EP1375813A2 - Heatable shade systems - Google Patents

Heatable shade systems Download PDFInfo

- Publication number

- EP1375813A2 EP1375813A2 EP03014321A EP03014321A EP1375813A2 EP 1375813 A2 EP1375813 A2 EP 1375813A2 EP 03014321 A EP03014321 A EP 03014321A EP 03014321 A EP03014321 A EP 03014321A EP 1375813 A2 EP1375813 A2 EP 1375813A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- space

- shading system

- pane

- individual

- disc

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000010438 heat treatment Methods 0.000 claims description 25

- 238000000576 coating method Methods 0.000 claims description 10

- 239000011248 coating agent Substances 0.000 claims description 9

- 230000000087 stabilizing effect Effects 0.000 claims description 5

- 239000005340 laminated glass Substances 0.000 claims description 4

- 125000006850 spacer group Chemical group 0.000 claims description 4

- 229920003023 plastic Polymers 0.000 claims description 2

- 229920005989 resin Polymers 0.000 claims description 2

- 239000011347 resin Substances 0.000 claims description 2

- XOLBLPGZBRYERU-UHFFFAOYSA-N tin dioxide Chemical compound O=[Sn]=O XOLBLPGZBRYERU-UHFFFAOYSA-N 0.000 claims description 2

- 229910001887 tin oxide Inorganic materials 0.000 claims description 2

- 229920002037 poly(vinyl butyral) polymer Polymers 0.000 description 4

- 239000007789 gas Substances 0.000 description 3

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 230000005855 radiation Effects 0.000 description 2

- 239000005336 safety glass Substances 0.000 description 2

- PXGOKWXKJXAPGV-UHFFFAOYSA-N Fluorine Chemical compound FF PXGOKWXKJXAPGV-UHFFFAOYSA-N 0.000 description 1

- 229910018503 SF6 Inorganic materials 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- -1 argon (Ar) Chemical class 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 229940079593 drug Drugs 0.000 description 1

- 239000003814 drug Substances 0.000 description 1

- 239000000428 dust Substances 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000005485 electric heating Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000005329 float glass Substances 0.000 description 1

- 229910052731 fluorine Inorganic materials 0.000 description 1

- 239000011737 fluorine Substances 0.000 description 1

- 230000004907 flux Effects 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 229910052738 indium Inorganic materials 0.000 description 1

- APFVFJFRJDLVQX-UHFFFAOYSA-N indium atom Chemical compound [In] APFVFJFRJDLVQX-UHFFFAOYSA-N 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 229910052743 krypton Inorganic materials 0.000 description 1

- DNNSSWSSYDEUBZ-UHFFFAOYSA-N krypton atom Chemical compound [Kr] DNNSSWSSYDEUBZ-UHFFFAOYSA-N 0.000 description 1

- 238000001755 magnetron sputter deposition Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000004377 microelectronic Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 229910052756 noble gas Inorganic materials 0.000 description 1

- 150000002835 noble gases Chemical class 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 239000010970 precious metal Substances 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- SFZCNBIFKDRMGX-UHFFFAOYSA-N sulfur hexafluoride Chemical compound FS(F)(F)(F)(F)F SFZCNBIFKDRMGX-UHFFFAOYSA-N 0.000 description 1

- 229960000909 sulfur hexafluoride Drugs 0.000 description 1

- 238000007669 thermal treatment Methods 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 230000036642 wellbeing Effects 0.000 description 1

- 229910052724 xenon Inorganic materials 0.000 description 1

- FHNFHKCVQCLJFQ-UHFFFAOYSA-N xenon atom Chemical compound [Xe] FHNFHKCVQCLJFQ-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/24—Screens or other constructions affording protection against light, especially against sunshine; Similar screens for privacy or appearance; Slat blinds

- E06B9/26—Lamellar or like blinds, e.g. venetian blinds

- E06B9/264—Combinations of lamellar blinds with roller shutters, screen windows, windows, or double panes; Lamellar blinds with special devices

Definitions

- the invention relates to a shading system according to the preamble of claim 1.

- glazing systems are increasingly used the tasks beyond the mere glazing function take.

- An inventive shading system has an inner disc and a outer disc, which form a first disc space, and one in the first disc space arranged slat blind with around its longitudinal axis pivotable and optionally additionally raised and lowered blades, with which the interior of a room can be shaded.

- At least one of the discs - Preferably, the inner pane - is electrically heated.

- the slats are pivotable and optionally in addition raised and lowered.

- This embodiment takes into account the experience that In practice, practically every user of a blind pivotable slats wishes, however, their lifting and lowering ability only in about 70 to 80% of the applications is required.

- a Venetian blind a state of maximum results Shading when the disc pack is extended downwards and the individual slats are turned against the sun.

- stepwise turning the fins can be selectively reduced to the shading until the slats standing horizontally. Starting from this state results in a booting the Slats only a slight further decrease in shading, the in The practice usually does not matter.

- a ramp up of the slats is usually only the aesthetic gain that the horizontal slats out of sight disappear.

- the heating takes place at this embodiment by embedded in the connection layer electrical Heating wires.

- the Production takes place by stacking of elastic films, preferably from PVB (polyvinyl butyral), in which heating wires are embedded, and slices of float glass and a subsequent thermal treatment of this composite under Pressure in an autoclave.

- This construction gives the shading system the properties of laminated safety glass.

- Security property is the property of laminated glass, at Impact not to break into small pieces.

- a stabilizing element be arranged, preferably in the form of a layer of transparent cured Casting resin or of transparent plastic, for example of PVB (polyvinyl butyral). This layer connects the two single panes and expands the system of laminated safety glass.

- the single disc in another preferred Embodiment may be spaced apart from each other and a second Make disk space.

- the heating takes place in this embodiment by an electrically conductive surface coating on top of that Surface of the adjoining the shadable space single disc applied is adjacent to the second disc space. This radiates the heat generated by the heating towards the interior of the shadable Room off.

- the surface coating is a hard coating of fluorine or indium doped tin oxide.

- Also in this embodiment can be a stabilizing element between the individual discs be arranged, with a completely or partially circumferential Spacer is preferred.

- the at the first disc space adjacent surface of the outer pane is a heat-reflecting Wear layer.

- This embodiment is particularly preferred because This heat losses are avoided by radiation to the outside. Especially In this way it will be the one generated by the electric heater Energy largely completely fed to the shadable space. The use this energy is 90% or more. Preference is given to soft coatings based on precious metals, which are produced by the magnetron sputtering process.

- gas and “gas-tight” should in the context of this description and in the protection claims relate both to normal atmospheric air and inert gases, which are used in the glazing technique for heat and / or sound insulation.

- protective gases are noble gases such as argon (Ar), krypton (Kr) and xenon (Xe) and sulfur hexafluoride (SF 6 ) or mixtures thereof.

- Another advantage is the possibility of incorporating an inventive Systems as windows or in a facade the climatic conditions to be able to influence.

- the summer months can be with the inside Venetian blind the heat and light flux are controlled.

- the Winter months and in the transitional heating season can be heated with Disk heat are generated, with their rapid availability already mentioned has been.

- the transitional heating period is especially an additional heating in question. This heat is available in the building, where classically the largest heat losses occur.

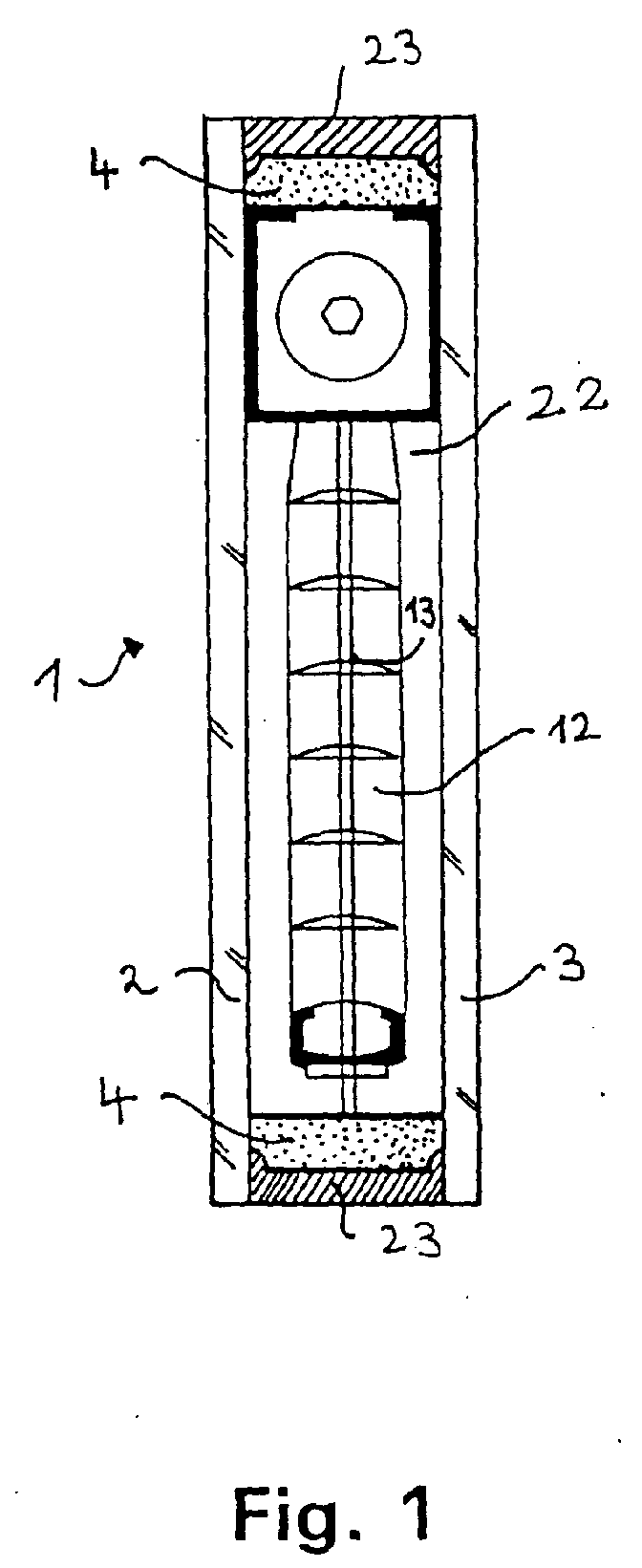

- Fig. 1 shows the basic structure of the shading system according to the invention 1 in section (hereafter "system”). Shown are the Venetian blind 12 with the lamellae 13, which is arranged between two panes 2, 3. Disc 2 forms the inner, disc 3, the outer disc. The venetian blind 12 is taken by a spacer 4, which consists of four pieces. These form a first space between the panes 22. Shown in FIG. 1 is also a Seal 23, which runs around all four sides of the discs 2, 3 and the system gas-tight.

- system Shown are the Venetian blind 12 with the lamellae 13, which is arranged between two panes 2, 3. Disc 2 forms the inner, disc 3, the outer disc. The venetian blind 12 is taken by a spacer 4, which consists of four pieces. These form a first space between the panes 22. Shown in FIG. 1 is also a Seal 23, which runs around all four sides of the discs 2, 3 and the system gas-tight.

- Fig. 2 shows a schematic representation of the heating of the invention Shading system according to a first embodiment.

- the inner pane 2 is made up of two individual panes 30, 31, wherein the single disc 30 to the shadable space and the other single disc 31 adjacent to the first disc space 22.

- the shadable Room is located to the left of the inner pane 2.

- the individual slices 30, 31 are connected to a connecting layer 33 arranged between them Laminated glass unit connected. To simplify the drawing are more Details such as the Venetian blind 12, fins 13 and the like. Not shown.

- the Heating takes place by electric heating wires 32, which are in the connecting layer 33 are embedded. So it is the inner pane 2 heated.

- Fig. 3 shows a schematic representation of the heating of the invention Shading system according to a second embodiment of the invention Shading system.

- the inner disc 2 is off two individual discs 30, 31 constructed.

- a single disc 30 is in turn adjacent to the shadable space and the other single disc 31 to the first Disc space 22 at.

- the shaded room is also located to the left of the inner disk 2.

- the individual disks 30, 31 are here from each other spaced apart and form a second disc space 35.

- the heating takes place by means of an electrically conductive surface coating 34. This is on a surface adjacent to the shadable room Single disc 30 applied, on the surface, to the second Disc space 35 adjacent. It is thus located between the surface coating 34 and the other single disc 31 still a layer in Shape of the second disc space 35, which consists of the filling gas consists. This arrangement causes the heat generated by the heating Heat largely completely towards the interior of the shadable Room - in the drawing so in the direction of the left - is radiated.

- the first space between the panes 22 adjacent surface of the outer pane 3 is a heat-reflecting Wear layer.

- Electrodes 36 for the voltage supply or for connecting the voltage. Possible are virtually point-shaped electrodes with relatively small area or more band-shaped electrodes with which the voltage can be created over a correspondingly larger area. With the Size of the electrodes (edge closure or surface connection) can be the current distribution control over the heated disk.

Landscapes

- Structural Engineering (AREA)

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Specific Sealing Or Ventilating Devices For Doors And Windows (AREA)

- Joining Of Glass To Other Materials (AREA)

- Securing Of Glass Panes Or The Like (AREA)

- Blinds (AREA)

- Transforming Light Signals Into Electric Signals (AREA)

- Secondary Cells (AREA)

- Baking, Grill, Roasting (AREA)

- Glass Compositions (AREA)

- Yarns And Mechanical Finishing Of Yarns Or Ropes (AREA)

Abstract

Es wird ein Beschattungssystem (1) beschrieben, aufweisend eine innere Scheibe (2) und eine äußere Scheibe (3), die einen ersten Scheibenzwischenraum (22) bilden und eine im ersten Scheibenzwischenraum (22) angeordnete Lamellenjalousie (12) mit um ihre Längsachse verschwenkbaren und wahlweise zusätzlich heb- und senkbaren Lamellen (13), mit der das Innere eines Raumes beschattbar ist. Mindestens eine der Scheiben (2, 3) ist elektrisch beheizbar. The invention relates to a shading system (1) comprising an inner pane (2) and an outer pane (3) which form a first space between the panes (22) and a venetian blind (12) arranged in the first pan space (22) and pivotable about its longitudinal axis and optionally additionally raisable and lowerable blades (13), with which the interior of a room is shadable. At least one of the discs (2, 3) is electrically heated.

Description

Die Erfindung betrifft ein Beschattungssystem gemäß dem Oberbegriff von Anspruch

1.The invention relates to a shading system according to the preamble of

In der Bau- und Fassadentechnik werden zunehmend Verglasungssysteme eingesetzt, die über die reine Verglasungsfunktion hinaus anspruchsvolle Aufgaben übernehmen. Es sind Systeme bekannt, mit denen das natürliche Sonnenlicht abgewiesen werden kann (Beschattung). Dies ist hauptsächlich in den Sommermonaten relevant. Daneben wurde auch in zunehmendem Umfang der Versuch unternommen, Verglasungssysteme in den Wintermonaten und in der Übergangszeit (Übergangsheizperiode) für die Raumheizung zu nutzen.In construction and facade technology, glazing systems are increasingly used the tasks beyond the mere glazing function take. There are known systems that use natural sunlight can be rejected (shading). This is mainly in the Summer months relevant. In addition, was increasingly the Attempted glazing systems in the winter months and in the Transitional period (transition heating period) to use for space heating.

Für die Beschattung eignen sich Lamellenjalousien, wie sie z.B. in der deutschen Offenlegungsschrift DE 39 04 763 A1 und in der europäischen Patentanmeldung EP 0 948 131 A1 beschrieben sind. For the shading lamellar blinds, as they are e.g. in the German Laid-open application DE 39 04 763 A1 and in the European patent application EP 0 948 131 A1 are described.

Es ist die Aufgabe der Erfindung, ein Verglasungssystem zur Verfügung zu stellen, mit dem sowohl die Beschattung als auch die Beheizung eines Raumes möglich ist.It is the object of the invention to provide a glazing system, with which both the shading and the heating of a room possible is.

Diese Aufgabe wird gelöst mit einem Beschattungssystem gemäß Anspruch 1.

Vorteilhafte Weiterbildungen des erfindungsgemäßen Systems sind in den Unteransprüchen

beschrieben.This object is achieved with a shading system according to

Ein erfindungsgemäßes Beschattungssystem weist eine innere Scheibe und eine äußere Scheibe auf, die einen ersten Scheibenzwischenraum bilden, und eine im ersten Scheibenzwischenraum angeordnete Lamellenjalousie mit um ihre Längsachse verschwenkbaren und wahlweise zusätzlich heb- und senkbaren Lamellen, mit der das Innere eines Raumes beschattbar ist. Mindestens eine der Scheiben - bevorzugt die innere Scheibe - ist elektrisch beheizbar.An inventive shading system has an inner disc and a outer disc, which form a first disc space, and one in the first disc space arranged slat blind with around its longitudinal axis pivotable and optionally additionally raised and lowered blades, with which the interior of a room can be shaded. At least one of the discs - Preferably, the inner pane - is electrically heated.

Erfindungsgemäß sind die Lamellen verschwenkbar und wahlweise zusätzlich heb- und senkbar. Diese Ausgestaltung trägt der Erfahrung Rechnung, daß sich in der Praxis praktisch jeder Benutzer einer Jalousie verschwenkbare Lamellen wünscht, deren Heb- und Senkbarkeit jedoch nur in etwa 70 bis 80 % der Anwendungsfälle gefordert wird. Bei einer Jalousie ergibt sich ein Zustand maximaler Beschattung, wenn deren Lamellenpaket nach unten ausgefahren und die einzelnen Lamellen gegen die Sonne gedreht sind. Durch schrittweises Drehen der Lamellen kann die Beschattung wahlweise verringert werden, bis die Lamellen waagrecht stehen. Ausgehend von diesem Zustand ergibt ein Hochfahren der Lamellen nur noch eine geringfügige weitere Abnahme der Beschattung, die in der Praxis meist keine Rolle spielt. Ein Hochfahren der Lamellen hat meist nur den ästhetischen Gewinn, daß die waagrecht stehenden Lamellen aus dem Gesichtsfeld verschwinden.According to the invention, the slats are pivotable and optionally in addition raised and lowered. This embodiment takes into account the experience that In practice, practically every user of a blind pivotable slats wishes, however, their lifting and lowering ability only in about 70 to 80% of the applications is required. With a Venetian blind, a state of maximum results Shading when the disc pack is extended downwards and the individual slats are turned against the sun. By stepwise turning the fins can be selectively reduced to the shading until the slats standing horizontally. Starting from this state results in a booting the Slats only a slight further decrease in shading, the in The practice usually does not matter. A ramp up of the slats is usually only the aesthetic gain that the horizontal slats out of sight disappear.

Gemäß einer bevorzugten Ausführungsform ist die innere Scheibe aus zwei Einzelscheiben aufgebaut, wobei eine Einzelscheibe an den beschattbaren Raum und die andere Einzelscheibe an den ersten Scheibenzwischenraum angrenzt und die Einzelscheiben mit einer zwischen ihnen angeordneten Verbindungsschicht zu einer Verbundglaseinheit verbunden sind. Die Beheizung erfolgt bei dieser Ausführungsform durch in die Verbindungsschicht eingelassene elektrische Heizdrähte. Bei auf dem Markt befindlichen Produkten dieser Art sind die Einzelscheiben mit der Verbindungsschicht und den Heizdrähten so miteinander verbunden, daß sie mit dem bloßen Auge praktisch nicht zu erkennen sind. Die Herstellung erfolgt durch Aufeinanderlegen von elastischen Folien, bevorzugt aus PVB (Polyvinylbutyral), in die Heizdrähte eingebettet sind, und Scheiben aus Floatglas und einer nachfolgenden thermischen Behandlung dieses Verbundes unter Druck in einem Autoklaven.According to a preferred embodiment, the inner disc of two individual discs built, with a single pane to the shadable room and the other single disc is adjacent to the first disc space and the individual disks with a connecting layer arranged between them are connected to a laminated glass unit. The heating takes place at this embodiment by embedded in the connection layer electrical Heating wires. For products of this kind on the market, the Single discs with the connecting layer and the heating wires together connected, that they are virtually invisible to the naked eye. The Production takes place by stacking of elastic films, preferably from PVB (polyvinyl butyral), in which heating wires are embedded, and slices of float glass and a subsequent thermal treatment of this composite under Pressure in an autoclave.

Dieser Aufbau gibt dem Beschattungssystem die Eigenschaften von Verbundsicherheitsglas. Sicherheitsrelevant ist die Eigenschaft von Verbundglas, bei Schlageinwirkung nicht in kleine Stücke zu zerspringen. Zwar laufen entstehende Sprünge über die betroffene Einzelscheibe, die innere Scheibe wird jedoch durch die Verbindungsschicht weiter zusammengehalten und bleibt in ihrer Gesamtstruktur erhalten. Zwischen den Einzelscheiben kann ein Stabilisierungselement angeordnet sein, bevorzugt in Gestalt einer Schicht aus transparentem gehärteten Gießharz oder aus transparentem Kunststoff, beispielsweise aus PVB (Polyvinylbutyral). Diese Schicht verbindet die beiden Einzelscheiben und erweitert das System des Verbundsicherheitsglases.This construction gives the shading system the properties of laminated safety glass. Security property is the property of laminated glass, at Impact not to break into small pieces. Although running arise Jumps over the affected single disc, the inner disc is, however, through the tie layer continues to be held together and remains in its overall structure receive. Between the individual discs, a stabilizing element be arranged, preferably in the form of a layer of transparent cured Casting resin or of transparent plastic, for example of PVB (polyvinyl butyral). This layer connects the two single panes and expands the system of laminated safety glass.

Ausgehend von dem beschriebenen Aufbau mit aus zwei Einzelscheiben aufgebauter innerer Scheibe können die Einzelscheiben bei einer anderen bevorzugten Ausführungsform auch voneinander beabstandet sein und einen zweiten Scheibenzwischenraum bilden. Die Beheizung erfolgt bei dieser Ausführungsform durch eine elektrisch leitende Flächenbeschichtung, die auf derjenigen Oberfläche der an den beschattbaren Raum angrenzenden Einzelscheibe aufgebracht ist, die an den zweiten Scheibenzwischenraum angrenzt. Dadurch strahlt die durch die Beheizung erzeugte Wärme in Richtung auf das Innere des beschattbaren Raumes ab. Bevorzugt ist die Flächenbeschichtung eine Hartbeschichtung aus mit Fluor oder Indium dotiertem Zinnoxid.Based on the described structure with built from two individual discs inner disc may be the single disc in another preferred Embodiment also be spaced apart from each other and a second Make disk space. The heating takes place in this embodiment by an electrically conductive surface coating on top of that Surface of the adjoining the shadable space single disc applied is adjacent to the second disc space. This radiates the heat generated by the heating towards the interior of the shadable Room off. Preferably, the surface coating is a hard coating of fluorine or indium doped tin oxide.

Auch bei dieser Ausführungsform kann zwischen den Einzelscheiben ein Stabilisierungselement angeordnet sein, wobei ein ganz oder teilweise umlaufender Abstandhalter bevorzugt ist. Also in this embodiment can be a stabilizing element between the individual discs be arranged, with a completely or partially circumferential Spacer is preferred.

Bei allen beschriebenen Ausführungsformen kann die an den ersten Scheibenzwischenraum angrenzende Oberfläche der äußeren Scheibe eine wärmereflektierende Schicht tragen. Diese Ausführungsform ist besonders bevorzugt, weil dadurch Wärmeverluste durch Abstrahlung nach außen vermieden werden. Insbesondere wird auf diese Weise die durch die elektrische Heizung erzeugte Energie weitgehend vollständig dem beschattbaren Raum zugeführt. Die Nutzung dieser Energie beträgt 90 % oder mehr. Bevorzugt sind Weichbeschichtungen auf Edelmetallbasis, die mit dem Magnetronsputterverfahren hergestellt sind.In all the described embodiments, the at the first disc space adjacent surface of the outer pane is a heat-reflecting Wear layer. This embodiment is particularly preferred because This heat losses are avoided by radiation to the outside. Especially In this way it will be the one generated by the electric heater Energy largely completely fed to the shadable space. The use this energy is 90% or more. Preference is given to soft coatings based on precious metals, which are produced by the magnetron sputtering process.

Die Begriffe "gas" und "gasdicht" sollen sich im Rahmen dieser Beschreibung und auch in den Schutzansprüchen sowohl auf normale atmosphärische Luft als auch auf Schutzgase beziehen, die in der Verglasungstechnik zum Wärme- und/oder Schallschutz eingesetzt werden. Solche Schutzgase sind Edelgase wie Argon (Ar), Krypton (Kr) und Xenon (Xe) sowie Schwefelhexafluorid (SF6) oder Gemische davon.The terms "gas" and "gas-tight" should in the context of this description and in the protection claims relate both to normal atmospheric air and inert gases, which are used in the glazing technique for heat and / or sound insulation. Such protective gases are noble gases such as argon (Ar), krypton (Kr) and xenon (Xe) and sulfur hexafluoride (SF 6 ) or mixtures thereof.

Nachfolgend werden die Einsatzmöglichkeiten und Vorteile des erfindungsgemäßen Beschattungs- und Lichtlenksystems (kurz "System" genannt") weiter beschrieben.The possible uses and advantages of the shading and light-guiding system according to the invention ( " system" for short) are described below.

Der grundsätzliche Vorteil einer elektrischen Heizung mit Fensterscheiben liegt in der schnellen Verfügbarkeit der Wärmeenergie. Das System hat - im Gegensatz zu allen anderen Heizungsarten - praktisch keine Verzögerungszeit. Die Wärme ist nicht nur schnell verfügbar, sondern entsteht auch in einer Weise, die herkömmliche Heizkörper (Radiatoren) überflüssig macht. Beides dient dem Wohlgefühl und der Lebensqualität des Bewohners.The basic advantage of an electric heater with window panes lies in the rapid availability of heat energy. The system has - in contrast to all other types of heating - practically no delay time. The heat Not only is it quickly available, it also emerges in a way that is conventional Radiator (radiators) makes unnecessary. Both serve the well-being and the quality of life of the resident.

Ein weitere Vorteil besteht in der Möglichkeit, durch den Einbau eines erfindungsgemäßen Systems als Fenster oder in eine Fassade die klimatischen Bedingungen beeinflussen zu können. In den Sommermonaten kann mit der innenliegenden Lamellenjalousie der Wärme- und Lichtfluß gesteuert werden. In den Wintermonaten und in der Übergangsheizperiode kann mit der beheizbaren Scheibe Wärme erzeugt werden, wobei deren schnelle Verfügbarkeit bereits erwähnt wurde. In der Übergangsheizperiode kommt besonders eine Zusatzheizung in Frage. Diese Wärme steht dort im Bauwerk zur Verfügung, wo klassischerweise die größten Wärmeverluste auftreten.Another advantage is the possibility of incorporating an inventive Systems as windows or in a facade the climatic conditions to be able to influence. In the summer months can be with the inside Venetian blind the heat and light flux are controlled. In the Winter months and in the transitional heating season can be heated with Disk heat are generated, with their rapid availability already mentioned has been. In the transitional heating period is especially an additional heating in question. This heat is available in the building, where classically the largest heat losses occur.

Durch die Scheibenbeheizung wird die Kondensation von Feuchtigkeit und das Beschlagen der Glasflächen verhindert. Die erzeugte Wärmeenergie entsteht als reine Wärmestrahlung und ereicht den Raum entweder auf direktem Wege oder nach Reflexion an der bevorzugt eingesetzten wärmereflektierenden Schicht der äußeren Scheibe. Auf Konvektion wird also weitgehend verzichtet. Die Beheizung erfolgt deshalb praktisch ohne Zugluft und ohne Transport von Staubpartikeln und leistet einen Beitrag zur Raumhygiene. Dieser Effekt ist besonders im Bereich der Medizin bedeutsam, beispielsweise in Operationssälen, Sterilräumen und Arztpraxen. Er spielt außerdem eine Rolle in Reinsträumen, in denen mikroelektronische Produkte hergestellt werden.Due to the disc heating, the condensation of moisture and the Fogging of the glass surfaces prevented. The generated heat energy arises as pure heat radiation and reaches the room either directly or after reflection on the preferably used heat-reflecting layer of outer disc. Convection is therefore largely dispensed with. The heating takes place therefore practically without drafts and without transport of dust particles and makes a contribution to room hygiene. This effect is especially in the field of Medicine is important, for example in operating rooms, sterile rooms and medical practices. He also plays a role in clean rooms, where microelectronic Products are manufactured.

Weitere Merkmale, Vorteile und Anwendungsmöglichkeiten der vorliegenden Erfindung ergeben sich aus der nachfolgenden Beschreibung von bevorzugten Ausführungsformen in Verbindung mit den Zeichnungen; es zeigen:

- Fig. 1:

- einen Querschnitt durch eine Ausführungsform eines erfindungsgemäßen Beschattungssystems;

- Fig. 2:

- eine schematische Darstellung der Heizung bei einer ersten Ausführungsform der Erfindung und

- Fig. 3:

- eine schematische Darstellung der Heizung bei einer zweiten Ausführungsform der Erfindung.

- Fig. 1:

- a cross section through an embodiment of a shading system according to the invention;

- Fig. 2:

- a schematic representation of the heater in a first embodiment of the invention and

- 3:

- a schematic representation of the heater in a second embodiment of the invention.

Fig. 1 zeigt den grundsätzlichen Aufbau des erfindungsgemäßen Beschattungssystems

1 im Schnitt (nachfolgend kurz "System"). Dargestellt sind die Lamellenjalousie

12 mit den Lamellen13, die zwischen zwei Scheiben 2, 3 angeordnet ist.

Scheibe 2 bildet die innere, Scheibe 3 die äußere Scheibe. Die Lamellenjalousie

12 ist durch einen Abstandhalter 4 gefaßt, der aus vier Stücken besteht. Diese

bilden einen ersten Scheibenzwischenraum 22. Gezeigt ist in Fig. 1 auch eine

Versiegelung 23, die um alle vier Seiten der Scheiben 2, 3 verläuft und das System

gasdicht abschließt. Fig. 1 shows the basic structure of the shading system according to the

Fig. 2 zeigt eine schematische Darstellung der Beheizung des erfindungsgemäßen

Beschattungssystems gemäß einer ersten Ausführungsform. Es ist zu erkennen,

dass die innere Scheibe 2 aus zwei Einzelscheiben 30, 31 aufgebaut ist,

wobei die Einzelscheibe 30 an den beschattbaren Raum und die andere Einzelscheibe

31 an den ersten Scheibenzwischenraum 22 angrenzt. Der beschattbare

Raum befindet sich links von der inneren Scheibe 2. Die Einzelscheiben 30, 31

sind mit einer zwischen ihnen angeordneten Verbindungsschicht 33 zu einer

Verbundglaseinheit verbunden. Zur Vereinfachung der Zeichnung sind weitere

Einzelheiten wie die Lamellenjalousie 12, Lamellen 13 und dgl. nicht gezeigt. Die

Beheizung erfolgt durch elektrische Heizdrähte 32, die in die Verbindungsschicht

33 eingelassen sind. Es ist also die innere Scheibe 2 beheizt.Fig. 2 shows a schematic representation of the heating of the invention

Shading system according to a first embodiment. It is recognizable,

the

Fig. 3 zeigt eine schematische Darstellung der Beheizung des erfindungsgemäßen

Beschattungssystems gemäß einer zweiten Ausführungsform des erfindungsgemäßen

Beschattungssystems. Auch hier ist die innere Scheibe 2 aus

zwei Einzelscheiben 30, 31 aufgebaut. Eine Einzelscheibe 30 grenzt wiederum

an den beschattbaren Raum und die andere Einzelscheibe 31 an den ersten

Scheibenzwischenraum 22 an. Der beschattbare Raum befindet sich ebenfalls

links von der inneren Scheibe 2. Die Einzelscheiben 30, 31 sind hier voneinander

beabstandet und bilden einen zweiten Scheibenzwischenraum 35.Fig. 3 shows a schematic representation of the heating of the invention

Shading system according to a second embodiment of the invention

Shading system. Again, the

Die Beheizung erfolgt durch eine elektrisch leitende Flächenbeschichtung 34.

Diese ist auf einer Oberfläche der an den beschattbaren Raum angrenzenden

Einzelscheibe 30 aufgebracht, und zwar auf der Oberfläche, die an den zweiten

Scheibenzwischenraum 35 angrenzt. Es befindet sich also zwischen der Flächenbeschichtung

34 und der anderen Einzelscheibe 31 noch eine Schicht in

Gestalt des zweiten Scheibenzwischenraums 35, die aus dem eingesetzten Füllgas

besteht. Diese Anordnung führt dazu, dass die durch die Beheizung erzeugte

Wärme weitgehend vollständig in Richtung auf das Innere des beschattbaren

Raumes - in der Zeichnung also in Richtung nach links - abgestrahlt wird.The heating takes place by means of an electrically

Wie bereits erwähnt und ausführlich beschrieben, kann die an den ersten Scheibenzwischenraum

22 angrenzende Oberfläche der äußeren Scheibe 3 eine wärmereflektierende

Schicht tragen. As already mentioned and described in detail, the first space between the

Gezeigt sind in Fig. 2 und 3 auch Elektroden 36 zur Spannungsversorgung bzw.

zum Anschluß der Spannung. Möglich sind quasi punktförmige Elektroden mit

relativ kleiner Fläche oder mehr bandförmige Elektroden, mit denen die Spannung

über eine entsprechend größere Fläche angelegt werden kann. Mit der

Größe der Elektroden (Randsschluß oder Flächenanschluß) läßt sich die Stromverteilung

über die beheizte Scheibe steuern. Shown in FIGS. 2 and 3 are also

- 11

- Beschattungssystemshading system

- 22

- innere Scheibeinner disc

- 33

- äußere Scheibeouter disc

- 44

- Abstandhalterspacer

- 1212

- LamellenjalousieVenetian blind

- 1313

- Lamellenslats

- 2222

- erster Scheibenzwischenraumfirst disc space

- 2323

- Versiegelungsealing

- 30, 3130, 31

- EinzelscheibenSingle discs

- 3232

- Heizdrähteheating wires

- 3333

- Verbindungsschichtlink layer

- 3434

- Flächenbeschichtungsurface coating

- 3535

- zweiter Scheibenzwischenraumsecond disc space

- 3636

- Elektrodeelectrode

Claims (9)

eine innere Scheibe (2) und eine äußere Scheibe (3), die einen ersten Scheibenzwischenraum (22) bilden und eine

im ersten Scheibenzwischenraum (22) angeordnete Lamellenjalousie (12) mit um ihre Längsachse verschwenkbaren und wahlweise zusätzlich hebund senkbaren Lamellen (13), mit der das Innere eines Raumes beschattbar ist,

dadurch gekennzeichnet, daß

mindestens eine der Scheiben (2, 3) elektrisch beheizbar ist.Shading system (1) comprising

an inner disc (2) and an outer disc (3) forming a first disc space (22) and one

arranged in the first space between the panes (22) Venetian blind (12) pivotable about its longitudinal axis and optionally additionally raise and lower slats (13) with which the interior of a room is shaded,

characterized in that

at least one of the discs (2, 3) is electrically heated.

die innere Scheibe (2) aus zwei Einzelscheiben (30, 31) aufgebaut ist, wobei eine Einzelscheibe (30) an den beschattbaren Raum und die andere Einzelscheibe (31) an den ersten Scheibenzwischenraum (22) angrenzt und die Einzelscheiben (30, 31) voneinander beabstandet sind und einen zweiten Scheinzwischenraum (35) bilden und

die Beheizung durch eine elektrisch leitende Flächenbeschichtung (34) erfolgt, die auf derjenigen Oberfläche der an den beschattbaren Raum angrenzenden Einzelscheibe (30) aufgebracht ist, die an den zweiten Scheinzwischenraum (35) angrenzt, wobei die durch die Beheizung erzeugte Wärme in Richtung auf das Innere des beschattbaren Raumes abstrahltShading system (1) according to claim 2, characterized in that

the inner disk (2) is constructed from two individual disks (30, 31), one individual disk (30) being adjacent to the shadable space and the other individual disk (31) being adjacent to the first disk space (22) and the individual disks (30, 31) spaced apart and form a second dummy gap (35) and

the heating takes place by means of an electrically conductive surface coating (34) which is applied to the surface of the single pane (30) adjoining the shadable space, which adjoins the second dummy gap (35), the heat generated by the heating being directed towards the Interior of the shadable room radiates

dadurch gekennzeichnet, daß das Stabilisierungselement von einer Schicht (35) aus transparentem gehärteten Gießharz oder aus transparentem Kunststoff gebildet wird.Shading system (1) according to claim 6 in conjunction with claim 3,

characterized in that the stabilizing element is formed by a layer (35) of transparent hardened cast resin or of transparent plastic.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE20209970U DE20209970U1 (en) | 2002-06-27 | 2002-06-27 | Heated shading system |

| DE20209970U | 2002-06-27 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1375813A2 true EP1375813A2 (en) | 2004-01-02 |

| EP1375813A3 EP1375813A3 (en) | 2004-03-24 |

| EP1375813B1 EP1375813B1 (en) | 2008-03-26 |

Family

ID=7972607

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03014321A Expired - Lifetime EP1375813B1 (en) | 2002-06-27 | 2003-06-25 | Heatable shade systems |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1375813B1 (en) |

| AT (1) | ATE390536T1 (en) |

| DE (2) | DE20209970U1 (en) |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2174745B (en) * | 1983-11-09 | 1988-05-18 | Partek Ab | Window |

| SE452899B (en) * | 1983-12-05 | 1987-12-21 | Termofrost Sweden Ab | WINDOWS WITH AN ELECTRIC LEADING LAYER |

| IT1220822B (en) | 1988-04-13 | 1990-06-21 | Adriano Torresan | GLASS STRUCTURE, ESPECIALLY FOR SOLAR RAY PROTECTION |

| DE4019268A1 (en) | 1990-03-10 | 1991-09-12 | Flachglas Ag | Vehicle double-glazing unit - including AM antenna element and combined heater and antenna element |

| CH688384A5 (en) | 1995-02-06 | 1997-08-29 | Geilinger Ag | Glass element with integrated store. |

| DE29711513U1 (en) | 1997-07-02 | 1997-09-04 | Schreier, Michael, 90765 Fürth | Windows or doors with double glazing and a third, external pane |

| DE29924398U1 (en) | 1999-12-07 | 2003-02-06 | SAINT-GOBAIN GLASS Deutschland GmbH, 52066 Aachen | Component with a cable entry |

-

2002

- 2002-06-27 DE DE20209970U patent/DE20209970U1/en not_active Expired - Lifetime

-

2003

- 2003-06-25 AT AT03014321T patent/ATE390536T1/en not_active IP Right Cessation

- 2003-06-25 DE DE50309446T patent/DE50309446D1/en not_active Expired - Lifetime

- 2003-06-25 EP EP03014321A patent/EP1375813B1/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| ATE390536T1 (en) | 2008-04-15 |

| DE50309446D1 (en) | 2008-05-08 |

| EP1375813B1 (en) | 2008-03-26 |

| DE20209970U1 (en) | 2002-09-05 |

| EP1375813A3 (en) | 2004-03-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69924092T2 (en) | glass panel | |

| DE3324221A1 (en) | HEAT WAVE SHIELDING LAMINATION | |

| DE102008018147A1 (en) | Transparent disc with a heatable coating and low-resistance conductive structures | |

| EP2110238A1 (en) | Blast effect-limiting glazing structure | |

| EP3701111B1 (en) | Building facade element embodied as an insulating glass unit | |

| DE19525263A1 (en) | Fire-resistant glazing | |

| EP3931161A1 (en) | Glazing unit and method for producing same | |

| EP0978620B1 (en) | Insulating glass element for the glazing of buildings | |

| DE69016476T2 (en) | Warming window. | |

| DE4417496C2 (en) | Window structure for fire protection glazing | |

| AT510186B1 (en) | TURN WINDOW | |

| DE3700076C2 (en) | ||

| EP2093052B1 (en) | Glass component comprising at least one glass element from a conventional glass and a functional coating | |

| DE68908848T2 (en) | Multi-layer warming window. | |

| EP1375813B1 (en) | Heatable shade systems | |

| EP1172496A2 (en) | Double facade | |

| DE10217045B4 (en) | Passive house suitable glazing element | |

| AT507154B1 (en) | INSULATING GLASS | |

| DE102007002467B4 (en) | Movable shading device in the space between the panes of an insulating glazing | |

| EP2507463B1 (en) | Heat insulating device and method of heat insulation | |

| EP2060734B1 (en) | Anti-dazzle device | |

| DE4140851A1 (en) | Sun-blind for protecting building from heating effect of solar radiation - has juxtaposed cells or channels separated by struts, with inner surfaces having larger reflective index for visible radiation than for solar and sky radiation components | |

| EP0984131A1 (en) | Darkening and light-deflecting system | |

| DE10158620A1 (en) | Daylight system with coated glass lamella for architectural applications has coated strips of flat glass arranged horizontally one above the other or vertically adjacent to each other | |

| WO2024104686A1 (en) | Glazing element with integrated sun protection |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: 7E 06B 9/264 A Ipc: 7H 05B 3/84 B |

|

| 17P | Request for examination filed |

Effective date: 20040924 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20050304 |

|

| 17Q | First examination report despatched |

Effective date: 20050304 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 50309446 Country of ref document: DE Date of ref document: 20080508 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080326 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080326 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080326 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080326 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080626 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080707 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080326 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080326 |

|

| BERE | Be: lapsed |

Owner name: KIRRLACHER GLASMANUFAKTUR ANDREAS HERZOG G.M.B.H. Effective date: 20080630 |

|

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080326 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080326 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080630 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20080626 |

|

| 26N | No opposition filed |

Effective date: 20081230 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090116 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080326 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080626 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080626 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080630 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080625 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080326 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080326 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080927 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080625 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080326 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080627 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20200709 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50309446 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220101 |