EP1567342B1 - Racle a reservoir d'encre - Google Patents

Racle a reservoir d'encre Download PDFInfo

- Publication number

- EP1567342B1 EP1567342B1 EP03775395A EP03775395A EP1567342B1 EP 1567342 B1 EP1567342 B1 EP 1567342B1 EP 03775395 A EP03775395 A EP 03775395A EP 03775395 A EP03775395 A EP 03775395A EP 1567342 B1 EP1567342 B1 EP 1567342B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- doctor blade

- clamping plate

- rod

- fasteners

- roller

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000000694 effects Effects 0.000 description 3

- 239000003973 paint Substances 0.000 description 3

- 238000005452 bending Methods 0.000 description 2

- 239000002655 kraft paper Substances 0.000 description 2

- 210000003739 neck Anatomy 0.000 description 2

- 238000005553 drilling Methods 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F31/00—Inking arrangements or devices

- B41F31/02—Ducts, containers, supply or metering devices

- B41F31/027—Ink rail devices for inking ink rollers

Definitions

- the WO 0078548 A1 shows a clamping device for a doctor blade, wherein a clamping rail has been provided with a T-shaped groove, so that this, in operative connection with the spring of the carrier, the doctor blade can clamp.

- the clamping plates are flexible plates which are held on the doctoring chamber body by screws or similar fixing means, but are not finally fixed. Clamping takes place on the side of the screws facing the roller, in that the fastening means elongated in the axial direction (z) of the roller exert a force on the clamping plate which points away from the doctor chamber body.

- the clamping plate is held by the screws on the doctoring chamber body so that the clamping plate bends and on the side of the screws facing the roller exerts a force on the doctor blade which is directed onto the doctoring chamber body and fixes the doctor blade to the doctoring chamber body. If the force exerted by the elongated fastener force effect is suppressed, no force is exerted on the doctor blade and possibly the clamping plate.

- the fastening means which are elongate in the axial direction (z) of the roller are rods with a partially round cross section, which are rotatably mounted in the doctor chamber body.

- the FIG. 1 shows a paint chamber doctor blade 1 of the prior art.

- the ink chamber 8 is limited by the inking roller 6 of the doctoring chamber body 5, which of course may also consist of several parts, and the doctor blade 2 is limited.

- the two doctor blades 2 of the ink chamber doctor blade 1 are each fixed by a clamping plate 3 which presses the doctor blade associated with it against the doctor chamber body 5.

- the force required for this purpose is the restoring force of the clamping plate, which arises because the clamping plate between the elongated fastening element 4, which is pronounced in the present case as a rod and the head of the screw 7 and the doctor chamber body 5 is bent.

- FIG. 3 shows a clamping plate, which for use in the in the Figures 1 and 2 illustrated doctoring chamber is suitable.

- the round holes 10 and the grooves 11 form the apertures 9.

- the diameter of the holes 10 is matched with the necessary play on the head of the screw 7, while the width of the groove 11 is tuned to the diameter of the screw neck.

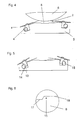

- FIG. 4 and 5 show a chamber doctor blade according to the invention, in which the clamping plates 3 is provided with an attachment piece 13 which comprises a connecting element 14.

- the connecting element is matched to the recess 15 of the rod 4.

- the shape of the recess 15 is in FIG. 6 shown again.

- FIG. 6 shows a plan view of the clamping plate 3, which in the in FIGS. 4 and 5 used chambered doctor blade according to the invention is used.

Landscapes

- Inking, Control Or Cleaning Of Printing Machines (AREA)

- Rotary Presses (AREA)

- Coating Apparatus (AREA)

- Pens And Brushes (AREA)

- Crystals, And After-Treatments Of Crystals (AREA)

- Liquid Crystal Substances (AREA)

Claims (6)

- Racle à réservoir d'encre (1)- avec deux lames de racle (2) applicables en forme de toit à un rouleau (6),- dont les deux lames de racle (2) peuvent être fixées avec une tôle de serrage (3) au corps de réservoir de racle (5)- et la tôle de serrage (3) est en liaison active avec des moyens de fixation (4) allongés dans la direction axiale (z) du rouleau (6)- qui sont disposés sensiblement parallèlement à la tôle de serrage (3)- et par lesquels est produite la force nécessaire pour la fixation d'au moins une lame de racle (2)- où la résultante de la force déployée par les moyens de fixation (4) est dirigée vers le corps de réservoir de racle (5),- où les moyens de fixation (4) sont formés par au moins une tige (4),- par le mouvement relatif de laquelle relativement à la racle à réservoir d'encre (1), la force nécessaire pour la fixation d'au moins une lame de racle (2) peut être mise à disposition,- caractérisée en ce que- la tige (4) dispose d'une face en section transversale sensiblement ronde,- qui présente un évidement (15) qui convient pour le serrage de la tôle de serrage (3).

- Racle à réservoir d'encre (1)- avec deux lames de racle (2) applicables en forme de toit à un rouleau (6),- dont les deux lames de racle (2) peuvent être fixées avec une tôle de serrage (3) au corps de réservoir de racle- et la tôle de serrage (3) est en liaison active avec des moyens de fixation (4) allongés dans la direction axiale (z) du rouleau (6)- qui sont disposés sensiblement parallèlement à la tôle de serrage (3)- et par lesquels est déployée la force nécessaire pour la fixation d'au moins une lame de racle (2),- où la résultante de la force déployée par les moyens de fixation (4) est dirigée sur le corps de réservoir de racle (5),- où les moyens de fixation (4) sont formés par au moins une tige (4),- par le déplacement relatif de laquelle relativement à la racle à réservoir d'encre (1), la force nécessaire pour la fixation d'au moins une lame de racle (2) peut être mise à disposition,- caractérisée en ce que- la tôle de serrage (3) présente au moins une pièce d'embout (13) spécialement formée qui établit la liaison active avec les moyens de fixation (4) allongés dans la direction axiale (z) du rouleau (6),- la tige (4) dispose d'une face en section transversale sensiblement ronde,- qui présente un évidement (15) qui convient pour le serrage d'une pièce d'embout (13).

- Racle à réservoir d'encre (1) selon l'une des revendications précédentes, caractérisée en ce que le mouvement relatif de la tige (4) réside en une rotation autour de son axe d'inertie principal.

- Racle à réservoir d'encre selon l'une des revendications précédentes, caractérisée en ce que la tige (4) est retenue d'une manière tournante dans le corps de réservoir de racle (5).

- Racle à réservoir d'encre (1) selon l'une des revendications 2 à 4, caractérisée en ce que la pièce d'embout (13) dispose d'un élément de liaison (14) qui peut être placé dans l'évidement (15) de la face en section transversale de la tige (4).

- Racle à réservoir d'encre (1) selon les revendications 2 à 5, caractérisée en ce que la longueur de la pièce d'embout (13), la position de l'élément de liaison (14) à la pièce d'embout (13) et la position de la tige (4) et de l'évidement (15) sont adaptées les unes aux autres de telle sorte- que l'élément de liaison (14) de la tôle de serrage (3) se trouvant à l'extérieur du réservoir de racle, au début du processus de fixation de la lame de racle, peut être inséré par concordance des formes dans l'évidement (15) eten ce que la rotation de la tige (4) nécessaire pour la fixation de la lame de racle (2) amène l'élément de liaison (14) et la tôle de serrage (3) dans la position (a) qui convient pour la fixation.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10255411A DE10255411A1 (de) | 2002-11-28 | 2002-11-28 | Farbkammerrakel |

| DE10255411 | 2002-11-28 | ||

| PCT/EP2003/013347 WO2004048097A1 (fr) | 2002-11-28 | 2003-11-26 | Racle a reservoir d'encre |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1567342A1 EP1567342A1 (fr) | 2005-08-31 |

| EP1567342B1 true EP1567342B1 (fr) | 2008-07-09 |

Family

ID=32335801

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03775395A Expired - Lifetime EP1567342B1 (fr) | 2002-11-28 | 2003-11-26 | Racle a reservoir d'encre |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US7287471B2 (fr) |

| EP (1) | EP1567342B1 (fr) |

| AT (1) | ATE400435T1 (fr) |

| AU (1) | AU2003283430A1 (fr) |

| DE (2) | DE10255411A1 (fr) |

| WO (1) | WO2004048097A1 (fr) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102007027384A1 (de) | 2007-06-11 | 2009-03-12 | Windmöller & Hölscher Kg | Farbkammerrakel in einem Farbwerk einer Rotationsdruckmaschine sowie Verfahren zur Herstellung einer Farbkammerrakel |

| DE102007027383A1 (de) | 2007-06-11 | 2008-12-24 | Windmöller & Hölscher Kg | Farbkammerrakel in einem Farbwerk einer Rotationsdruckmaschine |

| FR3080568B1 (fr) * | 2018-04-30 | 2020-04-03 | Bobst Lyon | Dispositif de fixation d'une racle sur un corps de chambre a racles |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4138807C1 (en) | 1991-11-26 | 1993-06-03 | Cornelis Wapenveld Nl Gorter | Colour chamber doctor - is for colour-transfer, screened circular cylindrical body such as screen roller or engraved cylinder |

| JP2596881Y2 (ja) | 1992-06-23 | 1999-06-21 | 旭光学工業株式会社 | レンズ鏡筒のフレキシブル基板の装着構造 |

| DE4320833C1 (de) | 1993-06-23 | 1994-09-22 | Roland Man Druckmasch | Verfahren und Vorrichtung zum Austausch eines Rakelblattes einer Kammerrakel für Rotationsdruckmaschinen |

| US5517918A (en) * | 1994-07-29 | 1996-05-21 | Fischer & Krecke Gmbh & Co. | Doctor blade clamping assembly for a printing press |

| DE19516224C2 (de) * | 1995-05-03 | 1997-03-20 | Windmoeller & Hoelscher | Rakelvorrichtung für ein Spülfarbwerk einer Rotationsdruckmaschine |

| US6202252B1 (en) * | 1999-06-03 | 2001-03-20 | Valmet Ltd. | Doctoring apparatus |

| AU762106B2 (en) * | 1999-06-22 | 2003-06-19 | Tresu Production A/S | Doctor blade system |

| EP1293342A1 (fr) * | 2001-09-14 | 2003-03-19 | Windmöller & Hölscher KG | Joint d'étanchéité pour un encreur à racles d'une machine à imprimer rotative |

| ITVR20020088A1 (it) * | 2002-09-09 | 2004-03-10 | Uteco Holding S P A | Macchina flessografica. |

-

2002

- 2002-11-28 DE DE10255411A patent/DE10255411A1/de not_active Ceased

-

2003

- 2003-11-26 AU AU2003283430A patent/AU2003283430A1/en not_active Abandoned

- 2003-11-26 DE DE50310126T patent/DE50310126D1/de not_active Expired - Lifetime

- 2003-11-26 US US10/529,554 patent/US7287471B2/en not_active Expired - Fee Related

- 2003-11-26 AT AT03775395T patent/ATE400435T1/de not_active IP Right Cessation

- 2003-11-26 EP EP03775395A patent/EP1567342B1/fr not_active Expired - Lifetime

- 2003-11-26 WO PCT/EP2003/013347 patent/WO2004048097A1/fr active IP Right Grant

Also Published As

| Publication number | Publication date |

|---|---|

| ATE400435T1 (de) | 2008-07-15 |

| US7287471B2 (en) | 2007-10-30 |

| EP1567342A1 (fr) | 2005-08-31 |

| US20060027112A1 (en) | 2006-02-09 |

| WO2004048097A1 (fr) | 2004-06-10 |

| DE10255411A1 (de) | 2004-06-24 |

| AU2003283430A1 (en) | 2004-06-18 |

| DE50310126D1 (de) | 2008-08-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69815115T2 (de) | Druckmaschine mit veränderlichem abstellmechanismus | |

| EP0374092B1 (fr) | Encrier pour machine d'impression | |

| EP1278636B1 (fr) | Dispositif pour fixer une plaque souple | |

| EP0986454A1 (fr) | Procede et dispositif pour perforer transversalement une bande de papier en defilement | |

| WO2018189066A1 (fr) | Imprimante servant à imprimer des bandes de marquage | |

| EP0496741B1 (fr) | Cylindre de coupe | |

| EP0638420A1 (fr) | Dispositif pour tendre dans une machine à imprimer rotative | |

| DE4218211C2 (de) | Waschvorrichtung für einen Gummituchzylinder einer Druckmaschine | |

| DE69507687T2 (de) | Rakelklemmanordnung für eine druckmaschine | |

| DE10324330A1 (de) | Plattenzylinder einer Druckmaschine | |

| DE4444062A1 (de) | Verstellbare Ausrichtvorrichtung für Druckplatten | |

| EP1567342B1 (fr) | Racle a reservoir d'encre | |

| EP0567906B1 (fr) | Dispositif pour le réglage d'un porte-racle contre un cylindre donneur d'encre dans une machine d'impression rotative | |

| DE19541249B4 (de) | Gummizylinder mit einer Gummitucheinheit und mit einer Vorrichtung zum Befestigen der Gummitucheinheit | |

| WO1998016388A1 (fr) | Dispositif pour enlever des plaques | |

| DE2552837A1 (de) | Druckvorrichtung | |

| CH686821A5 (de) | Farbwerk mit einendig gelagerter Rasterwalze sowie mit einendig gelagertem Formatzylinder. | |

| DE102008020393A1 (de) | Druckmaschinenzylinder-Reinigungsvorrichtung und Druckmaschine | |

| EP0705762B1 (fr) | Appareil de distribution d'étiquettes | |

| EP0638421A1 (fr) | Cylindre à blanchet ou cylindre d'impression | |

| DE2946597C2 (de) | Einspannvorrichtung für biegsame Druckplatten | |

| WO2000073066A2 (fr) | Dispositif pour serrer et/ou bloquer des plaques souples | |

| DE3402124C2 (fr) | ||

| EP0567908A1 (fr) | Dispositif pour la fixation et le réglage d'un porte-racle contre un cylindre donneur d'encre dans une machine d'impression rotative | |

| EP0598165A1 (fr) | Dispositif pour assembler des pièces de façon tournante, par exemple leviers à lames, entraîneurs de lames et métiers à tisser pourvu d'un tel dispositif |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050628 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20070920 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: CH Ref legal event code: NV Representative=s name: BOVARD AG PATENTANWAELTE |

|

| REF | Corresponds to: |

Ref document number: 50310126 Country of ref document: DE Date of ref document: 20080821 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081209 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081020 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081009 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 |

|

| BERE | Be: lapsed |

Owner name: WINDMOLLER & HOLSCHER Effective date: 20081130 |

|

| 26N | No opposition filed |

Effective date: 20090414 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081130 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20081126 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20090731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081126 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081126 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081126 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080709 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081010 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20101112 Year of fee payment: 8 Ref country code: DE Payment date: 20101130 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: WINDMOELLER & HOELSCHER Free format text: WINDMOELLER & HOELSCHER#MUENSTERSTRASSE 50#D-49525 LENGERICH (DE) -TRANSFER TO- WINDMOELLER & HOELSCHER#MUENSTERSTRASSE 50#D-49525 LENGERICH (DE) |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111130 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50310126 Country of ref document: DE Effective date: 20120601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120601 |