EP0806280B1 - Vorrichtung und Anlage zur Aufbereitung von Kunststoffgut - Google Patents

Vorrichtung und Anlage zur Aufbereitung von Kunststoffgut Download PDFInfo

- Publication number

- EP0806280B1 EP0806280B1 EP19970890072 EP97890072A EP0806280B1 EP 0806280 B1 EP0806280 B1 EP 0806280B1 EP 19970890072 EP19970890072 EP 19970890072 EP 97890072 A EP97890072 A EP 97890072A EP 0806280 B1 EP0806280 B1 EP 0806280B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- screw

- extruder

- plastic material

- screws

- aperture

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000004033 plastic Substances 0.000 title claims description 64

- 229920003023 plastic Polymers 0.000 title claims description 64

- 238000012545 processing Methods 0.000 title description 23

- 239000000463 material Substances 0.000 claims description 59

- 230000007423 decrease Effects 0.000 claims description 7

- 230000003247 decreasing effect Effects 0.000 claims description 4

- 230000001154 acute effect Effects 0.000 claims description 3

- 238000004804 winding Methods 0.000 claims description 2

- 238000007599 discharging Methods 0.000 claims 10

- 238000004064 recycling Methods 0.000 claims 4

- 239000012815 thermoplastic material Substances 0.000 claims 4

- 238000009434 installation Methods 0.000 claims 3

- 241000237858 Gastropoda Species 0.000 description 18

- 238000011068 loading method Methods 0.000 description 14

- 230000000694 effects Effects 0.000 description 6

- 229920001169 thermoplastic Polymers 0.000 description 5

- 239000004416 thermosoftening plastic Substances 0.000 description 5

- 230000006835 compression Effects 0.000 description 4

- 238000007906 compression Methods 0.000 description 4

- 238000010276 construction Methods 0.000 description 3

- 238000002156 mixing Methods 0.000 description 3

- 238000012856 packing Methods 0.000 description 3

- 239000013502 plastic waste Substances 0.000 description 3

- 230000001105 regulatory effect Effects 0.000 description 3

- 238000005406 washing Methods 0.000 description 3

- 238000005056 compaction Methods 0.000 description 2

- 238000013461 design Methods 0.000 description 2

- 238000011049 filling Methods 0.000 description 2

- 238000004898 kneading Methods 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 210000000056 organ Anatomy 0.000 description 2

- 238000002360 preparation method Methods 0.000 description 2

- 230000032258 transport Effects 0.000 description 2

- 230000009471 action Effects 0.000 description 1

- 238000005054 agglomeration Methods 0.000 description 1

- 230000002776 aggregation Effects 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000033228 biological regulation Effects 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 230000010006 flight Effects 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 230000033001 locomotion Effects 0.000 description 1

- 230000001050 lubricating effect Effects 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000000750 progressive effect Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000003252 repetitive effect Effects 0.000 description 1

- 230000000452 restraining effect Effects 0.000 description 1

- 238000005549 size reduction Methods 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B15/00—Details of, or accessories for, presses; Auxiliary measures in connection with pressing

- B30B15/30—Feeding material to presses

- B30B15/302—Feeding material in particulate or plastic state to moulding presses

- B30B15/308—Feeding material in particulate or plastic state to moulding presses in a continuous manner, e.g. for roller presses, screw extrusion presses

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B17/00—Recovery of plastics or other constituents of waste material containing plastics

- B29B17/0026—Recovery of plastics or other constituents of waste material containing plastics by agglomeration or compacting

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/30—Mixing; Kneading continuous, with mechanical mixing or kneading devices

- B29B7/34—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices

- B29B7/38—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary

- B29B7/40—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with single shaft

- B29B7/42—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with single shaft with screw or helix

- B29B7/422—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with single shaft with screw or helix with screw sections co-operating, e.g. intermeshing, with elements on the wall of the surrounding casing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/30—Mixing; Kneading continuous, with mechanical mixing or kneading devices

- B29B7/34—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices

- B29B7/38—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary

- B29B7/40—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with single shaft

- B29B7/42—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with single shaft with screw or helix

- B29B7/424—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with single shaft with screw or helix with conical screw surrounded by conical casing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/30—Mixing; Kneading continuous, with mechanical mixing or kneading devices

- B29B7/34—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices

- B29B7/38—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary

- B29B7/40—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with single shaft

- B29B7/42—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with single shaft with screw or helix

- B29B7/426—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with single shaft with screw or helix with consecutive casings or screws, e.g. for charging, discharging, mixing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/30—Mixing; Kneading continuous, with mechanical mixing or kneading devices

- B29B7/58—Component parts, details or accessories; Auxiliary operations

- B29B7/60—Component parts, details or accessories; Auxiliary operations for feeding, e.g. end guides for the incoming material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/375—Plasticisers, homogenisers or feeders comprising two or more stages

- B29C48/39—Plasticisers, homogenisers or feeders comprising two or more stages a first extruder feeding the melt into an intermediate location of a second extruder

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/50—Details of extruders

- B29C48/501—Extruder feed section

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/50—Details of extruders

- B29C48/68—Barrels or cylinders

- B29C48/685—Barrels or cylinders characterised by their inner surfaces, e.g. having grooves, projections or threads

- B29C48/686—Barrels or cylinders characterised by their inner surfaces, e.g. having grooves, projections or threads having grooves or cavities

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/03—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the shape of the extruded material at extrusion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/285—Feeding the extrusion material to the extruder

- B29C48/286—Raw material dosing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/375—Plasticisers, homogenisers or feeders comprising two or more stages

- B29C48/385—Plasticisers, homogenisers or feeders comprising two or more stages using two or more serially arranged screws in separate barrels

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W30/00—Technologies for solid waste management

- Y02W30/50—Reuse, recycling or recovery technologies

- Y02W30/62—Plastics recycling; Rubber recycling

Definitions

- the invention relates to a device for processing, in particular thermoplastic, plastic material, consisting of a container with a Loading opening for feeding plastic goods and a discharge opening for processed plastic material for connection to a downstream extruder with front or jacket-side filling opening.

- a known device for processing plastic material In a known device for processing plastic material, the processing plastic parts thrown from above into a receptacle in which a comminution organ rotates and washing liquid is supplied at the same time. At the end of the washing process and the washing liquid has run out Restraining the plastic parts in the container, the shredding device continues to rotate, until the plastic parts are compacted and agglomerated. After that it will solidified agglomerate via an outlet connection provided near the ground carried out.

- the disadvantage of this device is the complicated and operation-intensive procedures and the discontinuous mode of operation, which none allows satisfactory material throughput. In addition, the Compaction takes considerable time.

- devices for processing plastic goods consisting of standing, top-loading receptacles in which at least one in Comminution and mixing element arranged near the ground and equipped with knives, rotates about the container axis, the receiving container at the level of Shredding member has a jacket opening that is tangent to the Receiving container arranged, connected directly to the container Screw extruder is connected.

- the tangential connection of the Screw extruder can also be radial or secant in the Open the receptacle.

- the disadvantage of the aforementioned embodiments is that inadequate stuffing effect of the size reduction device on the extruder, which leads to that the extruder receives too little or no plastic material and therefore the Extruder screw runs through empty.

- DE-A-1 142 840 describes a device for processing of plastic goods according to the introductory part of claim 1 known.

- the invention has for its object an improved device for Preparation of, in particular thermoplastic, plastic material to provide at the remedy for the disadvantages of the prior art is created.

- the present invention provides a plastic processing device that includes a Solution of the problem of bridging the plastic goods in the receptacle offers and the sufficient tamping effect and satisfactory material supply offers a downstream extruder, with different packing densities and material compositions of the plastic feed material are processed can.

- thermoplastic, plastic material consisting of a container with a Loading opening for feeding plastic goods and a discharge opening for processed plastic material for connection to a downstream extruder with front or shell-side filling opening, at least in the container a first snail with a core and helix formed on it at least partially arranged within at least one second, hollow screw is whose helix is on the inner wall of a hollow snail body is formed, both screws are rotatably driven such that they Promote plastic material to the discharge opening of the container and leave the free space reduced between the two screws to the discharge opening of the container.

- Snail which are also referred to below as stuffing snails, is the Bridging of the plastic material outside the screw range by constant Keeping in motion prevented, resulting in adequate compression and regular supply of the material to the downstream extruder is guaranteed.

- an inner snail is surrounded by an outer snail

- the lengths of external and internal screws do not have to be the same, but it can be a snail on one or two sides protrude beyond the other snail.

- the direction of conveyance of external and internal screws is in the direction of Discharge opening of the container. This can be done either by the two Have snails in the same direction, and are rotatable in the same direction or but in that the two screws have opposite screw flights and are rotatable in opposite directions.

- the Containers in every position between the horizontal and the vertical to arrange, which in turn means that the conveying directions of the two Snails at any angle between the horizontal and the down pointing perpendicular.

- the preparation device becomes the feed material designed that the axes of rotation of the inner and outer screw either collapse or form an acute angle with each other or parallel and in Distance from each other.

- FIG rotatable part of the container the body of the outer screw, being at its Inner wall of the helix is formed.

- a rigid container part is provided on the inner wall, preferably spiral grooves are formed. The grooves prevent that the compacted plastic material rotates with the stuffing augers, causing the Funding would be reduced.

- the inner screw runs core progressively towards the discharge opening or theirs The depth of the passage is reduced and / or its slope is reduced.

- An embodiment of the serves the same purpose of supporting the compacting Invention, wherein the inner wall of the body of the outer screw to the discharge opening towards conical and or or the depth of the outer screw in the Course changed from the loading opening to the discharge opening.

- the aisle depth can increase continuously, for example, but one is preferred Design in which the flight depth of the outer worm in the course of the Feed opening to discharge opening first increased and then again decreased.

- the rotational speed of the outer and / or the inner Auger regulated depending on the current consumption of their respective drive motor be, with an increased current consumption a decrease in Rotation speed and vice versa.

- the Plastic feed rate to the loading opening of the device depending on the Current consumption of the drive motor of the outer and / or the inner worm and or or a downstream extruder screw regulated, an increased Current consumption leads to a reduction in the supply rate and vice versa.

- the Plastic feed rate is determined by varying the speed of one motorized feeder, e.g. a conveyor belt or a screw conveyor, regulated.

- the plastic material processing device be connected to a downstream extruder that the inner screw coaxial with the screw of the downstream extruder is coupled. This enables a simplified construction of the system that goes even further can be simplified if the inner screw integrally with the screw of the downstream extruder is formed.

- Downstream extruder can be provided that this in the feed area has grooved bushing, the grooves further in the conveying direction converge conically and / or decrease their depth.

- the invention also includes a system consisting of an inventive Device for processing, in particular thermoplastic, plastic material, the with a twin-screw extruder rotating in the same direction or in the opposite direction Extruder screws is interconnected.

- the choice of the direction of rotation depends on used plastic material. In general use cases opposite direction of rotation preferred.

- Direction of rotation becomes an improvement who prefers kneading and mixing properties for certain plastics.

- the invention further comprises a system consisting of at least two Devices for processing plastic material with a downstream Extruders are connected, the devices for processing plastic material are arranged in the feed area of the extruder around a part of the screw circumference. This enables loading from several sides, making the individual Processing devices can be made smaller.

- the invention comprises a system consisting of at least two Devices for processing, in particular thermoplastic, plastic material, which are interconnected with an extruder, the devices for Processing of plastic goods one after the other in the direction of conveyance of the extruder screw are arranged. In this way it can be ensured that the extruder run is stuffed with plastic material over its entire length.

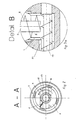

- FIG. 1 shows a first Embodiment of the device for processing plastic material in longitudinal section

- 2 shows a cross section along line A - A of FIG. 1

- FIG. 3a shows an enlarged detail B.

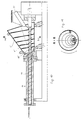

- Figures 3b and 3c cross-sectional views of two variants of the Downstream extruder according to the invention according to line C - C in Figure 1

- 4 shows a second embodiment of the invention in longitudinal section

- FIG Device for processing plastic material according to the invention shown.

- the device consists of a receptacle, generally designated 1 a truncated cone-shaped, rotatable container part 2, the 14 in multiple by bearings a mounting frame 11 is rotatably mounted, a loading opening 3 for to be processed plastic material, and a fixed container part 5, which to the rotatable container part 2 is adjacent and a discharge opening 6 is limited.

- a spiral screw 4 is arranged on the inner wall of the rotatable container part 2, whereby the container part 2 acting as a hollow screw body together with the Helix 4 forms an outer stuffing screw.

- This snail is made by one Drive 13 driven in the direction of arrow 10, whereby in the container Plastic material is conveyed towards the discharge opening 6.

- the outer snail surrounds an inner screw, consisting of a cylindrical screw body 7 with screw helix 8 mounted thereon, which is driven by a drive 12 in Arrow direction 9 is rotated and thus plastic material in the direction of the discharge opening 6 promotes.

- the axes of rotation of the outer and inner screws coincide.

- the Operation of the device is such that through the loading opening imported material, which can consist of various plastic waste, is conveyed through the two screws to the discharge opening, whereby through the steadily reducing free space between the screws a considerable compression of the plastic goods with accompanying agglomeration due to the resulting Heat is achieved.

- the frustoconical container design proves to be advantageous because they have a very large volume in the loading area for the mostly very offers loosely packed plastic waste, which increases with increasing compaction decreased.

- the pre-compressed plastic material finally gets into the fixed one Container part 5 with the discharge opening 6.

- the fixed container part 5 is designed as a grooved bush, as best in the Sectional view of Figure 2 can be seen.

- the inner wall of the container part 5 faces winding webs 16, between which grooves 15 are defined.

- the bridges can have a conical shape.

- the grooves have a pushing effect achieved the material and prevented it from rotating in a circle.

- the extruder 17 can be an extruder with a single screw 19 act as shown in Fig.3b, which is a cross section along line C - C in Fig.1 shows, where the screw can be conical, or alternatively - as in Fig.3c also shown in cross section along line C - C in Fig.1 - by one Double extruder 17 with two screws 19.

- the direction of rotation of the two screws can either be opposite, as by the two thick arrows in the snail's body shown, or in the same direction, in order to be better with certain plastics To achieve mixing or kneading. The latter case is due to the thin Arrows symbolized below the extruder.

- FIGS. 4, 5 and 6. A second embodiment of the invention is shown in FIGS. 4, 5 and 6. in the The difference to the first embodiment is the one according to the invention Plastic processing device coaxial with the downstream extruder 17 connected, the inner stuffing screw of the device being integral with the Extruder screw 19 is formed, namely as a section 19 'of this extruder screw.

- This embodiment offers the advantage of a simpler structure and the elimination of its own drive unit for the inner stuffing screw.

- the container is in the arranged substantially horizontally what the device of the invention known prior art differs.

- the remaining parts of the invention Devices are identical in construction or similar to the first embodiment and are therefore provided with the same reference numerals. On a repeated description of this Parts can be omitted; rather, reference is made to the detailed description above referred.

- the stuffing screw 19 is not cut all the way to its upstream end, but rather there merges into a cylindrical shaft.

- the outer screw 4 protrudes beyond the inner screw at the back and initially transports the feed Plastic goods only in the direction of the discharge opening.

- FIGS A third embodiment of the invention is described in FIGS is similar to the second embodiment, with the difference that the loading on Center of the base of the container 2 is that the turn with the screw 19 "of Downstream extruder 17 'integrally formed inner stuffing screw 19' Device is only slightly exceeded by the outer screw and that the Extruder 17 'is provided with a shell-side melt outlet opening, which requires that the extruder screw in its end region with a counter-rotating Helix is provided, which goes beyond the exit area Returns material. Since the compressed plastic material in the extruder is one exerts a certain lubricating effect, it is particularly important in this embodiment that the extruder is always filled with plastic material, for which the device according to the invention contrary to the state of the art. At most, several can Plastic processing devices according to the invention with an extruder can be combined to ensure sufficient material supply. The remaining Parts of this embodiment are essentially identical to the above Embodiments, which is why a repetitive description is omitted can.

- the outer Stuffing screw always coaxial with the inner stuffing screw.

- the inner wall of which is the outer screw helix 4 ' connects the axis of rotation of the inner stuffing screw 19 ', which is formed in one piece with the extruder screw 19, an acute angle, the lower generatrix of the container part 2 'parallel to The axis of rotation of the screw 19 'runs.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Environmental & Geological Engineering (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

- Extrusion Moulding Of Plastics Or The Like (AREA)

Description

Claims (25)

- Vorrichtung zur Aufbereitung von, insbesondere thermoplastischem, Kunststoffgut, bestehend aus einem Behälter mit einer Beschickungsöffnung zur Zuführung von Kunststoffgut und einer Austragsöffnung für aufbereitetes Kunststoffgut zum Anschluß an einen nachgeschalteten Extruder mit stirn- oder mantelseitiger Füllöffnung, wobei im Behälter (2) zumindest eine erste Schnecke (7,8;19') mit einem Kern (7) und darauf ausgebildeter Schneckenwendel (8) wenigstens teilweise innerhalb mindestens einer zweiten, hohlen Schnecke angeordnet ist, deren Schneckenwendel (4,4') an der Innenwand eines hohlen Schneckenkörpers (2,2') ausgebildet ist, und beide Schnecken solcherart drehbar antreibbar sind, daß sie Kunststoffgut zur Austragsöffnung (6) des Behälters fördern, dadurch gekennzeichnet, daß sich der Freiraum zwischen den beiden Schnecken zur Austragsöffnung des Behälters hin verringert.

- Vorrichtung nach Anspruch 1, dadurch gekennzeichnet, daß die beiden Schnecken gleichsinnige Schneckengänge aufweisen und gleichsinnig drehbar sind.

- Vorrichtung nach Anspruch 1, dadurch gekennzeichnet, daß die beiden Schnecken gegensinnige Schneckengänge aufweisen und gegensinnig drehbar sind.

- Vorrichtung nach einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, daß die Förderrichtungen der beiden Schnecken zwischen der Waagrechten und der nach unten weisenden Lotrechten liegen.

- Vorrichtung nach einem der Ansprüche 1 bis 4, dadurch gekennzeichnet, daß die Drehachsen der beiden Schnecken (8,19';4) zusammenfallen.

- Vorrichtung nach einem der Ansprüche 1 bis 4, dadurch gekennzeichnet, daß die Drehachsen der beiden Schnecken (19',4') miteinander einen spitzen Winkel bilden.

- Vorrichtung nach einem der Ansprüche 1 bis 4, dadurch gekennzeichnet, daß die Drehachsen der beiden Schnecken parallel und im Abstand zueinander verlaufen.

- Vorrichtung nach einem der Ansprüche 1 bis 7, dadurch gekennzeichnet, daß ein drehbarer Teil (2) des Behälters den Körper der äußeren Schnecke bildet, an dessen Innenwand die Schneckenwendel (4) ausgebildet ist.

- Vorrichtung nach Anspruch 8, dadurch gekennzeichnet, daß zwischen dem drehbaren Behälterteil (2) und der Austragsöffnung (6) ein starrer Behälterteil (5) vorgesehen ist, an dessen Innenwand, vorzugsweise gewundene, Nuten (15) ausgebildet sind.

- Vorrichtung nach Anspruch 9, dadurch gekennzeichnet, daß die Nuten (15) zur Austragsöffnung (6) hin konisch zusammenlaufen und bzw. oder sich die Nuttiefe zur Austragsöffnung hin verringert.

- Vorrichtung nach einem der Ansprüche 1 bis 10, dadurch gekennzeichnet, daß die innere Schnecke (7,8;19') zur Austragsöffnung hin kernprogressiv verläuft bzw. sich ihre Gangtiefe verringert und bzw. oder sich ihre Steigung verringert.

- Vorrichtung nach einem der Ansprüche 1 bis 11, dadurch gekennzeichnet, daß die Innenwand des Körpers der äußeren Schnecke zur Austragsöffnung hin konisch zusammenläuft.

- Vorrichtung nach einem der Ansprüche 1 bis 12, dadurch gekennzeichnet, daß sich die Gangtiefe der äußeren Schnecke (4,4') im Verlauf von der Beschickungsöffnung (3) zur Austragsöffnung (6) verändert.

- Vorrichtung nach Anspruch 13, dadurch gekennzeichnet, daß sich die Gangtiefe der äußeren Schnecke im Verlauf von der Beschickungsöffnung zur Austragsöffnung zunächst erhöht und anschließend wieder verringert.

- Vorrichtung nach einem der Ansprüche 1 bis 14, dadurch gekennzeichnet, daß die Drehgeschwindigkeit der äußeren und bzw. oder der inneren Schnecke in Abhängigkeit der Stromaufnahme des Motors einer nachgeschalteten Extruderschnecke regelbar ist, wobei eine erhöhte Stromaufnahme eine Verringerung der Drehgeschwindigkeit und vice versa zur Folge hat.

- Vorrichtung nach einem der Ansprüche 1 bis 14, dadurch gekennzeichnet, daß die Drehgeschwindigkeit der äußeren und bzw. oder der inneren Schnecke in Abhängigkeit der Stromaufnahme ihres jeweiligen Antriebsmotors regelbar ist, wobei eine erhöhte Stromaufnahme eine Verringerung der Drehgeschwindigkeit und vice versa zur Folge hat.

- Vorrichtung nach einem der Ansprüche 1 bis 14, dadurch gekennzeichnet, daß die Kunststoffgutzufuhrrate zur Beschickungsöffnung der Vorrichtung in Abhängigkeit der Stromaufnahme des Antriebsmotors der äußeren und bzw. oder der inneren Schnecke und bzw. oder einer nachgeschalteten Extruderschnecke regelbar ist, wobei eine erhöhte Stromaufnahme eine Verringerung der Zufuhrrate und vice versa zur Folge hat.

- Vorrichtung nach einem der Ansprüche 1 bis 17, dadurch gekennzeichnet, daß die innere Schnecke (19') koaxial mit der Schnecke (19,19") eines nachgeschalteten Extruders (17,17') gekoppelt ist.

- Vorrichtung nach Anspruch 18, dadurch gekennzeichnet, daß die innere Schnecke (19') einstückig mit der Schnecke (19,19") eines nachgeschalteten Extruders ausgebildet ist.

- Vorrichtung nach Anspruch 18 oder 19, dadurch gekennzeichnet, daß die kombinierte Anordnung aus innerer Schnecke und Extruderschnecke zur Düsenöffnung des Extruders hin kernprogressiv verläuft bzw. sich ihre Gangtiefe verringert und bzw. oder sich ihre Steigung verringert.

- Vorrichtung nach einem der Ansprüche 1 bis 20, dadurch gekennzeichnet, daß ein der Vorrichtung nachgeschalteter Extruder im Einzugsbereich eine mit Nuten versehene Buchse (20) aufweist.

- Vorrichtung nach Anspruch 21, dadurch gekennzeichnet, daß die Nuten in Förderrichtung konisch zusammenlaufen und bzw. oder sich ihre Tiefe verringert.

- Anlage, bestehend aus einer Vorrichtung zur Aufbereitung von, insbesondere thermoplastischem, Kunststoffgut nach einem der Ansprüche 1 bis 22, die mit einem Doppelschneckenextruder mit gleichsinnig oder gegensinnig drehenden Extruderschnecken zusammengeschaltet ist.

- Anlage, bestehend aus mindestens zwei Vorrichtungen zur Aufbereitung von, insbesondere thermoplastischem, Kunststoffgut nach einem der Ansprüche 1 bis 17, 21 und 22, die mit einem Extruder zusammengeschaltet sind, wobei die Vorrichtungen zur Aufbereitung von Kunststoffgut im Einzugsbereich des Extruders um einen Teil des Schneckenumfangs angeordnet sind.

- Anlage, bestehend aus mindestens zwei Vorrichtungen zur Aufbereitung von, insbesondere thermoplastischem, Kunststoffgut nach einem der Ansprüche 1 bis 17, 21 und 22, die mit einem Extruder zusammengeschaltet sind, wobei die Vorrichtungen zur Aufbereitung von Kunststoffgut hintereinander in Förderrichtung der Extruderschnecke angeordnet sind.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT0080696A AT407848B (de) | 1996-05-06 | 1996-05-06 | Vorrichtung und anlage zur aufbereitung von kunststoffgut |

| AT80696 | 1996-05-06 | ||

| AT806/96 | 1996-05-06 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0806280A2 EP0806280A2 (de) | 1997-11-12 |

| EP0806280A3 EP0806280A3 (de) | 1998-05-13 |

| EP0806280B1 true EP0806280B1 (de) | 2001-07-11 |

Family

ID=3500147

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19970890072 Expired - Lifetime EP0806280B1 (de) | 1996-05-06 | 1997-04-18 | Vorrichtung und Anlage zur Aufbereitung von Kunststoffgut |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0806280B1 (de) |

| AT (1) | AT407848B (de) |

| DE (1) | DE59703992D1 (de) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1176877A (zh) * | 1997-09-03 | 1998-03-25 | 青岛化工学院 | 挤出机螺旋啮合喂料方法 |

| US6186655B1 (en) | 1999-01-07 | 2001-02-13 | Owens Corning Fiberglass Technology, Inc. | Auger fed extruder |

| CN102241158B (zh) * | 2011-05-23 | 2015-07-08 | 苏光宝 | 塑料粉末成型机自动加粉装置 |

| RU2015137077A (ru) * | 2013-02-01 | 2017-03-06 | Руф Машиненбау Гмбх Унд Ко Кг | Подающее устройство для подвода штучного материала в брикетный пресс |

| CN105108140B (zh) * | 2015-09-18 | 2017-08-04 | 苏州萨伯工业设计有限公司 | 一种稀土磁性材料生产自动加粉装置 |

| ES2834524T3 (es) * | 2015-10-13 | 2021-06-17 | Collin Lab & Pilot Solutions Gmbh | Dispositivo que comprende un cabezal de impresión móvil y procedimiento correspondiente |

| DE102016224607A1 (de) * | 2016-12-09 | 2018-06-14 | Raumedic Ag | Silikonextrusionsanlage, Verfahren zur Silikonextrusion sowie hierdurch hergestelltes Silikonextrudat |

| DE102017114841B4 (de) * | 2017-07-04 | 2022-09-15 | Aim3D Gmbh | Vorrichtung und Verfahren zur Extrusion von thermo-mechanisch verformbaren granulatförmigen Materialien |

| DE102019217113A1 (de) * | 2019-02-28 | 2020-09-03 | Aim3D Gmbh | Befülleinrichtung für die Zuführung von Verarbeitungsmaterial an eine Extruderschnecke und Verfahren zur Zuführung von Verarbeitungsmaterial an eine Extruderschnecke |

| CN112357616B (zh) * | 2020-11-10 | 2025-02-11 | 广州红尚机械制造有限公司 | 一种出料装置 |

| CN114589828A (zh) * | 2022-02-22 | 2022-06-07 | 金华市华发新型建材有限公司 | 一种复合材料井盖生产系统 |

| CN118634563B (zh) * | 2024-08-15 | 2024-11-22 | 沈阳石油化工设计院有限公司 | 一种精细化工生产挤压过滤机 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB882517A (en) * | 1956-11-15 | 1961-11-15 | Meyer Schlioma Frenkel | Apparatus for mixing |

| US3496601A (en) * | 1967-04-14 | 1970-02-24 | Midland Ross Corp | Feeder for auger-type extruder |

| US3563514A (en) * | 1968-03-11 | 1971-02-16 | Borg Warner | Plasticizer with full diameter rotor |

| SU725891A1 (ru) * | 1977-10-19 | 1980-04-05 | Предприятие П/Я В-8406 | Дегазационное устройство к экструдеру дл полимерных материалов |

| DD227648B1 (de) * | 1984-08-23 | 1989-10-04 | Karl Marx Stadt Maschf | Vorrichtung zur beschickung von extrusionsmaschinen mit voluminoesen, schlecht rieselfaehigen verarbeitungsguetern, insbesondere thermoplastabfaellen |

-

1996

- 1996-05-06 AT AT0080696A patent/AT407848B/de not_active IP Right Cessation

-

1997

- 1997-04-18 DE DE59703992T patent/DE59703992D1/de not_active Expired - Fee Related

- 1997-04-18 EP EP19970890072 patent/EP0806280B1/de not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP0806280A3 (de) | 1998-05-13 |

| AT407848B (de) | 2001-06-25 |

| ATA80696A (de) | 2000-11-15 |

| EP0806280A2 (de) | 1997-11-12 |

| DE59703992D1 (de) | 2001-08-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| AT407972B (de) | Vorrichtung zum vorbehandeln und anschliessenden plastifizieren oder agglomerieren von kunststoffen | |

| EP3648946B1 (de) | Vorrichtung und verfahren zur extrusion von thermo-mechanisch verformbaren materialien in schüttgutform und schneckenextruder kompakter bauform | |

| EP2766164B1 (de) | Vorrichtung zum aufbereiten von kunststoffmaterial | |

| DE2703461C2 (de) | Stopwerk zur Vorverdichtung zerkleinerter voluminöser Polymerabfälle | |

| EP1628812B1 (de) | Vorrichtung zur aufbereitung von kunststoffmaterial zu recyclingzwecken | |

| DE4400330C2 (de) | Verfahren zum Herstellen eines geschäumten Produktes oder Schaumstoffmaterials aus nichtmodifizierter Stärke sowie Einrichtung zum Durchführen des Verfahrens | |

| EP0806280B1 (de) | Vorrichtung und Anlage zur Aufbereitung von Kunststoffgut | |

| AT413511B (de) | Vorrichtung zur aufbereitung von kunststoffmaterial zu recyclingzwecken | |

| WO1995017293A1 (de) | Vorrichtung zum aufbereiten thermoplastischen kunststoffgutes | |

| EP1263558B1 (de) | Aufbereitungsvorrichtung für kunststoffmaterial | |

| EP3898160B1 (de) | Aufbereitungsanlage sowie verfahren zur aufbereitung von kunststoffmaterial für dessen wiederverwertung | |

| DE69618459T2 (de) | Verfahren und vorrichtung zum materialzuführen für einen extruder | |

| DE1271973B (de) | Kontinuierlich arbeitende Schneckenpresse fuer thermoplastische Kunststoffe von extrem geringem Schuettgewicht | |

| EP3883733B1 (de) | Vorrichtung zur verarbeitung von material, insbesondere von kunststoffmaterial | |

| EP0071159A1 (de) | Trichterstück einer Einschneckenstrangpresse | |

| DE1729198B2 (de) | Schneckenstrangpresse fuer kunststoff | |

| AT522425B1 (de) | Schälschnecke | |

| DE3420643C2 (de) | Vorrichtung zum Wiederaufbereiten von thermoplastischen Abfällen | |

| EP1343623B1 (de) | Zuführaggregat einer extrusionsanlage für das recycling von kunststoffen | |

| EP1075367B1 (de) | Vorrichtung und verfahren zum kontinuierlichen agglomerieren von kunststoffgut, insbesondere zu recyclingzwecken | |

| EP4190530A1 (de) | Zuführeinrichtung für die zufuhr von kautschuk, insbesondere festsilikonkautschuk, in z. b. einen extruder | |

| WO2025024879A1 (de) | Aufbereitungsanlage für kunststoffmaterial | |

| WO2024119211A1 (de) | Verfahren und vorrichtung zur bearbeitung von polymermaterialien | |

| EP1343625A2 (de) | Extrusionseinrichtung | |

| DE10213022A1 (de) | Vorrichtung zum Mischen von wenigstens zwei Flüssigkomponenten mit Trockenschüttgut |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19980630 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 20000911 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| REF | Corresponds to: |

Ref document number: 59703992 Country of ref document: DE Date of ref document: 20010816 |

|

| ITF | It: translation for a ep patent filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20010925 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20020308 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20020320 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20020425 Year of fee payment: 6 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030418 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031101 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20030418 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031231 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050418 |