EP1106743B1 - Process and device for manufacturing a fibrous insulation web - Google Patents

Process and device for manufacturing a fibrous insulation web Download PDFInfo

- Publication number

- EP1106743B1 EP1106743B1 EP00710034A EP00710034A EP1106743B1 EP 1106743 B1 EP1106743 B1 EP 1106743B1 EP 00710034 A EP00710034 A EP 00710034A EP 00710034 A EP00710034 A EP 00710034A EP 1106743 B1 EP1106743 B1 EP 1106743B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- fibrous web

- process according

- cover layer

- partial webs

- large surfaces

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims description 51

- 238000009413 insulation Methods 0.000 title claims description 27

- 238000004519 manufacturing process Methods 0.000 title claims description 14

- 230000036961 partial effect Effects 0.000 claims description 54

- 239000000835 fiber Substances 0.000 claims description 48

- 239000011230 binding agent Substances 0.000 claims description 34

- 239000002557 mineral fiber Substances 0.000 claims description 21

- 230000006835 compression Effects 0.000 claims description 15

- 238000007906 compression Methods 0.000 claims description 15

- 238000005520 cutting process Methods 0.000 claims description 11

- 238000001035 drying Methods 0.000 claims description 11

- 239000004744 fabric Substances 0.000 claims description 5

- 230000003014 reinforcing effect Effects 0.000 claims description 5

- 239000002184 metal Substances 0.000 claims description 4

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 3

- 229910052799 carbon Inorganic materials 0.000 claims description 3

- 239000011521 glass Substances 0.000 claims description 3

- 238000007667 floating Methods 0.000 claims description 2

- 230000000284 resting effect Effects 0.000 claims 1

- 239000003570 air Substances 0.000 description 18

- 239000011490 mineral wool Substances 0.000 description 14

- 239000012774 insulation material Substances 0.000 description 10

- 230000000694 effects Effects 0.000 description 7

- 239000000463 material Substances 0.000 description 7

- 239000004745 nonwoven fabric Substances 0.000 description 7

- 238000007639 printing Methods 0.000 description 7

- 239000011810 insulating material Substances 0.000 description 6

- 238000005056 compaction Methods 0.000 description 4

- 238000010276 construction Methods 0.000 description 4

- 230000003247 decreasing effect Effects 0.000 description 4

- 238000011161 development Methods 0.000 description 4

- 241000446313 Lamella Species 0.000 description 2

- 229920001807 Urea-formaldehyde Polymers 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 238000013461 design Methods 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 239000003921 oil Substances 0.000 description 2

- 239000011505 plaster Substances 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- RMAQACBXLXPBSY-UHFFFAOYSA-N silicic acid Chemical class O[Si](O)(O)O RMAQACBXLXPBSY-UHFFFAOYSA-N 0.000 description 2

- 238000003980 solgel method Methods 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 206010023230 Joint stiffness Diseases 0.000 description 1

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 239000012080 ambient air Substances 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 238000002845 discoloration Methods 0.000 description 1

- 239000000839 emulsion Substances 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- LCDFWRDNEPDQBV-UHFFFAOYSA-N formaldehyde;phenol;urea Chemical compound O=C.NC(N)=O.OC1=CC=CC=C1 LCDFWRDNEPDQBV-UHFFFAOYSA-N 0.000 description 1

- 238000009432 framing Methods 0.000 description 1

- 239000011491 glass wool Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 230000002209 hydrophobic effect Effects 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- WSFSSNUMVMOOMR-NJFSPNSNSA-N methanone Chemical compound O=[14CH2] WSFSSNUMVMOOMR-NJFSPNSNSA-N 0.000 description 1

- 239000002105 nanoparticle Substances 0.000 description 1

- 238000004064 recycling Methods 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 238000010008 shearing Methods 0.000 description 1

- 235000012239 silicon dioxide Nutrition 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 230000036962 time dependent Effects 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

- 210000002268 wool Anatomy 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4209—Inorganic fibres

- D04H1/4218—Glass fibres

-

- D—TEXTILES; PAPER

- D02—YARNS; MECHANICAL FINISHING OF YARNS OR ROPES; WARPING OR BEAMING

- D02G—CRIMPING OR CURLING FIBRES, FILAMENTS, THREADS, OR YARNS; YARNS OR THREADS

- D02G1/00—Producing crimped or curled fibres, filaments, yarns, or threads, giving them latent characteristics

- D02G1/20—Combinations of two or more of the above-mentioned operations or devices; After-treatments for fixing crimp or curl

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4209—Inorganic fibres

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4209—Inorganic fibres

- D04H1/4218—Glass fibres

- D04H1/4226—Glass fibres characterised by the apparatus for manufacturing the glass fleece

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4209—Inorganic fibres

- D04H1/4234—Metal fibres

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4209—Inorganic fibres

- D04H1/4242—Carbon fibres

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/58—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties by applying, incorporating or activating chemical or thermoplastic bonding agents, e.g. adhesives

- D04H1/593—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties by applying, incorporating or activating chemical or thermoplastic bonding agents, e.g. adhesives to layered webs

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/70—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres characterised by the method of forming fleeces or layers, e.g. reorientation of fibres

- D04H1/72—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres characterised by the method of forming fleeces or layers, e.g. reorientation of fibres the fibres being randomly arranged

- D04H1/732—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres characterised by the method of forming fleeces or layers, e.g. reorientation of fibres the fibres being randomly arranged by fluid current, e.g. air-lay

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/70—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres characterised by the method of forming fleeces or layers, e.g. reorientation of fibres

- D04H1/74—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres characterised by the method of forming fleeces or layers, e.g. reorientation of fibres the fibres being orientated, e.g. in parallel (anisotropic fleeces)

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H13/00—Other non-woven fabrics

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/62—Insulation or other protection; Elements or use of specified material therefor

- E04B1/74—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls

- E04B1/76—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls specifically with respect to heat only

- E04B1/7654—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls specifically with respect to heat only comprising an insulating layer, disposed between two longitudinal supporting elements, e.g. to insulate ceilings

- E04B1/7658—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls specifically with respect to heat only comprising an insulating layer, disposed between two longitudinal supporting elements, e.g. to insulate ceilings comprising fiber insulation, e.g. as panels or loose filled fibres

- E04B1/7662—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls specifically with respect to heat only comprising an insulating layer, disposed between two longitudinal supporting elements, e.g. to insulate ceilings comprising fiber insulation, e.g. as panels or loose filled fibres comprising fiber blankets or batts

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/62—Insulation or other protection; Elements or use of specified material therefor

- E04B1/74—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls

- E04B1/76—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls specifically with respect to heat only

- E04B1/78—Heat insulating elements

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F15/00—Flooring

- E04F15/02—Flooring or floor layers composed of a number of similar elements

- E04F15/10—Flooring or floor layers composed of a number of similar elements of other materials, e.g. fibrous or chipped materials, organic plastics, magnesite tiles, hardboard, or with a top layer of other materials

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/62—Insulation or other protection; Elements or use of specified material therefor

- E04B1/74—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls

- E04B1/76—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls specifically with respect to heat only

- E04B2001/7683—Fibrous blankets or panels characterised by the orientation of the fibres

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/62—Insulation or other protection; Elements or use of specified material therefor

- E04B1/74—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls

- E04B1/76—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls specifically with respect to heat only

- E04B2001/7687—Crumble resistant fibrous blankets or panels using adhesives or meltable fibres

Definitions

- the invention relates to a method for producing a particular single Insulation panels of mineral fibers splittable Faserdämmstoffbahn with substantially mineral fibers oriented at right angles to their large surfaces, in which the mineral fibers withdrawn from a collection chamber and on a Conveyor belt as a primary web substantially parallel to the large surfaces aligned mineral fibers are deposited.

- the invention further relates a device for carrying out the method with a conveyor belt for conveying a primary web of mineral fibers from a collection chamber to a Pendulum station.

- Mineral wool insulation materials consist of vitreous solidified fibers, which can be classified as non-combustible insulating materials in order to maintain the elastic-springy properties, but with less than 8% by mass, with mineral wool insulation materials made of rock wool with approx 4% by mass of binders, in particular phenol-formaldehyde-urea resins are bonded. Inorganic binders, such as organic silicic acid compounds that react via sol-gel processes, are also used. Flexible, compressible mineral wool insulation materials made of glass wool have densities of less than 30 kg / m 3 . Comparable mineral wool insulation materials made of rock wool, which contain not inconsiderable amounts of non-fibrous constituents, are produced with densities between approximately 23 to 45 kg / m 3 . In addition, mechanically resilient mineral wool insulating materials, for example, for the insulation of flat roof constructions are known, the bulk densities greater than 130 kg / m 3 have. Such insulating materials can also be used in thermal insulation systems as plaster base plates.

- the mechanical and thermal properties of mineral wool insulation materials are u.a. depending on the orientation of the individual fibers. Are the fibers across the large surfaces of the mineral wool insulation aligned, the insulation material is compressible. At the same time the insulating material but also a low transverse tensile strength and thermal conductivity transverse to the fiber orientation. To mineral wool insulation materials with high strength values It is necessary to produce the individual fibers predominantly align at right angles to the large surfaces. This is usually a mass flow of fibers with its horizontal and flat inclined fibers inside by a continuous horizontal compression in one area folded between 1 to 2.5 and 1 to 3 with simultaneous vertical compression.

- binder drops, as it is here through the direct contact with the ambient air for a quick drying or Curing the binder comes. Furthermore, binder substance goes to the conveyor lost. In addition, rich on these surfaces of the primary nonwoven layers low binder fiber flakes and recycled fibers that form a composite weaken the fibers in this area from the outset.

- the Tempe- or Verfaltung of the fibers using the method described is in the Height limited, as with increasing thickness and increasing forces through Shaping mutual effects, such as parallel bearings to the can adjust to large surfaces. With increasing material thickness decreases also the uniformity of the structure.

- the endless fiber mass flow before Hardening furnace cut into sections, which sections subsequently to Rotated 90 °, compressed horizontally and compressed vertically by 20%. Also in this process, the fibers become underneath the large surfaces mostly horizontally stored, so that these areas to achieve optimal transverse tensile strength must be removed.

- Mineral wool insulation materials produced by this process have a maximum Material thickness of about 220 mm. Since in all process variants the Unfolding in the direction of production, are the bending, tensile and shear strength transverse to the production direction by a multiple higher than in production and Verfaltungsraum. To high transverse tensile strength at possibly even reduced To be able to achieve gross densities, insulation boards are made of such produced mineral wool insulation parallel to the production and unfolding direction sliced according to the desired insulation thickness. This process is relatively expensive, as it is not on the actual Production line can be done, but mostly using large format Sheets as semi-finished material on separate cutting and deflection systems must be performed.

- Lamella plates produced in this way which are often used as plaster base plates in external thermal insulation systems or as load-bearing insulating layer in sandwich constructions with metal sheets or wood wool lightweight panels as cover layers, are used to achieve a high shear or joint stiffness and a high transverse tensile strength of a particularly intensive Subjected to fiber layers.

- the gross densities of such lamella plates are in a range between about 70 to 105 kg / m 3 .

- the invention has for its object to provide a generic method and a generic device for implementing the method to the effect that fiber insulation webs can be prepared with an intense folding of the mineral fibers in a simple and cost-effective manner, whereby the mechanical properties in the two major axes of the horizontal plane are equal or nearly equal.

- the primary nonwoven is divided by at right angles to the large surfaces cuts in at least two, preferably several, in particular the same dimensions having partial webs that the partial webs are then rotated by 90 ° about its longitudinal axis and that the partial webs are suspended and joined together to form a secondary web.

- the partial webs of Primary fleece before turning about its longitudinal axis relative to the conveying plane one above the other to be ordered are after their rotation stacked around their longitudinal axis and together a pendulum device fed, which bounces the stack of partial webs to the primary web.

- the pendulum takes place in the horizontal direction in the conveying direction of the secondary web receiving conveyor belt.

- the partial webs and / or the secondary web during and / or compressed after flaring are substantially orthogonal directions.

- laterally arranged pressure bands are the secondary web or the partial webs compressed to the desired width.

- the compression is preferably carried out continuously to produce a uniformly compressed product.

- the secondary web then fed to a curing oven to cure the binder.

- the cover layer can be before or after the curing oven from the secondary web be separated.

- the mineral fibers are parallel to the large surfaces. If the cover layer is separated after the hardening furnace, so this results in a marketable product with pronounced laminar structure, the corresponding density, for example, for impact sound insulation can be used under floating screed.

- the cover layer separated is before the secondary web is fed to a curing oven.

- the cover layer uncured binder so that the cover layer after separation nor in terms of their material properties can be changed.

- the application-specific required bulk density of the cover layer by compression of the cover layer be set at uncured binder.

- the cover layer only after the passage of the secondary web is separated by the curing oven.

- the inventive method has the advantage that over several pendulums a plurality of nonwoven layers are guided to each other, for example, a Faserdämmstoffbahn to produce, which is sandwiched.

- a Faserdämmstoffbahn to produce, which is sandwiched.

- the primary nonwoven fabric with one or more nonwoven layers, in particular different properties is joined together. It can therefore, for example Nonwoven layers with higher and / or lower density or with higher or lower degree of compression, wherein the joining of the different nonwoven layers before the curing oven takes place, so that the connection between the nonwoven layers in particular through the not yet cured binder is possible.

- the primary nonwoven is compressed before or during the pendulum.

- the surfaces of the Sub-webs are impregnated with binders before the sub-webs merged become.

- a development of the method according to the invention provides that between adjacent sub-webs reinforcing fabric and / or nonwovens, for example Glass, carbon, metal, temperature resistant plastic and / or Natural fibers are arranged.

- Such fabrics can be used as reinforcement of the Faserdämmstoffbahnen serve and increase the load capacity of this Faserdämmstoffbahn produced insulating panels.

- the secondary web is preferably perpendicular before and / or in the curing oven to compressed its large surfaces. In this way, a fiber insulation sheet produced with defined dimensions, without the risk of bulging the pulp in the curing oven consists.

- hot air is both perpendicular to the large Surfaces, as well as passed through the longitudinal sides of the secondary web to a higher efficiency of the curing oven and thus improved curing of the binder to achieve.

- the secondary web will also be up after hardening of the binder guided clamped on all sides.

- the secondary web After curing of the binder, the secondary web becomes parallel to its cut large surfaces into individual sections.

- This approach has the advantage that a downstream dryer for the fiber insulation in compact design can be designed.

- the individual sections will be stacked next to and / or on top of each other and fed to the dryer.

- the fiber insulation by cuts perpendicular to their large surfaces in individual plates cuboid configuration can be divided.

- the longitudinal sides of the secondary web after curing of the binder for Crop education flat surfaces.

- the invention is based task a generic device for carrying out the above-described Method solved in that the conveyor belt is a cutting device comprising, with the primary web in side by side on the conveyor belt lying partial webs is divisible and that the cutting device is a rotating device is connected downstream, with the individual partial webs relative to its longitudinal axis rotatable by 90 °, before entering the shuttle station to form a secondary web enter.

- the conveyor belt is a cutting device comprising, with the primary web in side by side on the conveyor belt lying partial webs is divisible and that the cutting device is a rotating device is connected downstream, with the individual partial webs relative to its longitudinal axis rotatable by 90 °, before entering the shuttle station to form a secondary web enter.

- the cutting device has one of the number n of the required partial webs corresponding Number of n-1 saws, especially as band or circular saws are formed.

- pendulum station are preferably paired pressure belts or Roller conveyors intended for all partial webs.

- the shuttle station is possible to form a partial web, so that the inventive device a the number of partial webs corresponding number of pairs arranged Has pressure bands or roller conveyors.

- the shuttle station a curing oven with at least two Pressure belts downstream of which is on the large surfaces of the secondary web rest and passed through a heated gas, in particular hot air becomes.

- two further printing tapes are provided, which are on the longitudinal sides of the secondary web abut, so that the secondary web is clamped on one side in this embodiment is and can be compressed if necessary in the direction of all surfaces.

- the applied pressure bands on the longitudinal sides are adjustable relative to each other arranged in the curing oven, so that they to different widths secondary nonwovens can be adapted or with appropriate setting a planned Transfer compression to the secondary web.

- the pressure bands applied to the longitudinal sides of the secondary web are permeable to air formed and in particular have openings through the heated Gas, especially hot air, is conductive to additional heat energy to introduce the secondary web to cure the binder.

- the impregnated with a binder in a collection chamber collected primary nonwoven depending on the width and the thickness in split two or more sublanes.

- the partial webs are subsequently superimposed and individually deflected by 90 ° about its longitudinal axis and thus standing on one side and led on a collecting conveyor belt.

- the one above the other arranged partial webs are then fed to a pendulum, the off two parallel conveyor belts exists, which is a common Vertical axis oscillate, so that the partial webs meandering together parked the collection conveyor belt.

- the partial webs of the primary web which inwardpendelter form the secondary web, to a desired Width compressed.

- the compression can also by stroke-like movement of these construction elements be executed.

- the direction of movement of the printing tapes or the Pressure rollers are preferably at right angles to the conveying direction of the secondary web. But there is also the possibility of compression under one to execute any angle in the direction of the conveying direction.

- the withdrawn from the collection chamber Primary fleece is divided into several sub-webs, which then individual swinging conveyors, consisting of conveyor belts or roller sets be supplied. In this procedure, the partial webs are individually pendulated before being subsequently brought together and arranged laterally Printing tapes are supplied.

- reinforcing fabrics or nonwovens made of glass, carbon, Metal, temperature-resistant plastics or natural fibers on the side surfaces the partial webs or the primary web or secondary web but also between the partial webs are provided.

- the fleeces are here with opposite fed to the partial webs of smaller width, since the primary web in a further intermediate step before or after the hardening furnace on its long sides is cropped. Due to the intensive configuration of the partial webs or the secondary web form the inserted fabric or nonwovens over the entire surface the insulating panels formed from the fiber insulation sheet effective reinforcing elements.

- reinforcing elements have an effect, in particular with regard to on the transverse tensile strength of the insulation boards and can do the inevitable time-dependent, by hygrothermal and / or hydromechanical Stress-related strength losses of such insulation not only too but also lead to more safety in the application of such Insulation materials.

- the collection conveyor belt can from several individual conveyor belts or roller sets or combinations of both construction elements exist with decreasing Speed are operated and thus a compression of the secondary web effect in the transport direction. Furthermore, in the transport direction, i.e. across the width of the production plant several narrow bands or Roller sets can be arranged distributed across the width of the production line be driven at different speeds. This will achieve that the compaction and the framing also in the central areas of the secondary web can be influenced. For example, a lower conveyor belt supplemented by a mirror-image arranged upper pressure band, which on the pulp mass to be folded or compressed acts.

- This print tape has first and foremost the task of favoring the composition, with a too large one Compression in the horizontal direction should be excluded as possible.

- the lower and upper subbands with projections protruding from their surface be formed, which engage in the pulp, in particular the secondary web and move the fibers relative to each other.

- the secondary web can have a thickness between 200 and 2000 mm with a bulk density of about 40 to 300 kg / m 3 .

- the secondary non-woven fabric in the region below its large surfaces at certain depth fibers, which are not formed substantially perpendicular to the large surfaces. Since a Faserdämmstoffbahn is to be produced, which has almost exclusively aligned at right angles to the large surfaces mineral fibers, these areas are subsequently separated by horizontally guided cutting tools from the secondary web.

- the separated fibers can be fed to an internal recycling process in a known manner and remelted. However, there is also the possibility that the separated fiber layers are again fed to the primary web directly or the fiber mass flow in the collection chamber after appropriate loosening.

- Such a curing oven is usually made of two stable stacked Pressure belts through which hot air is sucked.

- At heights of secondary nonwovens of less than 200 mm is applied to the sealing of the side surfaces of the Secondary fleece no special value.

- the secondary web remains about 2 to 15 minutes, preferably less than 10 minutes in the curing oven, so that relatively hot air with temperatures of about 250 to 320 ° C are used must be in order to achieve sufficient curing of the binder.

- relatively hot air with temperatures of about 250 to 320 ° C are used must be in order to achieve sufficient curing of the binder.

- a destruction of the organic substance of the binder is avoided, as this discoloration occur, the for sale of the product produced.

- the added to the hydrophobization of the fibers oils, oil emulsions or the like is not yet substantially voluminous.

- the secondary webs presented by the method according to the invention have a width between 500 and 2400 mm width and material thicknesses up to 2000 mm.

- the leadership of the hot air through the secondary web naturally occurs the shortest path, i. in the indicated variations between thicknesses and Widths from top to bottom or vice versa and in sections Reversal.

- side pressure bands which also Partially permeable to air, hot air can be added continuously from top to bottom sucked or pressed by the fiber mass and in addition can be entered or removed via the side print bands.

- the existing openings can be transferred as much energy as they are to Drying and curing of organic binders such as phenol, Formaldehyde, urea-resin mixtures or the like together with the existing moisture in the order of 3 to 10% by mass within of about 2 to 8 minutes is needed, with the secondary web at a temperature from about 120 to 170 ° C is heated.

- organic binders such as phenol, Formaldehyde, urea-resin mixtures or the like

- binders such as silicic acid dispersed as nanoparticles, which cure via sol-gel processes, appropriate changes of the heating and holding time are to be provided.

- the structure of the secondary nonwoven fixed After curing of the binder in the curing oven is the structure of the secondary nonwoven fixed, so that the endless secondary web are transported freely can.

- the secondary web is now to avoid energy loss in one heated and sufficiently thermally insulated drying duct passed, in which the evaporate in inclusions or the enriched there resin existing water can.

- a drying time of approx. 40 to 80 minutes At a temperature of approx. 150 ° C, a drying time of approx. 40 to 80 minutes provided.

- the drying process is effectively supported or abbreviated as appropriate.

- the pulp After leaving the drying channel, the pulp becomes air in the room cooled.

- the energy content of the exhaust air can be used to heat the dryer air be used.

- the endless secondary web is now cut horizontally or divided into individual sections, which then form insulating panels.

- a reduction in the length of the downstream Trockners can reach the secondary web after curing of the binder are divided into sections in the hardening furnace.

- This block-like Sections are stacked next to and / or above each other. The by this procedure incurred energy losses must be replaced by a corresponding Increase of the temperature, but especially by a longer residence time in be compensated for the dryer.

- the secondary nonwoven cooled down conventionally by room air after curing of the binder and horizontally in insulation boards of the desired dimensions and split vertically.

- These insulation boards are then individually or passed in stacks over an air-permeable belt and by means of hot air heated to about 120 to 170 ° C, preferably 150 to 160 ° C and then piled up to larger units to prevent energy losses and nachgetrocknet according to the described process technology.

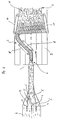

- FIG. 1 shows a plan view of a section of a device for producing a device in individual insulation boards of mineral fibers splittable Faserdämmstoffbahn 1.

- a primary web 2 of a cutting device 3 is supplied, which Cutting device 3 has three bandsaws 4, which the primary web 2 in four side by side lying on a conveyor not shown Part webs 5 divides.

- the partial webs 5 are then passed over each other and then in a region 6 each rotated by 90 ° about its longitudinal axis.

- the meandering deposited partial webs 5 of the primary web 2 are then laterally arranged pressure belts 10 supplied with their pendulum device 7 facing away from each other ends are aligned. Between the printing tapes 10, the partial webs 5 of the primary web 2 are compressed. The partial webs 5 of the primary web 2 form a secondary web at this time 11th

- the secondary web 11 is essentially characterized in that its Einzelfasem predominantly perpendicular to the large surfaces of the secondary web 11 are aligned.

- the mineral fibers in the primary web 2 an orientation substantially parallel to the large Surfaces of the primary nonwoven 2 have. Only in the immediate area of large surfaces are the individual mineral fibers of the secondary web 11 by the compression and the unfolding of the primary web 2 or secondary web 11 substantially parallel to the large surfaces of the secondary web 11 aligned.

- the secondary web 11 is connected to the printing tapes 10 further pressure bands Supplied according to Figure 3, which on the large surfaces of the secondary web 11 act.

- Another cutting device 14 is arranged, which consists of two saws 15, which saws 15 horizontally and parallel to the large surfaces of the secondary web 11 are aligned so that by means of these saws 15 cover layers 16th be separated in the region of both large surfaces of the secondary web 11 can.

- the cover layers 16 comprise the region of the secondary nonwoven 11, which has a Fiber profile arranged parallel to the large surfaces of the secondary nonwoven 11 Mineral fibers.

- the curing oven 13 is a secondary web 11 with almost exclusively perpendicular to the large surfaces of the Sekundärvlieses 11 extending fiber assembly supplied.

- the hardening furnace 13 in turn consists of two acting on the large surfaces Conveyor belts 17, which are permeable to air, so that hot air in Direction of the arrows 18 shown in Figure 3 by the secondary web 11 diffuse can.

- the secondary web 11 is after leaving the curing oven 13 a not fed dryer shown to subsequently after drying to be cut into individual insulation boards.

- FIG. 1 An alternative embodiment of the section according to FIG. 1 is shown in FIG.

- the partial webs individual pendulum devices 19 fed each consisting of two roller conveyors 20, which a decreasing in the conveying direction according to arrow 21 distance from each other to have.

- the individually suspended partial webs 5 are then together two further roller conveyors 100 fed, between which the individually pendulum Part webs 5 are interconnected and compressed.

- the Roller conveyors 100 also have a decreasing direction in the direction of arrow 21 Distance from each other and perform the same task as the Printing tapes 10 of the embodiment according to FIG. 1.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Architecture (AREA)

- Chemical & Material Sciences (AREA)

- Inorganic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Acoustics & Sound (AREA)

- Electromagnetism (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Nonwoven Fabrics (AREA)

Description

Die Erfindung betrifft ein Verfahren zur Herstellung einer insbesondere in einzelne Dämmstoffplatten aus Mineralfasern aufteilbare Faserdämmstoffbahn mit im wesentlichen zu ihren großen Oberflächen rechtwinklig ausgerichteten Mineralfasern, bei dem die Mineralfasern aus einer Sammelkammer abgezogen und auf einem Förderband als Primärvlies mit im wesentlichen parallel zu den großen Oberflächen ausgerichteten Mineralfasern abgelegt werden. Die Erfindung betrifft ferner eine Vorrichtung zur Durchführung des Verfahrens mit einem Förderband zur Förderung eines Primärvlieses aus Mineralfasem von einer Sammelkammer zu einer Pendelstation.The invention relates to a method for producing a particular single Insulation panels of mineral fibers splittable Faserdämmstoffbahn with substantially mineral fibers oriented at right angles to their large surfaces, in which the mineral fibers withdrawn from a collection chamber and on a Conveyor belt as a primary web substantially parallel to the large surfaces aligned mineral fibers are deposited. The invention further relates a device for carrying out the method with a conveyor belt for conveying a primary web of mineral fibers from a collection chamber to a Pendulum station.

Mineralwolle-Dämmstoffe bestehen aus glasig erstarrten Fasern, die zur Erhaltung der elastisch-federnden Eigenschaften, aber auch um als nicht brennbare Dämmstoffe eingestuft werden zu können, nur mit weniger als 8 Masse-%, bei Mineralwolle-Dämmstoffen aus Steinwolle mit ca. 2 bis 4 Masse-% Bindemitteln, insbesondere Phenol-Formaldehyd-Harnstoff-Harzen gebunden sind. Anorganische Bindemittel, wie organische Kieselsäure-Verbindungen, die über Sol-Gel-Prozesse reagieren, werden ebenfalls verwendet. Flexible, kompressible Mineralwolle-Dämmstoffe aus Glaswolle weisen Rohdichten von weniger als 30 kg/m3 auf. Vergleichbare Mineralwolle-Dämmstoffe aus Steinwolle, die nicht unbeträchtliche Anteile nichtfaseriger Bestandteile enthalten, werden mit Rohdichten zwischen ca. 23 bis 45 kg/m3 hergestellt. Darüber hinaus sind mechanisch belastbare Mineralwolle-Dämmstoffe, beispielsweise zur Dämmung von Flachdachkonstruktionen bekannt, die Rohdichten von größer 130 kg/m3 aufweisen. Derartige Dämmstoffe können auch bei Wärmedämmverbundsystemen als Putzträgerplatten eingesetzt werden.Mineral wool insulation materials consist of vitreous solidified fibers, which can be classified as non-combustible insulating materials in order to maintain the elastic-springy properties, but with less than 8% by mass, with mineral wool insulation materials made of rock wool with approx 4% by mass of binders, in particular phenol-formaldehyde-urea resins are bonded. Inorganic binders, such as organic silicic acid compounds that react via sol-gel processes, are also used. Flexible, compressible mineral wool insulation materials made of glass wool have densities of less than 30 kg / m 3 . Comparable mineral wool insulation materials made of rock wool, which contain not inconsiderable amounts of non-fibrous constituents, are produced with densities between approximately 23 to 45 kg / m 3 . In addition, mechanically resilient mineral wool insulating materials, for example, for the insulation of flat roof constructions are known, the bulk densities greater than 130 kg / m 3 have. Such insulating materials can also be used in thermal insulation systems as plaster base plates.

Die mechanischen, wie auch wärmeschutztechnischen Eigenschaften der Mineralwolle-Dämmstoffe sind u.a. abhängig von der Orientierung der einzelnen Fasern. Sind die Fasern quer zu den großen Oberflächen des Mineralwolle-Dämmstoffs ausgerichtet, so ist der Dämmstoff kompressibel. Gleichzeitig weist der Dämmstoff aber auch eine niedrige Querzugfestigkeit und Wärmeleitfähigkeit quer zur Faserorientierung auf. Um Mineralwolle-Dämmstoffe mit großen Festigkeitswerten herzustellen, ist es erforderlich, die einzelnen Fasern überwiegend rechtwinklig zu den großen Oberflächen auszurichten. Hierbei wird in der Regel ein Fasermassenstrom mit seinen darin horizontal und flachgeneigt liegenden Fasern durch eine kontinuierlich wirkende horizontale Stauchung in einem Bereich zwischen 1 zu 2,5 und 1 zu 3 bei gleichzeitig vertikaler Kompression aufgefaltet.The mechanical and thermal properties of mineral wool insulation materials are u.a. depending on the orientation of the individual fibers. Are the fibers across the large surfaces of the mineral wool insulation aligned, the insulation material is compressible. At the same time the insulating material but also a low transverse tensile strength and thermal conductivity transverse to the fiber orientation. To mineral wool insulation materials with high strength values It is necessary to produce the individual fibers predominantly align at right angles to the large surfaces. This is usually a mass flow of fibers with its horizontal and flat inclined fibers inside by a continuous horizontal compression in one area folded between 1 to 2.5 and 1 to 3 with simultaneous vertical compression.

Von außen auf den Fasermassenstrom wirkende Scherkräfte bewirken eine intensive Relativbewegung zwischen den einzelnen Fasern bzw. Faserschichten. Hierdurch kommt es zur Ausbildung von Gleitbahnen mit parallel zueinander orientierten Fasern innerhalb des aufgefalteten Fasernmassenstroms, der nachfolgend als Primärvlies bezeichnet wird. Entlang der Gleitbahnen weist das Primärvlies eine verringerte Haftung zwischen den Fasern bzw. Faserschichten auf. Diese Bereiche verringerter Haftung werden bevorzugt entlang der ursprünglichen Oberflächen des Primärvlieses angeordnet. Es handelt sich hierbei um Faserlagen, die in geringer Materialstärke aus eine Sammelkammer abgezogen und zu größeren Stapeln kontinuierlich übereinander gelegt werden. Beim Transport und dem Übereinanderlegen der Primärvlieslagen werden die Fasern in den oberflächennahen Zonen des Primärvlieses umorientiert. Darüber hinaus sinkt die Klebfähigkeit der in diesen Bereichen angeordneten Bindemitteltropfen, da es hier durch den direkten Kontakt mit der Umgebungsluft zu einem schnellen Antrocknen bzw. Aushärten des Bindemittels kommt. Ferner geht Bindemittelsubstanz an die Fördereinrichtung verloren. Zudem reichem sich auf diesen Oberflächen der Primärvlieslagen bindemittelarme Faserflocken und recycelte Fasern an, die einen Verbund der Fasern in diesem Bereich von vornherein schwächen. Diese Schwächezonen wirken sich insbesondere dann aus, wenn die Dämmstoffe wiederholt oder andauernd hydromechanischen Belastungen während des Gebrauchs ausgesetzt sind. Shearing forces acting on the pulp mass flow from outside cause an intensive Relative movement between the individual fibers or fiber layers. hereby it comes to the formation of slideways with parallel oriented Fibers within the unfolded fiber mass flow following is called primary nonwoven. Along the slideways has the primary web a reduced adhesion between the fibers or fiber layers. These Areas of reduced adhesion are preferred along the original surfaces arranged the primary web. These are fiber layers, the deducted in a small material thickness from a collection chamber and larger Stacking is done continuously. During transport and the Overlaying the primary nonwoven layers, the fibers become near the surface Reoriented zones of the primary web. In addition, the adhesiveness decreases the arranged in these areas binder drops, as it is here through the direct contact with the ambient air for a quick drying or Curing the binder comes. Furthermore, binder substance goes to the conveyor lost. In addition, rich on these surfaces of the primary nonwoven layers low binder fiber flakes and recycled fibers that form a composite weaken the fibers in this area from the outset. These weaknesses In particular, they have an effect if the insulating materials are repeated or constantly exposed to hydromechanical loads during use are.

Die Auf- bzw. Verfaltung der Fasern mit Hilfe der geschilderten Methode ist in der Höhe begrenzt, da sich mit zunehmender Dicke und steigenden Kräften durch Überformung gegenseitige Effekte, wie beispielsweise Parallellagerungen zu den großen Oberflächen einstellen können. Mit zunehmender Materialstärke sinkt auch die Gleichmäßigkeit der Struktur.The Auf- or Verfaltung of the fibers using the method described is in the Height limited, as with increasing thickness and increasing forces through Shaping mutual effects, such as parallel bearings to the can adjust to large surfaces. With increasing material thickness decreases also the uniformity of the structure.

Eine Verbesserung des voranstehend beschriebenen Verfahrens ist dadurch gegeben, daß der Fasermassenstrom durch ein System von Umlenkrollen geführt wird, wodurch die einzelnen Fasern in den Umlenkbereichen horizontal gelagert werden. Dieser zusätzliche Verfahrensschritt hat Auswirkungen auf die Querzugfestigkeit des Primärvlieses. Anstelle von Umlenkrollen kann eine Auffaltung auch mit Hilfe einer um eine horizontale Achse auf- und niederbewegten, d.h. pendelnden Transporteinrichtung erfolgen. Das aufgependelte Primärvlies wird als Sekundärvlies bezeichnet, welches zu einer Erhöhung seiner Querzugfestigkeit dahingehend bearbeitet wird, daß die im Bereich der beiden großen Oberflächen des Sekundärvlieses horizontal gelagerten Fasern nach dem Aushärten des Bindemittels bis in einen Bereich abgetrennt werden, in dem annähernd ausschließlich rechtwinklig zu den großen Oberflächen angeordnete Fasern vorliegen. Bei Dämmstoffen mit geringer Materialstärke von beispielsweise 100 mm müssen bis zu 20% des ursprünglichen Volumens auf diese Art entfernt werden, um ein Mineralwolle-Dämmstoffprodukt zu erzielen, das überwiegend rechtwinklig zu den großen Oberflächen ausgerichteten Einzelfasern hat.An improvement of the method described above is given by that the fiber mass flow passed through a system of pulleys is, whereby the individual fibers stored horizontally in the deflection become. This additional process step has effects on the transverse tensile strength of the primary fleece. Instead of pulleys, a folding can also by moving up and down about a horizontal axis, i. commuting Transport device done. The suspended primary fleece is used as secondary fleece referred to, which is to increase its transverse tensile strength that is processed in the area of the two large surfaces of the Secondary nonwoven horizontally stored fibers after curing of the binder be separated into an area in which almost exclusively fibers are arranged at right angles to the large surfaces. at Insulating materials with a low material thickness of, for example, 100 mm must be up to be removed to 20% of the original volume in this way, a mineral wool insulation product predominantly perpendicular to the large ones Surface-oriented single fibers has.

In einer weiteren Verfahrensvariante wird der endlose Fasermassenstrom vor dem Härteofen in einzelne Abschnitte abgelängt, welche Abschnitte anschließend um 90° gedreht, horizontal zusammengepreßt und vertikal um 20% komprimiert werden. Auch bei diesem Verfahren werden die Fasern unterhalb der großen Oberflächen überwiegend horizontal gelagert, so daß auch diese Bereiche zur Erreichung optimaler Querzugfestigkeit entfernt werden müssen.In a further process variant, the endless fiber mass flow before Hardening furnace cut into sections, which sections subsequently to Rotated 90 °, compressed horizontally and compressed vertically by 20%. Also in this process, the fibers become underneath the large surfaces mostly horizontally stored, so that these areas to achieve optimal transverse tensile strength must be removed.

Nach diesem Verfahren hergestellte Mineralwolle-Dämmstoffe weisen eine maximale Materialstärke von ca. 220 mm auf. Da bei allen Verfahrensvarianten die Auffaltung in Produktionsrichtung erfolgt, sind die Biege-, Zug- und Scherfestigkeit quer zur Produktionsrichtung um ein mehrfaches höher, als in Produktions- und Verfaltungsrichtung. Um hohe Querzugfestigkeiten bei gegebenenfalls sogar reduzierten Rohdichten erzielen zu können, werden Dämmstoffplatten aus derart produzierten Mineralwolledämmstoffen parallel zu der Produktions- und Auffaltungsrichtung entsprechend der gewünschten Dämmstoffdicke in Scheiben geschnitten. Dieser Prozeß ist relativ aufwendig, da er nicht auf der eigentlichen Produktionslinie erfolgen kann, sondern zumeist unter Verwendung großformatiger Platten als Vormaterial auf separaten Schneid- und Umlenkungsanlagen durchgeführt werden muß.Mineral wool insulation materials produced by this process have a maximum Material thickness of about 220 mm. Since in all process variants the Unfolding in the direction of production, are the bending, tensile and shear strength transverse to the production direction by a multiple higher than in production and Verfaltungsrichtung. To high transverse tensile strength at possibly even reduced To be able to achieve gross densities, insulation boards are made of such produced mineral wool insulation parallel to the production and unfolding direction sliced according to the desired insulation thickness. This process is relatively expensive, as it is not on the actual Production line can be done, but mostly using large format Sheets as semi-finished material on separate cutting and deflection systems must be performed.

Derart hergestellte Lamellen-Platten, die häufig als Putzträgerplatten in Wärmedämmverbundsystemen oder als tragende Dämmschicht in Sandwich-Konstruktionen mit Blechen oder Holzwolle-Leichtbauplatten als Deckschichten eingesetzt werden, werden zur Erreichung einer hohen Schub- bzw. Verbindungssteifigkeit sowie einer hohen Querzugfestigkeit einer besonders intensiven Verfaltung der Faserlagen unterzogen. Die Rohdichten derartiger Lamellenplatten liegen in einem Bereich zwischen ca. 70 bis 105 kg/m3.Lamella plates produced in this way, which are often used as plaster base plates in external thermal insulation systems or as load-bearing insulating layer in sandwich constructions with metal sheets or wood wool lightweight panels as cover layers, are used to achieve a high shear or joint stiffness and a high transverse tensile strength of a particularly intensive Subjected to fiber layers. The gross densities of such lamella plates are in a range between about 70 to 105 kg / m 3 .

Zur besseren Haftung von Putzen oder Klebern auf den grundsätzlich hydrophob eingestellten Mineralwolle-Dämmstoffen werden diese zumeist auf einer oder beiden großen Oberflächen mit geeigneten haftvermittelnden Schichten versehen. Der Auftrag dieser Mittel erfolgt durch Sprühen, Gießen, Auffalten, Einreiben oder dergleichen. Sowohl für die Herstellung von großformatigen Sandwich-Elementen als auch die Beschichtung ist es von großem Vorteil, wenn die Lamellenplatten wesentlich größere Formate aufweisen oder als endloses Faserband herstellbar sind.For better adhesion of plasters or adhesives to the basically hydrophobic adjusted mineral wool insulation materials these are mostly on one or both large surfaces provided with suitable adhesion-promoting layers. The application of these funds is done by spraying, pouring, unfolding, rubbing or like. Both for the production of large-sized sandwich elements as well as the coating, it is of great advantage if the lamellar plates have much larger formats or produced as an endless sliver are.

Ausgehend von diesem Stand der Technik liegt der Erfindung die Aufgabe zugrunde, ein gattungsgemäßes Verfahren bzw. eine gattungsgemäße Vorrichtung zur Durchführung des Verfahrens dahingehend zu schaffen, daß Faserdämmstoffbahnen mit einer intensiven Verfaltung der Mineralfasem in einfacher und kostengünstiger Weise herstellbar sind, wobei die mechanischen Eigenschaften in den beiden Hauptachsen der Horizontalebene gleich oder nahezu gleich sind.Starting from this prior art, the invention has for its object to provide a generic method and a generic device for implementing the method to the effect that fiber insulation webs can be prepared with an intense folding of the mineral fibers in a simple and cost-effective manner, whereby the mechanical properties in the two major axes of the horizontal plane are equal or nearly equal.

Die Lösung dieser Aufgabenstellung sieht bei einem erfindungsgemäßen Verfahren vor, daß das Primärvlies durch rechtwinklig zu den großen Oberflächen geführte Schnitte in zumindest zwei, vorzugsweise mehrere, insbesondere gleiche Abmessungen aufweisende Teilbahnen aufgeteilt wird, daß die Teilbahnen anschließend um 90° um ihre Längsachse gedreht werden und daß die Teilbahnen aufgependelt und zu einem Sekundärvlies zusammengefügt werden.The solution of this problem provides in a method according to the invention, that the primary nonwoven is divided by at right angles to the large surfaces cuts in at least two, preferably several, in particular the same dimensions having partial webs that the partial webs are then rotated by 90 ° about its longitudinal axis and that the partial webs are suspended and joined together to form a secondary web.

Bei dem erfindungsgemäßen Verfahren ist somit vorgesehen, daß ein in üblicher Weise hergestelltes Primärvlies in mehrere auf einem Förderband nebeneinander liegende Teilbahnen aufgeteilt wird, welche Teilbahnen anschließend um 90° um ihre Längsachse gedreht werden, woraufhin die Teilbahnen zu einem Sekundärvlies aufgependelt werden. Hierbei kann vorgesehen sein, daß alle Teilbahnen gemeinsam zu einem Sekundärvlies aufgependelt werden oder daß einzelne Teilbahnen aufgependelt und die aufgependelten Teilbahnen zu einem Sekundärvlies zusammengefügt werden.In the method according to the invention is thus provided that in a conventional Way produced primary nonwoven in several on a conveyor belt side by side lying sub-webs is divided, which sub-webs then by 90 ° their longitudinal axis are rotated, whereupon the partial webs to a secondary web be shuttled. It can be provided that all partial webs together be suspended to a secondary web or that individual partial webs suspended and the suspended partial webs to a secondary web be joined together.

Nach einer Weiterbildung der Erfindung ist vorgesehen, daß die Teilbahnen des Primärvlieses vor dem Drehen um ihre Längsachse relativ zur Förderebene übereinander angeordnet werden. Bei diesem Verfahren werden die Teilbahnen nach ihrem Drehen um ihre Längsachse aufgestapelt und gemeinsam einer Pendeleinrichtung zugeführt, die den Stapel der Teilbahnen zu dem Primärvlies aufpendelt. Das Aufpendeln erfolgt in horizontaler Richtung in Förderrichtung eines das Sekundärvlies aufnehmenden Förderbandes.According to a development of the invention it is provided that the partial webs of Primary fleece before turning about its longitudinal axis relative to the conveying plane one above the other to be ordered. In this method, the partial webs are after their rotation stacked around their longitudinal axis and together a pendulum device fed, which bounces the stack of partial webs to the primary web. The pendulum takes place in the horizontal direction in the conveying direction of the secondary web receiving conveyor belt.

Vorzugsweise werden die Teilbahnen und/oder das Sekundärvlies während und/oder nach dem Aufpendeln komprimiert. Insbesondere erfolgt die Kompression in zwei im wesentlichen rechtwinklig zueinander ausgerichteten Richtungen. Durch seitlich angeordnete Druckbänder werden das Sekundärvlies bzw. die Teilbahnen auf die gewünschte Breite komprimiert. Die Verdichtung erfolgt vorzugsweise kontinuierlich, um ein gleichmäßig komprimiertes Produkt zu erzeugen.Preferably, the partial webs and / or the secondary web during and / or compressed after flaring. In particular, the compression takes place in two substantially orthogonal directions. By laterally arranged pressure bands are the secondary web or the partial webs compressed to the desired width. The compression is preferably carried out continuously to produce a uniformly compressed product.

Es ist nach einem weiteren Merkmal der Erfindung vorgesehen, daß das Sekundärvlies anschließend einem Härteofen zugeführt wird, um das Bindemittel auszuhärten.It is provided according to a further feature of the invention that the secondary web then fed to a curing oven to cure the binder.

Es ist weiterhin vorgesehen, daß an den großen Oberflächen des Sekundärvlieses jeweils eine dünne Deckschicht abgetrennt wird. Hierdurch wird eine Faserdämmstoffbahn erzielt, die in weitaus überwiegendem Maße einen Faserverlauf aufweist, der rechtwinklig zu den großen Oberflächen ausgerichtet ist. Durch das Abtrennen der Deckschicht vor dem Härteofen wird der Vorteil erzielt, daß weniger eingebundene Fasern bei ausgehärtetem Bindemittel aus den Oberflächen herausgerissen werden, so daß sich insgesamt eine gleichmäßigere und ebene Oberfläche der Faserdämmstoffbahn ausbildet.It is further contemplated that on the large surfaces of the secondary web in each case a thin cover layer is separated. This is a Faserdämmstoffbahn achieved, the predominantly extent of a grain which is oriented at right angles to the large surfaces. By the Separating the cover layer before the hardening furnace achieves the advantage that less embedded fibers with hardened binder from the surfaces be torn out, so that overall a more even and even Surface of Faserdämmstoffbahn trains.

Die Deckschicht kann sowohl vor oder nach dem Härteofen vom Sekundärvlies abgetrennt werden. In der Deckschicht liegen die Mineralfasern parallel zu den großen Oberflächen vor. Wird die Deckschicht nach dem Härteofen abgetrennt, so ergibt sich hieraus ein marktfähiges Produkt mit ausgesprochen laminarer Struktur, das bei entsprechender Rohdichte beispielsweise für die Trittschalldämmung unter schwimmendem Estrich verwendet werden kann.The cover layer can be before or after the curing oven from the secondary web be separated. In the cover layer, the mineral fibers are parallel to the large surfaces. If the cover layer is separated after the hardening furnace, so this results in a marketable product with pronounced laminar structure, the corresponding density, for example, for impact sound insulation can be used under floating screed.

Bei dem erfindungsgemäßen Verfahren ist somit ergänzend vorgesehen, daß ein in üblicher Weise hergestelltes Primärvlies zu einem Sekundärvlies aufgependelt wird, aus welchem dann einerseits Mineralfaserplatten mit einer Lamellenstruktur und andererseits ein Mineralfaserprodukt mit laminarer Faserstruktur für die Trittschalldämmung hergestellt wird.In the method according to the invention is thus additionally provided that a commuted in a conventional manner primary web to a secondary web suspended becomes, from which then on the one hand mineral fiber plates with a lamellar structure and on the other hand a mineral fiber product with laminar fiber structure for impact sound insulation will be produced.

Nach einer Weiterbildung der Erfindung ist vorgesehen, daß die Deckschicht abgetrennt wird, bevor das Sekundärvlies einem Härteofen zugeführt wird. Bei dieser Ausführungsform weist die Deckschicht nicht ausgehärtetes Bindemittel auf, so dass die Deckschicht nach dem Abtrennen noch hinsichtlich ihrer Materialeigenschaften verändert werden kann. Insbesondere kann die anwendungsspezifisch erforderliche Rohdichte der Deckschicht durch Kompression der Deckschicht bei nicht ausgehärtetem Bindemittel eingestellt werden.According to a development of the invention it is provided that the cover layer separated is before the secondary web is fed to a curing oven. At this Embodiment has the cover layer uncured binder, so that the cover layer after separation nor in terms of their material properties can be changed. In particular, the application-specific required bulk density of the cover layer by compression of the cover layer be set at uncured binder.

Alternativ kann vorgesehen sein, dass die Deckschicht erst nach dem Durchlauf des Sekundärvlieses durch den Härteofen abgetrennt wird.Alternatively it can be provided that the cover layer only after the passage of the secondary web is separated by the curing oven.

Das erfindungsgemäße Verfahren bietet den Vorteil, daß über mehrere Pendel mehrere Vliesschichten zueinander geführt werden, um beispielsweise eine Faserdämmstoffbahn herzustellen, die sandwichartig aufgebaut ist. Hierzu ist vorgesehen, daß das Primärvlies mit einer oder mehreren Vliesschichten, insbesondere unterschiedlicher Eigenschaften zusammengefügt wird. Es können daher beispielsweise Vliesschichten mit höherer und/oder geringerer Rohdichte bzw. mit höherem oder geringerem Kompressionsgrad miteinander verbunden werden, wobei das Zusammenfügen der unterschiedlichen Vliesschichten vor dem Härteofen erfolgt, so daß die Verbindung zwischen den Vliesschichten insbesondere durch das noch nicht ausgehärtete Bindemittel möglich ist.The inventive method has the advantage that over several pendulums a plurality of nonwoven layers are guided to each other, for example, a Faserdämmstoffbahn to produce, which is sandwiched. For this purpose, it is provided that the primary nonwoven fabric with one or more nonwoven layers, in particular different properties is joined together. It can therefore, for example Nonwoven layers with higher and / or lower density or with higher or lower degree of compression, wherein the joining of the different nonwoven layers before the curing oven takes place, so that the connection between the nonwoven layers in particular through the not yet cured binder is possible.

Nach einem weiteren Merkmal der Erfindung ist vorgesehen, daß das Primärvlies vor oder während des Aufpendelns gestaucht wird. Um die Haftung der einzelnen Teilbahnen aneinander zu vergrößern ist vorgesehen, daß die Oberflächen der Teilbahnen mit Bindemitteln imprägniert werden, bevor die Teilbahnen zusammengeführt werden.According to a further feature of the invention it is provided that the primary nonwoven is compressed before or during the pendulum. To the liability of the individual To enlarge part tracks to each other is provided that the surfaces of the Sub-webs are impregnated with binders before the sub-webs merged become.

Eine Weiterbildung des erfindungsgemäßen Verfahrens sieht vor, daß zwischen benachbarten Teilbahnen verstärkende Gewebe und/oder Vliese aus beispielsweise Glas-, Kohlenstoff-, Metall-, temperaturbeständigen Kunststoff- und/oder Naturfasern angeordnet werden. Derartige Gewebe können als Armierung der Faserdämmstoffbahnen dienen und erhöhen die Belastbarkeit der aus dieser Faserdämmstoffbahn hergestellten Dämmstoffplatten. A development of the method according to the invention provides that between adjacent sub-webs reinforcing fabric and / or nonwovens, for example Glass, carbon, metal, temperature resistant plastic and / or Natural fibers are arranged. Such fabrics can be used as reinforcement of the Faserdämmstoffbahnen serve and increase the load capacity of this Faserdämmstoffbahn produced insulating panels.

Das Sekundärvlies wird vorzugsweise vor und/oder im Härteofen rechtwinklig zu seinen großen Oberflächen komprimiert. Auf diese Weise wird eine Faserdämmstoffbahn mit definierten Abmessungen erzeugt, ohne daß die Gefahr eines Aufwölbens der Fasermasse im Härteofen besteht.The secondary web is preferably perpendicular before and / or in the curing oven to compressed its large surfaces. In this way, a fiber insulation sheet produced with defined dimensions, without the risk of bulging the pulp in the curing oven consists.

Vorzugsweise wird im Härteofen Heißluft sowohl rechtwinklig zu den großen Oberflächen, als auch durch die Längsseiten des Sekundärvlieses geleitet, um einen höheren Wirkungsgrad des Härteofens und damit eine verbesserte Aushärtung des Bindemittels zu erzielen. Das Sekundärvlies wird darüber hinaus bis nach der Aushärtung des Bindemittels allseitig eingespannt geführt.Preferably, in the curing oven hot air is both perpendicular to the large Surfaces, as well as passed through the longitudinal sides of the secondary web to a higher efficiency of the curing oven and thus improved curing of the binder to achieve. The secondary web will also be up after hardening of the binder guided clamped on all sides.

Nach dem Aushärten des Bindemittels wird das Sekundärvlies parallel zu seinen großen Oberflächen in einzelne Abschnitte geschnitten. Diese Vorgehensweise hat den Vorteil, daß ein nachgeschalteter Trockner für die Faserdämmstoffbahn in kompakter Bauweise ausgelegt werden kann. Die einzelnen Abschnitte werden neben- und/oder übereinander gestapelt und dem Trockner zugeführt. Selbstverständlich kann auch bereits zu diesem Zeitpunkt die Faserdämmstoffbahn durch rechtwinklig zu ihren großen Oberflächen verlaufende Schnitte in einzelne Platten quaderförmiger Ausgestaltung unterteilt werden. Weiterhin besteht die Möglichkeit, die Längsseiten des Sekundärvlieses nach Aushärten des Bindemittels zur Bildung ebener Flächen zu beschneiden.After curing of the binder, the secondary web becomes parallel to its cut large surfaces into individual sections. This approach has the advantage that a downstream dryer for the fiber insulation in compact design can be designed. The individual sections will be stacked next to and / or on top of each other and fed to the dryer. Of course can already at this time the fiber insulation by cuts perpendicular to their large surfaces in individual plates cuboid configuration can be divided. It is also possible the longitudinal sides of the secondary web after curing of the binder for Crop education flat surfaces.

Die voranstehend genannte, der Erfindung zugrundeliegende Aufgabe wird bei einer gattungsgemäßen Vorrichtung zur Durchführung des voranstehend beschriebenen Verfahrens dadurch gelöst, daß das Förderband eine Schneidvorrichtung aufweist, mit der das Primärvlies in nebeneinander auf dem Förderband liegende Teilbahnen teilbar ist und daß der Schneidvorrichtung eine Dreheinrichtung nachgeschaltet ist, mit der die einzelnen Teilbahnen relativ zu ihrer Längsachse um 90° drehbar sind, bevor sie in die Pendelstation zur Bildung eines Sekundärvlieses einlaufen. The above-mentioned, the invention is based task a generic device for carrying out the above-described Method solved in that the conveyor belt is a cutting device comprising, with the primary web in side by side on the conveyor belt lying partial webs is divisible and that the cutting device is a rotating device is connected downstream, with the individual partial webs relative to its longitudinal axis rotatable by 90 °, before entering the shuttle station to form a secondary web enter.

Die Schneidvorrichtung weist eine der Anzahl n der erforderlichen Teilbahnen entsprechende Anzahl n-1 Sägen auf, die insbesondere als Band- oder Kreissägen ausgebildet sind.The cutting device has one of the number n of the required partial webs corresponding Number of n-1 saws, especially as band or circular saws are formed.

Als Pendelstation werden vorzugsweise paarig angeordnete Druckbänder oder Rollenbahnen für alle Teilbahnen vorgesehen. Alternativ besteht die Möglichkeit, die Pendelstation als paarig angeordnete Druckbänder oder Rollenbahnen für jeweils eine Teilbahn auszubilden, so daß die erfindungsgemäße Vorrichtung eine der Anzahl der Teilbahnen entsprechende Anzahl von paarig angeordneten Druckbändern oder Rollenbahnen aufweist.As pendulum station are preferably paired pressure belts or Roller conveyors intended for all partial webs. Alternatively, it is possible to the shuttle station as paired pressure belts or roller conveyors for each to form a partial web, so that the inventive device a the number of partial webs corresponding number of pairs arranged Has pressure bands or roller conveyors.

Es ist ferner vorgesehen, daß der Pendelstation ein Härteofen mit zumindest zwei Druckbändern nachgeschaltet ist, die auf den großen Oberflächen des Sekundärvlieses aufliegen und durch die ein erwärmtes Gas, insbesondere Heißluft geleitet wird.It is further contemplated that the shuttle station a curing oven with at least two Pressure belts downstream of which is on the large surfaces of the secondary web rest and passed through a heated gas, in particular hot air becomes.

In einer Weiterbildung der Vorrichtung ist vorgesehen, daß im Härteofen zwei weitere Druckbänder vorgesehen sind, die an den Längsseiten des Sekundärvlieses anliegen, so daß das Sekundärvlies bei dieser Ausgestaltung einseitig eingespannt ist und gegebenenfalls in Richtung aller Flächen komprimiert werden kann.In a further development of the device is provided that in the curing oven two further printing tapes are provided, which are on the longitudinal sides of the secondary web abut, so that the secondary web is clamped on one side in this embodiment is and can be compressed if necessary in the direction of all surfaces.