EP1569726B2 - Sporting apparatus comprising a safety mechanism - Google Patents

Sporting apparatus comprising a safety mechanism Download PDFInfo

- Publication number

- EP1569726B2 EP1569726B2 EP03785593A EP03785593A EP1569726B2 EP 1569726 B2 EP1569726 B2 EP 1569726B2 EP 03785593 A EP03785593 A EP 03785593A EP 03785593 A EP03785593 A EP 03785593A EP 1569726 B2 EP1569726 B2 EP 1569726B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- cord

- handle

- pull

- sports device

- tensioning element

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000007246 mechanism Effects 0.000 title claims description 18

- 230000033001 locomotion Effects 0.000 claims description 20

- 230000000694 effects Effects 0.000 claims description 6

- 230000009849 deactivation Effects 0.000 description 9

- 230000009471 action Effects 0.000 description 7

- 210000004247 hand Anatomy 0.000 description 5

- 230000008901 benefit Effects 0.000 description 3

- 230000001960 triggered effect Effects 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 2

- 229920001971 elastomer Polymers 0.000 description 2

- 239000000806 elastomer Substances 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 230000001105 regulatory effect Effects 0.000 description 2

- 230000007480 spreading Effects 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 241000498779 Myristica Species 0.000 description 1

- 235000009421 Myristica fragrans Nutrition 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000005489 elastic deformation Effects 0.000 description 1

- 235000019589 hardness Nutrition 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 230000009191 jumping Effects 0.000 description 1

- 231100000897 loss of orientation Toxicity 0.000 description 1

- 239000001702 nutmeg Substances 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- 210000000707 wrist Anatomy 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63H—MARINE PROPULSION OR STEERING

- B63H8/00—Sail or rigging arrangements specially adapted for water sports boards, e.g. for windsurfing or kitesurfing

- B63H8/10—Kite-sails; Kite-wings; Control thereof; Safety means therefor

- B63H8/16—Control arrangements, e.g. control bars or control lines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63H—MARINE PROPULSION OR STEERING

- B63H8/00—Sail or rigging arrangements specially adapted for water sports boards, e.g. for windsurfing or kitesurfing

- B63H8/10—Kite-sails; Kite-wings; Control thereof; Safety means therefor

- B63H8/18—Arrangements for connecting the user to a kite-sail; Kite-safety means, e.g. chicken loops, safety leashes or quick release mechanisms

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63H—MARINE PROPULSION OR STEERING

- B63H8/00—Sail or rigging arrangements specially adapted for water sports boards, e.g. for windsurfing or kitesurfing

- B63H8/50—Accessories, e.g. repair kits or kite launching aids

- B63H8/56—Devices to distribute the user's load, e.g. harnesses

Definitions

- the present invention relates to a sports device with a handle for holding and controlling the sports equipment and with a pulling device, which is operatively connected to the handle and exerts a pulling force on the handle and a coupled object in an active state.

- Such a sports equipment is from the prior art, for example, as a stunt kite, parachute, paraglider, kite or as a pleasure boat that pulls water skiing. There are many sports equipment that pull one or more people by means of a traction device. All these sports equipment should fall under the preamble of claims 1 and 24, provided that they have the features mentioned therein. Such a sports equipment is through DE-U-20 209 515 known.

- kite kites are used to power kite (surf) boards, snowkiteboards, skis, buggies and other sports vehicles.

- the kite is equipped with several lines which serve to control the direction of air movement and speed as well as the regulation of the angle of attack, i.e. the angle of flow.

- the steering lines are directly connected to a handle or a handlebar or bar.

- the lines for regulating the angle of attack are summarized above the bar to a tug or depower line.

- This depower line is passed through an opening in the center of the bar, or through a sleeve fixed centrally on the outside of the bar, and attached to the receptacle, i.e., a hook, eyelet, shackle, or the like, a trapezoidal belt tied around a user's body.

- a sleeve fixed centrally on the outside of the bar, and attached to the receptacle, i.e., a hook, eyelet, shackle, or the like, a trapezoidal belt tied around a user's body.

- the user connects a safety line to one of the flying lines, e.g. on a harness hook, a shackle or a wrist, or with the brake lines, as in a soft kite. If the user breaks away from the bar and the depower line, he remains connected to the kite which is now without power

- the stunt kite generates buoyancy forces due to wind flow according to the wing principle, which are transmitted as pulling forces over the lines to the bar and to the user.

- the lift-dependent traction forces can be regulated by relative length changes of the depower and stern lines.

- the control lines are relieved, and tilting or deconstructing the kite profile reduces lift and reduces pulling forces.

- An additional dynamic buoyancy is created when the kite is put into a proper motion, i.e. a flight on a circular path with a line-length radius, by unilateral line pulling left or right.

- a proper motion i.e. a flight on a circular path with a line-length radius

- the forces acting on the user increase. At the start of the driving movement or to increase the driving speed, such a control pulse is intentionally generated.

- the object of the invention is therefore to continue to form a sports equipment of the type mentioned in that a caused by a loss of control induced dangerous situation can be completed reliably and quickly.

- Another advantage of the present invention according to claim 2 is that the deactivation of the pulling device in response to a movement of the handle in a direction of action of the tensile force takes place. The user must move to deactivate only the handle in the direction of action of the pulling force of the pulling device to operate the trigger mechanism and disable the pulling device.

- deactivation of the traction device can also be done automatically by the safety device triggers upon reaching a predetermined limit and deactivated the towing device. This may be provided alternatively or in addition to the motion-dependent deactivation, e.g. to enable a safer training.

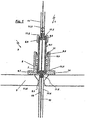

- FIG. 1 schematically a part of a sports equipment 1 is shown.

- a handle 3 is formed in the illustrated embodiment as a handlebar and has a fürgangsöfmung 3.1 in its center.

- the side of the grab handle 3, which in Fig. 1 is above the handle 3, is the so-called tension side, that is, the side of a pulling device acting on the handle 3 5 FIG. 3 ) is facing.

- the side which lies below the grab handle 3 is the side which faces a trapeze belt, object or user 7 (FIG. FIG. 3 ) is facing.

- a safety device 9 is arranged on the handle 3.

- the safety device 9 deactivates the traction device 5.

- the deactivation takes place in the present embodiment by a force decoupling of the handle 3 and the user 7 acting tensile force.

- the deactivation may optionally be initiated by the user during operation, that is, the threshold may be a subjectively perceived value for each user 7.

- the manual triggering of the deactivation of the traction device 5 takes place as a function of a movement of the handle 3 in a direction of action of the tensile force ( figure 4 ).

- the deactivation of the traction device 5 can also be triggered automatically as a function of reaching a predetermined limit value of the traction force. It is possible to set the threshold value of a tensile force before a start of operation. This can be done, for example, depending on the performance of the user 7. A criterion for the performance may be the level of training on the sports equipment but also the age of the user and his weight.

- the safety device 9 is arranged in the present embodiment on a line 11 which is guided through the opening 3.1 in the handle 3 therethrough.

- the safety device 9 is arranged on the leash 11 in the effective direction of the tensile force close to the action behind the handle 3, that is, on the tension side in FIG. 1 .

- effective proximity is meant herein such proximity, which in the event that the object 7 is a user, corresponds to a maximum of one arm length of the user.

- the distance is adjustable.

- the effect proximity should be such a proximity that the handle 3 can still act with a movement on the safety device 9.

- the safety device 9 has in inner clamping element 9.1 and an outer clamping element 9.2, which are biased against each other in a direction of action of the tensile force and are arranged relative to each other against the bias relative to each other.

- the outer clamping element 9.2 has a handle side, a flange 9.3, which wraps around the outer clamping element 9.2 and the handle side forms an abutment surface for the handle 3.

- the flange 9.3 is zug turc in a sleeve portion 9.4, which abuts with an inner wall slidably on an outer wall of the inner clamping element 9.1.

- the sleeve part 9.4 has at its zug detailen end a smaller wall thickness than at its flange end, wherein the inner wall of the sleeve part 9.4 is stepped at the Switzerland paragraphen end, so that there is formed between the sleeve part 9.4 and the inner clamping element 9.1 a receiving space for a spring element 9.5 ,

- the spring element 9.5 is in the present case a helical spring with a uniform spring constant. It is conceivable that the spring element 9.5 has a varying spring constant, so that the spring force via an adjustment mechanism (not shown) is adjustable.

- the inner clamping element 9.1 has at its circumference on a shoulder 9.6, which closes the zugueaum formed between the sleeve part 9.4 and the clamping element 9.1 zugmen.

- the spring element 9.5 is supported on the projection 9.6 and on the step in the sleeve part 9.4, whereby the inner clamping element 9.1 and the outer clamping element 9.2 are biased against each other.

- the inner clamping element 9.1 is sleeve-shaped and has at its handle-side end a first inner annular groove 9.7.

- the inner clamping element 9.1 also has at its karpracticen end a second inner annular groove 9.8.

- the line 11 has a first karillones linen part 11.1, which is connected at a free end 11.2 with a pin 11.3, which sits positively in the annular groove 9.8.

- a clamping element 9.9 is attached to the tension end of the inner clamping element 9.1, and generates a clamping voltage, such that the pin 11.3 is firmly clamped in the annular groove 9.8.

- the clamping element 11.3 may e.g. to be a nutmeg.

- the line 11 also includes a second user-side linen portion 11.4 having at its free end 11.5 a tripping pin 11.6, which is identical to the pin 11.3 in the present embodiment.

- the trigger pin 11.6 sits positively in the first annular groove 9.7 and is there firmly clamped by the outer clamping element 9.2.

- the line 11 or the line parts 11.1 and 11.4 and the pins 11.3 and 11.6 are hollow or formed with a central passage in which a safety line 13 runs.

- the clamping voltage is taken away to the first annular groove 9.7 and seated therein tripping pin 11.6, so that the user-side linen part 11.4 of the line 11 slips out of the first annular groove 9.7 and dissolves from the frictional connection with the tension-side linen part 11.1.

- the tensile force is decoupled.

- the leash 11 is not divided and in the inner clamping element 9.1 only an annular groove 9.8 or 9.7 is formed in which a projection formed on the leash is firmly seated.

- the further triggering mechanism may remain identical to that described above.

- the line 11 would in this case have user side of the annular groove a linen supply, which leads in the event of a tripping to a temporary force decoupling.

- Such an embodiment can be used where such temporary power decoupling is sufficient to regain secure control over the sports equipment 1.

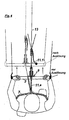

- FIG. 2 schematically a second embodiment of the safety device 9 is shown.

- the outer clamping element 9.2 in a region 9.10 has a groove recess, which is preferably wedge-shaped.

- the inner clamping element 9.1 has at its periphery a recess 9.11 in which a clamping element 9.13 is pivotally mounted on a ring element 9.12.

- the trigger pin 11.6 has at its periphery an annular groove 11.7, the zuggrass forms an edge 11.8.

- the clamping wedge 9.13 abuts the edge 11.8 of the annular groove 11.7.

- the clamping wedge 9.10 turns from the locking position in the annular groove 11.7 of the pin 11.6 in the wedge-shaped groove recess 9.10 and releases the user-side linen part 11.4.

- FIG. 2 The function of in FIG. 2 described embodiment for the application of the invention differs from the embodiment in FIG. 1 in the manner of the locking mechanism. If the connection of the upper and lower part of the line 11.4 is intended, then in the embodiment according to FIG. 1 to push the outer clamping element 9.2 first in the effective direction of the tensile force upwards, before the release pin can be inserted 11.6 against the spreading resistance of the handle-side end of the inner clamping element 9.1 in its annular groove 9.7. The outer clamping element 9.2 must therefore be moved against the force of the spring 9.5 relative to the inner clamping element 9.1.

- the trigger pin 11.6 can be inserted into the inner clamping element 9.1 without the outer clamping element must be operated 9.2.

- the trigger pin 11.6 pushes the insertion of the clamping wedge 9.10 in a rotational movement upwards and laterally against a spring tongue 9.14 in the groove recess 9.10 and thus releases the opening of the inner clamping element 9.1. If the trigger pin 9.6 inserted over the top of the clamping wedge 9.10 away in the opening of the inner clamping element 9.1, the spring tongue 9.14 pushes the clamping wedge 9.13 back and locks the trigger pin 11.6 in the FIG. 1 pictured position.

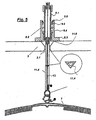

- FIG. 3 schematically the entire arrangement of the sports equipment 1 between a person (trapezoidal belt) 7 and shown with the safety device 9.

- FIG. 4 schematically the manual release of the safety device 9 is shown.

- the user 7 pushes with his hands the handle 3 in FIG. 1 upwards (arrow direction) and releases the user-side part of the line 11.4 from the safety device 9 ..

- FIG. 5 schematically a further development of the line 11.4 between the user 7 and the safety device 9 is shown.

- the handle 9 with its passage opening 3.1 and guided therein user-side linen part 11.4 and the safety line 13 offers the opportunity to be able to unravel it after rotation jumps or similar maneuvers freely.

- the leash 11 in the present embodiment is a so-called depower line, which in the prior art has a circular cross-section.

- Depowerleinenteils 11.4 With twists of the user-side Depowerleinenteils 11.4 and guided in the circular cavity of Depowerleinenteils 11.4 safety line 13 and subsequent untwisting of the handlebar 3 is not guaranteed without the additional use of bearings (shackles or the like) that also the depower 11.4 unturned again, because it slips along the inner walls of the guide a in the handlebar 3 along. It is therefore in FIG. 5 a development of Depowerleinenteils 11.4 shown, with which this can be forced to turn at a rotation of the handlebar 3 with.

- the Depowerleinenteil 11.4 is provided at least user side with a cross section having different radii. In FIG. 5 the cross-section is triangular.

- the cross section may be polygonal or oval. Due to the formation of at least the Depowerleinenteils 11.4 with a non-uniform radius and in particular by the formation of the cross section in the form of a triangle, the Depowerleine 11 at a turn of the handlebar synchronously rotate with, since a rotational relative motion is hindered by positive engagement. Such a depower line 11 or such a depower part 11. 4 having a cross section which has different radii can be compared with the embodiments in FIG FIG. 1 and FIG. 2 be combined.

- FIGS. 6 to 12 Further embodiments of the present invention and schematic representations are with the FIGS. 6 to 12 shown.

- FIG. 6 schematically another embodiment of the safety device 9 is shown.

- the lower part is 9.7 of the inner clamping element 9.1 formed as a pin.

- the connection to the lower part of the tug 11.4 is designed as a "cover 11.6".

- a movement of the handle 3 upwards, in the direction of the tension element 5, then performs as in the embodiment in FIG. 1

- the handle 3 overcomes the effect proximity to the safety device 9 and abuts against the surface 9.4 of the flange 9.3 and the outer clamping element 9.2 against the biasing force of the spring 9.5 moves upwards.

- the spring stop 9.6 of the inner clamping element 9.1 is formed as a threaded sleeve which is rotated to a thread in the upper circumference of the inner clamping element 9.1 and thus allows an individual default of the spring used 9.5.

- FIG. 7 is a further developed embodiment of the safety device 9 according to the first embodiment in FIG. 1 shown.

- the release sleeve 9.2 is provided in this embodiment with an expandable diameter constriction 9.14 at the top.

- the required for spreading the lower part of the inner sleeve 9.1 9.15 is created with a hole in the lower part of the outer sleeve 9.2.

- the tripping pin 11.6 is polygonal outside (not round) executed to prevent relative rotations to the inner sleeve 9.1.

- the expandable inner sleeve lower part 9.7 is divided several times according to the shape of the tripping pin 11.6. The corners of the tripping pin 11.6 can engage in the interstices of the multiply divided inner sleeve lower part 9.7.

- connection of the pulling line upper part takes place by insertion and knotting through hole 9.10 in the shaft on the upper part of the inner sleeve 9.1.

- the safety line 13 is guided through the bore 9.11 in the shaft at the top of the inner sleeve 9.1 and connected to the user-side part of the pull line in the recess at the top of the tripping pin 11.6.

- FIG. 8 shows a schematic plan view of a user who uses a non-inventive sports equipment and attacks with his hands on the handle, the solid lines show an active operating situation and the dashed lines show a disabling situation and motion arrows schematically represent the deactivation process.

- the functional diagram takes into account a connection with the handlebar 3 with a prior art collar or shackle release system 20 through the lines 18.

- the triggering mechanism 20 will be activated by the line 18 transmitted tensile force automatically actuated.

- the security line 13, which is centrally moved by the depower line 11, remains connected to the user 7.

- the handlebar 3 and the associated control lines 4 slip along the safety line 13 upwards.

- the stunt kite 5 falls down without pressure.

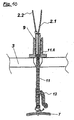

- Fig. 9 schematically shows a steering kite system that can be transferred in the variant shown on all other described embodiments.

- the Consistor 12 in the embodiment shown here below the handlebar 3 used in the depower line 3. This creates the possibility, with the simultaneous use of the safety device 9, one of the front lines 2.1 as a continuous safety line with the releasable Depowerleinenunterteil 11 to connect.

- FIG. 10 shows a detailed scheme of the embodiment according to FIG. 9 with the connection of the front line 2.2 to the upper part of the inner tensioning element 9.1 of the safety device 9 and the front line 2.1 as a continuous safety line with connection to the tripping pin 9.7 of the depower line 11 and the integration of the length adjustment 12 of the depower line below the handlebar. 3

- FIG. 11 schematically another further developed embodiment of the safety device 9 is shown.

- an elastomeric spring 9.5 is used in this embodiment, which can be adapted in various Shore hardnesses to individual needs of the release force.

- the replaceable elastomer spring 9.5 is stretched between release sleeve 9.2 and inner sleeve 9.1.

- Release sleeve 9.2 and inner sleeve 9.1 are assembled by means of an outer diameter extension at the lower end of the inner sleeve 9.1 9.7.

- the expandable lower part 9.7 of the inner sleeve 9.1 is compressed with disassembled trigger pin 11.6.

- the spring 9.5 and the outer sleeve 9.2 are pushed over the compressed inner sleeve lower part 9.7.

- a front line leads a short connecting line through a hole 9.11 in the upper lid he inner sleeve 9.1 and is secured with a knot against slipping.

- the other front line is passed as a continuous safety line through the second hole in the upper cover of the inner sleeve 9.1 and connected at the end of Depowerleinenunterteils 11 in the recess of the tripping pin 11.8.

- the recess for receiving the expandable inner sleeve lower part in the lower part of the outer sleeve is, as already based on FIG. 7 described, executed.

- the polygonal, ovale placed. not round shape of the tripping pin 11.6 with adapted form of the expandable lower part 9.7 of the inner sleeve 9.1 is described in accordance with the description of FIG. 7 executed.

- FIG. 12 showed a further embodiment of the safety device 9, which is similar to the described embodiment FIG. 11 is.

- the elastomeric spring used is 9.5 bonded to the bottom and top with centrally pierced discs 9.16.

- the spring element consisting of elastomer spring 9.5 and glued discs 9.16, screwed through the upper cover of the inner sleeve 9.1 with the inner sleeve 9.1.

- the second disc 9.16 on the lower part of the elastomeric spring 9.5 is screwed to the release sleeve 9.2.

- the embodiment shown here considers the use of an additional safety line 13, which is guided through the bore 9.11 in the cover at the top of the inner sleeve 9.1 and connected to the end of Depowerleinenunterteils 11 in the recess of the tripping pin 11.6.

- the upper part of the tug, to which the length adjuster 12 adjoins on the side facing the steer kite 5, is connected to a stirrup which is fastened to the upper side of the cover of the inner sleeve 9.1.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- Ocean & Marine Engineering (AREA)

- Steering Devices For Bicycles And Motorcycles (AREA)

- Emergency Lowering Means (AREA)

- Orthopedics, Nursing, And Contraception (AREA)

- Motorcycle And Bicycle Frame (AREA)

- Professional, Industrial, Or Sporting Protective Garments (AREA)

Abstract

Description

Die vorliegende Erfindung betrifft ein Sportgerät mit einem Haltegriff zum Festhalten und Steuern des Sportgerätes und mit einer Zugeinrichtung, die mit dem Haltegriff wirkverbunden ist und in einem aktiven Zustand eine Zugkraft auf den Haltegriff und ein angekoppeltes Objekt ausübt.The present invention relates to a sports device with a handle for holding and controlling the sports equipment and with a pulling device, which is operatively connected to the handle and exerts a pulling force on the handle and a coupled object in an active state.

Ein solches Sportgerät ist aus dem Stand der Technik z.B. als Lenkdrachen, Fallschirm, Paraglider, Flugdrachen oder auch als Sportboot, das Wasserski zieht. Es gibt viele Sportgeräte, die eine oder mehrere Personen mittels einer Zugeinrichtung ziehen. Alle diese Sportgeräte sollen unter den Oberbegriff der Ansprüche 1 und 24 fallen, sofern sie die darin genannten Merkmale aufweisen. Ein solches Sportgerät ist durch

Die vorliegende Erfindung betrifft aber insbesondere solche Sportgeräte, bei denen die Zugeinrichtung ein Lenkdrachen ist. Sogenannte Lenkdrachenkites werden als Antrieb von Kite(Surf)-Boards, Snowkiteboards, Skiern, Buggies und anderen Fahrzeugen zu Sportzwecken verwendet. Der Kite ist dabei mit mehreren Leinen ausgestattet, die die Steuerung der Flugbewegungsrichtung und -geschwindigkeit sowie der Regulierung des Anstellwinkels, d.h., des Strömungswinkels, dienen. Die Steuerleinen sind dabei direkt mit einem Haltegriff bzw. einer Lenkstange oder Bar verbunden. Die Leinen zur Regulierung des Anstellwinkels werden noch oberhalb der Bar zu einer Zugleine bzw. Depowerleine zusammengefaßt. Diese Depowerleine wird durch eine Öffnung in der Barmitte oder durch eine mittig außen an der Bar befestigte Hülse geführt und an der Aufnahme, d.h., einem Haken, einer Öse, einem Schäkel o. dgl., eines um den Körper eines Benutzers gebundenen Trapezgurtes befestigt.However, the present invention relates in particular to those sports equipment in which the towing device is a stunt kite. So-called kite kites are used to power kite (surf) boards, snowkiteboards, skis, buggies and other sports vehicles. The kite is equipped with several lines which serve to control the direction of air movement and speed as well as the regulation of the angle of attack, i.e. the angle of flow. The steering lines are directly connected to a handle or a handlebar or bar. The lines for regulating the angle of attack are summarized above the bar to a tug or depower line. This depower line is passed through an opening in the center of the bar, or through a sleeve fixed centrally on the outside of the bar, and attached to the receptacle, i.e., a hook, eyelet, shackle, or the like, a trapezoidal belt tied around a user's body.

Zusätzlich verbindet den Benutzer bei den bekannten Systemen eine Sicherheitsleine mit einer der Flugleinen, z.B. an einem Trapezhaken, einem Schäkel oder einem Handgelenk, oder mit den Bremsleinen, wie bei einem Softkite. Löst sich der Benutzer von der Bar und der Depowerleine, bleibt er mit dem nun zugkraftlosen Kite verbundenIn addition, in the known systems the user connects a safety line to one of the flying lines, e.g. on a harness hook, a shackle or a wrist, or with the brake lines, as in a soft kite. If the user breaks away from the bar and the depower line, he remains connected to the kite which is now without power

Der Lenkdrachen erzeugt durch Windströmung nach dem Tragflügelprinzip Auftriebskräfte, die als Zugkräfte über die Leinen zur Bar und zum Benutzer übertragen werden. Die auftriebsabhängigen Zugkräfte können durch relative Längenänderungen der Depower-und Heckleinen reguliert werden.The stunt kite generates buoyancy forces due to wind flow according to the wing principle, which are transmitted as pulling forces over the lines to the bar and to the user. The lift-dependent traction forces can be regulated by relative length changes of the depower and stern lines.

Schiebt der Benutzer die Bar über die mit dem Trapezgurt verbundene Depowerleine vom Körper weg, so werden die Steuerleinen entlastet, durch Kippen bzw. Entwölben des Kite-Profils wird der Auftrieb verringert, die Zugkräfte werden reduziert. Ein zusätzlicher dynamischer Auftrieb wird erzeugt, wenn der Kite durch einseitigen Leinenzug links oder rechts in eine Eigenbewegung, d.h., einen Flug auf einer Kreisbahn mit einem Radius in Leinenlänge, versetzt wird. Mit zunehmender Fluggeschwindigkeit des Drachens erhöht sich der dynamische Auftrieb nach dem Bernoullischen Prinzip. Die auf den Benutzer wirkenden Kräfte nehmen zu. Beim Start der Fahrbewegung oder zur Erhöhung der Fahrgeschwindigkeit wird ein solcher Steuerimpuls absichtlich erzeugt.If the user pushes the bar away from the body via the depower line connected to the trapeze belt, the control lines are relieved, and tilting or deconstructing the kite profile reduces lift and reduces pulling forces. An additional dynamic buoyancy is created when the kite is put into a proper motion, i.e. a flight on a circular path with a line-length radius, by unilateral line pulling left or right. As the speed of the kite increases, dynamic lift increases according to the Bernoulli principle. The forces acting on the user increase. At the start of the driving movement or to increase the driving speed, such a control pulse is intentionally generated.

Bei böigen, plötzlich stark zunehmenden Winden, fehlerhaften (überzogenen) Steuerbewegungen oder Orientierungsverlusten bei Sprung- oder Trickmanövern etc. wird ein sprunghafter Zugkraftanstieg jedoch auch unbeabsichtigt und unkontrolliert ausgelöst. In einem sich aus einer solchen beschriebenen Situation entwickelnden Notfall wird der Kite Kräfte entwickeln, die ein Mehrfaches des Eigengewichts des Benutzers betragen können, wobei mehr als 200 kg möglich sind.In gusty, suddenly strong winds, erroneous (exaggerated) control movements or orientation losses in jumping or trick maneuvers etc., however, a sudden increase in traction is also triggered unintentionally and uncontrollably. In an emergency evolving from such a described situation, the kite will develop forces that can amount to several times the user's own weight, with more than 200 kg being possible.

Die Folge ist ein totaler Kontrollverlust. Der Benutzer wird in der Regel bei zusätzlicher Eigenrotation um die Körperlängsachse orientierungslos hinter dem Kite hergezogen. Dieser Zustand hält an, bis das Kite aus seiner Eigenbewegung möglicherweise abstürzt oder der Benutzer unter Zugkraft gegen Hindernisse geschleudert wird.The result is a total loss of control. As a rule, the user is pulled behind the body longitudinal axis with no additional self-rotation behind the kite. This condition persists until the kite may crash out of its own motion or the user may be thrown against obstacles with traction.

Zur Gefahrenabwehr für den Benutzer und für Dritte ergibt sich damit eine Notwendigkeit, die Zugkraftverbindung zwischen dem Benutzer und dem Kite in der Weise ohne einschränkende Bedingungen entkoppeln zu können, daß der Kite möglichst schnell zugkraftlos wird. Bei einem bloßen Lösen der Hände von der Bar bleiben die über die Depowerleine zum Trapezgurt des Benutzers übertragenen Zugkräfte erhalten. Die Gefahrensituation wird dadurch nicht entspannt.To avoid danger to the user and third parties, this results in a need to be able to decouple the tensile force connection between the user and the kite in such a way without restrictive conditions that the kite is as fast as possible without power. By simply releasing the hands from the bar, the traction forces transmitted via the depower line to the trapeze belt of the user are maintained. The danger situation is not relaxed thereby.

Bislang sind zum Lösen der kritischen Verbindung zwischen Benutzer und Depowerleine nur Klapphaken, sogenannte Panikschäkel oder Panikhaken, Klettbandverbindungen und leashes bekannt, die in der Depowerleine unterhalb der Bar, also auf der dem Benutzer zugewandten Seite, eingesetzt oder direkt mit dem Trapezhaken und/oder der Trapezplatte verbunden werden.So far, only folding hooks, so-called panic shackles or panic hooks, Velcro connections and leashes are known to solve the critical connection between the user and Depowerleine used in the depower line below the bar, ie on the user side facing, or directly to the harness hook and / or Trapezoidal be connected.

Alle bekannten Systeme ermöglichen die Entkopplung der Zugkraftübertragung erst unter den folgenden, sicherheitsrelevant einschränkenden Bedingungen:

- 1. Der Benutzer muß mindestens eine Hand von dem Handgriff bzw. der Lenkstange lösen, um den Auslöser erreichen zu können.

- 2. Der Benutzer muß nach dem Loslassen der Lenkstange in einer zielgerichteten und damit kontrollierten Handlung nach dem Bedienteil greifen und dieses blind finden, um den Mechanismus auslösen zu können.

- 1. The user must detach at least one hand from the handle or the handlebar to reach the trigger can.

- 2. The user must grab after releasing the handlebar in a targeted and thus controlled action for the control panel and find this blind to trigger the mechanism can.

Die bekannten Systeme lassen das erhebliche Sicherheitsproblem damit weitgehend ungelöst, da gerade in einer Notsituation, die in der hier zu bewertenden Weise von einem systemimmanenten Orientierungs- und Kontrollverlust begleitet wird, die zur Kraftentkopplung erforderlichen zielgerichteten und kontrollierten Handlungen nicht mehr ausführbar sind. Dies gilt um so mehr, da der Benutzer das einzig zur Verfügung stehende Kontrollinstrument, nämlich die Lenkstange, loslassen muß, bevor der zielgerichtete Griff nach der Auslösevorrichtung überhaupt erst folgen kann.The known systems leave the considerable security problem largely unresolved since, especially in an emergency situation, which is accompanied in the manner to be evaluated here by a system-inherent loss of orientation and control, for power decoupling necessary targeted and controlled actions are no longer executable. This is even more so since the user must release the only control instrument available, namely the handlebar, before the targeted grip on the triggering device can follow at all.

Die Aufgabe der Erfindung ist daher, ein Sportgerät der eingangs genannten Art dahin gehend weiter zu bilden, daß eine durch einen Kontrollverlust herbei geführte Gefahrensituation zuverlässig und schnell beendet werden kann.The object of the invention is therefore to continue to form a sports equipment of the type mentioned in that a caused by a loss of control induced dangerous situation can be completed reliably and quickly.

Die Aufgabe wird durch die kennzeichnenden Merkmale des Anspruchs 1 gelöst.The object is solved by the characterizing features of claim 1.

Mit der erfindungsgemäßen Vorrichtung nach Anspruch 1 ist es möglich, daß eine Kraftentkopplung direkt über den Haltegriff betätigt werden kann, ohne daß der Benutzer seine Hände von dem Haltegriff lösen muß.With the device according to the invention according to claim 1, it is possible that a power decoupling can be operated directly on the handle without the user must solve his hands from the handle.

Ein weiterer Vorteil der vorliegenden Erfindung gemäß Anspruch 2 besteht darin, daß die Deaktivierung der Zugeinrichtung in Abhängigkeit von einer Bewegung des Haltegriffs in einer Wirkrichtung der Zugkraft erfolgt. Der Benutzer muß zur Deaktivierung lediglich den Haltegriff in Wirkrichtung der Zugkraft der Zugeinrichtung bewegen, um den Auslösemechanismus zu betätigen und die Zugeinrichtung zu deaktivieren.Another advantage of the present invention according to claim 2 is that the deactivation of the pulling device in response to a movement of the handle in a direction of action of the tensile force takes place. The user must move to deactivate only the handle in the direction of action of the pulling force of the pulling device to operate the trigger mechanism and disable the pulling device.

Ein weiterer Vorteil gemäß Anspruch 3 besteht darin, daß die Deaktivierung der Zugeinrichtung auch automatisch erfolgen kann, indem die Sicherheitseinrichtung bei Erreichen eines vorbestimmten Grenzwertes auslöst und die Zugeinrichtung deaktiviert. Dies kann alternativ oder zusätzlich zu der bewegungsabhängigen Deaktivierung vorgesehen sein, um z.B. ein sichereres Training zu ermöglichen.Another advantage according to

Ausführungsform der vorliegenden Erfindung werden im folgenden anhand der Zeichnungen näher beschrieben. Es zeigen:

-

Fig. 1 eine schematische Teilansicht im Querschnitt eines Haltegriffs im Bereich des Durchgangs einer Leine bzw. Depowerleine und mit einer erfindungsgemäßen Sicherheitseinrichtung; -

Fig. 2 eine schematische Teilansicht im Querschnitt einer zweiten Ausführungsform der vorliegenden Erfindung; -

Fig. 3 eine schematische Ansicht eines Sportgerätes gemäß vorliegender Erfindung, an welchem der Haltegriff ausFig. 1 oderFig. 2 angebracht ist; -

Fig. 4 eine schematische Draufsicht auf einen Benutzer, der das erfindungsgemäße Sportgerät benutzt und mit seinen Händen an den Haltegriff angreift, wobei die durchgezogenen Linien eine aktive Betriebssituation zeigen und gestrichelte Linien eines deaktive Situation zeigen und Bewegungspfeile den Deaktivierungsvorgang schematisch darstellen; -

Fig. 5 eine schematische Darstellung einer erfindungsgemäßen Depowerleine; -

Fig.6 eine schematische Darstellung einer zweiten Ausführungsform der Sicherheitseinrichtung; -

Fig. 7 eine schematische Darstellung einer dritten Ausführungsform der Sicherheitseinrichtung; -

Fig. 8 eine schematische Draufsicht auf das Sportgerät in einer dritten Ausführungsform; -

Fig. 9 eine schematische Darstellung eines erfindungsgemäßen Lenkdrachensystems; -

Fig. 10 eine Detaildarstellung der Ausführungsform nachFigur 9 -

Fig. 11 eine schematische Darstellung einer vierten Ausführungsform der Sicherheitseinrichtung; und -

Fig. 12 eine schematische Darstellung einer fünften Ausführungsform der Sicherheitseinrichtung.

-

Fig. 1 a schematic partial view in cross section of a handle in the region of the passage of a leash or depower line and with a safety device according to the invention; -

Fig. 2 a schematic partial view in cross section of a second embodiment of the present invention; -

Fig. 3 a schematic view of a sports equipment according to the present invention, on which the handle fromFig. 1 orFig. 2 is appropriate; -

Fig. 4 a schematic plan view of a user who uses the sports equipment according to the invention and attacks with his hands on the handle, the solid lines show an active operating situation and dashed lines show an inactive situation and movement arrows schematically illustrate the deactivation process; -

Fig. 5 a schematic representation of a depower line according to the invention; -

Figure 6 a schematic representation of a second embodiment of the safety device; -

Fig. 7 a schematic representation of a third embodiment of the safety device; -

Fig. 8 a schematic plan view of the sports equipment in a third embodiment; -

Fig. 9 a schematic representation of a steering kite system according to the invention; -

Fig. 10 a detailed representation of the embodiment according toFIG. 9 ; -

Fig. 11 a schematic representation of a fourth embodiment of the safety device; and -

Fig. 12 a schematic representation of a fifth embodiment of the safety device.

In

An dem Haltegriff 3 ist eine Sicherheitseinrichtung 9 angeordnet. Wenn die Zugeinrichtung 5 in einem aktiven Zustand, das heißt, im Betrieb des Sportgerätes 1 eine Zugkraft auf den Haltegriff 3 ausübt und ein Schwellenwert erreicht wird, deaktiviert die Sicherheitseinrichtung 9 die Zugeinrichtung 5. Die Deaktivierung erfolgt in der vorliegenden Ausführungsform durch eine Kraftentkopplung der auf den Haltegriff 3 und den Benutzer 7 wirkenden Zugkraft. Die Deaktivierung kann wahlfrei durch den Benutzer während des Betriebes ausgelöst werden, das heißt, der Schwellenwert kann für jeden Benutzer 7 ein subjektiv wahrgenommener Wert sein. Die manuelle Auslösung der Deaktivierung der Zugeinrichtung 5 erfolgt in Abhängigkeit von einer Bewegung des Haltegriffs 3 in einer Wirkrichtung der Zugkraft (

Die Sicherheitseinrichtung 9 ist in der vorliegenden Ausführungsform an einer Leine 11 angeordnet, die durch die Öffnung 3.1 in dem Haltegriff 3 hindurch geführt ist. Die Sicherheitseinrichtung 9 ist an der Leine 11 in Wirkrichtung der Zugkraft in Wirknähe hinter dem Haltegriff 3 angeordnet, das heißt, auf der Zugseite in

Die Sicherheitseinrichtung 9 weist in inneres Spannelement 9.1 und eine äußeres Spannelement 9.2 auf, die in einer Wirkrichtung der Zugkraft gegeneinander vorgespannt sind und gegen die Vorspannung relativ zueinander verschiebbar angeordnet sind. Das äußere Spannelement 9.2 weist haltegriffseitig einen Flansch 9.3 auf, der das äußere Spannelement 9.2 kranzförmig umschließt und haltegriffseitig eine Anstoßfläche für den Haltegriff 3 bildet. Der Flansch 9.3 geht zugseitig in einen Hülsenteil 9.4 über, der mit einer Innenwand gleitfähig an einer Außenwand des inneren Spannelement 9.1 anliegt. Das Hülsenteil 9.4 weist an seinem zugseitigen Ende eine geringere Wandstärke auf als an seinem flanschseitigen Ende, wobei die Innenwand des Hülsenteils 9.4 am zugseitigen Ende abgestuft ist, so daß dort zwischen dem Hülsenteil 9.4 und dem inneren Spannelement 9.1 ein Aufnahmeraum für ein Federelement 9.5 ausgebildet ist. Das Federelement 9.5 ist im vorliegenden Fall eine Schraubenfeder mit einer einheitlichen Federkonstante. Es ist denkbar, daß das Federelement 9.5 eine variierende Federkonstante hat, so daß die Federkraft über einen Einstellmechanismus (nicht dargestellt) einstellbar ist. Das innere Spannelement 9.1 weist an seinem Umfang einen Ansatz 9.6 auf, der den zwischen dem Hülsenteil 9.4 und dem Spannelement 9.1 gebildeten Aufnahmeraum zugseitig abschließt. Das Federelement 9.5 stützt sich an dem Ansatz 9.6 und an der Stufe im Hülsenteil 9.4 ab, wodurch das innere Spannelement 9.1 und das äußere Spannelement 9.2 gegeneinander vorgespannt sind.The

Das innere Spannelement 9.1 ist hülsenförmig ausgebildet und weist an seinem haltegriffseitigen Ende eine erste innen liegende Ringnut 9.7 auf. Das innere Spannelement 9.1 weist zudem an seinem zugseitigen Ende eine zweite innen liegende Ringnut 9.8 auf. Die Leine 11 weist ein erstes zugseitiges Leinenteil 11.1 auf, das an einem freien Ende 11.2 mit einem Zapfen 11.3 verbunden ist, der formschlüssig in der Ringnut 9.8 sitzt. Ein Klemmelement 9.9 ist am zugseitigen Ende des inneren Spannelements 9.1 angebracht, und erzeugt eine Klemmspannung, derart, daß der Zapfen 11.3 fest in der Ringnut 9.8 eingespannt ist. Das Klemmelement 11.3 kann z.B. eine Klemmmutter sein. Die Leine 11 umfaßt auch ein zweites benutzerseitiges Leinenteil 11.4, das an seinem freien Ende 11.5 einen Auslösezapfen 11.6 aufweist, der in der vorliegenden Ausführungsform identisch mit dem Zapfen 11.3 ist. Der Auslösezapfen 11.6 sitzt formschlüssig in der ersten Ringnut 9.7 und ist dort durch das äußere Spannelement 9.2 fest eingespannt. Die Leine 11 bzw. die Leinenteile 11.1 und 11.4 sowie die Zapfen 11.3 und 11.6 sind hohl bzw. mit einem zentralen Durchgang ausgebildet, in welchem eine Sicherheitsleine 13 verläuft.The inner clamping element 9.1 is sleeve-shaped and has at its handle-side end a first inner annular groove 9.7. The inner clamping element 9.1 also has at its zugseitigen end a second inner annular groove 9.8. The

Eine Bewegung des Haltegriffs 3 in

Alternativ wäre auch vorstellbar, daß die Leine 11 nicht geteilt ist und in dem innere Spannelement 9.1 nur eine Ringnut 9.8 oder 9.7 ausgebildet ist, in der ein an der Leine ausgebildeter Vorsprung fest sitzt. Die weitere Auslösemechanik kann identisch zu derjenigen bleiben, die vorstehend beschrieben wurde. Die Leine 11 müßte in diesem Fall benutzerseitig von der Ringnut einen Leinenvorrat aufweisen, der im Falle einer Auslösung zu einer vorübergehenden Kraftentkopplung führt. Eine solche Ausführungsform kann dort eingesetzt werden, wo eine solche vorübergehende Kraftentkopplung ausreicht, um eine sichere Kontrolle über das Sportgerät 1 wieder zu gewinnen.Alternatively, it would also be conceivable that the

In

Die Funktion des in

Wird die Verbindung von Ober- und Unterteil der Leine 11 in dem Ausführungsbeispiel aus

In

In

In

Zu diesem Zweck ist das Depowerleinenteil 11.4 wenigstens benutzerseitig mit einem Querschnitt versehen, der unterschiedliche Radien aufweist. In

For this purpose, the Depowerleinenteil 11.4 is provided at least user side with a cross section having different radii. In

Weitere Ausführungsformen der vorliegenden Erfindung und schematische Darstellungen werden mit den

In

Ein weiterer Unterschied ergibt sich in der Ausführung des Federanschlages 9.6 des inneren Spannelementes 9.1. In der hier vorliegenden Ausführungsform ist der Federanschlag 9.6 als Gewindehülse ausgebildet, die auf ein Gewinde im oberen Umfang des inneren Spannelementes 9.1 gedreht wird und damit eine individuelle Voreinstellung der verwendeten Feder 9.5 zuläßt.Another difference arises in the embodiment of the spring stop 9.6 of the inner clamping element 9.1. In the present embodiment, the spring stop 9.6 is formed as a threaded sleeve which is rotated to a thread in the upper circumference of the inner clamping element 9.1 and thus allows an individual default of the spring used 9.5.

In

Die Auslösehülse 9.2 wird in dieser Ausführungsform mit einer spreizbaren Durchmesserverengung 9.14 am oberen Ende versehen. Bei Verschiebung der Auslösehülse 9.2 über den Federanschlag 9.6 der Innenhülse 9.1 nach oben hin weg werden beide Elemente gegen die Vorspannung der Feder 9.5 durch Einrasten der Durchmesserverengung 9.14 miteinander verriegelt. Der zur Spreizung des Unterteiles der Innenhülse 9.1 erforderliche Raum 9.15 wird mit einer Bohrung im Unterteil der Außenhülse 9.2 geschaffen. Der Auslösezapfen 11.6 wird außen mehreckig (nicht rund) ausgeführt, um relative Rotationen zur Innenhülse 9.1 zu verhindern. Das spreizbare Innenhülsenunterteil 9.7 wird entsprechend der Form des Auslösezapfens 11.6 mehrfach geteilt. Die Ecken des Auslösezapfens 11.6 können in die Zwischenräume des mehrfach geteilten Innenhülsenunterteils 9.7 eingreifen.The release sleeve 9.2 is provided in this embodiment with an expandable diameter constriction 9.14 at the top. Upon displacement of the release sleeve 9.2 on the spring stop 9.6 of the inner sleeve 9.1 upwards away both elements locked against the bias of the spring 9.5 by engaging the diameter constriction 9.14 each other. The required for spreading the lower part of the inner sleeve 9.1 9.15 is created with a hole in the lower part of the outer sleeve 9.2. The tripping pin 11.6 is polygonal outside (not round) executed to prevent relative rotations to the inner sleeve 9.1. The expandable inner sleeve lower part 9.7 is divided several times according to the shape of the tripping pin 11.6. The corners of the tripping pin 11.6 can engage in the interstices of the multiply divided inner sleeve lower part 9.7.

Der Anschluß des Zugleinenoberteils erfolgt durch Einführen und Verknoten durch Bohrung 9.10 im Schaft am Oberteil der Innenhülse 9.1. Die Sicherheitsleine 13 wird durch die Bohrung 9.11 im Schaft an der Oberseite der Innenhülse 9.1 geführt und mit dem benutzerseitigen Teil der Zugleine in der Aussparung an der Oberseite des Auslösezapfens 11.6 verbunden.The connection of the pulling line upper part takes place by insertion and knotting through hole 9.10 in the shaft on the upper part of the inner sleeve 9.1. The

Mit dem hier gezeigten Auslöseschema können nach dem Stand der Technik bereits bekannte Manschetten- oder Schäkelsysteme, die teilweise marktgängig sind, ebenfalls durch aktives Wegdrücken der Lenkstange 3 in Richtung des Lenkrachens 5 oder abhängig von der Einstellung durch bloßes Loslassen der Hände von der Lenkstange 3 zuverlässig entkoppelt werden.With the triggering scheme shown here can already known cuff or Schäkelsysteme that are partially marketable, also by actively pushing away the

Im Gegensatz zu den bisher gezeigten Anordnungsschemata wird die Verwendung einer zusätzlichen Sicherheitsleine 13 in dieser Ausführungsform nicht notwendig. Wird die Sicherheitseinrichtung 9 ausgelöst, so rutscht die Lenkstange 3 mit den daran befestigten Steuerleinen 4 sowie die Sicherheitseinrichtung 9 mit der an deren Oberteil befestigten zweiten Frontleine 2.2 auf der als Sicherheitsleine durchlaufenden Frontleine 2.1 in Richtung des Lenkdrachens 5. Der nur noch durch die als durchlaufende Sicherheitsleine verwendete Frontleine 2.1 mit dem Benutzer 7 verbundene Lenkdrachen 5 fällt dann drucklos herunter.In contrast to the arrangement schemes shown so far, the use of an

In

Wesentliche Vorteile der hier vorliegenden Ausführungsform entstehen durch die Einfachheit der einzelnen Elemente und die begrenzte Anzahl der Gesamtstückzahl der zu verwendenden Komponenten. Ferner wird das System unanfällig gegenüber äußeren Einflüssen bei der Benutzung (Salz, Sand beim Einsatz als Wassersportgerät in freier Umgebung).Significant advantages of the present embodiment arise from the simplicity of the individual elements and the limited number of the total number of components to be used. Furthermore, the system is not susceptible to external influences during use (salt, sand when used as a water sports device in a free environment).

Die austauschbare Elastomerfeder 9.5 wird zwischen Auslösehülse 9.2 und Innenhülse 9.1 gespannt. Auslösehülse 9.2 und Innenhülse 9.1 werden mit Hilfe einer Außendurchmessererweiterung am unteren Ende 9.7 der Innenhülse 9.1 zusammengefügt. Zur Montage von Innenhülse 9.1 und Außenhülse 9.5 wird das spreizbare Unterteil 9.7 der Innenhülse 9.1 bei demontiertem Auslösezapfen 11.6 zusammengedrückt. Die Feder 9.5 und die Außenhülse 9.2 werden über das zusammengedrückte Innenhülsenunterteil 9.7 geschoben. Bei Überfahren der Durchmessererweiterung des Innenhülsenunterteils 9.7 mit der inneren Unterkante der Auslösehülse 9.2 werden die Komponenten durch Entspannung der elastischen Verformung des spreizbaren Innenhülsenunterteils 9.7 verriegelt.The replaceable elastomer spring 9.5 is stretched between release sleeve 9.2 and inner sleeve 9.1. Release sleeve 9.2 and inner sleeve 9.1 are assembled by means of an outer diameter extension at the lower end of the inner sleeve 9.1 9.7. For mounting of inner sleeve 9.1 and outer sleeve 9.5, the expandable lower part 9.7 of the inner sleeve 9.1 is compressed with disassembled trigger pin 11.6. The spring 9.5 and the outer sleeve 9.2 are pushed over the compressed inner sleeve lower part 9.7. When driving over the diameter extension of the inner sleeve lower part 9.7 with the inner lower edge of the release sleeve 9.2, the components are locked by relaxation of the elastic deformation of the expandable inner sleeve lower part 9.7.

Zur Befestigung einer Frontleine führt eine kurze Anschlußleine durch eine Bohrung 9.11 im oberen Deckel er Innenhülse 9.1 und wird mit einem Knoten gegen Durchrutschen gesichert. Die andere Frontleine wird als durchlaufende Sicherheitsleine durch die zweite Bohrung im oberen Deckel der Innenhülse 9.1 geführt und am Ende des Depowerleinenunterteils 11 in der Aussparung des Auslösezapfens 11.8 angebunden. Die Aussparung zur Aufnahme des spreizbaren Innenhülsenunterteils im Unterteil der Außenhülse wird, wie bereits anhand von

Im Unterschied zu der Ausführungsform in

Claims (18)

- Sports device (1) with a handle (3) for holding and guiding the sports device (1), and with a tension mechanism (5) which, when in an active condition, is efficiently connected to the user by means of a pull-cord (11) and exerts a tensile force on the user (7), and with a safety mechanism (9) for uncoupling the tensile force acting on the pull-cord (11), the user (7) grasping the handle (3) in the active condition,

characterized in that

the complete safety mechanism (9) together with its releasing mechanism is positioned on the handle (3) at the tension side in effective proximity to the user (7), in the active condition said safety mechanism (9) being releasable from an adjustable distance to the user (7) at the pull-cord (11) by a movement of the handle (3) in an effective direction of the tensile force, and when released uncouples the tensile force that is acting upon the pull-cord (11). - Sports device as in claim 1,

characterised in that

the safety mechanism (9) on the pull-cord (11) is positioned on the handle (3) in the effective direction of the tensile force. - Sports device as in claim 1 or 2,

characterised in that

the pull-cord (11) passes inside the handle (3). - Sports device as in one of claims 1 to 3,

characterised in that

the safety mechanism (9) has an inner tensioning element (9.1), on the outside of which is mounted an outer tensioning element (9.2) which can be moved axially against prestress force from a locked setting to a released setting. - Sports device as in claim 4,

characterised in that

the outer tensioning element (9.2) exerts, when in operation, a tension that is essentially at right angles to the effective direction of the tensile force on the inner tensioning element (9.1), in such a manner that the pull-cord (11) is firmly gripped in the inner tensioning element (9.1). - Sports device as in claim 5,

characterised in that

the movement of the handle in an effective direction of the tensile force effects a movement of the outer tensioning element (9.2) against the prestress force and relative to the inner tensioning element (9.1), and releases the firm gripping of the pull-cord (11) in the inner tensioning element (9.1). - Sports device as in one of claims 1 to 6,

characterised in that

the pull-cord (11) has a first part (11.1) which is positioned between the safety mechanism (9) and the tension mechanism (5), and a second part (11.4) which is positioned between the user (7) and the safety mechanism (9), the two parts (11.1, 11.4) of the cord being connected, in operation, in the safety device (9). - Sports device as in claim 7,

characterised in that

the first part of the cord (11.1) is firmly gripped at one tension-side end of the inner tensioning element (9.1), and the second part of the cord (11.4) is firmly gripped at one handle-side end of the inner tensioning element (9.1) by the tensioning effect of the outer tensioning element (9.2) at right angles to the effective direction of the tensile force. - Sports device as in claim 8,

characterised in that

the movement of the handle (3) in an effective direction of the tensile force effects a movement of the outer tensioning element (9.2) against the prestress force relative to the inner tensioning element (9.1), and releases the firm gripping of the second part of the cord (11.4) in the inner tensioning element (9.1). - Sports device as in one of claims 1 to 9,

characterised in that

the second part (11.4) of the pull-cord (11) is passed through the handle (3). - Sports device as in one of claim 5 to 10.

characterised in that

the pull-cord (11) is a depower line. - Sports device as in one of the preceding claims,

characterised in that

the handle (3) is a steering bar. - Sports device as in one of the preceding claims,

characterised in that

the tension mechanism (5) is a stunt kite. - Sports device as in claim 11,

characterised in that

the pull-cord (11) in the form of a depower line is made hollow and has a cross-section of different radii. - Sports device as in claim 14,

characterised in that

in the pull-cord (11) in the form of a depower line, a safety cord (13) is passed through the handle (3). - Sports device as in claim 14 or 15,

characterised in that

the pull-cord (11) in the form of a depower line is polygonal in cross-section. - Sports device as in claims 14 to 16,

characterised in that

the pull-cord (11) in the form of a depower line is triangular in cross-section. - Sports device as in claim 14 and 17,

characterised in that

the pull-cord (11) in the form of a depower line is oval in cross-section.

Applications Claiming Priority (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10258637A DE10258637C5 (en) | 2002-12-13 | 2002-12-13 | Sports equipment with a safety device |

| DE10258637 | 2002-12-13 | ||

| DE20302460U DE20302460U1 (en) | 2002-12-13 | 2003-02-15 | Sports equipment with a safety device |

| DE20302460U | 2003-02-15 | ||

| DE20303089U | 2003-02-26 | ||

| DE20303089U DE20303089U1 (en) | 2002-12-13 | 2003-02-26 | Sports equipment with a safety device |

| PCT/DE2003/004200 WO2004054659A2 (en) | 2002-12-13 | 2003-12-12 | Sport equipment item comprising a safety mechanism |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1569726A2 EP1569726A2 (en) | 2005-09-07 |

| EP1569726B1 EP1569726B1 (en) | 2006-11-02 |

| EP1569726B2 true EP1569726B2 (en) | 2012-08-15 |

Family

ID=32600537

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03785593A Expired - Lifetime EP1569726B2 (en) | 2002-12-13 | 2003-12-12 | Sporting apparatus comprising a safety mechanism |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP1569726B2 (en) |

| AT (1) | ATE344096T1 (en) |

| DE (1) | DE50305607D1 (en) |

| ES (1) | ES2276141T5 (en) |

| WO (1) | WO2004054659A2 (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2875788B1 (en) * | 2004-09-24 | 2006-12-15 | Ronan Saliou | TRACTION KITE FOR SPORT SPORTS |

| IT1396531B1 (en) * | 2009-10-22 | 2012-12-14 | Flaccomio Nardi Dei | DEVICE FOR THE AUTOMATIC RELEASE OF A LINE, IN PARTICULAR A LINE OF CONNECTION OF A SAILING FROM KITE SURFING TO THE BODY OF THE SURFER |

| US8814098B2 (en) | 2010-06-17 | 2014-08-26 | Neil Pryde Limited | Control system for a traction wing |

| DE102010053320B3 (en) * | 2010-12-01 | 2012-06-14 | Christian OTTERBACH | Training tool for sports kite, varies angle of traction cable with respect to lever by applied force and arrangement of deflection roller relative to lever so that lifting height of traction cable is increased under weight of user |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20020084384A1 (en) † | 2000-11-16 | 2002-07-04 | Bellacera John D. | Kite control systems |

| DE20209515U1 (en) † | 2002-06-19 | 2002-10-17 | Huber, Christian, 83236 Übersee | Passive safety system for 4-line kites |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5816636A (en) * | 1997-06-24 | 1998-10-06 | Gibson; Daniel R. | Self-releasing log choker |

| DE10047452A1 (en) * | 2000-09-26 | 2002-01-03 | Peter Stiewe | Control rod for kite has clamping mechanism to lock central line |

| DE20107925U1 (en) * | 2001-05-10 | 2002-01-24 | FlySurfer GmbH, 65185 Wiesbaden | Line system for controlling a kite |

| DE10262138B4 (en) * | 2002-12-13 | 2007-06-21 | Dirk Schiffmann | Automatic safety line release mechanism for large kites |

-

2003

- 2003-12-12 WO PCT/DE2003/004200 patent/WO2004054659A2/en active IP Right Grant

- 2003-12-12 ES ES03785593T patent/ES2276141T5/en not_active Expired - Lifetime

- 2003-12-12 EP EP03785593A patent/EP1569726B2/en not_active Expired - Lifetime

- 2003-12-12 DE DE50305607T patent/DE50305607D1/en not_active Expired - Lifetime

- 2003-12-12 AT AT03785593T patent/ATE344096T1/en active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20020084384A1 (en) † | 2000-11-16 | 2002-07-04 | Bellacera John D. | Kite control systems |

| DE20209515U1 (en) † | 2002-06-19 | 2002-10-17 | Huber, Christian, 83236 Übersee | Passive safety system for 4-line kites |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1569726A2 (en) | 2005-09-07 |

| WO2004054659A2 (en) | 2004-07-01 |

| EP1569726B1 (en) | 2006-11-02 |

| DE50305607D1 (en) | 2006-12-14 |

| ES2276141T5 (en) | 2012-10-30 |

| ATE344096T1 (en) | 2006-11-15 |

| WO2004054659A3 (en) | 2004-08-19 |

| WO2004054659B1 (en) | 2004-11-04 |

| ES2276141T3 (en) | 2007-06-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CH615833A5 (en) | ||

| EP1569726B2 (en) | Sporting apparatus comprising a safety mechanism | |

| DE20303089U1 (en) | Sports equipment with a safety device | |

| DE10258637B4 (en) | Sports equipment with a safety device | |

| WO2004067381A2 (en) | Piece of sports equipment comprising two steering lines and a safety device | |

| EP1516810B1 (en) | Control system for a traction kite | |

| DE102010021462B4 (en) | Safety device for a kite and kite | |

| DE202004006143U1 (en) | Trapeze harness for windsurfer has quick release catch with carabiner hook and release loop | |

| DE202009002826U1 (en) | Safety device on the tug of large kites | |

| DE20315464U1 (en) | Kitebar for kite surfing has the control lines looped over the ends and secured by a rapid release clamp | |

| DE10242455B4 (en) | Connecting element of a steerable kite | |

| DE202019101286U1 (en) | Safety leash and safety device with a safety leash | |

| DE202006019043U1 (en) | Safety device for steerable kite e.g. for kite surfing, has clamping device which can be anchored to pulling line by one-hand operation | |

| DE202009010309U1 (en) | Turn-out safety leash on large kites | |

| WO2005023631A2 (en) | Improved safety system for a steerable 4-line kite | |

| DE202019103607U1 (en) | Linen system of a steering kite | |

| DE102006005620A1 (en) | Tube kite with support line, has first lateral zone joined to second lateral zone by support line | |

| DE202010009294U1 (en) | Magnetic device for supporting the release sleeve on a safety device of large kites | |

| DE202024000573U1 (en) | Redirected coupling of the tow and safety line for a large stunt kite | |

| DE202011103240U1 (en) | Connecting a strand of the tug of large stunt kites with a flying line | |

| DE9210393U1 (en) | Bicycle dog leash | |

| DE202011100415U1 (en) | Stop on the tugboat of large stunt kites to limit the effective length of the haul rope when used as a safety line | |

| DE10340360A1 (en) | Safety device for kite surfing comprises an emergency triggering unit containing a control unit arranged on the hook plate of the trousers of the user | |

| DE10241757A1 (en) | Kite-surfing safety arrangement comprises an emergency release mechanism which is fixed to the surfer's hook plate and is combined by means of a safety line with the control bar | |

| DE202014005686U1 (en) | Stop element for coupling the leash of large stunt kites with a safety line |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050428 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061102 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061102 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061102 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061102 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061102 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061102 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 50305607 Country of ref document: DE Date of ref document: 20061214 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070202 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070202 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070202 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070402 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2276141 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| PLAA | Information modified related to event that no opposition was filed |

Free format text: ORIGINAL CODE: 0009299DELT |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26N | No opposition filed |

Effective date: 20070803 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: NEIL PRYDE LIMITED Effective date: 20070802 |

|

| D26N | No opposition filed (deleted) | ||

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: NEIL PRYDE LIMITED |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070203 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070503 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061102 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061212 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061102 |

|

| PLCK | Communication despatched that opposition was rejected |

Free format text: ORIGINAL CODE: EPIDOSNREJ1 |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PLAY | Examination report in opposition despatched + time limit |

Free format text: ORIGINAL CODE: EPIDOSNORE2 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20110630 Year of fee payment: 8 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20120815 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 50305607 Country of ref document: DE Effective date: 20120815 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: DC2A Ref document number: 2276141 Country of ref document: ES Kind code of ref document: T5 Effective date: 20121030 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111212 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20130703 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111213 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20171219 Year of fee payment: 15 Ref country code: GB Payment date: 20171221 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20190103 Year of fee payment: 16 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20181212 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20181231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181212 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20191219 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20191218 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20200122 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20200101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200101 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50305607 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 344096 Country of ref document: AT Kind code of ref document: T Effective date: 20201212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201231 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210701 |