EP1552140B1 - Soupape de regulation de debit volumetrique - Google Patents

Soupape de regulation de debit volumetrique Download PDFInfo

- Publication number

- EP1552140B1 EP1552140B1 EP03757826A EP03757826A EP1552140B1 EP 1552140 B1 EP1552140 B1 EP 1552140B1 EP 03757826 A EP03757826 A EP 03757826A EP 03757826 A EP03757826 A EP 03757826A EP 1552140 B1 EP1552140 B1 EP 1552140B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- control

- piston

- volume flow

- regulating valve

- section

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000001105 regulatory effect Effects 0.000 title claims 6

- 239000006185 dispersion Substances 0.000 claims 1

- 239000000446 fuel Substances 0.000 description 9

- 239000007788 liquid Substances 0.000 description 5

- 238000002485 combustion reaction Methods 0.000 description 4

- 238000002347 injection Methods 0.000 description 4

- 239000007924 injection Substances 0.000 description 4

- 230000005540 biological transmission Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000003801 milling Methods 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M63/00—Other fuel-injection apparatus having pertinent characteristics not provided for in groups F02M39/00 - F02M57/00 or F02M67/00; Details, component parts, or accessories of fuel-injection apparatus, not provided for in, or of interest apart from, the apparatus of groups F02M39/00 - F02M61/00 or F02M67/00; Combination of fuel pump with other devices, e.g. lubricating oil pump

- F02M63/0012—Valves

- F02M63/0014—Valves characterised by the valve actuating means

- F02M63/0015—Valves characterised by the valve actuating means electrical, e.g. using solenoid

- F02M63/0017—Valves characterised by the valve actuating means electrical, e.g. using solenoid using electromagnetic operating means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D7/00—Other fuel-injection control

- F02D7/002—Throttling of fuel passages between pumps and injectors or overflow passages

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M59/00—Pumps specially adapted for fuel-injection and not provided for in groups F02M39/00 -F02M57/00, e.g. rotary cylinder-block type of pumps

- F02M59/20—Varying fuel delivery in quantity or timing

- F02M59/34—Varying fuel delivery in quantity or timing by throttling of passages to pumping elements or of overflow passages, e.g. throttling by means of a pressure-controlled sliding valve having liquid stop or abutment

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M63/00—Other fuel-injection apparatus having pertinent characteristics not provided for in groups F02M39/00 - F02M57/00 or F02M67/00; Details, component parts, or accessories of fuel-injection apparatus, not provided for in, or of interest apart from, the apparatus of groups F02M39/00 - F02M61/00 or F02M67/00; Combination of fuel pump with other devices, e.g. lubricating oil pump

- F02M63/0012—Valves

- F02M63/0031—Valves characterized by the type of valves, e.g. special valve member details, valve seat details, valve housing details

- F02M63/004—Sliding valves, e.g. spool valves, i.e. whereby the closing member has a sliding movement along a seat for opening and closing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M63/00—Other fuel-injection apparatus having pertinent characteristics not provided for in groups F02M39/00 - F02M57/00 or F02M67/00; Details, component parts, or accessories of fuel-injection apparatus, not provided for in, or of interest apart from, the apparatus of groups F02M39/00 - F02M61/00 or F02M67/00; Combination of fuel pump with other devices, e.g. lubricating oil pump

- F02M63/0012—Valves

- F02M63/0031—Valves characterized by the type of valves, e.g. special valve member details, valve seat details, valve housing details

- F02M63/0056—Throttling valves, e.g. having variable opening positions throttling the flow

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M63/00—Other fuel-injection apparatus having pertinent characteristics not provided for in groups F02M39/00 - F02M57/00 or F02M67/00; Details, component parts, or accessories of fuel-injection apparatus, not provided for in, or of interest apart from, the apparatus of groups F02M39/00 - F02M61/00 or F02M67/00; Combination of fuel pump with other devices, e.g. lubricating oil pump

- F02M63/02—Fuel-injection apparatus having several injectors fed by a common pumping element, or having several pumping elements feeding a common injector; Fuel-injection apparatus having provisions for cutting-out pumps, pumping elements, or injectors; Fuel-injection apparatus having provisions for variably interconnecting pumping elements and injectors alternatively

- F02M63/0225—Fuel-injection apparatus having a common rail feeding several injectors ; Means for varying pressure in common rails; Pumps feeding common rails

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M69/00—Low-pressure fuel-injection apparatus ; Apparatus with both continuous and intermittent injection; Apparatus injecting different types of fuel

- F02M69/16—Low-pressure fuel-injection apparatus ; Apparatus with both continuous and intermittent injection; Apparatus injecting different types of fuel characterised by means for metering continuous fuel flow to injectors or means for varying fuel pressure upstream of continuously or intermittently operated injectors

- F02M69/18—Low-pressure fuel-injection apparatus ; Apparatus with both continuous and intermittent injection; Apparatus injecting different types of fuel characterised by means for metering continuous fuel flow to injectors or means for varying fuel pressure upstream of continuously or intermittently operated injectors the means being metering valves throttling fuel passages to injectors or by-pass valves throttling overflow passages, the metering valves being actuated by a device responsive to the engine working parameters, e.g. engine load, speed, temperature or quantity of air

Definitions

- the invention relates to a volume flow control valve.

- Such volume flow control valves are used in particular for controlling the fuel volume flow in the inlet to a high-pressure pump, which promotes fuel in a high pressure accumulator of a common rail injection system of an internal combustion engine.

- the flow control valve must firstly ensure that sufficient fuel is constantly available according to the operating conditions of the internal combustion engine. On the other hand, however, not too much fuel should be pumped into the high pressure accumulator, since the excess fuel is returned via a high pressure valve in the tank of the internal combustion engine and thus leads to heating of the fuel in the tank. In addition, the compression of unneeded fuel reduces the efficiency of the injection system.

- a valve in particular for the metering of fuel in an injection system of an internal combustion engine is already known.

- the valve consists of a valve body with an inlet and an outlet opening.

- a control piston is movably mounted with a control groove.

- the control piston is moved via an adjusting mechanism against the force of a return spring.

- the outlet opening is closed or it is released from the piston more or less large passage cross-section in the outlet opening.

- the fuel flows at an at least partially released outlet opening from the inlet opening via the control groove to the outlet.

- the control groove is formed by a rotationally symmetrical recess in the control piston. Due to the shape of the control piston results in a linear course of the valve characteristic.

- a characteristic here is the ratio of drive signal or piston stroke referred to the volume flow.

- a characteristic curve is frequently desired which permits a flat characteristic curve for low values of the drive signal and a steeper characteristic curve for higher values of the drive signal. This can not be realized with the usual flow control valve.

- EP 1 199 467 A2 discloses a volume flow control valve with three control edges and two flow areas.

- the object of the invention is therefore to provide a flow control valve that is simple and inexpensive to manufacture and that allows different slopes of the valve characteristic.

- the invention is characterized in that the control piston is designed as a stepped piston, which is flowed around the outside and in its lateral surface has a control geometry which is designed such that arise in dependence on the position of the control piston different slopes in the valve characteristic.

- the advantage of the invention is that even the most complicated control geometries can be easily introduced, for example, by milling in the lateral surface of the stepped piston. A deburring of the control geometry is easily possible because the edge on the lateral surface the control piston is located and thus easily accessible. Through the simple production of even complicated control geometries, a wide variety of valve characteristics can be realized cost-effectively.

- the inlet and outlet can be made by simple and inexpensive holes in the valve body.

- the piston stroke can be proportional to the control signal.

- a proportional relationship between piston stroke and control signal can be achieved with simple and inexpensive actuators, for example, an electromagnetic actuator.

- a preferred embodiment of the invention provides to introduce the Abströmgeometrie multiple radially distributed over the circumference in the control piston. This can increase the flow and in addition the radial forces are reduced to the valve piston.

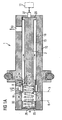

- the volume flow control valve consists essentially of the valve housing 10, the control piston 2 and the return spring 4.

- the valve housing 10 has an inlet 12 and an outlet 13, which are introduced radially into the valve housing 10.

- In the axial direction is the valve housing 10 provided with a sliding bore 18 in which the control piston 2 is guided axially movable.

- an inlet groove 16 is screwed on the inner circumference of the valve housing.

- the control piston 2 is designed as a stepped piston. Between a first end portions 28 and a second end portion 29 of the control piston 2, a control groove 15 is screwed into the control piston 2.

- the outflow geometry 8 has a first control edge 19, a second control edge 20 and a third control edge 34, by which a first flow cross-section 21 and a second flow cross-section 22 are delimited.

- the two flow cross sections 21, 22 are indicated by the dashed lines.

- the control piston 2 For receiving the return spring 4, the control piston 2 in its first end portion 28, a spring receiving bore 24 which is formed as a blind hole on.

- the return spring 4 is supported on one side on the end face of the spring receiving bore 24 and on the opposite side in a spring plate 25, which is preferably inserted into the valve housing 10 by pressing.

- the control piston 2 is displaced by an actuator 11 and a transmission member 27 against the force of the return spring 4.

- an actuator for example, an electromagnetic, mechanical, hydraulic or pneumatic adjusting is suitable.

- the adjusting member preferably allows a proportional relationship between the drive signal and the piston stroke.

- the actuator 11 If the actuator 11 receives a control signal, it shifts the control piston 2 by means of the transmission member 27 against the spring force of the return spring 4.

- the control piston moves from its first end position 5 out in the direction of a second end position 6, which in Figure 1 a left the first end position is located.

- the control piston 2 initially sets, starting from its first end position, a stroke length s1 (FIG. 1 b), in which the control piston 2 continues to completely close the inlet 12. After the control piston 2 has covered the stroke length s1, the first control edge 19, the outflow geometry 8 in the control piston 2, overlaps with the inlet edge 30 of the inlet groove 16 in the valve housing 10.

- a first flow cross-section 21 is initially established and subsequently additionally the second flow cross-section 22 is released.

- the liquid flows from the inlet 12, through the inlet groove 16, the outflow geometry 8, the control groove 15 to the outlet 13.

- the Abströmgeometrie 8 is formed in the known embodiment so that a first and a second flow area 21, 22 is formed.

- the two flow cross sections 21, 22 merge into one another, the transition being characterized by the second control edge 20. Due to the smaller width of the first flow cross-section 21, the increase in cross-section in the region of the first flow cross-section 21 with respect to the piston stroke is less than in the region of the second flow cross-section 22.

- This behavior illustrates the valve characteristic shown in FIG. In this case, the volumetric flow Q is plotted against the drive current I. At a very low drive current I, ie with a small piston stroke, the inlet groove 16 still remains completely closed, so that no liquid flows through the volume flow control valve flows.

- the control piston 2 With increasing Anstreuerstrom the control piston 2 is pressed further to the left against the force of the return spring 4. The first flow cross-section 21 is released and liquid can flow through the flow control valve. Since the cross-sectional area increase in this area is only very small, the characteristic curve has only a shallow gradient. If the control piston 2 reaches the inlet region 12, 16 with its second control edge 20, the second flow cross-section 22 is additionally released. Due to the greater width of the second flow cross-section 22, with respect to the first flow cross-section 21, there is a greater increase in the cross-sectional area. This allows more liquid flow through the flow control valve, this is reflected in the steeper course of the valve characteristic.

- the outflow geometry 8 thus enables a very fine regulation of the volume flow at low drive currents and at high drive currents a fast opening of the valve to provide the required, large amount of liquid.

- the particular advantage of the invention is that almost any Abströmgeometrie can be realized by the simple introduction of Abströmgeometrie 8 in the lateral surface 7 of the control piston 2.

- a valve characteristic can be realized with three different slopes. It is conceivable that the characteristic has, for example, at the beginning and at the end a flat and in the middle region a steep course.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Magnetically Actuated Valves (AREA)

- Lift Valve (AREA)

Claims (5)

- Soupape de régulation de débit volumique (1) comportant un piston de commande (2), monté dans un carter de soupape (10), pouvant se déplacer axialement, en s'opposant à la force d'un ressort de rappel (4), d'une première position finale (5) vers une deuxième position finale (6), le piston de commande (2) étant réalisé sous la forme d'un piston étagé et étant entouré extérieurement de liquide, et une géométrie de commande (8) étant imbriquée dans la surface enveloppe extérieure existante (7), cette géométrie étant réalisée de telle façon que, dans le piston de commande (2), soit réalisé un espace de commande qui présente exclusivement une section de passage ouverte vers la surface enveloppe extérieure (7) et une section de passage ouverte vers une face frontale du piston de commande (2), la section de passage ouverte vers la surface enveloppe extérieure (7) étant plus ou moins recouverte en fonction de chaque position du piston de commande par le carter de soupape (10), et, de ce fait, une section de passage effective plus ou moins grande étant libérée, la géométrie de commande étant réalisée de telle façon qu'il en résulte une première section de passage et une deuxième section de passage, qui se combinent l'une dans l'autre, de sorte qu'il en résulte une première arête de commande (19), une deuxième arête de commande (20) ainsi qu'une troisième arête de commande (34),

caractérisée en ce qu'il existe une quatrième arête de commande pour réaliser une courbe caractéristique de soupape comportant trois pentes montantes différentes. - Soupape de régulation de débit volumique suivant la revendication 1, caractérisée en ce qu'il existe une correspondance proportionnelle entre un signal d'enclenchement et la course du piston.

- Soupape de régulation de débit volumique suivant l'une des revendications précédentes, caractérisée en ce que la géométrie d'échappement (8) est imbriquée en plusieurs fois dans le piston de commande (2), répartie radialement sur la périphérie.

- Soupape de régulation de débit volumique suivant l'une des revendications précédentes, caractérisée en ce que le piston de commande (2) est déplacé électromagnétiquement.

- Soupape de régulation de débit volumique suivant l'une des revendications 1 à 3, caractérisée en ce que le piston de commande (2) est déplacé mécaniquement, hydrauliquement ou pneumatiquement.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10247774 | 2002-10-14 | ||

| DE2002147774 DE10247774B4 (de) | 2002-10-14 | 2002-10-14 | Volumenstromregelventil |

| PCT/EP2003/010135 WO2004036032A1 (fr) | 2002-10-14 | 2003-09-11 | Soupape de regulation de debit volumetrique |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1552140A1 EP1552140A1 (fr) | 2005-07-13 |

| EP1552140B1 true EP1552140B1 (fr) | 2007-05-16 |

Family

ID=32038624

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03757826A Expired - Lifetime EP1552140B1 (fr) | 2002-10-14 | 2003-09-11 | Soupape de regulation de debit volumetrique |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1552140B1 (fr) |

| DE (2) | DE10247774B4 (fr) |

| WO (1) | WO2004036032A1 (fr) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT1398734B1 (it) * | 2010-03-04 | 2013-03-18 | Bosch Gmbh Robert | Impianto per l'alimentazione di carburante ad un motore a combustione interna |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3642642C3 (de) * | 1986-12-13 | 1994-09-01 | Rexroth Mannesmann Gmbh | Schaltungsanordnung zur Lage- und Vorschubregelung eines hydraulischen Antriebes |

| DE3838914A1 (de) * | 1988-11-17 | 1990-05-23 | Bosch Gmbh Robert | Ventil |

| US5092299A (en) * | 1990-11-30 | 1992-03-03 | Cummins Engine Company, Inc. | Air fuel control for a PT fuel system |

| DE4308297A1 (fr) * | 1992-03-20 | 1993-09-23 | Rexroth Mannesmann Gmbh | |

| DE4443352A1 (de) * | 1994-12-06 | 1996-06-13 | Kermi Gmbh | Vorrichtung zur Steuerung eines Durchflusses, insbesondere Ventil |

| DE4444417B4 (de) * | 1994-12-14 | 2005-01-05 | Robert Bosch Gmbh | Kraftstoffversorgungsanlage |

| EP0762256B1 (fr) * | 1995-08-14 | 2001-10-31 | LuK Fahrzeug-Hydraulik GmbH & Co. KG | Soupape de régulation de débit |

| DE19933198A1 (de) * | 1999-07-15 | 2001-01-18 | Fev Motorentech Gmbh | Verfahren zur Druckregelung an einer Einspritzvorrichtung für flüssige Kraftstoffe |

| DE10023621A1 (de) * | 2000-05-13 | 2001-11-15 | Bosch Gmbh Robert | Kraftstoffeinspritzsystem für Brennkraftmaschinen |

| JP2002004977A (ja) * | 2000-06-26 | 2002-01-09 | Denso Corp | 流量制御装置 |

| ATE285035T1 (de) * | 2000-10-16 | 2005-01-15 | Woodward Governor Co | Kraftstoffeinspritzsystem |

-

2002

- 2002-10-14 DE DE2002147774 patent/DE10247774B4/de not_active Expired - Fee Related

-

2003

- 2003-09-11 WO PCT/EP2003/010135 patent/WO2004036032A1/fr active IP Right Grant

- 2003-09-11 DE DE50307301T patent/DE50307301D1/de not_active Expired - Lifetime

- 2003-09-11 EP EP03757826A patent/EP1552140B1/fr not_active Expired - Lifetime

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| DE10247774A1 (de) | 2004-04-22 |

| DE50307301D1 (de) | 2007-06-28 |

| EP1552140A1 (fr) | 2005-07-13 |

| DE10247774B4 (de) | 2005-09-29 |

| WO2004036032A1 (fr) | 2004-04-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2382520B1 (fr) | Soupape de régulation de pression proportionnelle et son utilisation pour connection hydraulique | |

| EP2236853B1 (fr) | Dispositif de robinet de vapeur réglable | |

| DE102004012831B4 (de) | Entkoppeltes Rückschlag-Druckbegrenzungsventil | |

| DE4212550C2 (de) | Ventilanordnung mit einem Wegeventil | |

| EP2243979B1 (fr) | Amortisseur d'oscillations réglable doté d'une soupape de fonctionnement d'urgence | |

| DE102008042624A1 (de) | Schieberventil zur hydraulischen Steuerung in einem Kraftfahrzeug-Automatikgetriebe | |

| DE2700058C2 (de) | Ventilanordnung | |

| DE10019254C2 (de) | Drucksteuerventil | |

| WO2003027450A1 (fr) | Actionneur a commande hydraulique pour l'actionnement d'une soupape | |

| EP0836982A2 (fr) | Clapet amortisseur | |

| EP1577565B1 (fr) | Soupape de régulation de pression | |

| DE69407704T2 (de) | Durchflussregelventil | |

| DE2336512C2 (de) | Ventil | |

| DE19514733B4 (de) | Bremsventil | |

| DE2926539C2 (de) | Regelventil für Fahrzeugbremsanlagen mit zwei Bremskreisen | |

| EP1552140B1 (fr) | Soupape de regulation de debit volumetrique | |

| DE3226809C2 (fr) | ||

| EP1001196B1 (fr) | Soupape de limitation de pression, en particulier pour des véhicules | |

| DE102018208352A1 (de) | Hydraulische Spülventilanordnung | |

| WO2008052782A1 (fr) | Soupape de non-retour | |

| DE69221377T2 (de) | Durchflussregelvorrichtung | |

| WO2004027251A1 (fr) | Unite de dosage de carburant conçue pour un dispositif d'injection de carburant | |

| WO1998021486A1 (fr) | Systeme de valve anti-retour | |

| EP1137564B1 (fr) | Soupape de frein de remorque | |

| DE19710983C2 (de) | Rückschlagventil |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050411 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): DE FR GB IT |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REF | Corresponds to: |

Ref document number: 50307301 Country of ref document: DE Date of ref document: 20070628 Kind code of ref document: P |

|

| ET | Fr: translation filed | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 20070516 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20080219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070516 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070516 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180930 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20190926 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50307301 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 50307301 Country of ref document: DE Owner name: VITESCO TECHNOLOGIES GMBH, DE Free format text: FORMER OWNER: CONTINENTAL AUTOMOTIVE GMBH, 30165 HANNOVER, DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200930 |