EP1069652A1 - Female contact for electrical connectors - Google Patents

Female contact for electrical connectors Download PDFInfo

- Publication number

- EP1069652A1 EP1069652A1 EP00114141A EP00114141A EP1069652A1 EP 1069652 A1 EP1069652 A1 EP 1069652A1 EP 00114141 A EP00114141 A EP 00114141A EP 00114141 A EP00114141 A EP 00114141A EP 1069652 A1 EP1069652 A1 EP 1069652A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- contact

- socket

- sleeve body

- strips

- contact spring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/02—Contact members

- H01R13/15—Pins, blades or sockets having separate spring member for producing or increasing contact pressure

- H01R13/187—Pins, blades or sockets having separate spring member for producing or increasing contact pressure with spring member in the socket

Definitions

- the invention relates to a contact socket for electrical connectors, which from a stable sleeve body formed from a sheet material and one lying in it, a plurality with one to be inserted into the socket Contact pin in line-shaped or strip-shaped contacting contacting means, such as contact wires or contact strips, contact spring bushing there is, the contact wires or contact strips of the contact spring bushing aligned around the socket axis and at both ends with a Edge strips of sheet metal are connected, and furthermore the contact spring bush is mechanically and electrically connected to the sleeve body.

- Lamellar spring contact sockets are known per se and are distinguished on the one hand by particularly excellent contacting properties and on the other hand by their economical producibility.

- a first known type of such a contact socket is characterized in that the contact spring socket has a number of contact strips, which are aligned obliquely to the longitudinal axis of the contact spring socket.

- Characteristic of contact bushes of this configuration is the fact that their contact spring bushings have a number of strip-shaped contacting means which are formed from a number of contact strips formed by punching out a continuous strip of contact material and remaining connected to one another at the upper and lower ends of the contact spring bushing via edge strips.

- the invention is therefore based on the object of producing at low cost Contact socket of the type described at the beginning for electrical connectors to show which on one side a secure anchoring of the contact spring bush guaranteed in the stable sleeve body and on the other side is also easy to implement in mechanical series production.

- This task is based on a contact socket according to the generic term of claim 1 according to the invention essentially solved in that the sleeve body with at least one directed transversely to the longitudinal axis of the contact socket and is provided with at least one protrusion, which with one of the two the contact wires or contact strips of the contact spring socket interconnecting edge strips made of sheet metal in a form-fitting manner Intervention stands.

- the purely positive connection of the contact spring bushing according to the invention and stable sleeve body is initially characterized by the preference, that a contact-safe connection is created and still on all thermal engineering Connection methods, such as welding or soldering and the like, for mutual purposes Connection of contact spring bushing and stable sleeve part dispensed with can be and therefore no heat distortion or similar undesirable Phenomena can occur.

- the purely mechanical form-fit permits Fixing the contact spring bushing in a stable sleeve body simple manufacture of the contact socket overall with exclusive use of cutting and shaping tools, which means manufacturing the contact sockets very accommodating from continuous strips of material, especially in that that by means of a punching and / or cutting tool from a continuous Material strips with a crimp part for connecting the contact socket to a Single conductor one-piece contact spring bushings cut and punched and can then be rolled up more or less completely in some areas, in such a way that the areas of the cutouts forming the contact spring bushings rolled into a cylinder body and the areas forming the crimp parts the free cuts only to a U-shaped profile cross section, for example can be bent.

- the prefabricated contact spring bushings are then without prejudice to the maintenance of their connection by means of a transport lane in a mechanically producible, form-fitting manner by mutual Clawing or interlocking free cuts and abutments with them

- Pre-made stable by cutting and rolling a sheet metal material

- Sleeve bodies connected to a usable contact sleeve, the free cuts but preferably not exclusively in the stable sleeve body and the abutments are arranged accordingly on the contact spring bush or are trained.

- the reversal of this is alternate Arrangement of free cuts and abutments in the area of the present Invention.

- one of a contact spring bushing and one stable sleeve body existing contact socket is provided that the contacting means the contact spring bushing from a continuous Tape material punched out contact strip sequence exist and mutually at both ends connected to each other via marginal meetings of the continuous strip material and are held at constant mutual intervals and that the sleeve body two forms spaced apart in the axial direction each with one of the two, the contact strips at both ends interconnecting edge strips is in positive engagement.

- one of a contact spring bushing and a stable sleeve body existing contact socket can also be provided be that at least one of the two the contact strips of the contact spring bushing edge strips connecting at both ends with a window recess is provided and the sleeve body at least one cut free and has tongue with the window recess in positive engagement.

- the window recess is advantageously in the free end of the contact socket opposite edge strips arranged and in the circumferential direction the contact spring bush aligned so that the positive connection between Contact spring bush and stable sleeve body to the area of the connection the contact socket is shifted towards the single conductor.

- An advantageous design of the positive connection of the contact spring bush with the stable sleeve body is that in which the free Edge of the contact spring bush opposite the end of the contact bush arranged window recess has a rectangular plan shape and in the sleeve body two opposite and angled inwards Tongues are cut free, which with the narrow sides of the window recess to be in positive engagement.

- This training is particularly there of particular advantage, where it is further provided that the two in the sleeve body cut out tongues pointing towards each other and each of the two tongues in one of the two longitudinal edges of the one forming the sleeve body Sheet material blank is cut free expiring.

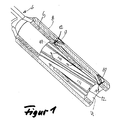

- a contact spring bush shown in FIGS. 1 to 5 for electrical connectors are in an originally smooth surface Strip 1 of a strip material made of an electrically conductive sheet material

- a large number of free cuts 2 are punched out, such that between the punched out Open cuts 2, in the embodiment shown strip-shaped, contacting means 3 remain, which have a rectangular cross-sectional shape and also connected to each other at both ends via an edge strip 4 or 5 stay.

- contacting means 3 is also simultaneously a crimp connection 6 cut out of the strip of strip material 1.

- the one with the the contact spring bushing 7 forming cut areas in one piece, crimp connections 6 forming cutting areas remain in total and constantly with one an area of the starting material forming a transport strip.

- the Contact spring bushing 7 is in turn in one of the two embodiments shown through a flat material section rolled into a cylinder body formed, stable sleeve body 8 received and fixed positively.

- the stable sleeve body is 8 with two cut out and aligned opposite to each other Center of the sleeve body 8 through, designed as tongues 9 and 10 Provide free cuts, the tongues 9 and 10 with their free ends 11 each rest on the inner end face 12 of the edge strips 4 and 5 and so a stable axial and radial support of the contact spring bushing 7 in the stable Form sleeve body 8.

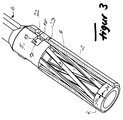

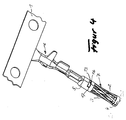

- the edge strip 4 as is particularly clear from the illustration in FIG. 4 evident, a rectangular plan and in the circumferential direction of the edge strip 4 aligned window recess 13.

- the stable sleeve body 8 Complementary to the window recess 13 there are two in the stable sleeve body 8 likewise aligned in the circumferential direction, arranged opposite one another and cut free tongues 14 and 15 with their free ends and bent inward with respect to the contact sleeve such that they in positive engagement with the narrow edges 16 and 17 of the window recess 13 stand.

- the two tongues 14 and 15 are in the shown Embodiment in one of the two longitudinal edges 18 or 19 of the sleeve body 8 sheet metal blank cut out expired cut out. Is further from the illustration in FIG.

Landscapes

- Manufacturing Of Electrical Connectors (AREA)

- Coupling Device And Connection With Printed Circuit (AREA)

- Connector Housings Or Holding Contact Members (AREA)

- Connecting Device With Holders (AREA)

Abstract

Description

Die Erfindung bezieht sich auf eine Kontaktbuchse für elektrische Steckverbinder, welche aus einen stabilen aus einem Blechmaterial gebildeten Hülsenkörper und einer in diesem einliegenden, eine Vielzahl mit einem in die Buchse einzuführenden Kontaktstift in linienförmigen oder streifenförmigen Kontakt tretender Kontaktierungsmitteln, wie Kontaktdrähte oder Kontaktstreifen aufweisenden, Kontaktfederbuchse besteht, wobei die Kontaktdrähte oder Kontaktstreifen der Kontaktfederbuchse um die Buchsenachse verdreht ausgerichtet und beidendig mit einem Randstreifen aus Blechmaterial verbunden sind, und wobei ferner die Kontaktfederbuchse mechanisch und elektrisch mit dem Hülsenkörper verbunden ist.The invention relates to a contact socket for electrical connectors, which from a stable sleeve body formed from a sheet material and one lying in it, a plurality with one to be inserted into the socket Contact pin in line-shaped or strip-shaped contacting contacting means, such as contact wires or contact strips, contact spring bushing there is, the contact wires or contact strips of the contact spring bushing aligned around the socket axis and at both ends with a Edge strips of sheet metal are connected, and furthermore the contact spring bush is mechanically and electrically connected to the sleeve body.

Solche, vielfach auch als Drahtfeder-bzw. Lamellenfeder-Kontaktbuchsen bezeichnete

Kontaktbuchsen sind an sich bekannt und zeichnen sich zum einen durch besonders

hervorragende Kontaktierungseigenschaften und zum anderen durch eine

wirtschaftliche Herstellbarkeit aus.

Eine erste bekannte Bauart einer solchen Kontaktbuchse zeichnet sich dadurch

aus, daß die Kontaktfederbuchse eine Anzahl von Kontaktstreifen aufweist, welche

insgesamt schräg zur Längsachse der Kontaktfederbuchse ausgerichtet sind. Charakteristisch

für Kontaktbuchsen dieser Ausgestaltung ist der Umstand, daß

deren Kontaktfederbuchsen eine Anzahl von streifenförmigen Kontaktierungsmitteln

aufweisen, die aus einer Anzahl durch Ausstanzen eines fortlaufenden Streifens

eines Kontaktmaterials gebildeten und am oberen und unteren Ende der

Kontaktfederbuchse über Randstreifen untereinander verbunden bleibenden Kontaktstreifen

gebildet sind. Im Zusammenhang mit der Anwendung aus einem Kontaktmaterial

freigeschnittener streifenförmiger Kontaktierungsmittel ist es ferner

bekannt die mittels entsprechender Ausstanzungen aus einem fortlaufenden Materialstreifen

hergestellten und zu einer Kontaktfederbuchse bzw. einer Kontaktierungsauskleidung

eines stabilen Hülsenkörpers gerollten Zuschnitte entlang

schräger Schnittlinien vom fortlaufenden Materialstreifen abzulängen und die beiden

Schnittkanten des die Kontaktfederbuchse bildenden Zuschnittes dann entlang

einer schräg zur Buchsenachse ausgerichteten Verbindungslinie miteinander zu

verbinden, um eine schräg zur Buchsenachse ausgerichtete bzw. um die Buchsenachse

tordiert ausgerichtete Anordnung der streifenförmigen Kontaktierungen

zu erreichen.Such, often also as wire spring or. Lamellar spring contact sockets are known per se and are distinguished on the one hand by particularly excellent contacting properties and on the other hand by their economical producibility.

A first known type of such a contact socket is characterized in that the contact spring socket has a number of contact strips, which are aligned obliquely to the longitudinal axis of the contact spring socket. Characteristic of contact bushes of this configuration is the fact that their contact spring bushings have a number of strip-shaped contacting means which are formed from a number of contact strips formed by punching out a continuous strip of contact material and remaining connected to one another at the upper and lower ends of the contact spring bushing via edge strips. In connection with the use of strip-shaped contacting means cut free from a contact material, it is also known to cut the blanks along oblique cutting lines from the continuous material strip by means of corresponding punchings from a continuous material strip and rolled them into a contact spring bushing or a contacting lining of a stable sleeve body, and to cut the two cutting edges of the die Then connect the contact spring bushing-forming blank along a connecting line oriented obliquely to the socket axis in order to achieve an arrangement of the strip-shaped contacts oriented obliquely to the socket axis or twisted around the socket axis.

Alle derartigen Kontaktbuchsen für elektrische Steckverbinder haftet ein gewisser Nachteil dahingehend an, daß es verhältnismäßig aufwendig ist die vergleichsweise labile Kontaktfederbuchse mit einem stabilen Hülsenkörper zu einer verwendbaren Kontaktbuchse zu verbinden, ohne die Kontaktierungseigenschaften der Kontaktfederbuchse nachteilig zu beeinträchtigen.All such contact sockets for electrical connectors are liable to a certain extent Disadvantage in that it is relatively expensive unstable contact spring bushing with a stable sleeve body to a usable one To connect the contact socket without the contacting properties of the contact spring socket adversely affect.

Der Erfindung liegt daher die Aufgabe zugrunde eine preisgünstig herstellbare Kontaktbuchse der eingangs beschriebenen Bauart für elektrische Steckverbinder aufzuzeigen, welche auf der einen Seite eine sichere Verankerung der Kontaktfederbuchse in dem stabilen Hülsenkörper gewährleistet und auf der anderen Seite auch in der mechanischen Serienfertigung leicht zu verwirklichen ist.The invention is therefore based on the object of producing at low cost Contact socket of the type described at the beginning for electrical connectors to show which on one side a secure anchoring of the contact spring bush guaranteed in the stable sleeve body and on the other side is also easy to implement in mechanical series production.

Diese Aufgabe wird ausgehend von einer Kontaktbuchse nach dem Oberbegriff des Anspruches 1 erfindungsgemäß im Wesentlichen dadurch gelöst, daß der Hülsenkörper mit wenigstens einem quer zur Längsachse der Kontaktbuchse gerichteten und mindestens durch eine Ausprägung gebildeten Vorsprung versehen ist, welcher mit einem der beiden die Kontaktdrähte oder Kontaktstreifen der Kontaktfederbuchse untereinander verbindenden Randstreifen aus Blechmaterial im formschlüssigen Eingriff steht. This task is based on a contact socket according to the generic term of claim 1 according to the invention essentially solved in that the sleeve body with at least one directed transversely to the longitudinal axis of the contact socket and is provided with at least one protrusion, which with one of the two the contact wires or contact strips of the contact spring socket interconnecting edge strips made of sheet metal in a form-fitting manner Intervention stands.

Die erfindungsgemäß rein formschlüssige Verbindungsweise von Kontaktfederbuchse und stabilen Hülsenkörper zeichnet sich zunächst durch den Vorzug aus, daß eine kontaktsichere Verbindung entsteht und trotzdem auf alle wärmetechnischen Verbindungsweisen, wie Schweißen oder Löten und dergl. mehr, zum gegenseitigen Verbinden von Kontaktfederbuchse und stabilen Hülsenteil verzichtet werden kann und daß daher auch kein Wärmeverzug oder ähnliche unerwünschten Erscheinungen auftreten können. Weiterhin gestattet die rein mechanischformschlüssige Festlegung der Kontaktfederbuchse im stabilen Hülsenkörper eine einfache Herstellung der Kontaktbuchse insgesamt unter ausschließlicher Anwendung von Schneid-und Formwerkzeugen, was einer Fertigung der Kontaktbuchsen aus fortlaufenden Materialstreifen sehr entgegenkommt, insbesondere dahingehend, daß mittels eines Stanz-und/oder Schneidwerkzeuges aus einem fortlaufenden Materialstreifen mit einem Crimpteil zum Anschluß der Kontaktbuchse an einen Einzelleiter einteilig Kontaktfederbuchsen freigeschnitten und freigestanzt und anschließend bereichsweise mehr oder minder vollständig eingerollt werden können, in der Weise, daß die die Kontaktfederbuchsen bildenden Bereiche der Freischnitte zu einem Zylinderkörper eingerollt und die die Crimpteile bildenden Bereiche der Freischnitte lediglich zu einem beispielsweise U-förmigen Profilquerschnitt gebogen werden können. Die solcherart vorgefertigten Kontaktfederbuchsen werden dann unbeschadet der Beibehaltung ihrer Verbindung mut einem Transportstreifen in einer mechanischen herstellbaren, formschlüssigen Weise durch gegenseitiges Verkrallen oder Verzahnen von Freischnitten und Widerlagern mit ihrerseits durch Ablängen und Einrollen eines Blechmatterials vorgefertigten stabilen Hülsenkörpern zu einer brauchbaren Kontakthülse verbunden, wobei die Freischnitte vorzugsweise aber nicht ausschließlicherweise in dem stabilen Hülsenkörper und die Widerlager entsprechend an der Kontaktfederbuchse angeordnet bzw. ausgebildet sind. Selbstverständlich liegt auch die Umkehrung dieser wechselweisen Anordnung von Freischnitten und Widerlagern im Bereich der vorliegenden Erfindung. The purely positive connection of the contact spring bushing according to the invention and stable sleeve body is initially characterized by the preference, that a contact-safe connection is created and still on all thermal engineering Connection methods, such as welding or soldering and the like, for mutual purposes Connection of contact spring bushing and stable sleeve part dispensed with can be and therefore no heat distortion or similar undesirable Phenomena can occur. Furthermore, the purely mechanical form-fit permits Fixing the contact spring bushing in a stable sleeve body simple manufacture of the contact socket overall with exclusive use of cutting and shaping tools, which means manufacturing the contact sockets very accommodating from continuous strips of material, especially in that that by means of a punching and / or cutting tool from a continuous Material strips with a crimp part for connecting the contact socket to a Single conductor one-piece contact spring bushings cut and punched and can then be rolled up more or less completely in some areas, in such a way that the areas of the cutouts forming the contact spring bushings rolled into a cylinder body and the areas forming the crimp parts the free cuts only to a U-shaped profile cross section, for example can be bent. The prefabricated contact spring bushings are then without prejudice to the maintenance of their connection by means of a transport lane in a mechanically producible, form-fitting manner by mutual Clawing or interlocking free cuts and abutments with them Pre-made stable by cutting and rolling a sheet metal material Sleeve bodies connected to a usable contact sleeve, the free cuts but preferably not exclusively in the stable sleeve body and the abutments are arranged accordingly on the contact spring bush or are trained. Of course, the reversal of this is alternate Arrangement of free cuts and abutments in the area of the present Invention.

In einer ersten Verwirklichungsform einer aus einer Kontaktfederbuchse und einem stabilen Hülsenkörper bestehenden Kontaktbuchse ist vorgesehen, daß die Kontaktierungsmittel der Kontaktfederbuchse aus einer aus einem fortlaufenden Bandmaterial freigestanzten Kontaktstreifenfolge bestehen und untereinander beidendig über Randstreffen des fortlaufenden Bandmaterials untereinander verbunden sowie in gleichbleibenden gegenseitigen Abständen gehalten sind und daß der Hülsenkörper zwei in axialer Richtung zueinander beabstandete Ausprägungen aufweist deren jede mit jeweils einem der beiden die Kontaktstreifen beidendig untereinander verbindenden Randstreifen im formschlüssigen Eingriff steht. Dabei kann im Einzelnen weiter noch vorgesehen sein, daß die radial zu dessen Längsachse gerichteten Vorsprünge des Hülsenkörpers durch zungenförmige nach innen durchgestellte Freischnitte gebildet sind und jeweils in eine Lücke zwischen benachbarten Kontaktstreifen der Kontaktfederbuchse eingreifend formschlüssig am inneren Rand der die Kontaktstreifen beidendig untereinander verbindenden Randstreifen anliegen.In a first embodiment, one of a contact spring bushing and one stable sleeve body existing contact socket is provided that the contacting means the contact spring bushing from a continuous Tape material punched out contact strip sequence exist and mutually at both ends connected to each other via marginal meetings of the continuous strip material and are held at constant mutual intervals and that the sleeve body two forms spaced apart in the axial direction each with one of the two, the contact strips at both ends interconnecting edge strips is in positive engagement. there can be further provided in detail that the radial to its longitudinal axis directed projections of the sleeve body through tongue-shaped inwards through cuts are formed and each in a gap between adjacent Contact strips of the contact spring bush engaging form-fitting on inner edge of the contact strips connecting the two at each other Edge strips are in contact.

Gemäß einer zweiten Verwirklichungsform einer aus einer Kontaktfederbuchse und einem stabilen Hülsenkörper bestehenden Kontaktbuchse kann aber auch vorgesehen sein, daß mindestens einer der beiden die Kontaktstreifen der Kontaktfederbuchse beidendig untereinander verbindenden Randstreifen mit einer Fensterausnehmung versehen ist und der Hülsenkörper wenigstens eine freigeschnittene und mit der Fensterausnehmung im formschlüssigen Eingriff stehende Zunge aufweist.According to a second embodiment, one of a contact spring bushing and a stable sleeve body existing contact socket can also be provided be that at least one of the two the contact strips of the contact spring bushing edge strips connecting at both ends with a window recess is provided and the sleeve body at least one cut free and has tongue with the window recess in positive engagement.

Die Fensterausnehmung ist vorteilhafterweise in dem dem freien Ende der Kontaktbuchse gegenüberliegenden Randstreifen angeordnet und in Umfangsrichtung der Kontaktfederbuchse ausgerichtet, so daß die formschlüssige Verbindung zwischen Kontaktfederbuchse und stabilem Hülsenkörper zum Bereich des Anschlusses der Kontaktbuchse an den Einzelleiter hin verlagert ist. The window recess is advantageously in the free end of the contact socket opposite edge strips arranged and in the circumferential direction the contact spring bush aligned so that the positive connection between Contact spring bush and stable sleeve body to the area of the connection the contact socket is shifted towards the single conductor.

Eine vorteilhafte Gestaltungsweise der formschlüssigen Verbindung der Kontaktfederbuchse mit dem Stabilen Hülsenkörper besteht darin, daß die in dem dem freien Ende der Kontaktbuchse gegenüberliegenden Randstreifen der Kontaktfederbuchse angeordnete Fensterausnehmung eine rechteckige Grundrißform aufweist und im Hülsenkörper zwei einander gegenüberliegende und nach innen abgewinkelte Zungen freigeschnitten sind, welche mit den Schmalseiten der Fensterausnehmung im formschlüssigen Eingriff stehen. Diese Ausbildung ist insbesondere dort von besonderem Vorteil, wo im Weiteren vorgesehen ist, daß die beiden im Hülsenkörper freigeschnittenen Zungen gegeneinander zeigend ausgerichtet und jede der beiden Zungen in einen der beiden Längsränder des den Hülsenkörper bildenden Blechmaterialzuschnittes auslaufend freigeschnitten ist.An advantageous design of the positive connection of the contact spring bush with the stable sleeve body is that in which the free Edge of the contact spring bush opposite the end of the contact bush arranged window recess has a rectangular plan shape and in the sleeve body two opposite and angled inwards Tongues are cut free, which with the narrow sides of the window recess to be in positive engagement. This training is particularly there of particular advantage, where it is further provided that the two in the sleeve body cut out tongues pointing towards each other and each of the two tongues in one of the two longitudinal edges of the one forming the sleeve body Sheet material blank is cut free expiring.

In weiterer vorteilhafter Ausgestaltung wird noch vorgeschlagen, daß die Stoßränder des die Kontaktfederbuchse bildenden Materialzuschnittes und des den Hülsenkörper bildenden Materialzuschnittes um wenigstens 45° gegeneinander verdreht angeordnet sind.In a further advantageous embodiment, it is also proposed that the abutting edges of the material blank forming the contact spring bushing and of the sleeve body forming material cut rotated against each other by at least 45 ° are arranged.

Die Erfindung ist in der nachfolgenden Beispielsbeschreibung anhand zweier in der Zeichnung dargestellter Ausführungsbeispiele im Einzelnen beschrieben. In der Zeichnung zeigt die

- Figur 1

- eine teilweise aufgeschnittene schaubildliche Darstellung einer ersten Verwirklichungsform einer Kontaktbuchse;

Figur 2- eine schaubildliche Darstellung einer zweiten Verwirklichungsform einer Kontaktbuchse;

- Figur 3

- eine aufgeschnittene Darstellung der zweiten Verwirklichungsform nach

Figur 2; Figur 4- eine schaubildliche Einzeldarstellung einer Kontaktfederbuchse mit angeformtem Crimpteil;

Figur 5- eine schaubildliche Darstellung der Lage einer Kontaktfederbuchse in einem stabilen Hülsenkörper.

- Figure 1

- a partially cutaway perspective view of a first embodiment of a contact socket;

- Figure 2

- a perspective view of a second embodiment of a contact socket;

- Figure 3

- a cutaway representation of the second embodiment of Figure 2;

- Figure 4

- a detailed illustration of a contact spring bush with molded crimp part;

- Figure 5

- a graphical representation of the position of a contact spring bushing in a stable sleeve body.

Bei allen in den Figuren 1 bis 5 dargestellten Ausführungsformen einer Kontaktfederbuchse

für elektrische Steckverbinder sind in einem ursprünglich glattflächigen

Streifen 1 eines Bandmaterials aus einem elektrisch leitenden Blechmaterial eine

Vielzahl von Freischnitten 2 ausgestanzt, derart, daß zwischen den ausgestanzten

Freischnitten 2, in der gezeigten Ausführungsform streifenförmige, Kontaktierungsmittel

3 erhalten bleiben, welche eine rechteckige Querschnittsform aufweisen

und zudem beidendig über je einem Randstreifen 4 bzw. 5 miteinander verbunden

bleiben. Zusammen mit den Kontaktierungsmitteln 3 wird gleichzeitig auch

ein Crimpanschluß 6 aus dem Bandmaterialstreifen 1 freigeschnitten. Die mit den

die Kontaktfederbuchse 7 bildenden Zuschnittsbereichen einteiligen, Crimpanschlüsse

6 bildenden Zuschnittsbereiche bleiben insgesamt und ständig mit einem

einen Transportstreifen bildenden Bereich des Ausgangsmaterials verbunden. Die

Kontaktfederbuchse 7 ist in beiden gezeigten Ausführungsformen in einem seinerseits

durch einen zu einem Zylinderkörper eingerollten Flachmaterialabschnitt

gebildeten, stabilen Hülsenkörper 8 aufgenommen und formschlüssig festgelegt.

Gemäß der in der Figur 1 gezeigten Ausführungsform ist der stabile Hülsenkörper

8 mit zwei zueinander entgegengesetzt ausgerichtet freigeschnittenen und zur

Mitte des Hülsenkörpers 8 hin durchgestellten, als Zungen 9 und 10 ausgebildeten

Freischnitten versehen, wobei die Zungen 9 und 10 mit ihren freien Enden 11 jeweils

an der innenliegenden Stirnfläche 12 der Randstreifen 4 bzw. 5 anliegen und

so eine stabile axiale und radiale Abstützung der Kontaktfederbuchse 7 im stabilen

Hülsenkörper 8 bilden. In all the embodiments of a contact spring bush shown in FIGS. 1 to 5

for electrical connectors are in an originally smooth surface

Strip 1 of a strip material made of an electrically conductive sheet material

A large number of

Bei der in den Figuren 2 bis 5 dargestellten Ausführungsform sind die die Kontaktierungsmittel

3 untereinander verbindenden Randstreifen 4 bzw. 5 von deren einem

freien zu deren anderen dem Crimpanschluß 6 benachbarten Ende der Kontaktfederbuchse

7 hin unterschiedlich breit ausgeführt und zwar derart, daß der

dem Crimpanschluß 6 benachbarte Randstreifen 5 eine größere axiale Erstreckung

aufweist als der dem freien Ende der Kontaktbuchse zugewandte Randstreifen 4.

In dem Randstreifen 4 ist, wie besonders deutlich aus der Darstellung der Figur 4

ersichtlich, eine einen rechteckigen Grundriß aufweisende sowie in Umfangsrichtung

des Randstreifen 4 ausgerichtete Fensterausnehmung 13 ausgespart. Komplementär

zur Fensterausnehmung 13 sind in dem stabilen Hülsenkörper 8 zwei

gleichfalls in Umfangsrichtung ausgerichtete, einander gegenüberliegend angeordnete

und mit ihren freien Enden zueinander zeigende Zungen 14 und 15 freigeschnitten

und bezüglich der Kontakthülse derart nach innen gebogen, daß sie im

formschlüssigen Eingriff mit den schmalseitigen Rändern 16 und 17 der Fensterausnehmung

13 stehen. Die beiden Zungen 14 und 15 sind bei der gezeigten

Ausführungsform in einen der beiden Längsränder 18 oder 19 des den Hülsenkörper

8 bildenden Blechmaterialzuschnittes auslaufend freigeschnitten. Weiter ist

aus der Darstellung der Figur 5 noch ersichtlich, daß die Stoßränder 20 und 21

des die Kontaktfederbuchse 7 bildenden Materialzuschnittes und die Stoßränder

18 oder 19 des den Hülsenkörper 8 bildenden Materialzuschnittes um wenigstens

45° gegeneinander verdreht angeordnet sind. Insbesondere aus den Figuren 2 und

3 ist darüber hinaus besonders deutlich ersichtlich, daß die in die beiden Längsränder

18 und 19 auslaufenden Zungen 14 und 15 des stabilen Hülsenkörpers 8

entlang ihrer beiden Längsseiten jeweils mit einem breiten, eine bequemen Werzeugansatz

gewährleistenden Freischnittraum 22, 23 freigeschnitten sind.In the embodiment shown in FIGS. 2 to 5, these are the contacting means

3 interconnecting

Claims (8)

dadurch gekennzeichnet,

daß der Hülsenkörper mit wenigstens einem quer zur Längsachse der Kontaktbuchse gerichteten und mindestens durch eine Ausprägung gebildeten Vorsprung versehen ist, welcher mit einem der beiden die Kontaktdrähte oder Kontaktstreifen der Kontaktfederbuchse untereinander verbindenden Randstreifen aus Blechmaterial im formschlüssigen Eingriff steht.Contact socket for electrical connectors, which consists of a stable sleeve body formed from a sheet metal material and an inserted therein, a plurality with a contact pin to be inserted into the socket in linear or strip-shaped contacting means, such as contact wires or contact strips, contact spring socket, the contact wires or Contact strips of the contact spring socket are aligned rotated about the socket axis and are connected at both ends to an edge strip made of sheet metal material, and the contact spring socket is also mechanically and electrically connected to the sleeve body,

characterized,

that the sleeve body is provided with at least one projection directed transversely to the longitudinal axis of the contact socket and formed by at least one protrusion, which is in positive engagement with one of the two edge strips made of sheet metal material connecting the contact wires or contact strips of the contact spring socket to one another.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19933091A DE19933091A1 (en) | 1999-07-15 | 1999-07-15 | Contact socket for electrical connectors |

| DE19933091 | 1999-07-15 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1069652A1 true EP1069652A1 (en) | 2001-01-17 |

| EP1069652B1 EP1069652B1 (en) | 2003-09-17 |

Family

ID=7914832

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00114141A Expired - Lifetime EP1069652B1 (en) | 1999-07-15 | 2000-07-11 | Female contact for electrical connectors |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US6425786B1 (en) |

| EP (1) | EP1069652B1 (en) |

| AT (1) | ATE250286T1 (en) |

| DE (2) | DE19933091A1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007084085A3 (en) * | 2006-01-19 | 2007-09-07 | Mkem Spol S R O | Contact tube with lamella |

| WO2017121564A1 (en) * | 2015-12-15 | 2017-07-20 | Amphenol-Tuchel Electronics Gmbh | Radial contact socket |

| CN108110469A (en) * | 2018-01-26 | 2018-06-01 | 深圳市特拉利线簧端子技术有限公司 | A kind of metal spring leaf, plugging hole component and electric connector |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2002023678A1 (en) * | 2000-09-15 | 2002-03-21 | Alcoa Fujikura Ltd. | Electrical terminal socket assembly for vehicular component |

| US6656002B2 (en) * | 2000-09-15 | 2003-12-02 | Alcoa Fujikura Limited | Electrical terminal socket assembly including T shaped sealed connectors |

| US6860768B2 (en) * | 2000-09-15 | 2005-03-01 | Alcoa Fujikura Limited | Combination sleeve and spring cage incorporated into a one-piece female terminal for interengaging a corresponding male terminal and method of configuring such a sleeve and spring cage from a blank shape |

| DE10235058A1 (en) * | 2002-07-31 | 2004-02-12 | Siemens Ag | Removable electrical contact in which there is a sleeve element that is fitted onto the end of a contact bush and is retained by applying a turning moment |

| DE10235053A1 (en) * | 2002-07-31 | 2004-02-12 | Siemens Ag | Manufacture of an electrical contact in which there is a sleeve element that is fitted onto the end of a contact bush and is laser welded |

| US6848922B2 (en) * | 2003-03-10 | 2005-02-01 | Hypertronics Corporation | Socket contact with integrally formed arc arresting portion |

| US6997750B2 (en) | 2003-07-23 | 2006-02-14 | Fci Americas Technology, Inc. | Electrical connector contact |

| DE102005043692A1 (en) * | 2005-09-14 | 2007-03-15 | Robert Bosch Gmbh | Electrical connector with preloaded contact blades |

| CH704749B1 (en) * | 2007-09-05 | 2012-10-15 | Preci Dip Sa | contact clip. |

| DE202010003649U1 (en) * | 2010-03-16 | 2010-07-15 | Rosenberger Hochfrequenztechnik Gmbh & Co. Kg | High Power Connectors |

| DE102011054316B4 (en) * | 2011-10-07 | 2021-04-01 | Te Connectivity Germany Gmbh | Two-part crimp contact element |

| US20150244096A1 (en) * | 2014-02-27 | 2015-08-27 | Amphenol Corporation | Electrical socket with improved misalignment tolerance |

| WO2018063928A1 (en) * | 2016-09-30 | 2018-04-05 | Molex, Llc | Socket connector |

| CN106684603A (en) * | 2017-03-03 | 2017-05-17 | 王轶 | A compact receptacle connector with torsion spring contacts |

| CN108365371B (en) * | 2017-11-07 | 2020-10-02 | 得意精密电子(苏州)有限公司 | Electric connector and manufacturing method thereof |

| US10541489B2 (en) * | 2018-03-29 | 2020-01-21 | Amphenol Corporation | Electrical socket with contoured contact beams |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5147230A (en) * | 1991-12-19 | 1992-09-15 | General Motors Corporation | Two piece electrical female terminal |

| US5474479A (en) * | 1994-09-28 | 1995-12-12 | The Whitaker Corporation | Louvered contact electrical connector |

| US5921822A (en) * | 1995-07-25 | 1999-07-13 | Framatome Connectors Interlock Inc. | Connector assembly |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4128293A (en) * | 1977-11-02 | 1978-12-05 | Akzona Incorporated | Conductive strip |

| DE2852267C2 (en) * | 1978-12-02 | 1982-02-18 | Wampfler Gmbh, 7858 Weil | Connection device for conductor rails |

| DE3531845C2 (en) * | 1985-09-06 | 1994-05-26 | Daut & Rietz Trw | Contact part, shaped as a socket or plug part for insertion in socket or plug housings |

| DE3625384A1 (en) * | 1986-07-26 | 1988-02-04 | Reinshagen Kabelwerk Gmbh | ELECTRICAL CONNECTOR |

| US4973272A (en) * | 1987-01-30 | 1990-11-27 | Wyle Laboratories | Electrical connector with contactors |

| DE4203379A1 (en) * | 1992-02-06 | 1993-08-12 | Daut & Rietz Trw | U=shaped spring contact for electric flat connector - has openings in strips along base of upper spring element giving clearance for deflection of contact arms |

| US5810627A (en) * | 1996-01-11 | 1998-09-22 | Molex Incorporated | Female electrical terminal |

| FR2758213B1 (en) * | 1997-01-07 | 1999-01-29 | Cinch Connecteurs Sa | FEMALE ELECTRIC CONTACT MEMBER |

| US6062919A (en) * | 1997-08-29 | 2000-05-16 | Thomas & Betts International, Inc. | Electrical connector assembly having high current-carrying capability and low insertion force |

| DE19802821B4 (en) * | 1998-01-26 | 2008-02-07 | The Whitaker Corp., Wilmington | Electrical connection terminal |

-

1999

- 1999-07-15 DE DE19933091A patent/DE19933091A1/en not_active Withdrawn

-

2000

- 2000-07-11 EP EP00114141A patent/EP1069652B1/en not_active Expired - Lifetime

- 2000-07-11 DE DE50003701T patent/DE50003701D1/en not_active Expired - Lifetime

- 2000-07-11 AT AT00114141T patent/ATE250286T1/en active

- 2000-07-12 US US09/614,315 patent/US6425786B1/en not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5147230A (en) * | 1991-12-19 | 1992-09-15 | General Motors Corporation | Two piece electrical female terminal |

| US5474479A (en) * | 1994-09-28 | 1995-12-12 | The Whitaker Corporation | Louvered contact electrical connector |

| US5921822A (en) * | 1995-07-25 | 1999-07-13 | Framatome Connectors Interlock Inc. | Connector assembly |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007084085A3 (en) * | 2006-01-19 | 2007-09-07 | Mkem Spol S R O | Contact tube with lamella |

| WO2017121564A1 (en) * | 2015-12-15 | 2017-07-20 | Amphenol-Tuchel Electronics Gmbh | Radial contact socket |

| US10535943B2 (en) | 2015-12-15 | 2020-01-14 | Amphenol-Tuchel Electronics Gmbh | Radial contact socket |

| CN108110469A (en) * | 2018-01-26 | 2018-06-01 | 深圳市特拉利线簧端子技术有限公司 | A kind of metal spring leaf, plugging hole component and electric connector |

| CN108110469B (en) * | 2018-01-26 | 2024-04-05 | 深圳市特拉利线簧端子技术有限公司 | Metal reed, jack assembly and electric connector |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1069652B1 (en) | 2003-09-17 |

| DE19933091A1 (en) | 2001-02-01 |

| US6425786B1 (en) | 2002-07-30 |

| ATE250286T1 (en) | 2003-10-15 |

| DE50003701D1 (en) | 2003-10-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1069652A1 (en) | Female contact for electrical connectors | |

| DE3817803C2 (en) | ||

| EP1103088B1 (en) | Bushing contact | |

| EP0520950A1 (en) | Contact member and fabrication procedure | |

| EP3196981B1 (en) | Crosswise connector for in-line terminals | |

| DE10310899B3 (en) | Fork contact assembly complementary with blade contact carrying medium to high current, assembles fork springs on contact strips in flush arrangement | |

| EP0716474A1 (en) | Contact element for connecting two contact pieces | |

| EP0536523B1 (en) | Terminal | |

| DE3116731C2 (en) | Contact element | |

| EP0198408B1 (en) | Tool for manufacturing an electrical contact pin for printed-circuit boards | |

| DE202008008656U1 (en) | Protective earth connection device made of metal | |

| DE102005017988B3 (en) | Electric contact sleeve has band bent to close off inner space of contact sleeve | |

| DE102005063286A1 (en) | Contact socket for a pin | |

| DE69503902T2 (en) | CONTACT FOR CUTTING CLAMP CONNECTORS | |

| DE102019204704A1 (en) | Rollable punched strips with increased flexibility | |

| EP1763111B1 (en) | Socket contact with at least two contact points in the plug direction | |

| DE29912351U1 (en) | Contact socket for electrical connectors | |

| EP1114493A1 (en) | Method for producing contact bushings for electric plug-in connectors | |

| DE29805916U1 (en) | Contact socket for electrical connectors | |

| EP0650222B1 (en) | Female terminal for an electrical connection of flat contact pins | |

| BE1032048B1 (en) | Lamellar body for a connector part | |

| BE1032011B1 (en) | Electrical contact element | |

| DE9304392U1 (en) | Contact element with insulation displacement and crimp connection | |

| EP1213790A2 (en) | Electrical connecting terminal | |

| DE102013203546A1 (en) | Socket connected to plug for ensuring high current plug connection between electrical conductor elements, has contact slat that is provided in inside of case and is comprised with 8-shaped cross-section |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20010306 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 20021202 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030917 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030917 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030917 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030917 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 50003701 Country of ref document: DE Date of ref document: 20031023 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20031217 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20031217 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20031217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20031226 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20031228 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: KIRKER & CIE SA Ref country code: CH Ref legal event code: PFA Owner name: HYPERTAC GMBH Free format text: INTERCONNECTRON GMBH#AUWIESENSTRASSE 5#94469 DEGGENDORF (DE) -TRANSFER TO- HYPERTAC GMBH#AUWIESENSTRASSE 5#94469 DEGGENDORF (DE) |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040104 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: HYPERTAC GMBH |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040711 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040731 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040731 |

|

| 26N | No opposition filed |

Effective date: 20040618 |

|

| BERE | Be: lapsed |

Owner name: *INTERCONNECTRON G.M.B.H. Effective date: 20040731 |

|

| BERE | Be: lapsed |

Owner name: *INTERCONNECTRON G.M.B.H. Effective date: 20040731 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20170712 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20170626 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 250286 Country of ref document: AT Kind code of ref document: T Effective date: 20180711 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180731 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180711 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180731 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20190619 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20190625 Year of fee payment: 20 Ref country code: IT Payment date: 20190719 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20190710 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 50003701 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20200710 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20200710 |