EP1446546B1 - A hinging device for a glazing system - Google Patents

A hinging device for a glazing system Download PDFInfo

- Publication number

- EP1446546B1 EP1446546B1 EP20020774798 EP02774798A EP1446546B1 EP 1446546 B1 EP1446546 B1 EP 1446546B1 EP 20020774798 EP20020774798 EP 20020774798 EP 02774798 A EP02774798 A EP 02774798A EP 1446546 B1 EP1446546 B1 EP 1446546B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- piece

- locking

- hinging

- frame part

- hinging piece

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000011521 glass Substances 0.000 claims abstract description 50

- 239000000463 material Substances 0.000 description 3

- 239000002184 metal Substances 0.000 description 2

- 238000005452 bending Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000009418 renovation Methods 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 210000002105 tongue Anatomy 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/92—Doors or windows extensible when set in position

- E06B3/922—Doors or windows extensible when set in position with several wings opening horizontally towards the same side of the opening and each closing a separate part of the opening

- E06B3/924—Doors or windows extensible when set in position with several wings opening horizontally towards the same side of the opening and each closing a separate part of the opening positioned in one plane when closed

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05D—HINGES OR SUSPENSION DEVICES FOR DOORS, WINDOWS OR WINGS

- E05D15/00—Suspension arrangements for wings

- E05D15/06—Suspension arrangements for wings for wings sliding horizontally more or less in their own plane

- E05D15/0604—Suspension arrangements for wings for wings sliding horizontally more or less in their own plane allowing an additional movement

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2201/00—Constructional elements; Accessories therefor

- E05Y2201/20—Brakes; Disengaging means; Holders; Stops; Valves; Accessories therefor

- E05Y2201/218—Holders

- E05Y2201/22—Locks

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2201/00—Constructional elements; Accessories therefor

- E05Y2201/60—Suspension or transmission members; Accessories therefor

- E05Y2201/622—Suspension or transmission members elements

- E05Y2201/688—Rollers

- E05Y2201/692—Rollers having vertical axes

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2900/00—Application of doors, windows, wings or fittings thereof

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2900/00—Application of doors, windows, wings or fittings thereof

- E05Y2900/10—Application of doors, windows, wings or fittings thereof for buildings or parts thereof

- E05Y2900/13—Type of wing

- E05Y2900/148—Windows

- E05Y2900/15—Balcony glazing

Definitions

- the invention relates to a hinging device according to the preamble of claim 1.

- the invention also relates to a frame part of a hinging arrangement for a glazing system according to the preamble of claim 15.

- a hinging device and a frame part as in the preambles of Claims 1 and 15, respectively is known from WO 92/17673 .

- glazing systems of prior art are installed in connection with balconies, said glazing systems being called for example balcony glazings.

- the systems typically comprise an upper profile and a lower profile inside which necessary guide members are placed, single glass panes being suspended between said guide members.

- the profiles typically extend horizontally and they are fastened to the structures of the building.

- guide members it is possible to open and close individual glass panes, typically around a vertical axis of rotation, and they can also be transferred aside along the profiles, wherein several glass panes form a vertical stack, and the balcony is completely open.

- the guide members comprise a hinging and locking piece for each glass pane, by means of which the glass panes that have been turned aside are interlocked.

- the pieces are positioned against each other and locked when the glass panes are turned and taken close to each other.

- Said pieces are positioned at a distance from each other when the glass panes extend straight up, wherein the glass panes form a continuous wall, and the distance of the pieces corresponds to the width of the glass panes.

- Application publication EP 1 085 156 A1 discloses a known method for locking the hinging piece and the pivoted glass pane in their places, but there is, however, such a problem that the hinging piece must be fixed precisely at the location of the locking piece, said locking pieces being located only within a fixed minimum distance from each other.

- the hinging piece must be fixed precisely at the location of the locking piece, said locking pieces being located only within a fixed minimum distance from each other.

- the tongues that function as locking devices must be positioned accurately and in a stationary manner to a predetermined position.

- the glass pane does not have to be positioned in relation to the profile in connection with the locking, wherein it is sufficient that the glass panes, and at the same time the locking pieces are pressed against each other. Furthermore, the locking piece guides itself to the correct position inside the profile, wherein it is not necessary to fix the locking piece to a predetermined position, wherein it can rotate freely.

- the structure of the locking piece is, however, problematic in view of the torque forces, wherein bending forces are exerted thereon that are caused by the weight of the glass panes that hang on the support of a hinge pin. This restricts the selection of materials and the forces may force the locking piece for example due to deformation to a position in which the locking cannot be performed successfully or the locking piece is not capable of easily moving inside the profile.

- the hinging piece according to the invention is presented in claim 1.

- the frame part of a hinging arrangement for a glazing system is presented in claim 15.

- the locking piece can be suspended from the hinge pin in such a manner that it is capable of hanging freely.

- the hinge pin according to the invention carries the entire weight of the glass panes, and the weight is not transmitted to the locking piece, to the locking means or through them to the guide. In connection with the locking it is not necessary to apply any more force that is necessary to turn the glass pane, and the locking does not require accurate positioning with respect to the profile.

- the way in which the locking piece is attached enables the use of quite different locking pieces, and their easy replacement, and it is not even necessary to install the locking pieces to the hinging piece, if locking is not necessary.

- the locking piece does, however, contain the necessary locking means, wherein it is especially easy to add the locking at a later stage. When the locking is added, it is not necessary to change the profile or attach additional parts.

- the hinging piece according to the invention contains a set of wheels and locking means as well as fastening means for the glass panes arranged in the same piece that pivots around a rotating axis in the Y direction and supports the glass panes.

- the locking means are intended to function together with the locking piece that is fastened to the adjacent hinging piece.

- a glazing system that has been installed in its place typically comprises several successive glass panes 1 that can be moved.

- the glass panes 1 have a rectangular form, and they are positioned in the X and Y direction, wherein they are in an upright position, forming a closed wall when placed one after the other. They can be transferred in the X direction that is typically the horizontal direction.

- the glass panes 1 can be opened into a position in which they extend in the Y and Z direction, said position being perpendicular to the closed position. In this position the glass panes 1 can be moved aside in such a manner that they are positioned side by side close to each other, wherein they are stored on one side of an opening 3 in a building 2.

- the upper profile 4 and the lower profile 5 are positioned in parallel to the X direction and each one of them comprises the necessary guide members 6 and 7 to which the glass panes 1 are fastened both from above and below.

- Fig. 2 shows in more detail a locking piece 8 of related art that belongs to the necessary guide members and is placed especially in the upper profile 4.

- the piece 8 comprises rolls 9, on the support of which the glass panes 1 of Fig. 1 hang from the upper profile, and a hinge pin 10 that constitutes the necessary hinging piece and is fastened pivotably to the piece 8 and via which the glass pane is fastened to the piece 8.

- the locking piece 14 shown in Fig. 3 is constructed according to the aforementioned principle.

- the hinge pin 10 extends in parallel to the Y direction.

- the lateral direction, i.e. the Z direction is perpendicular both to the X direction and to the Y direction, wherein an orthogonal system of coordinates is formed at the same time.

- the piece 8 contains a rear end 82 that comprises fitting means 83 for fastening the hinge pin 10, the hinge pin 10 also pivoting in said fitting means, being at the same time arranged in said guide members.

- the piece 8 also contains a front end 81 comprising locking means 84 for locking the hinge pin 10 in a determined rotating position.

- the hinge pin 10 that can be locked is fastened to a preceding similar piece.

- the pieces 8 are typically identical, wherein the structure and the dimensions are similar.

- the pieces 8 are typically also symmetrical in relation to such a plane that coincides with the X and Y directions and is located on the central line of the piece.

- the front end 81 and the rear end 82 comprise an upper surface and a lower surface each, said surfaces being planar in the X and Z directions.

- the locking prevents the divergence of the pieces 8 in the X direction.

- the pieces 8 are transferred against each other, and the hinge pin 10 must be positioned in a locking gap 85.

- the width of the hinge pin 10 in the first rotating position A is smaller than in its predetermined second rotating position B. In the position A it has access to and away from the locking gap 85, but not in the position B.

- the aperture 86 of the locking gap 85 controls the access inside and outside.

- the glass panes typically also contain a fillet or a profile 12 to which the hinge pin 10 is fastened by means of a groove 13.

- Fig. 3 shows a locking piece 14 according to a preferred embodiment that is utilized in the invention.

- the piece 14 also contains a rear end 142 comprising fitting means 143 for fastening the hinge pin 10 (not shown in the drawing).

- the means 143 comprise at least an opening 146 that extends through the rear end 142 in the vertical direction and a recess 147 surrounding the opening 146, which recess is shown in the side projection of Fig. 4 (cross-section C - C) and in the position of Fig. 3 underneath the rear end 142.

- the hinge pin rotates in the opening 146 and the collar in the hinge pin is positioned in the recess 147, wherein the piece 14 can at the same time hang on the support of the hinge pin, wherein it is not necessary for the piece 14 to slide along the upper profile, wherein it does not support the glass panes on the upper profile. If necessary, it is possible to arrange a separate, preferably replaceable plate part of plastic material underneath the piece 14, which plate part slides well when needed.

- the structures inside the profile control the position of the piece 14 at least in the Z direction, if necessary.

- the piece 14 also contains a front end 141 comprising locking members 144 in whose locking gap 144a the hinge pin is positioned.

- the dimensioning of the aperture 144b of the locking gap 144a is adapted to allow the passage of the hinge pin in the position A of Fig. 2 , but not in the position B.

- the front end 141 is positioned underneath the rear end of the preceding piece and the rear end 142 is positioned underneath the front end of the next piece. Because of the step-shaped structure of the piece 14, the front and rear ends of the other pieces are positioned on different sides of the piece 14.

- the locking means 144 form a bifurcate fork 144c, 144d.

- the locking gap 144a is positioned between the branches 144c, 144d.

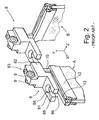

- Figure 5 shows a hinging piece 15 according to a preferred embodiment of the invention.

- the hinging piece 15 is placed together with the locking piece 14 inside a profile functioning as an upper profile.

- the hinging piece 15 can be connected especially to a locking piece 14 according to Fig. 3 , wherein they form the necessary guide members for the glazing system.

- the guide members are shown in Fig. 5 in a cross-section in the Y direction at the location of rotation axis 19, when positioned inside a profile 16 that is parallel to the X direction.

- the hinging piece 15 comprises two wheels 17 and 18 positioned in the horizontal plane on top of each other, said wheels forming a set of wheels on the same axis of rotation and symmetry 19 in the Y direction.

- the glass panes that are attached to a fillet 29 rest on the support of the wheels 17, 18, which, in turn, rest on the projections 20, 21 inside the upper profile 16 by means of their conical side surface.

- the projections 20 and 21 extend to opposite directions and they are positioned on different sides of the axis 19.

- Each wheel 17, 18 rests on the support of only one projection 20 or 21, along which the wheel rolls, wherein the wheels 17, 18 are capable of rotating around the rotation axis 19, wherein the glass panes and the guide members move by rolling along the profile 16 in the X direction.

- Each wheel 17, 18 comprises a hub part 24 or 25 that is typically made of metal, and a ring part 26 or 27 that is typically made of plastic material.

- the hub parts 24, 25 are locked in fixed manner, but the ring part 26, 27 is allowed to rotate centrally around the axis 19 and freely around the hub part 24, 25.

- intermediate rings 28 of metal must be placed between the hub parts 24, 25, wherein the height of the hub part 24, 25 is arranged to be greater than the height of the ring part 26, 27, so that the ring part would rotate freely.

- the hub part 24, 25 also contains at least one horizontal shoulder whose surface is directed downward, and a corresponding shoulder in the ring part 26, 27 is pressed against said horizontal shoulder.

- the hub parts 24 and 25, the ring parts 26 and 27, the screw 23 and the intermediate rings 28 are rotationally symmetrical in relation to the axis 19.

- a corresponding hinging piece 15 is placed inside the lower profile, but it is positioned upside down, and for example wheels 17 and 18 are not typically fastened thereto, wherein it does not contain a bearing part 31 and the narrowing of the frame part 22 extends all the way to the end.

- the screw 23 and the recess 30 are missing, wherein the purpose of the frame part 22 is to connect the glass panes to the lower profile and to prevent the movement in the Z direction.

- the parts 34, 35 are also higher, because the distance between the window pane and the lower profile is typically greater than in the upper profile.

- the frame part is preferably placed symmetrically and centrally on the axis 19.

- the frame part is also shown in Fig. 8 .

- the bearing means on top of the frame part 22 comprise a bearing part 31 that extends on a higher level than the locking piece 14, wherein the height of the piece 14 in the Y direction is smaller by the recess 147 than the height of the narrow collar i.e. the section 311 of the bearing part 31.

- the piece 14 is capable of rotating freely, if necessary, even if there was an intermediate ring 32 between the hub part 25 and the frame part 22.

- the hub part 25 can also be pressed directly against the frame part 22, wherein they are interlocked by means of a screw 23.

- the piece 14 must, however, be capable of pivoting freely, if necessary.

- the bearing part 31 also comprises a wide collar, i.e. a section 312 that is placed in the recess 147 of the piece 14, wherein the piece 14 rests on the support of the upper surface of the section 312, wherein the section 312 is preferably horizontal and its upper surface is directed upward.

- the height of the section 312 is smaller or equally great than the height of the recess 147, wherein the second locking piece moving underneath the rear end 142 of the piece 14 does not cling to the section 312.

- the frame part 22 extends downward in the Y direction and its diameter is preferably equal to the diameter of the section 312.

- the locking means formed in the frame part 22 comprise a locking part 33 that is intended to function together with the locking gap 144 of the locking piece 14 in the manner disclosed hereinabove and in connection with Fig. 2 as well.

- the horizontal cross-section of the locking part 33 follows the shape of a rectangular in such a manner that the distance between the short sides is greater than the distance between the long sides.

- the sides are preferably located symmetrically in relation to the axis 19, and the long sides are parallel to each other and extend vertically in the Y direction.

- the ring part 35 is capable of rotating freely around the rotation axis 19 and the bearing part 34, and it rests on the inner edges of the gap of the profile 16.

- the gap extending in the X direction is located on the lower surface of the profile 16.

- the diameter of the ring part 35 corresponds to the width of the gap, and thus it is possible to utilize the same to remove the clearance in the Z direction and to position the hinge pin 15 to the desired point, typically in the middle of the gap.

- the diameter of the ring part 35 can also be slightly larger than the width of the gap, wherein symmetrical narrowings must be made on the opposite sides of the ring part 35, the distance between the narrowings complying with the width of the gap.

- the diameter of the bearing part 34 is preferably slightly smaller than the greatest diameter of the locking part 33, wherein the ring part 35 rests against the shoulder between the locking part 33 and the bearing part 34.

- the ring part 35 also rests against the shoulder of the foot part 36, thus remaining by the gap in the profile 16.

- the bearing part 34 and the ring part 35 form the necessary sliding means by means of which the hinging part slides along the profile 19.

- the clearance between the ring part 35 and the bearing part 34 is arranged in such a manner that when the ring part 35 is pressed at the location of the narrowing in the bearing part 34, the ring part 35 yields, and it can be lifted up past the shoulder.

- the narrowings are arranged on opposite sides of the bearing part 34 and symmetrically in relation to the rotation axis 19. The narrowings are parallel to the narrowings in the locking part 33.

- the diameter of the section 312 must also be smaller than the inner diameter of the ring part 35.

- the widest part of the frame part 22 is located by the section 312.

- the hinge pin 15 is fastened to the fillet 29 by means of the foot part 36 that is presented in more detail also in Fig. 7 , wherein the glass panes are mounted underneath the piece 15 in the Y direction.

- the fillet 29 contains a gap extending in the X direction, said gap being narrower than the space inside the fillet 29 in which the foot part 36 is positioned.

- In the upper part of the foot part 36 there is a symmetrical narrowing 361 whose horizontal cross-section follows the shape of a rectangular in such a manner that the distance between the long sides equals the width of the gap.

- the long sides and their surfaces are parallel to the other narrowing surfaces of the frame part 22.

- the foot part 36 there is a symmetrical widening 362 whose width is greater than the width of the gap in the fillet 29 and it complies with the width of the free inner space of the fillet 29, wherein the foot part 36 and its widening 362 support the fillet 29.

- the widening 362 has preferably a substantially rectangular cross-section, but it can also be partly circular.

- On at least one side of the widening 362 there is an extension that extends in the X direction and whose width is greater than the width of the gap in the fillet 29.

- the width of the extension 363 preferably complies with the width of the widening 362 and on top of the extension there is a gap 37 that is open at least upward, preferably also to the sides in the Z direction.

- the recess 37 In the X direction of the fillet 29 the recess 37 is lined on one hand by the widening 362 and on the other hand by the end of the extension 363. It is possible to place a nut 38 in the recess 37, the outer appearance of said nut being such that its rotation in the recess 37 around the Y direction is prevented.

- the nut 38 is wider than the gap in the fillet 29, wherein it is possible to utilize said nut to fasten the foot part 36 and the fillet 29 together in a stationary manner, if a threaded screw 39 (shown by broken lines) is placed and tightened in the nut from above.

- the threaded screw 39 on one hand lifts up the nut 38 against the inner upper surface of the fillet 29, and on the other hand presses the foot part 36 against the inner lower surface of the fillet 29, wherein the hinge pin 15 and its frame part 22 are locked in their place in the X direction.

- the foot part 36, the nut 38 and the threaded screw 39 constitute the means intended for fastening of the glass panes, when the glass panes also comprise a fillet 29.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Mechanical Engineering (AREA)

- Securing Of Glass Panes Or The Like (AREA)

- Hinges (AREA)

- Closing And Opening Devices For Wings, And Checks For Wings (AREA)

- Superstructure Of Vehicle (AREA)

- Re-Forming, After-Treatment, Cutting And Transporting Of Glass Products (AREA)

- Glass Compositions (AREA)

Abstract

Description

- The invention relates to a hinging device according to the preamble of

claim 1. The invention also relates to a frame part of a hinging arrangement for a glazing system according to the preamble ofclaim 15. A hinging device and a frame part as in the preambles ofClaims WO 92/17673 - Known balcony glazings are disclosed in patent publication

FI 84645 application publication EP 1 085 153 A2 , and in patent publicationFI 92517 WO 92/17673 - According to the patent publication

FI 84645 -

Application publication EP 1 085 156 A1 discloses a known method for locking the hinging piece and the pivoted glass pane in their places, but there is, however, such a problem that the hinging piece must be fixed precisely at the location of the locking piece, said locking pieces being located only within a fixed minimum distance from each other. In the system it is not possible to lock the glass pane steplessly to any position in relation to the profile, and the use of glass panes also requires special attention because the pieces must be positioned with respect to each other to enable the locking. Furthermore, it should be noted that the tongues that function as locking devices must be positioned accurately and in a stationary manner to a predetermined position. - In the solution disclosed in the patent publication

FI 84645 - It is an aim of the invention to eliminate the aforementioned problems by introducing a hinge pin of a new type. The hinging piece according to the invention is presented in

claim 1. The frame part of a hinging arrangement for a glazing system is presented inclaim 15. - By means of the invention it is possible to avoid torque forces and other force effects exerted on the locking piece that result for example from the weight of glass panes and the handling and moving of the same. By means of the invention the locking piece can be suspended from the hinge pin in such a manner that it is capable of hanging freely. The hinge pin according to the invention carries the entire weight of the glass panes, and the weight is not transmitted to the locking piece, to the locking means or through them to the guide. In connection with the locking it is not necessary to apply any more force that is necessary to turn the glass pane, and the locking does not require accurate positioning with respect to the profile. The way in which the locking piece is attached enables the use of quite different locking pieces, and their easy replacement, and it is not even necessary to install the locking pieces to the hinging piece, if locking is not necessary. The locking piece does, however, contain the necessary locking means, wherein it is especially easy to add the locking at a later stage. When the locking is added, it is not necessary to change the profile or attach additional parts.

- The hinging piece according to the invention contains a set of wheels and locking means as well as fastening means for the glass panes arranged in the same piece that pivots around a rotating axis in the Y direction and supports the glass panes. The locking means are intended to function together with the locking piece that is fastened to the adjacent hinging piece.

- In the following, the invention will be illustrated in more detail by means of a preferred embodiment, wherein reference is at the same time made to the appended drawings, in which

- Fig. 1

- shows a cross-section of a glazing system of related art, said glazing system being a balcony glazing,

- Fig. 2

- shows a perspective view of two locking pieces of related art that are positioned successively, the glass panes being suspended on their support,

- Fig. 3

- shows in a perspective view a locking piece according to a preferred embodiment of the invention,

- Fig. 4

- shows the locking piece of

Fig. 3 in the Z direction, cut from the point C-C, - Fig. 5

- shows the guide members and the hinge pin according to a preferred embodiment of the invention in a cross-section seen in the X direction,

- Fig. 6

- shows the hinge pin according to

Fig. 5 seen from below in the Y direction, cut from the point D - D ofFig. 5 , - Fig. 7

- shows the frame part of the hinge pin according to

Fig. 5 , seen from the side in the Z direction, and - Fig. 8

- shows the frame part of the hinge pin according to

Fig. 5 in a perspective view. - According to

Fig. 1 , a glazing system that has been installed in its place typically comprises severalsuccessive glass panes 1 that can be moved. Typically theglass panes 1 have a rectangular form, and they are positioned in the X and Y direction, wherein they are in an upright position, forming a closed wall when placed one after the other. They can be transferred in the X direction that is typically the horizontal direction. Theglass panes 1 can be opened into a position in which they extend in the Y and Z direction, said position being perpendicular to the closed position. In this position theglass panes 1 can be moved aside in such a manner that they are positioned side by side close to each other, wherein they are stored on one side of anopening 3 in abuilding 2. Theupper profile 4 and thelower profile 5 are positioned in parallel to the X direction and each one of them comprises thenecessary guide members glass panes 1 are fastened both from above and below. -

Fig. 2 shows in more detail alocking piece 8 of related art that belongs to the necessary guide members and is placed especially in theupper profile 4. Thepiece 8 comprisesrolls 9, on the support of which theglass panes 1 ofFig. 1 hang from the upper profile, and ahinge pin 10 that constitutes the necessary hinging piece and is fastened pivotably to thepiece 8 and via which the glass pane is fastened to thepiece 8. Thelocking piece 14 shown inFig. 3 is constructed according to the aforementioned principle. When thepieces 8 ofFig. 2 move in the X direction, thehinge pin 10 extends in parallel to the Y direction. The lateral direction, i.e. the Z direction is perpendicular both to the X direction and to the Y direction, wherein an orthogonal system of coordinates is formed at the same time. - The

piece 8 contains arear end 82 that comprisesfitting means 83 for fastening thehinge pin 10, thehinge pin 10 also pivoting in said fitting means, being at the same time arranged in said guide members. Thepiece 8 also contains afront end 81 comprising locking means 84 for locking thehinge pin 10 in a determined rotating position. Thehinge pin 10 that can be locked is fastened to a preceding similar piece. Thepieces 8 are typically identical, wherein the structure and the dimensions are similar. Thepieces 8 are typically also symmetrical in relation to such a plane that coincides with the X and Y directions and is located on the central line of the piece. Thefront end 81 and therear end 82 comprise an upper surface and a lower surface each, said surfaces being planar in the X and Z directions. - The locking prevents the divergence of the

pieces 8 in the X direction. For the locking thepieces 8 are transferred against each other, and thehinge pin 10 must be positioned in alocking gap 85. The width of thehinge pin 10 in the first rotating position A is smaller than in its predetermined second rotating position B. In the position A it has access to and away from the lockinggap 85, but not in the position B. Theaperture 86 of the lockinggap 85 controls the access inside and outside. The glass panes typically also contain a fillet or aprofile 12 to which thehinge pin 10 is fastened by means of agroove 13. -

Fig. 3 shows alocking piece 14 according to a preferred embodiment that is utilized in the invention. Thepiece 14 also contains arear end 142 comprising fitting means 143 for fastening the hinge pin 10 (not shown in the drawing). The means 143 comprise at least anopening 146 that extends through therear end 142 in the vertical direction and arecess 147 surrounding theopening 146, which recess is shown in the side projection ofFig. 4 (cross-section C - C) and in the position ofFig. 3 underneath therear end 142. The hinge pin rotates in theopening 146 and the collar in the hinge pin is positioned in therecess 147, wherein thepiece 14 can at the same time hang on the support of the hinge pin, wherein it is not necessary for thepiece 14 to slide along the upper profile, wherein it does not support the glass panes on the upper profile. If necessary, it is possible to arrange a separate, preferably replaceable plate part of plastic material underneath thepiece 14, which plate part slides well when needed. The structures inside the profile control the position of thepiece 14 at least in the Z direction, if necessary. - The

piece 14 also contains afront end 141 comprising lockingmembers 144 in whoselocking gap 144a the hinge pin is positioned. The dimensioning of theaperture 144b of thelocking gap 144a is adapted to allow the passage of the hinge pin in the position A ofFig. 2 , but not in the position B. Thefront end 141 is positioned underneath the rear end of the preceding piece and therear end 142 is positioned underneath the front end of the next piece. Because of the step-shaped structure of thepiece 14, the front and rear ends of the other pieces are positioned on different sides of thepiece 14. The locking means 144 form abifurcate fork locking gap 144a is positioned between thebranches -

Figure 5 shows ahinging piece 15 according to a preferred embodiment of the invention. Thehinging piece 15 is placed together with the lockingpiece 14 inside a profile functioning as an upper profile. Thehinging piece 15 can be connected especially to alocking piece 14 according toFig. 3 , wherein they form the necessary guide members for the glazing system. The guide members are shown inFig. 5 in a cross-section in the Y direction at the location ofrotation axis 19, when positioned inside aprofile 16 that is parallel to the X direction. - The

hinging piece 15 comprises twowheels symmetry 19 in the Y direction. The glass panes that are attached to afillet 29 rest on the support of thewheels projections upper profile 16 by means of their conical side surface. Theprojections axis 19. Eachwheel projection wheels rotation axis 19, wherein the glass panes and the guide members move by rolling along theprofile 16 in the X direction. There are preferably at least two wheels. Thewheels frame part 22 of the hinge pin by means of a screw (shown with a broken line) and for that purpose theframe part 22 is equipped with a threadedrecess 30 extending in the Y direction. Eachwheel hub part ring part hub parts ring part axis 19 and freely around thehub part intermediate rings 28 of metal must be placed between thehub parts hub part ring part hub part ring part hub parts ring parts screw 23 and theintermediate rings 28 are rotationally symmetrical in relation to theaxis 19. - A corresponding

hinging piece 15 is placed inside the lower profile, but it is positioned upside down, and forexample wheels part 31 and the narrowing of theframe part 22 extends all the way to the end. Thus, also thescrew 23 and therecess 30 are missing, wherein the purpose of theframe part 22 is to connect the glass panes to the lower profile and to prevent the movement in the Z direction. In thepiece 15 inside the lower profile theparts - The frame part is preferably placed symmetrically and centrally on the

axis 19. The frame part is also shown inFig. 8 . The bearing means on top of theframe part 22 comprise abearing part 31 that extends on a higher level than the lockingpiece 14, wherein the height of thepiece 14 in the Y direction is smaller by therecess 147 than the height of the narrow collar i.e. thesection 311 of the bearingpart 31. Thus, thepiece 14 is capable of rotating freely, if necessary, even if there was anintermediate ring 32 between thehub part 25 and theframe part 22. Thehub part 25 can also be pressed directly against theframe part 22, wherein they are interlocked by means of ascrew 23. Thepiece 14 must, however, be capable of pivoting freely, if necessary. Thus, thepiece 14 can move to a suitable position inside theprofile 16, under the guidance of its various projections. The bearingpart 31 also comprises a wide collar, i.e. asection 312 that is placed in therecess 147 of thepiece 14, wherein thepiece 14 rests on the support of the upper surface of thesection 312, wherein thesection 312 is preferably horizontal and its upper surface is directed upward. The height of thesection 312 is smaller or equally great than the height of therecess 147, wherein the second locking piece moving underneath therear end 142 of thepiece 14 does not cling to thesection 312. - The

frame part 22 extends downward in the Y direction and its diameter is preferably equal to the diameter of thesection 312. The locking means formed in theframe part 22 comprise a lockingpart 33 that is intended to function together with thelocking gap 144 of the lockingpiece 14 in the manner disclosed hereinabove and in connection withFig. 2 as well. According toFig. 6 , the horizontal cross-section of the lockingpart 33 follows the shape of a rectangular in such a manner that the distance between the short sides is greater than the distance between the long sides. The sides are preferably located symmetrically in relation to theaxis 19, and the long sides are parallel to each other and extend vertically in the Y direction. - With reference to

Fig. 5 , there is abearing part 34 in theframe part 22, underneath the lockingpart 33, said bearing part being circular in relation to theaxis 19, and aring part 35 that is typically made of plastic is installed centrally around said bearing part as a bearing. Thering part 35 is capable of rotating freely around therotation axis 19 and the bearingpart 34, and it rests on the inner edges of the gap of theprofile 16. The gap extending in the X direction is located on the lower surface of theprofile 16. The diameter of thering part 35 corresponds to the width of the gap, and thus it is possible to utilize the same to remove the clearance in the Z direction and to position thehinge pin 15 to the desired point, typically in the middle of the gap. The diameter of thering part 35 can also be slightly larger than the width of the gap, wherein symmetrical narrowings must be made on the opposite sides of thering part 35, the distance between the narrowings complying with the width of the gap. The diameter of the bearingpart 34 is preferably slightly smaller than the greatest diameter of the lockingpart 33, wherein thering part 35 rests against the shoulder between the lockingpart 33 and the bearingpart 34. Thering part 35 also rests against the shoulder of thefoot part 36, thus remaining by the gap in theprofile 16. The bearingpart 34 and thering part 35 form the necessary sliding means by means of which the hinging part slides along theprofile 19. - The clearance between the

ring part 35 and the bearingpart 34 is arranged in such a manner that when thering part 35 is pressed at the location of the narrowing in the bearingpart 34, thering part 35 yields, and it can be lifted up past the shoulder. The narrowings are arranged on opposite sides of the bearingpart 34 and symmetrically in relation to therotation axis 19. The narrowings are parallel to the narrowings in the lockingpart 33. The diameter of thesection 312 must also be smaller than the inner diameter of thering part 35. The widest part of theframe part 22 is located by thesection 312. - The

hinge pin 15 is fastened to thefillet 29 by means of thefoot part 36 that is presented in more detail also inFig. 7 , wherein the glass panes are mounted underneath thepiece 15 in the Y direction. Thefillet 29 contains a gap extending in the X direction, said gap being narrower than the space inside thefillet 29 in which thefoot part 36 is positioned. In the upper part of thefoot part 36 there is asymmetrical narrowing 361 whose horizontal cross-section follows the shape of a rectangular in such a manner that the distance between the long sides equals the width of the gap. The long sides and their surfaces are parallel to the other narrowing surfaces of theframe part 22. In the lower part of thefoot part 36 there is asymmetrical widening 362 whose width is greater than the width of the gap in thefillet 29 and it complies with the width of the free inner space of thefillet 29, wherein thefoot part 36 and its widening 362 support thefillet 29. The widening 362 has preferably a substantially rectangular cross-section, but it can also be partly circular. On at least one side of the widening 362 there is an extension that extends in the X direction and whose width is greater than the width of the gap in thefillet 29. The width of theextension 363 preferably complies with the width of the widening 362 and on top of the extension there is agap 37 that is open at least upward, preferably also to the sides in the Z direction. - In the X direction of the

fillet 29 therecess 37 is lined on one hand by the widening 362 and on the other hand by the end of theextension 363. It is possible to place anut 38 in therecess 37, the outer appearance of said nut being such that its rotation in therecess 37 around the Y direction is prevented. Thenut 38 is wider than the gap in thefillet 29, wherein it is possible to utilize said nut to fasten thefoot part 36 and thefillet 29 together in a stationary manner, if a threaded screw 39 (shown by broken lines) is placed and tightened in the nut from above. The threadedscrew 39 on one hand lifts up thenut 38 against the inner upper surface of thefillet 29, and on the other hand presses thefoot part 36 against the inner lower surface of thefillet 29, wherein thehinge pin 15 and itsframe part 22 are locked in their place in the X direction. Thefoot part 36, thenut 38 and the threadedscrew 39 constitute the means intended for fastening of the glass panes, when the glass panes also comprise afillet 29. - When the guide members are in the Y direction positioned on top of each other in the manner disclosed hereinabove, a compact structure is attained, by means of which it is possible to achieve the advantages mentioned hereinabove. The way in which the set of

wheels wheels frame part 22 are capable of easily rotating with respect to each other. The wearing of wheels changes the position of thehinge pin 15 in the vertical direction, but this can be easily taken into account by means of sufficient clearances. The structure is as short as possible both in the X direction and in the Y direction, and only vertical forces are transmitted in theframe part 22, and said forces are not transmitted to thelocking piece 14. - The invention is not restricted solely to the advantageous embodiment presented above, but it may vary according to the appended claims.

Claims (17)

- A hinging piece (15) of a glazing system, which, when installed in its place, is intended movable in the X direction when it is arranged in a guide profile (16) of the glazing system, to which the glass panes (1) of the glazing system are intended to be suspended by means of said hinging piece (15), said piece comprising:- a horizontal set of wheels (17, 18) that is arranged on a rotation axis (19) extending in the Y direction and intended to support the hinging piece (15) on the guide profile (16), and- a frame part (22) that is arranged to rotate around said rotating axis (19) with the glass panes,characterized in that the frame part (22) comprises at least:- fastening means (36) for suspending the glass panes to the hinging piece (15),- locking means (33) that are arranged for locking the hinging piece (15) to a locking piece when the frame part (22) is in a predetermined rotating position, said locking piece being attached to the adjacent hinging piece when two hinging pieces (15) are positioned successively, wherein the locking prevents the divergence of adjacent hinging pieces (15) from each other in the X direction, and- bearing means (31) that are arranged for fastening a locking piece (14) to the frame part (22) in such a manner that the frame part (22) is capable of pivoting around said rotation axis (19) in relation to the locking piece (14).

- The hinging piece according to claim 1, characterized in that the overall width of the locking means (33) in the Z direction is smaller in the first rotating position (A) than in the predetermined second rotating position (B).

- The hinging piece according to claim 1 or 2, characterized in that the bearing means (31) comprise a first collar (311) and a second collar (312) whose diameter is larger than that of the first collar (311) and that is positioned underneath the first collar (311), wherein the locking piece (14) is arranged to rest on the support of the second collar (312) in such a manner that its rotation on the rotating axis (19) is allowed.

- The hinging piece according to any of the claims 1 to 3, characterized in that the set of wheels (17, 18) intended for moving the hinging piece (15) comprises at least one wheel (17, 18) that is arranged to rotate around the rotating axis (19) extending in the Y direction, wherein the frame part (22) is suspended underneath the set of wheels (17,18).

- The hinging piece according to claim 4, characterized in that the wheel (17, 18) comprises a hub part (24, 25) via which the wheel is attached to the frame part (22), and a ring part (26, 27) arranged to pivot around the hub part (24, 25) and the rotating axis (19).

- The hinging piece according to any of the claims 1 to 5, characterized in that it also comprises sliding means (34, 35) that are arranged to be positioned against the guide profile, when the hinging piece (15) moves in the X direction and to support the hinging piece in its place in the Z direction, said sliding means comprising a ring (35) that is locked around the frame part (22), the rotation of said ring part around the rotating axis (19) being allowed.

- The hinging piece according to any of the claims 1 to 5, characterized in that the fastening means (36) comprise a widening (362) that is arranged to be positioned inside a fillet (29), to which fillet, in turn, the glass is attached, and a narrowing (361) that is intended to be positioned in a gap in the fillet (29), and an extension (363) to the widening (362) extending in the X direction in such a manner that the combination of a nut and a screw can be placed between the fillet (29) and the extension (363) inside the fillet (29), said combination tightening and locking the extension (363) against the fillet (29).

- The hinging piece according to any of the claims 1 to 7, characterized in that the hinging piece (15) is arranged to pivot to a first rotating position (A) that corresponds to the position of the glass pane in which its surface coincides with the X and Y directions, and at least to a second rotating position (B) that corresponds to the position of the glass pane in which its surface coincides with the Y and Z directions, wherein the X direction and the Z direction are substantially horizontal directions, and the Y direction is a substantially vertical direction.

- The hinging piece according to any of the claims 1 to 8, characterized in that the locking piece (14) comprises:- a rear end (142) comprising fitting means (143) for fastening the hinging piece (15), in which the hinging piece (15) supporting the glass pane and extending substantially in the Y direction is intended to pivot, and- a front end (141) comprising locking means (144) for locking the locking piece (14) to the adjacent hinging piece in a predetermined rotating position of the frame part (22), when two hinging pieces (15) are positioned successively in the X direction, wherein the locking prevents the divergence of adjacent hinging pieces (15) from each other.

- The hinging piece according to claim 9, characterized in that the front end (141) s arranged to be positioned underneath the rear end of the adjacent locking piece in the Y direction, and that the rear end (142) is arranged to be positioned underneath the front end of the second adjacent locking piece in the Y direction, wherein the front end (141) is also arranged to be positioned on a different side of the piece than the rear end (142).

- The hinging piece according to claim 9 or 10, characterized in that the locking means (144) of the locking piece (14) comprise a locking gap (144a) extending through the front end (141) in the Y direction and opening towards the adjacent locking piece in the X direction, said locking gap being arranged to receive the hinging piece of the preceding locking piece, wherein the aperture (144b) of the locking gap (144a) is arranged to allow the access of said hinge pin inside, when it is in a predetermined rotating position (A) and to prevent the access of said hinge pin outside when it is in a second predetermined position (B).

- The hinging piece according to claim 11, characterized in that the locking means (144) comprise a bifurcate fork that is arranged for guiding the hinging piece to the locking gap (144a) positioned between the branches.

- The hinging piece according to any of the claims 9 to 12, characterized in that the overall width of the locking means of the hinging piece (15) in the Z direction in the first rotating position (A) is smaller than in the predetermined second rotating position (B), and that the overall width of the aperture of the locking gap in the Z direction is smaller than the overall width of the locking means in the second rotating position (B) and larger than the overall width of the locking means in the first rotating position (A).

- The hinging piece according to any of the claims 9 to 13, characterized in that the fitting means of the locking piece (14) comprise at least an opening (146) extending in the Y direction and through the rear end, and a recess (147) surrounding the opening, which is located between the rear end (142) and the front end of the next piece.

- A frame part (22) for a hinging piece of a glazing system, which, when installed in its place, is intended movable in the X direction when it is arranged in a guide profile (16) of the glazing system, wherein the glass panes (1) of the glazing system are intended to be suspended or connected by means of said frame part (22) of the hinging piece (15) that is arranged to rotate with the glass panes around a rotating axis (A) extending in the Y direction,

characterized in that the frame part (22) comprises at least:- fastening means (36) for suspending the glass panes to the frame part (22),- locking means (33) that are arranged for locking the frame part (22) to a locking piece when the frame part (22) is in a predetermined rotating position, said locking piece being attached to the adjacent frame part of the hinging arrangement when two frame parts (22) are positioned successively, wherein the locking prevents the divergence of adjacent frame parts (22) from each other in the X direction. - The frame part (22) according to claim 15, characterized in that it also comprises sliding means (34, 35) that are arranged to be positioned against the guide profile, when the frame part (22) moves in the X direction and to support the hinging piece in its place in the Z direction, said sliding means comprising a ring (35) that is locked around the frame part (22), the rotation of said ring part around the rotating axis (19) being allowed.

- The frame part (22) according to claim 15 or 16, characterized in that it also comprises bearing means (31) that are arranged for fastening a locking piece (14) to the frame part (22) in such a manner that the frame part (22) is capable of rotating around said rotation axis (19) in relation to the locking piece (14).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FI20012130 | 2001-11-05 | ||

| FI20012130A FI116694B (en) | 2001-11-05 | 2001-11-05 | Glazing system hinge piece |

| PCT/FI2002/000858 WO2003042482A1 (en) | 2001-11-05 | 2002-11-05 | A hinging device for a glazing system |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1446546A1 EP1446546A1 (en) | 2004-08-18 |

| EP1446546B1 true EP1446546B1 (en) | 2009-12-09 |

Family

ID=8562180

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20020774798 Expired - Lifetime EP1446546B1 (en) | 2001-11-05 | 2002-11-05 | A hinging device for a glazing system |

Country Status (10)

| Country | Link |

|---|---|

| EP (1) | EP1446546B1 (en) |

| CN (1) | CN100338328C (en) |

| AT (1) | ATE451530T1 (en) |

| DE (1) | DE60234709D1 (en) |

| DK (1) | DK1446546T3 (en) |

| ES (1) | ES2337988T3 (en) |

| FI (1) | FI116694B (en) |

| NO (1) | NO326740B1 (en) |

| PT (1) | PT1446546E (en) |

| WO (1) | WO2003042482A1 (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT7572U3 (en) * | 2004-12-09 | 2006-08-15 | Franz Haiderer | SLIDING WALL SYSTEM |

| AT501398B1 (en) * | 2004-12-09 | 2008-01-15 | Franz Haiderer | Sliding wall system for use in e.g. parking space, has separable sliding wall units movably supported and running in slide rail, and slide rail part with guiding device for disengagement/separation or connection/engagement of units |

| FI119254B (en) | 2006-08-16 | 2008-09-15 | Lumon Oy | Panel system and control of its locking |

| FI119001B (en) | 2006-08-16 | 2008-06-13 | Lumon Oy | Panel systems and upper controls for the same |

| FI125865B (en) | 2008-05-15 | 2016-03-15 | Lumon Oy | Molding that can be locked to a panel and glass panel |

| FI125283B (en) | 2012-11-01 | 2015-08-14 | Lumon Invest Oy | Panel System |

| ES1156759Y (en) * | 2016-03-14 | 2016-08-09 | Gonzalez Francisco Javier Ona | CLOSED DEVICE FOR SLIDING AND PIVOT DOOR |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2076596U (en) * | 1990-08-23 | 1991-05-08 | 刘新伯 | Sliding mechanism for opening window |

| FI89532C (en) * | 1991-10-14 | 1993-10-11 | Jarmo Sjoeholm | Hinge device |

| FI97990C (en) * | 1995-04-21 | 1997-03-25 | Lasimyynti Juvonen Oy | Hinge arrangement for balcony glazing structure or the like |

| FI97636C (en) * | 1995-04-21 | 1997-01-27 | Vantaan Asennuspalvelu Oy | The locking system |

| FI101823B1 (en) * | 1997-04-15 | 1998-08-31 | Iloxi Oy | locking device |

| SE513747C2 (en) * | 1998-03-04 | 2000-10-30 | Benth Loennberg | Device for rotatable and slidable suspension of discs |

-

2001

- 2001-11-05 FI FI20012130A patent/FI116694B/en not_active IP Right Cessation

-

2002

- 2002-11-05 AT AT02774798T patent/ATE451530T1/en active

- 2002-11-05 ES ES02774798T patent/ES2337988T3/en not_active Expired - Lifetime

- 2002-11-05 DE DE60234709T patent/DE60234709D1/de not_active Expired - Lifetime

- 2002-11-05 EP EP20020774798 patent/EP1446546B1/en not_active Expired - Lifetime

- 2002-11-05 DK DK02774798T patent/DK1446546T3/en active

- 2002-11-05 WO PCT/FI2002/000858 patent/WO2003042482A1/en not_active Application Discontinuation

- 2002-11-05 PT PT02774798T patent/PT1446546E/en unknown

- 2002-11-05 CN CNB028220943A patent/CN100338328C/en not_active Expired - Fee Related

-

2004

- 2004-05-04 NO NO20041843A patent/NO326740B1/en not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| CN1582361A (en) | 2005-02-16 |

| ES2337988T3 (en) | 2010-05-03 |

| FI116694B (en) | 2006-01-31 |

| NO326740B1 (en) | 2009-02-09 |

| ATE451530T1 (en) | 2009-12-15 |

| FI20012130A0 (en) | 2001-11-05 |

| DE60234709D1 (en) | 2010-01-21 |

| NO20041843L (en) | 2004-05-04 |

| EP1446546A1 (en) | 2004-08-18 |

| CN100338328C (en) | 2007-09-19 |

| PT1446546E (en) | 2010-03-01 |

| DK1446546T3 (en) | 2010-04-12 |

| FI20012130A (en) | 2003-05-06 |

| WO2003042482A1 (en) | 2003-05-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1446546B1 (en) | A hinging device for a glazing system | |

| EP1679281B1 (en) | Track jack system | |

| NZ584905A (en) | Wheeled carriage for suspending a wing with an adjusting wedge for changing the height of the suspended wing | |

| CA2052996A1 (en) | Adjustable bracket for building construction | |

| WO1994027015A1 (en) | Sliding door or sliding window system | |

| JP3480934B2 (en) | Slide element device | |

| CN101316783A (en) | Door device for elevator | |

| US20160201373A1 (en) | Running track device for the displaceable support of at least one first roller carriage and at least one second roller carriage | |

| EP1442192B1 (en) | A hinging and locking piece for a glazing system | |

| EP2886763A1 (en) | Glass element | |

| EP1889996B1 (en) | A panel system with an upper guiding member for it | |

| KR100596183B1 (en) | Opening and shutting apparatus of safety door using architecture | |

| FI105711B (en) | Hinge | |

| EP1947277A2 (en) | Balcony glazing structure | |

| CN214275253U (en) | Line-surface type positioning wall hanging device | |

| JPH10121750A (en) | Metal tool for releasing load | |

| CA2923572A1 (en) | Sliding door system for glass doors | |

| FI91184C (en) | Sliding Window Design | |

| JPH0527656Y2 (en) | ||

| AU743128B2 (en) | Overhead door track structure | |

| EP2518248A1 (en) | Glazing arrangement |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20040507 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: LUMON INVEST OY |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 60234709 Country of ref document: DE Date of ref document: 20100121 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20100219 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: OFFICE ERNEST T. FREYLINGER S.A. C/O SCHLUEP & DEG |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20100400429 Country of ref document: GR |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2337988 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100309 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091209 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091209 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091209 |

|

| 26N | No opposition filed |

Effective date: 20100910 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091209 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20141126 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20141121 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20141030 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20141125 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20141118 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20151123 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20160505 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160602 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160505 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: ML Ref document number: 20100400429 Country of ref document: GR Effective date: 20160602 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20161117 Year of fee payment: 15 Ref country code: DK Payment date: 20161122 Year of fee payment: 15 Ref country code: EE Payment date: 20161129 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20161121 Year of fee payment: 15 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151130 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161105 |

|

| REG | Reference to a national code |

Ref country code: EE Ref legal event code: MM4A Ref document number: E004082 Country of ref document: EE Effective date: 20171130 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20171130 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20171201 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 451530 Country of ref document: AT Kind code of ref document: T Effective date: 20171105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171130 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20191120 Year of fee payment: 18 Ref country code: SE Payment date: 20191118 Year of fee payment: 18 Ref country code: FI Payment date: 20191030 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20191115 Year of fee payment: 18 Ref country code: ES Payment date: 20191205 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20191118 Year of fee payment: 18 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20191105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191105 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 60234709 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FI Ref legal event code: MAE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201106 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210601 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20220131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201106 |