EP0944112B1 - Halogen incandescent lamp, electric lamp and method for manufacturing a halogen incandescent lamp - Google Patents

Halogen incandescent lamp, electric lamp and method for manufacturing a halogen incandescent lamp Download PDFInfo

- Publication number

- EP0944112B1 EP0944112B1 EP99103807A EP99103807A EP0944112B1 EP 0944112 B1 EP0944112 B1 EP 0944112B1 EP 99103807 A EP99103807 A EP 99103807A EP 99103807 A EP99103807 A EP 99103807A EP 0944112 B1 EP0944112 B1 EP 0944112B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- luminous element

- incandescent lamp

- halogen incandescent

- foil

- power supply

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01K—ELECTRIC INCANDESCENT LAMPS

- H01K1/00—Details

- H01K1/40—Leading-in conductors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J61/00—Gas-discharge or vapour-discharge lamps

- H01J61/02—Details

- H01J61/36—Seals between parts of vessels; Seals for leading-in conductors; Leading-in conductors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01K—ELECTRIC INCANDESCENT LAMPS

- H01K1/00—Details

- H01K1/02—Incandescent bodies

- H01K1/04—Incandescent bodies characterised by the material thereof

- H01K1/06—Carbon bodies

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01K—ELECTRIC INCANDESCENT LAMPS

- H01K1/00—Details

- H01K1/18—Mountings or supports for the incandescent body

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01K—ELECTRIC INCANDESCENT LAMPS

- H01K3/00—Apparatus or processes adapted to the manufacture, installing, removal, or maintenance of incandescent lamps or parts thereof

- H01K3/06—Attaching of incandescent bodies to mount

Definitions

- the invention is based on a halogen incandescent lamp according to the preamble of claim 1. These are in particular squeezed on two sides Incandescent lamps with an axially arranged filament.

- a generic halogen incandescent lamp is already known from the document EP-A 475 508 known.

- An end region of the cylindrical filament is through a power supply inserted therein is mechanically supported by the Power supply is bent asymmetrically in one plane. In particular is they shaped so that on a first axially parallel leg of the Power supply a second leg is formed with a free end.

- the free end hooks behind a turn of the filament that is spaced from the end of the filament is one-sided, while the first leg opposite the free end on the turns of the filament is applied.

- the film-side end of the power supply is more common on the film Way welded.

- the disadvantage of this construction is that the centering of the filament and the power supply system because of asymmetrical shape of the power supply is not reliably guaranteed is. In addition, the welding process is very time-consuming and costly.

- the present invention is based on a simple design, if possible symmetrical power supply, which is advantageous spring action exerts on the illuminant and thus automatically the centering of the filament ensures.

- the concept of this power supply has the particular advantage that the connection to the film is not by welding, but by mechanical contact. It doesn't just mean that Costs and manufacturing time significantly reduced, but there are also no potential Weaknesses. Previously, an expensive platinum paste had to be used for welding to be used. The area of the welding spot was also previously the Exposed to oxidation, which reduced the lifespan.

- the halogen incandescent lamp according to the invention has a hermetic seal sealed piston made of translucent material on the one Lamp axis defined. Furthermore, it has a preferably axially arranged coiled (and thus cylindrically shaped) filament with two ends and a power supply system that connects to the two end areas of the filament is connected.

- the power supply system includes a film and an inner and outer power supply, the filament side inner end of the power supply the end region of the filament from the inside.

- the foil-side outer end of the power supply is connected to the film.

- the power supply itself is U-shaped bent by two free legs, advantageously loaded with spring force lie in one plane and connected to each other via a straight base are.

- the section on the filament side is at the end of the associated film folded back and forms a fold in which the base is mechanically held is.

- the ends of the free legs protrude into an end region of the filament into it.

- At least one hook part is on one of the free legs to the outside. This hook part engages between two turns of the Filament.

- the area of the folded end portion of the film is normal rectangular.

- Such a folded-over rectangular end section of the film is already known from EP-A 780 883. However, this area is now preferred reduced to at least one or both free corners. This facilitates the automatic hooking of the power supply in the fold of the Foil. This also saves film material.

- the folded one Section is preferably triangular (symmetrical or asymmetrical). However, it can also be rounded, for example. This cheap In principle, the design of the end section of the film is independent of the special way of providing a power supply suspended in the film. In principle, it is for both external and internal power supply suitable. For this special shape of the folded end section with a reduced area therefore becomes independent of the special one The shape of the power supply hooked into it requires protection. This one folded In principle, the end section can also be used with other lamp types (especially discharge lamps with metal halide filling) are used become.

- Each of the two legs preferably has a hook part. This will improved the bracket and ensured the centering even better.

- the legs are usually the same length. However, it is for special applications advantageous to use legs of different lengths.

- the concept according to the invention is particularly good for a halogen incandescent lamp suitable, which is squeezed on two or one side. You can both end areas are supported by a new type of power supply.

- the diameter of the wire is advantageous for the power supply is used, at least as large as the distance between two turns of the filament.

- the bracket is not only by the tension between the two ends of the filament caused, but also or mainly by a clamping intervention of the hook part between two turns of the filament.

- the wire diameter of the power supply is greater than the distance between two Turns of the filament, so that the filament when inserting the Power supply is spread slightly; it is preferably 10 to 30% larger, see above that on the one hand the clamping intervention is easy to accomplish and on the other hand the holding force is still sufficiently safe.

- the hook part preferably protrudes slightly above the lamp outwards.

- the free legs can run straight and axially parallel, which is the easiest is to be produced.

- the legs are shaped so that the width of the film regardless of dimensions of the filament can be selected.

- the legs are either inclined inwards towards the axis, or the two legs point in one particularly preferred embodiment just before the end of the Filament has an inward curvature that defines the distance between the thigh ends reduced. This shape is the end area of the filament ideally adjusted so that the holder and centering of the filament works particularly reliably.

- the hook part preferably forms an outwardly protruding angle to Leg, the hook part at an angle ⁇ between 30 ° and 120 °, in particular about 50 ° to 60 °, is bent relative to the free leg.

- the legs should at least two turns, preferably more than 3 turns, in the end area of the filament are introduced.

- the power supply is mostly made of tungsten or molybdenum.

- the hook part must be designed so that the filament side Width when compressed is always smaller than that Inner diameter of the filament is.

- the length of the two hook parts in the case of their right-angled bend) or their length in projection transverse to the lamp axis (in the event that the hook parts are at an acute angle to the Legs are arranged) may therefore at most half the inner diameter correspond to the cylinder formed by the filament. In the event of of a single hook part is accordingly a length up to the full Inside diameter permitted.

- a method of manufacturing the halogen incandescent lamp described above is based on the fact that the power supply with the two legs initially is squeezed.

- the power supply is in this state introduced the end region of the filament at least two turns.

- the legs snap open when the power supply is relaxed outside and press evenly from the inside against the end area of the Illuminant.

- the hook part (s) press into the space jamming between two turns.

- the tension is the Helix advantageous because it increases the distance between two turns.

- the lamp-side section of the film initially angled only by more than 90 ° (preferably at least 100 °) that there is a fold in the film.

- the internal power supply is in this with its base hooked in and the filament in relation to the foil underneath Tension held. Then the angled section of the Angled the film further until it describes a bend of a total of 180 ° Has.

- the tension is maintained so that the The hook part cannot slip out of the fold of the film.

- squeezing of the piston end around the film are preferably pinch jaws with an in used about central knob. The knob is raised against the rest Squeeze area and causes a lot of piston material (is preferred Quartz glass used) pressed between the legs of the power supply becomes. This not only ensures a secure hold of the power supply, but also achieved that the film itself in the squeezing process the center of the bruise remains centered.

- the invention is preferred for double-sided pinched halogen incandescent lamps (Festoons) suitable. But the application is also with other lamps possible, for example with lamps pinched on one side.

- FIG. 1 shows a double-ended, socketed halogen incandescent lamp 1 (Soffitte) for general lighting with an output of 150 W. It is for suitable for direct connection to the 230 V network and has a cylindrical Piston 2 made of quartz glass. A pump stem 3 is attached in the middle. The two ends of the piston are each closed with a pinch seal 4. The piston 2 is filled with argon, which is known per se Halogen additive is attached.

- An axially arranged filament 5 with a luminous central section is simply spiraled (or in another embodiment double coiled).

- the (primary) spiral of the simply spiraled Filament (or the secondary coil of the double-coiled Luminous body) thus forms a cylindrical body.

- the distance between two turns is about 50 ⁇ m with a wire diameter of about 190 ⁇ m.

- the luminous element 5 has an end region 6 at each end with a steep incline. There the distance between two turns is about 500 ⁇ m.

- the luminous element is connected via internal power supply lines 7

- Molybdenum foils 8 in the press seals 4 at the ends of the piston are embedded, connected.

- electrical external leads (external power supply lines) 9 are welded on, which are connected to contacts in the ceramic bases 10.

- the power supply system is shown in more detail.

- the end area 6 of the filament extends over a few turns (only one turn is shown schematically).

- the power supply 7 from Tungsten with a wire diameter of approximately 600 ⁇ m is approximately U-shaped bent and has a straight base 15. It is in a fold 12 the film hung, which by folding back an end portion 11 of the Foil is formed, the filament side of the film 8 in the form of a is arranged asymmetrically to the lamp axis arranged triangle.

- the free ends 18 are angled inwards (17) and up to extend the interior of the end portion 6 of the filament.

- the bend 17 forms an inward shortly before the end of the filament Bend 17, the free leg ends 18 each on the inside Windings of the end region 6 are applied.

- the leg ends 18 are advantageous bent slightly outwards before insertion into the filament, see above that they still exert a certain spring force when installed.

- This version is suitable for small wattages where the Luminous body is relatively small and unstable for electrical reasons.

- the first leg end 18 shaped exactly as in Figure 2 with a hook end.

- the second Leg end 19 is, however, much longer than the first. It serves as a guide. With him the hook part is directed inwards.

- the end section 13 of the film is rounded in this embodiment.

- the luminous element is 25 a high-watt lamp (500 W) so stable that the hook parts 26, the are bent back at an acute angle at an angle ⁇ of 45 ° are hooked in after the second turn.

- the curvature 27 of the legs 28 is bent more smoothly than in the first embodiment.

- This variant is preferably applicable with a relatively large diameter of the power supply.

- the folded end portion 14 has the shape of a triangle that is symmetrical is arranged to the lamp axis.

- the legs 30 are set at right angles to the base 31 and run parallel to each other.

- the hook parts 32 are angled by 90 ° and protrude opposite each other perpendicularly from the plane of the legs 30 out.

- legs 35 are inclined obliquely inwards on the base 36 stated.

- the hook parts 37 are angled at 110 ° and remain in the System level consisting of leg 35 and base 36.

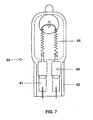

- FIG. 7 shows a halogen incandescent lamp 40 which is pinched on one side and whose two molybdenum foils 41 parallel to one another in a single pinch 42 are embedded.

- Both inner power supply lines 43 are similar to that in FIG Figure 2 described constructed and hold the ends of a U-shaped curve Filament 44.

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Vessels And Coating Films For Discharge Lamps (AREA)

- Electric Stoves And Ranges (AREA)

Description

Die Erfindung geht aus von einer Halogenglühlampe gemäß dem Oberbegriff des Anspruchs 1. Es handelt sich dabei insbesondere um zweiseitig gequetschte Glühlampen mit einem axial angeordneten Leuchtkörper.The invention is based on a halogen incandescent lamp according to the preamble of claim 1. These are in particular squeezed on two sides Incandescent lamps with an axially arranged filament.

Aus der Schrift EP-A 475 508 ist bereits eine gattungsgemäße Halogenglühlampe bekannt. Ein Endbereich des zylindrischen Leuchtkörpers ist durch eine darin eingeführte Stromzuführung mechanisch gehaltert, indem die Stromzuführung in einer Ebene unsymmetrisch gebogen ist. Im einzelnen ist sie so geformt, daß an einen ersten achsparallel ausgerichteten Schenkel der Stromzuführung ein zweiter Schenkel mit freiem Ende angeformt ist. Das freie Ende hakt hinter einer Windung des Leuchtkörpers, die beabstandet vom Ende des Leuchtkörpers ist, einseitig ein, während der erste Schenkel gegenüberliegend dem freien Ende an den Windungen des Leuchtkörpers anliegt. Das folienseitige Ende der Stromzuführung ist an der Folie in üblicher Weise verschweißt. Nachteilig an dieser Konstruktion ist, daß die Zentrierung des Leuchtkörpers und des Stromzuführungssystems wegen der unsymmetrischen Gestalt der Stromzuführung nicht zuverlässig gewährleistet ist. Außerdem ist der Schweißvorgang sehr zeit- und kostenaufwendig. A generic halogen incandescent lamp is already known from the document EP-A 475 508 known. An end region of the cylindrical filament is through a power supply inserted therein is mechanically supported by the Power supply is bent asymmetrically in one plane. In particular is they shaped so that on a first axially parallel leg of the Power supply a second leg is formed with a free end. The free end hooks behind a turn of the filament that is spaced from the end of the filament is one-sided, while the first leg opposite the free end on the turns of the filament is applied. The film-side end of the power supply is more common on the film Way welded. The disadvantage of this construction is that the centering of the filament and the power supply system because of asymmetrical shape of the power supply is not reliably guaranteed is. In addition, the welding process is very time-consuming and costly.

Es ist Aufgabe der vorliegenden Erfindung, eine Halogenglühlampe gemäß dem Oberbegriff des Anspruchs 1 bereitzustellen, die eine gute Zentrierung des Leuchtkörpers gewährleistet und deren Herstellkosten trotzdem sehr niedrig sind. Eine weitere Aufgabe ist es außerdem, eine Halogenglühlampe bereitzustellen, die einfach und schnell herzustellen ist.It is an object of the present invention to provide a halogen incandescent lamp provide the preamble of claim 1, the good centering guaranteed of the filament and their manufacturing costs very much are low. Another task is also a halogen light bulb to provide, which is easy and quick to manufacture.

Diese Aufgabe wird durch die kennzeichnenden Merkmale des Anspruchs 1 gelöst. Besonders vorteilhafte Ausgestaltungen finden sich in den abhängigen Ansprüchen.This object is achieved by the characterizing features of claim 1 solved. Particularly advantageous configurations can be found in the dependent ones Claims.

Die vorliegende Erfindung basiert auf einer einfach gestalteten, möglichst symmetrisch aufgebauten Stromzuführung, die vorteilhaft eine Federwirkung auf den Leuchtkörper ausübt und somit automatisch die Zentrierung des Leuchtkörpers sicherstellt. Das Konzept dieser Stromzuführung hat den besonderen Vorteil, daß die Verbindung mit der Folie nicht durch Schweißen, sondern durch mechanischen Kontakt erfolgt. Damit werden nicht nur Kosten und Herstelldauer deutlich gesenkt, sondern es entfallen auch potentielle Schwachpunkte. Bisher mußte beim Schweißen eine teure Platinpaste benutzt werden. Der Bereich des Schweißpunkts war außerdem bisher der Oxidation ausgesetzt, was die Lebensdauer verringerte.The present invention is based on a simple design, if possible symmetrical power supply, which is advantageous spring action exerts on the illuminant and thus automatically the centering of the filament ensures. The concept of this power supply has the particular advantage that the connection to the film is not by welding, but by mechanical contact. It doesn't just mean that Costs and manufacturing time significantly reduced, but there are also no potential Weaknesses. Previously, an expensive platinum paste had to be used for welding to be used. The area of the welding spot was also previously the Exposed to oxidation, which reduced the lifespan.

Im einzelnen weist die erfindungsgemäße Halogenglühlampe einen hermetisch abgedichteten Kolben aus lichtdurchlässigem Material auf, der eine Lampenachse definiert. Des weiteren besitzt sie einen, bevorzugt axial angeordneten, gewendelten (und somit zylindrisch geformten) Leuchtkörper mit zwei Enden und ein Stromzuführungssystem, das mit den beiden Endbereichen des Leuchtkörpers verbunden ist. Das Stromzuführungssystem umfaßt eine Folie und eine innere und äußere Stromzuführung, wobei das leuchtkörperseitige innere Ende der Stromzuführung den Endbereich des Leuchtkörpers von innen her haltert. Das folienseitige äußere Ende der Stromzuführung ist mit der Folie verbunden. Die Stromzuführung selbst ist U-förmig gebogen, indem zwei freie, vorteilhaft mit Federkraft beaufschlagte Schenkel in einer Ebene liegen und über eine gerade Basis miteinander verbunden sind. Der leuchtkörperseitige Abschnitt am Ende der zugehörigen Folie ist zurückgeklappt und bildet eine Falte, in der die Basis mechanisch gehaltert ist. Die Enden der freien Schenkel ragen in einen Endbereich des Leuchtkörpers hinein. Mindestens ein Hakenteil an einem der freien Schenkeln steht nach außen ab. Dieses Hakenteil greift zwischen zwei Windungen des Leuchtkörpers ein.In particular, the halogen incandescent lamp according to the invention has a hermetic seal sealed piston made of translucent material on the one Lamp axis defined. Furthermore, it has a preferably axially arranged coiled (and thus cylindrically shaped) filament with two ends and a power supply system that connects to the two end areas of the filament is connected. The power supply system includes a film and an inner and outer power supply, the filament side inner end of the power supply the end region of the filament from the inside. The foil-side outer end of the power supply is connected to the film. The power supply itself is U-shaped bent by two free legs, advantageously loaded with spring force lie in one plane and connected to each other via a straight base are. The section on the filament side is at the end of the associated film folded back and forms a fold in which the base is mechanically held is. The ends of the free legs protrude into an end region of the filament into it. At least one hook part is on one of the free legs to the outside. This hook part engages between two turns of the Filament.

Die Fläche des umgeklappten Endabschnitts der Folie ist normalerweise rechteckig. Ein derartig umgeklappter rechteckiger Endabschnitt der Folie ist bereits aus EP-A 780 883 vorbekannt. Diese Fläche ist aber nunmehr bevorzugt an mindestens einer oder auch an beiden freien Ecke(n) reduziert. Dies erleichtert das automatische Einhängen der Stromzuführung in der Falte der Folie. Außerdem wird dadurch Folienmaterial gespart. Der umgeklappte Abschnitt ist bevorzugt dreieckig (symmetrisch oder asymmetrisch) geformt. Er kann aber beispielsweise auch abgerundet geformt sein. Diese günstige Gestaltung des Endabschnitts der Folie ist im Prinzip unabhängig von der speziellen Art der Bereitstellung einer in der Folie eingehängten Stromzuführung. Sie ist im Prinzip sowohl für die äußere als auch innere Stromzuführung geeignet. Für diese besondere Form des umgeklappten Endabschnitts mit reduzierter Fläche wird daher unabhängig von der speziellen Gestalt der darin eingehängten Stromzuführung Schutz begehrt. Dieser umgeklappte Endabschnitt kann im Prinzip auch bei anderen Lampentypen (insbesondere Entladungslampen mit Metallhalogenidfüllung) verwendet werden.The area of the folded end portion of the film is normal rectangular. Such a folded-over rectangular end section of the film is already known from EP-A 780 883. However, this area is now preferred reduced to at least one or both free corners. This facilitates the automatic hooking of the power supply in the fold of the Foil. This also saves film material. The folded one Section is preferably triangular (symmetrical or asymmetrical). However, it can also be rounded, for example. This cheap In principle, the design of the end section of the film is independent of the special way of providing a power supply suspended in the film. In principle, it is for both external and internal power supply suitable. For this special shape of the folded end section with a reduced area therefore becomes independent of the special one The shape of the power supply hooked into it requires protection. This one folded In principle, the end section can also be used with other lamp types (especially discharge lamps with metal halide filling) are used become.

Bevorzugt weist jeder der beiden Schenkel ein Hakenteil auf. Dadurch wird die Halterung verbessert und die Zentrierung noch besser sichergestellt. Each of the two legs preferably has a hook part. This will improved the bracket and ensured the centering even better.

Die Schenkel sind normalerweise gleich lang. Es ist jedoch für spezielle Anwendungen vorteilhaft, unterschiedlich lange Schenkel zu verwenden.The legs are usually the same length. However, it is for special applications advantageous to use legs of different lengths.

Das erfindungsgemäße Konzept ist besonders gut für eine Halogenglühlampe geeignet, die zweiseitig oder auch einseitig gequetscht ist. Dabei können beide Endbereiche durch eine neuartige Stromzuführung gehaltert werden.The concept according to the invention is particularly good for a halogen incandescent lamp suitable, which is squeezed on two or one side. You can both end areas are supported by a new type of power supply.

Vorteilhaft ist der Durchmesser des Drahtes, der für die Stromzuführung verwendet wird, mindestens genauso so groß wie der Abstand zweier Windungen des Leuchtkörpers. Auf diese Weise wird die Halterung nicht nur durch die Zugspannung zwischen den beiden Enden des Leuchtkörpers bewirkt, sondern auch oder hauptsächlich durch einen klemmenden Eingriff des Hakenteils zwischen zwei Windungen des Leuchtkörpers. Bevorzugt ist der Drahtdurchmesser der Stromzuführung größer als der Abstand zweier Windungen des Leuchtkörpers, so daß die Wendel beim Einführen der Stromzuführung etwas gespreizt wird; bevorzugt ist er 10 bis 30 % größer, so daß einerseits der klemmende Eingriff leicht zu bewerkstelligen und andererseits die Haltekraft trotzdem ausreichend sicher ist.The diameter of the wire is advantageous for the power supply is used, at least as large as the distance between two turns of the filament. In this way, the bracket is not only by the tension between the two ends of the filament caused, but also or mainly by a clamping intervention of the hook part between two turns of the filament. Is preferred the wire diameter of the power supply is greater than the distance between two Turns of the filament, so that the filament when inserting the Power supply is spread slightly; it is preferably 10 to 30% larger, see above that on the one hand the clamping intervention is easy to accomplish and on the other hand the holding force is still sufficiently safe.

Am einfachsten ist das Hakenteil in der Ebene der Stromzuführung gebogen. Es kann jedoch auch außerhalb dieser Ebene gebogen sein, wobei u.U. die beiden Hakenteile der beiden Schenkel in entgegengesetzte Richtungen zeigen.The easiest way is to hook the hook part in the plane of the power supply. However, it can also be curved outside of this level. the Point the two hook parts of the two legs in opposite directions.

Um ein Herausrutschen des Hakenteils aus dem Leuchtkörper zuverlässig zu vermeiden, ragt das Hakenteil bevorzugt geringfügig über den Leuchtkörper nach außen hinaus.To reliably prevent the hook part from slipping out of the lamp avoid, the hook part preferably protrudes slightly above the lamp outwards.

Die freien Schenkel können gerade und achsparallel verlaufen, was am einfachsten herzustellen ist. In einer anderen Ausführungsform sind die Schenkel so geformt, daß die Breite der Folie unabhängig von den Abmessungen des Leuchtkörpers gewählt werden kann. Dazu sind die Schenkel entweder nach innen zur Achse hin geneigt, oder die beiden Schenkel weisen in einer besonders bevorzugten Ausführungsform kurz vor dem Endbereich des Leuchtkörpers eine Krümmung nach innen auf, die den Abstand zwischen den Schenkelenden verringert. Diese Form ist dem Endbereich des Leuchtkörpers ideal angepaßt, so daß die Halterung und Zentrierung des Leuchtkörpers besonders zuverlässig funktioniert.The free legs can run straight and axially parallel, which is the easiest is to be produced. In another embodiment, the legs are shaped so that the width of the film regardless of dimensions of the filament can be selected. For this, the legs are either inclined inwards towards the axis, or the two legs point in one particularly preferred embodiment just before the end of the Filament has an inward curvature that defines the distance between the thigh ends reduced. This shape is the end area of the filament ideally adjusted so that the holder and centering of the filament works particularly reliably.

Das Hakenteil bildet bevorzugt einen nach außen abstehenden Winkel zum Schenkel, wobei das Hakenteil in einem Winkel α zwischen 30° und 120°, insbesondere etwa 50° bis 60°, relativ zum freien Schenkel abgebogen ist.The hook part preferably forms an outwardly protruding angle to Leg, the hook part at an angle α between 30 ° and 120 °, in particular about 50 ° to 60 °, is bent relative to the free leg.

Um eine sichere Halterung zu gewährleisten, sollen die Schenkel mindestens zwei Windungen weit, bevorzugt mehr als 3 Windungen weit, in den Endbereich des Leuchtkörpers eingeführt werden.In order to ensure a secure mounting, the legs should at least two turns, preferably more than 3 turns, in the end area of the filament are introduced.

Die Stromzuführung ist meist aus Wolfram oder auch Molybdän gefertigt.The power supply is mostly made of tungsten or molybdenum.

Zu beachten ist, daß das Hakenteil so konstruiert sein muß, daß die leuchtkörperseitige Breite im zusammengedrückten Zustand immer kleiner als der Innendurchmesser des Leuchtkörpers ist. Die Länge der beiden Hakenteile (im Falle ihrer rechtwinkeligen Abwinkelung) bzw. deren Länge in Projektion quer zur Lampenachse (im Falle, daß die Hakenteile spitzwinkelig zu den Schenkeln angeordnet sind) darf daher maximal dem halben Innendurchmesser des vom Leuchtkörper gebildeten Zylinders entsprechen. Im Falle eines einzigen Hakenteils ist dementsprechend eine Länge bis zum vollen Innendurchmesser zulässig.It should be noted that the hook part must be designed so that the filament side Width when compressed is always smaller than that Inner diameter of the filament is. The length of the two hook parts (in the case of their right-angled bend) or their length in projection transverse to the lamp axis (in the event that the hook parts are at an acute angle to the Legs are arranged) may therefore at most half the inner diameter correspond to the cylinder formed by the filament. In the event of of a single hook part is accordingly a length up to the full Inside diameter permitted.

Ein Verfahren zum Herstellen der oben beschriebenen Halogenglühlampe basiert darauf, daß die Stromzuführung mit den beiden Schenkeln zunächst zusammengedrückt wird. Die Stromzuführung wird in diesem Zustand in den Endbereich des Leuchtkörpers mindestens zwei Windungen weit eingeführt. Beim Entspannen der Stromzuführung schnellen die Schenkel nach außen und drücken gleichmäßig von innen gegen den Endbereich des Leuchtkörpers. Das oder die Hakenteil(e) pressen sich in den Zwischenraum zwischen zwei Windungen klemmend hinein. Dafür ist das Spannen der Wendel vorteilhaft, weil es den Abstand zwischen zwei Windungen vergrößert. Anschließend wird eine Baueinheit, bestehend aus der Folie und der daran befestigten Außenzuleitung, an der Basis der inneren Stromzuführung befestigt. Zu diesem Zweck wird der leuchtkörperseitige Abschnitt der Folie zunächst nur um mehr als 90° (bevorzugt mindestens 100°) abgewinkelt, so daß eine Falte in der Folie entsteht. In diese wird die innere Stromzuführung mit ihrer Basis eingehängt und der Leuchtkörper in bezug auf die Folie unter Zugspannung gehalten. Anschließend wird der abgewinkelte Abschnitt der Folie weiter abgewinkelt, bis er eine Biegung um insgesamt 180° beschrieben hat. Für den Transport zu den weiteren Fertigungsschritten (insbesondere Einquetschen) wird die Zugspannung weiter aufrechterhalten, damit das Hakenteil nicht aus der Falte der Folie herausrutschen kann. Beim Quetschen des Kolbenendes um die Folie werden bevorzugt Quetschbacken mit einer in etwa zentralen Noppe verwendet. Die Noppe ist erhöht gegen die übrige Quetschfläche und bewirkt, daß viel Kolbenmaterial (bevorzugt wird Quarzglas verwendet) zwischen die Schenkel der Stromzuführung gedrückt wird. Dadurch wird nicht nur ein sicherer Halt der Stromzuführung gewährleistet, sondern auch erreicht, daß beim Quetschvorgang selbst die Folie in der Mitte der Quetschung zentriert bleibt.A method of manufacturing the halogen incandescent lamp described above is based on the fact that the power supply with the two legs initially is squeezed. The power supply is in this state introduced the end region of the filament at least two turns. The legs snap open when the power supply is relaxed outside and press evenly from the inside against the end area of the Illuminant. The hook part (s) press into the space jamming between two turns. For that the tension is the Helix advantageous because it increases the distance between two turns. Then a unit consisting of the film and the attached external lead, at the base of the inner power supply attached. For this purpose, the lamp-side section of the film initially angled only by more than 90 ° (preferably at least 100 °) that there is a fold in the film. The internal power supply is in this with its base hooked in and the filament in relation to the foil underneath Tension held. Then the angled section of the Angled the film further until it describes a bend of a total of 180 ° Has. For transport to the further production steps (in particular Squeeze) the tension is maintained so that the The hook part cannot slip out of the fold of the film. When squeezing of the piston end around the film are preferably pinch jaws with an in used about central knob. The knob is raised against the rest Squeeze area and causes a lot of piston material (is preferred Quartz glass used) pressed between the legs of the power supply becomes. This not only ensures a secure hold of the power supply, but also achieved that the film itself in the squeezing process the center of the bruise remains centered.

Die Erfindung ist bevorzugt für zweiseitig gequetschte Halogenglühlampen (Soffitten) geeignet. Doch ist die Anwendung bei anderen Lampen ebenfalls möglich, beispielsweise bei einseitig gequetschten Lampen.The invention is preferred for double-sided pinched halogen incandescent lamps (Festoons) suitable. But the application is also with other lamps possible, for example with lamps pinched on one side.

Im folgenden soll die Erfindung anhand mehrerer Ausführungsbeispiele näher erläutert werden. Es zeigen:

- Figur 1

- eine Soffittenlampe

Figur 2- eine vergrößerte Darstellung des Stromzuführungssystems

Figur 3- ein weiteres Ausführungsbeispiel des Stromzuführungssystems

Figur 4- ein weiteres Ausführungsbeispiel des Stromzuführungssystems

Figur 5- ein weiteres Ausführungsbeispiel einer Stromzuführung

Figur 6- ein weiteres Ausführungsbeispiel einer Stromzuführung

Figur 7- ein Ausführungsbeispiel einer einseitig gequetschten Halogenglühlampe

- Figure 1

- a festoon lamp

- Figure 2

- an enlarged view of the power supply system

- Figure 3

- another embodiment of the power supply system

- Figure 4

- another embodiment of the power supply system

- Figure 5

- another embodiment of a power supply

- Figure 6

- another embodiment of a power supply

- Figure 7

- an embodiment of a halogen lamp pinched on one side

Figur 1 zeigt eine zweiseitig gequetschte, gesockelte Halogenglühlampe 1

(Soffitte) für Allgemeinbeleuchtung mit einer Leistung von 150 W. Sie ist für

den direkten Anschluß an das 230 V-Netz geeignet und besitzt einen zylindrischen

Kolben 2 aus Quarzglas. Mittig ist ein Pumpstengel 3 angebracht.

Die beiden Enden des Kolbens sind jeweils mit einer Quetschdichtung 4 verschlossen.

Der Kolben 2 ist mit Argon gefüllt, dem ein an sich bekannter

Halogenzusatz beigefügt ist.FIG. 1 shows a double-ended, socketed halogen incandescent lamp 1

(Soffitte) for general lighting with an output of 150 W. It is for

suitable for direct connection to the 230 V network and has a

Ein axial angeordneter Leuchtkörper 5 mit einem leuchtenden Zentralabschnitt

ist einfach gewendelt (oder in einem anderen Ausführungsbeispiel

doppelt gewendelt). Das (Primär-)Gewendel des einfach gewendelten

Leuchtkörpers (bzw. das Sekundärgewendel des doppelt gewendelten

Leuchtkörpers) bildet somit einen zylindrischen Körper. Der Abstand zwischen

zwei Windungen beträgt etwa 50 µm bei einem Drahtdurchmesser von

etwa 190 µm. Der Leuchtkörper 5 weist an jedem Ende einen Endbereich 6

mit großer Steigung auf. Dort beträgt der Abstand zwischen zwei Windungen

etwa 500 µm. Der Leuchtkörper ist über innere Stromzuführungen 7 mit

Molybdänfolien 8, die in die Quetschdichtungen 4 an den Enden des Kolbens

eingebettet sind, verbunden. An den äußeren Enden der Molybdänfolien

sind elektrische Außenzuleitungen (äußere Stromzuführungen) 9 angeschweißt,

die mit Kontakten in den Keramiksockeln 10 verbunden sind.An axially arranged

In Figur 2 ist das Stromzuführungssystem im Detail näher gezeigt. Der Endbereich

6 des Leuchtkörpers erstreckt sich über einige Windungen

(schematisiert ist nur eine Windung gezeigt). Die Stromzuführung 7 aus

Wolfram mit einem Durchmesser des Drahts von etwa 600 µm ist in etwa U-förmig

gebogen und weist eine gerade Basis 15 auf. Sie ist in einer Falte 12

der Folie eingehängt, die durch Zurückklappen eines Endabschnitts 11 der

Folie gebildet wird, der leuchtkörperseitig an der Folie 8 in Gestalt eines

asymmetrisch zur Lampenachse angeordneten Dreiecks angesetzt ist. An der

Basis 15 der Stromzuführung setzen rechtwinkelig zwei federnde Schenkel

16 an, deren freie Enden 18 nach innen abgewinkelt (17) sind und sich bis in

das Innere des Endbereichs 6 des Leuchtkörpers erstrecken. Die Abwinkelung

17 bildet kurz vor dem Ende des Leuchtkörpers eine nach innen gerichtete

Kröpfung 17, wobei die freien Schenkelenden 18 jeweils innen an den

Windungen des Endbereichs 6 anliegen. Die Schenkelenden 18 sind vorteilhaft

vor dem Einführen in den Leuchtkörper leicht nach außen gebogen, so

daß sie im eingebauten Zustand immer noch eine gewisse Federkraft ausüben.In Figure 2, the power supply system is shown in more detail. The

An den Enden der Schenkelenden sind etwa 1 mm kurze Hakenteile 20 etwa

rechtwinkelig nach außen abgebogen. Sie sind zwischen zwei Windungen

des Leuchtkörpers eingeklemmt und ragen über die Windungen hinaus nach

außen.At the ends of the leg ends there are approximately 1 mm

Diese Ausführung ist für kleinwattige Leistungen geeignet, bei denen der Leuchtkörper aus elektrischen Gründen relativ klein und instabil ist.This version is suitable for small wattages where the Luminous body is relatively small and unstable for electrical reasons.

In einem weiteren Ausführungsbeispiel gemäß Figur 3 ist das erste Schenkelende

18 genauso wie in Figur 2 mit einem Hakenende geformt. Das zweite

Schenkelende 19 ist jedoch wesentlich länger als das erste. Es dient als Führungshilfe.

Bei ihm ist das Hakenteil nach innen gerichtet. Der Endabschnitt

13 der Folie ist in diesem Ausführungsbeispiel abgerundet.In a further exemplary embodiment according to FIG. 3, the

In einem weiteren Ausführungsbeispiel gemäß Figur 4 ist der Leuchtkörper

25 einer hochwattigen Lampe (500 W) so stabil, daß die Hakenteile 26, die

spitzwinkelig unter einem Winkel α von 45° zurückgebogen sind, bereits

nach der zweiten Windung eingehängt sind. Die Krümmung 27 der Schenkel

28 ist sanfter gebogen als im ersten Ausführungsbeispiel. Diese Variante ist

bevorzugt bei relativ großem Durchmesser der Stromzuführung anwendbar.

Der umgeklappte Endabschnitt 14 hat die Gestalt eines Dreiecks, das symmetrisch

zur Lampenachse angeordnet ist.In a further exemplary embodiment according to FIG. 4, the luminous element is

25 a high-watt lamp (500 W) so stable that the

In einem weiteren Ausführungsbeispiel eines Stromzuführungssystems 29

gemäß Figur 5 sind die Schenkel 30 an der Basis 31 rechtwinkelig angesetzt

und laufen parallel zueinander. Die Hakenteile 32 sind um 90° abgewinkelt

und ragen entgegengesetzt zueinander senkrecht aus der Ebene der Schenkel

30 heraus.In a further exemplary embodiment of a

In einem weiteren Ausführungsbeispiel eines Stromzuführungssystems 34

gemäß Figur 6 sind die Schenkel 35 schräg nach innen geneigt an der Basis 36

angesetzt. Die Hakenteile 37 sind um 110° abgewinkelt und verbleiben in der

Ebene des Systems, das aus Schenkel 35 und Basis 36 besteht.In a further exemplary embodiment of a

In Figur 7 ist eine einseitig gequetschte Halogenglühlampe 40 gezeigt, deren

zwei Molybdänfolien 41 parallel zueinander in einer einzigen Quetschung 42

eingebettet sind. Beide inneren Stromzuführungen 43 sind ähnlich wie in

Figur 2 beschrieben aufgebaut und halten die Enden eines U-förmig gebogenen

Leuchtkörpers 44.FIG. 7 shows a halogen

Claims (13)

- Halogen incandescent lamp having a hermetically sealed bulb (2) which is made from transparent material and defines a lamp axis, having a coiled luminous element (5) which forms a cylinder and has two end regions (6), and having a power supply system which is connected to the two end regions (6) of the luminous element, the power supply system comprising foils (8), a section (11) at the end, on the side of the luminous element, of the associated foil being folded back and forming a fold (12), characterized in that the power supply system comprises additional supply leads (7), the inner end, on the side of the luminous element, of the supply lead holding the end region (6) of the luminous element from inside, and the outer end, on the foil side, of the supply lead being connected to the foil (8), and the supply lead (7) being bent in a U-shaped fashion by interconnecting two free limbs (16), which lie in a plane, via a straight base (15) and being held mechanically in the fold (12), the ends (18) of the limbs (16) projecting into the end region (6) of the luminous element, and at least one hook part (20) projecting outwards at one of the limb ends which engages between two turns of the luminous element.

- Halogen incandescent lamp according to Claim 1, characterized in that each of the two limb ends (18) has a hook part (20).

- Halogen incandescent lamp according to Claim 1, characterized in that the halogen incandescent lamp (1;40) is pinched at two ends or at one end.

- Halogen incandescent lamp according to Claim 1, characterized in that the diameter of the wire of the supply lead (7) is at least as large as, preferably 10 to 30% larger than, the spacing between two turns of the luminous element in the region where the hook parts engage.

- Halogen incandescent lamp according to Claim 1, characterized in that the hook part (20) is bent in the plane of the supply lead.

- Halogen incandescent lamp according to Claim 1, characterized in that the hook part (20) projects outwards beyond the luminous element.

- Halogen incandescent lamp according to Claim 1, characterized in that the free limbs are axially parallel (Figure 5) or run in a fashion inclined rectilinearly inwards, towards the axis (Figure 6), or have a curvature (17;27) which reduces the spacing between them.

- Halogen incandescent lamp according to Claim 1, characterized in that the hook part is bent away at an angle α of between 30° and 120°, in particular approximately 50° to 60°, relative to the limb end.

- Halogen incandescent lamp according to Claim 1, characterized in that the limb ends are inserted at least as far as two turns into the end region (6) of the luminous element.

- Halogen incandescent lamp according to Claim 1, characterized in that at at least one of its two free corners, the folded-over section (11) of the foil has a reduced surface and is, in particular, shaped like a triangle or rounded off.

- Electric lamp having a hermetically sealed bulb (2) which is made from transparent material and defines a lamp axis, a luminous means (5), which has two end regions (6) and a power supply system which is connected to the two end regions (6) of the luminous means, the power supply system comprising foils (8), at least one section (11) at one end of the foil being folded back and forming a fold (12), characterized in that the power supply system additionally comprises supply leads (7), the inner end, on the side of the luminous element, of the inner supply lead holding the luminous element with the aid of two limbs (16) which are interconnected in a plane, via a straight base (15), and the outer end, on the foil side, of the inner supply lead being connected, just like the outer supply lead (9), to the foil (8), and at least one of the supply leads being held mechanically on the base (15), in this at least one fold (12), and at at least one of its two free corners, the folded-over section (11) of the foil having a reduced surface and being, in particular, shaped like a triangle or rounded off.

- Method for producing a halogen incandescent lamp according to Claim 1, characterized in that the supply lead (7) with the two limbs (16) is firstly compressed and inserted into the end region (6) of the luminous element at least as far as two turns and is then released such that upon release the limbs press outwards and bear uniformly from inside against the end region of the luminous element, while the hook parts (20) press inwards in a clamping fashion into the interspace between two turns.

- Method according to Claim 12, characterized in that the end section, on the side of the luminous element, of the foil (8) is firstly bent away only by more than 90° (preferably at least 100°), so that a fold (12) is produced in the foil and the supply lead (7) is suspended with its base (15) in the fold, and subsequently the bent-away section of the foil is completely bent away so that it experiences a bend of 180° overall.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03013242A EP1355344A3 (en) | 1998-03-20 | 1999-02-26 | Electric lamp |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19812379A DE19812379A1 (en) | 1998-03-20 | 1998-03-20 | Halogen bulb with hermetically sealed envelope of transparent material which defines lamp axis |

| DE19812379 | 1998-03-20 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03013242A Division EP1355344A3 (en) | 1998-03-20 | 1999-02-26 | Electric lamp |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0944112A2 EP0944112A2 (en) | 1999-09-22 |

| EP0944112A3 EP0944112A3 (en) | 1999-09-29 |

| EP0944112B1 true EP0944112B1 (en) | 2003-07-23 |

Family

ID=7861750

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99103807A Expired - Lifetime EP0944112B1 (en) | 1998-03-20 | 1999-02-26 | Halogen incandescent lamp, electric lamp and method for manufacturing a halogen incandescent lamp |

| EP03013242A Withdrawn EP1355344A3 (en) | 1998-03-20 | 1999-02-26 | Electric lamp |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03013242A Withdrawn EP1355344A3 (en) | 1998-03-20 | 1999-02-26 | Electric lamp |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US6291934B1 (en) |

| EP (2) | EP0944112B1 (en) |

| JP (1) | JPH11329370A (en) |

| CN (1) | CN1296965C (en) |

| CA (1) | CA2265397A1 (en) |

| DE (2) | DE19812379A1 (en) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2795553A1 (en) * | 1999-06-28 | 2000-12-29 | Koninkl Philips Electronics Nv | INCANDESCENT LAMP COMPRISING A TUBULAR SHAPE GLASS BULB IN WHICH A AXIS OF A FILAMENT IS ARRANGED |

| JP3085303B1 (en) * | 1999-07-05 | 2000-09-04 | ウシオ電機株式会社 | Discharge lamp |

| EP1308988B1 (en) * | 2001-10-23 | 2016-07-13 | Koninklijke Philips N.V. | System for hooking a filament to an inlead |

| US20050093420A1 (en) * | 2003-11-05 | 2005-05-05 | Fridrich Elmer G. | Spurred light source lead wire for handling and for assembling with a filament |

| DE102004061734A1 (en) * | 2004-12-22 | 2006-07-06 | Patent-Treuhand-Gesellschaft für elektrische Glühlampen mbH | Fixing method and lamp manufactured after |

| DE112007003666A5 (en) * | 2007-11-14 | 2010-12-23 | Osram Gesellschaft mit beschränkter Haftung | Foil for lamps and associated power supply system |

| DE202008008379U1 (en) | 2008-06-23 | 2008-09-04 | Osram Gesellschaft mit beschränkter Haftung | Film for lamps and associated power supply system and electric lamp, each with such a film |

| DE102008037319A1 (en) | 2008-08-11 | 2010-02-18 | Osram Gesellschaft mit beschränkter Haftung | Film for lamps and electric lamp with such a film and associated manufacturing method |

| DE102011089810A1 (en) | 2011-12-23 | 2013-06-27 | Evonik Industries Ag | Mixed oxide containing the elements lithium, nickel, cobalt and manganese and process for their preparation |

| US20140038117A1 (en) * | 2012-07-31 | 2014-02-06 | Bishara Tannous | Ignition device and method |

| CN104588899B (en) * | 2014-12-01 | 2017-02-01 | 广明源光科技股份有限公司 | Automatic spot welding technology and automatic spot welding machine of halogen lamp |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB663309A (en) * | 1948-05-01 | 1951-12-19 | British Thomson Houston Co Ltd | Improvements relating to the production of quartz-to-metal seals |

| US2786882A (en) * | 1951-01-25 | 1957-03-26 | Krefft Hermann Eduard | Lead-in seal for electrical discharge devices |

| DE1589294A1 (en) | 1967-06-19 | 1970-06-04 | Patra Patent Treuhand | Halogen light bulbs, especially for motor vehicle headlights |

| GB1340778A (en) * | 1971-12-02 | 1974-01-30 | Thorn Electrical Ind Ltd | Filament assejbly for incandescent lamps |

| US4208606A (en) * | 1979-01-10 | 1980-06-17 | Westinghouse Electric Corp. | Filament-support means for a tubular incandescent lamp |

| US5140217A (en) * | 1990-09-07 | 1992-08-18 | North American Philips Corporation | Electric lamp having a push-in filament insert for filament mounting |

| US5241239A (en) * | 1991-12-18 | 1993-08-31 | North American Philips Corporation | Tubular electric lamp having a lamp base sleeve with an access port for securing a contact to a current-conductor |

| DE19548523A1 (en) * | 1995-12-22 | 1997-06-26 | Patent Treuhand Ges Fuer Elektrische Gluehlampen Mbh | Lamp pinched on both sides |

-

1998

- 1998-03-20 DE DE19812379A patent/DE19812379A1/en not_active Withdrawn

-

1999

- 1999-02-26 EP EP99103807A patent/EP0944112B1/en not_active Expired - Lifetime

- 1999-02-26 DE DE59906318T patent/DE59906318D1/en not_active Expired - Lifetime

- 1999-02-26 EP EP03013242A patent/EP1355344A3/en not_active Withdrawn

- 1999-03-12 US US09/267,810 patent/US6291934B1/en not_active Expired - Fee Related

- 1999-03-17 CA CA002265397A patent/CA2265397A1/en not_active Abandoned

- 1999-03-17 JP JP11071816A patent/JPH11329370A/en active Pending

- 1999-03-22 CN CNB991041682A patent/CN1296965C/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| EP0944112A3 (en) | 1999-09-29 |

| EP0944112A2 (en) | 1999-09-22 |

| US6291934B1 (en) | 2001-09-18 |

| EP1355344A2 (en) | 2003-10-22 |

| CA2265397A1 (en) | 1999-09-20 |

| JPH11329370A (en) | 1999-11-30 |

| DE59906318D1 (en) | 2003-08-28 |

| DE19812379A1 (en) | 1999-09-23 |

| CN1296965C (en) | 2007-01-24 |

| EP1355344A3 (en) | 2009-04-01 |

| CN1230011A (en) | 1999-09-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3121077C2 (en) | ||

| EP0944112B1 (en) | Halogen incandescent lamp, electric lamp and method for manufacturing a halogen incandescent lamp | |

| EP0239006B1 (en) | Incandescent lamp and method for its manufacture | |

| EP2337061A1 (en) | Electric lamp having an outer bulb, a stem and an integrated lamp | |

| EP0446460B1 (en) | Halogen incandescent lamp having a single pinch | |

| EP0451647A2 (en) | High-pressure discharge lamp and method for its manufacture | |

| EP2483913B1 (en) | High pressure discharge lamp having a starting aid | |

| DE19856871A1 (en) | Bulb-free lamp | |

| DE4305503A1 (en) | Electric lamp with base on one side | |

| WO2010124904A1 (en) | Discharge lamp | |

| DE29910604U1 (en) | Reflector lamp | |

| EP0758142A2 (en) | Halogen incandescent lamp | |

| DE2118061B2 (en) | Process for the manufacture of incandescent lamps | |

| DE10325552A1 (en) | Electric lamp with outer bulb has carrying body to which getter material is applied; carrying body is curved carrying band for mounting in bulb without auxiliary arrangement | |

| DE69011145T2 (en) | Metal vapor discharge lamp pinched on one side. | |

| DE1953276U (en) | LIGHT BULB WITH A FIXING DEVICE FOR THE GLOW THREAD. | |

| DE4230815A1 (en) | High-pressure discharge lamp and manufacturing method for a high-pressure discharge lamp | |

| DE3406775A1 (en) | ELECTRIC LAMP WITH SELF-HOLDING FRAME ASSEMBLY AND METHOD FOR THEIR PRODUCTION | |

| DE10312720A1 (en) | Dielectric barrier discharge lamp with crimp seal | |

| EP0446461B1 (en) | Halogen incandescent lamp having a single pinch | |

| DE9102566U1 (en) | Halogen bulb | |

| DE3886730T2 (en) | LOW PRESSURE GAS DISCHARGE LAMP WITH GLOW ELECTRODE. | |

| WO2011018326A1 (en) | High-pressure discharge lamp having an ignition aid | |

| WO2011018118A1 (en) | High-pressure discharge lamp having a starting aid | |

| DE202004012220U1 (en) | Single-ended electric lamp |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): BE DE FR GB IT NL |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 19991019 |

|

| AKX | Designation fees paid |

Free format text: BE DE FR GB IT NL |

|

| RTI1 | Title (correction) |

Free format text: HALOGEN INCANDESCENT LAMP, ELECTRIC LAMP AND METHOD FOR MANUFACTURING A HALOGEN INCANDESCENT LAMP |

|

| RTI1 | Title (correction) |

Free format text: HALOGEN INCANDESCENT LAMP, ELECTRIC LAMP AND METHOD FOR MANUFACTURING A HALOGEN INCANDESCENT LAMP |

|

| RTI1 | Title (correction) |

Free format text: HALOGEN INCANDESCENT LAMP, ELECTRIC LAMP AND METHOD FOR MANUFACTURING A HALOGEN INCANDESCENT LAMP |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): BE DE FR GB IT NL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REF | Corresponds to: |

Ref document number: 59906318 Country of ref document: DE Date of ref document: 20030828 Kind code of ref document: P |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20031103 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20040426 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20060214 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20060215 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20060228 Year of fee payment: 8 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20070226 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20070901 |

|

| BERE | Be: lapsed |

Owner name: *PATENT-TREUHAND-G.- FUR ELEKTRISCHE GLUHLAMPEN M. Effective date: 20070228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070226 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20060209 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070226 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 59906318 Country of ref document: DE Owner name: OSRAM GMBH, DE Free format text: FORMER OWNER: OSRAM GESELLSCHAFT MIT BESCHRAENKTER HAFTUNG, 81543 MUENCHEN, DE Effective date: 20111130 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20120227 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20120420 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 59906318 Country of ref document: DE Owner name: OSRAM GMBH, DE Free format text: FORMER OWNER: OSRAM AG, 81543 MUENCHEN, DE Effective date: 20130205 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 59906318 Country of ref document: DE Owner name: OSRAM GMBH, DE Free format text: FORMER OWNER: OSRAM GMBH, 81543 MUENCHEN, DE Effective date: 20130822 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20131031 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59906318 Country of ref document: DE Effective date: 20130903 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130228 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130903 |