EP1488694B1 - Station für die vorbereitung, reinigung, desinfektion, entlausung und wassermassage von tieren - Google Patents

Station für die vorbereitung, reinigung, desinfektion, entlausung und wassermassage von tieren Download PDFInfo

- Publication number

- EP1488694B1 EP1488694B1 EP02718220A EP02718220A EP1488694B1 EP 1488694 B1 EP1488694 B1 EP 1488694B1 EP 02718220 A EP02718220 A EP 02718220A EP 02718220 A EP02718220 A EP 02718220A EP 1488694 B1 EP1488694 B1 EP 1488694B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- washing

- station

- animals

- disinfection

- hydromassaging

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01K—ANIMAL HUSBANDRY; CARE OF BIRDS, FISHES, INSECTS; FISHING; REARING OR BREEDING ANIMALS, NOT OTHERWISE PROVIDED FOR; NEW BREEDS OF ANIMALS

- A01K13/00—Devices for grooming or caring of animals, e.g. curry-combs; Fetlock rings; Tail-holders; Devices for preventing crib-biting; Washing devices; Protection against weather conditions or insects

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01K—ANIMAL HUSBANDRY; CARE OF BIRDS, FISHES, INSECTS; FISHING; REARING OR BREEDING ANIMALS, NOT OTHERWISE PROVIDED FOR; NEW BREEDS OF ANIMALS

- A01K13/00—Devices for grooming or caring of animals, e.g. curry-combs; Fetlock rings; Tail-holders; Devices for preventing crib-biting; Washing devices; Protection against weather conditions or insects

- A01K13/001—Washing, cleaning, or drying devices

Definitions

- the present invention relates to a station for conditioning, washing, deparasitation and hydromassage of animals, from among assemblies comprising an enclosure with the means required for conditioning, washing, disinfection and deparasitation of animals, which are also provided with means for control, safety and programming the assembly.

- the invention is characterised by its special configuration, which allows including in a single assembly the means needed for conditioning before and after washing, disinfection, deparasitation, hydromassage and drying.

- the station consists of a glassed module insulated from the outside in which the pet is conditioned before bathing it; inside this glassed module is an enclosure where a disinfection process takes place before washing and rinsing, with the hydromassage effect obtained for animals by means of water applied at a controlled pressure; the animals are also dried and deparasitised inside this enclosure.

- This hydraulic circuit incorporates a lime remover at the inlet of the general water mains for processing the water, providing an improved performance on the animal's fur and preventing lime deposits on the circuit elements.

- the invention is also characterised by incorporating a hydraulic circuit that performs a disinfection process of the cabin before each new animal is bathed.

- Liquids are drained by a single motorised pump and logical switching of the washing and rinsing circuit electrovalves.

- Said module is also provided with an extractor fan for evacuating bad odours and renewing the air.

- a pressure controller (pressostat) as a safety device which, in the event of a pressure increase, will electrically disconnect the circulation pump and cut off water passage to the hydraulic circuit.

- a pressure gauge indicates the working pressure in the hydraulic circuit.

- the hydraulic circuit includes a regulator to set the pressure and flow best suited for the animals and the working process of the equipment.

- the floor of the enclosure on which the animal is placed can swivel and fold, and incorporates a load cell which detects the presence of the animal and blocks and prevents the disinfection process, as highly concentrated products are used with a high disinfecting capacity to eliminate viruses, bacteria and fungi.

- the load cell records the weight of the animal on a digital display.

- a pressostat is provided that detects the variation of water pressure between the microfilter inlet and outlet, sending a signal to the PLC so that if the pressure is lower than a predetermined one a signal is sent to the command control to indicate that the filter is saturated. After the filter has been cleaned the warning lamp and sound will be turned off.

- the air generation turbine incorporates an air generation turbine to obtain the flow and pressure required to dry the animals.

- the air is projected through an opening located on the top of the cabin, allowing to displace the water on the animals downward.

- the air generation turbine is controlled with a frequency variator-converter that allows adjusting the pressure and airflow according to each animal. This adjustment is made from the control board.

- a pressurised air generator is used to perform an automatic nozzle cleaning.

- the present invention belongs to the field of means used to condition, wash, disinfect and hydromassage animals.

- None of the known systems is provided with a lime-removal unit for processing the water.

- the enclosure where cleaning is performed lacks a module in which the pet can be conditioned before washing, or one to brush and groom it after washing. Likewise, available enclosures do not allow supplying additional products for washing, disinfection and deparasitation either manually or automatically.

- Drying systems are known that use a fan, but which have the disadvantage of lacking a variator-converter to regulate the air pressure and flow. None of the presently known systems incorporate means for charging by tokens, cards or coins.

- the object of the present invention is to overcome the above disadvantages by developing a station for conditioning, washing, disinfection and deparasitation and hydromassage as described below.

- a station for conditioning, washing, disinfection and deparasitation and hydromassage of animals comprises a glassed module with an area in which the animal can be conditioned before and after washing and drying, provided with an inner lamp, an extraction fan for air renewal and evacuation of bad odours.

- the station is provided with an enclosure that is entered through a glassed door, which door incorporates a device that stops the various cycles if the door should be opened. It incorporates an internal lamp that is automatically turned on when a cycle begins and is turned off when it ends. Together with the enclosure are provided the necessary activation, control and safety verification means.

- the station walls are made of a material that insulates from heat and cold, having a glassed area and another are provided with removable doors that allow accessing the machinery and equipment.

- the enclosure where the washing, disinfection and deparasitation and hydromassage operation takes place is designed to ensure the comfort of the animals without causing them any harm or injury, as there are no moving or sharp elements inside it.

- the top part of the enclosure, its ceiling, is set inclined so that water drops will not fall on the animal after the washing, rinsing, deparasitation and drying operation has finished.

- Both the washing and rinsing process and the liquid evacuation process are performed by a single pump and logical switching of the washing and rinsing circuit electrovalves, thereby simplifying the circuit.

- the water circuit is provided with a cold water inlet from the mains water system through a lime remover that feeds a gas heater or electrical heater and simultaneously a thermostatic mixing valve, allowing to mix the cold water from the general system and the hot water from said gas heater or electrical heater in order to obtain the suitable water temperature for the animal washing and rinsing operation.

- This mixed water is sent to a hot water maintenance unit where the water is kept at the correct temperature for the washing and rinsing process.

- the hot water maintenance unit has a temperature probe that constantly sends signals to a temperature controller, which compares actual values with preselected ones and sends a signal to the programmable automat or PLC provided in the electronics system, so that if the temperature of the water maintenance unit is above or below the temperature selected in the temperature controller the corresponding electrovalve is opened, adding cold or hot water until the water is cooled or heated to the temperature selected in said controller. Likewise, if the water temperature is above or below said selected temperature, as a safety system the washing and rinsing cycles are blocked until the temperature matches the selected temperature.

- Said maintenance unit has two indicators for the minimum and maximum levels in order to monitor the water level and an overflow system that acts as an emergency drain.

- the invention is also characterised in that it incorporates a hydraulic system that performed a cabin disinfection process before washing each different animal.

- the floor of the enclosure where the animals are washed disinfected and deparasitised can swivel and fold, so that a load cell can be activated. If this cell detects the presence of an animal in the enclosure it sends a signal to the automat preventing the disinfection process from taking place, as the products used are highly concentrated and have high disinfection strength. It also sends a signal to a digital display where the animal's weight is displayed.

- the enclosure where the animal is washed, disinfected and deparasitised has with an overflow pipe at a certain height, which acts as an emergency drain if the gauge that controls the liquid-emptying means should fail.

- the hydraulic circuit includes a device for controlling the water flow and pressure with which the pressure is adjusted to a suitable one for washing and rinsing the animals.

- a safety device or pressostat which controls and disconnects the electrical system, cutting off the water flow if there is a possible overpressure, preventing harm to the animal and equipment.

- a pressure gauge installed in the hydraulic system indicates the working pressure at all times.

- the enclosure is provided with means to supply the liquids or other products required for washing and disinfection: a Venturi-effect system for automated aspiration activated by a water-circuit absorption and depression system.

- the flow is controlled by manual cone-needle regulation valves, and it is opened by electrovalves provided for such purpose. It is also possible to automatically supply the liquids or gels for washing and disinfection by pulse electrovalves or by a hydraulic injector.

- the hydraulic circuit includes check valves to prevent water from returning to the disinfection and washing product tanks.

- the spray nozzles provided inside the enclosure are removable nozzles that are designed and built in order to obtain a mist effect.

- water particles will not harm the animal, providing a hydromassage effect, and on the other they will soak the animal's fur so that the skin is reached, carrying away any dirt that may be there.

- All of the station safety systems and programs are controlled by a PLC (Programmable Logic Programmer) in which are programmed the various cycles for washing, rinsing, deparasitising and disinfecting. It is provided with sequential indicators by which it is possible at all times to know the operation that is being performed and to view safety messages. Also provided is a sound system that uses a voice system to describe the various steps reached in the different cycles. A voice will provide the information displayed on the sequential indicators. It may be programmed in several languages.

- the different processes are initiated by a manual or automatic selector with a token, card or coin operated charging system.

- Both the door of the washing cabin and the door of the electrical board have a safety switch that will stop any cycle if the door is opened.

- a manual stop switch is installed to stop the cycle at will.

- a pressurised air generator is included to provide the airflow and pressure required to dry the animals.

- the air is propelled through an upper slit of the enclosure, so that the water is pushed down to facilitate drying the animal.

- a frequency variator-converter is installed for the drying cycle that allows adjusting the airflow and pressure generated by the turbine depending on the type of animal.

- This variator-converter is also used to adjust the rotation speed and pressure of the hydraulic circuit at the motor pump for washing, recirculation and drainage. This drive and control function is performed from the control board, thus allowing to set the different frequencies and voltages used in other countries.

- the drying circuit includes a safety system to disconnect the drying cycle if the drying circuit overheats.

- This system is also provided with a temperature detector that constantly sends a signal to a temperature controller, which compares the actual values with the preselected ones, sending a signal to the programmable automat or PLC of the electronic system; if the drying temperature is higher than that preselected in the controller, the electrical supply is disconnected until the air is cooled to the selected temperature.

- a filter is installed in the hydraulic circuit to retain any impurities that are removed from the animal, while a second microfilter collects water impurities to stop them from reaching the drain.

- a pressostat is incorporated at the outlet of the microfilter to detect the variation of water pressure between the microfilter inlet and outlet, sending a signal to the PLC if the pressure is less than the predetermined one and sending a signal to the control panel to indicate that the filter is saturated. After the filter has been cleaned the filter warning lamp and sound are turned off.

- the station is provided with an extraction fan to renew the internal air and evacuate bad odours.

- An automatic hygrometer is installed inside the enclosure of the station machinery and equipment; if this hygrometer detects a higher humidity than the set one another extraction fan, that is not the same as mentioned in the previous paragraph, is connected to extract the humidity from the enclosure.

- the machine is provided with counters to control the number of washings and dryings performed.

- Figure 1 shows how the station object of the invention is provided with a glassed module (2), inside which there is sufficient space to house a table and condition animals before and after washing. It is also provided with its own enclosure (1) for washing, rinsing, disinfecting and drying, with a control panel (3).

- FIG 2 shows the control panel (3), which is provided with a token slot (4) for the washing and drying service and another token slot (5) for optional drying. Also shown is the emergency stop button (6), the disinfection button (26) and the safety warnings (7), such as for water too hot or not enough water. Also provided is a warning system (7) to indicate that the microfilter (48) ( Figure 11) is saturated. Process sequential indication system (74).

- Figures 3 and 4 show the minimum (10) and maximum (11) levels of the hot water maintenance unit (8) and the overflow pipe (70) as the safety measure if the control level should fail; also shown in the figure 4 is the temperature probe (50), the cold water inlet (78) and hot water inlet (79) to the maintenance unit that allow to adjust the preselected temperature, while figure 5 shows the overflow pipe (12) inside the enclosure (1) as a safety means in the event that the level monitor (37) should fail.

- FIG. 6 and figure 11 show the mixing thermostatic valve (39) meant to mix the cold water from the general mains (65) and the hot water from the electrical heater or gas heater (51).

- the outlet of mixed water from the thermostatic valve feeds the maintenance unit with said water at a controlled temperature (8), being provided with temperature control means (50) that send a signal indicating the temperature of the water to the controller, which then compares this with the preselected temperature; if the temperature is higher or lower than the preselected one a signal is sent to the PLC to open the electrovalves that supply hot or cold water, allowing to adjust the water temperature to the programmed temperature.

- temperature control means 50

- FIG. 7 shows part of the hydraulic circuit, which comprises a motor pump (53) for recirculating the liquids used in the washing and rinsing process.

- this motor pump (53) is also used together with the logical switching of the electrovalves (15, 16, 52 and 62) to evacuate said liquids; a pressure gauge (20) indicating the working pressure, a pressure and flow meter (64) ( Figure 11), a pressostat (22) as an overpressure safety measure, as well as for electrovalve (14), for filling the maintenance unit (8), the electrovalve (15) for initiating the filling of the hot water maintenance unit (8) and the electrovalve (16) for recirculating the water collected at the bottom of the enclosure (1).

- Figure 8 shows the impulse electrovalve (17) next to a hydraulic injector (75) that can be used instead of the impulse electrovalve; said electrovalve is provided with a liquid inlet check valve (17.1) and an outlet check valve (17.2), a regulator (17.3), a scale selector (17.4), an impulse electrovalve switch (17.5) and a protection fuse (17.6).

- Figure 9 shows an enlarged view of a safety capacitance sensor (68) installed on the frame of the enclosure door (72), so that if said door should open during the operational cycle of the machine the system will stop.

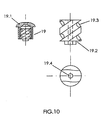

- Figure 10 shows the spray nozzle (19), which can be removed and which comprises an external body (19.1) that houses a cylindrical element (19.2) which is provided on its perimeter with a semicircular section propeller (19.3) with a through orifice (19.4)

- Figure 11 shows the hydraulic circuit of the assembly that is the object of the invention, revealing the inlet (65) of mains water that after passing through a manual valve (54), passes through the lime remover (73) and continues towards both the thermostatic valve (39) and the gas heater or electrical heater (51), with two check valves (38) provided before it.

- the electrical or gas heater (51) heats the water and then with the thermostatic valve (39) mixes the cold water (65) from the mains and the water from the electric or gas heater (51) at the pre-programmed washing temperature, storing it in the maintenance unit (8).

- this unit is provided with a temperature probe (50) that sends a signal to the PLC, so that if the temperature in this unit should be higher or lower than the selected temperature it is adjusted by means of an independent circuit with an inlet of cold water from the mains with a manual valve (54) and an electrovalve (74) and an inlet from the electric or gas heater (51) with a manual valve (54) and an electrovalve (77), adjusting the water temperature in said unit to that previously selected with the controller.

- the maintenance unit is provided with sensors that detect the minimum level (10) and the maximum level (11) for controlling the unit's emptying and filling.

- the controlled water maintenance unit (8) is provided at its top with an overflow pipe (70) so that if the valve (14) is not properly closed the water can leave through said pipe directly to the drain (66).

- Said figure also shows the electrovalve (14) for filling the maintenance unit (8), the electrovalve (15) for starting the wash and the electrovalves (16) and (62) for recirculation, while the electrovalve (52) performs the drainage (66).

- the entire assembly requires only one motor pump (53) for washing, rinsing, recirculation and for evacuation of the liquids, by virtue of a logical programmed switching of the electrovalves (15, 16, 52 and 62).

- the part comprising the Venturi system for disinfection shows an opening and closing electrovalve (57), a storage deposit (55) and a level monitor (56), as well as a needle valve for manual control (58), as well as the corresponding check valve (38) to prevent an early mixture of the products.

- a further electrovalve (63) opens the air supply for automatic cleaning of the spray nozzles, provided with the corresponding manual valve (54) and check valves (38).

- the inside of the enclosure (1) is also shown to have a swivelling and folding floor (36) beneath which is a load cell (35) meant to detect the presence of the animal and therefore to prevent the activation of the disinfection process in the enclosure (1).

- a filter (47) At the outlet of the enclosure base is a filter (47) which prevents any impurities from entering the hydraulic circuit.

- a safety overflow pipe (12) and a level monitor (37) for the enclosure water are also provided.

- microfilter (48) located in the drain circuit that collects impurities in the used water in order to prevent these from reaching the elements of the circuit and the drain (66).

- a pressostat (59) that detects the pressure difference in the hydraulic circuit between the filter inlet and outlet, showing on the control panel that the filter is saturated if the pressure is beneath a predetermined pressure. The warning message will remain until the filter has been cleaned.

- the hydraulic circuit is provided with a safety pressostat (22), a pressure and flow regulator (64) and a pressure gauge (20) that shows the circuit pressure.

- the station is provided on the inside with an air expeller-suctioner (71) for vacuuming and hygiene of the enclosure (2).

- the materials, shape, size and arrangement of the elements may vary as long as the essence of the invention remains unchanged.

Claims (22)

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren, dadurch gekennzeichnet, dass die besagte Station aus Platten besteht, die diese von Aussen isolieren und ein Glassmodul (2) umfasst, in dem es möglich ist, das Tier vor und nach dem Waschen vor- und nachzubereiten, weiterhin umfasst sie das Waschgehäuse (1) an sich und das Schaltpult (3), das über einen manuell betriebenen Knopf (26) verfügt, um den Desinfektionszyklus vor jedem Waschen zu beginnen und einen Notstoppknopf (6), sowie Münzschlitze zum Waschen, Suplen und Trocknen (4) und zusätzlichem Trocknen (5), ein sequenzielles Zyklussystem (74), bei den die gesamte Einheit von eine programmierbaren logischen Kontrollgerät (PLC) kontrolliert wird, das über ein Fernkommunikationssystem verfügt und einen Geruchsextraktor; ein weiterer Extraktor, der durch ein automatisiertes Hygrometer kontrolliert wird, um die interne Feuchtigkeit abzusaugen, einen Frequenzumwandler, sowie Anzeigen für das höchste (11) und niedrigste (10) Niveau der Heisswassereinheit (8); innerhalb des Gehäuses (1) ist eine Ladezelle (25) installliert, die durch das Gewicht des Tiers aktiviert wird, mittels des schwenkbaren und faltbaren Bodens (36), so dass die interne Desinfizierung des Waschgehäuses (1) nicht möglich ist, während sich ein Tier im Inneren befindet; Das Gehäusedach ist geneigt und verfügt über Sprühdüsen (19), durch die das Wasser gedrückt wird und die abnehmbar und selbstreinigend sind; zusätzlich umfasst der Wasserkreislauf Sicherheitsvorrichtungen, Drosselventile (38), Handventile (54) und Elektroventile (14, 15, 16, 52, 62, 76 und 77), einen Wasserdruck- und Flussregler (64), eine Motorpumpe (53) zum Waschen, Spülen, Rezirkulieren und Drainieren, sowie ein thermostatisches Mischventil (39); ein System zum Beladen mittels, Karten, Münzen oder Geldstücken (4) (5), Wasch- und Trockenzähler, einen Kalkentferner (73).

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, gekennzeichnet durch eine Wartungseinheit (8), die Wasser bei einer vorgewählten Temperatur speichert und eine Temperaturerkennungsvorrichtung (5), die ein Signal zum Temperaturregler sendet, der die aktuelle Temperatur mit der vorgewählten Temperatur abgleicht und ein Signal an das PLC sendet, das durch die Elektroventile (76) und (77) entweder heisses oder kaltes Wasser in die Wartungseinheit einspeist, wodurch die Temperatur an den vorgewählten Wert angepasst wird; zusätzlich verfügt jede Wartungseinheit (8) über eine Höchststandanzeige (11) und Niedrigststandanzeige (10) und eine Wasserüberlaufsystem (70) als Notentwässerung.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass das Thermostat- oder Mischventil (39) es erlaubt, die programmierte Temperatur für den Zyklus zu wählen, indem kaltes Wasser des Rohrnetzes (65) mit heissem Wasser aus dem elektrischen oder gasbetriebenen Boiler (51) gemischt wird.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass die Spraydüsen (19) erneuert und mit Pressluft automatisch gereinigt werden können; sie umfassen einen externen Körper (19.1), einen internen Teil (19.2), der über einen Propeller (19.3) verfügt mit einem halbrunden Querschnitt und einem vertikalen durchgehenden Loch (19.4), das Nebel und einen Wassermassageeffekt erzeugt; für das automatische Reinigen der Düsen ist ein Druckluftgenerator vorgesehen.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass der Desinfektionsmittelspender ein Depot (55) umfasst und einen Niveauanzeige (56), wobei das Desinfektionsmittel dem Wasserkreislauf manuell kontrolliert durch ein Venturi-System zugeführt wird, mit einem manuell regulierten Kegelnadel-Ventil (58), während das Öffnen und Schliessen durch die Elektroventile (57) und (61) durchgeführt wird, die hierzu mit den entsprechenden Drosselventilen (38) versehen sind.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass der Wasserkreislauf Drosselventile (38) umfasst, die den Rückfluss verschiedener Flüssigkeiten in den Heisswassereinheit und das Zusatzflüssigkeitendepot verhindert, damit es nicht zu frühen und nicht kontrollierten Mischungen kommt.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass die Motorpumpe (53) des Wasserkreislaufs, die für das Waschen und Spülen und Rezirkulieren der Flüssigkeiten verwendet wird, auch dazu verwendet wird, die besagten Flüssigkeiten abzulassen, nachdem die Elektroventile des Kreislaufs logischerweise umgestellt wurden.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass die Gels oder Reinigungsprodukte automatisch durch Impulselektroventile und Speicherdepots (18) mit einer Niveauanzeige (21) zugeführt werden.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass die Station über einen Geruchsextraktor verfügt und einen zweiten Extraktor, der an ein automatisches Hygrometer angeschlossen ist, der das Feuchtigkeitsniveau in dem Gehäuse und den Elementen und der Ausrüstungskabine reduziert.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass sowohl das verglaste Modul (2), als auch das Gehäuse (1) über eine innere Lampe verfügen, wobei die Lampe des Gehäuses (1) automatisch angestellt wird, wenn der Zyklus beginnt und ausgestellt wird, wenn der Zyklus beendet ist.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass das Gehäuse (1) unter dem dreh- und faltbaren Boden (36) über eine Ladezelle (35) verfügt, die einerseits als Sicherheitselement dient, um zu verhindern, dass der Desinfektionszyklus beginnt, wenn sich ein Tier im Inneren des Gehäuses (1) befindet und ausserdem als Mittel verwendet wird, um das Gewicht des Tiers anzuzeigen, das auf einem digitalen Display erscheint; zusätzlich verfügt das Innere des besagten Gehäuses (1) über ein Überlaufrohr als Notentwässerung (12) und eine Wasserniveauanzeige (37).

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass die unterschiedlichen Verfahren durch eine sequenzielle Anzeigevorrichtung (74) angezeigt werden und akkustisch durch ein Stimmsystem angezeigt werden.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass sie über ein Interkommunikationssystem verfügt, durch das der Betrieb der Stationen fernüberprüft werden kann und das Niveau der Zusatzflüssigkeiten kontrolliert werden kann.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass ein Filter (47) in den Wasserkreislauf eingebaut wird, um Unreinheiten aufzuhalten und zu verhindern, dass diese das Tier während des Rezierkulierungsverfahrens erreichen oder die Elemente des Wasserkreislaufs , während ein zweiter Mikrofilter (48) Unreinheiten aus dem Wasser sammelt, um zu verhindertn, dass sie die Kreislaufelemente oder die Entwässerung erreichen. Am Ausgang des Mikrofilters (48) ist ein Druckmesser (59) vorgesehen, der die Veränderungen des Drucks im Wasserkreislauf zwischen dem Aus- und dem Eingang des besagten Mikrofilters entdeckt und ein Signal an das PLC sendet, und wenn der Druck unter einen bestimmten Wert fällt, wird ein Signal an das Schaltpult (3) gesendet, um anzuzeigen, dass der Filter gesättigt ist; ist der Filter gesäubert, gehen das Warnlicht und das akkustische Signal aus.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass die Tür (72) des Gehäuses (1) über einen Kapazitätsensor (68) verfügt, der den Zyklus unterbricht, wenn die besagte Tür (72) geöffnet werden sollte, während die Tür des elektrischen Schaltsschranks mit einem Sicherheitsschalter ausgestattet ist, der die Stromgeneralversorgung der Einrichtung ausschaltet, wenn die besagte Tür geöffnet wird.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass der Wasserkreislauf einen Wasserdruck- und Flussregler (64) umfasst, sowie einen Druckmesser (20), der den Druck des Wasserkreislaufs anzeigt, um diesen zu regulieren, wobei als Sicherheitsvorrichtung ein Druckmesser (22) angebracht ist, der im Falle eines Druckanstiegs das Wassersystem abstellt.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass ein Luftausstosser und -ansauger in der Station installiert wird, um den Waschvorgang bei dem Tier abzuschliessen und das Gehäuse zu saugen und hygienisch zu halten.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass en Frequenzumwandler installiert ist, der verwendet wird, um sowohl die verschiedenen Geschwindigkeiten der Trockenturbine zu regulieren und die Umdrehungsgeschwindigkeit der Motorpumpe (53), als auch als Mittel, um die Station an die verschiedenen Frequenzen und Spannungen der Stromnetze anderer Länder anzupassen.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass ein Sicherheitssystem in dem Trockensystem installiert ist, das den Trockenzyklus ausstellt, wenn der Kreislauf überhitzt ist; das System verfügt auch über eine Temperaturanzeige, die ständig ein Signal zu einer Temperaturkontrolle sendet, die die aktuellen Werte mit den vorgewählten Werten vergleicht und dem programmierbaren Automaten oder dem im elektronischen System vogesehenen PLC ein Signal sendet, so dass bei Übersteigen der vorgewählten Temperatur bei der Kontrollvorrichtung, der elektrische Strom augeschaltet wird, bis die Luft auf die besagte vorgewählte Temperatur abgekühlt ist.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass die regulierte Wassererhaltungseinheit (8) über einen oberen Teil mit einem Überlaufrohr (70) ausgestattet wird, so dass, wenn das Elektroventil (14) nicht richtig schliesst, dieses als Notentwässerung dient, wodurch das Wasser direkt (66) die Hauptentwässerung erreichen kann; ein weiteres Überlaufrohr (12) auf der Rückseite des Gehäuses (1) ermöglicht das Ablassen des Wassers, wenn die Anzeige (37) ausfallen sollte.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 1, dadurch gekennzeichnet, dass die Drucklufterzeugungseinheit (6) verwendet wird, um die Spraydüsen (19) automatisch durch das Elektroventil (63) und das Handventil (54) zu reinigen.

- Station zum Vorbereiten, Waschen, Desinfizieren, Ungezieferentfernen und Wassermassieren von Tieren gemäss Anspruch 8, dadurch gekennzeichnet, dass die Reinigungsgels oder -flüssigkeiten automatisch durch eine Hydraulikeinspritzung (75) zugeführt werden.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/ES2002/000146 WO2003079774A1 (es) | 2002-03-22 | 2002-03-22 | Estacion para la limpieza, desinfeccion y desparasitacion e hidromasaje de animales |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1488694A1 EP1488694A1 (de) | 2004-12-22 |

| EP1488694B1 true EP1488694B1 (de) | 2007-01-17 |

Family

ID=28051933

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02718220A Expired - Lifetime EP1488694B1 (de) | 2002-03-22 | 2002-03-22 | Station für die vorbereitung, reinigung, desinfektion, entlausung und wassermassage von tieren |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US7011044B2 (de) |

| EP (1) | EP1488694B1 (de) |

| JP (1) | JP4087796B2 (de) |

| KR (1) | KR20050002870A (de) |

| AU (1) | AU2002249294A1 (de) |

| DE (1) | DE60217725D1 (de) |

| ES (1) | ES2278908T3 (de) |

| MX (1) | MXPA04009219A (de) |

| TN (1) | TNSN04153A1 (de) |

| WO (1) | WO2003079774A1 (de) |

Families Citing this family (41)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5985557A (en) | 1996-01-24 | 1999-11-16 | Third Wave Technologies, Inc. | Invasive cleavage of nucleic acids |

| ES2250005B1 (es) * | 2004-09-30 | 2007-06-01 | Netwash Aplicaciones Tecnicas Del Lavado, S.L. | Maquina automatica de hidromasaje para mascotas. |

| ES2277508B1 (es) * | 2005-03-15 | 2008-06-01 | Javier Rebenaque Nieto | Maquina de hidromasaje para mascotas. |

| US20090044137A1 (en) * | 2005-06-09 | 2009-02-12 | Whirlpool Corporation | Consumable holder with user interface data |

| US20090044129A1 (en) * | 2005-06-09 | 2009-02-12 | Whirlpool Corporation | Graphical user interface to control interactions between an appliance and a consumable holder |

| US20090040066A1 (en) * | 2005-06-09 | 2009-02-12 | Whirlpool Corporation | Consumable holder with routable data packet for an appliance |

| US8477007B2 (en) * | 2005-06-09 | 2013-07-02 | Whirlpool Corporation | Appliance and a consumable holder in a network |

| US8264318B2 (en) * | 2005-06-09 | 2012-09-11 | Whirlpool Corporation | Consumable holder with converter |

| US8395476B2 (en) * | 2005-06-09 | 2013-03-12 | Whirlpool Corporation | Consumable holder with taxonomy |

| US8442042B2 (en) * | 2005-06-09 | 2013-05-14 | Whirlpool Corporation | Appliance and a consumable holder with an embedded virtual router |

| US8314678B2 (en) * | 2005-06-09 | 2012-11-20 | Whirlpool Corporation | Consumable holder with a cycle structure for an appliance |

| US7677202B2 (en) * | 2005-09-14 | 2010-03-16 | Shoei Butsuryu Co., Ltd. | Pet cleaning apparatus |

| US20080190375A1 (en) * | 2007-02-12 | 2008-08-14 | German Michael K | Animal Grooming Apparatus |

| US20080282991A1 (en) * | 2007-05-17 | 2008-11-20 | Suzan Kimberly Krasoff | Coin-operated dog crate |

| US8461959B2 (en) * | 2008-10-23 | 2013-06-11 | Whirlpool Corporation | Consumable holder with process control apparatus |

| US20100102051A1 (en) * | 2008-10-23 | 2010-04-29 | Whirlpool Corporation | Consumable holder with electronics to communicate with an appliance |

| US20100125364A1 (en) * | 2008-11-20 | 2010-05-20 | Whirlpool Corporation | Configurable consumable holder for an appliance |

| US8118997B2 (en) * | 2008-10-23 | 2012-02-21 | Whirlpool Corporation | Smart filter for an appliance |

| US8010211B2 (en) * | 2008-10-23 | 2011-08-30 | Whirlpool Corporation | Appliance with a service interface for communicating with a consumable holder |

| US20100266776A1 (en) * | 2009-04-21 | 2010-10-21 | Mt Industries, Inc. | Automated skin spray and dry system |

| US20110017147A1 (en) * | 2009-07-22 | 2011-01-27 | Dale Petruzzi | Pet grooming station and system |

| US8784390B2 (en) | 2009-12-04 | 2014-07-22 | Sunless, Inc. | Skin treatment spray nozzle system for automatic spray gantry |

| US20110202019A1 (en) * | 2009-12-04 | 2011-08-18 | Mt Industries, Inc. | Hand held skin treatment spray system with air heating element |

| CA2824654C (en) * | 2011-01-11 | 2016-01-05 | Gea Farm Technologies, Inc. | A device and method to treat animal hooves |

| US8416554B2 (en) * | 2011-04-27 | 2013-04-09 | The Boeing Company | Multi-phase decontamination of aircraft cabin interior |

| US8544418B2 (en) * | 2011-05-17 | 2013-10-01 | Hong Kong Tesla Technology Limited | Intelligent doghouse |

| US8790319B2 (en) | 2011-07-15 | 2014-07-29 | Sunless, Inc. | Method and system for applying a heated skin treatment spray |

| US8544419B1 (en) * | 2011-11-23 | 2013-10-01 | Spalding Laboratories, Inc. | Livestock insect-removal systems and related methods |

| US8505493B2 (en) * | 2011-11-23 | 2013-08-13 | North Carolina State University | Livestock insect-removal systems and related methods |

| KR101285033B1 (ko) * | 2011-12-19 | 2013-07-11 | 지철묵 | 자동 애완동물 목욕장치 |

| CA2827099A1 (en) | 2012-09-17 | 2014-03-17 | Sunless, Inc. | Precision pumping system for spray treatment cycles |

| JP5478763B1 (ja) * | 2013-09-14 | 2014-04-23 | 株式会社ドリーム産業 | ペット用ボックスドライヤー |

| JP5751652B1 (ja) * | 2014-05-30 | 2015-07-22 | 株式会社ドリーム産業 | トリミングボックス |

| KR101961748B1 (ko) * | 2017-11-28 | 2019-07-17 | 문병철 | 반려동물용 스타일러 하우스 |

| CN108703085B (zh) * | 2018-05-23 | 2023-08-01 | 四川大学 | 能均匀换热的变截面禽舍、禽舍组、禽舍设计和改建方法 |

| CN112352753B (zh) * | 2020-11-06 | 2022-04-12 | 南阳市经济作物技术推广站 | 一种食用菌栽培用灭虫装置 |

| KR102585742B1 (ko) * | 2021-05-21 | 2023-10-06 | 주식회사제이앤케이씨 | 스마트 반려동물 샤워 장치 |

| CN113456286B (zh) * | 2021-06-12 | 2024-03-19 | 梅胜尧 | 一种实验动物连续滴注药物用固定装置 |

| KR102386900B1 (ko) * | 2022-01-21 | 2022-04-14 | 엠넥스텍 주식회사 | 지능형 복합 키오스크 시스템 |

| CN114600789B (zh) * | 2022-02-23 | 2023-08-22 | 陕西鑫汉宝生物科技有限公司 | 一种具有除菌驱虫效果的烘干式动物保健护理装置 |

| CN115104547B (zh) * | 2022-08-16 | 2023-06-16 | 安徽中龙神力生物科技有限公司 | 一种牲畜体表驱虫药物喷洒装置 |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2499174A (en) * | 1944-09-30 | 1950-02-28 | Turner James Paul | Cattle treating apparatus |

| US3884191A (en) * | 1974-02-21 | 1975-05-20 | Pansy M Stout | Animal bathing and drying apparatus |

| US4056078A (en) * | 1976-08-03 | 1977-11-01 | Clem Blafford | Automatic dog washer |

| US4057032A (en) * | 1976-08-09 | 1977-11-08 | James Christ Dimitriadis | Animal bathing apparatus |

| IT8052906V0 (it) | 1980-02-01 | 1980-02-01 | Hogar Srl | Apparecchio automatico per il lavaggio di cani e simili animali |

| US4382424A (en) * | 1981-11-27 | 1983-05-10 | Hogar S.R.L. | Automatic apparatus for cleaning dogs and similar animals |

| US4549502A (en) * | 1982-04-19 | 1985-10-29 | Bahram Namdari | Apparatus for washing animals |

| IT8254051V0 (it) * | 1982-12-10 | 1982-12-10 | Mario Altissimo | Apparecchio automatico per il lavaggio di cani e simili animali |

| JPH035243Y2 (de) * | 1985-04-27 | 1991-02-12 | ||

| ES1027445Y (es) | 1994-03-24 | 1995-02-16 | Perez Miguel Romagosa | Maquina automatica para el lavado, secado y tratamiento antiseptico de animales. |

| US5448966A (en) * | 1994-08-26 | 1995-09-12 | Mckinnon; Brenda | Automatic animal washing system |

| GB2293532B (en) * | 1994-09-28 | 1998-03-04 | Chen Yen Liang | Multi-function apparatus for caring for pets |

| US5630379A (en) * | 1996-02-12 | 1997-05-20 | Ssi Corporation | Electrically controlled spraying device for cleaning and treating animals |

| FR2753877B1 (fr) | 1996-09-27 | 1999-05-28 | Besnard Michel | Cabine autonome et transportable pour le nettoyage des animaux, en particulier des animaux domestiques |

| US5769029A (en) * | 1996-11-04 | 1998-06-23 | Marshall; William J. | Animal bathing and drying system |

| EP0861590B1 (de) | 1997-02-28 | 2000-11-15 | Leadercan, S.L. | Automatische Vorrichtung zum Waschen und Trocknen von Tieren |

| US5724918A (en) * | 1997-03-03 | 1998-03-10 | Leadercan, S.L. | Automatic washing and drying machine for animals |

| ES1043452Y (es) | 1999-05-07 | 2000-05-01 | Munoz Angel Maria Segura | Maquina para la limpieza, desinfeccion y desparasitacion de animales. |

| JP2003310080A (ja) * | 2002-04-17 | 2003-11-05 | Meitetsu Lee | 愛玩犬洗浄装置及びその制御方法 |

-

2002

- 2002-03-22 KR KR10-2004-7014738A patent/KR20050002870A/ko not_active Application Discontinuation

- 2002-03-22 DE DE60217725T patent/DE60217725D1/de not_active Expired - Lifetime

- 2002-03-22 JP JP2003577618A patent/JP4087796B2/ja not_active Expired - Fee Related

- 2002-03-22 MX MXPA04009219A patent/MXPA04009219A/es active IP Right Grant

- 2002-03-22 WO PCT/ES2002/000146 patent/WO2003079774A1/es active IP Right Grant

- 2002-03-22 AU AU2002249294A patent/AU2002249294A1/en not_active Abandoned

- 2002-03-22 EP EP02718220A patent/EP1488694B1/de not_active Expired - Lifetime

- 2002-03-22 US US10/503,715 patent/US7011044B2/en not_active Expired - Fee Related

- 2002-03-22 ES ES02718220T patent/ES2278908T3/es not_active Expired - Lifetime

-

2004

- 2004-08-11 TN TNP2004000153A patent/TNSN04153A1/en unknown

Also Published As

| Publication number | Publication date |

|---|---|

| ES2278908T3 (es) | 2007-08-16 |

| AU2002249294A1 (en) | 2003-10-08 |

| KR20050002870A (ko) | 2005-01-10 |

| EP1488694A1 (de) | 2004-12-22 |

| US20050150467A1 (en) | 2005-07-14 |

| DE60217725D1 (de) | 2007-03-08 |

| MXPA04009219A (es) | 2005-09-13 |

| JP4087796B2 (ja) | 2008-05-21 |

| TNSN04153A1 (en) | 2007-03-12 |

| JP2005520525A (ja) | 2005-07-14 |

| WO2003079774A1 (es) | 2003-10-02 |

| US7011044B2 (en) | 2006-03-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1488694B1 (de) | Station für die vorbereitung, reinigung, desinfektion, entlausung und wassermassage von tieren | |

| EP3358945B1 (de) | Automatisierte tierwaschsysteme | |

| US4425672A (en) | Shower bath units | |

| MX2007003783A (es) | Maquina automatica de hidromasaje para mascotas. | |

| CN2817404Y (zh) | 宠物洗澡机 | |

| JP6099531B2 (ja) | サウナ装置 | |

| JP5259532B2 (ja) | サウナ装置 | |

| CN110367137B (zh) | 一种智能宠物笼 | |

| KR20160104955A (ko) | 자동 손 세척장치 | |

| KR20160011766A (ko) | 목장용 자동 보온 급수기 | |

| JP2001104441A (ja) | 蒸気発生装置とその洗浄方法、およびサウナ装置 | |

| CN212629528U (zh) | 一种多功能宠物洗澡护理机器 | |

| JP5203820B2 (ja) | サウナ装置 | |

| CN216146997U (zh) | 一种配备实验动物自动饮水功能的无菌制水机 | |

| JP5384864B2 (ja) | サウナ装置 | |

| CN214546491U (zh) | 一种自动毛发清洗吹干机 | |

| JPH0335328Y2 (de) | ||

| JP5179421B2 (ja) | サウナ装置 | |

| JP2021025735A (ja) | 加熱調理器 | |

| JP2003174976A (ja) | 入浴装置 | |

| KR101626719B1 (ko) | 태양열 전기 및 보일러 열원을 활용한 빨래 및 신발건조대 | |

| JPH11290241A (ja) | 手指乾燥器 | |

| ES2277508B1 (es) | Maquina de hidromasaje para mascotas. | |

| JPH0453253Y2 (de) | ||

| JP2001070396A (ja) | 人体洗浄装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20040715 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070117 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070117 Ref country code: LI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070117 Ref country code: CH Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070117 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070117 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20070220 Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 60217725 Country of ref document: DE Date of ref document: 20070308 Kind code of ref document: P |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20070327 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070417 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070618 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20070117 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2278908 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20071018 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20070619 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070418 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070418 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080221 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080130 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20080312 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081001 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20081001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070322 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080322 |

|

| BERE | Be: lapsed |

Owner name: ANGEL SEGURA MUNOZ Effective date: 20090331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070117 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090322 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20091130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091123 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090322 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: PC2A Owner name: SHOWER DOG, SL. Effective date: 20130215 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20210422 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20220804 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20220323 |