

| WO2005085080A2 (en) | 2005-09-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2522595B1 (en) | Multi-layer film for peel-open packaging | |

| EP1306209B1 (en) | Multilayered film produced by co-extrusion | |

| EP1777167B1 (en) | Film bag | |

| EP1918094A1 (en) | Packaging film | |

| DE102004026980A1 (en) | Stand-up pouches with optimized tear properties and process for its production | |

| AT519866A4 (en) | Recyclable, easy-to-tear packaging laminate with good barrier effect and process for its production | |

| EP1849579A1 (en) | Method for manufacturing a film for tearable packagings | |

| DE102018132343A1 (en) | Plastic film composite, plastic packaging and method for producing a plastic film composite | |

| EP2374604B1 (en) | Film cover for closing a container and method for producing same | |

| DE10201480B4 (en) | stretch film | |

| WO2005085080A2 (en) | Film bag consisting of a double-layered or multi-layered composite film comprising a punched-out grip region | |

| WO2006058621A1 (en) | Twist-wrap film and the use thereof as packaging film | |

| EP1055612B1 (en) | Method of making a tearable pouch | |

| EP0686478B1 (en) | Lined metal article and method for its manufacture | |

| DE102009043360A1 (en) | Tear-open package e.g. closed foil bag, has foil with tearing zone formed from weakening lines for facilitating tearing during opening, where weakening lines taper diagonally to each other based on side edge or break edge of package | |

| DE10320429B3 (en) | Composite film for tear-open packaging and process for its production | |

| DE102013214076A1 (en) | Multilayer plastic drug film | |

| DE102017123135A1 (en) | Laminate comprising a film composite, process for producing the laminate, packaging produced from the laminate, use of the film composite for producing the laminate and use of the laminate for producing a packaging | |

| DE102009021082A1 (en) | Multi-layered laminate, useful for producing packing for partially dehydrated food, comprises a barrier layer arranged between a printable and/or paintable outer layer and an inner layer of polylactic acid | |

| DE10307250A1 (en) | film element | |

| EP1439056A1 (en) | Laminated structure comprising two film materials of different tear strength, especially of polyester and polyethylene | |

| WO2015132018A1 (en) | Film material for producing a packaging | |

| DE102009026309B4 (en) | Method for manufacturing and packaging hygiene articles | |

| WO2015028221A1 (en) | Multi-layered plastic film | |

| DE102018206381A1 (en) | Use of a COC-containing flexible film laminate for producing a cold-drawn flexible packaging |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20050726 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20070323 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: BLOCK, JOACHIM |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: KELLER & PARTNER PATENTANWAELTE AG Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 502004007219 Country of ref document: DE Date of ref document: 20080703 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2302991 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E003832 Country of ref document: HU |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081021 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080821 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20090224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080821 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080822 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080521 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20120326 Year of fee payment: 9 Ref country code: IE Payment date: 20120322 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20120322 Year of fee payment: 9 Ref country code: BE Payment date: 20120329 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20120327 Year of fee payment: 9 |

|

| BERE | Be: lapsed |

Owner name: NORDENIA DEUTSCHLAND HALLE G.M.B.H. Effective date: 20130331 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20131001 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130331 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130308 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130331 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130331 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20140312 Year of fee payment: 11 Ref country code: ES Payment date: 20140320 Year of fee payment: 11 Ref country code: IT Payment date: 20140327 Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 396119 Country of ref document: AT Kind code of ref document: T Effective date: 20150308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150308 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20160928 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150309 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20210323 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20210226 Year of fee payment: 18 Ref country code: DE Payment date: 20210305 Year of fee payment: 18 Ref country code: GB Payment date: 20210324 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: HU Payment date: 20210420 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004007219 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20220308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220309 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220308 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220331 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220308 |