EP0872702A2 - Pyrotechnic charge located within a tube - Google Patents

Pyrotechnic charge located within a tube Download PDFInfo

- Publication number

- EP0872702A2 EP0872702A2 EP98106895A EP98106895A EP0872702A2 EP 0872702 A2 EP0872702 A2 EP 0872702A2 EP 98106895 A EP98106895 A EP 98106895A EP 98106895 A EP98106895 A EP 98106895A EP 0872702 A2 EP0872702 A2 EP 0872702A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- tube

- pyrotechnic charge

- ball

- closure

- silicone layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F42—AMMUNITION; BLASTING

- F42B—EXPLOSIVE CHARGES, e.g. FOR BLASTING, FIREWORKS, AMMUNITION

- F42B8/00—Practice or training ammunition

- F42B8/12—Projectiles or missiles

- F42B8/26—Hand grenades

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F42—AMMUNITION; BLASTING

- F42B—EXPLOSIVE CHARGES, e.g. FOR BLASTING, FIREWORKS, AMMUNITION

- F42B4/00—Fireworks, i.e. pyrotechnic devices for amusement, display, illumination or signal purposes

Definitions

- the invention relates to a pyrotechnic charge in a pipe the preamble of claim 1.

- DE 26 44 230 A1 discloses a practice hand grenade with an ignition delay, in which a pyrotechnic charge u. a. generated a bang. This is this charge is placed in a tube inside the grenade. The pipe closes with one, when the pyrotechnic charge is ignited by the building gas pressure tearing ground. It cannot be ruled out that large parts of the ground fly away with high kinetic energy, which according to the applicable regulations is not permitted.

- the object of the invention is therefore a closure for a pyrotechnic charge to create, in which parts fly away but these have a very low mass have, so that the energy transmitted through these parts far below a permissible value remain.

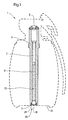

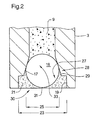

- FIG. 1 shows a hand grenade in longitudinal section and FIG. 2 shows an enlarged one drawn section of a charge tube according to FIG. 1.

- a practice hand grenade 1 shown in dash-dot lines has a central charge tube 3 with primer 5, a time-delayed set 7 and a bang charge 9 on.

- the charge tube 3 closes with its free end face 11 approximately with the lower one Face 13 of the practice grenade 1.

- a bore 15 takes the bang charge 9 on.

- the charge tube 3 has a conical seat 17 for a ball 18 from a light, foamed styrene and a recess 19 for one disk-shaped or lid-shaped silicone layer 21 consisting of a vulcanizable Silicone rubber.

- This is crater-shaped 27 and in relation to the ball 18 with respect to the conical seat 17 conical 28.

- the ball 18 is seated in the conical seat 17 with a slight preload, with about 50% of the Ball surface is glued to the silicone layer 21.

- the silicone layer 21 is in turn over the surface of the recess 19 and part of the conical seat 17 glued to the charge tube 3.

- a very thin, membrane-shaped layer 31 of the silicone layer 21 enables the Ball 18 exits charge tube 3.

- the diameter 23 of the recess 19 is larger than the diameter 25 of the Ball 18. Because of this and through the conical seat 17, 28 or the edge 29 there is a Large adhesive surface of the silicone layer 21 on the charge tube 3 and on the ball 18 before. In the event of hard impacts in the axial direction of the charge tube 3, this ensures that the bang charge 9 applied to the ball 18 by the ball 18 and the silicone layer 21 existing closure 30 an opening 33 of the charge tube 3 closes securely.

- the time-delayed set 7 burns and ignites the bang charge 9.

- the gas pressure of the bang charge 9 drives the ball 18 out of it Tapered seat 17.

- the silicon layer 21 increases in the area of the layer 31 deformed until the ball 18, the increasingly thin silicon layer 21, 31st pierces.

- the silicone layer 21, 31 therefore remains on the charge tube 3 while the ball 18 due to its very low mass and due to the large air resistance quickly falls to the ground. The given conditions for the kinetic Energy and flying distance of flying parts are not reached, so that the safety conditions are met.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Air Bags (AREA)

- Toys (AREA)

- Materials For Medical Uses (AREA)

Abstract

Description

Die Erfindung bezieht sich auf eine pyrotechnische Ladung in einem Rohr nach dem Oberbegriff des Anspruchs 1.The invention relates to a pyrotechnic charge in a pipe the preamble of claim 1.

Aus der DE 26 44 230 A1 ist eine Übungshandgranate mit Zündverzögerung bekannt, bei der eine pyrotechnische Ladung u. a. einem Knall erzeugt. Hierzu ist diese Ladung in einem Rohr innerhalb der Handgranate angeordnet. Das Rohr schließt mit einem, bei Anzündung der pyrotechnischen Ladung durch den sich aufbauenden Gasdruck zerreißenden Boden ab. Dabei ist nicht auszuschließen, daß große Teile des Bodens mit hoher kinetischer Energie wegfliegen, was nach den geltenden Bestimmungen nicht zulässig ist.DE 26 44 230 A1 discloses a practice hand grenade with an ignition delay, in which a pyrotechnic charge u. a. generated a bang. This is this charge is placed in a tube inside the grenade. The pipe closes with one, when the pyrotechnic charge is ignited by the building gas pressure tearing ground. It cannot be ruled out that large parts of the ground fly away with high kinetic energy, which according to the applicable regulations is not permitted.

Aufgabe der Erfindung ist es daher, einen Verschluß für eine pyrotechnische Ladung zu schaffen, bei dem zwar Teile wegfliegen aber diese eine sehr geringe Masse aufweisen, so daß die durch diese Teile übertragene Energie weit unterhalb eines zulässigen Wertes bleiben.The object of the invention is therefore a closure for a pyrotechnic charge to create, in which parts fly away but these have a very low mass have, so that the energy transmitted through these parts far below a permissible value remain.

Die Erfindung löst diese Aufgabe entsprechend den kennzeichnenden Merkmalen des Anspruches 1. Vorteilhafte Weiterbildungen der Erfindung sind den Unteransprüchen zu entnehmen.The invention solves this problem according to the characterizing features of claim 1. Advantageous further developments of the invention are the dependent claims refer to.

Ein Ausführungsbeispiel der Erfindung ist in der Zeichnung dargestellt.An embodiment of the invention is shown in the drawing.

Es zeigt Fig. 1 eine Übungshandgranate im Längsschnitt und Fig. 2 einen vergrößert gezeichneten Abschnitt eines Ladungsrohres nach Fig. 1. 1 shows a hand grenade in longitudinal section and FIG. 2 shows an enlarged one drawn section of a charge tube according to FIG. 1.

Eine strichpunktiert gezeichnete Übungshandgranate 1 weist ein zentrales Ladungsrohr

3 mit Zündkapsel 5, einen zeitverzögernden Satz 7 und eine Knalladung

9 auf.A practice hand grenade 1 shown in dash-dot lines has a

Das Ladungsrohr 3 schließt mit seiner freien Stirnseite 11 etwa mit der unteren

Stirnfläche 13 der Übungshandgranate 1 ab. Eine Bohrung 15 nimmt die Knalladung

9 auf. Endseitig weist das Ladungsrohr 3 einen Kegelsitz 17 für eine Kugel

18 aus einem leichten, geschäumten Styrol und eine Ausnehmung 19 für eine

scheiben- oder deckelförmige Silikonschicht 21 bestehend aus einem vulkanisierbaren

Silikonkautschuk auf. Diese ist in Bezug auf die Kugel 18 kraterförmig 27 und

bezüglich des Kegelsitzes 17 keglig 28 ausgebildet. Dadurch liegt ein spitz zulaufender

Rand 29 vor, der die Kugel 18 streifenförmig einhüllt.The

Im Kegelsitz 17 sitzt die Kugel 18 mit leichter Vorspannung, wobei etwa 50 % der

Kugeloberfläche mit der Silikonschicht 21 verklebt ist. Die Silikonschicht 21 ist

ihrerseits über die Oberfläche der Ausnehmung 19 und eines Teils des Kegelsitzes

17 mit dem Ladungsrohr 3 verklebt.The

Eine sehr dünne, membranförmige Schicht 31 der Silikonschicht 21 ermöglicht der

Kugel 18 den Austritt aus dem Ladungsrohr 3.A very thin, membrane-

Der Durchmesser 23 der Ausnehmung 19 ist größer als der Durchmesser 25 der

Kugel 18. Dadurch und durch den Kegelsitz 17, 28 bzw. den Rand 29 liegt eine

große Klebeoberfläche der Silikonschicht 21 am Ladungsrohr 3 und an der Kugel

18 vor. Bei harten Stößen in Achsrichtung des Ladungsrohres 3 ist damit gewährleistet,

daß die an der Kugel 18 anliegende Knalladung 9 durch den, aus der Kugel

18 und der Silikonschicht 21 bestehenden Verschluß 30 eine Öffnung 33 des Ladungsrohres

3 sicher verschließt.The

Nach Zündung der Zündkapsel 5 brennt der zeitverzögernde Satz 7 ab und zündet

die Knalladung 9. Der Gasdruck der Knalladung 9 treibt die Kugel 18 aus ihrem

Kegelsitz 17. Dabei wird die Silikonschicht 21 im Bereich der Schicht 31 zunehmend

verformt, bis die Kugel 18 die immer dünner werdende Silikonschicht 21, 31

durchstößt. Die Silikonschicht 21, 31 verbleibt daher am Ladungsrohr 3, während

die Kugel 18 aufgrund ihrer sehr geringen Masse und aufgrund des großen Luftwiderstandes

rasch zu Boden fällt. Die vorgegebenen Bedingungen für die kinetische

Energie und Flugdistanz von wegfliegenden Teilen werden nicht erreicht, so daß

die Sicherheitsbedingungen erfüllt sind.After ignition of the

Claims (8)

dadurch gekennzeichnet,

daß der Verschluß (30) wenigstens zweiteilig ist, indem eine äußere Silikonschicht (21) im Bereich der Öffnung (33) des Rohres (3) einen sehr leichten Verschlußkörper (18) mit dem Rohr (3) verbindet.Pyrotechnic charge in a tube for a practice grenade or fireworks item, in which the tube is closed by a closure that can be opened by the gas pressure,

characterized by

that the closure (30) is at least in two parts by an outer silicone layer (21) in the region of the opening (33) of the tube (3) connecting a very light closure body (18) to the tube (3).

dadurch gekennzeichnet,

daß der Verschlußkörper (18) aus einem geschäumten Werkstoff wie Styrol besteht.Pyrotechnic charge according to claim 1,

characterized by

that the closure body (18) consists of a foamed material such as styrene.

dadurch gekennzeichnet,

daß der Verschlußkörper als Kugel (18) ausgebildet ist und das Rohr (3) für die Lagerung der Kugel (18) mit einem Kegelsitz (17) versehen ist.Pyrotechnic charge according to claim 1,

characterized by

that the closure body is designed as a ball (18) and the tube (3) for mounting the ball (18) is provided with a conical seat (17).

dadurch gekennzeichnet,

daß das Rohr (3) eine Ausnehmung (19) zur Aufnahme der etwa scheibenförmigen Silikonschicht (21) aufweist und der Durchmesser (23) der Ausnehmung (19) größer ist als die Kugel (18).Pyrotechnic charge according to claim 3,

characterized by

that the tube (3) has a recess (19) for receiving the approximately disc-shaped silicone layer (21) and the diameter (23) of the recess (19) is larger than the ball (18).

dadurch gekennzeichnet,

daß die Silikonschicht (21) aus einem vulkanisierbarem Silikonkautschuk besteht. Pyrotechnic charge according to claim 1,

characterized by

that the silicone layer (21) consists of a vulcanizable silicone rubber.

dadurch gekennzeichnet,

daß die Silikonschicht (21) in der Hauptachse des Rohres (3) mit einer membranförmigen Schicht (31) an der Kugel (18) anliegt bzw. mit der Kugel (18) verklebt ist.Pyrotechnic charge according to claim 1,

characterized by

that the silicone layer (21) lies in the main axis of the tube (3) with a membrane-shaped layer (31) on the ball (18) or is glued to the ball (18).

dadurch gekennzeichnet,

daß die pyrotechnische Ladung (9) an dem Verschlußkörper (18) anliegt.Pyrotechnic charge according to claim 1,

characterized by

that the pyrotechnic charge (9) abuts the closure body (18).

dadurch gekennzeichnet,

daß der Verschlußkörper (18) etwa zur Hälfte seiner Oberfläche mit der Silikonschicht (21) verklebt ist, wobei die Silikonschicht mit einem spitz zulaufenden Rand (29) den Verschlußkörper (18) zu einem Teil einhüllt.Pyrotechnic charge according to claims 1 and 3,

characterized by

that the closure body (18) is glued to about half of its surface with the silicone layer (21), the silicone layer with a tapered edge (29) enveloping the closure body (18) in part.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19716511 | 1997-04-19 | ||

| DE19716511A DE19716511A1 (en) | 1997-04-19 | 1997-04-19 | Pyrotechnic charge in a tube |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0872702A2 true EP0872702A2 (en) | 1998-10-21 |

| EP0872702A3 EP0872702A3 (en) | 2000-01-26 |

| EP0872702B1 EP0872702B1 (en) | 2003-10-01 |

Family

ID=7827084

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98106895A Expired - Lifetime EP0872702B1 (en) | 1997-04-19 | 1998-04-16 | Pyrotechnic charge located within a tube |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0872702B1 (en) |

| AT (1) | ATE251301T1 (en) |

| DE (2) | DE19716511A1 (en) |

| DK (1) | DK0872702T3 (en) |

| NO (1) | NO317408B1 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202004018014U1 (en) * | 2004-11-20 | 2006-04-27 | Diehl Bgt Defence Gmbh & Co. Kg | Pipe with a pyrotechnic charge comprises a closure layer adhered to a closure member over one end |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2644230A1 (en) | 1976-03-15 | 1977-09-29 | Francesco Moneta | HAND GRENADE WITH END DELAY |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR844961A (en) * | 1937-10-20 | 1939-08-07 | Anciens Ets Skoda | Dynamic self-timer projectile and relay |

| FR1439815A (en) * | 1961-03-13 | 1966-05-27 | Zd Y Rijnove Revoluce Narodni | Explosion-proof, delayed electric detonator |

| DE1969984U (en) * | 1967-02-28 | 1967-10-05 | Bock Geb | BANGERS WITH CANNON STRIKE. |

| DE7235812U (en) * | 1972-09-29 | 1973-02-08 | Diehl | Training hand grenade |

| AT396304B (en) * | 1991-03-26 | 1993-08-25 | Oregon Ets Patentverwertung | Practice hand grenade detonator (fuze) |

-

1997

- 1997-04-19 DE DE19716511A patent/DE19716511A1/en not_active Withdrawn

-

1998

- 1998-04-16 DK DK98106895T patent/DK0872702T3/en active

- 1998-04-16 EP EP98106895A patent/EP0872702B1/en not_active Expired - Lifetime

- 1998-04-16 AT AT98106895T patent/ATE251301T1/en not_active IP Right Cessation

- 1998-04-16 NO NO19981703A patent/NO317408B1/en unknown

- 1998-04-16 DE DE59809762T patent/DE59809762D1/en not_active Expired - Fee Related

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2644230A1 (en) | 1976-03-15 | 1977-09-29 | Francesco Moneta | HAND GRENADE WITH END DELAY |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE251301T1 (en) | 2003-10-15 |

| DK0872702T3 (en) | 2004-02-02 |

| NO981703D0 (en) | 1998-04-16 |

| EP0872702A3 (en) | 2000-01-26 |

| NO317408B1 (en) | 2004-10-25 |

| DE59809762D1 (en) | 2003-11-06 |

| DE19716511A1 (en) | 1998-10-22 |

| EP0872702B1 (en) | 2003-10-01 |

| NO981703L (en) | 1998-10-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0680857B1 (en) | Gasgenerator for a vehicle restraint system | |

| DE4401396C2 (en) | Device for breaking a vehicle window | |

| DE7905783U1 (en) | FOG CAN | |

| DE2747313C2 (en) | Sub-caliber arrow projectile with a resistance-stabilizing conical tail section | |

| DE2826497A1 (en) | DRIVING MIRROR FLOOR WITH PYROTECHNICAL SET | |

| DE1240760B (en) | Tank incendiary bullet | |

| CH662646A5 (en) | BULLET WITH A TUBULAR BODY. | |

| EP0872702A2 (en) | Pyrotechnic charge located within a tube | |

| DE1910779A1 (en) | IMPROVEMENTS TO THE EFFECTIVENESS OF HOLLOW CHARGE | |

| DE3408476A1 (en) | FULL-CALIBRATION TRAINING FLOOR | |

| DE720097C (en) | Whisker | |

| DE4220176C2 (en) | Core generating charge | |

| EP0255570A1 (en) | Sabot projectile, especially an arrow-type projectile | |

| DE2856286C2 (en) | Projectile flying at supersonic speed | |

| DE3819251A1 (en) | Multiple projectile | |

| DE102020120538A1 (en) | Window frame assembly and method of providing a window frame assembly for a ballistic vehicle | |

| EP0238817A1 (en) | Sabot-type projectile having a tail part on which a socket of said sabot is fixed through a line of weakness | |

| DE2639719A1 (en) | Plastic e.g. polystyrene cover for a rocket tube - is made in segments flexibly attached to the tube end | |

| DE2457563C3 (en) | Explosive projectile with a projectile fuse | |

| DE1966993C3 (en) | Bullet | |

| DE7528912U (en) | exercise floor | |

| DE2155467C3 (en) | KurzbahngeschoB | |

| EP0455980A2 (en) | Signal device for emergency approach of aircraft stationed on ships | |

| DE10005414B4 (en) | Tail stabilized training projectile | |

| AT229194B (en) | Rotating projectile detonators |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE DE DK FI FR GB GR IT NL SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| RIC1 | Information provided on ipc code assigned before grant |

Free format text: 7F 42B 8/26 A, 7F 42B 12/36 B, 7F 42B 4/00 B |

|

| 17P | Request for examination filed |

Effective date: 20000121 |

|

| AKX | Designation fees paid |

Free format text: AT BE DE DK FI FR GB GR IT NL SE |

|

| 17Q | First examination report despatched |

Effective date: 20020218 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE DE DK FI FR GB GR IT NL SE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: DIEHL STIFTUNG & CO. KG |

|

| REF | Corresponds to: |

Ref document number: 59809762 Country of ref document: DE Date of ref document: 20031106 Kind code of ref document: P |

|

| NLT2 | Nl: modifications (of names), taken from the european patent patent bulletin |

Owner name: DIEHL STIFTUNG & CO. KG |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 Ref country code: GR Ref legal event code: EP Ref document number: 20030405319 Country of ref document: GR |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040119 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20040309 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20040329 Year of fee payment: 7 Ref country code: FR Payment date: 20040329 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20040401 Year of fee payment: 7 Ref country code: AT Payment date: 20040401 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20040402 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20040428 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20040429 Year of fee payment: 7 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20040702 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050416 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050416 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050416 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050417 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20050427 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050430 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20050621 Year of fee payment: 8 |

|

| BERE | Be: lapsed |

Owner name: *DIEHL STIFTUNG & CO. K.G. Effective date: 20050430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051103 |

|

| EUG | Se: european patent has lapsed | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20050416 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051230 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20051101 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20051230 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061101 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| BERE | Be: lapsed |

Owner name: *DIEHL STIFTUNG & CO. K.G. Effective date: 20050430 |